Unlocking Value: A Strategic Analysis of the Belt Blower Market

Introduction: Navigating the Global Market for belt blower

Navigating the intricate landscape of the global market for belt blowers can pose significant challenges for international B2B buyers. With diverse applications ranging from industrial ventilation to HVAC systems, sourcing the right belt blower tailored to specific operational needs is crucial. This guide offers a comprehensive overview of belt blowers, detailing the various types available, their applications across different sectors, and essential considerations for supplier vetting.

Moreover, it explores cost factors, maintenance requirements, and the latest technological advancements that enhance performance and efficiency. Buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Nigeria—will find actionable insights that empower them to make informed purchasing decisions.

Whether you’re looking for high-performance options for heavy-duty applications or energy-efficient solutions for sustainable operations, this guide serves as a vital resource. By understanding the nuances of belt blowers, you can navigate the market with confidence, ensuring that your investment meets both your operational needs and budget constraints effectively.

Understanding belt blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Drive Blowers | Utilizes a belt and pulley system for power transmission | HVAC systems, industrial ventilation | Pros: Reliable, efficient; Cons: Requires periodic maintenance. |

| Positive Pressure Ventilation Fans | Designed for high air volume and pressure; often portable | Firefighting, construction sites | Pros: High performance; Cons: Heavier and may require more power. |

| Backward Inclined Blowers | Blades are angled backward; quieter operation | Dust collection, material handling | Pros: Efficient airflow; Cons: Limited to specific applications. |

| Gas-Powered Belt Blowers | Combines gas engine with belt-drive system for mobility | Outdoor applications, emergency services | Pros: High CFM output; Cons: Noise and emissions concerns. |

| Industrial Belt Blowers | Heavy-duty construction for continuous operation | Manufacturing, processing plants | Pros: Durable and robust; Cons: Higher initial investment. |

