How to Source Graphite Blocks Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for graphite blocks

In an increasingly interconnected global marketplace, sourcing high-quality graphite blocks poses a significant challenge for B2B buyers across diverse industries. As the demand for graphite blocks continues to grow—driven by their essential applications in sectors ranging from aerospace to energy generation—buyers must navigate a complex landscape of suppliers, specifications, and pricing strategies. This guide serves as a comprehensive resource, meticulously detailing the various types of graphite blocks, their specific applications, and critical factors to consider when vetting suppliers.

Understanding the nuances of graphite block manufacturing, including material grades and machining capabilities, is crucial for making informed purchasing decisions. Additionally, this guide will provide insights into cost considerations and market trends that can impact procurement strategies, enabling businesses to secure the best value.

Designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—this guide empowers stakeholders to make strategic, data-driven decisions. By leveraging the knowledge contained within, businesses can enhance their supply chain efficiency and ensure they select the right graphite blocks tailored to their operational needs.

Understanding graphite blocks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fuel Graphite Blocks | Hexagonal prisms with fuel holes, high thermal stability | Nuclear reactors, energy generation | Pros: High durability and thermal conductivity; Cons: Regulatory compliance requirements can complicate procurement. |

| Control Rod Guide Blocks | Similar shape to fuel blocks, designed for control rods | Nuclear reactors, safety systems | Pros: Ensures precise control in reactors; Cons: Limited availability may increase lead times. |

| Isotropic Graphite Blocks | Uniform structure, excellent mechanical properties | Aerospace, automotive, and electrical industries | Pros: Superior strength and wear resistance; Cons: Higher cost compared to standard grades. |

| High-Purity Graphite Blocks | Low impurity levels, enhanced performance characteristics | Semiconductor manufacturing, high-tech applications | Pros: Excellent electrical conductivity; Cons: Costly due to stringent manufacturing processes. |

| Medium Extruded Graphite Blocks | Versatile shapes, moderate mechanical properties | General industrial applications, machining | Pros: Cost-effective and adaptable; Cons: May not meet high-performance requirements in specialized applications. |

What are Fuel Graphite Blocks and Their Key Characteristics?

Fuel graphite blocks are specifically designed for use in nuclear reactors. Their hexagonal prism shape, complete with fuel holes, allows for efficient neutron moderation and heat transfer. These blocks are made from high-quality graphite, ensuring they can withstand extreme temperatures and pressures. When purchasing, B2B buyers should consider regulatory compliance, as these materials are subject to strict safety standards.

How Do Control Rod Guide Blocks Function in Nuclear Applications?

Control rod guide blocks play a crucial role in the operation of nuclear reactors. They are designed to accommodate control rods, ensuring precise control of the nuclear reaction. Their structural integrity is paramount, as any failure could lead to safety issues. Buyers should evaluate the availability and lead times for these components, as they are often custom-manufactured and can have long delivery periods.

What Sets Isotropic Graphite Blocks Apart from Other Types?

Isotropic graphite blocks are characterized by their uniform structure, which provides excellent mechanical properties, including strength and wear resistance. These blocks are often used in demanding applications such as aerospace and automotive industries. For B2B buyers, the investment in isotropic graphite blocks can yield significant performance benefits, but they come at a higher price point compared to standard graphite options.

Why Are High-Purity Graphite Blocks Essential for High-Tech Industries?

High-purity graphite blocks are manufactured with low impurity levels, making them ideal for high-tech applications like semiconductor manufacturing. Their enhanced performance characteristics, including superior electrical conductivity, make them a preferred choice in these sectors. Buyers should be prepared for higher costs and ensure they have suppliers who can meet the stringent quality standards required for these applications.

Illustrative image related to graphite blocks

How Do Medium Extruded Graphite Blocks Serve General Industrial Needs?

Medium extruded graphite blocks are versatile and commonly used across various industrial applications. They offer moderate mechanical properties and are often more cost-effective than specialized grades. While they are suitable for general machining and industrial uses, B2B buyers should assess whether their performance meets specific application requirements, as they may not be adequate for high-performance needs.

Key Industrial Applications of graphite blocks

| Industry/Sector | Specific Application of graphite blocks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Nuclear Energy | Fuel and control rod guide blocks in reactors | Enhanced safety and efficiency in nuclear operations | Ensure compliance with nuclear-grade specifications and certifications. |

| Aerospace | Thermal protection and structural components | High-temperature resistance and lightweight design | Verify material properties for aerospace-grade applications. |

| Metallurgy | Crucibles and molds for metal casting | Improved durability and thermal conductivity | Source high-purity graphite to prevent contamination of metals. |

| Electrical Engineering | Insulating materials in electrical components | High dielectric strength and thermal stability | Confirm electrical insulation properties and thermal conductivity. |

| Automotive | Friction materials in braking systems | Enhanced performance and longevity of brake systems | Assess wear resistance and compatibility with various braking systems. |

How Are Graphite Blocks Utilized in the Nuclear Energy Sector?

In the nuclear energy sector, graphite blocks serve as critical components in both fuel and control rod guide assemblies within reactors. Their isotropic properties ensure uniform performance under extreme conditions, enhancing safety and operational efficiency. International buyers should prioritize sourcing blocks that meet stringent nuclear-grade specifications, ensuring they can withstand radiation and thermal stresses while maintaining structural integrity.

What Role Do Graphite Blocks Play in Aerospace Applications?

Graphite blocks are extensively used in aerospace for thermal protection and structural components, particularly in high-temperature environments. Their lightweight nature combined with excellent thermal resistance makes them ideal for applications like engine components and thermal shields. Buyers in this sector need to verify that the sourced graphite meets aerospace standards for material properties, ensuring reliability and performance in critical applications.

