How to Source Charolas De Aluminio Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for charolas de aluminio

In an increasingly interconnected world, sourcing high-quality charolas de aluminio (aluminum trays) presents a significant challenge for international B2B buyers. Whether you are operating in the hospitality sector, food service, or catering industries across Africa, South America, the Middle East, or Europe, the need for reliable suppliers and products that meet diverse market demands is paramount. This guide aims to navigate the complexities of the global market for aluminum trays, providing insights into various types, applications, and essential factors to consider when making purchasing decisions.

Buyers will discover detailed information about the different styles and sizes of charolas de aluminio, from disposable options for events to durable trays for commercial kitchens. Understanding the applications of these trays—from food presentation to storage—will empower businesses to select the right products that enhance operational efficiency. Additionally, this guide addresses supplier vetting processes, pricing strategies, and logistics, ensuring that buyers can make informed decisions that align with their business objectives.

By equipping B2B buyers with actionable insights and comprehensive knowledge, this resource serves as a vital tool in fostering successful procurement strategies. Whether you are looking to streamline your supply chain or enhance product offerings, understanding the global market landscape for charolas de aluminio will enable you to thrive in your respective industry.

Understanding charolas de aluminio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Disposable Aluminum Trays | Lightweight, single-use, often pre-formed for convenience | Catering, food service, events | Pros: Cost-effective, easy cleanup. Cons: Not eco-friendly, limited durability. |

| Heavy-Duty Aluminum Pans | Thicker gauge aluminum, reusable, designed for heavy loads | Restaurants, bakeries, food processing | Pros: Durable, can withstand high temperatures. Cons: Higher initial cost, requires washing. |

| Aluminum Steam Table Pans | Designed to fit steam tables, often with lids | Buffets, catering, large events | Pros: Convenient for serving, helps maintain food temperature. Cons: Limited to specific uses. |

| Baking Aluminum Trays | Non-stick coating options, various sizes for baking | Bakeries, restaurants, home kitchens | Pros: Versatile, great for baking. Cons: Can warp under extreme heat. |

| Multi-Purpose Aluminum Trays | Available in various shapes and sizes, suitable for diverse uses | General food storage, meal prep | Pros: Versatile, can be used for many applications. Cons: May lack specialized features of other types. |

What Are the Characteristics of Disposable Aluminum Trays?

Disposable aluminum trays are designed for one-time use, making them ideal for catering and food service applications. They are lightweight and come pre-formed in various shapes and sizes, facilitating quick service during events. Their cost-effectiveness makes them a popular choice for large gatherings where convenience is key. However, buyers should consider the environmental impact, as these trays contribute to waste and are not typically recyclable.

How Do Heavy-Duty Aluminum Pans Differ from Other Types?

Heavy-duty aluminum pans are made from thicker gauge aluminum, allowing them to handle heavier loads without bending or warping. They are reusable and designed for repeated use in commercial kitchens, bakeries, and food processing environments. Their durability makes them suitable for high-temperature cooking and baking. While the initial investment is higher compared to disposable options, the long-term savings from reusability can be significant, making them a wise choice for businesses focused on sustainability.

What Are the Benefits of Using Aluminum Steam Table Pans?

Aluminum steam table pans are specifically designed to fit steam tables and often come with lids to maintain food temperature during service. They are commonly used in buffets and catering for large events, providing a practical solution for serving hot foods. These pans are typically lightweight and easy to handle, but their utility is somewhat limited to specific applications. Buyers should ensure they select the correct size to fit their steam tables for optimal performance.

Why Choose Baking Aluminum Trays for Your Kitchen?

Baking aluminum trays are versatile and can come with non-stick coatings, making them suitable for various baking applications. They are available in multiple sizes, accommodating everything from cookies to casseroles. While they offer great baking performance, buyers should be cautious of potential warping under extreme heat. Investing in high-quality baking trays can enhance baking results, making them a valuable addition to any commercial kitchen or bakery.

What Makes Multi-Purpose Aluminum Trays a Good Investment?

Multi-purpose aluminum trays are designed for versatility, available in various shapes and sizes to accommodate a wide range of applications. They are suitable for general food storage, meal prep, and even serving. Their adaptability makes them a practical choice for businesses that need flexibility in their food service operations. However, buyers should consider that these trays may not have the specialized features of other types, which could limit their effectiveness in certain applications.

Key Industrial Applications of charolas de aluminio

| Industry/Sector | Specific Application of charolas de aluminio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Catering and Event Management | Provides lightweight, disposable options for serving food, reducing cleanup time. | Ensure compliance with food safety regulations and quality standards. |

| Hospitality | Meal Preparation in Hotels and Restaurants | Durable and heat-resistant, ideal for baking and serving. | Consider size variations and bulk purchasing options for cost efficiency. |

| Manufacturing | Packaging for Industrial Goods | Protects products during transport and storage while being recyclable. | Look for suppliers who offer custom sizes and bulk discounts. |

| Retail | Food Display and Takeaway Solutions | Enhances presentation and convenience for takeaway orders. | Evaluate the aesthetics and branding opportunities in packaging. |

| Healthcare | Meal Distribution in Hospitals and Clinics | Ensures hygienic transport of meals, reducing contamination risks. | Confirm materials are safe for food contact and comply with health regulations. |

How Are Charolas de Aluminio Used in Food Service?