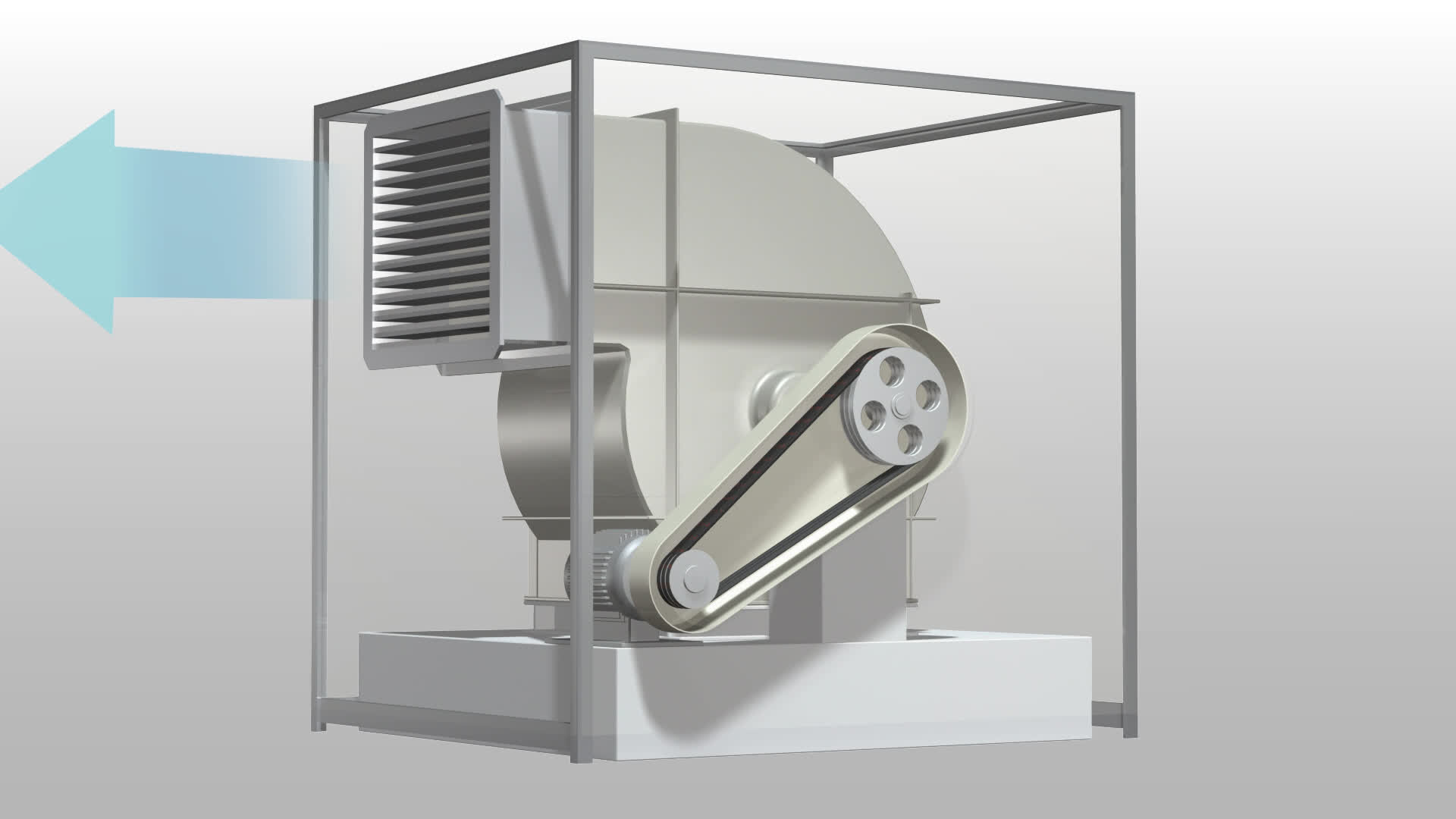

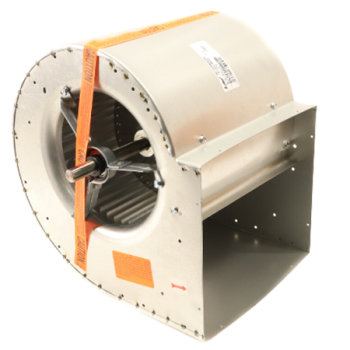

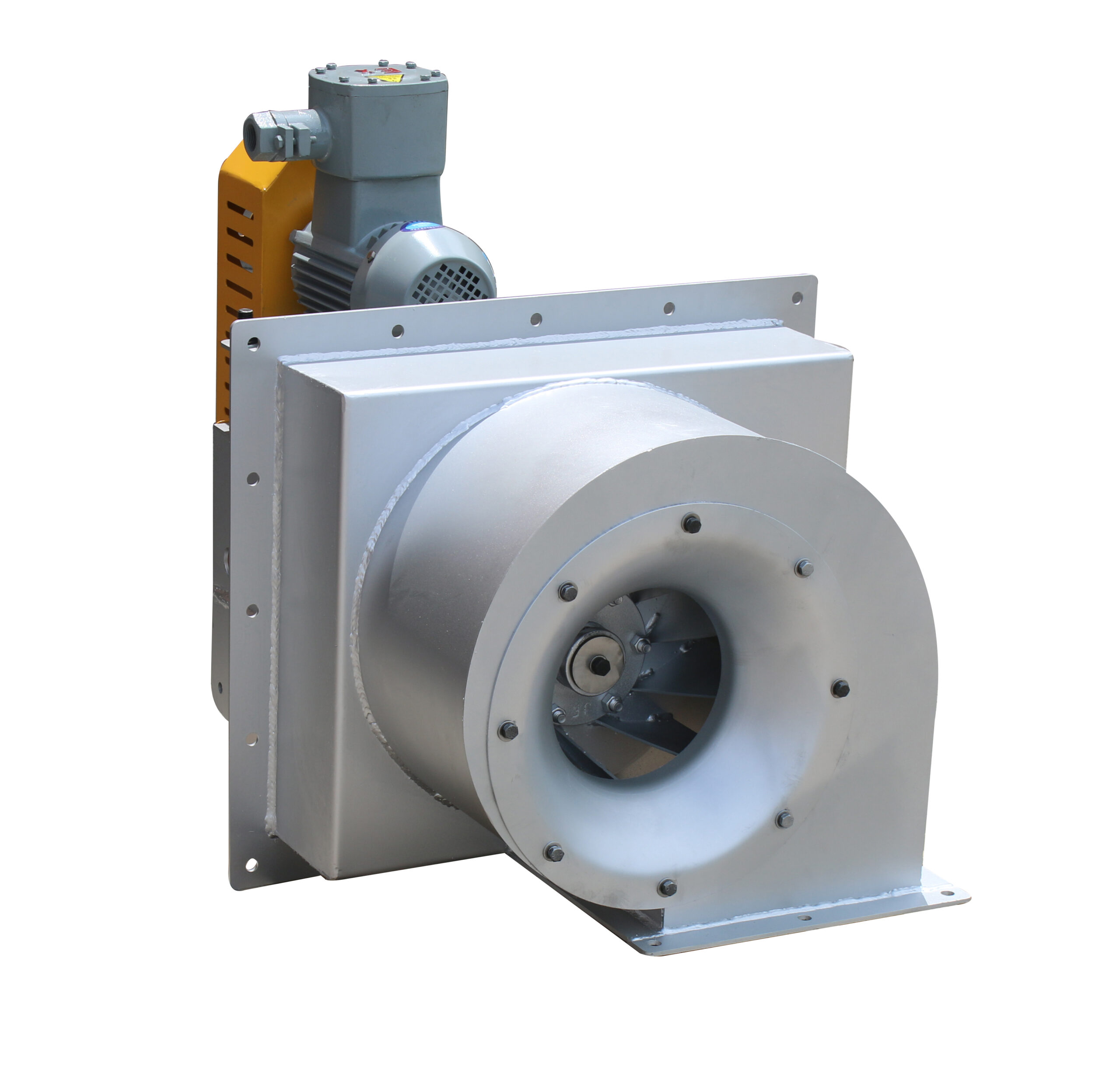

What Are the Key Characteristics of Belt Drive Blowers?

Belt Drive Blowers are essential for various industrial applications, primarily utilizing a belt and pulley system for power transmission. This design allows for greater efficiency and reliability, making them suitable for HVAC systems and general ventilation. Buyers should consider the maintenance requirements, as these blowers may need regular checks on belts and pulleys to ensure optimal performance.

How Do Positive Pressure Ventilation Fans Differ?

Positive Pressure Ventilation Fans are specifically designed to generate high air volume and pressure, making them ideal for applications such as firefighting and construction. Their portable nature allows for easy relocation to different job sites. While they deliver excellent performance, the added weight and power requirements can be a consideration for buyers, particularly in terms of transportation and operational costs.

What Advantages Do Backward Inclined Blowers Offer?

Backward Inclined Blowers feature blades angled backward, which helps reduce noise and enhance efficiency. These blowers are particularly effective in dust collection and material handling applications. However, their specialized design limits their use to specific environments, which buyers should keep in mind when assessing their needs.

Why Choose Gas-Powered Belt Blowers for Outdoor Use?

Gas-Powered Belt Blowers combine the advantages of a gas engine with a belt-drive system, providing high airflow output (CFM) for outdoor applications, including emergency services. While they are powerful and effective, potential buyers must weigh the noise levels and emissions against their operational needs, especially in urban settings.

What Makes Industrial Belt Blowers a Good Investment?

Industrial Belt Blowers are built for heavy-duty applications, ensuring durability and continuous operation in demanding environments such as manufacturing and processing plants. While they represent a higher initial investment, their robust construction and long-term reliability can lead to cost savings over time. Buyers should consider their specific operational demands and budget when evaluating these options.