Why Are Graphite Blocks Essential in Metallurgy?

In metallurgy, graphite blocks are crucial for manufacturing crucibles and molds used in metal casting. Their high thermal conductivity and resistance to thermal shock improve the efficiency and durability of the casting process. B2B buyers must focus on sourcing high-purity graphite blocks to prevent contamination, which could compromise the quality of the cast metals.

How Do Graphite Blocks Benefit Electrical Engineering?

Graphite blocks find applications in electrical engineering as insulating materials for various components. Their high dielectric strength and thermal stability make them suitable for use in capacitors and other electrical devices. Buyers should ensure that the graphite blocks sourced have reliable electrical insulation properties, as well as thermal conductivity, to meet the demands of advanced electrical systems.

What Advantages Do Graphite Blocks Offer in Automotive Applications?

In the automotive industry, graphite blocks are used as friction materials in braking systems, contributing to enhanced performance and longevity. Their ability to withstand high temperatures and pressures ensures effective braking without compromising safety. Buyers should assess the wear resistance and compatibility of graphite blocks with different braking systems to optimize performance and reliability in various vehicle models.

3 Common User Pain Points for ‘graphite blocks’ & Their Solutions

Scenario 1: Inconsistent Quality and Performance of Graphite Blocks

The Problem: B2B buyers often face challenges related to the quality and consistency of graphite blocks sourced from different suppliers. Variations in material properties, such as density, thermal conductivity, and mechanical strength, can lead to significant performance issues in applications like nuclear reactors or high-temperature environments. This inconsistency can result in increased downtime, higher operational costs, and potential safety hazards if the materials do not meet specifications.

The Solution: To mitigate this issue, buyers should establish robust quality control measures when sourcing graphite blocks. This includes selecting suppliers who provide detailed certifications for their products, including batch testing results and compliance with international standards. Additionally, buyers should request samples for independent testing prior to bulk purchases to confirm that the material properties align with the intended application. Establishing long-term relationships with reputable suppliers known for consistency can also ensure a stable supply of high-quality graphite blocks.

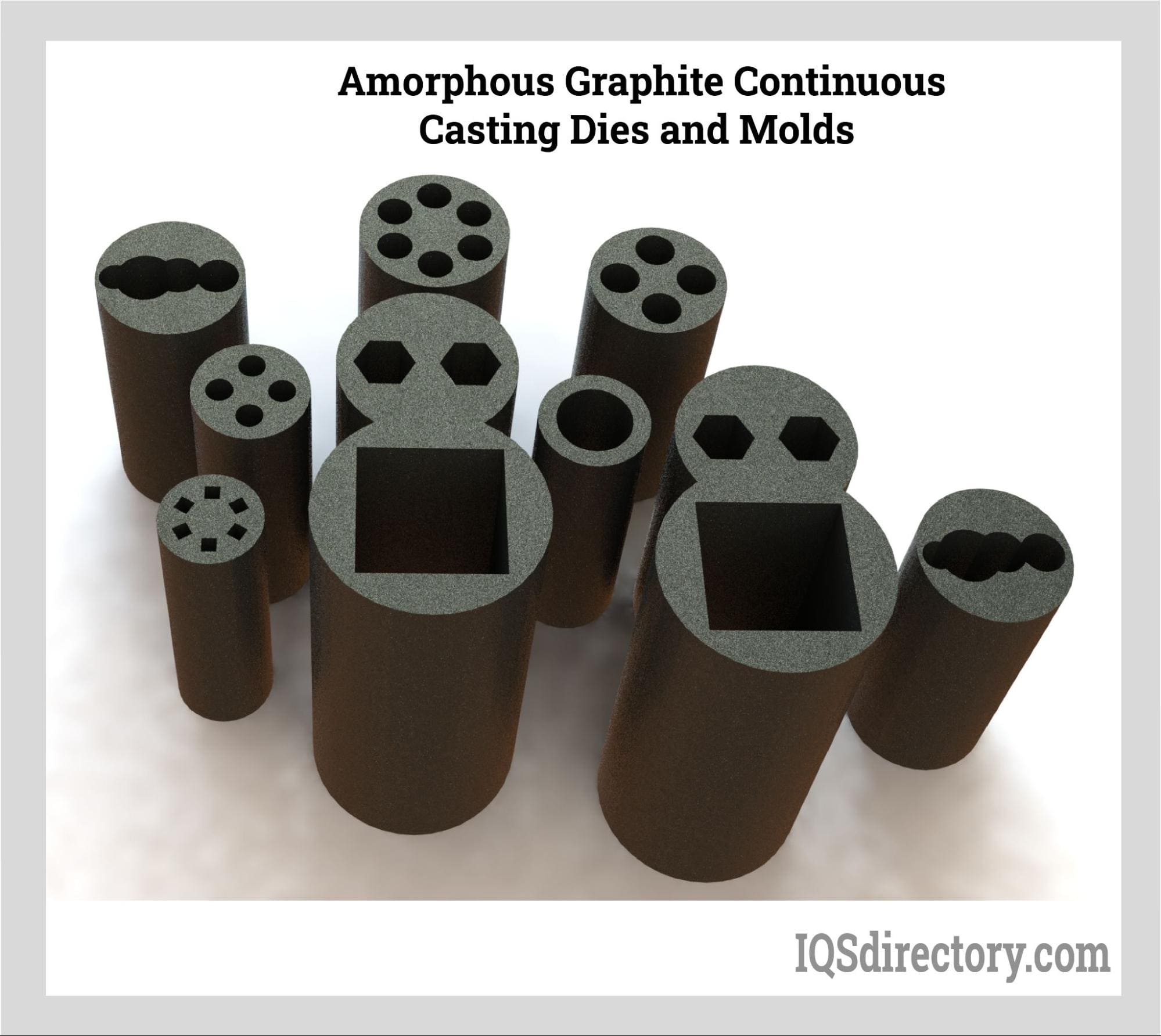

Illustrative image related to graphite blocks

Scenario 2: Difficulty in Machining Graphite Blocks for Custom Applications

The Problem: Many industries require customized graphite components, and buyers frequently encounter difficulties in machining graphite blocks to specific dimensions or shapes. The challenge lies not only in finding the right tools but also in ensuring that the machining process does not compromise the material’s integrity. Poor machining can lead to surface defects, dimensional inaccuracies, and increased waste, ultimately inflating production costs.

