Perf Panel Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for perf panel

In the dynamic world of construction and design, sourcing high-quality perforated panels can pose significant challenges for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As businesses increasingly seek materials that combine functionality with aesthetic appeal, understanding the diverse applications and specifications of perforated panels becomes crucial. This comprehensive guide delves into the various types of perf panels available, their applications in industries ranging from architecture to filtration, and the essential factors to consider when vetting suppliers.

By providing insights into material options—such as aluminum, stainless steel, and plastics—alongside considerations for cost, durability, and design flexibility, this guide empowers international buyers to make informed purchasing decisions. With a focus on practical applications and supplier credibility, it aims to simplify the often-complex process of sourcing perforated panels. Whether you’re a buyer in Saudi Arabia looking for innovative architectural solutions or a procurement officer in Germany seeking reliable filtration systems, this resource will equip you with the knowledge necessary to navigate the global market effectively. Embrace the potential of perforated panels to enhance your projects, ensuring you not only meet industry standards but also exceed client expectations.

Understanding perf panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Perforated Panels | Circular holes, versatile hole sizes | Architectural facades, equipment screens | Pros: Aesthetic appeal, good ventilation; Cons: Limited structural support compared to solid panels. |

| Square Perforated Panels | Square holes, uniform spacing | Signage, partitions, filtration systems | Pros: Strong structural integrity; Cons: Less aesthetic flexibility than round panels. |

| Slotted Perforated Panels | Elongated holes, customizable slot dimensions | Acoustic panels, ventilation systems | Pros: Enhanced airflow, sound absorption; Cons: Requires precise installation for optimal performance. |

| Hexagonal Perforated Panels | Honeycomb-like pattern, high open area percentage | Decorative applications, partitions | Pros: Unique visual appeal, lightweight; Cons: Potentially less durable under heavy loads. |

| Designer Perforated Panels | Custom patterns and designs tailored for aesthetics | High-end architectural projects, art installations | Pros: Tailored aesthetics, branding opportunities; Cons: Higher cost and longer lead times. |

What Are the Characteristics of Round Perforated Panels?

Round perforated panels feature circular holes that can be customized in various sizes and spacing arrangements. They are widely used in architectural facades and equipment screens, providing a balance between aesthetics and functionality. Buyers should consider the strength-to-weight ratio and the desired airflow when selecting round panels, as they offer good ventilation but may not provide the structural support needed for heavy-duty applications.

How Do Square Perforated Panels Stand Out?

Square perforated panels are characterized by their uniform square holes, making them ideal for applications requiring structural integrity, such as signage and partitions. Their design allows for effective filtration in various industrial settings. When purchasing, businesses should weigh the benefits of strength and durability against the limited design flexibility compared to other perforation types.

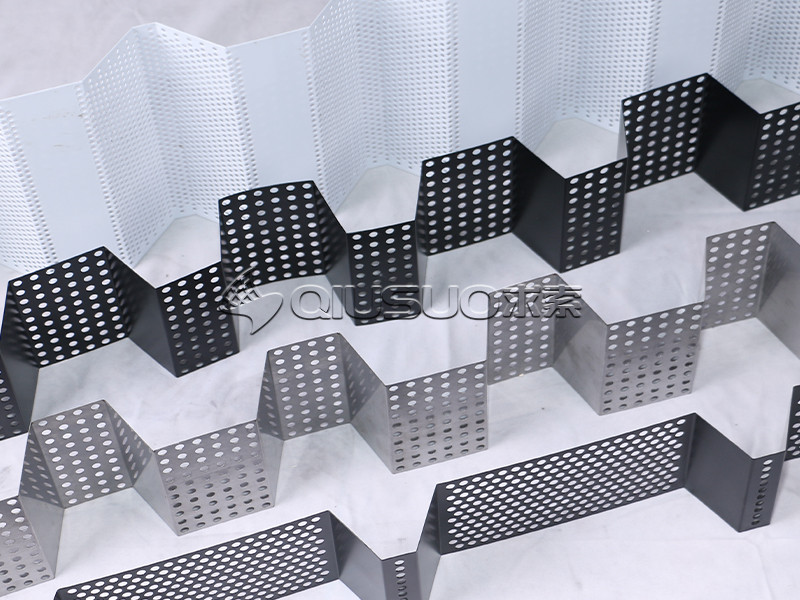

Illustrative image related to perf panel

What Are the Advantages of Slotted Perforated Panels?

Slotted perforated panels have elongated holes that allow for enhanced airflow and sound absorption, making them suitable for acoustic panels and ventilation systems. The customization options for slot dimensions can meet specific project requirements. Buyers must ensure precise installation to achieve optimal performance, as misalignment can diminish the effectiveness of airflow and sound control.

Why Choose Hexagonal Perforated Panels?

Hexagonal perforated panels offer a unique honeycomb pattern that provides a high percentage of open area, making them visually striking and lightweight. They are often used in decorative applications and partitions. While they enhance aesthetic appeal, buyers should consider their load-bearing capacity, as hexagonal panels may not be as robust as other types under heavy loads.

What Makes Designer Perforated Panels Unique?

Designer perforated panels allow for custom patterns and designs, catering to high-end architectural projects and art installations. They provide significant branding opportunities and aesthetic appeal. However, buyers should be prepared for higher costs and longer lead times when opting for these specialized products, making them suitable for projects where visual impact is paramount.