Key Industrial Applications of belt blower

| Industry/Sector | Specific Application of belt blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Ventilation in livestock barns | Improved animal health and productivity | Durability, energy efficiency, and ease of maintenance are crucial. Consider local climate conditions. |

| Manufacturing | Material handling and dust control | Enhanced workplace safety and operational efficiency | Sourcing for high-performance motors and noise reduction features is essential. |

| Food Processing | Air circulation in drying processes | Consistent product quality and reduced spoilage | Compliance with food safety standards and energy efficiency ratings are vital. |

| Waste Management | Odor control in waste treatment facilities | Improved environmental compliance and public health | Reliability in harsh conditions and ease of installation should be prioritized. |

| Construction | Ventilation in confined spaces | Enhanced worker safety and productivity | Mobility, power source options, and robustness are key factors to consider. |

How Are Belt Blowers Used in Agriculture and What Problems Do They Solve?

In agriculture, belt blowers are essential for providing ventilation in livestock barns, which helps maintain optimal temperature and air quality. This is crucial for the health and productivity of animals, particularly in regions with extreme climates like Saudi Arabia and Nigeria. Buyers should focus on the durability of materials to withstand harsh conditions and energy efficiency to minimize operating costs.

What Role Do Belt Blowers Play in Manufacturing?

In manufacturing settings, belt blowers are utilized for material handling and dust control. They help maintain a clean and safe work environment by efficiently removing dust and debris, reducing the risk of accidents and improving overall operational efficiency. Buyers in this sector should consider blowers with high-performance motors and features that minimize noise, ensuring a better working atmosphere.

How Are Belt Blowers Beneficial in Food Processing?

In the food processing industry, belt blowers are used for air circulation in drying processes. This ensures consistent product quality and reduces spoilage, which is critical for maintaining food safety standards. International buyers should prioritize compliance with food safety regulations and seek energy-efficient models to keep operational costs manageable.

Why Are Belt Blowers Important in Waste Management?

Belt blowers are vital in waste management for odor control in treatment facilities. They help mitigate unpleasant odors, which is essential for environmental compliance and public health. Buyers should look for robust models that can operate reliably in harsh conditions and are easy to install, as these factors greatly impact operational efficiency.

What Are the Applications of Belt Blowers in Construction?

In construction, belt blowers are used for ventilation in confined spaces, enhancing worker safety and productivity. Proper ventilation is crucial to minimize exposure to hazardous fumes and maintain air quality. Buyers should consider the mobility of the blowers, power source options, and overall robustness to ensure they meet the demands of various construction environments.

Illustrative image related to belt blower

3 Common User Pain Points for ‘belt blower’ & Their Solutions

Scenario 1: Frequent Breakdowns During Operations

The Problem: A manufacturing plant in Nigeria relies heavily on belt blowers for material handling processes. Recently, the plant has experienced frequent breakdowns, causing unexpected downtime and productivity loss. The maintenance team struggles to pinpoint the causes of these failures, which often stem from poor maintenance practices and inadequate replacement parts. This scenario is particularly frustrating for B2B buyers who face pressure to maintain operational efficiency while managing budget constraints.

The Solution: To mitigate breakdown issues, B2B buyers should implement a proactive maintenance schedule that includes regular inspections and timely replacements of belts and bearings. Partnering with reliable suppliers who can provide high-quality, OEM-standard components is critical. Buyers should also invest in training their maintenance staff to recognize early warning signs of wear and tear. Utilizing condition monitoring technologies can further help in identifying potential failures before they occur. By ensuring that the belt blowers are serviced regularly and equipped with the right parts, companies can significantly reduce downtime and associated costs.

Scenario 2: Inconsistent Performance Leading to Product Quality Issues

The Problem: A food processing company in South America faces challenges with inconsistent airflow from their belt blowers, leading to uneven cooling and drying of products. This inconsistency affects product quality, resulting in customer complaints and potential revenue loss. The company’s management is concerned about the impact on their brand reputation and the financial implications of wasted materials.

The Solution: To enhance performance consistency, B2B buyers should conduct a comprehensive assessment of their existing belt blower systems. This includes evaluating the blower’s specifications against the specific requirements of their processes. Buyers should consider upgrading to advanced models that offer variable speed control, allowing for better airflow management. Additionally, regular calibration and maintenance of the system are essential to ensure optimal performance. Engaging with manufacturers who provide detailed product specifications and support can also help buyers identify the best solutions for their unique operational needs.

Scenario 3: High Energy Costs Due to Inefficient Equipment

The Problem: A construction firm in the Middle East is struggling with soaring energy costs attributed to their outdated belt blower systems. The inefficiency of older models not only increases operational expenses but also hinders the company’s ability to remain competitive in a price-sensitive market. This scenario highlights the growing concern among B2B buyers about balancing performance with energy efficiency.

The Solution: B2B buyers should consider investing in energy-efficient belt blowers designed to reduce power consumption while maintaining high performance. Conducting an energy audit can provide insights into the current system’s efficiency and highlight areas for improvement. When sourcing new equipment, buyers should prioritize models that comply with energy efficiency standards and offer advanced features such as electronically commutated motors (ECMs) that adapt power usage based on demand. Additionally, taking advantage of energy-saving programs or incentives offered by local governments can help offset initial investment costs. By focusing on energy-efficient solutions, companies can lower operational costs and contribute to sustainability goals.

Strategic Material Selection Guide for belt blower

When selecting materials for belt blowers, it is essential to consider the specific properties and performance characteristics required for optimal operation. The choice of material can significantly affect durability, maintenance needs, and overall efficiency. Below is an analysis of four common materials used in belt blower construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Aluminum in Belt Blowers?

Aluminum is a lightweight, corrosion-resistant metal widely used in various industrial applications, including belt blowers. Its excellent strength-to-weight ratio makes it ideal for components that require both durability and reduced weight.

Pros & Cons: Aluminum is relatively easy to manufacture and can be extruded or cast into complex shapes. However, it can be more expensive than steel, and its lower tensile strength compared to steel may limit its use in high-pressure applications.

Impact on Application: Aluminum is suitable for applications involving air and non-corrosive gases. It is not recommended for environments with high humidity or corrosive chemicals, which may lead to oxidation.