In the food service industry, charolas de aluminio are essential for catering and event management. These disposable trays facilitate the efficient serving of meals at large gatherings, significantly reducing the time required for cleanup. Catering companies benefit from the lightweight nature of aluminum trays, which allows for easy transport and handling. When sourcing, businesses should prioritize compliance with food safety regulations, ensuring that the trays are suitable for direct food contact and are made from high-quality materials.

What Role Do Charolas de Aluminio Play in Hospitality?

In hotels and restaurants, charolas de aluminio are widely used for meal preparation and serving. Their durability and heat resistance make them ideal for baking and serving hot dishes, ensuring that food maintains its temperature. The ability to stack and store these trays efficiently is a significant advantage for kitchens with limited space. Buyers in this sector should consider the variety of sizes available and explore bulk purchasing options to optimize costs and meet operational needs.

How Do Charolas de Aluminio Benefit Manufacturing Industries?

Manufacturers often utilize charolas de aluminio for packaging industrial goods. These trays provide a protective layer during transportation and storage, safeguarding products from damage while being environmentally friendly due to their recyclability. When sourcing aluminum trays for manufacturing, companies should seek suppliers that offer custom sizes to fit specific product dimensions and bulk discounts to enhance cost-effectiveness.

In What Ways Are Charolas de Aluminio Utilized in Retail?

In the retail sector, charolas de aluminio serve as effective solutions for food display and takeaway orders. These trays enhance the visual presentation of food items, making them more appealing to customers while providing a convenient option for takeaway services. Retailers should evaluate the aesthetics of the trays and consider branding opportunities to enhance customer experience. Sourcing from reliable suppliers who can provide consistent quality is crucial for maintaining brand reputation.

How Are Charolas de Aluminio Used in Healthcare Settings?

In healthcare, charolas de aluminio are vital for meal distribution in hospitals and clinics. They ensure the hygienic transport of meals, minimizing contamination risks and promoting patient safety. The trays are designed to be disposable, which helps maintain cleanliness and efficiency in meal service. When sourcing for healthcare applications, it is essential to confirm that the materials used meet stringent health regulations and are safe for food contact, ensuring patient welfare is prioritized.

3 Common User Pain Points for ‘charolas de aluminio’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Bulk Orders of Charolas de Aluminio

The Problem: B2B buyers often face the challenge of ensuring the quality of aluminum trays when ordering in bulk. Discrepancies in quality can arise from different suppliers or manufacturing processes, leading to variations in thickness, durability, and resistance to heat. This is particularly crucial for businesses in the food service industry, where the integrity of the trays directly impacts food safety and presentation. If a buyer receives subpar products, it can result in wasted resources, dissatisfied customers, and potential financial losses.

The Solution: To mitigate quality concerns, it’s essential for buyers to establish clear specifications before placing orders. Create a detailed quality checklist that includes material thickness, resistance ratings, and design specifications. Additionally, consider requesting samples from potential suppliers before committing to a large order. This allows you to evaluate the product firsthand. Building a long-term relationship with a reputable supplier known for consistent quality can also significantly reduce risks. Regular quality audits and maintaining open communication with suppliers will help ensure that the products meet your established standards.

Scenario 2: Managing Supply Chain Disruptions for Charolas de Aluminio

The Problem: Supply chain disruptions can pose a significant challenge for businesses relying on aluminum trays, especially during peak seasons or unforeseen global events. Delays in delivery can lead to stock shortages, hampering service capabilities and causing frustration among clients. This is particularly pressing for companies in the catering and event planning sectors, where timely access to products is crucial for operational success.

The Solution: To effectively manage supply chain disruptions, consider diversifying your supplier base. Engage with multiple suppliers across different regions to reduce dependency on a single source. Establishing relationships with local manufacturers can also help in securing quicker deliveries during crises. Furthermore, implementing a robust inventory management system can provide real-time visibility into stock levels, allowing for proactive ordering. Regularly reviewing and updating contingency plans will ensure your business can adapt swiftly to disruptions, maintaining service levels and client satisfaction.

Scenario 3: Understanding Regulatory Compliance for Charolas de Aluminio

The Problem: B2B buyers often grapple with the complexities of regulatory compliance concerning food safety and packaging materials. Different regions have varying standards for the use of aluminum trays, especially regarding food contact safety. Non-compliance can lead to legal issues, product recalls, and damage to a company’s reputation, particularly for businesses exporting products internationally.

Illustrative image related to charolas de aluminio

The Solution: To navigate regulatory compliance, it is crucial to stay informed about the specific regulations applicable in your target markets. Collaborate with suppliers who have a thorough understanding of local and international standards, ensuring that all products meet necessary food safety certifications. Conduct periodic training sessions for your procurement team on compliance requirements and best practices. Additionally, maintain thorough documentation of compliance certifications and test results for all products purchased. This proactive approach not only safeguards your business but also builds trust with clients and stakeholders by demonstrating a commitment to quality and safety.