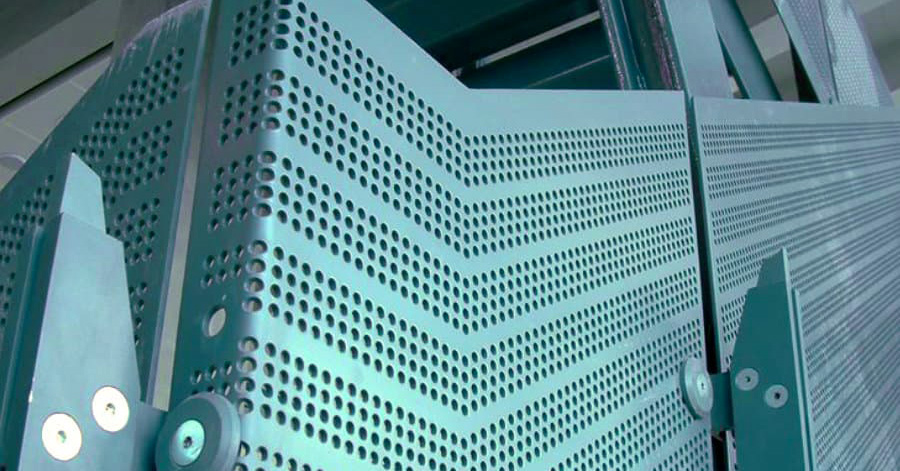

Illustrative image related to perf panel

Key Industrial Applications of perf panel

| Industry/Sector | Specific Application of perf panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Architectural Facades and Screens | Enhances aesthetic appeal while providing ventilation | Material durability, design specifications, and local regulations |

| Automotive | Grilles and Ventilation Systems | Improves airflow, reduces weight, and enhances design | Compatibility with vehicle models, corrosion resistance, and aesthetic alignment |

| HVAC Systems | Air Filters and Louvers | Efficient airflow management and filtration efficiency | Filtration capabilities, maintenance requirements, and compliance with industry standards |

| Industrial Equipment | Guards and Safety Screens | Increases safety while maintaining visibility | Material strength, hole size specifications, and compliance with safety regulations |

| Electronics Manufacturing | Acoustic Panels for Noise Reduction | Enhances sound quality and reduces operational noise | Acoustic performance, material properties, and environmental considerations |

How is ‘perf panel’ Used in Construction Projects?

In the construction industry, perforated panels are often employed in architectural facades and screens. These panels not only enhance the aesthetic appeal of buildings but also allow for airflow and light penetration, contributing to energy efficiency. Buyers should consider the material’s durability and design specifications to ensure compliance with local building codes, especially in regions like Europe and the Middle East, where architectural standards can be stringent.

What Role Do Perforated Panels Play in Automotive Applications?

In the automotive sector, perforated panels are utilized for grilles and ventilation systems. They facilitate improved airflow while reducing the overall weight of vehicles, which can enhance fuel efficiency. Buyers in this sector must ensure compatibility with specific vehicle models and consider factors such as corrosion resistance and design aesthetics, particularly in markets like South America and Africa, where environmental conditions can vary significantly.

How are Perforated Panels Beneficial in HVAC Systems?

Perforated panels serve a critical role in HVAC systems as air filters and louvers. They manage airflow efficiently while providing effective filtration of particles and contaminants. For international B2B buyers, sourcing considerations include the panel’s filtration capabilities, maintenance requirements, and adherence to industry standards, which can differ across regions like Europe and the Middle East.

Illustrative image related to perf panel

Why are Perforated Panels Important for Industrial Equipment?

In industrial settings, perforated panels are commonly used as guards and safety screens. These applications increase safety by preventing accidental contact with moving parts while maintaining visibility for operational monitoring. Buyers should focus on the material strength and hole size specifications to ensure compliance with safety regulations, particularly in high-risk industries prevalent in Africa and South America.

How Do Perforated Panels Enhance Electronics Manufacturing?

In electronics manufacturing, perforated panels are often used as acoustic panels to reduce noise levels in production environments. This application enhances sound quality and minimizes operational noise, contributing to a better working atmosphere. Buyers should evaluate the acoustic performance of the panels, along with their material properties, to ensure they meet environmental considerations and industry standards, especially in European markets where noise regulations are more stringent.

3 Common User Pain Points for ‘perf panel’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Material for Specific Applications

The Problem: B2B buyers often struggle to identify the appropriate material for their perforated panel needs, especially when considering factors such as strength, weight, and environmental conditions. For example, a construction firm in Saudi Arabia may require perforated panels for exterior cladding that can withstand high temperatures and humidity, while a manufacturer in Germany might need panels for soundproofing in an industrial setting. This lack of clarity can lead to costly mistakes, project delays, and reduced performance of the final product.

The Solution: To overcome this challenge, buyers should start by clearly defining the application requirements, including environmental factors, load-bearing needs, and aesthetic preferences. Engage with suppliers who offer a diverse range of materials such as aluminum, stainless steel, or galvanized steel, and request detailed specifications. Suppliers with extensive inventories, like McNICHOLS, can provide samples and technical guidance on the best material choices for specific applications. It’s also advisable to consult with engineers or architects who can assist in evaluating the mechanical properties of various materials, ensuring that the chosen perforated panels meet the required standards for durability and functionality.