The Solution: Buyers should invest in training for their machining teams on the specific properties of graphite and the best practices for machining it. This includes using the appropriate cutting tools, such as diamond-tipped bits or specialized graphite machining tools, and implementing coolant systems to manage heat during the process. Collaborating with experienced machining partners who specialize in graphite can also streamline the process. Furthermore, leveraging advanced technologies such as CNC machining can enhance precision and reduce waste, ensuring that custom components meet the required specifications.

Scenario 3: Challenges in Thermal Management and Conductivity

The Problem: In high-performance applications, the thermal management capabilities of graphite blocks are critical. Buyers may struggle with selecting the right type of graphite block that offers optimal thermal conductivity for their specific use case, leading to inefficiencies and potential overheating in systems like furnaces or reactors. Misjudging the thermal properties can result in equipment failures or reduced performance.

The Solution: To address these thermal management challenges, buyers should conduct a thorough analysis of their operational requirements and the specific thermal properties needed for their applications. This includes understanding the thermal conductivity ratings of different graphite grades and their behavior under varying temperatures. Buyers can work closely with suppliers to obtain detailed thermal property data and conduct comparative analyses. Additionally, incorporating thermal simulation software can help in predicting how different graphite block designs will perform in real-world applications. Engaging with experts in thermal management can also provide valuable insights into optimizing the selection of graphite blocks for maximum efficiency and reliability.

Illustrative image related to graphite blocks

Strategic Material Selection Guide for graphite blocks

What Are the Key Properties of Different Graphite Block Materials?

When selecting graphite blocks for industrial applications, understanding the properties of the materials used is crucial. Here, we analyze four common materials used in the production of graphite blocks: IG-110 graphite, PGX graphite, ASR-0RB carbon, and isotropic fine-grained graphite. Each material offers distinct advantages and limitations that can impact performance, durability, and cost.

What Are the Key Properties of IG-110 Graphite?

IG-110 graphite is a high-performance nuclear-grade graphite known for its isotropic properties. It exhibits excellent thermal conductivity (around 80 W/mK at 600 K) and a high mean compressive strength of 76.8 MPa. This material can withstand high temperatures and pressures, making it suitable for applications in nuclear reactors.

Pros: IG-110 graphite is durable and has a high resistance to thermal shock, which is essential in high-temperature environments. Its isotropic nature ensures uniform performance across all directions.

Cons: The primary drawback is its cost, as IG-110 graphite is generally more expensive than other options. Additionally, its manufacturing complexity can lead to longer lead times.

Impact on Application: IG-110 is particularly suited for nuclear applications where neutron moderation and heat transfer are critical. Its compatibility with coolant channels enhances operational efficiency.

How Does PGX Graphite Compare?

PGX graphite is another high-performance material, though it is less isotropic than IG-110. It has a lower thermal conductivity (approximately 75 W/mK) and compressive strength (30.6 MPa), making it suitable for less demanding applications.

Pros: PGX graphite is more cost-effective than IG-110, which can be advantageous for projects with budget constraints. Its manufacturing process is also less complex, resulting in shorter production times.

Cons: The lower strength and thermal conductivity may limit its use in high-performance applications, particularly in nuclear settings.

Impact on Application: PGX graphite is ideal for applications that do not require the extreme performance characteristics of IG-110, such as certain industrial heating applications.

What Are the Benefits of ASR-0RB Carbon?

ASR-0RB carbon offers a unique blend of properties, including a mean tensile strength of 6.8 MPa and a bulk density of 1.65×10³ kg/m³. This material is often used in applications where moderate performance is acceptable.

Pros: ASR-0RB carbon is relatively inexpensive and easy to manufacture, making it a popular choice for applications with budget limitations.

Cons: However, its lower strength and thermal resistance may pose challenges in high-stress environments.

Illustrative image related to graphite blocks

Impact on Application: ASR-0RB carbon is suitable for applications where cost is a primary concern, but it may not be ideal for high-temperature or high-pressure applications.

Why Choose Isotropic Fine-Grained Graphite?

Isotropic fine-grained graphite is known for its uniform properties and excellent thermal conductivity. It typically has a compressive strength of around 50.4 MPa, making it a versatile option for various applications.

Pros: This material provides excellent machinability and can be easily shaped into complex designs, which is beneficial for custom applications. Its thermal properties make it suitable for high-temperature environments.

Cons: While it offers good performance, the cost can be moderate to high, depending on the specific grade and manufacturing process.

Illustrative image related to graphite blocks

Impact on Application: Isotropic fine-grained graphite is ideal for applications requiring intricate shapes and high thermal performance, such as in aerospace or advanced manufacturing.