Strategic Material Selection Guide for charolas de aluminio

What Are the Key Materials Used in Charolas de Aluminio?

When selecting charolas de aluminio for various applications, understanding the materials involved is crucial for ensuring product performance and compliance with industry standards. Here, we analyze four common materials used in the manufacturing of aluminum trays, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum Alloy 1100

Key Properties:

Aluminum Alloy 1100 is known for its excellent corrosion resistance and formability. It has a melting point around 660°C and can withstand moderate temperatures, making it suitable for food service applications.

Pros & Cons:

This alloy is lightweight and cost-effective, which is advantageous for shipping and handling. However, it has lower strength compared to other alloys, making it less suitable for heavy-duty applications.

Illustrative image related to charolas de aluminio

Impact on Application:

Ideal for food trays, 1100 alloy is compatible with a wide range of food products and can be used in both hot and cold applications.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with food safety standards such as ASTM and DIN, which govern materials used in food contact applications.

2. Aluminum Alloy 3003

Key Properties:

Aluminum Alloy 3003 offers good corrosion resistance and is known for its excellent workability. It has a higher strength than 1100, with a melting point of approximately 660°C.

Pros & Cons:

This alloy is durable and can handle higher pressures, making it suitable for various applications. However, it is slightly more expensive than Alloy 1100 and may require more complex manufacturing processes.

Impact on Application:

3003 alloy is often used for trays that need to hold heavier food items or withstand more rigorous handling, making it ideal for catering and food service industries.

Considerations for International Buyers:

Compliance with international standards is critical. Buyers should verify that suppliers adhere to regulations such as JIS in Japan or EN in Europe for quality assurance.

3. Aluminum Alloy 5052

Key Properties:

Aluminum Alloy 5052 is characterized by its high strength and excellent corrosion resistance, particularly in marine environments. It has a melting point around 650°C.

Pros & Cons:

While it is more expensive than both 1100 and 3003, its durability and strength make it suitable for heavy-duty applications. The downside is that it can be more challenging to work with due to its increased strength.

Impact on Application:

This alloy is ideal for trays used in industrial kitchens or outdoor catering where durability is paramount. Its resistance to corrosion makes it suitable for various food types, including acidic foods.

Considerations for International Buyers:

Buyers should ensure that the material meets local and international standards for food safety and manufacturing quality, particularly in regions with stringent regulations.

Illustrative image related to charolas de aluminio

4. Aluminum Alloy 6061

Key Properties:

Aluminum Alloy 6061 is known for its excellent mechanical properties and corrosion resistance. It has a melting point of approximately 660°C and is suitable for structural applications.

Pros & Cons:

While it offers high strength and versatility, 6061 is generally more expensive and may require specialized manufacturing techniques.

Impact on Application:

This alloy is suitable for trays that need to withstand significant wear and tear, making it ideal for industrial applications and transport.

Considerations for International Buyers:

Compliance with ASTM standards is essential for buyers in North America, while European buyers should check for compliance with EN standards to ensure product safety and quality.

Summary Table of Material Selection for Charolas de Aluminio

| Material | Typical Use Case for charolas de aluminio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 1100 | Food trays for light applications | Lightweight and cost-effective | Lower strength compared to others | Low |

| Aluminum Alloy 3003 | Catering trays for moderate loads | Good durability and workability | Higher cost and manufacturing complexity | Medium |

| Aluminum Alloy 5052 | Industrial kitchen trays | High strength and corrosion resistance | More expensive and harder to work with | High |

| Aluminum Alloy 6061 | Heavy-duty transport trays | Excellent mechanical properties | Requires specialized manufacturing | High |

This guide provides a comprehensive overview of the materials used in charolas de aluminio, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for charolas de aluminio

What Are the Main Stages in the Manufacturing Process of Charolas de Aluminio?

The manufacturing of aluminum trays, or charolas de aluminio, involves several critical stages to ensure that the final product meets both quality and performance standards. Understanding these stages is essential for B2B buyers looking to source high-quality products.

Illustrative image related to charolas de aluminio

Material Preparation: How Is Aluminum Processed for Trays?

The first step in the manufacturing process is the preparation of aluminum sheets. High-quality aluminum, often alloyed to enhance durability, is sourced from reliable suppliers. The sheets are cleaned and treated to remove any impurities or oxidation that could affect product quality. This preparation is crucial, as it ensures the trays will be resistant to corrosion and can withstand various cooking and storage conditions.

Forming: What Techniques Are Used to Shape Aluminum Trays?

Once the aluminum sheets are prepared, they undergo forming, which can be accomplished through various techniques such as stamping, die-cutting, or extrusion. Stamping is commonly used for creating trays with specific dimensions and shapes, while die-cutting allows for intricate designs. The choice of technique often depends on the desired tray specifications and production volume. After forming, the trays are typically trimmed to remove any excess material, ensuring uniformity across batches.

Assembly: How Are Charolas de Aluminio Finished?

While many aluminum trays are single-piece constructions, some designs may require assembly. In cases where multiple components are used, such as lids or dividers, the assembly process involves precise alignment and secure fastening. This stage may also include additional features like handles or insulation materials for specific applications. The assembly must be executed with precision to maintain the integrity and functionality of the trays.

