A B2B Buyer’s Guide to Plate Exchanger Diagram: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for plate exchanger diagram

Navigating the complexities of sourcing a plate exchanger diagram can pose significant challenges for B2B buyers in an increasingly interconnected global market. With the urgent need for sustainable solutions and energy efficiency, understanding the intricacies of plate heat exchangers is crucial for businesses aiming to optimize their thermal management systems. This comprehensive guide explores various types of plate heat exchangers, their specific applications across industries, and critical factors in supplier vetting. Additionally, we delve into cost considerations and maintenance best practices, equipping buyers with the knowledge needed to make informed decisions.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Saudi Arabia—this guide serves as an essential resource. It not only demystifies the technical aspects of plate exchangers but also highlights the importance of selecting reliable suppliers who can meet local regulations and standards. By empowering decision-makers with actionable insights, this guide aims to enhance operational efficiency and sustainability in heat transfer processes. As you navigate the global market for plate exchangers, let this guide be your strategic partner in driving value and innovation within your organization.

Understanding plate exchanger diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gasketed Plate Heat Exchanger | Removable plates sealed with gaskets for easy maintenance | Food & Beverage, HVAC, Chemical | Pros: Easy cleaning, cost-effective; Cons: Potential for leaks over time. |

| Brazed Plate Heat Exchanger | Plates are permanently joined using brazing for compact design | Refrigeration, HVAC, Marine | Pros: Compact, high efficiency; Cons: Difficult to clean, limited to lower pressure applications. |

| Welded Plate Heat Exchanger | Plates are welded together, suitable for high-temperature fluids | Oil & Gas, Chemical Processing | Pros: Highly durable, ideal for corrosive materials; Cons: Not serviceable, higher initial cost. |

| Semi-Welded Plate Heat Exchanger | Combination of welded and gasketed plates for flexibility | Pharmaceutical, Petrochemical | Pros: Reduced risk of leaks, easier maintenance; Cons: Higher cost than gasketed options. |

| Shell and Tube Heat Exchanger | Consists of tubes within a shell for large temperature differences | Power Generation, Oil Refining | Pros: Handles large temperature differentials, low pressure loss; Cons: Larger footprint, higher maintenance needs. |

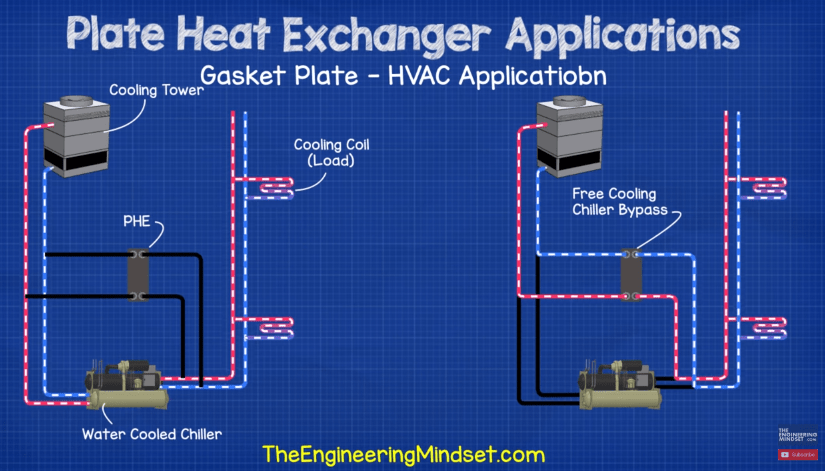

What Are Gasketed Plate Heat Exchangers and Their Applications?

Gasketed plate heat exchangers feature plates sealed with gaskets, allowing for easy disassembly and cleaning. This design is particularly suited for industries such as food and beverage, HVAC, and chemicals, where hygiene and maintenance are critical. When considering a gasketed option, buyers should evaluate the potential for gasket wear over time, which can lead to leaks, but the ease of maintenance often outweighs this concern.

How Do Brazed Plate Heat Exchangers Stand Out?

Brazed plate heat exchangers are known for their compact design achieved through the brazing process, which permanently joins plates. They are commonly used in refrigeration and HVAC systems where space is limited. For B2B buyers, the high efficiency and compactness are major advantages; however, the inability to clean the plates can be a significant drawback, especially in applications where fouling is a concern.

What Are the Benefits of Welded Plate Heat Exchangers?

Welded plate heat exchangers are characterized by plates that are welded together, making them exceptionally robust and suitable for high-temperature and corrosive fluids. Industries like oil and gas and chemical processing benefit from their durability. While these exchangers offer excellent performance, the lack of serviceability means that buyers must weigh the higher initial investment against long-term operational savings.

Why Choose Semi-Welded Plate Heat Exchangers?

Semi-welded plate heat exchangers combine the benefits of welded and gasketed designs, allowing for a mix of serviceability and leak prevention. They are ideal for applications in pharmaceuticals and petrochemicals, where fluid integrity is paramount. Buyers should consider the higher upfront costs but recognize the long-term savings in maintenance and reduced risk of fluid loss.

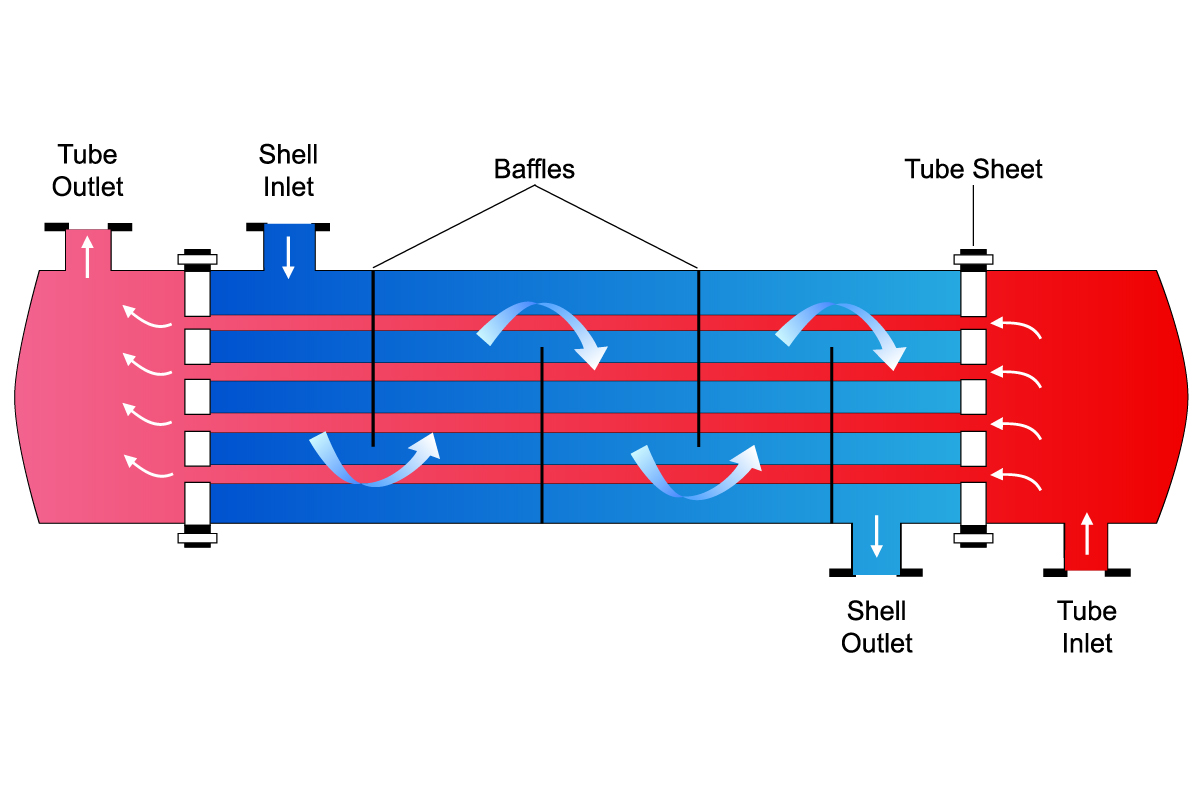

When to Use Shell and Tube Heat Exchangers?

