Power Supply Transformer Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for power supply transformer

In today’s dynamic global market, sourcing reliable power supply transformers poses a significant challenge for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. These essential components play a crucial role in ensuring the smooth operation of various industrial applications, from energy distribution to manufacturing processes. As businesses seek to enhance their operational efficiency and minimize downtime, understanding the complexities of selecting the right power supply transformers becomes paramount.

This guide offers a comprehensive overview of power supply transformers, covering various types, applications, and key considerations for effective supplier vetting. Buyers will gain insights into the critical factors influencing cost and performance, enabling them to make informed purchasing decisions. We will delve into the differences between power transformers and power supplies, explore compliance standards across different regions, and highlight the significance of customization to meet specific operational needs.

By equipping international B2B buyers with actionable knowledge, this guide empowers them to navigate the complexities of the power supply transformer market. Whether you are in Saudi Arabia or Brazil, understanding these nuances will help you secure the most suitable solutions for your business, ultimately driving productivity and fostering sustainable growth. As you read on, you will discover how to streamline your procurement process and ensure that your electrical infrastructure is both reliable and efficient.

Understanding power supply transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

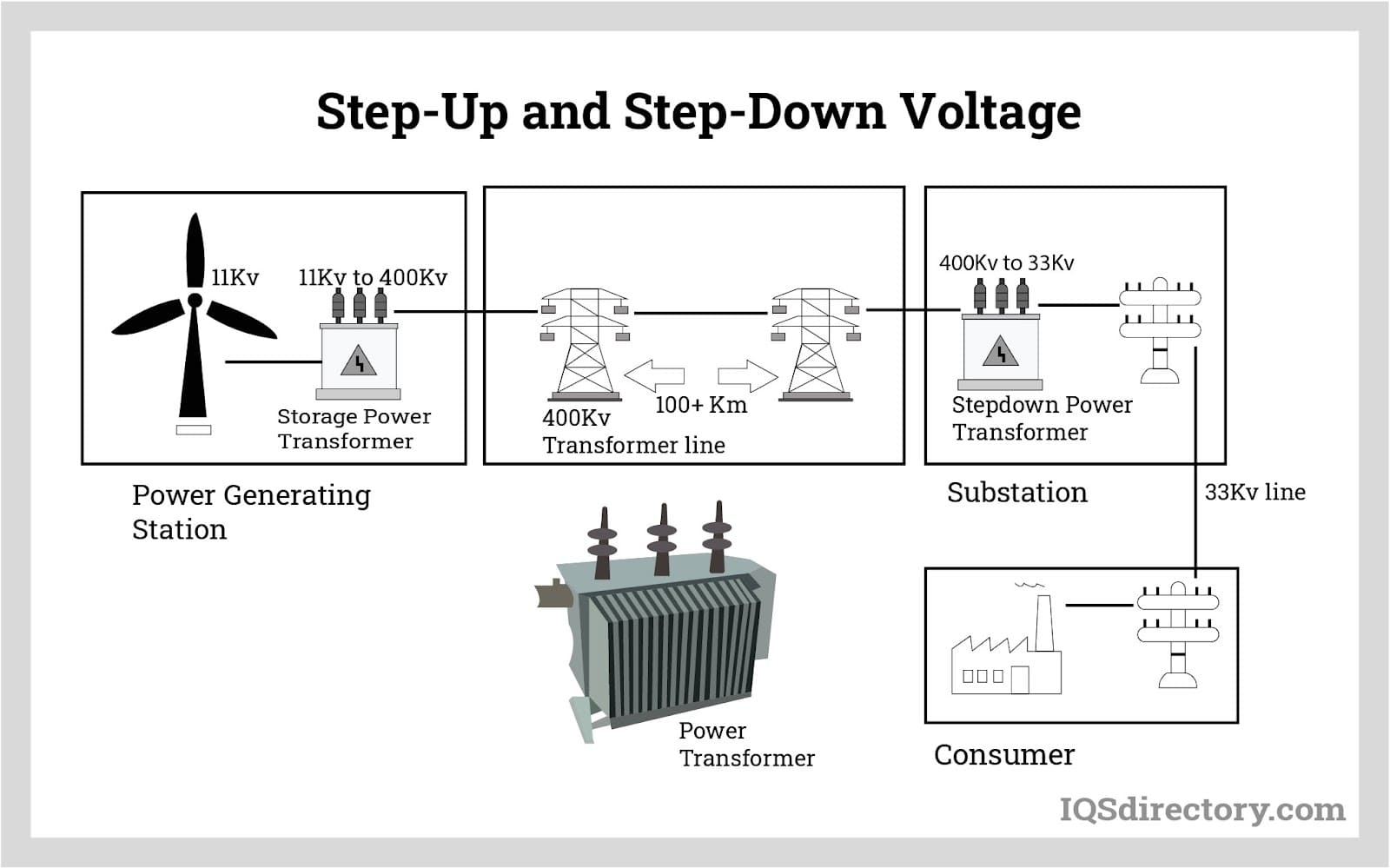

| Power Transformers | High-capacity, used for stepping up/down voltage for transmission | Industrial power distribution | Pros: Efficient for large-scale applications. Cons: Higher initial investment. |