Considerations for International Buyers: Buyers from regions like Saudi Arabia or Nigeria should ensure compliance with local standards, such as ASTM or DIN, particularly for corrosion resistance. The availability of aluminum may vary, impacting lead times and costs.

Illustrative image related to belt blower

How Does Steel Compare as a Material for Belt Blowers?

Steel, particularly carbon steel, is another popular choice for belt blowers due to its high strength and durability. It can withstand significant mechanical stress and is well-suited for high-pressure applications.

Pros & Cons: Steel is generally less expensive than aluminum and offers excellent tensile strength. However, it is heavier and more prone to rust if not properly coated or treated. This necessitates regular maintenance to prevent corrosion, especially in humid environments.

Impact on Application: Steel is ideal for handling air and gases under high pressure. Its robustness makes it suitable for heavy-duty applications, but it may not be appropriate for environments with corrosive elements unless adequately protected.

Considerations for International Buyers: Buyers in regions with high humidity or salt exposure, such as coastal areas in South America, should consider stainless steel or coated options to enhance corrosion resistance and meet local standards.

What are the Benefits of Composite Materials in Belt Blowers?

Composite materials, such as fiberglass-reinforced plastics, are increasingly used in belt blowers due to their lightweight and corrosion-resistant properties. These materials are particularly beneficial in applications where weight reduction is crucial.

Pros & Cons: Composites are highly resistant to corrosion and can be molded into complex shapes, offering design flexibility. However, they can be more expensive to produce and may have lower tensile strength compared to metals, limiting their use in high-stress applications.

Impact on Application: Composites are suitable for applications where chemical resistance is necessary, such as in industries handling corrosive gases. They also perform well in low-pressure applications.

Considerations for International Buyers: Buyers should verify that composite materials meet international standards for safety and performance, especially in regions like Europe, where regulations may be stricter.

Illustrative image related to belt blower

How Do Rubber and Elastomers Contribute to Belt Blower Performance?

Rubber and elastomers are typically used in seals and gaskets within belt blowers. Their flexibility and resilience make them ideal for preventing air leaks and ensuring efficient blower operation.

Pros & Cons: Rubber is cost-effective and provides excellent sealing capabilities. However, it may degrade over time due to exposure to heat and chemicals, requiring regular replacement.

Impact on Application: Rubber components are essential for maintaining the efficiency of belt blowers, especially in applications where vibration and movement are present.

Illustrative image related to belt blower

Considerations for International Buyers: Buyers should consider the specific environmental conditions in their region, such as temperature fluctuations and chemical exposure, to select the appropriate rubber compounds that meet local standards.

Summary Table of Material Selection for Belt Blowers

| Material | Typical Use Case for belt blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight blowers for air/gas | Corrosion-resistant, lightweight | Higher cost, lower tensile strength | Medium |

| Steel | Heavy-duty blowers for high pressure | High strength, cost-effective | Heavier, prone to rust | Low |

| Composite | Chemical-resistant applications | Lightweight, design flexibility | Higher production cost, lower strength | High |

| Rubber/Elastomers | Seals and gaskets in blowers | Excellent sealing capability | Degrades over time | Low |

This analysis provides a comprehensive overview of material options for belt blowers, enabling international B2B buyers to make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for belt blower

What Are the Key Stages in the Manufacturing Process of Belt Blowers?

The manufacturing process of belt blowers involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess supplier capabilities and reliability.

Illustrative image related to belt blower

Material Preparation: What Materials Are Used for Belt Blowers?

The manufacturing of belt blowers begins with careful selection and preparation of raw materials. Common materials include:

- Steel: Used for frames and structural components due to its strength and durability.

- Aluminum: Often utilized for shrouds and fan blades because it is lightweight and resistant to corrosion.

- Composite Materials: Increasingly used for blades to enhance performance while minimizing weight. These materials are designed to disintegrate safely upon impact, reducing the risk of injury.

Suppliers may implement advanced material processing techniques such as laser cutting and CNC machining to ensure precision and consistency in component dimensions.

How Are Belt Blowers Formed and Assembled?

Once the materials are prepared, the next stage involves forming and assembling the components. Key techniques include:

Illustrative image related to belt blower

- Stamping and Molding: Used to create complex shapes for components like impellers and shrouds.

- Welding and Fastening: Critical for assembling the frame and housing. High-quality welding techniques ensure structural integrity and long-term durability.

- Precision Machining: Ensures moving parts fit together seamlessly, which is essential for optimal performance and efficiency.

Assembly is typically performed in a controlled environment to minimize contamination and ensure consistent quality across products.

What Quality Assurance Practices Are Essential for Belt Blowers?

Quality assurance (QA) is crucial in the manufacturing of belt blowers, as it directly affects performance and safety. B2B buyers should be familiar with the relevant standards and practices that suppliers should adhere to.

Which International Standards Should Suppliers Comply With?

Belt blower manufacturers often align their quality management systems with international standards such as:

- ISO 9001: Focuses on quality management principles including customer satisfaction and continuous improvement.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for blowers used in oil and gas applications, ensuring reliability and performance under specific conditions.

Compliance with these standards not only enhances product quality but also boosts the supplier’s credibility in international markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

To ensure that manufacturing processes meet quality standards, suppliers implement several checkpoints, including:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitors critical stages of the manufacturing process to catch defects early. This may involve dimensional checks and functional testing.

- Final Quality Control (FQC): Conducts comprehensive testing on the finished product to verify performance metrics such as airflow, noise levels, and safety features.

These checkpoints are critical for maintaining high-quality production and minimizing defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When assessing potential suppliers, B2B buyers should take proactive steps to verify their quality control practices. Here are some effective methods:

What Documentation and Reports Should Buyers Request?

Buyers should ask for:

- Quality Management System Documentation: Suppliers should provide evidence of their adherence to ISO 9001 or other relevant standards.

- Inspection and Test Reports: These documents outline the results of various quality checks and tests conducted throughout the manufacturing process.

- Certificates of Compliance: Suppliers should be able to provide certifications for CE marking or other applicable standards.

