Top 5 How Paint Booth Works Suppliers (And How to Choose)

Introduction: Navigating the Global Market for how paint booth works

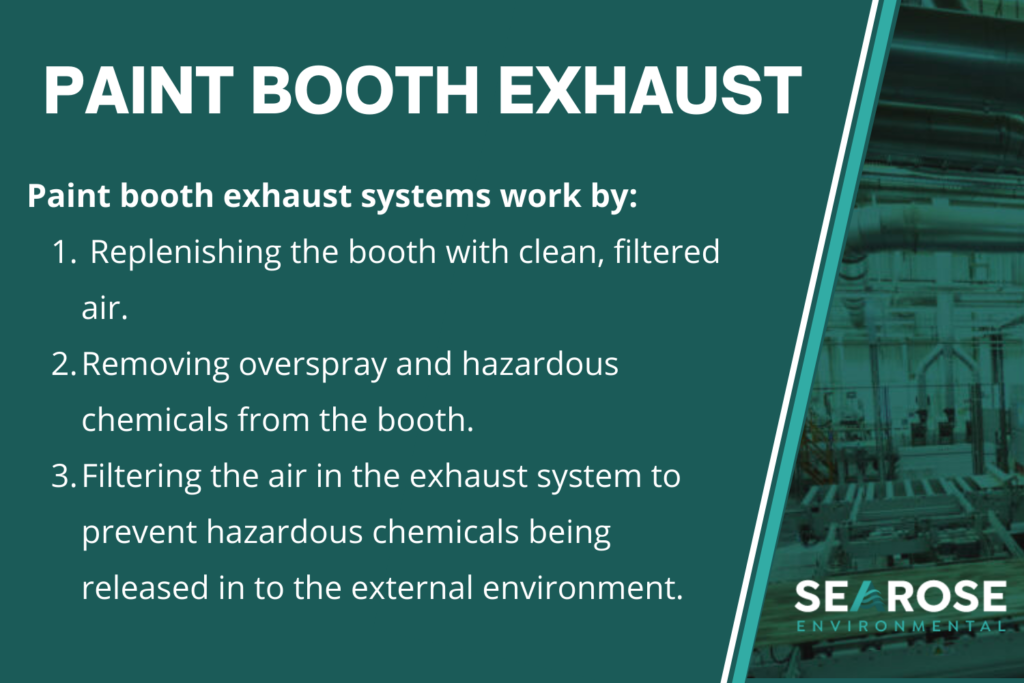

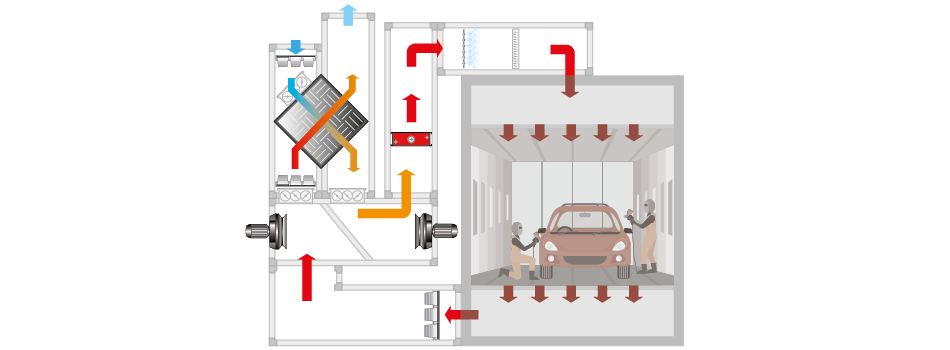

In today’s competitive landscape, sourcing high-quality paint booths that enhance operational efficiency while ensuring compliance with safety standards is a critical challenge for international B2B buyers. Understanding how paint booths work is essential for making informed purchasing decisions that align with specific business needs. This comprehensive guide delves into the intricacies of paint booth functionality, focusing on air flow dynamics, booth types, and operational applications.

From understanding the role of Air Makeup Units (AMUs) in maintaining optimal air pressure to evaluating the importance of selecting the right exhaust systems, this guide equips buyers with the knowledge to navigate the complexities of the global market. Additionally, it outlines essential criteria for vetting suppliers, assessing cost structures, and understanding regional compliance requirements, particularly for buyers in Africa, South America, the Middle East, and Europe, including Brazil and Germany.

By providing actionable insights and expert recommendations, this guide empowers businesses to optimize their procurement strategies, ensuring they select the most suitable paint booth solutions for their operational needs. Whether you are looking to improve production efficiency or enhance the quality of your finishing applications, understanding the mechanics of paint booths will drive success in your purchasing decisions.

Understanding how paint booth works Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cross Flow Booth | Airflow moves horizontally across the booth; efficient for small items. | Automotive refinishing, furniture | Pros: Cost-effective; Cons: Limited space usage. |

| Downdraft Booth | Air is pulled downward from the ceiling, ensuring optimal overspray removal. | Automotive, aerospace, industrial | Pros: Cleaner finish; Cons: Higher installation costs. |

| Side Downdraft Booth | Air enters from the sides and exits downward; versatile for various items. | Manufacturing, metalworking | Pros: Flexible design; Cons: Requires more space. |

| Open Face Booth | No front wall, allowing for larger items; often used for quick jobs. | Large-scale manufacturing, DIY | Pros: Easy access; Cons: Less control over overspray. |

| Mobile Paint Booth | Portable design for on-site jobs; often used for smaller projects. | Construction, repair services | Pros: Versatile; Cons: Limited airflow control. |

What Are the Characteristics of Cross Flow Paint Booths?

Cross flow paint booths feature a horizontal airflow system, where air is drawn in from one side and exhausted from the opposite side. This design is particularly effective for smaller items, making it a popular choice in automotive refinishing and furniture manufacturing. B2B buyers should consider the cost-effectiveness of cross flow booths, as they generally require less investment compared to more complex systems. However, their limited space may restrict larger projects, which is a crucial consideration for businesses expecting to handle a diverse range of products.