Shell and tube heat exchangers are designed for applications with significant temperature differences between fluids. They are widely used in power generation and oil refining due to their ability to handle extreme conditions. While they provide low pressure loss and are robust, their larger footprint and higher maintenance requirements may not suit all buyers, particularly in space-constrained environments.

Key Industrial Applications of plate exchanger diagram

| Industry/Sector | Specific Application of plate exchanger diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Pasteurization of liquids | Enhances food safety and extends shelf life | Compliance with food safety standards and materials certification |

| Chemical Processing | Heat recovery in exothermic reactions | Increases energy efficiency and reduces operational costs | Material compatibility with corrosive substances and high temperatures |

| HVAC (Heating, Ventilation, Air Conditioning) | Temperature control in district heating systems | Improves energy conservation and reduces emissions | Size and capacity to match system requirements |

| Pharmaceutical Manufacturing | Cooling and heating in production processes | Ensures product quality and compliance with regulations | Precision in temperature control and maintenance ease |

| Renewable Energy | Heat exchange in biomass energy systems | Optimizes energy output and supports sustainability | Durability in high-temperature applications and efficient design |

How is the Plate Exchanger Diagram Utilized in the Food & Beverage Industry?

In the food and beverage sector, plate heat exchangers are crucial for processes such as pasteurization, where they efficiently transfer heat to liquids while minimizing temperature fluctuations. This ensures that harmful microorganisms are eliminated, enhancing food safety and extending the shelf life of products. International buyers should prioritize suppliers who comply with food safety regulations and can provide certifications for materials used, ensuring that the equipment meets stringent hygiene standards.

What Role Does the Plate Exchanger Diagram Play in Chemical Processing?

In chemical processing, plate heat exchangers are employed for heat recovery in exothermic reactions, allowing companies to maximize energy efficiency. By capturing and reusing heat, businesses can significantly lower operational costs while minimizing environmental impact. When sourcing these exchangers, buyers must consider the material compatibility with various chemicals and the ability to withstand high temperatures and pressures, ensuring reliability in demanding environments.

How is the Plate Exchanger Diagram Applied in HVAC Systems?

In HVAC applications, plate heat exchangers facilitate temperature control in district heating systems, enhancing energy conservation and reducing greenhouse gas emissions. They allow for the efficient transfer of heat between different fluids, contributing to overall system performance. Buyers should focus on the size and capacity of the exchangers to match their specific system requirements, along with the ease of maintenance to ensure long-term efficiency.

Why are Plate Exchanger Diagrams Important in Pharmaceutical Manufacturing?

The pharmaceutical industry relies on precise temperature control during production processes, making plate heat exchangers invaluable. They ensure that products are manufactured under optimal conditions, maintaining quality and compliance with strict regulatory standards. Buyers in this sector should look for exchangers that offer precision in temperature control and ease of maintenance, as these factors are critical for operational efficiency and product integrity.

How Do Plate Exchanger Diagrams Contribute to Renewable Energy Applications?

In renewable energy, particularly in biomass energy systems, plate heat exchangers are utilized to optimize heat exchange processes, improving energy output and supporting sustainability initiatives. They play a vital role in maintaining efficient thermal management within these systems. Buyers should consider the durability of the exchangers, especially in high-temperature applications, as well as their overall design efficiency to maximize energy conversion and output.

3 Common User Pain Points for ‘plate exchanger diagram’ & Their Solutions

Scenario 1: Navigating Complex Specifications for Plate Exchanger Diagrams

The Problem: B2B buyers often face challenges when trying to understand the intricate specifications of plate exchanger diagrams. These diagrams contain detailed information about dimensions, flow rates, and thermal properties, which can be overwhelming for those who are not engineers or technical experts. Misinterpretation of these diagrams can lead to incorrect equipment selection, resulting in operational inefficiencies and increased costs.

The Solution: To effectively navigate plate exchanger diagrams, buyers should invest in training or workshops that focus on interpreting these technical documents. Collaborating with the manufacturer or a qualified engineer can also provide clarity on the specific needs of their operations. Buyers should create a checklist that includes critical parameters such as temperature ranges, pressure drops, and flow rates, aligning these with the specifications outlined in the diagram. This structured approach helps in making informed decisions and ensures that the selected plate exchanger meets the operational requirements.

Scenario 2: Overcoming Maintenance and Cleaning Challenges

The Problem: Regular maintenance and cleaning of plate heat exchangers can be a significant pain point for B2B buyers. Ineffective maintenance can lead to fouling, reduced heat transfer efficiency, and ultimately, equipment failure. Buyers may struggle with determining the best cleaning methods or schedules, especially in regions where water quality and temperature fluctuations can affect the cleaning process.

The Solution: To mitigate maintenance challenges, buyers should adopt a proactive maintenance strategy that includes a detailed maintenance schedule based on operational conditions and fluid properties. Utilizing a combination of chemical and mechanical cleaning methods can enhance the cleaning process. It is advisable to refer to the manufacturer’s guidelines and consider investing in maintenance training for staff to ensure they are equipped with the right techniques. Additionally, employing a maintenance management system can help track cleaning schedules, monitor performance metrics, and prompt timely interventions before issues arise.

Scenario 3: Addressing Leakage and Integrity Issues in Plate Exchangers

The Problem: Leakage is a common concern with plate heat exchangers, especially in gasketed models where aging gaskets can fail. For B2B buyers, this not only leads to product loss but also poses safety risks and environmental concerns. Identifying the early signs of leakage and knowing how to address them can be challenging, especially for companies operating in industries with stringent regulatory requirements.

The Solution: Buyers should implement a robust monitoring system that includes regular inspections and pressure testing to detect leaks before they escalate. Investing in high-quality gaskets and choosing a reliable supplier can also minimize leakage risks. Additionally, it’s important to create a contingency plan that outlines immediate actions in the event of a leak, including protocols for isolating the equipment and addressing the fluid loss. For long-term solutions, buyers should consider upgrading to semi-welded or brazed plate heat exchangers that offer improved durability and reduced risk of leakage. Regular training sessions for maintenance personnel on gasket condition assessment and replacement can further enhance equipment integrity and operational safety.

Strategic Material Selection Guide for plate exchanger diagram

What Are the Key Materials Used in Plate Exchanger Diagrams?

When selecting materials for plate heat exchangers, it’s essential to consider the specific properties and performance characteristics that align with your application needs. Below, we analyze four common materials used in plate exchanger diagrams, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel: The Industry Standard

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance, typically rated up to 300°C (572°F). It can withstand pressures exceeding 30 bar, making it suitable for a variety of applications.

Pros & Cons:

Stainless steel is durable and has a long lifespan, which reduces the need for frequent replacements. However, it is more expensive than other materials, and its manufacturing complexity can lead to higher initial costs.

Impact on Application:

This material is compatible with a wide range of media, including water, oils, and various chemicals, making it versatile for different industries.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4401. In regions like Europe and South America, there is a strong preference for stainless steel due to its reliability.

2. Titanium: The Corrosion Fighter

Key Properties:

Titanium offers exceptional corrosion resistance, particularly in aggressive environments, with temperature ratings up to 600°C (1112°F). It is lightweight yet strong, with pressure ratings similar to stainless steel.