Summary Table of Material Properties for Graphite Blocks

| Material | Typical Use Case for graphite blocks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| IG-110 Graphite | Nuclear reactors | High thermal conductivity and strength | High cost and complex manufacturing | High |

| PGX Graphite | Industrial heating | More cost-effective than IG-110 | Lower strength and thermal conductivity | Medium |

| ASR-0RB Carbon | Budget-sensitive applications | Inexpensive and easy to manufacture | Limited performance in high-stress areas | Low |

| Isotropic Fine-Grained Graphite | Aerospace and advanced manufacturing | Excellent machinability and thermal properties | Moderate to high cost | Medium/High |

This strategic material selection guide provides a comprehensive overview of the key materials for graphite blocks, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite blocks

What Are the Key Manufacturing Processes for Graphite Blocks?

The manufacturing of graphite blocks involves several critical stages, each ensuring that the final product meets the stringent requirements for various industrial applications. Understanding these processes is essential for B2B buyers seeking reliable suppliers.

Illustrative image related to graphite blocks

Material Preparation: How Are Raw Materials for Graphite Blocks Processed?

The first step in the manufacturing process is the preparation of raw materials, primarily high-purity graphite. The graphite is typically sourced from natural or synthetic origins and is processed to achieve the desired granularity. This involves crushing, milling, and sieving the graphite to create a uniform particle size.

In addition to graphite, other additives may be introduced to enhance properties such as strength and thermal conductivity. The mixture is then subjected to a thorough quality check to ensure that it meets the specifications before moving to the next stage.

What Techniques Are Used for Forming Graphite Blocks?

Forming is the next crucial phase, where the prepared graphite material is shaped into blocks. The two main techniques employed are:

-

Extrusion: In this method, the graphite paste is pushed through a die to form a continuous shape, which is then cut into blocks of specified dimensions. This technique is advantageous for producing uniform shapes and is widely used in the manufacturing of graphite blocks.

-

Molding: For more complex shapes or sizes, molding techniques such as die pressing or isostatic pressing are employed. In die pressing, the graphite powder is compressed in a mold under high pressure. Isostatic pressing applies pressure uniformly from all directions, resulting in a denser and more uniform block.

Both methods require precision to ensure the blocks have the correct dimensions and structural integrity.

How Is Assembly Conducted in the Production of Graphite Blocks?

In some cases, graphite blocks may require assembly, especially when they are part of a larger system like nuclear reactors. This involves fitting together multiple blocks with precision dowel and socket connections to ensure proper alignment and structural stability.

The assembly process must be conducted in a controlled environment to minimize contamination and ensure that the blocks fit together seamlessly. This is critical for applications where thermal and mechanical properties are paramount.

What Finishing Processes Are Important for Graphite Blocks?

Once the blocks are formed and assembled, they undergo finishing processes to enhance their surface quality and performance characteristics. This may include machining, grinding, or polishing to achieve the required surface finish and tolerances.

Illustrative image related to graphite blocks

Machining is particularly important for applications requiring high precision, such as in aerospace or nuclear industries. The finished blocks are then subject to a final quality inspection to ensure they meet all specifications before being packaged for delivery.

What Quality Assurance Standards Apply to Graphite Block Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for graphite blocks, ensuring that they meet international standards and customer expectations.

Which International Standards Are Relevant for Quality Control?

Key international standards that apply to the manufacturing of graphite blocks include:

- ISO 9001: This standard outlines the criteria for a quality management system and is essential for manufacturers aiming to demonstrate their ability to provide consistent quality products and services.

- CE Marking: For products marketed within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards can be crucial for ensuring product reliability and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is typically conducted at various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before processing.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections and tests are conducted to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): After production, the finished graphite blocks undergo comprehensive testing to verify their compliance with specifications.

Common testing methods include dimensional checks, density measurements, and mechanical property tests, such as tensile and compressive strength evaluations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensure the reliability of the graphite blocks being procured. Here are several strategies to consider:

What Audit Processes Should Buyers Implement?

Conducting on-site audits of potential suppliers can provide valuable insights into their quality management systems. During these audits, buyers can assess the manufacturing processes, quality checkpoints, and overall adherence to international standards.

Illustrative image related to graphite blocks

Buyers should look for evidence of compliance with ISO 9001 and other relevant standards, including documentation of past audits and corrective actions taken.

How Important Are Quality Control Reports and Certifications?

Requesting quality control reports and certifications from suppliers is vital for verifying their claims regarding product quality. These documents should detail the results of testing conducted at various stages of production and confirm compliance with specified standards.

Certificates from recognized third-party inspection agencies can further enhance a supplier’s credibility, providing assurance to buyers regarding the quality and reliability of the graphite blocks.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is crucial. Each market may have specific requirements that differ from international norms, and suppliers must be well-versed in these regulations to ensure compliance.

Buyers should engage in thorough communication with suppliers to clarify any regional standards that may impact the procurement process. This includes understanding import/export regulations and any additional certifications required for specific applications.

Conclusion: Ensuring Quality in Graphite Block Procurement

In summary, the manufacturing processes and quality assurance protocols for graphite blocks are intricate and vital for ensuring product reliability. B2B buyers must be proactive in understanding these processes, verifying supplier capabilities, and ensuring compliance with international and regional standards. By prioritizing quality assurance, buyers can secure high-performance graphite blocks that meet their specific industrial needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite blocks’

This guide provides a structured approach for B2B buyers looking to procure graphite blocks, ensuring that all critical factors are considered during the sourcing process. By following this checklist, buyers can make informed decisions that align with their technical requirements and business goals.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to outline the specific technical requirements for the graphite blocks you need. Consider factors such as dimensions, density, thermal conductivity, and mechanical strength. Having a clear set of specifications helps streamline the sourcing process and ensures that the products meet your application needs.