How Can Buyers Conduct Audits and Inspections?

Conducting supplier audits can provide deeper insights into a manufacturer’s quality control practices. Buyers can:

- Schedule On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes firsthand and assess the quality of materials and workmanship.

- Engage Third-Party Inspection Services: Independent inspectors can provide unbiased assessments of the manufacturing and quality control processes, ensuring compliance with international standards.

What Testing Methods Are Commonly Used for Belt Blowers?

Testing is an essential component of the quality assurance process. Various methods are employed to ensure that belt blowers perform reliably under expected operating conditions:

- Performance Testing: Measures airflow, pressure, and efficiency to ensure the blower meets specified performance criteria.

- Durability Testing: Involves simulating long-term use conditions to evaluate how well components withstand wear and tear.

- Safety Testing: Ensures that blowers meet safety standards, particularly for features like blade integrity and electrical safety.

How Do Quality Control Nuances Affect International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is vital. Different regions may have varying regulatory requirements and expectations regarding product performance and safety.

- Regional Compliance: Buyers should ensure that products comply with local regulations in their respective markets, which may differ from the manufacturer’s country.

- Cultural Considerations: Understanding local market expectations regarding product quality and safety can aid in selecting suppliers that align with these needs.

By being informed about manufacturing processes, quality control practices, and regional nuances, B2B buyers can make more informed decisions when sourcing belt blowers, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt blower’

To assist B2B buyers in sourcing the right belt blower for their operations, this practical guide provides a step-by-step checklist to ensure informed purchasing decisions. Each step is designed to address critical aspects of the procurement process, from understanding technical requirements to evaluating suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial in ensuring that the belt blower meets your operational needs. Consider factors such as airflow capacity (CFM), pressure ratings, and noise levels. Additionally, identify the power source—electric or gas—and any specific features required for your industry.

- Airflow Capacity: Determine the volume of air needed for your application.

- Pressure Ratings: Ensure the blower can handle the pressure required for optimal performance.

Step 2: Research Market Options

Conduct thorough market research to identify potential brands and models of belt blowers. Look for reputable manufacturers known for quality and reliability. Pay attention to customer reviews and industry ratings to gauge performance and durability.

- Manufacturer Reputation: Focus on brands with a history of producing reliable blowers.

- Product Range: Ensure the manufacturer offers a variety of models to meet different requirements.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; gather insights into their customer service and after-sales support.

- Supplier Experience: Inquire about their experience in your industry.

- Customer Testimonials: Look for feedback from other businesses regarding product performance and service.

Step 4: Verify Compliance and Certifications

Ensure that the belt blower complies with international safety and quality standards. Check for certifications such as CE, UL, or ISO, which indicate adherence to industry regulations. Compliance is essential for ensuring the blower’s safe operation and longevity.

- Safety Standards: Verify that the blower meets local and international safety requirements.

- Quality Assurance: Look for products that undergo rigorous testing and quality checks.

Step 5: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotes. Ensure that the quotes include all relevant costs, such as shipping and installation. Comparing prices will help you identify the best value while ensuring you are not compromising on quality.

- Cost Breakdown: Look for transparency in pricing, including any hidden fees.

- Long-term Value: Consider the total cost of ownership, including maintenance and operational efficiency.

Step 6: Assess After-Sales Support and Warranty

A strong after-sales support system is vital for the longevity of your investment. Inquire about warranty terms and the availability of spare parts. A reliable supplier will offer comprehensive support to address any issues that may arise post-purchase.

Illustrative image related to belt blower

- Warranty Coverage: Understand what the warranty covers and for how long.

- Technical Support: Ensure that the supplier provides technical assistance when needed.

Step 7: Finalize Your Purchase and Arrange Logistics

After selecting the supplier and confirming all details, finalize your purchase. Arrange for logistics, including delivery timelines and installation if necessary. Clear communication with the supplier at this stage is critical to avoid any misunderstandings.

- Delivery Schedule: Confirm expected delivery dates and any potential delays.

- Installation Requirements: Discuss any installation support that may be provided by the supplier.

By following this checklist, B2B buyers can confidently navigate the sourcing process for belt blowers, ensuring they select a product that meets their needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for belt blower Sourcing

What Are the Key Cost Components for Belt Blower Sourcing?

When sourcing belt blowers, understanding the cost structure is crucial for B2B buyers. The primary components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the price. High-quality steel, specialized composites, and robust rubber components used in belt drive systems can lead to increased costs but also enhance durability and performance. Buyers should evaluate material specifications to align with their operational needs.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with higher labor costs will reflect this in the product pricing. It’s beneficial for buyers to consider suppliers in countries with competitive labor markets, particularly in Africa and South America, where production costs may be lower.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. A well-managed production facility can optimize these costs, thereby potentially reducing the final price for buyers.

-

Tooling: Custom tooling for specialized blowers can drive up initial costs. For projects requiring unique specifications or large orders, negotiating for shared tooling costs can be advantageous.

-

Quality Control: Implementing rigorous QC processes ensures reliability and performance, which may increase production costs but is essential for minimizing long-term operational risks. Certifications such as ISO can also add to the cost but provide assurance of quality.

-

Logistics: Transportation costs can significantly influence pricing, especially for international shipments. Factors like distance, shipping methods, and customs duties should be factored into the total cost.

-

Margin: Supplier margins will vary based on market conditions and competition. Understanding the typical margin for your supplier’s industry can assist in negotiations.

How Do Price Influencers Affect Belt Blower Costs?

Several factors can influence the pricing of belt blowers, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract volume discounts, reducing the per-unit cost. Buyers should assess their needs and negotiate MOQs to achieve cost efficiency.

-

Specifications and Customization: Customized blowers with specific features or sizes can incur higher costs. Buyers should balance the need for customization against budget constraints and consider standardized options where feasible.

-

Material Quality and Certifications: Higher-quality materials and certified products typically come at a premium. However, investing in durable blowers can lead to lower maintenance and replacement costs in the long run.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, but they can also offer better customer service and product support.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total landed costs, including shipping and insurance.