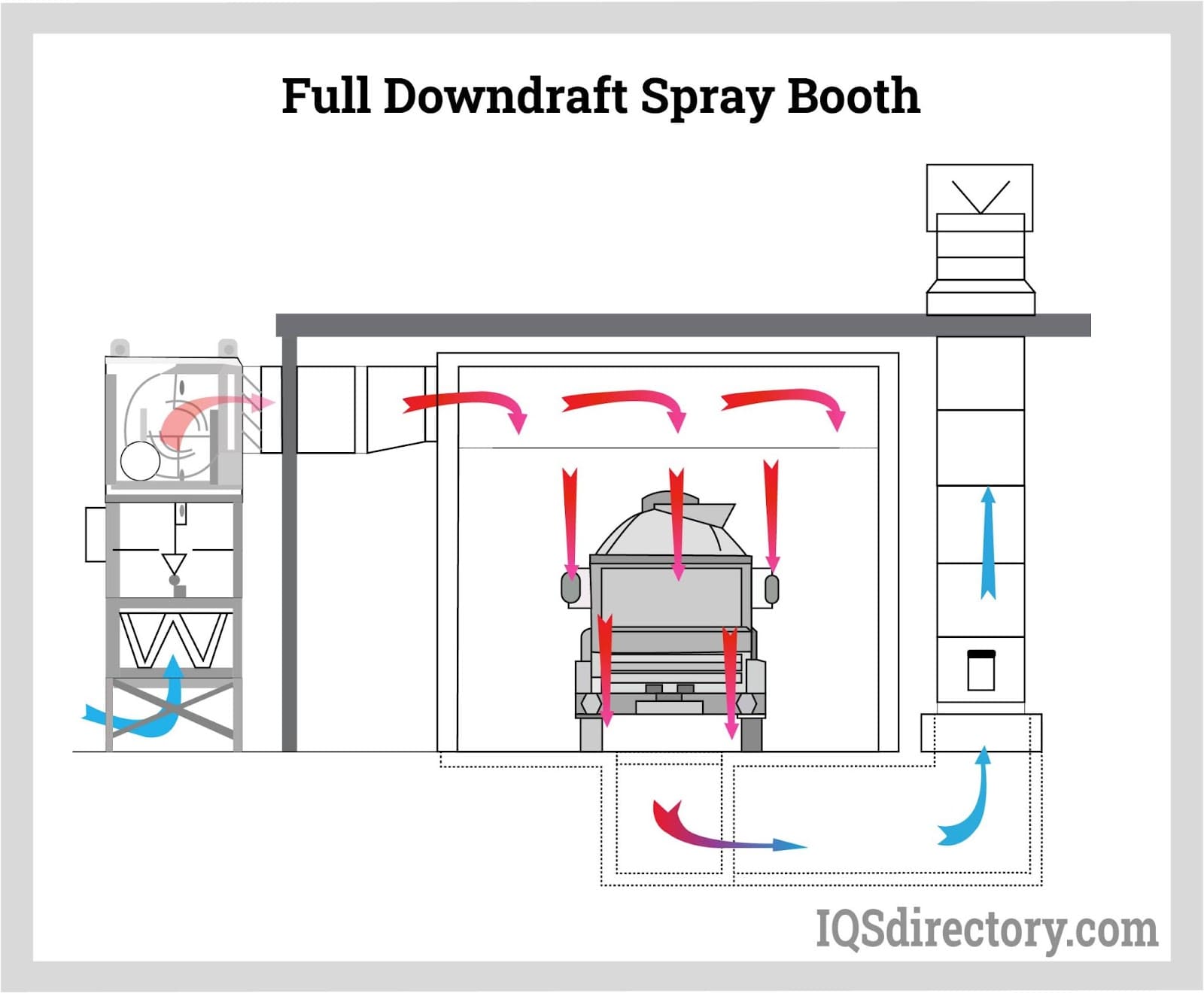

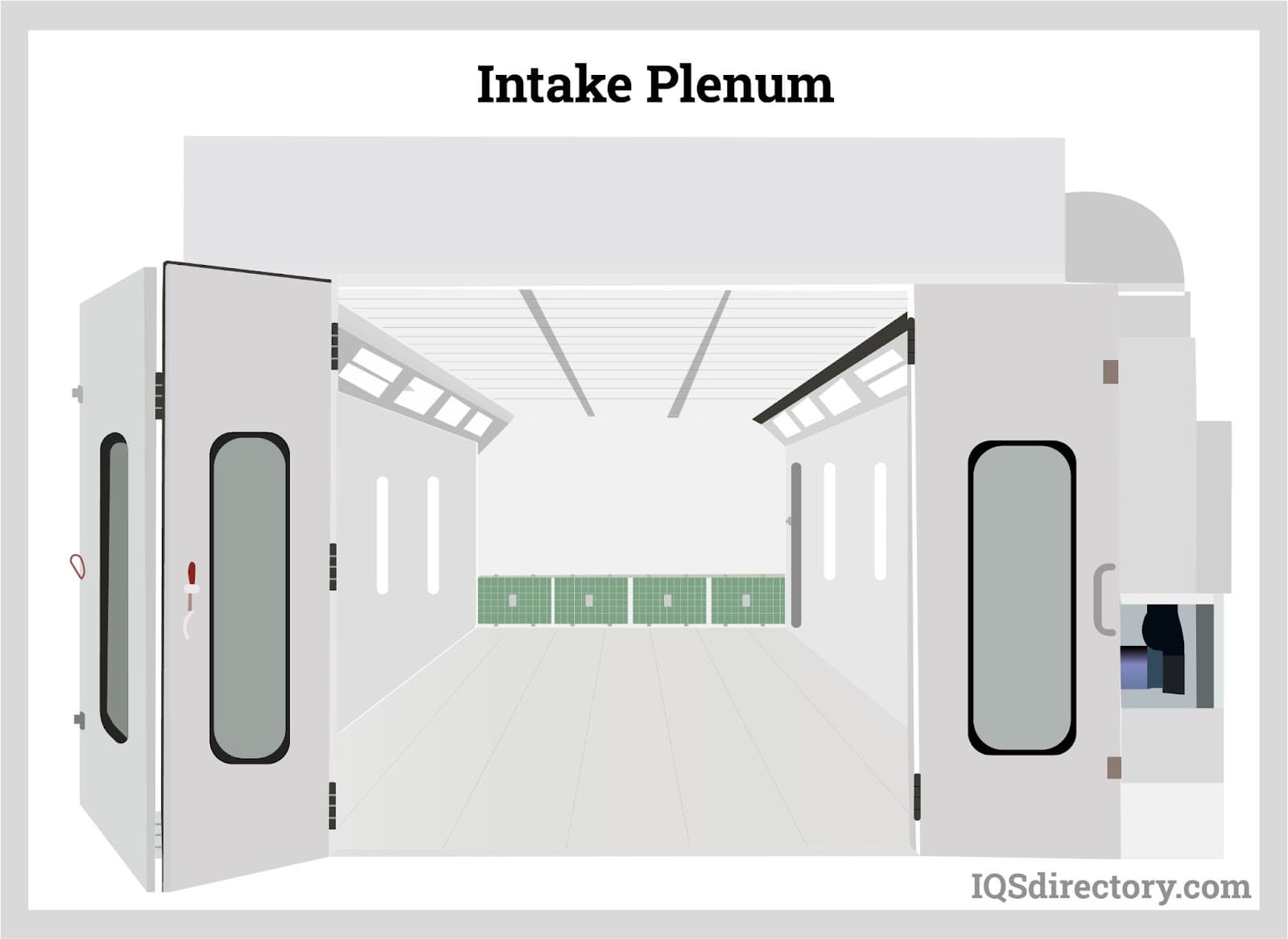

How Do Downdraft Paint Booths Ensure Quality Finishing?

Downdraft paint booths utilize a ceiling-mounted exhaust system that pulls air downward, ensuring that overspray is effectively removed from the work area. This design is ideal for industries such as automotive and aerospace, where a high-quality finish is essential. The primary advantage of downdraft booths is their ability to create a cleaner environment, reducing the risk of contaminants affecting the paint job. However, buyers should be aware of the higher installation costs associated with this type of booth, which could impact budget considerations.