Scenario 2: Inconsistent Quality and Performance of Perforated Panels

The Problem: Many B2B buyers face issues with the quality and consistency of perforated panels, which can vary significantly between manufacturers. This inconsistency may manifest in uneven hole sizes, inadequate strength-to-weight ratios, or poor finishing, which can compromise the integrity of projects and lead to rework. A buyer in South America may experience this firsthand when panels sourced from different suppliers perform differently, affecting the overall project timeline and budget.

The Solution: To mitigate quality concerns, buyers should establish a robust vetting process for suppliers. Look for manufacturers that provide detailed quality assurance protocols and certifications, such as ISO standards. It is beneficial to request product samples and conduct comparative testing before placing large orders. Additionally, consider forming long-term relationships with suppliers who have a proven track record in the industry, as this can lead to better quality assurance practices. Engaging in regular communication with suppliers regarding quality expectations can also foster accountability and transparency.

Scenario 3: Complex Installation Processes Leading to Increased Labor Costs

The Problem: Installation of perforated panels can often be more complicated than anticipated, leading to increased labor costs and extended project timelines. For instance, a construction company in Europe may find that the installation requires specialized skills or tools that their crew lacks, resulting in project delays and unexpected expenses. This challenge is compounded when the panels are custom-sized or require specific finishing touches.

Illustrative image related to perf panel

The Solution: To streamline the installation process, buyers should prioritize sourcing perforated panels that come with clear installation guidelines and support from the manufacturer. Engaging with suppliers who offer installation training or technical assistance can significantly reduce the learning curve for on-site teams. Furthermore, opting for prefabricated panels can minimize installation complexity, as these are often designed for easier assembly and compatibility with existing structures. Lastly, consider hiring experienced contractors who specialize in perforated panel installations to ensure that projects are completed efficiently and correctly, thus avoiding unnecessary costs and delays.

Strategic Material Selection Guide for perf panel

What Are the Key Properties of Common Materials Used for Perf Panels?

When selecting materials for perforated panels, it’s essential to understand the properties that influence their performance in various applications. Here, we analyze four common materials: Aluminum, Carbon Steel, Stainless Steel, and Galvanized Steel.

Aluminum: Lightweight and Versatile

Aluminum is a popular choice for perforated panels due to its lightweight nature and excellent corrosion resistance. It typically performs well in a range of temperatures, making it suitable for both indoor and outdoor applications. The material’s high strength-to-weight ratio allows for ease of installation and versatility in design.

Pros: Aluminum is durable, resistant to rust, and offers aesthetic appeal, making it ideal for architectural applications. It is also relatively easy to fabricate, which can reduce manufacturing complexity.

Illustrative image related to perf panel

Cons: While aluminum is generally cost-effective, it can be more expensive than some steel options. Additionally, it may not be suitable for high-load applications without proper reinforcement.

Impact on Application: Aluminum panels are often used in environments where weight is a concern, such as in facades or partitions. They effectively diffuse light and sound, making them suitable for both aesthetic and functional applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly in regions like Europe or the Middle East, where regulations may dictate specific material properties.

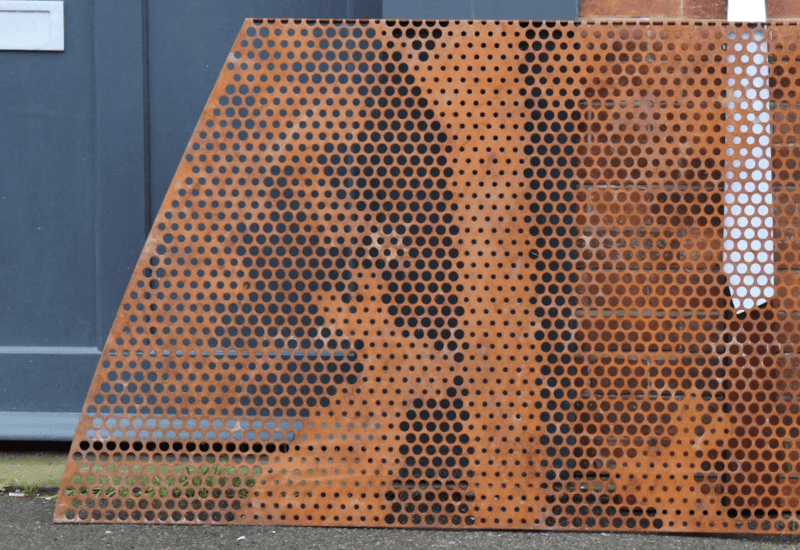

Carbon Steel: Strength and Cost-Effectiveness

Carbon steel is known for its high strength and durability, making it suitable for heavy-duty applications. It can withstand significant pressure and is often used in industrial settings.

Pros: The primary advantage of carbon steel is its cost-effectiveness, particularly for large-scale projects. It is widely available and can be manufactured into various shapes and sizes.

Cons: Carbon steel is prone to corrosion and requires protective coatings or finishes, which can increase long-term maintenance costs. It is also heavier than aluminum, which may complicate installation.

Impact on Application: Carbon steel perforated panels are often used in structural applications, such as safety guards and enclosures. However, they may not be suitable for environments with high moisture or corrosive elements.