| Distribution Transformers | Step-down voltage for local distribution; typically lower capacity | Commercial buildings, substations | Pros: Cost-effective for local use. Cons: Limited to lower voltage applications. |

| Dry-Type Transformers | Air-cooled, safe for indoor use; no oil required | HVAC systems, indoor applications | Pros: Low fire risk, maintenance-free. Cons: May require more space. |

| Cast-Resin Transformers | Encapsulated in resin for enhanced safety and compact design | Sensitive equipment, substations | Pros: Excellent fire resistance, durable. Cons: Higher cost compared to traditional types. |

| Switching Power Supplies | Converts AC to DC with high efficiency, often compact design | Electronics, automation systems | Pros: Energy-efficient, versatile. Cons: May generate electromagnetic interference. |

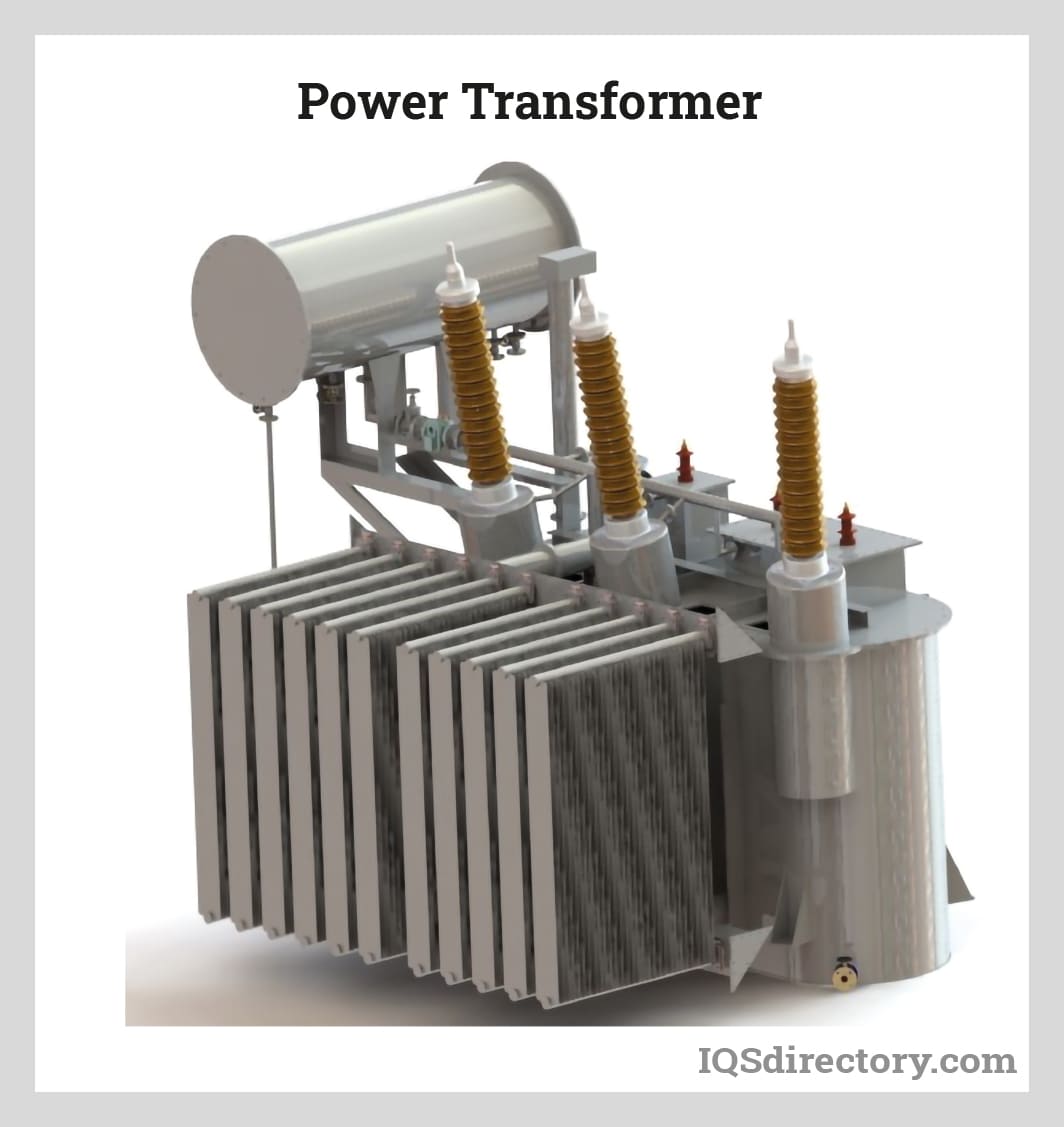

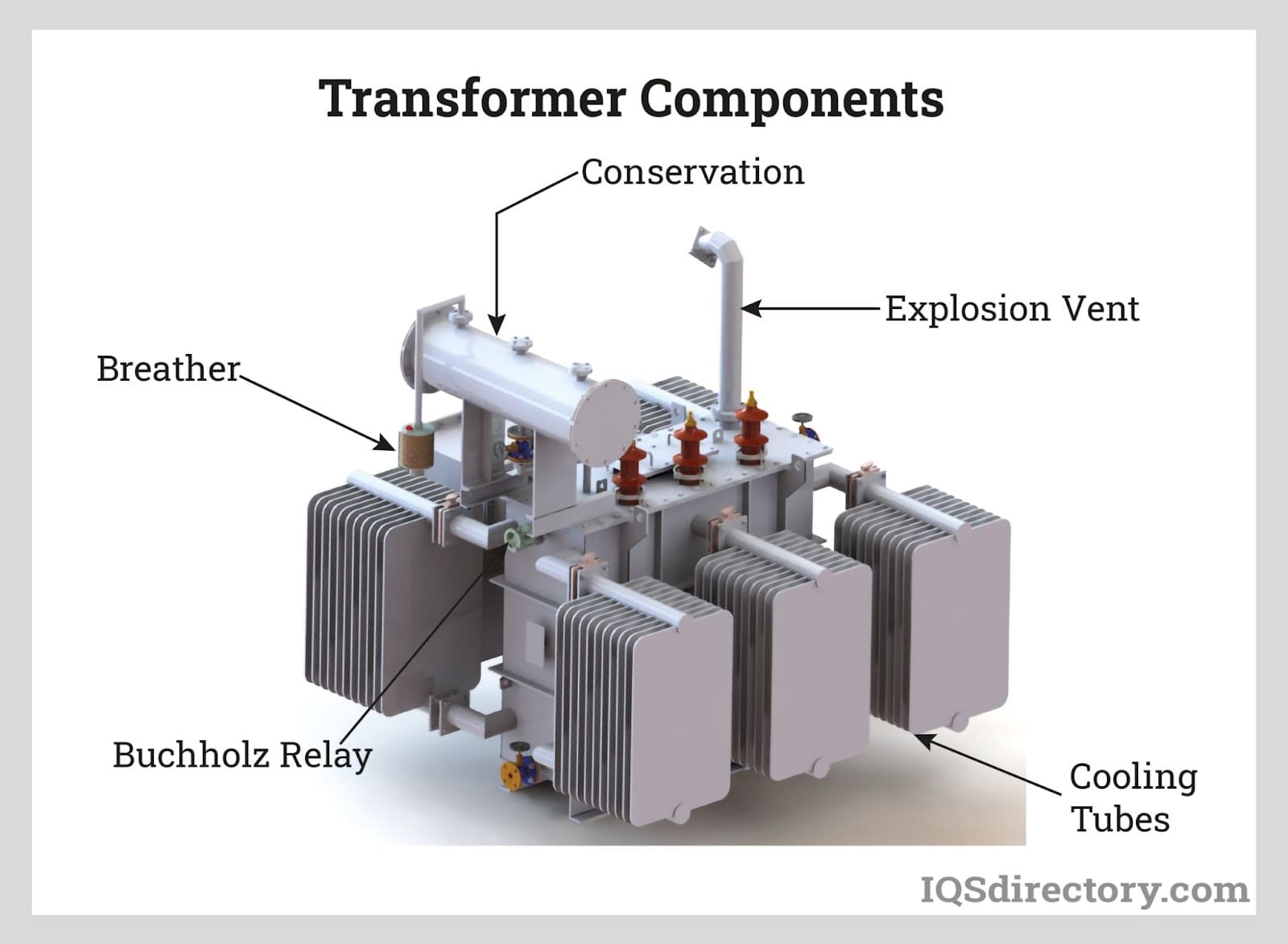

What Are Power Transformers and Their Key Features?

Power transformers are essential in high-capacity applications, facilitating the step-up or step-down of voltage for efficient long-distance transmission. These transformers are primarily used in industrial power distribution systems, ensuring that electricity is delivered at appropriate voltage levels for various equipment. When considering a power transformer, buyers should evaluate the capacity requirements, efficiency ratings, and installation costs, as these factors significantly influence operational effectiveness and long-term savings.

How Do Distribution Transformers Function in B2B Settings?