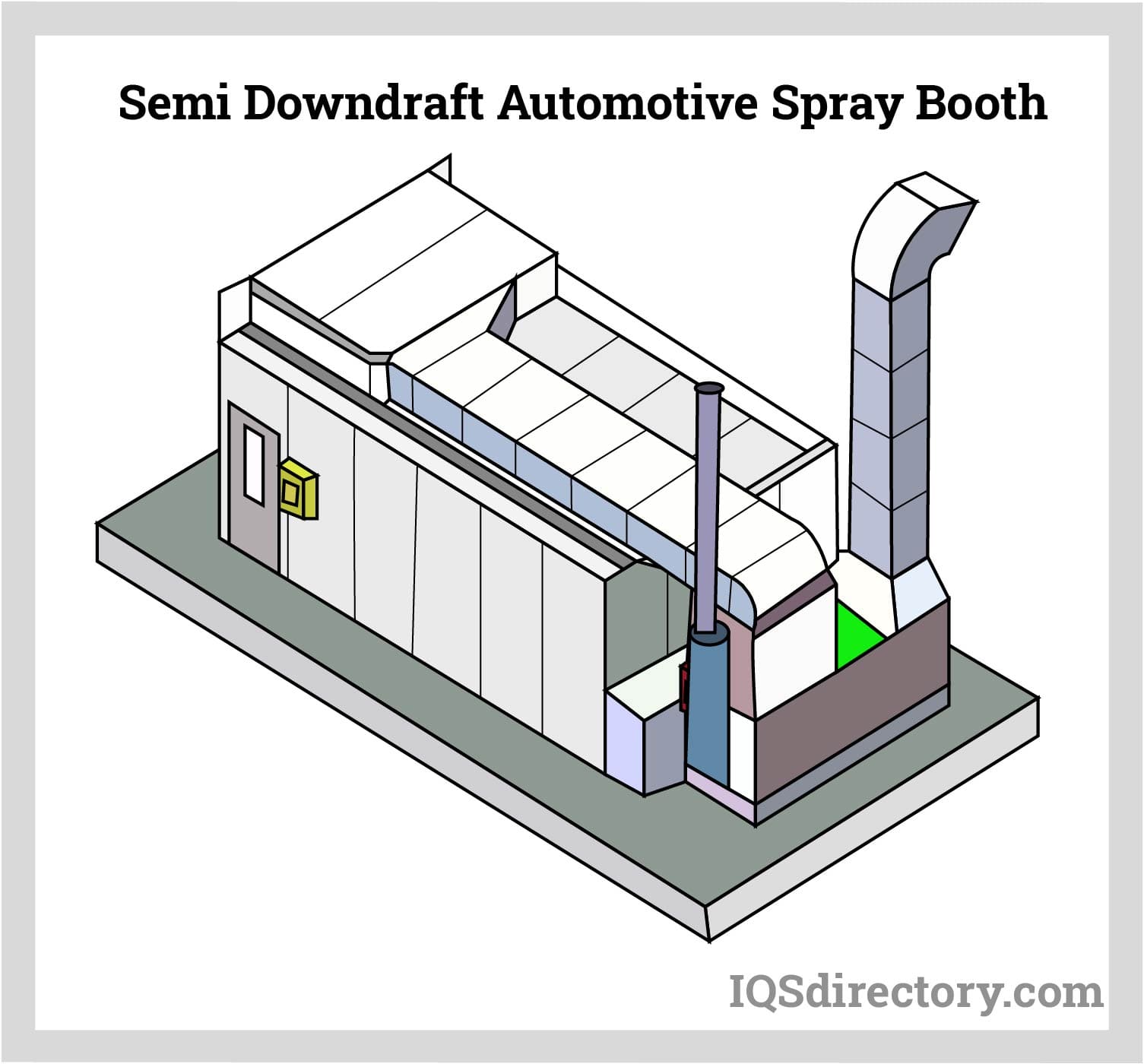

What Makes Side Downdraft Paint Booths Versatile?

Side downdraft paint booths combine the airflow characteristics of both side and down-draft systems, allowing air to enter from the sides and exit downward. This versatility makes them suitable for a wide range of applications, including manufacturing and metalworking. The key benefit for B2B buyers is the flexibility in design, accommodating various sizes and shapes of items. However, potential buyers must also consider the spatial requirements of these booths, as they typically need more floor space compared to other types.

Why Choose Open Face Paint Booths for Quick Jobs?

Open face paint booths are characterized by their lack of a front wall, facilitating easy access for larger items or quick jobs. They are commonly used in large-scale manufacturing and DIY projects. The primary advantage is the convenience and speed of operation, which can significantly enhance productivity. However, buyers should note that the absence of a controlled environment can lead to challenges with overspray and contamination, making this option less suitable for high-precision work.

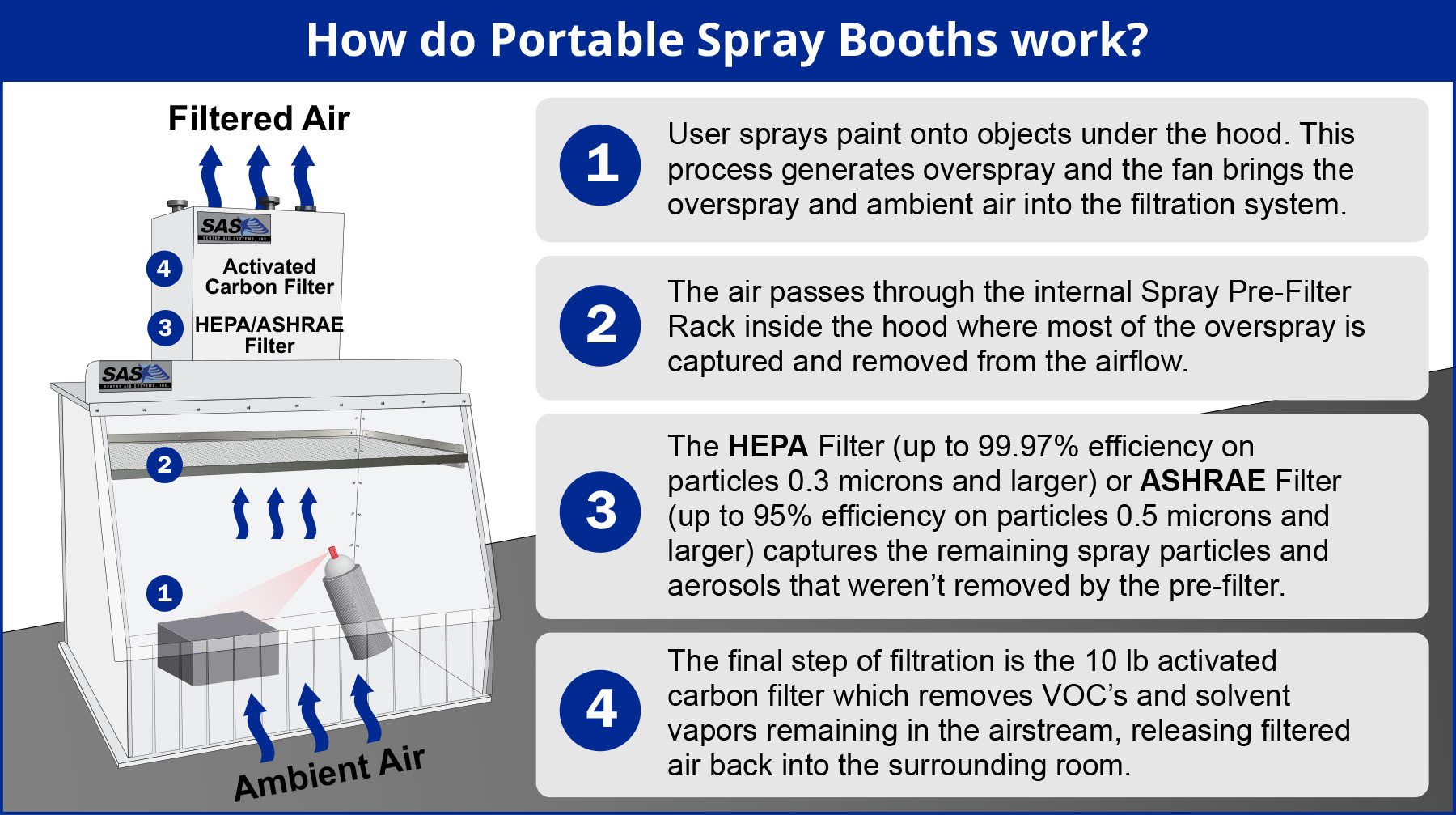

What Are the Benefits of Mobile Paint Booths for On-Site Jobs?

Mobile paint booths offer a portable solution for businesses that require flexibility in their operations, particularly in construction and repair services. These booths can be easily transported to various job sites, allowing for quick and efficient painting tasks. The primary benefit is their versatility, enabling businesses to adapt to different project demands. However, B2B buyers should be cautious of the limited airflow control in mobile booths, which may affect the quality of the finish, especially in demanding applications.