Illustrative image related to charolas de aluminio

Finishing: What Surface Treatments Enhance Performance?

Finishing processes for aluminum trays often include anodizing or coating to enhance resistance to heat, moisture, and chemicals. Anodizing creates a protective oxide layer, which not only improves durability but also provides aesthetic options. Coatings may include non-stick finishes, making the trays easier to clean and use in food preparation. These treatments are essential for ensuring that the trays meet the performance standards required in various industries, including food service and catering.

What International Standards Govern Quality Assurance in Charolas de Aluminio Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for aluminum trays, ensuring that products meet international standards and customer expectations. Various certifications and quality control measures play a vital role in this aspect.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for manufacturers that comply with international standards like ISO 9001, which outlines requirements for a quality management system. Compliance with ISO ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Other relevant certifications may include CE marking for products sold in Europe and industry-specific standards such as API for food service applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control in the manufacturing of charolas de aluminio typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials for quality and compliance before they enter the production process. It helps prevent defects from the outset.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring production processes to identify and rectify issues in real-time. This includes checking dimensions, weight, and surface quality at various stages.

-

Final Quality Control (FQC): After production, FQC ensures that the finished trays meet all specifications and standards. This may involve visual inspections, functional testing, and compliance checks against relevant standards.

What Common Testing Methods Are Used to Ensure Quality in Aluminum Trays?

Various testing methods are employed to ensure the quality and safety of aluminum trays. These methods may include:

Illustrative image related to charolas de aluminio

-

Visual Inspection: A thorough examination of the trays for any visible defects, such as dents, scratches, or irregular shapes.

-

Dimensional Testing: Measuring the trays to ensure they meet specified dimensions and tolerances.

-

Weight Testing: Confirming that the trays can support the specified weight without deformation.

-

Corrosion Resistance Testing: Exposing trays to various environmental conditions to assess their resistance to corrosion and degradation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some actionable insights:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting recent audit reports from suppliers can provide insight into their quality management systems. These reports should detail compliance with relevant standards and any corrective actions taken in response to previous quality issues.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality assurance measures. These inspections can be conducted at various stages of production, offering an additional layer of confidence for buyers.

What Are the Quality Control Nuances for International Buyers?

When sourcing charolas de aluminio from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

-

Regulatory Compliance: Ensure that the products comply with local regulations and standards in the buyer’s country, as these may vary significantly between regions.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and partnerships.

-

Logistical Challenges: Consider the logistics involved in shipping and customs clearance, as these can impact product delivery timelines and costs.

By understanding the manufacturing processes and quality assurance practices associated with charolas de aluminio, B2B buyers can make informed decisions and select suppliers that align with their quality and performance requirements.

Illustrative image related to charolas de aluminio

Practical Sourcing Guide: A Step-by-Step Checklist for ‘charolas de aluminio’

To successfully procure charolas de aluminio, it’s essential to follow a systematic approach. This guide provides a step-by-step checklist designed for B2B buyers, ensuring that your sourcing process is efficient, effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications required for your aluminum trays, including dimensions, weight capacity, and intended use (e.g., food service, baking, or storage). This step is critical as it helps ensure that the products meet your operational requirements and comply with industry standards.

- Considerations:

- Specify whether you need disposable or reusable trays.

- Determine the thickness of the aluminum, which affects durability and cost.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in aluminum trays. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential partners.

- Tips:

- Look for suppliers with a strong reputation in your target markets, such as Africa, South America, and Europe.

- Pay attention to their product range and whether they offer customization options.

Step 3: Evaluate Supplier Certifications and Compliance

Before making a commitment, verify that potential suppliers hold the necessary certifications, such as ISO or food safety standards. This ensures that the products are manufactured under safe and regulated conditions.

- Key Points:

- Check for certifications relevant to your region (e.g., FDA compliance for food contact materials).

- Request documentation to substantiate their claims.

Step 4: Request Product Samples

Always request samples of the charolas de aluminio before placing a bulk order. This allows you to assess the quality, design, and functionality of the trays firsthand.

- What to Look For:

- Inspect the material for sturdiness and finish.

- Test usability, particularly if the trays are meant for food service.

Step 5: Compare Pricing and Terms of Sale

Once you have evaluated the quality of the products, compare the pricing and terms of sale among different suppliers. This will help you understand the market rate and negotiate better terms.

- Considerations:

- Look at bulk pricing discounts and shipping costs.

- Review payment terms and return policies to ensure they align with your financial practices.

Step 6: Assess Supplier Communication and Support

Evaluate how responsive and communicative potential suppliers are during the inquiry process. Good communication is vital for resolving any issues that may arise during the order process.

- Indicators of Good Support:

- Prompt responses to inquiries and willingness to provide additional information.

- Availability of customer service options for post-purchase support.

Step 7: Finalize Your Order and Establish a Relationship

Once you have selected a supplier, finalize your order and consider establishing a long-term relationship. Building rapport with your supplier can lead to better pricing, priority service, and more favorable terms in the future.

Illustrative image related to charolas de aluminio

- Tips for Relationship Building:

- Maintain regular communication to provide feedback on product performance.