Pros & Cons:

The primary advantage of titanium is its unmatched resistance to corrosion, making it ideal for applications involving seawater or acidic media. However, it is significantly more expensive than stainless steel, and its manufacturing process is complex, which can lead to longer lead times.

Impact on Application:

Titanium is particularly suited for applications in marine and chemical processing industries where corrosion is a significant concern.

Considerations for International Buyers:

International buyers should be aware of the need for specialized suppliers who can meet ASTM B265 or JIS H4600 standards. Titanium’s high cost may be a limiting factor for projects with tight budgets.

3. Copper: The Thermal Conductor

Key Properties:

Copper is a highly effective thermal conductor with a thermal conductivity rating significantly higher than that of stainless steel. It can handle temperatures up to 200°C (392°F) and moderate pressures.

Pros & Cons:

The main advantage of copper is its excellent heat transfer efficiency, which can lead to energy savings. However, it is less resistant to corrosion compared to stainless steel and titanium, and it may require protective coatings in certain environments.

Impact on Application:

Copper is best suited for applications involving water and other non-corrosive fluids, making it a popular choice in HVAC systems.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM B75 for copper and be aware of regional preferences, especially in Europe, where copper is widely accepted in plumbing and heating applications.

4. Carbon Steel: The Cost-Effective Option

Key Properties:

Carbon steel is a cost-effective option with good strength and pressure ratings, typically up to 250°C (482°F). However, it is prone to corrosion if not properly treated.

Pros & Cons:

The affordability of carbon steel makes it an attractive option for many applications. However, its susceptibility to rust and corrosion can lead to higher maintenance costs and reduced lifespan.

Impact on Application:

Carbon steel is suitable for applications involving water and other non-corrosive fluids but is not recommended for aggressive media.

Considerations for International Buyers:

International buyers should ensure compliance with standards like ASTM A36 and consider protective coatings to enhance corrosion resistance, especially in humid climates prevalent in Africa and parts of South America.

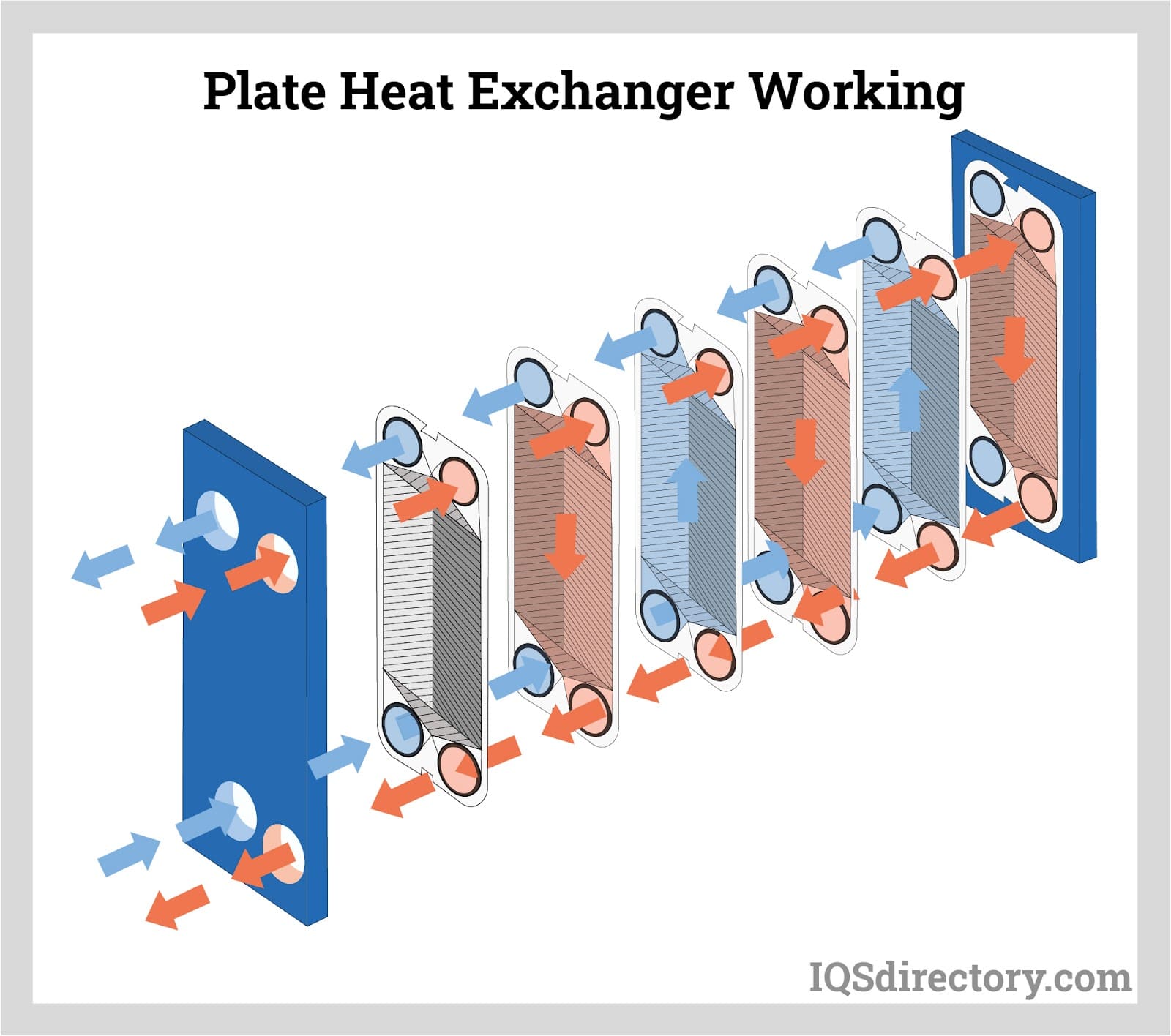

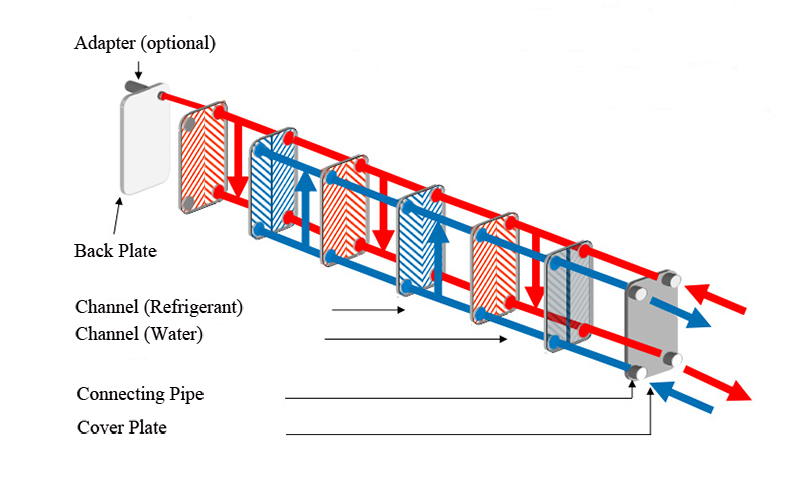

Illustrative image related to plate exchanger diagram

Summary Table of Material Selection for Plate Exchangers

| Material | Typical Use Case for plate exchanger diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Versatile applications in various industries | Excellent corrosion resistance | Higher initial cost | High |

| Titanium | Marine and chemical processing applications | Unmatched corrosion resistance | Very high cost, complex manufacturing | High |

| Copper | HVAC systems and non-corrosive fluids | Superior heat transfer efficiency | Prone to corrosion | Medium |

| Carbon Steel | Water systems and non-aggressive media | Cost-effective | Susceptible to rust | Low |