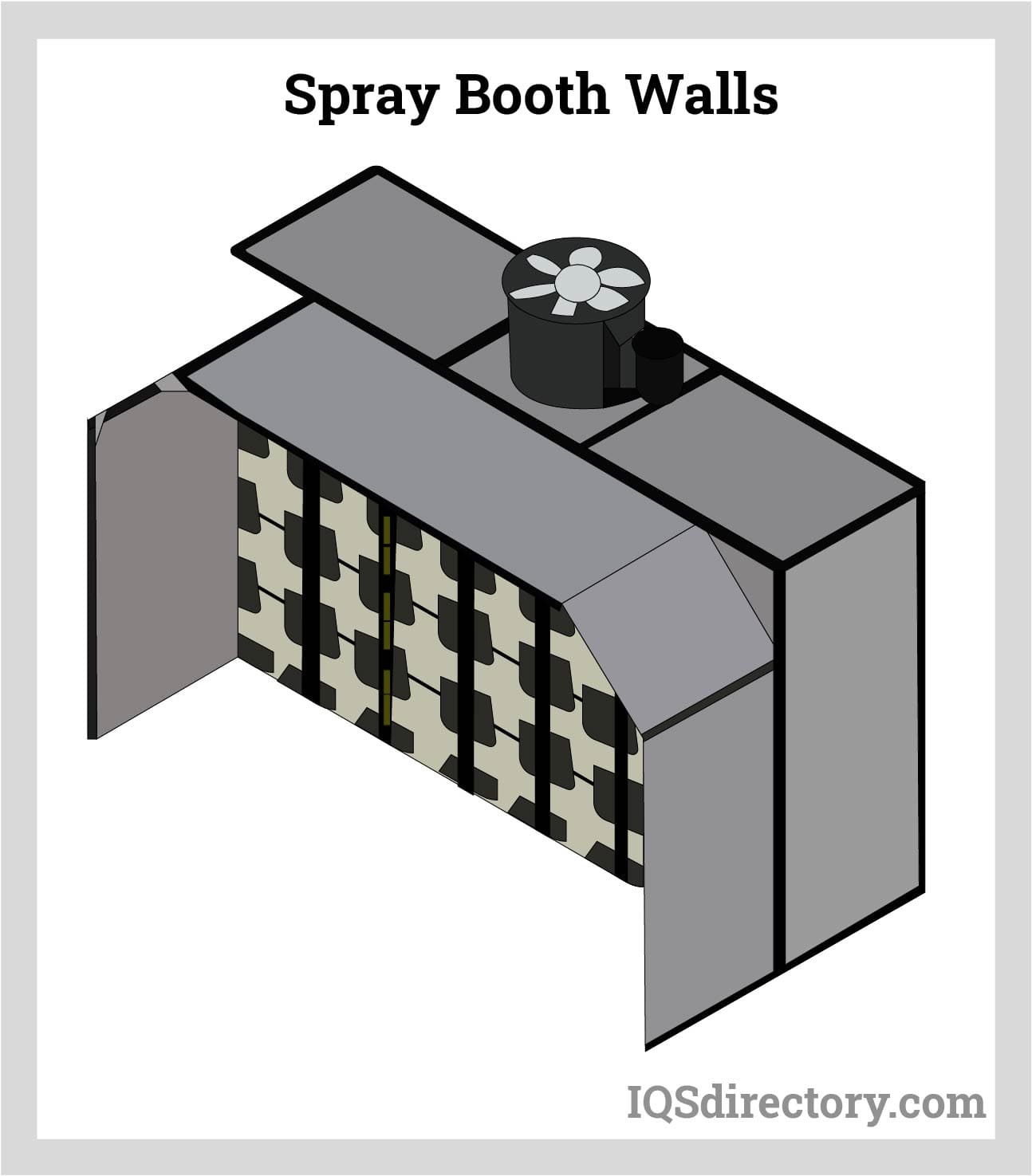

Illustrative image related to how paint booth works

Key Industrial Applications of how paint booth works

| Industry/Sector | Specific Application of how paint booth works | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Application of paint booths for vehicle finishing | Enhanced finish quality and reduced contamination risks | Compliance with local safety regulations; energy efficiency |

| Aerospace | Use of paint booths for aircraft component coating | Improved durability and performance of coatings | Need for specialized ventilation and filtration systems |

| Furniture Production | Paint booths for finishing wooden and metal furniture | Consistent application and reduced overspray waste | Sourcing for eco-friendly materials and compliance with VOC regulations |

| Electronics | Coating of electronic components in controlled environments | Protection from corrosion and enhanced aesthetics | Precision in air flow control to prevent contamination |

| Heavy Equipment | Painting of machinery and equipment parts | Extended equipment lifespan and improved marketability | Need for robust filtration systems to handle heavy coatings |

How Are Paint Booths Used in Automotive Manufacturing?

In the automotive sector, paint booths are essential for the finishing process of vehicles. The controlled environment minimizes contamination, ensuring a high-quality finish that meets industry standards. Buyers must consider energy-efficient systems that comply with local regulations, particularly in regions like Brazil and Germany, where environmental compliance is stringent. Additionally, they should evaluate the booth’s air flow capabilities to ensure optimal paint application and curing.

What Role Do Paint Booths Play in Aerospace Applications?

In aerospace, paint booths are critical for applying protective coatings to aircraft components. These coatings not only enhance aesthetics but also improve durability against harsh environmental conditions. Buyers in this industry must prioritize specialized ventilation systems that prevent dust and debris from compromising the coating process. Compliance with aviation safety standards is also crucial, requiring thorough sourcing of equipment that meets these regulations.

How Are Paint Booths Beneficial for Furniture Production?

Furniture manufacturers utilize paint booths to achieve a consistent and high-quality finish on wooden and metal products. The controlled environment reduces overspray and waste, leading to cost savings and improved production efficiency. Buyers should focus on sourcing eco-friendly materials that comply with volatile organic compound (VOC) regulations, especially in Europe, where sustainability is increasingly prioritized. The ability to adjust air flow and temperature is also vital for optimizing the curing process.

Illustrative image related to how paint booth works

In What Ways Are Paint Booths Used in Electronics?

In the electronics industry, paint booths are employed for coating components to protect against corrosion and enhance their visual appeal. The need for precision in air flow is paramount, as even minor contamination can lead to significant product failures. Buyers should seek paint booths equipped with advanced filtration systems to ensure a clean environment, particularly in regions with varying humidity and temperature levels that could affect the coating process.

What Are the Key Considerations for Paint Booths in Heavy Equipment?

Heavy equipment manufacturers rely on paint booths for coating machinery and parts, ensuring protection and aesthetic appeal. The extended lifespan of equipment due to high-quality coatings can significantly enhance marketability. Buyers need to consider robust filtration systems that can handle the thickness of heavy coatings and ensure compliance with local environmental regulations. Additionally, sourcing energy-efficient systems can contribute to overall operational cost savings.

3 Common User Pain Points for ‘how paint booth works’ & Their Solutions

Scenario 1: Managing Airflow Imbalances in Paint Booths

The Problem: B2B buyers often struggle with maintaining optimal airflow in their paint booths, leading to issues such as over-pressurization or contamination. A common scenario involves the booth’s exhaust system pulling air out at a higher rate than the makeup air unit can replenish. This imbalance can result in negative pressure, drawing in dirt and debris from outside, which compromises the quality of the paint job and increases rework costs. Additionally, when exhaust filters become clogged with overspray, the airflow is further disrupted, leading to inefficient operations and increased operational costs.

The Solution: To effectively manage airflow in a paint booth, it’s crucial to implement a balanced air management strategy. Buyers should consider investing in advanced Air Makeup Units (AMUs) that allow for real-time adjustments of airflow based on the booth’s conditions. Sourcing AMUs with variable frequency drives enables operators to fine-tune the air input according to the volume of air being exhausted. Regular maintenance and monitoring of exhaust filters are also essential; replacing filters promptly ensures optimal airflow and prevents over-pressurization. Training operators on how to monitor booth pressure and adjust the AMU settings will lead to a cleaner working environment and better paint finishes.

Scenario 2: Overcoming Temperature Control Challenges During Curing

The Problem: Many B2B buyers find it challenging to maintain consistent temperatures during the curing phase of the painting process. Fluctuations in temperature can lead to poor curing results, affecting adhesion and finish quality. This issue is particularly pronounced in regions with extreme weather conditions, where external temperatures can significantly influence the booth’s internal environment. Operators may struggle to balance heat settings, especially if they lack a sophisticated system to monitor and control temperature variations.