Illustrative image related to graphite blocks

Step 2: Research Market Trends and Applications

Understanding the current market landscape and applications for graphite blocks is crucial. Analyze how different industries utilize these materials, such as in nuclear reactors, electrical components, and manufacturing processes. Familiarity with market trends will help you identify potential suppliers and gauge the competitiveness of pricing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your standards. Request detailed company profiles, customer references, and case studies relevant to your industry. It’s also advisable to check their production capabilities and quality control processes to ascertain reliability.

- Considerations:

- Certifications (ISO, ASTM) that demonstrate adherence to industry standards.

- Experience in supplying to similar markets or applications.

Step 4: Request Samples and Conduct Testing

Once you have shortlisted potential suppliers, request samples of the graphite blocks. Testing these samples against your defined specifications is vital to verify their performance characteristics. Look for any discrepancies in quality that could affect your final application.

Step 5: Assess Pricing Structures and Terms

Engage suppliers in discussions about pricing structures, payment terms, and potential discounts for bulk orders. Understanding the complete cost, including shipping and handling, is crucial for budgeting. Ensure clarity on any additional fees that may arise during the procurement process.

Step 6: Confirm Delivery and Lead Times

Establish clear expectations regarding delivery timelines and logistics. Discuss with suppliers their capabilities to meet your required timelines, especially if your projects are time-sensitive. Timely delivery is essential to maintain production schedules and avoid costly delays.

Step 7: Negotiate Contracts and Terms of Service

Once you have selected a supplier, focus on negotiating favorable contract terms. Ensure that the agreement includes detailed specifications, pricing, delivery schedules, and quality assurance processes. A well-structured contract protects both parties and helps mitigate risks associated with the procurement process.

By diligently following this sourcing checklist, B2B buyers can effectively navigate the complexities of procuring graphite blocks and ensure that they select the right suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for graphite blocks Sourcing

What Are the Key Cost Components Involved in Sourcing Graphite Blocks?

When sourcing graphite blocks, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The quality of graphite significantly influences pricing. High-purity, isotropic grades such as IG-110 are more expensive due to their superior properties and applications, particularly in nuclear and aerospace industries.

-

Labor: Skilled labor is required for the machining and finishing processes. Labor costs can vary based on the region, with developed countries typically having higher wage rates than emerging markets.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, and indirect labor. Efficient production processes can mitigate overhead costs, but newer facilities may have higher initial expenses.

-

Tooling: Custom tooling for specific graphite block designs can add significant costs. The complexity of the tooling will depend on the specifications and volume of production.

-

Quality Control (QC): Ensuring that graphite blocks meet stringent quality standards can add to costs. Certifications and quality inspections are essential, particularly for industries that require precise specifications.

-

Logistics: Transportation costs can vary widely based on the origin, destination, and shipping methods chosen. International shipping often incurs additional fees such as tariffs, insurance, and customs duties.

-

Margin: Suppliers typically mark up prices to maintain profitability. Understanding supplier margins can be beneficial in negotiations.

What Factors Influence the Pricing of Graphite Blocks?

Several factors can significantly influence the pricing of graphite blocks:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Suppliers may set a MOQ, which can affect pricing structures for smaller buyers.

-

Specifications and Customization: Customized graphite blocks tailored to specific applications can command higher prices. Standardized products usually offer better pricing.

-

Materials and Quality Certifications: The type of graphite used and the certifications obtained (like ISO or ASTM) will impact pricing. Higher-grade materials typically incur higher costs.

-

Supplier Factors: Established suppliers with a reputation for quality may charge a premium. Reliability and service levels also play a role in pricing.

-

Incoterms: The choice of Incoterms affects the total landed cost of graphite blocks. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter the pricing dynamics by including or excluding shipping and insurance costs.

How Can B2B Buyers Optimize Costs When Sourcing Graphite Blocks?

To effectively negotiate and secure the best pricing for graphite blocks, consider the following tips:

-

Leverage Volume Discounts: Plan purchases strategically to meet MOQ requirements, enabling cost savings through bulk ordering.

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also logistics, quality assurance, and potential downtime due to inferior materials. This comprehensive approach helps in making informed decisions.

-

Negotiate Wisely: Build relationships with suppliers and negotiate terms that can lead to better pricing. Discuss long-term contracts that can secure favorable rates.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce logistics costs and lead times.

-

Be Aware of Pricing Nuances: International buyers must account for currency fluctuations, tariffs, and import regulations which can affect overall costs.

Conclusion

While the cost and pricing analysis for graphite blocks can be complex, understanding the key components, price influencers, and strategic negotiation tactics can empower international B2B buyers. By applying these insights, companies can navigate the procurement landscape effectively, ensuring they secure high-quality graphite blocks at competitive prices. Keep in mind that prices can vary significantly based on market conditions, supplier relationships, and specific project requirements; thus, always conduct thorough research and due diligence before making purchasing decisions.

Alternatives Analysis: Comparing graphite blocks With Other Solutions

Exploring Alternatives to Graphite Blocks: A Comparative Analysis

In the industrial landscape, selecting the right material or technology can significantly impact efficiency, performance, and cost-effectiveness. Graphite blocks are widely recognized for their unique properties, particularly in applications such as nuclear reactors and high-temperature environments. However, various alternatives exist that can also fulfill similar roles. This analysis compares graphite blocks with two viable alternatives: alumina ceramics and zirconia ceramics, providing insights for B2B buyers in diverse markets.

| Comparison Aspect | Graphite Blocks | Alumina Ceramics | Zirconia Ceramics |

|---|---|---|---|

| Performance | High thermal conductivity; stable under heat | Excellent hardness; suitable for high wear applications | High strength and toughness; good thermal stability |

| Cost | Moderate to high initial investment | Generally lower cost than graphite | Higher cost due to advanced processing |

| Ease of Implementation | Requires precise machining and handling | Easier to shape and mold with standard techniques | Complex processing; requires advanced machining |

| Maintenance | Low; stable under normal conditions | Moderate; can wear down over time | Low; resistant to wear and thermal shock |

| Best Use Case | Nuclear applications, high-temperature processes | Aerospace, automotive, and industrial applications | Medical devices, cutting tools, and thermal barriers |

Pros and Cons of Alumina Ceramics

Alumina ceramics are known for their exceptional hardness and wear resistance, making them suitable for applications where durability is crucial. They can be manufactured using various shaping techniques such as injection molding and slip casting, which simplifies the production process. However, their performance in high-temperature environments is not on par with graphite blocks, which may limit their use in certain applications. Additionally, while they are generally more cost-effective, they can wear down over time, necessitating more frequent replacements.