This strategic material selection guide provides valuable insights for B2B buyers in Africa, South America, the Middle East, and Europe, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for plate exchanger diagram

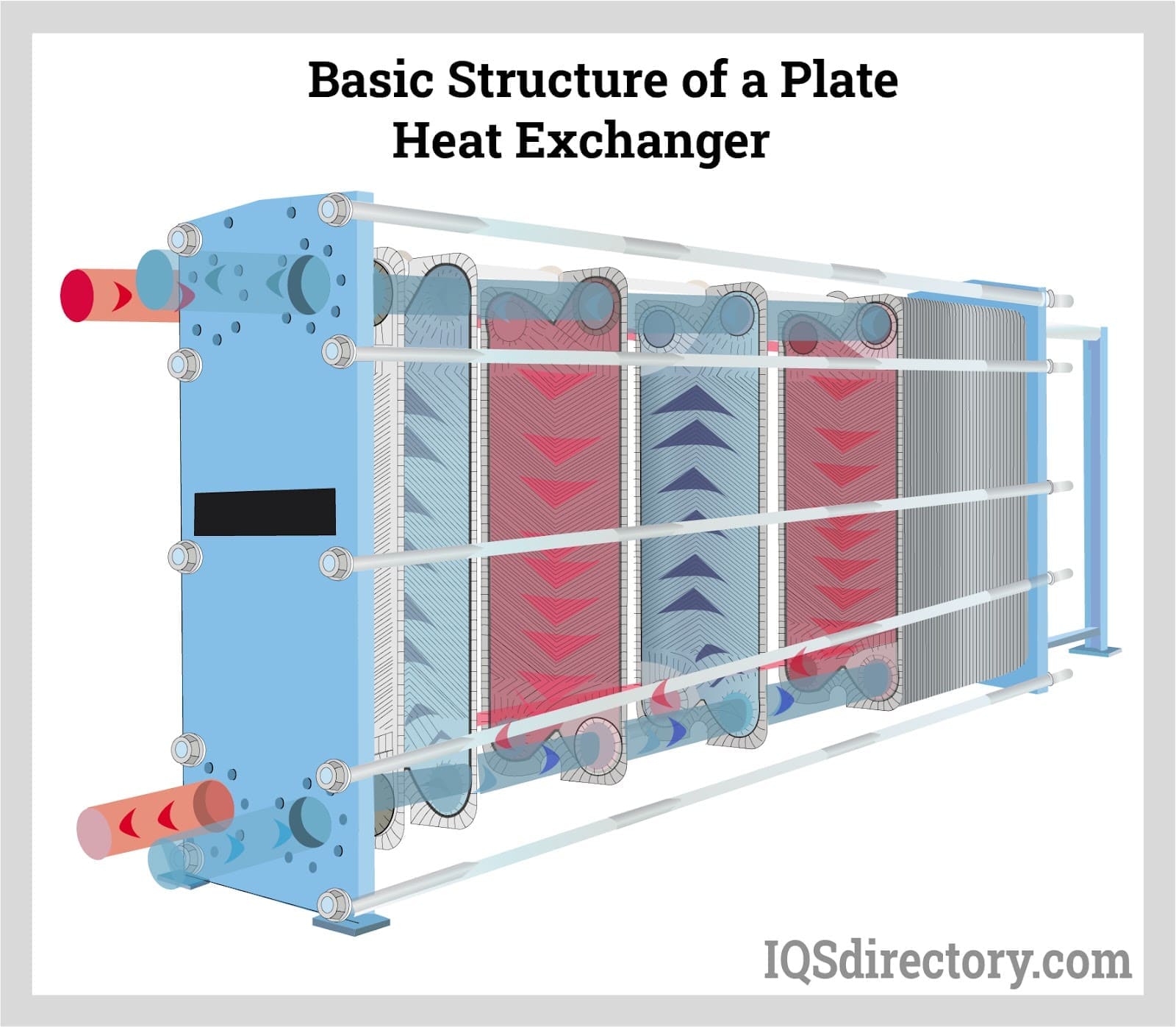

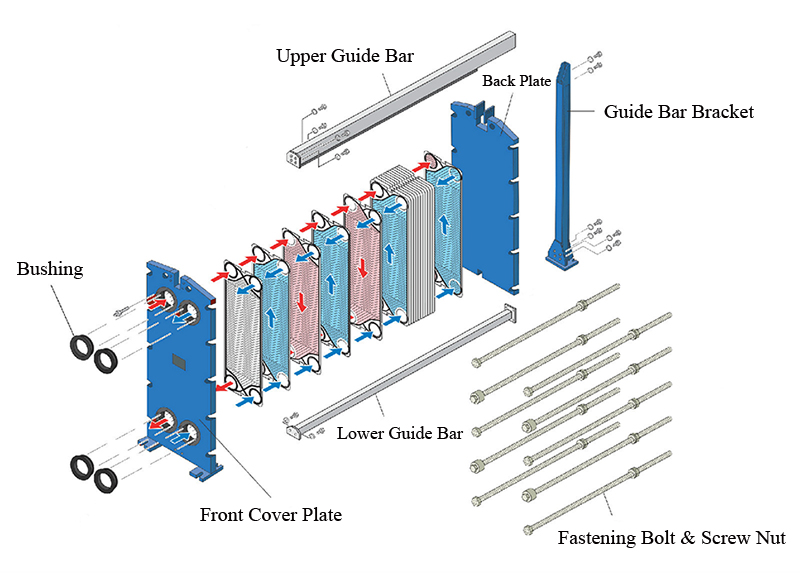

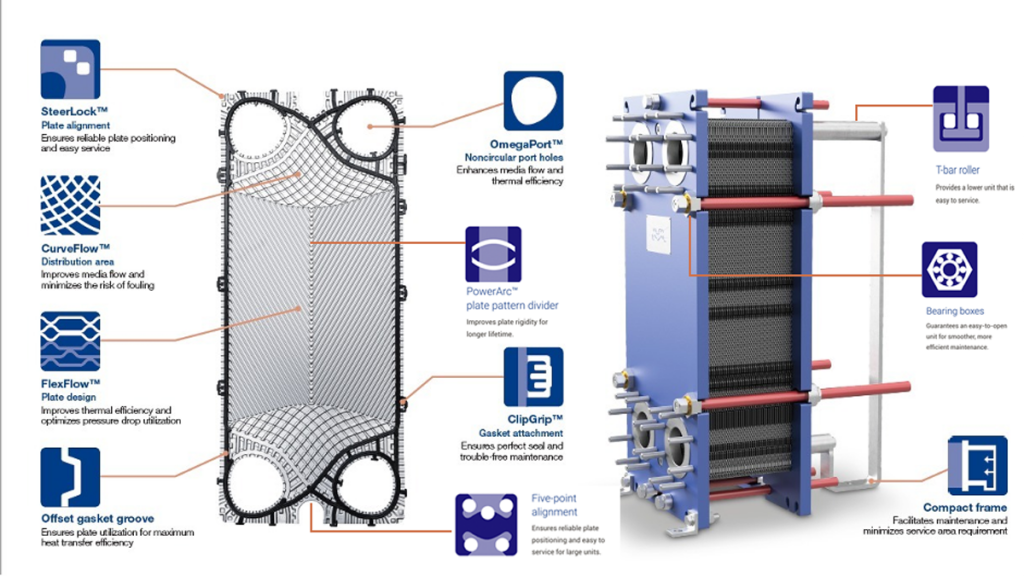

What Are the Main Stages of Manufacturing Plate Heat Exchangers?

Manufacturing plate heat exchangers involves several key stages, each critical for ensuring the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Plate Heat Exchanger Manufacturing?