Illustrative image related to how paint booth works

The Solution: To address temperature control issues, buyers should invest in paint booths equipped with state-of-the-art heating systems, such as those with integrated control panels that allow for precise temperature adjustments. These systems should include features like user-adjustable flash, cure, and cool-down times tailored to the specific materials being used. Additionally, implementing a monitoring system that tracks temperature and humidity levels in real-time will provide operators with the data needed to make informed adjustments. Regular training on the operation of these systems will enhance efficiency, reduce waste, and improve product quality, ensuring that paint jobs meet the highest industry standards.

Scenario 3: Ensuring Safety Compliance in Paint Booth Operations

The Problem: Navigating safety regulations in paint booth operations can be a daunting task for B2B buyers, especially in regions with stringent compliance requirements. Buyers often face difficulties ensuring that their paint booths meet OSHA and NFPA regulations, which can vary significantly by region. Non-compliance can lead to severe penalties, shutdowns, or worse, safety incidents that jeopardize worker safety and business continuity.

The Solution: To ensure safety compliance, buyers should prioritize sourcing paint booths that are designed with built-in safety features, such as flame failure remote reset and multi-service disconnects. It’s essential to work with manufacturers who can provide detailed documentation of compliance with local safety regulations. Conducting regular safety audits and training sessions for staff on operational safety protocols is also vital. Buyers should implement a proactive maintenance schedule to regularly check safety systems and equipment functionality. Establishing a culture of safety within the organization will not only enhance compliance but also foster a safer working environment, ultimately leading to improved productivity and employee morale.

Strategic Material Selection Guide for how paint booth works

What Are the Key Materials Used in Paint Booth Construction?

When selecting materials for paint booths, it is essential to consider properties that affect performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction and operation of paint booths, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high strength and durability, with a temperature rating that can withstand significant heat during the curing process. It also has good corrosion resistance when treated with appropriate coatings.

Illustrative image related to how paint booth works

Pros & Cons:

Steel is robust and can support heavy equipment, making it ideal for structural components. However, it can be susceptible to rust if not properly coated, leading to higher maintenance costs. The manufacturing complexity is moderate, as steel components can be welded or bolted together.

Impact on Application:

Steel is compatible with various media used in paint booths, including solvents and water-based paints. Its strength allows for the installation of heavy-duty fans and exhaust systems.

Considerations for International Buyers:

Steel must comply with local standards such as ASTM in the U.S. and DIN in Germany. Buyers should ensure that coatings used on steel meet environmental regulations, particularly in regions with strict VOC emissions standards.

2. Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance. It can handle temperatures up to 600°F (316°C), making it suitable for various paint booth applications.

Pros & Cons:

The primary advantage of aluminum is its resistance to rust and corrosion, reducing long-term maintenance costs. However, it is generally more expensive than steel, which may deter budget-conscious buyers. The manufacturing process can be complex due to the need for specialized welding techniques.

Illustrative image related to how paint booth works

Impact on Application:

Aluminum is particularly effective in environments where moisture is prevalent, as it does not corrode easily. Its lightweight nature allows for easier installation and adjustments in paint booths.

Considerations for International Buyers:

Aluminum components must meet international standards such as JIS in Japan and EN in Europe. Additionally, buyers should consider the availability of aluminum in their region, as it may be less common in certain markets.

3. Fiberglass Reinforced Plastic (FRP)

Key Properties:

FRP is highly resistant to chemicals and moisture, with a temperature tolerance of up to 200°F (93°C). It is lightweight and can be molded into various shapes.

Pros & Cons:

FRP offers excellent corrosion resistance and is easy to clean, making it ideal for paint booths. However, it can be less durable than metals and may require replacement after several years. The manufacturing process is less complex, allowing for quicker production.

Impact on Application:

FRP is particularly suitable for areas exposed to harsh chemicals, ensuring a longer lifespan for paint booth components. It is compatible with a wide range of paint types, including solvent-based products.

Illustrative image related to how paint booth works

Considerations for International Buyers:

FRP must comply with local safety and environmental regulations, particularly regarding flammability and chemical resistance. Buyers should verify that the FRP used meets international standards for fire safety.

4. Stainless Steel

Key Properties:

Stainless steel is highly resistant to corrosion and staining, with a temperature rating similar to that of regular steel. It is durable and can withstand harsh cleaning agents.

Pros & Cons:

The main advantage of stainless steel is its longevity and low maintenance needs. However, it is typically more expensive than both carbon steel and aluminum, which may be a significant factor for budget-sensitive projects. The manufacturing process can be more complex due to the material’s hardness.

Impact on Application:

Stainless steel is ideal for paint booths that require frequent cleaning and exposure to various chemicals. Its durability ensures that it can handle heavy-duty equipment without compromising structural integrity.

Considerations for International Buyers:

Stainless steel must meet specific standards such as ASTM and EN for corrosion resistance. Buyers should also consider the availability of different grades of stainless steel in their region, as this can impact cost and performance.

Summary Table

| Material | Typical Use Case for how paint booth works | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and framework | High strength and durability | Susceptible to rust without coatings | Medium |

| Aluminum | Lightweight structural components | Excellent corrosion resistance | Higher cost compared to steel | High |

| Fiberglass Reinforced Plastic (FRP) | Walls and interior surfaces | Easy to clean and chemical resistant | Less durable than metals | Medium |

| Stainless Steel | Equipment supports and cleaning surfaces | Low maintenance and longevity | Higher initial cost | High |

This analysis provides a comprehensive overview of the materials commonly used in paint booths, highlighting their properties, advantages, and considerations for international buyers. Understanding these factors can help businesses make informed decisions when selecting materials for their paint booth operations.

In-depth Look: Manufacturing Processes and Quality Assurance for how paint booth works

What Are the Key Stages in the Manufacturing Process of Paint Booths?

The manufacturing process of paint booths involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages allows B2B buyers to assess the quality and reliability of potential suppliers.

Material Preparation: What Materials Are Used in Paint Booth Manufacturing?

The first stage is material preparation, which involves sourcing high-quality raw materials that comply with international standards. Common materials include steel for structural components, aluminum for lightweight parts, and specialized coatings that resist corrosion and chemical damage. The selection of materials impacts not only the durability of the paint booth but also its performance in various environmental conditions.

Forming: How Are Paint Booth Components Shaped and Assembled?

Once materials are prepared, the next step is forming. This stage employs techniques such as cutting, bending, and welding to create individual components. Advanced machinery like CNC (Computer Numerical Control) machines ensures precision in forming parts, which is crucial for maintaining the integrity of the booth’s airflow dynamics. High-quality forming techniques result in a more efficient and effective paint booth, which is vital for achieving superior finishes.

Illustrative image related to how paint booth works

Assembly: What Techniques Are Used to Construct the Paint Booth?

After forming, components are assembled into the final paint booth structure. This stage often utilizes robotic assembly systems for consistency and speed. Key techniques include fastening, sealing, and integrating electrical systems that control airflow and temperature. Quality assembly practices are essential for minimizing air leaks, ensuring optimal performance, and enhancing the longevity of the paint booth.

Finishing: How Is the Surface Quality of Paint Booths Enhanced?

Finishing processes, such as powder coating or painting, are applied to protect the booth from harsh chemicals and enhance its aesthetic appeal. These coatings not only improve durability but also contribute to safety by reducing the risk of fire hazards. The finishing stage is critical for ensuring that the paint booth meets regulatory requirements and provides a safe working environment.

How is Quality Assurance Implemented in Paint Booth Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each paint booth meets both international standards and customer specifications. B2B buyers must understand the various QA checkpoints and certifications that validate the reliability of the product.

Illustrative image related to how paint booth works

What International Standards Are Relevant for Paint Booth Manufacturing?