What Tips Should Buyers Consider for Cost-Efficiency in Belt Blower Sourcing?

-

Negotiation Strategies: Engage suppliers in discussions about pricing structures, and don’t hesitate to ask for discounts on larger orders or longer-term contracts. Establishing a strong relationship can also lead to better terms.

-

Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the TCO, which includes maintenance, energy consumption, and potential downtime costs. A slightly higher upfront cost may yield savings over the equipment’s lifespan.

-

Regional Market Dynamics: For buyers from Africa, South America, the Middle East, and Europe, understanding regional market dynamics can provide leverage. Familiarity with local suppliers and market conditions can lead to better pricing and terms.

-

Pricing Nuances: Be aware of currency fluctuations and economic factors that can influence pricing in international markets. Consider locking in prices or negotiating contracts that account for potential changes.

Disclaimer on Indicative Prices

The prices of belt blowers can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing belt blower With Other Solutions

In the competitive landscape of industrial ventilation and air-moving solutions, understanding alternative technologies to belt blowers is crucial for B2B buyers. This analysis will compare belt blowers with two viable alternatives: direct drive blowers and regenerative blowers. Each solution has unique advantages and limitations that can significantly influence the decision-making process for international buyers across diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to belt blower

| Comparison Aspect | Belt Blower | Direct Drive Blower | Regenerative Blower |

|---|---|---|---|

| Performance | High efficiency, versatile use | High RPM, compact design | Consistent airflow, low noise |

| Cost | Moderate initial investment | Lower upfront cost | Higher upfront cost |

| Ease of Implementation | Requires more setup and space | Easier to install, less space | Complex installation and setup |

| Maintenance | Moderate, belt replacement needed | Low maintenance | Requires regular checks |

| Best Use Case | Industrial applications, HVAC | Residential, small commercial | Applications needing constant flow |

What Are the Advantages and Disadvantages of Direct Drive Blowers Compared to Belt Blowers?

Direct drive blowers utilize a motor directly connected to the fan, eliminating belts and pulleys. This design results in a smaller footprint and lower maintenance needs, as there are fewer moving parts that require attention. However, they often operate at higher RPMs, which can lead to increased noise levels. While direct drive blowers are generally less expensive upfront, their efficiency may not match that of belt-driven models in high-demand industrial applications.

How Do Regenerative Blowers Stack Up Against Belt Blowers?

Regenerative blowers are designed to provide a consistent airflow, making them ideal for applications that require a steady supply of air, such as wastewater treatment or pneumatic conveying. They operate quietly and efficiently, which is a significant advantage in noise-sensitive environments. However, regenerative blowers come with a higher initial cost and a more complex installation process compared to belt blowers. Regular maintenance is also essential to ensure optimal performance, particularly in preventing wear on the internal components.

How Can B2B Buyers Make the Right Choice Among These Options?

When selecting the right blower solution, B2B buyers should carefully assess their specific operational requirements, including performance needs, budget constraints, and maintenance capabilities. Belt blowers are suitable for larger industrial applications where efficiency and versatility are paramount. In contrast, direct drive blowers may be more appropriate for smaller spaces and lower operational costs. Regenerative blowers are best suited for applications requiring consistent airflow and low noise levels, albeit at a higher investment.

Illustrative image related to belt blower

Ultimately, understanding the unique strengths and weaknesses of each option will empower buyers to make informed decisions that align with their operational goals and financial parameters. By evaluating these factors, businesses can ensure they choose a solution that not only meets their immediate needs but also supports their long-term operational strategy.

Essential Technical Properties and Trade Terminology for belt blower

What Are the Key Technical Properties of a Belt Blower?

When evaluating belt blowers for industrial applications, several technical specifications stand out as critical for ensuring optimal performance and longevity. Understanding these properties can significantly impact decision-making for B2B buyers.

-

Airflow Capacity (CFM)

Airflow capacity, measured in cubic feet per minute (CFM), indicates the volume of air a blower can move. This specification is essential for applications requiring specific air exchange rates, such as in HVAC systems or industrial ventilation. A higher CFM typically translates to more efficient operation, making it crucial for buyers to match the blower’s capacity with their operational needs. -

Motor Power (HP)

The power of the motor, usually rated in horsepower (HP), directly influences the blower’s efficiency and capability. Buyers should consider the motor’s power to ensure it meets the demands of the intended application. A higher HP rating often correlates with increased performance, particularly in challenging environments or when handling heavier loads. -

Material Construction

The materials used in a belt blower’s construction—such as steel, aluminum, or composite materials—affect durability and performance. For instance, blowers made from corrosion-resistant materials are preferable in humid or chemically aggressive environments, reducing maintenance costs and downtime. Buyers should assess material properties to ensure the blower can withstand operational conditions. -

Belt Drive System

The belt drive system is a critical component that transmits power from the motor to the blower. It influences efficiency, vibration levels, and maintenance needs. A well-designed belt drive system reduces wear and tear on the motor, thus prolonging its life. Buyers should inquire about the quality of the belt and its replacement cycle as part of their purchasing decision. -

Noise Level (dB)

Noise levels, measured in decibels (dB), are essential for compliance with workplace safety standards and comfort. Industries with strict noise regulations, such as healthcare or education, must prioritize blowers that operate quietly. Buyers should request noise specifications to ensure compliance with local regulations and workplace standards.

Which Trade Terms Are Commonly Used in the Belt Blower Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to belt blowers:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of belt blowers, OEM parts are often preferred for their quality and compatibility with existing systems. Buyers should verify whether components are OEM to ensure reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, particularly in budgeting and inventory management. A high MOQ may necessitate larger upfront investments, which can be a barrier for smaller businesses or projects. -

RFQ (Request for Quotation)

An RFQ is a formal request for pricing and terms from suppliers. It is a critical step in the procurement process, allowing buyers to compare offerings and negotiate favorable terms. Crafting a clear RFQ can lead to better pricing and service conditions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. These terms clarify who is responsible for shipping costs, insurance, and liability during transit. Familiarity with Incoterms is essential for international buyers to mitigate risks and understand their obligations. -

Lead Time

Lead time refers to the time required from order placement to delivery. It is a crucial factor in project planning and inventory management. Buyers must communicate their lead time requirements to suppliers to ensure timely project execution.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing belt blowers, ensuring they meet their operational needs and comply with industry standards.