The manufacturing process begins with material selection. Common materials for plate heat exchangers include stainless steel, titanium, and nickel alloys due to their excellent thermal conductivity and corrosion resistance. After selecting the appropriate material, it undergoes various processes such as cutting, shearing, and cleaning to prepare it for further processing. Quality control at this stage is vital to ensure that the materials meet the specified standards for thickness, surface quality, and composition.

What Techniques Are Used in the Forming Process of Plate Heat Exchangers?

The forming process typically involves techniques such as stamping or pressing to create the corrugated plates that maximize surface area for heat transfer. This process is crucial as the geometry of the plates significantly affects the efficiency of the heat exchanger. Advanced technology, such as CNC (Computer Numerical Control) machines, is often employed to ensure precision in the dimensions and shapes of the plates. The plates are then subjected to rigorous quality checks to confirm that they meet the design specifications.

Illustrative image related to plate exchanger diagram

How Is the Assembly of Plate Heat Exchangers Carried Out?

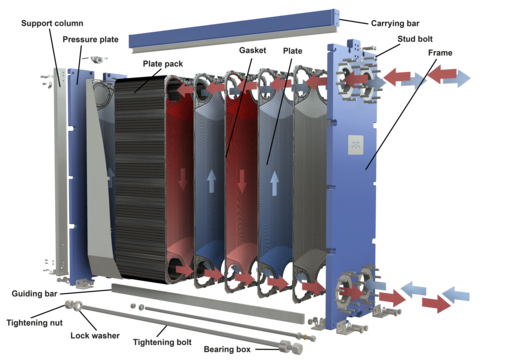

Once the plates are formed, they are assembled into a frame. The assembly process involves stacking the plates with spacers and gaskets to create the desired flow paths for the fluids. The assembly must be done with care to prevent leaks and ensure optimal performance. During this stage, manufacturers might use techniques like welding or brazing for specific designs, depending on the type of heat exchanger being produced. Quality checkpoints during assembly are crucial to ensure proper alignment and sealing.

What Finishing Processes Are Important for Plate Heat Exchangers?

The finishing stage typically includes cleaning, surface treatment, and coating, if necessary. Cleaning is essential to remove any contaminants that could affect performance or lead to corrosion. Surface treatments, such as passivation or electropolishing, enhance corrosion resistance and improve heat transfer efficiency. Finishing processes may also include the application of protective coatings to enhance durability, particularly for units intended for harsh environments.

What Quality Assurance Standards Are Relevant for Plate Heat Exchangers?

Quality assurance is critical in the manufacturing of plate heat exchangers. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain consistent quality in their processes and products. In addition to ISO standards, industry-specific certifications like CE marking for European markets or API (American Petroleum Institute) standards for the oil and gas industry may be required, depending on the application of the heat exchangers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) in plate heat exchanger manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials before they enter the production process. Ensuring that materials meet specified standards is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are performed to ensure that the components meet quality standards. This includes checking dimensions, material integrity, and adherence to design specifications.

-

Final Quality Control (FQC): After assembly and finishing, the completed heat exchangers undergo thorough testing, including pressure tests and thermal performance assessments. This final inspection ensures that the product performs as intended before shipment.

What Common Testing Methods Are Used in Quality Control?

Several testing methods are employed to ensure the quality and reliability of plate heat exchangers:

-

Pressure Testing: This method assesses the integrity of the heat exchanger by applying pressure to check for leaks. It ensures that the unit can withstand operational pressures.

-

Thermal Performance Testing: This evaluates the heat transfer efficiency of the exchanger. It involves running fluids through the system and measuring temperature changes to confirm that the exchanger meets performance specifications.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant inspections are used to detect flaws or defects in the materials without damaging them.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to mitigate risks. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into their quality control processes. During an audit, buyers can assess compliance with international standards and evaluate the effectiveness of QC measures.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control procedures, testing results, and certifications. This transparency can help buyers verify that the supplier meets industry standards.

-

Engage Third-Party Inspectors: Hiring independent third-party inspectors can provide an unbiased evaluation of the manufacturing processes and the quality of the finished products. This step can be particularly useful for buyers entering new markets or working with unfamiliar suppliers.

What Are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, buyers must be aware of specific nuances that may affect quality control:

-

Regulatory Compliance: Different countries have varying regulatory requirements. Understanding these can help buyers ensure that the products they receive are compliant with local laws and standards.

-

Cultural Differences in Quality Standards: Different regions may have different interpretations of quality. Buyers should engage in clear communication with suppliers to ensure that expectations are aligned.

-

Logistics and Supply Chain Factors: The quality of materials can be affected by transportation and storage conditions. Buyers should discuss these factors with suppliers to mitigate risks related to product integrity.

In summary, understanding the manufacturing processes and quality assurance measures for plate heat exchangers is vital for B2B buyers. By being informed about manufacturing stages, QC standards, and verification methods, buyers can make educated decisions, ensuring they select reliable suppliers that meet their operational needs.