One of the most recognized quality standards in manufacturing is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established a process for continuous improvement and customer satisfaction. Additionally, certifications like CE mark (Europe) and API (American Petroleum Institute) standards ensure that the paint booth complies with safety and performance requirements relevant to various markets.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. It ensures that all materials meet specified standards and specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC monitors processes to identify defects early. Regular inspections during forming, assembly, and finishing stages help maintain product quality.

-

Final Quality Control (FQC): This final checkpoint occurs after assembly and finishing. It involves comprehensive testing of the completed paint booth, focusing on functionality, safety features, and adherence to specifications.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure that paint booths meet quality standards. Common methods include:

-

Airflow Testing: Ensures that the booth maintains appropriate air pressure and flow rates, which are critical for effective painting and safety.

-

Temperature Testing: Verifies that the booth can reach and maintain necessary curing temperatures, which is essential for optimal paint application.

-

Structural Integrity Testing: Assesses the durability and strength of the booth, ensuring it can withstand operational demands.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are some actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes and quality control measures firsthand. This direct engagement can reveal insights into their operational efficiency and adherence to standards.

-

Quality Reports: Requesting detailed quality reports can provide visibility into a supplier’s performance. These reports should outline compliance with relevant standards, results from QC checkpoints, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This adds a layer of assurance, especially for buyers unfamiliar with local suppliers.

What Are the Quality Certification Nuances for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, must consider specific certification requirements. For instance, the CE mark is crucial for European markets, while buyers in the Middle East may prioritize compliance with local safety regulations. Understanding these nuances helps buyers ensure that the paint booths they purchase not only meet their operational needs but also comply with local regulations.

Conclusion: Why Understanding Manufacturing and Quality Assurance Matters for B2B Buyers

For B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance practices of paint booths is essential. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control measures, buyers can make informed decisions that enhance their operational efficiency and product quality. This knowledge ultimately leads to better supplier relationships and increased competitiveness in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how paint booth works’

This guide serves as a comprehensive checklist for B2B buyers looking to understand how paint booths operate and what to consider when sourcing them. By following these steps, you can ensure that you select the right paint booth equipment that meets your operational needs while maintaining efficiency and safety standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first crucial step in sourcing a paint booth. Consider the dimensions of your workspace, the types of materials you will be spraying, and the desired production volume. This will help in determining the size and type of paint booth required, including airflow requirements (CFM ratings) and the necessary features like heating and filtration systems.

Step 2: Understand Airflow Dynamics

Grasping the principles of airflow within a paint booth is essential. You need to ensure the booth maintains proper air pressure to prevent contamination. Research the concepts of positive and negative air pressure, as these will affect the quality of your paint jobs and the efficiency of your operation. Look for booths equipped with advanced Air Makeup Units (AMUs) to regulate airflow effectively.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from businesses in similar sectors or regions. It’s important to ensure that the suppliers are reputable and have a proven track record of delivering high-quality paint booths that align with your specifications.

Illustrative image related to how paint booth works

- Key Considerations:

- Review their years of experience in the industry.

- Ask for client testimonials or success stories.

- Check if they offer post-purchase support and maintenance services.

Step 4: Assess Compliance with Safety Standards

Safety compliance is non-negotiable when it comes to sourcing paint booths. Verify that the equipment meets local and international safety regulations, such as OSHA and NFPA standards. This ensures that your operations are not only safe but also legally compliant, reducing the risk of fines or operational shutdowns.

- What to Check:

- Certification documents from recognized safety organizations.

- Safety features included in the booth design, such as explosion-proof components.

Step 5: Request Detailed Quotes

Once you have narrowed down your options, request detailed quotations from your shortlisted suppliers. Ensure that these quotes include all costs associated with the purchase, installation, and potential maintenance of the paint booth. This transparency will help you compare offers effectively and avoid unexpected expenses later on.

- Important Elements to Include:

- Breakdown of equipment costs, installation fees, and ongoing maintenance.

- Any additional charges for custom features or options.

Step 6: Conduct On-site Visits

If possible, conduct on-site visits to observe the booths in operation. This gives you firsthand insight into the quality of the equipment, the efficiency of the airflow, and the overall operational setup. It also allows you to assess the supplier’s capability and the condition of their facilities.

Step 7: Negotiate Terms and Finalize Purchase

Finally, engage in negotiations to ensure the best terms for your purchase. Discuss warranty options, service agreements, and delivery timelines to secure a deal that meets your operational needs. Once all terms are agreed upon, finalize the purchase and prepare for the installation process.

By following this checklist, B2B buyers can navigate the complexities of sourcing paint booths more effectively, ensuring they invest in equipment that enhances productivity and quality in their operations.

Illustrative image related to how paint booth works

Comprehensive Cost and Pricing Analysis for how paint booth works Sourcing

What Are the Key Cost Components for Sourcing Paint Booths?

When evaluating the cost structure for sourcing paint booths, several critical components come into play. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel or aluminum for the booth structure, durable finishes, and specialized filters are essential for longevity and performance. The cost can vary based on availability and local market conditions, which is particularly relevant for international buyers.

-

Labor: Labor costs encompass wages for assembly, installation, and maintenance technicians. The complexity of the paint booth design can increase labor hours, particularly for customized solutions tailored to specific client needs.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Overhead can fluctuate depending on the location of the manufacturing facility and its operational efficiency.

-

Tooling: Initial tooling costs for custom designs can be significant, especially for bespoke booths. These costs should be amortized over the expected production volume to understand their impact on unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure that the paint booths meet industry standards and client specifications. The costs associated with testing and certification should be factored into the overall pricing.

-

Logistics: Transporting paint booths involves freight costs, tariffs, and insurance, particularly for international shipments. The choice of shipping method (air vs. sea) can also influence delivery times and costs.

-

Margin: Suppliers will typically add a profit margin based on their operational costs and market competition. This margin varies widely depending on the supplier’s reputation and market position.

How Do Price Influencers Affect Paint Booth Costs?

Numerous factors influence the pricing of paint booths, which can vary significantly based on the buyer’s needs and market conditions.

-

Volume/MOQ: Bulk purchases often yield lower unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to maximize savings.

-

Specifications and Customization: Custom features such as advanced airflow systems, integrated technology, or specific dimensions can substantially increase costs. Buyers must balance the need for customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or OSHA compliance) typically come at a premium. Buyers should assess whether the benefits justify the additional expense.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer superior quality and service, reducing risks for the buyer.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define responsibilities regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Are Some Effective Buyer Tips for Negotiating Paint Booth Prices?

When negotiating the purchase of paint booths, international buyers should consider the following strategies to enhance cost-efficiency:

-

Conduct Thorough Market Research: Understanding the price range and features of various suppliers allows buyers to negotiate more effectively and identify fair pricing.

-

Leverage Total Cost of Ownership (TCO): Assess the long-term costs associated with the paint booth, including maintenance, energy consumption, and operational efficiency. A higher upfront cost may be justified if it leads to lower operational costs.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing dynamics based on local demand, currency fluctuations, and trade regulations. Buyers from Africa, South America, the Middle East, and Europe should be prepared for these variations.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns, especially for large investments. Explore options for phased payments or financing plans.

-

Consider After-Sales Support: Evaluate the supplier’s commitment to after-sales service, including warranty terms and availability of spare parts. Quality support can prevent additional costs in the long run.

Disclaimer

The pricing and cost analyses provided are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek detailed quotes and conduct due diligence before finalizing any purchase.