- Discuss future needs and opportunities for collaboration on new products.

By following this checklist, B2B buyers can ensure a more streamlined and effective sourcing process for charolas de aluminio, leading to successful procurement that meets business needs.

Comprehensive Cost and Pricing Analysis for charolas de aluminio Sourcing

When sourcing charolas de aluminio (aluminum trays), understanding the cost structure and pricing dynamics is essential for international B2B buyers. This analysis covers the key cost components, price influencers, and practical tips for optimizing purchasing strategies.

What Are the Key Cost Components in Sourcing Charolas de Aluminio?

-

Materials: The primary cost driver is the aluminum itself. Prices can fluctuate based on market demand and availability. High-quality aluminum, which offers better durability and resistance to corrosion, may come at a premium. Suppliers often provide different grades of aluminum, impacting both cost and performance.

-

Labor: Labor costs vary significantly depending on the region of production. For instance, countries in Asia may have lower labor costs compared to those in Europe. Additionally, skilled labor involved in intricate manufacturing processes can increase costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Efficient production processes can mitigate overhead costs, making suppliers with optimized operations more competitive.

-

Tooling: Custom tooling for specific tray designs can be a significant one-time cost. Buyers should consider whether the investment aligns with their volume needs and product lifecycle.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to overall costs. Certifications (like ISO) may also be required for certain markets, further influencing pricing.

-

Logistics: Shipping costs can be substantial, particularly for international orders. Factors such as distance, shipping method, and Incoterms (which define responsibilities between buyers and sellers) play a crucial role in the overall logistics cost.

-

Margin: Suppliers typically build in a profit margin, which can vary based on market conditions, competition, and buyer relationships. Understanding typical margins in different markets can help buyers negotiate effectively.

How Do Price Influencers Affect Charolas de Aluminio Pricing?

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Higher order volumes can lead to bulk discounts, while smaller orders may not benefit from the same economies of scale.

-

Specifications and Customization: Customized trays that meet specific dimensions or features can incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Quality and Certifications: Higher quality products or those with specific certifications can command higher prices. Buyers should assess the necessity of these factors based on their intended use.

-

Supplier Factors: Supplier reliability, reputation, and production capacity can influence pricing. Established suppliers may charge a premium due to perceived value, while newer suppliers might offer lower prices to build market share.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should be aware of the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) when calculating total costs.

What Tips Can Help Buyers Optimize Their Sourcing Strategy?

-

Negotiation: Engage in discussions with suppliers to explore price flexibility, especially for larger orders or long-term contracts. Building a strong relationship can lead to better pricing and service.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, handling, and potential waste. This holistic view can reveal the true cost-effectiveness of various options.

-

Understand Regional Nuances: Buyers from Africa, South America, the Middle East, and Europe should consider regional supply chain dynamics, tariffs, and trade agreements that may affect pricing and availability.

-

Stay Informed on Market Trends: Regularly monitor aluminum market trends and forecasts to anticipate price movements and adjust procurement strategies accordingly.

Disclaimer on Indicative Prices

Prices for charolas de aluminio can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and supplier assessments to obtain accurate and current pricing information tailored to their specific needs.

Alternatives Analysis: Comparing charolas de aluminio With Other Solutions

In the B2B marketplace, making informed decisions about packaging and serving solutions is crucial for operational efficiency and cost management. Charolas de aluminio, or aluminum trays, are widely recognized for their versatility and durability. However, various alternative solutions can also fulfill similar roles, each with unique benefits and limitations. This section compares charolas de aluminio with other viable alternatives to help international buyers identify the best option for their specific needs.

| Comparison Aspect | Charolas De Aluminio | Biodegradable Trays | Plastic Containers |

|---|---|---|---|

| Performance | High resistance to heat and moisture; reusable and recyclable | Good for cold items; limited heat resistance | Durable; can be airtight for freshness |

| Cost | Moderate cost per unit; bulk discounts available | Generally higher initial cost | Low cost per unit; bulk pricing widely available |

| Ease of Implementation | Easy to use; no special equipment needed | Requires user education on disposal | Simple to use; widely accepted in food service |

| Maintenance | Low maintenance; can be reused multiple times | Single-use; no maintenance needed | Can be reused but may require cleaning |

| Best Use Case | Ideal for catering, baking, and food storage | Best for environmentally conscious events | Suitable for takeout and delivery services |

What Are the Pros and Cons of Biodegradable Trays Compared to Charolas de Aluminio?

Biodegradable trays are an eco-friendly alternative, appealing particularly to businesses focused on sustainability. They perform well for cold dishes and are designed for single-use, eliminating the need for cleaning. However, their heat resistance is limited, making them unsuitable for hot foods, which can lead to a compromised product quality. Additionally, the initial cost is often higher, which could impact profitability for businesses operating on tight margins.

How Do Plastic Containers Stack Up Against Charolas de Aluminio?