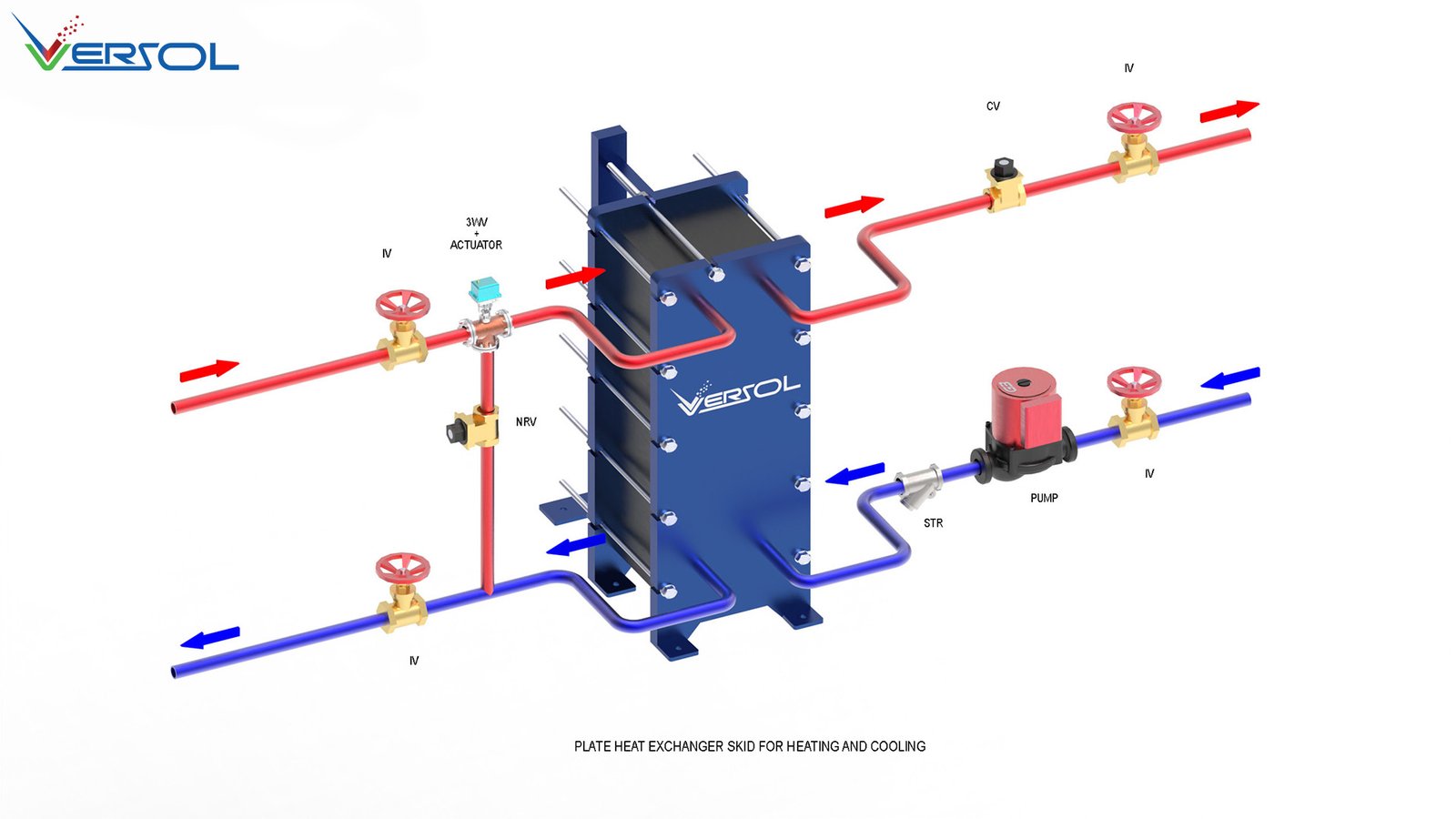

Illustrative image related to plate exchanger diagram

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plate exchanger diagram’

This guide aims to provide B2B buyers with a structured checklist for sourcing plate heat exchangers effectively. By following these steps, you can ensure that your procurement process is thorough, efficient, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of fluids involved, operating temperatures, pressures, and desired heat transfer efficiency. Ensuring that these specifications are well-defined helps in selecting the right type of plate heat exchanger—whether it be gasketed, brazed, or welded—tailored to your specific application.

Step 2: Research Industry Standards and Regulations

Understanding the relevant industry standards and regulations is crucial. Check for certifications such as ASME or ISO that ensure the heat exchanger meets safety and performance benchmarks. Compliance with local and international standards not only guarantees quality but also mitigates risks associated with equipment failure.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in manufacturing plate heat exchangers that meet your technical specifications and compliance requirements.

- Check for Experience: Prioritize suppliers who have been in the business for several years and understand the intricacies of heat exchange technology.

- Customer Feedback: Seek testimonials or reviews from previous clients to gauge satisfaction levels and service quality.

Step 4: Request Detailed Quotations

Once you have a shortlist of potential suppliers, request detailed quotations. Ensure these include not just pricing but also lead times, warranties, and after-sales support. This transparency helps you compare offers comprehensively and understand the total cost of ownership.

- Clarify Inclusions: Check if installation, maintenance, and training are included in the quote.

- Hidden Costs: Be wary of any additional fees that might arise post-purchase.

Step 5: Assess Supply Chain Reliability

Evaluate the supplier’s supply chain capabilities. This includes their ability to deliver on time and their sourcing of quality materials. A reliable supply chain is vital to ensure that you receive your heat exchangers without delays that could impact your operations.

- Production Capacity: Assess whether the supplier can handle your order size and any future scaling needs.

- Logistics and Support: Ensure they have robust logistics in place for international shipping, especially if you’re sourcing from regions like Europe or South America.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange site visits or virtual tours of the manufacturing facilities. This firsthand insight allows you to assess production practices and quality control measures. Understanding the manufacturing environment can provide confidence in the supplier’s capabilities.

- Quality Control Measures: Inquire about their quality assurance processes and testing protocols.

- Technology and Innovation: Evaluate their use of modern technology in manufacturing, as this can impact the efficiency and quality of the heat exchangers.

Step 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, ensure that all agreements are clearly documented. This includes payment terms, delivery schedules, and warranty details. A well-defined contract protects both parties and sets clear expectations for the procurement process.

- Legal Review: Consider having a legal expert review the contract to ensure all terms are fair and binding.

- Flexibility Clauses: Include clauses that allow for adjustments in case of unforeseen circumstances, ensuring adaptability in your agreement.

By diligently following these steps, you can navigate the procurement of plate heat exchangers with confidence, ensuring that your choice aligns with your operational requirements and strategic goals.

Comprehensive Cost and Pricing Analysis for plate exchanger diagram Sourcing

In the global marketplace, understanding the cost structure and pricing dynamics of plate heat exchangers is essential for B2B buyers seeking to optimize their procurement strategies. This analysis will delve into the various cost components involved in sourcing plate exchanger diagrams, the price influencers that affect overall costs, and provide actionable tips for buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Plate Exchanger Diagrams?

When evaluating the cost structure for plate heat exchangers, several key components come into play:

Illustrative image related to plate exchanger diagram

-

Materials: The choice of materials significantly impacts costs. Common materials include stainless steel, which offers corrosion resistance and durability, and aluminum, which is lighter but may not provide the same longevity. Specialty coatings can also add to material costs.

-

Labor: Labor costs encompass the workforce required for manufacturing and assembly. Skilled labor is essential for ensuring quality, particularly in the welding and assembly processes of heat exchangers.

-

Manufacturing Overhead: This includes costs associated with facility operation, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in pricing.

-

Tooling: The initial investment in tooling and machinery is a significant factor. Custom designs may require specialized tooling, increasing the upfront costs.

-

Quality Control (QC): Rigorous QC processes ensure that the plate exchangers meet industry standards and specifications. This can include testing for leaks, pressure resistance, and thermal efficiency, all of which contribute to overall costs.

-

Logistics: Shipping and handling costs vary by region and can be influenced by factors such as distance, shipping method, and import/export tariffs.

-

Margin: Suppliers typically apply a margin to cover costs and earn profit. This margin can fluctuate based on market demand and competitive pricing strategies.

How Do Price Influencers Affect the Sourcing of Plate Exchanger Diagrams?

Several factors can influence the pricing of plate exchangers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing discounts, making it crucial for buyers to assess their volume needs against supplier MOQs.

-

Specifications and Customization: Customized designs tailored to specific applications can significantly increase costs. Standardized models usually offer better pricing due to lower production complexity.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, ASME) can raise costs but may also enhance reliability and performance, which are essential for critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and reliability.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is vital, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can all affect the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers in Sourcing Plate Exchangers?

To maximize value when sourcing plate heat exchangers, buyers should consider the following tips:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime costs. A lower upfront cost may lead to higher TCO if the equipment requires frequent repairs.

-

Leverage Competitive Quotes: Obtaining multiple quotes from different suppliers can provide leverage during negotiations. Ensure that each quote is for comparable specifications to make informed decisions.

-

Build Long-term Relationships: Establishing a partnership with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

-

Stay Informed on Market Trends: Being aware of market dynamics, such as material costs and demand fluctuations, can inform negotiation strategies and timing for purchases.

Disclaimer on Pricing

Pricing for plate heat exchangers can vary widely based on numerous factors, including specifications, supplier location, and market conditions. It is advisable for buyers to conduct thorough market research and consult directly with suppliers to obtain accurate and current pricing information tailored to their specific needs.

By understanding these cost structures and influencers, B2B buyers can make more informed purchasing decisions, ensuring they secure the best value for their investment in plate heat exchangers.

Alternatives Analysis: Comparing plate exchanger diagram With Other Solutions

In the pursuit of optimizing thermal management systems, businesses often explore various heat exchange solutions. While the plate exchanger diagram offers a robust method for transferring heat between fluids, it’s essential to evaluate alternative technologies to determine the most suitable option for specific applications. Below, we compare the plate exchanger diagram with shell and tube heat exchangers and spiral heat exchangers, two viable alternatives in the industry.