Considerations for International Buyers: Buyers in regions like South America and Africa should be aware of the need for protective coatings to comply with local environmental conditions.

Stainless Steel: Corrosion Resistance and Longevity

Stainless steel is highly valued for its corrosion resistance and longevity, making it ideal for harsh environments. It maintains its structural integrity under high temperatures and pressures.

Pros: The durability of stainless steel makes it a long-term investment, as it requires minimal maintenance. It is also aesthetically pleasing and can be polished for a high-end finish.

Cons: The initial cost of stainless steel is higher than that of aluminum and carbon steel. Additionally, its weight can pose challenges in terms of handling and installation.

Impact on Application: Stainless steel panels are commonly used in food processing, chemical plants, and other environments where hygiene and corrosion resistance are critical.

Illustrative image related to perf panel

Considerations for International Buyers: Compliance with international standards, such as JIS in Japan or ASTM in the U.S., is crucial for buyers in Europe and the Middle East to ensure product quality and safety.

Galvanized Steel: Cost-Effective Corrosion Protection

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. This material is popular for outdoor applications where exposure to moisture is a concern.

Pros: The galvanization process provides a cost-effective solution for corrosion protection, making it a popular choice for budget-conscious projects. It also offers good strength and durability.

Cons: While galvanized steel is resistant to rust, the coating can wear off over time, requiring maintenance or re-coating. It is also heavier than aluminum, which may complicate installation.

Illustrative image related to perf panel

Impact on Application: Galvanized perforated panels are often used in outdoor structures, such as fencing and roofing, where durability is essential.

Considerations for International Buyers: Buyers should verify the quality of galvanization to ensure compliance with local standards, especially in humid or coastal environments.

Summary Table of Material Properties for Perf Panels

| Material | Typical Use Case for perf panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Architectural facades, partitions | Lightweight and corrosion-resistant | Higher cost than some steels | Medium |

| Carbon Steel | Safety guards, industrial applications | Cost-effective and strong | Prone to corrosion | Low |

| Stainless Steel | Food processing, chemical plants | Long-lasting and low maintenance | Higher initial cost | High |

| Galvanized Steel | Outdoor structures, fencing | Cost-effective corrosion protection | Coating can wear off | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for perf panel

What Are the Key Stages in the Manufacturing Process of Perforated Panels?

The manufacturing process of perforated panels is a multi-stage procedure that ensures the final product meets the specific requirements of various applications. The main stages involved include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate raw materials, which can include aluminum, stainless steel, carbon steel, or plastic. The choice of material is crucial as it affects the panel’s strength, corrosion resistance, and aesthetic appeal. Sheets are typically cut to size based on the specified dimensions for the perforated panels.

-

Forming Techniques: This stage involves the actual perforation of the material. Various techniques are employed, such as punch pressing, laser cutting, or water jet cutting, depending on the desired hole size, shape, and pattern. Punch pressing is commonly used for high-volume production as it offers speed and precision. Laser cutting allows for intricate designs and is ideal for custom orders.

-

Assembly: After perforation, the panels may undergo additional processes such as bending, welding, or assembling into larger structures. This step is particularly relevant for applications that require the panels to be integrated into frameworks or systems, such as enclosures or partitions.

-

Finishing: The final stage involves applying protective coatings or treatments to enhance durability and aesthetics. This may include anodizing, powder coating, or painting. Finishing not only improves the visual appeal but also provides resistance against environmental factors, which is essential for outdoor applications.

How Is Quality Assurance Implemented in Perforated Panel Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for perforated panels, ensuring that the products meet both international standards and specific customer requirements.

-

International Standards: Adhering to recognized standards such as ISO 9001 is vital for manufacturers aiming to maintain a high level of quality management. This certification indicates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE marking (European Conformity) and API (American Petroleum Institute) may apply, depending on the panel’s intended use.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the production process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the specified criteria before being used in manufacturing.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to identify any deviations from quality standards, allowing for immediate corrective actions.

– Final Quality Control (FQC): Completed panels undergo thorough inspections to verify dimensions, perforation accuracy, and surface finish before they are packaged and shipped. -

Common Testing Methods: Various testing methods are employed to assess the quality and performance of perforated panels. These may include:

– Dimensional verification using calipers or laser measurement tools.

– Tensile and shear tests to evaluate the mechanical strength of the material.

– Corrosion resistance tests, particularly for panels intended for outdoor use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers to ensure consistent product quality.

Illustrative image related to perf panel

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. During the audit, buyers can assess the equipment, workforce qualifications, and adherence to quality standards.

-

Reviewing Quality Reports: Suppliers should provide documentation that outlines their quality control processes, including inspection reports and certification records. Buyers should request these documents to ensure compliance with relevant standards and regulations.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing processes and conduct random sampling of finished products to verify compliance with quality standards.

What Are the Quality Control Nuances for International Buyers?

Navigating the complexities of quality control in international trade can present unique challenges for B2B buyers. Understanding the nuances can help mitigate risks.

-

Cultural Differences: Different regions may have varying approaches to quality assurance. Buyers should familiarize themselves with the local manufacturing practices and standards to better understand what to expect.

-

Regulatory Compliance: It is crucial for buyers to be aware of the regulatory requirements in their home country as well as the exporting country. Ensuring that the supplier complies with both sets of regulations can prevent potential legal and logistical issues.