Illustrative image related to belt blower

Navigating Market Dynamics and Sourcing Trends in the belt blower Sector

What Are the Key Market Dynamics Influencing the Belt Blower Sector?

The belt blower market is experiencing transformative changes driven by several global factors. First, the increasing demand for efficient air-moving solutions across industries such as HVAC, manufacturing, and agriculture is a primary driver. Businesses are increasingly focused on optimizing operational efficiency, leading to a rise in the adoption of belt-driven blowers due to their reliability and cost-effectiveness. Moreover, technological advancements are facilitating the integration of IoT capabilities in blowers, allowing for real-time monitoring and predictive maintenance, which appeals to B2B buyers looking for long-term operational stability.

Emerging markets in Africa and South America are witnessing significant growth in industrial activities, further amplifying the demand for belt blowers. Countries like Nigeria and Brazil are enhancing their infrastructure, which drives the need for efficient ventilation and air management systems. In the Middle East, particularly in Saudi Arabia, the push towards diversifying the economy beyond oil is prompting investments in various sectors, including construction and manufacturing, where belt blowers play a crucial role.

Additionally, sustainability is becoming a key factor in sourcing decisions. B2B buyers are increasingly interested in suppliers that prioritize energy-efficient products and sustainable manufacturing processes. This trend aligns with global efforts to reduce carbon footprints, as businesses are compelled to meet regulatory requirements and consumer expectations around environmental responsibility.

How Important Is Sustainability and Ethical Sourcing in the Belt Blower Industry?

As sustainability becomes a cornerstone of business strategy, the belt blower sector is no exception. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, prompting buyers to seek out suppliers committed to ethical sourcing. This includes the use of recyclable materials, energy-efficient manufacturing practices, and adherence to environmental regulations.

B2B buyers are now prioritizing suppliers who can demonstrate compliance with recognized ‘green’ certifications, such as ISO 14001 for environmental management or ENERGY STAR for energy efficiency. These certifications not only signify a commitment to sustainability but also provide a competitive edge in a market that increasingly values environmental stewardship.

Moreover, the demand for environmentally friendly products has led to innovations in material science, resulting in the development of composite materials for blower blades that are lighter and more durable, thus reducing energy consumption during operation. This not only enhances performance but also contributes to lower operational costs over time, making ethical sourcing a strategic advantage for B2B buyers.

What Is the Evolution of the Belt Blower Technology?

The belt blower technology has evolved significantly since its inception, adapting to the changing needs of various industries. Initially, these blowers were primarily mechanical devices with limited efficiency and performance capabilities. Over the decades, advancements in engineering and materials science have transformed them into sophisticated machines that offer high performance, durability, and energy efficiency.

The introduction of computer-aided design (CAD) and simulation technologies has allowed manufacturers to optimize blower designs for maximum airflow and minimal energy consumption. Additionally, the integration of smart technologies has enabled remote monitoring and diagnostics, which are particularly beneficial for international buyers looking to enhance their operational efficiency and reduce downtime.

As industries continue to evolve, the belt blower sector is poised for further innovation, with a focus on sustainability and automation driving its future trajectory. International B2B buyers can leverage these advancements to enhance their operational capabilities while aligning with global sustainability goals.

Illustrative image related to belt blower

Frequently Asked Questions (FAQs) for B2B Buyers of belt blower

-

How do I select the right belt blower for my industrial application?

Choosing the right belt blower involves evaluating several key factors, including airflow requirements (measured in CFM), pressure specifications, and the specific application needs, such as ventilation or material handling. Consider the environment in which the blower will operate—factors like temperature, humidity, and potential exposure to corrosive materials can impact performance. Additionally, assess the blower’s efficiency ratings and maintenance requirements to ensure long-term reliability and cost-effectiveness. -

What maintenance is required for a belt blower?

Regular maintenance is crucial for the longevity and efficiency of a belt blower. This includes routine inspections of belts for wear and tension, checking bearings and lubrication points, and cleaning air filters to prevent clogs. It is also important to monitor the blower’s performance metrics, such as airflow and pressure, to detect any anomalies early. Establishing a maintenance schedule based on the manufacturer’s recommendations can help minimize downtime and repair costs. -

What are the typical lead times for ordering belt blowers internationally?

Lead times for international orders of belt blowers can vary significantly based on the supplier, production schedules, and shipping methods. Typically, you should expect lead times ranging from 4 to 12 weeks. Factors such as customs clearance and local regulations can also affect delivery times. It is advisable to communicate directly with suppliers to get an accurate estimate and to plan your inventory needs accordingly. -

What customization options are available for belt blowers?

Many manufacturers offer customization options to meet specific application needs. This can include modifications to size, airflow capacity, motor specifications, and additional features such as variable speed drives or specialized coatings for corrosion resistance. When discussing customization with suppliers, be clear about your operational requirements and any industry-specific standards that must be met to ensure compliance and performance. -

What is the minimum order quantity (MOQ) for belt blowers?

The MOQ for belt blowers can vary by manufacturer and product type. Typically, MOQs can range from a single unit for standard models to larger quantities for custom or specialized blowers. When sourcing, clarify the MOQ with potential suppliers and discuss the possibility of smaller orders or samples, particularly if you are testing a new application or entering a new market. -

How do I vet suppliers for belt blowers effectively?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with international standards. Look for established suppliers with positive reviews and case studies that demonstrate their expertise in your industry. Request certifications related to quality management (e.g., ISO) and ask for references from other B2B clients. Engaging in direct communication and site visits can also provide insights into their operational practices and reliability. -

What payment terms are common when purchasing belt blowers?