Plastic containers are another alternative, well-known for their durability and versatility. They can be airtight, making them an excellent choice for preserving food freshness, especially in takeout or delivery scenarios. However, they are typically designed for single use, leading to environmental concerns similar to those associated with biodegradable trays. Furthermore, while plastic containers are often less expensive, they may require cleaning and maintenance if reused, which could add labor costs.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting between charolas de aluminio and its alternatives, B2B buyers should consider several factors. The nature of the food being served—hot or cold—will significantly influence the choice. For businesses committed to sustainability, biodegradable trays may align better with their values despite higher costs. Conversely, if cost-efficiency and durability are priorities, charolas de aluminio or plastic containers might be the more practical options. Ultimately, understanding the specific requirements of your operations, including budget constraints and customer expectations, will guide you toward the most suitable solution.

Essential Technical Properties and Trade Terminology for charolas de aluminio

What Are the Key Technical Properties of Charolas de Aluminio?

When sourcing charolas de aluminio (aluminum trays), understanding their technical specifications is crucial for making informed purchasing decisions. Below are some essential properties that B2B buyers should consider:

-

Material Grade: Aluminum trays are typically made from various grades of aluminum, with 3003 and 5052 being among the most common. The grade determines the tray’s strength, weight, and resistance to corrosion. Selecting the right grade ensures the trays can withstand the intended use, whether for food service or industrial applications.

-

Thickness: The thickness of aluminum trays usually ranges from 0.5 mm to 1.5 mm. Thicker trays offer enhanced durability and resistance to deformation under weight, making them ideal for heavy-duty applications. Conversely, thinner trays may be more cost-effective for single-use scenarios. Buyers should assess their needs to choose the appropriate thickness.

-

Load Capacity: This specification refers to the maximum weight that a tray can safely hold without compromising its structural integrity. Load capacity is vital for applications that involve transporting or serving food, as it ensures safety and prevents spills. Trays with higher load capacities are often preferred in commercial kitchens and catering services.

-

Temperature Resistance: Aluminum trays are known for their ability to withstand high temperatures, making them suitable for baking and roasting. The temperature resistance typically ranges from -40°C to 250°C. This property is particularly important for food service applications where trays may be exposed to extreme conditions.

-

Finish Type: The finish of aluminum trays can vary, with options including anodized, coated, or plain surfaces. Anodized trays have a protective layer that enhances corrosion resistance and improves aesthetic appeal. Understanding the finish type helps buyers select trays that meet hygiene and visual standards.

-

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. B2B buyers increasingly consider sustainability in their procurement decisions. Choosing recyclable trays not only meets corporate social responsibility goals but may also reduce disposal costs.

What Are Common Trade Terms Related to Charolas de Aluminio?

Familiarizing yourself with trade terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms relevant to charolas de aluminio:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminum trays, understanding OEM relationships can help buyers identify reliable suppliers who can meet specific design or branding requirements.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest number of units a supplier is willing to sell. This is critical for B2B buyers, as it affects inventory management and cash flow. Understanding the MOQ helps businesses plan their purchases efficiently and avoid overstocking or stockouts.

-

RFQ (Request for Quotation): An RFQ is a formal document requesting pricing and terms from suppliers. B2B buyers use RFQs to gather competitive bids for charolas de aluminio, ensuring they receive the best value for their investment. It’s a crucial step in the sourcing process, enabling informed decision-making.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping, insurance, and delivery obligations effectively.

-

Lead Time: This term refers to the time taken from placing an order until the goods are delivered. In industries that rely on aluminum trays, understanding lead times is critical for inventory planning and operational efficiency. Buyers should inquire about lead times during negotiations to ensure timely availability of products.

-

BOM (Bill of Materials): A BOM is a comprehensive list of materials, components, and assemblies needed to manufacture a product. For charolas de aluminio, a BOM helps buyers understand the specifications and quantities required for production, aiding in accurate budgeting and resource allocation.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right charolas de aluminio for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the charolas de aluminio Sector

What Are the Key Market Dynamics and Trends in the Charolas de Aluminio Sector?

The charolas de aluminio sector is currently experiencing significant growth, driven by increasing demand across various industries, including food service, catering, and hospitality. The global shift toward convenience and efficiency has led to a rise in disposable cookware, particularly in regions like Africa, South America, the Middle East, and Europe. This trend is further fueled by the growing popularity of takeout and delivery services, which require reliable and economical packaging solutions.

Emerging B2B technologies, such as automated ordering systems and AI-driven supply chain management, are transforming how businesses source charolas de aluminio. Companies are increasingly leveraging e-commerce platforms and marketplaces to streamline their procurement processes, allowing for quicker access to a diverse range of products. Additionally, the adoption of data analytics is helping buyers make informed decisions about inventory management and supplier selection, ultimately leading to cost savings and improved operational efficiency.

As international B2B buyers navigate this landscape, they must consider regional market dynamics, such as varying regulations, import tariffs, and local manufacturing capabilities. Understanding these nuances can help buyers identify strategic sourcing opportunities and build robust supplier relationships that enhance their competitive edge.

How Is Sustainability Influencing Sourcing Decisions for Charolas de Aluminio?

Sustainability is becoming a cornerstone of sourcing strategies in the charolas de aluminio sector. With increasing awareness of environmental issues, businesses are under pressure to adopt more sustainable practices. The production of aluminum itself has significant environmental implications, from energy-intensive extraction processes to waste generation. As a result, ethical sourcing has gained traction among B2B buyers who are looking for suppliers committed to reducing their carbon footprint.