Illustrative image related to plate exchanger diagram

Comparison Table

| Comparison Aspect | Plate Exchanger Diagram | Shell & Tube Heat Exchanger | Spiral Heat Exchanger |

|---|---|---|---|

| Performance | High heat transfer efficiency, compact design | Excellent for large temperature differentials, low pressure loss | Good for low to medium flow rates, compact design |

| Cost | Moderate initial investment, lower maintenance costs | Higher initial cost, but durable | Generally lower cost, but efficiency varies |

| Ease of Implementation | Requires skilled labor for assembly and maintenance | More complex installation, requires space | Simple installation, less space required |

| Maintenance | Easy to disassemble for cleaning, prone to leaks | Low maintenance but difficult to clean | Moderate maintenance, less prone to fouling |

| Best Use Case | Ideal for applications with small temperature differences | Best for extreme temperature applications | Suitable for limited space and lower flow rates |

Detailed Breakdown of Alternatives

Shell & Tube Heat Exchanger

Shell and tube heat exchangers consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid, facilitating heat transfer. Their robust design allows them to handle high-pressure applications and extreme temperature differentials effectively. However, they come with a higher initial cost and require more space for installation. Maintenance can be challenging, as cleaning often necessitates disassembly, which can lead to downtime. They are best suited for industries where high temperatures and pressures are prevalent, such as oil and gas or chemical processing.

Spiral Heat Exchanger

Spiral heat exchangers feature a unique design where two fluids flow in a spiral configuration, enhancing the heat transfer surface area while maintaining a compact footprint. Their installation is straightforward, making them a preferred choice for facilities with limited space. They are particularly effective at handling lower flow rates and can accommodate viscous fluids, making them suitable for food processing and wastewater applications. However, the efficiency can vary based on the specific application, and they may require moderate maintenance to prevent fouling.

Conclusion: How to Choose the Right Heat Exchange Solution

For B2B buyers, selecting the right heat exchange solution hinges on understanding the specific operational requirements and constraints of their applications. The plate exchanger diagram excels in environments with small temperature differentials and offers ease of maintenance, making it suitable for many industrial applications. In contrast, shell and tube heat exchangers are ideal for high-temperature scenarios, while spiral heat exchangers provide a space-efficient option for lower flow rates. Evaluating these aspects—performance, cost, ease of implementation, and maintenance—will enable decision-makers to choose the most effective solution for their thermal management needs, ultimately enhancing operational efficiency and sustainability.

Essential Technical Properties and Trade Terminology for plate exchanger diagram

What Are the Key Technical Properties of Plate Exchangers?

When considering plate heat exchangers for industrial applications, understanding specific technical properties is crucial for optimizing performance and ensuring reliability. Below are essential specifications to evaluate:

1. Material Grade

Plate heat exchangers are commonly constructed from stainless steel, titanium, or nickel alloys. The choice of material significantly impacts corrosion resistance, thermal conductivity, and overall durability. For example, stainless steel is favored for its resistance to oxidation and ability to handle high temperatures, making it ideal for food and pharmaceutical applications. In contrast, titanium is used in corrosive environments, such as seawater applications, due to its superior resistance to corrosive agents.

2. Plate Thickness

Plate thickness typically ranges from 0.5 mm to 1.5 mm. Thicker plates can withstand higher pressures and temperatures but may reduce heat transfer efficiency due to increased thermal mass. Conversely, thinner plates enhance heat transfer but may limit the exchanger’s operational capacity. Selecting the appropriate thickness is essential for balancing durability and efficiency, particularly in high-pressure applications.

Illustrative image related to plate exchanger diagram

3. Flow Configuration

Understanding the flow configuration—counterflow, parallel flow, or crossflow—is vital for optimizing heat transfer efficiency. Counterflow configurations typically offer the highest thermal efficiency as the fluids move in opposite directions, maintaining a higher temperature differential throughout the heat exchanger. This can lead to reduced energy consumption and lower operational costs, making it a preferred choice for many industrial applications.

4. Pressure Drop

The pressure drop across the heat exchanger is a critical factor affecting system efficiency. A lower pressure drop translates to reduced pumping costs and energy consumption, which is particularly important in large-scale operations. Manufacturers often provide pressure drop specifications, allowing buyers to assess compatibility with existing systems and ensure optimal performance.

5. Thermal Efficiency (U-Value)

The U-value measures the heat transfer efficiency of the plate heat exchanger, typically expressed in W/m²K. A higher U-value indicates better performance, allowing for more effective heat transfer between fluids. Evaluating the U-value helps buyers select exchangers that meet specific thermal performance requirements, ultimately influencing energy savings and operational efficiency.

6. Fouling Resistance

Fouling refers to the accumulation of unwanted materials on heat transfer surfaces, which can significantly reduce efficiency. Plate heat exchangers are designed with features that enhance fouling resistance, such as corrugated plates that promote turbulence and self-cleaning effects. Understanding fouling characteristics is essential for selecting the right exchanger for applications with high fouling potential, minimizing maintenance costs and downtime.

What Are Common Trade Terms Related to Plate Exchangers?

Familiarity with industry jargon can facilitate smoother negotiations and enhance decision-making. Here are several key terms relevant to plate heat exchangers:

1. OEM (Original Equipment Manufacturer)

An OEM produces components that are used in another company’s end products. Understanding OEM specifications is crucial for ensuring compatibility and performance when integrating plate heat exchangers into existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers to understand as it affects inventory management and purchasing strategies, especially in projects with tight budgets or specific requirements.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. This term is essential in the procurement process, as it helps businesses compare offers and negotiate terms effectively, ensuring they receive the best value for their investments.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for buyers involved in cross-border procurement, as they dictate cost allocation and risk management.

Illustrative image related to plate exchanger diagram

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for project planning and inventory management, particularly in industries where timely delivery is critical to operational success.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting plate heat exchangers, ensuring that they meet operational needs while optimizing cost efficiency.

Navigating Market Dynamics and Sourcing Trends in the plate exchanger diagram Sector

What Are the Current Market Dynamics and Key Trends in the Plate Exchanger Diagram Sector?

The global market for plate heat exchangers is experiencing significant growth, driven by increasing industrialization and the demand for energy-efficient technologies. Key trends include the rise of compact designs that offer superior heat transfer efficiency, catering to industries ranging from food and beverage to HVAC and petrochemicals. International B2B buyers, especially from emerging markets like Africa, South America, the Middle East, and parts of Europe, are increasingly seeking advanced solutions to improve operational efficiency and reduce energy consumption.

Technological advancements, such as the integration of IoT for real-time monitoring and predictive maintenance, are reshaping sourcing strategies. Buyers are keen on products that not only meet performance standards but also offer digital features that facilitate operational transparency. Additionally, the shift towards sustainability is influencing purchasing decisions, with businesses prioritizing suppliers who demonstrate a commitment to reducing environmental impact.

Furthermore, trade dynamics are shifting as countries aim to bolster local manufacturing capabilities while navigating supply chain disruptions. Buyers should stay informed about geopolitical factors and trade agreements that could affect sourcing options and costs. Understanding these dynamics is crucial for making informed procurement decisions in a competitive landscape.

How Is Sustainability Influencing Sourcing Trends in the Plate Exchanger Diagram Sector?

Sustainability is becoming a pivotal factor in the sourcing of plate heat exchangers. As global awareness of environmental issues grows, businesses are increasingly pressured to adopt practices that minimize their ecological footprint. This has led to a surge in the demand for heat exchangers that utilize eco-friendly materials and designs that optimize energy efficiency.

B2B buyers are not just looking for functional equipment; they are also evaluating suppliers based on their environmental credentials. Certifications such as ISO 14001 for environmental management and the use of recyclable materials are becoming critical in the selection process. Suppliers who can demonstrate a commitment to ethical sourcing and sustainability practices are more likely to gain the trust of international buyers.