-

Communication and Documentation: Clear communication with suppliers regarding quality expectations is essential. Buyers should establish documentation protocols that outline quality requirements, inspection processes, and timelines to avoid misunderstandings.

-

Sustainability Considerations: Increasingly, buyers are prioritizing suppliers who demonstrate a commitment to sustainability in their manufacturing processes. This includes using eco-friendly materials and implementing waste reduction practices. Buyers should inquire about the supplier’s sustainability initiatives as part of their quality assurance evaluation.

Conclusion

The manufacturing processes and quality assurance practices for perforated panels are integral to delivering high-quality products that meet diverse applications. By understanding the key manufacturing stages, implementing robust quality control measures, and verifying supplier capabilities, international B2B buyers can confidently source perforated panels that fulfill their specific requirements. This comprehensive approach not only ensures product quality but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perf panel’

This guide serves as a comprehensive checklist for B2B buyers looking to source perforated panels (perf panels) effectively. By following these steps, you can ensure that you make informed decisions, leading to successful procurement outcomes.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for your perforated panels. This includes determining the desired materials (such as aluminum, stainless steel, or carbon steel), hole patterns, sizes, thicknesses, and finishes.

- Material Considerations: Different materials offer varying strength, weight, and aesthetic qualities. For example, aluminum is lightweight and corrosion-resistant, making it suitable for diverse applications, while stainless steel provides enhanced durability.

- Hole Patterns: Specify the type of perforation you need—round, square, or hexagonal—and the size and spacing of the holes to meet your functional and design criteria.

Step 2: Identify Your Application Needs

Understanding the specific applications for which you need perf panels is crucial. Whether for architectural design, ventilation, filtration, or aesthetic purposes, your application will dictate the technical requirements.

Illustrative image related to perf panel

- Functional Requirements: Assess whether the panels will serve structural purposes, such as load-bearing, or if they are primarily for decorative use.

- Environmental Factors: Consider the operating environment, including exposure to moisture, chemicals, or extreme temperatures, which may influence material selection.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and deliver quality products. Request detailed company profiles, product catalogs, and case studies.

- Supplier Reputation: Look for suppliers with a proven track record in your industry and region. Reviews and testimonials from other buyers can provide insight into reliability and service quality.

- Certifications and Standards: Verify that suppliers adhere to relevant industry standards and possess necessary certifications, which can ensure product quality and compliance.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of the perf panels. This step allows you to assess the quality and suitability of the materials firsthand.

- Quality Assessment: Evaluate the finish, strength, and overall aesthetics of the samples. Ensure they align with your defined specifications and application needs.

- Testing: Conduct tests if applicable, such as load tests or environmental resistance evaluations, to confirm that the panels will perform as expected in their intended use.

Step 5: Compare Pricing and Terms

With samples in hand, compare pricing from different suppliers while considering the total cost of ownership. Look beyond just the unit price; consider shipping costs, lead times, and payment terms.

- Value Assessment: Ensure that the price reflects the quality and service level. Sometimes a higher upfront cost may lead to better long-term value through durability and lower maintenance.

- Negotiation: Don’t hesitate to negotiate terms, especially if you’re placing a large order or establishing a long-term partnership.

Step 6: Finalize Logistics and Delivery Plans

Once you’ve selected a supplier, finalize logistics and delivery arrangements. Ensure that you have clear communication regarding timelines and shipping methods.

Illustrative image related to perf panel

- Delivery Expectations: Confirm lead times and shipping methods to avoid delays in your project.

- Installation Support: Inquire about any installation support or technical assistance that may be available from the supplier to facilitate a smooth deployment.

Step 7: Review and Monitor Supplier Performance

After the procurement process, continuously monitor supplier performance and product quality. This step is essential for maintaining quality standards and ensuring that future orders meet your specifications.

- Feedback Loop: Establish a feedback mechanism to share your experiences with the supplier, which can help improve their services and products.

- Long-Term Relationship: Building a strong relationship with your supplier can lead to better terms and conditions in future transactions, fostering collaboration and mutual growth.

By following these steps, you can ensure a streamlined and efficient process for sourcing perforated panels that meet your business needs.

Comprehensive Cost and Pricing Analysis for perf panel Sourcing

What Are the Key Cost Components in Perf Panel Sourcing?

Understanding the cost structure for perforated panels is crucial for B2B buyers to make informed sourcing decisions. The primary cost components include:

-

Materials: The type of material significantly impacts the price. Common options like aluminum, stainless steel, and galvanized steel vary in cost based on market demand and availability. Aluminum is typically lighter and resistant to corrosion, while stainless steel offers enhanced strength and durability.

-

Labor: Labor costs can fluctuate depending on the region and the complexity of the manufacturing process. Skilled labor is essential for precision perforation and quality assurance, influencing overall production costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, maintenance, and indirect labor. Efficient manufacturing processes can help lower these costs, benefiting buyers.

-

Tooling: Custom tooling for specific perforation patterns can add to initial costs. However, once established, these tools can reduce per-unit costs for larger orders, making them an essential consideration for high-volume buyers.

-

Quality Control (QC): Ensuring that perforated panels meet required standards involves additional QC costs. Suppliers with rigorous QC processes may charge a premium, but this can lead to reduced defect rates and long-term savings.