Pros and Cons of Zirconia Ceramics

Zirconia ceramics stand out due to their impressive strength and toughness, alongside good thermal stability. They are particularly effective in applications requiring resistance to thermal shock and wear, such as in medical devices and cutting tools. However, the initial cost of zirconia ceramics can be higher than graphite blocks, primarily due to the advanced processing techniques required for their production. Furthermore, while they offer excellent performance, the complexity of their manufacturing can lead to longer lead times, which may be a consideration for B2B buyers in need of quick solutions.

Making the Right Choice: How to Decide on the Best Solution

When choosing between graphite blocks and alternative materials like alumina or zirconia ceramics, B2B buyers should assess their specific application requirements. Considerations such as thermal performance, cost constraints, ease of implementation, and maintenance needs will guide the decision-making process. For industries focused on high-temperature applications, graphite blocks may be the preferred option. In contrast, for applications prioritizing cost-effectiveness and wear resistance, alumina or zirconia ceramics could offer compelling benefits. By evaluating these factors against their operational goals, buyers can select the material or technology that best aligns with their strategic objectives.

Illustrative image related to graphite blocks

Essential Technical Properties and Trade Terminology for graphite blocks

What Are the Key Technical Properties of Graphite Blocks?

Graphite blocks are vital components in various industrial applications, particularly in sectors such as nuclear energy, manufacturing, and electronics. Understanding their essential technical properties is crucial for B2B buyers aiming to make informed purchasing decisions.

1. Material Grade

Material grade refers to the specific type of graphite used in the production of the blocks. Common grades include IG-110 and PGX, which are isotropic fine-grained graphites. The material grade affects the block’s thermal conductivity, strength, and resistance to oxidation. For B2B buyers, selecting the right material grade is essential for ensuring the durability and performance of the blocks in high-temperature and high-stress environments.

2. Bulk Density

Bulk density is a measure of the mass of the graphite block per unit volume, typically expressed in kg/m³. For example, IG-110 has a bulk density of approximately 1,780 kg/m³. This property influences the block’s mechanical strength and thermal performance. Buyers should consider bulk density when evaluating the suitability of graphite blocks for specific applications, as higher density often correlates with enhanced durability.

Illustrative image related to graphite blocks

3. Compressive Strength

Compressive strength measures how much load a graphite block can withstand before failing, typically expressed in megapascals (MPa). IG-110 has a mean compressive strength of around 76.8 MPa. For B2B buyers, understanding compressive strength is critical for applications where mechanical stability and structural integrity are paramount, such as in nuclear reactors or high-load machinery.

4. Thermal Conductivity

Thermal conductivity indicates how efficiently a material can conduct heat, measured in watts per meter-kelvin (W/mK). Graphite blocks often exhibit high thermal conductivity, making them ideal for applications requiring effective heat dissipation. Buyers should prioritize thermal conductivity when selecting graphite blocks for systems where temperature management is crucial.

5. Tolerance

Tolerance refers to the allowable deviation from specified dimensions during the manufacturing of graphite blocks. Precise tolerances are vital in applications where the fit and alignment of components are critical, such as in nuclear reactors. B2B buyers must ensure that suppliers can meet stringent tolerance requirements to avoid operational issues.

What Are Common Trade Terms Associated with Graphite Blocks?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms related to graphite blocks:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of graphite blocks, OEM suppliers often provide customized solutions that meet specific client requirements. B2B buyers should consider OEM options for tailored solutions that fit their unique applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For graphite blocks, MOQs can vary significantly based on the manufacturer and the material grade. B2B buyers need to be aware of MOQs to manage their inventory and production schedules effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products, including graphite blocks. It typically outlines the required specifications, quantities, and delivery timelines. B2B buyers should prepare detailed RFQs to ensure they receive accurate and competitive pricing.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to mitigate risks and ensure smooth transactions when sourcing graphite blocks globally.

5. Lead Time

Lead time refers to the time taken from placing an order until the delivery of the product. In the graphite block industry, lead times can be influenced by manufacturing processes and material availability. B2B buyers should factor in lead times for planning and to avoid disruptions in their supply chain.

By comprehensively understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing graphite blocks, ensuring they meet their operational needs efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the graphite blocks Sector

What are the Current Market Trends Influencing the Graphite Blocks Sector?

The graphite blocks market is experiencing significant growth, driven by increasing demand across various industries such as nuclear energy, aerospace, and automotive sectors. The global shift towards renewable energy sources and electric vehicles is particularly noteworthy, as graphite blocks are essential components in batteries and high-temperature gas-cooled reactors. Additionally, emerging markets in Africa, South America, and the Middle East are expanding their industrial capabilities, further fueling the demand for graphite blocks.