Alternatives Analysis: Comparing how paint booth works With Other Solutions

In the quest for optimal painting solutions, B2B buyers often consider various technologies and methods to achieve high-quality finishes while ensuring efficiency and safety. Understanding the alternatives to traditional paint booths can provide valuable insights for decision-makers looking to enhance their operations.

| Comparison Aspect | How Paint Booth Works | Alternative 1: Spray Booth with Water Wash | Alternative 2: Open-Air Spray Systems |

|---|---|---|---|

| Performance | High efficiency in controlling air flow and pressure, leading to superior finishes. | Effective at reducing overspray and VOC emissions; can improve air quality. | Lower control over contaminants; dependent on environmental conditions. |

| Cost | Higher initial investment but lower long-term operational costs due to energy efficiency. | Moderate investment; operational costs can vary based on water usage and maintenance. | Low initial cost but potentially higher long-term costs due to environmental factors and rework. |

| Ease of Implementation | Requires specialized setup and training but integrates well with existing systems. | May require additional plumbing and water management systems. | Simple installation but may need frequent adjustments based on weather. |

| Maintenance | Regular maintenance needed for filters and fans; long lifespan with proper care. | Requires consistent water supply and filter changes; may need more frequent maintenance. | Minimal maintenance; however, quality control can be compromised without proper oversight. |

| Best Use Case | Ideal for high-volume production with strict quality control. | Best for eco-friendly operations focused on reducing emissions. | Suitable for small-scale projects or low-budget operations where air quality is less of a concern. |

What Are the Benefits and Drawbacks of Using a Water Wash Spray Booth?

Water wash spray booths utilize water to capture overspray and reduce volatile organic compounds (VOCs). This technology is beneficial in settings where environmental regulations are stringent, as it helps maintain compliance while improving air quality. However, the initial setup can be more complex due to the need for plumbing and water management systems. Additionally, ongoing maintenance can be more frequent as filters must be cleaned or replaced regularly to maintain performance.

How Do Open-Air Spray Systems Compare to Paint Booths?

Open-air spray systems are a cost-effective alternative that allows for painting in an outdoor or semi-enclosed environment. This method is easy to implement and requires minimal initial investment. However, the performance is highly variable, as it is susceptible to weather conditions and air quality issues. Contaminants such as dust and pollen can significantly impact the quality of the finish, leading to potential rework and increased costs over time.

How Can B2B Buyers Choose the Right Painting Solution?

When selecting the appropriate painting solution, B2B buyers should carefully assess their operational needs, budget constraints, and environmental regulations. Understanding the specific advantages and disadvantages of each method allows businesses to align their choice with their production goals. For high-volume operations focused on quality, a traditional paint booth is often the best choice. Conversely, for eco-conscious organizations looking to minimize their environmental footprint, a water wash booth may be more suitable. Open-air systems can serve well for smaller projects but may require careful management to ensure quality outcomes. By evaluating these factors, buyers can make informed decisions that enhance their operational efficiency and product quality.

Essential Technical Properties and Trade Terminology for how paint booth works

What Are the Key Technical Properties of Paint Booths?

Understanding the essential technical properties of paint booths is crucial for B2B buyers to make informed purchasing decisions. Here are several critical specifications that influence the performance, efficiency, and safety of paint booths:

-

Airflow Rate (CFM)

– Definition: Cubic Feet per Minute (CFM) measures the volume of air moving in and out of the paint booth.

– Importance: Adequate airflow is essential to ensure effective overspray removal and maintain a clean environment. For optimal performance, the airflow must be balanced; for instance, if a booth exhausts 8,000 CFM, an equal amount must be supplied to avoid negative pressure, which can introduce contaminants. -

Pressure Control

– Definition: This refers to the regulation of air pressure within the booth, either positive or negative.

– Importance: Positive pressure helps prevent dirt and debris from entering the booth, while negative pressure can lead to contamination during the painting process. Proper pressure control enhances finish quality and operational safety. -

Material Grade

– Definition: The quality of materials used in the construction of the paint booth, such as steel or aluminum.

– Importance: Higher-grade materials offer better durability and resistance to corrosion, which is vital in environments where flammable coatings are used. This affects the longevity and maintenance costs of the booth. -

Temperature Control Range

– Definition: The range of temperatures that can be maintained within the booth during the curing process.

– Importance: Effective temperature control is crucial for achieving optimal curing times and paint adhesion. Buyers should consider systems that allow precise temperature adjustments to enhance productivity and finish quality. -

Energy Efficiency Rating

– Definition: A measure of how effectively the paint booth uses energy, often indicated by specific standards or certifications.

– Importance: Energy-efficient booths lower operational costs and align with sustainability goals. This is particularly significant in regions where energy costs are high or where environmental regulations are stringent. -

Filter Efficiency

– Definition: The ability of the booth’s filters to capture particulates and contaminants from the air.

– Importance: High-efficiency filters not only improve air quality inside the booth but also enhance the overall quality of the paint job. Regular maintenance of filters is necessary to ensure consistent performance and prevent over-pressurization.

Which Common Terms Should B2B Buyers Know When Considering Paint Booths?

Familiarity with industry jargon is essential for effective communication and negotiation in the paint booth market. Here are some common terms that B2B buyers should understand:

Illustrative image related to how paint booth works

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Buyers often seek OEM parts for reliability and compatibility, ensuring that their paint booths operate efficiently. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers plan their purchases and manage inventory effectively, especially for bulk orders. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Relevance: An RFQ is crucial for comparing supplier offerings and negotiating favorable terms. It ensures that buyers receive competitive pricing for their paint booth needs. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations, which are critical when importing paint booths from abroad. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of the product.

– Relevance: Knowing lead times is vital for project planning and inventory management, especially in industries with tight production schedules. -

BIM (Building Information Modeling)

– Definition: A digital representation of the physical and functional characteristics of a facility.

– Relevance: BIM can be beneficial in the design and integration of paint booths into existing facilities, ensuring optimal layout and efficiency.

By understanding these technical properties and industry terms, B2B buyers can navigate the complexities of paint booth procurement more effectively, ensuring they choose the right solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the how paint booth works Sector

What Are the Key Trends Influencing the Paint Booth Market?

The global paint booth market is currently shaped by several key drivers, including advancements in technology, regulatory changes, and a growing emphasis on operational efficiency. Notably, the integration of automation and IoT technologies is revolutionizing how paint booths operate, enabling real-time monitoring and control of airflow and environmental conditions. This is particularly significant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where manufacturers seek to optimize production while adhering to stringent environmental regulations.

Emerging trends such as the adoption of variable frequency drives (VFDs) and energy-efficient air makeup units (AMUs) are also gaining traction. These technologies not only enhance the precision of airflow management but also contribute to significant energy savings. As sustainability becomes a focal point for many companies, buyers are increasingly interested in sourcing equipment that aligns with their environmental goals. For instance, paint booths equipped with advanced filtration systems are essential for minimizing overspray and VOC emissions, which is crucial for compliance with local regulations in countries like Germany and Brazil.

Furthermore, the market dynamics are shifting as manufacturers expand their offerings to include customizable solutions tailored to specific industry needs. This flexibility allows B2B buyers to select paint booths that best fit their operational requirements, ultimately leading to improved efficiency and product quality.

How Is Sustainability Reshaping B2B Sourcing in the Paint Booth Sector?

Sustainability is no longer just a buzzword; it has become a core principle in B2B sourcing, particularly in the paint booth sector. The environmental impact of paint application processes, including VOC emissions and waste generation, has prompted a shift toward greener practices. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable operations, which includes using eco-friendly materials and technologies.

Illustrative image related to how paint booth works

The importance of ethical supply chains cannot be overstated. B2B buyers are seeking partners who adhere to environmental standards and certifications, such as ISO 14001 or Green Seal. These certifications not only validate a supplier’s commitment to sustainability but also assure buyers that the products they source meet rigorous environmental criteria. Additionally, the use of ‘green’ materials, such as low-VOC paints and sustainable coatings, is becoming a key factor in procurement decisions.

Investing in sustainable paint booth technologies, such as advanced filtration systems and energy-efficient equipment, is proving beneficial for businesses. Not only do these innovations reduce the ecological footprint, but they also lead to long-term cost savings through improved operational efficiency and reduced regulatory liabilities. As a result, B2B buyers are encouraged to adopt a holistic approach to sourcing that emphasizes sustainability without compromising on performance or quality.