-

Logistics: Shipping costs can vary based on the supplier’s location, the delivery destination, and chosen shipping methods. International buyers should consider tariffs and import duties as part of their logistics expenses.

-

Margin: Suppliers typically include a profit margin, which can vary based on the supplier’s market position, brand reputation, and the level of competition. Understanding the typical margins in your specific market can aid in negotiation.

How Do Price Influencers Affect Perf Panel Costs?

Several factors can influence the pricing of perforated panels:

-

Volume/MOQ: Larger orders often come with discounts due to economies of scale. Buyers should assess their needs and consider bulk purchasing to lower per-unit costs.

-

Specifications and Customization: Custom designs and specific perforation patterns may incur extra charges. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and any required certifications (e.g., ISO, CE) can significantly affect pricing. High-quality materials may have a higher upfront cost but can lead to lower maintenance expenses over time.

-

Supplier Factors: Relationships with suppliers, their market reputation, and production capabilities can all influence pricing. Building strong partnerships can lead to better pricing and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are Effective Buyer Tips for Sourcing Perf Panels?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiate Wisely: Leverage volume discounts and long-term contracts to negotiate better prices. Clear communication of your needs and expectations can help in obtaining favorable terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Sometimes, a higher initial investment in quality materials can yield savings in the long run.

-

Understand Pricing Nuances: Be aware of regional pricing variations and market trends. For instance, fluctuating material costs in Europe may differ significantly from those in Africa or South America.

-

Build Relationships: Strong supplier relationships can lead to better pricing, priority service, and access to new products. Frequent communication and feedback can foster trust and collaboration.

Disclaimer on Pricing

Prices for perforated panels can vary widely based on the factors discussed. The figures provided are indicative and should be confirmed with suppliers for accurate quotes tailored to specific project requirements. Always conduct thorough market research and supplier comparisons to ensure competitive pricing.

Illustrative image related to perf panel

Alternatives Analysis: Comparing perf panel With Other Solutions

When considering solutions for architectural and industrial applications, it’s essential to evaluate various options that can meet specific needs. The ‘perf panel’ serves as a versatile choice, but understanding its alternatives allows buyers to make informed decisions tailored to their project requirements. Below, we compare the perf panel against two prominent alternatives: perforated metal sheets and solid panels.

| Comparison Aspect | Perf Panel | Perforated Metal Sheets | Solid Panels |

|---|---|---|---|

| Performance | Excellent for sound and light diffusion | High strength-to-weight ratio, good for ventilation | Strong structural integrity, less airflow |

| Cost | Moderate initial investment | Varies widely based on material (aluminum, steel) | Generally higher upfront costs |

| Ease of Implementation | Requires specific design considerations | Readily available, easy to customize | Standardized sizes, installation may require additional framing |

| Maintenance | Low maintenance, durable | Durable, but may require cleaning | Minimal maintenance, but repair can be costly |

| Best Use Case | Acoustical applications, decorative elements | Enclosures, screens, architectural features | Structural applications, insulation needs |

What Are the Advantages and Disadvantages of Perforated Metal Sheets Compared to Perf Panels?

Perforated metal sheets offer a strong alternative to perf panels, especially in applications requiring ventilation or filtration. They are available in various materials, including aluminum, stainless steel, and plastic, providing versatility across industries. The cost-effectiveness of perforated sheets can vary significantly based on material selection and customization options. However, while they excel in structural integrity and airflow, they may not provide the same level of aesthetics or acoustic performance as perf panels.

How Do Solid Panels Stack Up Against Perf Panels?

Solid panels, while providing excellent structural integrity and insulation, typically lack the airflow and light diffusion capabilities of perf panels. They are often used in applications requiring robust support and weather resistance. The upfront costs for solid panels can be higher, but they generally require less maintenance over time. The trade-off is that solid panels do not offer the same design flexibility or aesthetic appeal, making them less suitable for projects where visual impact and acoustic control are critical.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right solution involves assessing the specific requirements of your project, including performance, cost, and aesthetic considerations. Buyers should evaluate the intended application: if sound attenuation and light diffusion are priorities, perf panels may be the best choice. Conversely, for structural integrity and insulation, solid panels might be more appropriate. Perforated metal sheets provide a balance of these factors, often serving as a versatile option for various industrial and architectural needs. By analyzing these aspects, B2B buyers can select the solution that aligns most closely with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for perf panel

What Are the Essential Technical Properties of Perf Panels?

When selecting perforated panels for various applications, understanding the essential technical properties is crucial. Here are some of the key specifications that B2B buyers should consider:

Illustrative image related to perf panel

-

Material Grade

– Definition: This refers to the type of material used in the production of perf panels, such as aluminum, stainless steel, galvanized steel, or plastic.

– Importance: Different materials offer varying levels of strength, corrosion resistance, and aesthetic appeal. For example, stainless steel is ideal for high-stress environments due to its durability, while aluminum is lightweight and cost-effective for architectural applications. -

Hole Size and Type

– Definition: This specification details the diameter and shape of the holes perforated in the panel, such as round, square, or slotted.