Technological advancements in machining and processing techniques are also transforming the market landscape. Automation and precision engineering are becoming standard in the production of graphite blocks, allowing for improved quality and reduced costs. International B2B buyers are increasingly seeking suppliers who can leverage these technologies to ensure consistent product quality and shorter lead times. Furthermore, the rise of Industry 4.0 is prompting manufacturers to adopt smart manufacturing practices, enhancing supply chain transparency and operational efficiency.

Another trend shaping the market is the consolidation of suppliers. As competition intensifies, larger firms are acquiring smaller players to expand their product offerings and geographical reach. This trend can lead to more competitive pricing but may also reduce the diversity of suppliers available to buyers, necessitating careful sourcing strategies.

How is Sustainability Influencing Sourcing Decisions for Graphite Blocks?

Sustainability is becoming a central concern for B2B buyers in the graphite blocks sector. As environmental regulations tighten globally, there is a growing emphasis on ethical sourcing and minimizing the environmental impact of graphite extraction and production. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as responsible mining, waste reduction, and energy efficiency.

The use of ‘green’ certifications is gaining traction among suppliers, helping buyers to identify responsible sourcing options. Certifications like ISO 14001 for environmental management systems and adherence to the OECD Due Diligence Guidance for Responsible Supply Chains are becoming essential criteria in the supplier selection process. These certifications not only enhance a company’s reputation but also appeal to environmentally conscious consumers and stakeholders.

Additionally, the industry is witnessing a push towards recycled graphite materials, which can significantly reduce the carbon footprint associated with new graphite production. B2B buyers should consider suppliers who offer recycled options or who engage in initiatives aimed at reducing the environmental impact of their operations. By aligning sourcing strategies with sustainability goals, buyers can enhance their brand image while contributing to global efforts to combat climate change.

How Has the Graphite Blocks Sector Evolved Over Time?

The evolution of the graphite blocks sector can be traced back to the early 20th century when graphite was primarily used in lubricants and pencils. However, the demand for high-performance materials in industrial applications led to the development of specialized graphite blocks, particularly for use in nuclear reactors and aerospace components.

Over the decades, advancements in manufacturing processes and material science have significantly enhanced the properties of graphite blocks, making them suitable for high-temperature and high-stress applications. The introduction of isotropic graphite, which offers superior strength and thermal conductivity, has further revolutionized the sector. As industries evolve and new technologies emerge, the graphite blocks market continues to adapt, offering innovative solutions that meet the demands of modern applications.

In conclusion, the graphite blocks sector is witnessing dynamic changes influenced by technological advancements, sustainability concerns, and evolving market needs. For international B2B buyers, understanding these trends is crucial for making informed sourcing decisions and staying competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite blocks

-

How do I choose the right graphite block for my application?

Selecting the right graphite block depends on several factors, including the specific requirements of your application, such as temperature resistance, mechanical strength, and thermal conductivity. Evaluate the operational conditions, such as the presence of corrosive materials or extreme temperatures. It’s also important to consider the dimensions and shapes needed for your project. Collaborating with suppliers who understand your industry can help ensure you choose a block that meets your specifications and enhances your operational efficiency. -

What are the primary uses of graphite blocks in industrial applications?

Graphite blocks are commonly used in various industries, including nuclear, aerospace, and manufacturing. They serve crucial roles such as fuel components in high-temperature gas-cooled reactors, thermal insulators, and structural materials in machinery. Their unique properties, such as low thermal expansion and excellent thermal conductivity, make them ideal for applications requiring high precision and durability. Understanding your industry’s specific requirements will help you leverage the benefits of graphite blocks effectively. -

What customization options are available for graphite blocks?

Many suppliers offer customization options for graphite blocks, including size, shape, and material grade. Customization can also extend to surface finishes and machining tolerances to meet specific application requirements. When discussing options with suppliers, be clear about your needs and any industry standards that must be met. This will ensure you receive a product tailored to your specifications, potentially improving performance and reducing waste in your processes. -

What is the minimum order quantity (MOQ) for graphite blocks?

Minimum order quantities for graphite blocks can vary significantly among suppliers, influenced by factors such as manufacturing processes and material costs. Typically, MOQs may range from a few pieces to several tons for bulk orders. When sourcing, inquire about the MOQ and discuss your needs with potential suppliers. Some may offer flexibility, especially for first-time buyers or ongoing partnerships, enabling you to start with a smaller order while securing better rates for larger volumes in the future. -

How can I verify the quality of graphite blocks from suppliers?

To ensure the quality of graphite blocks, request certifications and test reports that demonstrate compliance with industry standards. Look for suppliers who conduct rigorous quality assurance processes, including material testing for properties like density, thermal conductivity, and mechanical strength. Additionally, consider visiting the supplier’s facility or requesting samples for initial evaluation. Building relationships with reputable suppliers can also help ensure consistent quality over time. -

What payment terms are typically offered for international orders of graphite blocks?

Payment terms for international orders of graphite blocks can vary based on supplier policies and the size of the order. Common terms include upfront payment, net 30, or letters of credit, especially for larger transactions. It’s essential to discuss payment terms early in negotiations to avoid misunderstandings. Additionally, consider the implications of currency fluctuations and transaction fees when budgeting for your purchase, especially when dealing with suppliers from different regions. -

What logistics considerations should I keep in mind when sourcing graphite blocks internationally?

When sourcing graphite blocks internationally, consider factors such as shipping methods, lead times, and customs regulations. Ensure that your supplier has experience with international shipping to navigate customs efficiently and avoid delays. Evaluate the total landed cost, including shipping, duties, and taxes, to ensure accurate budgeting. Working with logistics partners who specialize in international trade can streamline the process and help you manage any potential challenges. -

What are the key factors affecting the price of graphite blocks?