What Is the Historical Context of Paint Booth Technology in B2B Operations?

The evolution of paint booth technology is marked by significant advancements that have transformed the industry. Initially, paint booths were rudimentary structures designed primarily to contain overspray. However, as regulatory pressures increased and environmental awareness grew, manufacturers began to innovate. The introduction of sophisticated air management systems, including exhaust and makeup air units, revolutionized how paint booths functioned, leading to greater efficiency and improved working conditions.

In the 1990s and early 2000s, the shift towards automation and digital monitoring began to take shape. This period saw the integration of control systems that allowed for real-time adjustments to airflow and environmental conditions, catering to the growing demand for precision in paint application. Today, with the advent of IoT and smart technologies, paint booths are evolving into highly automated systems that not only enhance productivity but also align with sustainability goals.

Illustrative image related to how paint booth works

As the paint booth sector continues to evolve, international B2B buyers are presented with a range of innovative solutions that cater to diverse operational needs, emphasizing the importance of staying informed about the latest trends and technologies.

Frequently Asked Questions (FAQs) for B2B Buyers of how paint booth works

-

How do I solve airflow issues in my paint booth?

To resolve airflow issues, first assess the balance between air intake and exhaust. Ensure that your Air Makeup Unit (AMU) is calibrated to push in an equivalent volume of air that the exhaust fan pulls out. Inspect filters for clogs, as full filters can impede airflow and create over-pressurization, leading to dirt contamination. Regular maintenance and cleaning of both the intake and exhaust systems are crucial for optimal performance. If problems persist, consider consulting a specialist to evaluate your booth’s design and airflow configuration. -

What is the best paint booth configuration for my specific needs?

The optimal paint booth configuration depends on factors such as the size of the items being painted, the volume of work, and the types of finishes used. Crossflow booths are suitable for smaller jobs, while downdraft booths are preferred for larger items requiring high-quality finishes. Consult with a supplier who can assess your requirements and recommend a customized solution. Factors like energy efficiency, ventilation, and ease of use should also be considered to maximize productivity. -

How can I ensure the quality of my paint booth supplier?

When vetting a paint booth supplier, consider their industry experience and reputation. Request references and case studies from previous clients to evaluate their performance. Verify certifications and compliance with international standards, such as OSHA and NFPA, which indicate adherence to safety regulations. Additionally, assess their customer support and warranty policies, as responsive service can be critical for maintaining your equipment and ensuring operational efficiency. -

What are the minimum order quantities (MOQ) for paint booths?

Minimum order quantities can vary significantly based on the manufacturer and the complexity of the paint booth. Some suppliers may offer flexibility with MOQs for custom orders, while others may have strict requirements. It’s essential to communicate your needs clearly to potential suppliers and inquire about their policies. If you are a small business or startup, look for suppliers who cater to lower volume orders or consider purchasing used equipment to minimize initial investment. -

What payment terms should I expect when purchasing a paint booth?

Payment terms for paint booths typically involve a deposit followed by the balance upon delivery or installation. Common arrangements include 30% upfront, with the remaining amount due before shipment. Some suppliers may offer financing options or extended payment plans for larger purchases. Always clarify payment schedules and any potential penalties for late payments before finalizing your order to avoid unexpected costs. -

How do I ensure compliance with international shipping regulations for my paint booth?

To comply with international shipping regulations, start by understanding the import/export laws specific to your country and the supplier’s location. Ensure that the paint booth meets the required safety and environmental standards, as non-compliance can lead to delays or fines. Work closely with your supplier to obtain necessary documentation, such as certificates of compliance and customs declarations. Engaging a logistics partner experienced in international trade can also help streamline the shipping process and mitigate risks. -

What are the key factors to consider in paint booth customization?

When customizing a paint booth, consider factors such as size, airflow design, and energy efficiency. Evaluate your specific application needs, such as the type of materials being painted and the desired finish quality. Additional features like integrated heating or cooling systems, specialized lighting, and automation can enhance efficiency. Collaborate closely with your supplier to ensure that the customization aligns with your operational goals and complies with relevant safety standards. -

How can I improve operational efficiency in my paint booth?

To enhance operational efficiency, focus on optimizing airflow and reducing downtime. Regular maintenance of filters and exhaust systems ensures proper airflow, while automation features can streamline processes like curing and cooling. Implementing a structured workflow for painting tasks can minimize idle time and maximize throughput. Training your staff on best practices for using the booth can also lead to improved quality and reduced waste, ultimately driving productivity.

Top 5 How Paint Booth Works Manufacturers & Suppliers List

1. Heppner’s Auto Body – Paint Booth Solutions

Domain: heppnersautobody.com

Registered: 2001 (24 years)

Introduction: Auto body paint booths are specialized, controlled environments designed to optimize the painting process for vehicles while ensuring safety, efficiency, and high-quality results. Key features include: 1. Controlled Environment: Clean, enclosed space to prevent contamination from dust, debris, and insects, with filtered air intake and exhaust systems. 2. Airflow Systems: – Crossdraft: Horizontal a…

2. IQS Directory – Spray Booths

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Spray Booths: Purpose-built enclosures for spray painting projects, designed to contain and eliminate overspray and vapors. Commonly used for coating metal surfaces to prevent corrosion. Features include fire and explosion-resistant properties, ideal for controlled environments. Key components include: 1. Walls: Single-skin (budget-friendly, easy to clean) and dual-skin (durable, insulated, better…

3. Searose Environmental – Spray Booth Solutions

Domain: searose.com.au

Introduction: Searose Environmental specializes in spray booths for various industries including cabinet making, welding, agriculture, plastics, engineering, mining, concrete, blocks, minerals, sandblasting, HVAC, and architectural ducting. They offer installation and maintenance services for spray booths, dust collectors, fume extraction systems, and more. Spray booths provide a controlled environment for high…

4. Allied Cleanrooms – Paint Booths

Domain: alliedcleanrooms.com

Registered: 2012 (13 years)

Introduction: Paint Booths are controlled environments designed to provide clean air and ventilation during the painting process, removing dust, overspray, and other contaminants. There are several types of paint booths categorized by airflow direction: 1. Downdraft Paint Booths – air flows from ceiling to floor, ideal for automotive use. 2. Semi-Downdraft Paint Booths – air enters from the ceiling and exits th…

5. Gelengg – Paint Booth Solutions

Domain: gelengg.com

Registered: 2004 (21 years)

Introduction: Paint Booth Types: Cross Draft, Downdraft, Semi-Downdraft, Portable Booths. Key Features: Airflow Management (Cross Draft, Downdraft, Semi-Downdraft), Filtration Systems (Pre-Filters, Main Filters, Activated Carbon Filters), Ventilation Systems, Lighting (LED), Temperature and Humidity Control (HVAC), Safety Features (Explosion-Proof Equipment, Emergency Shut-Offs, PPE). Cost: ₹7,00,000 to over ₹7…

Strategic Sourcing Conclusion and Outlook for how paint booth works

In conclusion, understanding how a paint booth operates is crucial for businesses seeking to optimize their finishing processes. Key insights include the importance of managing air flow through exhaust and Air Make-Up Units (AMUs), which directly influence the quality of paint applications and overall operational efficiency. Ensuring balanced air pressure is essential not only for maintaining a clean environment but also for preventing contamination that could compromise product quality.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality paint booth systems can enhance production capabilities and reduce operational costs. Investing in advanced technology such as the Sure-Cure AMU can significantly improve air circulation, reduce energy consumption, and increase throughput.

As the global market continues to evolve, the demand for efficient and effective paint application solutions will only grow. We encourage you to explore state-of-the-art paint booth technologies that align with your operational needs. Engage with trusted suppliers and stay ahead of industry trends to ensure your business remains competitive and responsive to market demands. The future of paint application is bright—make sure you are part of it.

Illustrative image related to how paint booth works

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.