To align with these sustainability goals, many companies are seeking out ‘green’ certifications and eco-friendly materials. For example, sourcing aluminum from recycled materials not only minimizes environmental impact but also often leads to cost savings in production. Certifications such as ISO 14001 for environmental management systems and other sustainability standards are becoming essential for suppliers looking to differentiate themselves in a competitive market.

Moreover, buyers are increasingly scrutinizing their supply chains to ensure ethical labor practices and compliance with environmental regulations. Establishing partnerships with suppliers who prioritize sustainability can enhance brand reputation and appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context of Charolas de Aluminio in B2B Markets?

The evolution of charolas de aluminio can be traced back to the mid-20th century when aluminum became a popular material due to its lightweight, durability, and resistance to corrosion. Initially used primarily in the aerospace and automotive industries, aluminum began to find applications in food service as demand for disposable and convenient food packaging grew.

Over the years, technological advancements in manufacturing processes have led to the production of high-quality disposable aluminum trays that cater to diverse customer needs. The introduction of various sizes and designs has enabled businesses to use charolas de aluminio for everything from catering large events to individual meal preparations. This adaptability has solidified aluminum trays as a staple in the food service industry, making them indispensable for international B2B buyers looking for reliable and versatile solutions.

As the market continues to evolve, it is essential for buyers to stay informed about industry trends, sustainability practices, and technological innovations that shape the future of charolas de aluminio sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of charolas de aluminio

-

How do I choose the right type of charolas de aluminio for my business needs?

When selecting charolas de aluminio, consider factors such as the size, weight capacity, and intended use. For catering and food service, opt for heavy-duty options that can withstand high temperatures and heavy loads. Also, assess whether you need disposable or reusable trays based on your operational model. Engaging with suppliers to sample products can help determine the best fit for your specific requirements. -

What is the best supplier for sourcing charolas de aluminio internationally?

Identifying the best supplier involves researching manufacturers with a strong reputation in quality and reliability. Look for suppliers with certifications that meet international standards, such as ISO or FDA compliance. Additionally, evaluate their experience in exporting to your region and read reviews from other B2B buyers. Attending trade shows or utilizing online B2B platforms can also facilitate connections with reputable suppliers. -

What are the minimum order quantities (MOQs) for charolas de aluminio?

MOQs can vary significantly depending on the supplier and type of charolas. Typically, manufacturers may set MOQs ranging from a few hundred to several thousand units. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms, especially if you are a smaller business. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders. -

What customization options are available for charolas de aluminio?

Many suppliers offer customization options such as printing logos, specific sizes, or unique designs to meet your branding needs. Discuss your requirements with the supplier to understand the available options and any associated costs. Customization may involve a minimum order quantity, so ensure you clarify this during your discussions to avoid misunderstandings. -

What payment terms should I expect when sourcing charolas de aluminio?

Payment terms can vary widely among suppliers. Common terms include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may also offer credit terms based on your relationship and order history. It’s crucial to establish clear payment terms upfront to ensure a smooth transaction process. -

How can I ensure quality assurance when sourcing charolas de aluminio?

To ensure quality, request product samples before placing a bulk order and conduct inspections upon receipt. Establishing quality assurance protocols with your supplier is also essential. This may include third-party inspections or audits of the manufacturing process. Communicating your quality expectations clearly will help maintain product standards throughout the supply chain. -

What are the shipping options and logistics for importing charolas de aluminio?

Shipping options can include air freight for faster delivery or sea freight for cost-effective bulk shipments. Discuss logistics with your supplier, as they may offer shipping services or suggest reliable freight forwarders. Be aware of import regulations in your country, including tariffs and duties, which can impact overall costs and delivery timelines. -

How do I handle potential issues with my order of charolas de aluminio?

In the event of issues such as damaged goods or incorrect items, it’s essential to communicate promptly with your supplier. Document the problem with photographs and detailed descriptions to support your claim. Most reputable suppliers will have a return policy or offer replacements for faulty products. Establishing a good relationship with your supplier can facilitate smoother resolution processes.

Top 7 Charolas De Aluminio Manufacturers & Suppliers List

1. Instacart – Charolas de Aluminio

Domain: instacart.com

Registered: 1996 (29 years)

Introduction: Charolas de Aluminio (each) available for delivery or pickup via Instacart. $0 delivery fee on first 3 orders. Pricing varies by retailer. Delivery fees start at $3.99 for same-day orders over $35. Pickup fee typically $1.99 for non-Instacart+ members. Optional Instacart+ membership offers $0 delivery fee on orders over $35. Replacement options available if out of stock. Payment accepted via Visa,…

2. Lavasconia – Utensilios de Cocina

Domain: lavasconia.com

Registered: 2012 (13 years)

Introduction: {“shipping”:”Envío gratis en pedidos desde $1,499″,”categories”:[“Baterías”,”Sartenes”,”Ollas Express® y Refacciones”,”Cuchillos / Tablas”,”Utensilios / Auxiliares”,”Ollas / Cacerolas”,”Línea Profesional”,”Consumibles”,”Reposteria”,”Termos & Hidratación”,”Contenedores”,”Mesa”,”Accesorios”],”brands”:[“EKCO®”,”VASCONIA®”,”PRESTO®”,”DELEITE®”,”VITA®”,”BRASSA MASTERS®”,”ALUREY®”,”ALUPAK®”],”products”:…