The price of graphite blocks is influenced by various factors, including raw material costs, production methods, and market demand. Additionally, customization, quality standards, and shipping logistics can impact the final price. When sourcing, compare quotes from multiple suppliers and consider the total cost of ownership, which includes not only the purchase price but also potential savings from improved performance and reduced downtime. Engaging in discussions about bulk pricing or long-term contracts can also provide cost advantages.

Top 5 Graphite Blocks Manufacturers & Suppliers List

1. Graphite Store – Medium Extruded Graphite Block & Rod

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: This company, Graphite Store – Medium Extruded Graphite Block & Rod, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

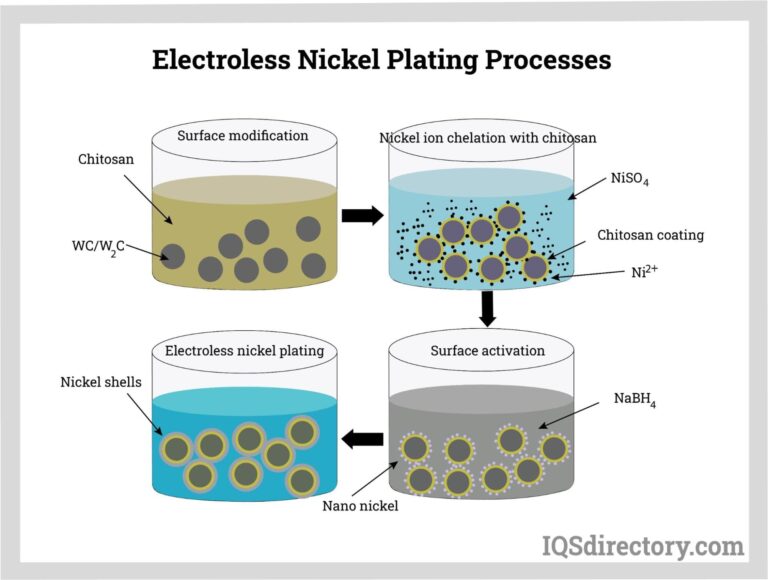

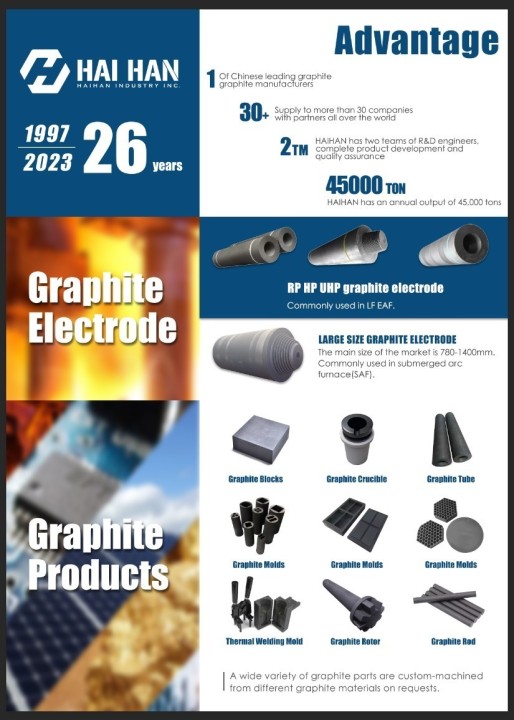

2. IQS Directory – Graphite Blocks

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Graphite blocks are crafted from crystalline carbon and designed with specific characteristics including density, electrical resistance, hardness, porosity, compressive strength, flexural strength, thermal expansion, and thermal conductivity. They can be made from natural graphite (NG) or synthetic graphite, with high-purity graphite blocks containing up to 99.99% carbon content. Natural graphite …

3. Jerry’s Artarama – Quality Art Supplies

Domain: jerrysartarama.com

Registered: 1999 (26 years)

Introduction: This company, Jerry’s Artarama – Quality Art Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. ScienceDirect – IG-110 Graphite Blocks

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Graphite blocks are hexagonal right prisms made from IG-110 graphite, with dimensions of 360 mm across flats and 580 mm in height. They feature an array of fuel holes and are designed for proper orientation within a column using three dowel pins on the top face that engage with dowel sockets on the bottom face of the block above. The blocks are used in high-temperature gas-cooled reactors and are …

5. Graphite Sales – Specialty Graphite Blocks & Rounds

Domain: graphitesales.com

Registered: 1999 (26 years)

Introduction: Graphite Blocks & Rounds offered by Graphite Sales, Inc. include a complete line of specialty graphite, carbon, and carbon-carbon materials. Product sizes range from 0.25 inch diameter up to 55 inch diameter rounds and blocks as large as 16 inch thick by 32 inches wide and 110 inches long. Raw material offerings include standard mold stock (0.030 inch maximum particle size), ultra fine grain mold …

Strategic Sourcing Conclusion and Outlook for graphite blocks

As the demand for graphite blocks continues to rise across various industries, strategic sourcing becomes increasingly crucial for international B2B buyers. Understanding the diverse applications of graphite blocks—from nuclear reactors to high-performance industrial uses—enables businesses in regions like Africa, South America, the Middle East, and Europe to make informed purchasing decisions. Key considerations include material specifications, supplier reliability, and logistical efficiencies, all of which can significantly impact operational success.

By fostering partnerships with reputable manufacturers and suppliers, companies can ensure access to high-quality graphite products that meet stringent industry standards. As markets evolve and technological advancements emerge, staying ahead of trends will be essential.

The future of graphite block sourcing looks promising, with innovations in production processes and applications on the horizon. Buyers are encouraged to actively engage with suppliers, explore emerging markets, and invest in sustainable practices that can lead to long-term benefits. Together, let’s seize the opportunities in this dynamic landscape and propel your business toward success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.