Payment terms can vary widely based on the supplier and the scale of the order. Common terms include upfront payment, a deposit with the balance due upon shipment, or net terms (e.g., net 30 or net 60 days) for established relationships. Always negotiate terms that align with your cash flow and operational needs. Additionally, consider using secure payment methods or letters of credit to protect your investment in international transactions. -

How can I ensure quality assurance (QA) for my belt blower order?

To ensure quality assurance for your belt blower order, request detailed product specifications and quality control processes from the supplier. Many manufacturers will conduct testing and provide certifications for performance metrics and safety standards. Consider including QA checkpoints in your contract, such as pre-shipment inspections or third-party audits, to verify that the products meet your requirements before they are shipped. Regular communication with the supplier throughout the production process can also help address any potential issues proactively.

Top 8 Belt Blower Manufacturers & Suppliers List

1. Tempest – Belt-Drive Gas Power Blower

Domain: tempest.us.com

Introduction: Tempest Belt-Drive Gas Power Blower features an exclusive belt-drive design that reduces engine wear, improves CFM performance, and provides greater stability. It includes AirFlex composition impellers for maximum air volume, velocity, and pressure. The welded steel roll cage frame enhances strength and eliminates maintenance on nuts and bolts. The ergonomic design allows for easy transport, and t…

2. Canarm – Belt Drive Equipment Blowers

Domain: canarm.com

Registered: 1997 (28 years)

Introduction: Belt Drive Equipment Blowers (OEM) include various models such as: 400 Series FC Exhauster, 800 Series DWDI Blowers with Frame, 900 Series DWDI Framed Heavy Duty Blowers, 900-BI Backward Inclined Blower, DPL Series Flat Blade Plenum Fans, DPL-AF Series Air Foil Blade Plenum Fans, and G Series Double Inlet Belt Drive Blowers. Canarm’s HVAC Division designs and manufactures these products for indust…

3. Good Vibrations Motorsports – Blower Belts

Domain: goodvibesracing.com

Registered: 1999 (26 years)

Introduction: Blower Belts available by appointment only for will call. Open Monday-Friday 7:00 am – 4:30 pm PST. Online orders typically ship same day if ordered by 3:00 pm PST. Good Vibrations Motorsports is a large stocking distributor of Blower Belts, including sizes: 1/2″ Pitch, 8mm, 11mm, 13.9mm, and 14mm. Types of belts include: 1/2″ Pitch, 8mm Rubber, 8mm Star Racer, 8mm Gates Carbon/Kevlar, 11mm Gates …

4. Electric Motor Warehouse – Belt Drive Furnace Blower Motors

Domain: electricmotorwarehouse.com

Registered: 1999 (26 years)

Introduction: Belt Drive Furnace Blower Motors from brands like Century, Nidec, and Marathon. Available for various applications including HVAC, oil burners, and unit heaters. Features include direct drive and belt drive options, with a range of mounting brackets and accessories. Common replacements for various OEM brands such as Armstrong, Amana, Carrier, Goodman, Lennox, Rheem, and Trane. Motors suitable for …

5. RPM – Can-Am Maverick X3 ECF Electric Clutch Fan

Domain: rpmsxs.com

Registered: 2020 (5 years)

Introduction: RPM Can-Am Maverick X3 ECF Electric Clutch Fan, designed to lower clutch belt temperature, enhancing performance and reliability.

6. RPM – Can-Am Maverick X3 Electric Clutch Blower Fan Kit

Domain: maverickforums.net

Registered: 2012 (13 years)

Introduction: RPM Can-Am Maverick X3 “ECF” Electric Clutch Blower Fan Kit – Designed to lower clutch and belt temperatures to extend belt and clutch life. Suitable for UTV owners engaged in activities like trail riding, rock crawling, and dune riding, especially under increased load conditions. The fan kit operates at 225 CFM, but some users suggest this may not be sufficient for effective cooling, especially a…

7. Zoro – Belt Drive Blowers

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Belt Drive Blowers are air-moving devices powered by a belt drive system, used in various applications including heating, cooling, and air circulation. Types include belt drive squirrel cage fans, belt driven centrifugal fans, and belt driven furnace blowers. They are made from metal components, rubber belts, and bearings, designed to withstand high temperatures and long-term wear. Common industri…

8. UTV Source – Alba Racing RZR XP Turbo Belt Blower Cooler Kit

Domain: utvsource.com

Registered: 2009 (16 years)

Introduction: The Belt Coolers category offers innovative products designed to keep vehicle belts cool and functioning optimally. Key products include: 1. Alba Racing RZR XP Turbo Belt Blower Cooler Kit – Features a powerful blower fan that circulates air onto the belt to prevent overheating and reduce belt failure risk. 2. GBoost Technology Polaris Mud Monster Drive Belt – Engineered for extreme off-road condi…

Strategic Sourcing Conclusion and Outlook for belt blower

What Are the Key Takeaways for Sourcing Belt Blowers?

In conclusion, strategic sourcing of belt blowers is pivotal for businesses aiming to enhance operational efficiency and cost-effectiveness. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer reliable performance, innovative design, and robust after-sales support. The advantages of belt-driven blowers, such as reduced engine wear and enhanced air volume, make them a compelling choice for various industrial applications.

How Can Strategic Sourcing Benefit Your Business?

Investing in quality belt blowers not only improves productivity but also minimizes downtime and maintenance costs. By engaging in thorough market research and building relationships with reputable manufacturers, businesses can secure favorable pricing and customized solutions that align with their specific needs. Additionally, understanding the local market dynamics and regulatory requirements will facilitate smoother transactions and compliance.

What’s Next for International Buyers in the Belt Blower Market?

As industries continue to evolve, the demand for efficient and durable belt blowers will only grow. International buyers are encouraged to stay abreast of technological advancements and market trends to make informed purchasing decisions. Explore partnerships with leading suppliers today to ensure your operations are equipped with the best tools for success. Your strategic sourcing journey starts now—don’t miss the opportunity to leverage the benefits of high-quality belt blowers in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.