3. Isimart – Charolas Rectangulares y Ovaladas

Domain: isimart.com

Registered: 2010 (15 years)

Introduction: {“products”:[{“type”:”Charola Chica Rectangular”,”dimensions”:”31.7 x 26.2 x 5.7 cm”},{“type”:”Charola Grande Rectangular”,”dimensions”:”45 x 32.6 x 6 cm”},{“type”:”Charola Grande Ovalada”,”dimensions”:”46 x 34.3 x 7.5 cm”},{“type”:”1 LB Charola Rectangular Food service”,”dimensions”:”7.9 x 10.7 x 4 cm”},{“type”:”1.5 LB Charola Rectangular Food service”,”dimensions”:”6.5 x 11.6 x 4.2 cm”},{“type”:…

4. Scoil Bhríde – Rectangular Disposable Aluminum Foil Pan

Domain: scoil-bhride.com

Registered: 2003 (22 years)

Introduction: Rectangular Disposable Aluminum Foil Pan for Take-Out Food

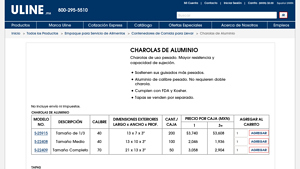

5. ULINE – Charolas de Aluminio Tamaño Completo

Domain: es.uline.mx

Registered: 2010 (15 years)

Introduction: Charolas de Aluminio Tamaño Completo en Existencia – ULINE. Charolas de uso pesado, mayor resistencia y capacidad de sujeción. Sostienen guisados pesados. Aluminio de calibre pesado, no requieren doble charola. Cumplen con FDA y Kosher. Tapas se venden por separado. Modelos disponibles: S-25915 (Tamaño de 1/3, 40, 13 x 7 x 3″, 200 por caja, $3,740), S-22408 (Tamaño Medio, 40, 13 x 10 x 3″, 100 por…

6. Sams – Charolas de Aluminio Brilo Medianas

Domain: sams.com.mx

Registered: 2000 (25 years)

Introduction: {“product_name”: “Charolas de Aluminio Brilo Medianas”, “quantity”: “10 pzas”, “price”: “$203.57”, “payment_options”: “Hasta 3 meses sin intereses de $67.86”, “promotion_period”: “1 al 30 de septiembre 2025”, “shipping_info”: “Envío en 24 hrs. a Miguel Hidalgo, 11220”, “category”: “Limpieza y Cuidado de la Ropa / Papel y Desechables / Productos Desechables”}

7. Travessa – Charola para Pizza Aluminio 35cm

Domain: cristalerialaunica.com.mx

Registered: 2014 (11 years)

Introduction: [{‘name’: ‘Charola para Pizza Aluminio 35cm’, ‘brand’: ‘Travessa’, ‘price’: ‘$128.00 MXN’, ‘availability’: ‘Agotado’}, {‘name’: ‘Charola Ovalada 56x68cm’, ‘brand’: ‘Travessa’, ‘price’: ‘$535.00 MXN’, ‘availability’: ‘Agotado’}, {‘name’: ‘Charola Aluminio 38×53.3cm’, ‘brand’: ‘Travessa’, ‘price’: ‘$307.00 MXN’, ‘availability’: ‘Agotado’}, {‘name’: ‘Charola Rectangular Aluminio 33×45.7cm’, ‘brand’: …

Strategic Sourcing Conclusion and Outlook for charolas de aluminio

What Are the Key Takeaways for Sourcing Charolas de Aluminio?

Strategic sourcing of charolas de aluminio offers significant advantages for international B2B buyers. By understanding the diverse product offerings across different markets, businesses can secure high-quality, cost-effective solutions tailored to their specific needs. The growing demand for disposable aluminum trays, particularly in food service and event management sectors, highlights the importance of establishing strong relationships with reliable suppliers who can ensure consistent quality and timely delivery.

How Does Strategic Sourcing Enhance Supply Chain Efficiency?

Investing in strategic sourcing not only enhances supply chain efficiency but also mitigates risks associated with price fluctuations and supply disruptions. By diversifying sourcing channels and leveraging local suppliers in key regions such as Africa, South America, and Europe, companies can better navigate the complexities of international trade. This approach not only fosters resilience but also promotes sustainability, as local sourcing often reduces carbon footprints associated with transportation.

What’s Next for International Buyers in the Charolas de Aluminio Market?

Looking ahead, B2B buyers should proactively explore emerging trends and innovations in the charolas de aluminio sector, including eco-friendly options and custom designs. Engaging in market analysis and supplier evaluations will be crucial in identifying opportunities for growth. As the demand for efficient, disposable solutions continues to rise, now is the ideal time for businesses to refine their sourcing strategies and capitalize on market dynamics. Embrace the future of strategic sourcing and position your business for success in the competitive landscape of charolas de aluminio.

Illustrative image related to charolas de aluminio

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.