– Importance: The hole size impacts airflow, light diffusion, and sound attenuation. Selecting the appropriate hole type is vital for applications like sound barriers or decorative facades, where both functionality and aesthetics matter. -

Open Area Percentage

– Definition: This refers to the ratio of the total area of the holes to the overall area of the panel, typically expressed as a percentage.

– Importance: A higher open area percentage allows for better ventilation and light passage, making it suitable for applications like equipment enclosures or architectural features where airflow is essential. -

Thickness

– Definition: The thickness of the perf panel material, usually measured in gauge or millimeters.

– Importance: Thickness affects the panel’s strength, weight, and durability. Thicker panels can withstand greater stress and are often preferred in industrial settings, while thinner panels may be used for lighter applications. -

Tolerance

– Definition: This specification indicates the allowable deviation from a standard measurement during manufacturing.

– Importance: Tight tolerances are critical in applications requiring precise fitting, such as in architectural designs where panels must align seamlessly. Understanding tolerances helps ensure quality and compatibility with other components.

What Common Trade Terms Should B2B Buyers Know When Sourcing Perf Panels?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some common terms related to perforated panels:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reputable suppliers and assess the quality of components that will be used in their products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budget planning and inventory management, especially for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

– Definition: A document sent by a buyer to suppliers requesting pricing and terms for a specific quantity of goods or services.

– Relevance: An RFQ streamlines the procurement process by providing a structured way to gather offers from multiple suppliers, enabling better decision-making based on cost and terms. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Understanding Incoterms helps buyers navigate shipping responsibilities, costs, and risks, which is particularly important in global sourcing scenarios. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Relevance: Knowing the lead time is vital for project planning and inventory management, ensuring that materials are available when needed.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing perforated panels, ensuring they meet their specific requirements while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the perf panel Sector

What Are the Key Market Dynamics and Trends Affecting the Perf Panel Sector?

The perf panel market is experiencing notable growth driven by several global factors. The construction and architectural industries are increasingly adopting perforated metal products for their versatility in applications ranging from facades to interior partitions. In regions such as Africa and South America, urbanization and infrastructure development are key growth drivers, while in Europe and the Middle East, aesthetic and functional requirements are pushing demand for innovative design solutions. Additionally, the rise of smart buildings and energy-efficient structures is motivating the use of materials that not only meet functional requirements but also enhance energy performance.

Emerging technologies are reshaping sourcing trends in the perf panel sector. Automation and advanced manufacturing processes, including digital fabrication and 3D printing, are making it easier for suppliers to customize perforated products to meet specific client needs. This trend is particularly relevant for international B2B buyers seeking unique designs that set their projects apart. Furthermore, the integration of e-commerce platforms is streamlining procurement processes, allowing buyers from diverse regions to access a wider range of products and suppliers.

How Is Sustainability and Ethical Sourcing Impacting the Perf Panel Sector?

Sustainability has become a crucial consideration for B2B buyers in the perf panel market. The environmental impact of production processes and materials used in perforated panels is under scrutiny, prompting companies to adopt more sustainable practices. This includes utilizing recycled materials and ensuring that manufacturing processes minimize waste and energy consumption.

Ethical sourcing is equally important, as companies are increasingly held accountable for their supply chain practices. Buyers are now prioritizing suppliers who demonstrate commitment to transparency and responsibility, particularly in regions with stringent regulations regarding environmental impact. Certifications such as LEED (Leadership in Energy and Environmental Design) and other green certifications are becoming essential for suppliers looking to attract environmentally conscious clients. For instance, perforated panels made from recycled aluminum not only contribute to sustainability goals but also appeal to a growing market segment focused on green building practices.

How Has the Perf Panel Sector Evolved Over Time?

The evolution of the perf panel sector can be traced back to the early adoption of perforated materials in industrial applications. Initially, these materials were primarily used for functional purposes, such as filtration and ventilation. However, as architectural design evolved, so did the applications of perforated panels.

Today, they are integral to modern architectural aesthetics, providing solutions for both functionality and design. Innovations in manufacturing technology have allowed for greater customization in terms of hole size, shape, and spacing, enabling architects and designers to push creative boundaries. This shift reflects a broader trend where functionality meets artistry, making perforated panels a vital component in contemporary building designs across various markets, including Europe, the Middle East, Africa, and South America.

By understanding these market dynamics, trends, and sustainability considerations, B2B buyers can make informed decisions that align with their project goals while also contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of perf panel

-

How do I solve challenges related to sourcing perforated panels internationally?

Sourcing perforated panels from international suppliers can present challenges like language barriers, time zone differences, and varying quality standards. To mitigate these issues, establish clear communication channels, utilize translation services when necessary, and ensure that all specifications are documented. It’s also helpful to request samples before placing large orders and to conduct virtual meetings to discuss project requirements. Partnering with local agents or distributors can further streamline the process and help navigate regional regulations. -

What is the best material for perforated panels in industrial applications?

The best material for perforated panels in industrial applications largely depends on the specific requirements of your project. Carbon steel is robust and cost-effective for heavy-duty applications, while stainless steel offers superior corrosion resistance, making it ideal for environments exposed to moisture or chemicals. Aluminum is lightweight and versatile, suitable for both structural and aesthetic applications. Consider factors like environmental exposure, load requirements, and budget constraints when selecting the appropriate material. -

What customization options are available for perforated panels?