The importance of creating ethical supply chains cannot be overstated. Buyers are now more conscious of the entire lifecycle of their products, from material sourcing to end-of-life disposal. This trend is particularly strong in regions like Europe, where regulatory frameworks increasingly favor sustainable practices. By prioritizing suppliers that align with these values, businesses can enhance their brand reputation and ensure compliance with evolving regulations.

Illustrative image related to plate exchanger diagram

What Is the Brief Evolution of Plate Heat Exchangers in the B2B Context?

The evolution of plate heat exchangers dates back to the early 20th century when they were first introduced as an alternative to traditional shell-and-tube heat exchangers. Initially limited to specific applications, advancements in design and material technology have significantly broadened their use across various industries.

The introduction of gaskets and advanced plate designs improved their efficiency and reliability, making them a preferred choice for many applications. Over the years, innovations such as brazed and welded plate heat exchangers have emerged, catering to specialized needs such as high-pressure and high-temperature environments.

Today, plate heat exchangers are recognized for their compact size and superior heat transfer capabilities, making them essential in industries that prioritize energy efficiency and sustainability. As the market continues to evolve, ongoing research and development are likely to yield even more efficient solutions, further solidifying the role of plate heat exchangers in modern industrial applications.

Illustrative image related to plate exchanger diagram

Frequently Asked Questions (FAQs) for B2B Buyers of plate exchanger diagram

-

How do I solve issues related to plate exchanger efficiency?

To enhance the efficiency of a plate heat exchanger, regularly monitor and maintain the system. This includes cleaning the plates to prevent fouling, checking for leaks, and ensuring proper fluid flow rates. Additionally, consider optimizing the inlet temperatures and flow configurations to maximize heat transfer. If persistent inefficiencies arise, consult with technical experts who can analyze your specific application and recommend design modifications or equipment upgrades. -

What is the best type of plate heat exchanger for high-temperature applications?

For high-temperature applications, welded plate heat exchangers are generally the best choice. Unlike gasketed models, welded designs can withstand higher pressures and temperatures without the risk of gasket degradation. They are ideal for transferring fluids that are corrosive or operate at extreme temperatures. However, consider the cleaning challenges associated with welded units, as they cannot be disassembled for maintenance, making semi-welded models a good compromise for some applications. -

What factors should I consider when sourcing a plate exchanger diagram?

When sourcing a plate exchanger diagram, focus on the specific requirements of your application, including fluid types, temperatures, and pressures. Additionally, evaluate the design for maintenance accessibility, the materials used for construction, and the expected heat transfer efficiency. Ensure that the supplier provides detailed technical specifications and support to help you understand how the diagram translates into operational efficiency. -

How can I vet suppliers for plate heat exchangers?

To effectively vet suppliers, check their industry certifications and quality assurance processes. Request references from previous clients and assess their experience with similar projects. Evaluate their manufacturing capabilities, including technology used and compliance with international standards. Additionally, consider their financial stability and ability to provide after-sales support, as this can significantly impact your long-term satisfaction with the product. -

What are typical minimum order quantities (MOQs) for plate heat exchangers?

Minimum order quantities (MOQs) for plate heat exchangers can vary significantly by supplier and region. Typically, MOQs range from 1 to 10 units, depending on customization needs and production capabilities. For large-scale projects, suppliers may offer lower MOQs or discounts for bulk orders. It’s advisable to discuss your specific requirements with potential suppliers to negotiate favorable terms that align with your purchasing strategy. -

What payment terms should I expect when purchasing from international suppliers?

Payment terms for international purchases of plate heat exchangers often include options like advance payment, letters of credit, or installment payments based on shipment milestones. Standard practices may require a deposit (often 30-50%) before production, with the balance due upon shipment or delivery. Always clarify payment terms and conditions with your supplier to avoid misunderstandings and ensure a smooth transaction process. -

How do I ensure quality assurance (QA) for my plate exchanger?

To ensure quality assurance for your plate exchanger, request detailed documentation on the manufacturing process and quality control measures from your supplier. Implement a pre-shipment inspection to verify that the product meets your specifications. Additionally, consider requesting third-party certifications that demonstrate compliance with industry standards. Establishing a clear communication channel with your supplier for ongoing QA discussions can also help maintain product quality. -

What logistics considerations should I keep in mind when importing plate heat exchangers?

When importing plate heat exchangers, consider shipping costs, customs duties, and the lead time required for delivery. Collaborate with logistics providers experienced in handling industrial equipment to navigate complex international shipping regulations. Ensure that the packaging is robust to prevent damage during transit. Additionally, familiarize yourself with local import regulations and necessary documentation to avoid delays at customs.

Top 6 Plate Exchanger Diagram Manufacturers & Suppliers List

1. Facebook – Plate Heat Exchanger Diagram

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This detailed diagram of a plate heat exchanger highlights its main components and functional design. The frame plate forms the outer structure, while tightening bolts secure the channel plates together to create sealed flow paths. Connections on the frame plate allow media to enter and exit the exchanger, with threaded studs securing pipes and preventing corrosion through protective linings. The …

2. WCRUK – Plate Heat Exchangers

Domain: wcruk.com

Registered: 2003 (22 years)

Introduction: This company, WCRUK – Plate Heat Exchangers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Thermopedia – Plate and Frame Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Plate and Frame Heat Exchangers are designed for efficient heat transfer with a patented concept dating back to the late 19th century. The first successful model was introduced in 1923 by Dr. Richard Seligman. Key features include:

– Operating pressures ranging from 1 to 25 atmospheres.

– Constructed from various materials such as stainless steel, titanium, and Hastelloy.

– Plates are pressed t…

4. Savree – Plate Heat Exchangers

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Plate heat exchangers (PHE) are efficient, robust, and easy to maintain. They consist of few parts including plates, gaskets, a carry bar, clamping bolts, and two covers (one movable and one fixed). The plates are designed with a small gap for good thermal contact, large surface area for high heat transfer rates, and corrugations to promote turbulent flow and prevent deposits. Gaskets maintain sea…

5. ScienceDirect – Plate Heat Exchanger

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A plate heat exchanger (PHE) is a type of heat exchanger commonly used in the food industry, known for its high efficiency of up to 95%. It can be configured in gasketed, welded, or brazed forms. PHEs consist of several thin metallic plates stacked together to form flow channels, allowing heat transfer between fluids while preventing cross-contamination. The plates can be flat or corrugated, and f…

6. Plate Heat Exchangers – Key Benefits and Types

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: Plate heat exchangers use metal plates to transfer heat between two fluids flowing in alternating passages. They are classified into three types: plate and frame, brazed, or welded, depending on how the plates are joined. Key benefits include compact size and high efficiency, while limitations include restricted operating pressures and temperatures, as well as susceptibility to fouling. Overall, p…

Strategic Sourcing Conclusion and Outlook for plate exchanger diagram

In the evolving landscape of industrial efficiency, the adoption of plate heat exchangers represents a strategic advantage for businesses across various sectors. These systems not only enhance thermal efficiency but also contribute to sustainability by reducing energy consumption. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of plate exchanger technology is crucial for making informed procurement decisions that align with both operational needs and environmental goals.

Strategic sourcing plays a pivotal role in selecting the right heat exchanger type—be it gasketed, brazed, or semi-welded—tailored to specific applications and fluid dynamics. By investing in high-quality equipment and maintenance practices, companies can maximize uptime, reduce operational costs, and mitigate risks associated with leakage and pressure drops.

As the demand for energy-efficient solutions continues to grow, now is the time for international buyers to engage with suppliers who can provide innovative, reliable, and sustainable heat exchanger options. Embrace the opportunity to enhance your operational efficiency and contribute to a greener future. Reach out to industry experts today to explore how plate heat exchangers can elevate your business performance and sustainability initiatives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to plate exchanger diagram

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.