Customization options for perforated panels include variations in hole size, shape, and spacing, as well as the choice of materials and finishes. Many suppliers offer tailored designs to meet specific project needs, allowing for unique patterns that enhance both functionality and aesthetics. It’s advisable to discuss your design requirements with the supplier early in the process to explore available options and ensure that your specifications are feasible for production. -

What are the minimum order quantities (MOQs) for perforated panels?

Minimum order quantities for perforated panels can vary significantly by supplier and material type. Generally, MOQs may range from a few sheets to several hundred, depending on the manufacturer’s production capabilities and the complexity of the order. To avoid excess inventory, it’s essential to clarify MOQs during initial discussions with suppliers. If your needs are below the MOQ, consider collaborating with other buyers to meet the threshold or inquire about the possibility of a one-time order. -

What payment terms should I expect when purchasing perforated panels internationally?

Payment terms for international purchases of perforated panels can vary based on the supplier’s policies and your buyer-seller relationship. Common options include advance payment, net 30/60/90 days, or letters of credit. It is crucial to negotiate terms that protect your investment while ensuring timely production and delivery. Always review the supplier’s payment policies and consider using secure payment methods to mitigate risks associated with international transactions. -

How do I ensure quality assurance for perforated panels?

Ensuring quality assurance for perforated panels involves selecting reputable suppliers with robust quality control processes. Request certifications, such as ISO standards, and inquire about their manufacturing practices. Conducting factory audits or quality inspections before shipment can also help verify that the panels meet your specifications. Additionally, establishing a clear return policy can provide recourse if the delivered products do not meet the agreed-upon standards. -

What logistics considerations should I keep in mind when importing perforated panels?

When importing perforated panels, consider factors such as shipping methods, customs regulations, and lead times. Choose between air and sea freight based on your budget and urgency. Familiarize yourself with the customs procedures in your country to avoid delays. It’s advisable to work with a freight forwarder who can assist with documentation and ensure compliance with international shipping regulations. Always factor in potential tariffs or duties when calculating total costs. -

How can I vet suppliers of perforated panels effectively?

Vetting suppliers of perforated panels involves researching their industry reputation, production capacity, and customer reviews. Utilize online platforms like LinkedIn or industry-specific directories to gather insights about potential suppliers. Request references from previous clients and inquire about their experience with product quality and customer service. Additionally, consider starting with a smaller order or trial run to assess the supplier’s reliability and responsiveness before committing to larger orders.

Top 5 Perf Panel Manufacturers & Suppliers List

1. Kele – Perforated Panels for BAS & HVAC

Domain: kele.com

Registered: 1995 (30 years)

Introduction: This company, Kele – Perforated Panels for BAS & HVAC, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Petersen – Perforated Aluminum Wall Panels

Domain: pac-clad.com

Registered: 1996 (29 years)

Introduction: Perforated Aluminum Wall Panels & Flat Sheet: Petersen offers perforation of select PAC-CLAD aluminum wall panels and flat sheet. Perforated aluminum provides a contrasting look with non-perforated metal, creating visual interest. Applications include equipment screens, partitions, sign panels, parking decks, guards, interior acoustical applications, and enclosures. Available in various hole sizes…

3. Hammond Manufacturing – Perf Panel 13 x 18.5

Domain: rackmountsolutions.net

Registered: 2001 (24 years)

Introduction: {“name”: “Perf Panel 13 x 18.5 – Fits Encl. 16 x 20 – Steel/Gray”, “SKU”: “AP1620PP”, “manufacturer”: “Hammond Manufacturing”, “price”: “$24.98”, “material”: “16 ga steel”, “features”: [“Accepts self tapping screws eliminating timely measurement, marking and drilling of component mounting holes”, “1/8\” dia holes on 1/4\” staggered centers”, “ANSI 61 gray powder finish”], “compliance”: [“USMCA Com…

4. McMaster – Perforated Steel Sheets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Perforated Steel Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. nVent – Perforated Panel for Medium Enclosure Type 1

Domain: nvent.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Perforated Panel for Medium Enclosure Type 1”, “Dimensions”: “24×24 inches”, “Color”: “Gray”, “Material”: “Steel”, “Catalog Number”: “A24N24MPP”, “Description”: “Perforated panel is ideal for mounting lightweight control components in Small and Medium Type 1 and 3R enclosures. It accepts self-tapping screws and eliminates the need to measure, mark and drill when mounting componen…

Strategic Sourcing Conclusion and Outlook for perf panel

As the demand for perforated panels continues to rise across diverse industries, international B2B buyers must prioritize strategic sourcing to maximize their procurement efficiency. The versatility of perforated metal, with applications ranging from architectural design to functional filtration, underscores its value in various markets. Buyers should consider factors such as material selection, hole patterns, and weight-to-strength ratios to ensure they choose the right product for their specific needs.

Furthermore, the importance of establishing strong supplier relationships cannot be overstated. Engaging with manufacturers that offer customizable solutions and extensive inventories can lead to cost savings and improved project timelines. This approach not only enhances product quality but also fosters innovation, allowing businesses to stay competitive in their respective markets.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should leverage technological advancements and sustainable practices in sourcing perforated panels. By embracing these strategies, companies can enhance their operational efficiency and meet evolving market demands. Now is the time to take action—connect with reliable suppliers, explore innovative designs, and elevate your projects with high-quality perforated panels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.