Distribution transformers play a critical role in local voltage regulation, stepping down high-voltage electricity for use in commercial buildings and substations. They are typically lower in capacity compared to power transformers, making them suitable for localized applications. Buyers should consider the voltage requirements of their facilities, the load capacity, and the installation environment when selecting distribution transformers, as these factors will impact overall performance and reliability.

What Advantages Do Dry-Type Transformers Offer for Indoor Use?

Dry-type transformers are air-cooled and do not utilize oil, making them ideal for indoor applications where fire risk is a concern. Commonly used in HVAC systems and commercial buildings, they require minimal maintenance and offer a safe, reliable solution for voltage regulation. When purchasing dry-type transformers, B2B buyers should assess the installation space, cooling requirements, and specific load demands to ensure optimal performance.

Why Choose Cast-Resin Transformers for Sensitive Equipment?

Cast-resin transformers are encapsulated in resin, providing excellent fire resistance and a compact design, making them particularly suitable for sensitive equipment and substations. Their durability and safety features make them an attractive option for industries where equipment reliability is paramount. Buyers should weigh the higher initial costs against the long-term benefits of reduced maintenance and increased safety when considering cast-resin transformers.

How Do Switching Power Supplies Enhance Efficiency in Modern Applications?

Switching power supplies are designed to convert AC power to DC with high efficiency and compact form factors, making them popular in electronics and automation systems. They are versatile and can handle various voltage outputs, but potential electromagnetic interference should be considered. B2B buyers should focus on efficiency ratings, output stability, and compatibility with existing systems when selecting switching power supplies to ensure they meet operational needs effectively.

Key Industrial Applications of power supply transformer

| Industry/Sector | Specific Application of power supply transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Voltage regulation for CNC machinery | Ensures optimal performance and longevity of equipment | Compliance with local electrical standards and regulations |

| Renewable Energy | Integration with solar inverters | Maximizes energy conversion efficiency | Compatibility with existing infrastructure and scalability |

| Telecommunications | Power supply for data centers | Enhances reliability and uptime of services | Energy efficiency ratings and thermal management features |

| Healthcare | Powering medical imaging equipment | Guarantees stable operation and patient safety | Certifications for medical equipment and stringent quality control |

| Construction & Mining | Power supply for heavy machinery | Supports continuous operation in remote locations | Durability and resistance to harsh environmental conditions |

How is Power Supply Transformer Used in Manufacturing?

In the manufacturing sector, power supply transformers are crucial for CNC (Computer Numerical Control) machinery, which requires precise voltage regulation to operate efficiently. These transformers ensure that the machinery receives the correct voltage levels, preventing malfunctions and extending equipment lifespan. For international buyers, especially those in Africa and South America, it’s vital to consider local electrical standards, as well as the transformer’s capacity to handle fluctuations in power supply, which can be common in these regions.

What Role Does Power Supply Transformer Play in Renewable Energy?

In the renewable energy sector, particularly solar energy, power supply transformers are used to integrate solar inverters into the grid. They step down high voltages generated by solar panels to safe levels suitable for local distribution. This application maximizes energy conversion efficiency and helps in maintaining grid stability. Buyers in regions like the Middle East, where solar energy is abundant, should focus on sourcing transformers that are compatible with their existing systems and can scale as energy needs grow.

How Do Power Supply Transformers Support Telecommunications?

Telecommunications companies rely heavily on power supply transformers to ensure that data centers operate smoothly. These transformers provide a stable power supply that enhances the reliability and uptime of services, which is critical in a sector where downtime can lead to significant revenue loss. For B2B buyers in Europe, sourcing transformers with high energy efficiency ratings and effective thermal management features can lead to long-term cost savings and improved service quality.

Why Are Power Supply Transformers Essential in Healthcare?

In the healthcare industry, power supply transformers are essential for powering medical imaging equipment such as MRI and CT scanners. These devices require a consistent and stable power supply to ensure accurate diagnostics and patient safety. Buyers must ensure that the transformers meet specific certifications for medical equipment and adhere to stringent quality control standards, particularly in regions with strict healthcare regulations.

What is the Importance of Power Supply Transformers in Construction & Mining?

In construction and mining, power supply transformers are vital for powering heavy machinery in remote locations where grid access may be limited. These transformers ensure that equipment operates continuously, which is crucial for project timelines. Buyers should prioritize sourcing transformers that are durable and capable of withstanding harsh environmental conditions, particularly in areas of Africa and South America where infrastructure may be less reliable.

Illustrative image related to power supply transformer

3 Common User Pain Points for ‘power supply transformer’ & Their Solutions

Scenario 1: Voltage Compatibility Issues in Industrial Settings

The Problem: Many B2B buyers, particularly those in regions like Africa and the Middle East, face challenges with voltage compatibility when integrating power supply transformers into their existing electrical infrastructure. Different equipment may require various voltage levels, and mismatches can lead to operational inefficiencies, equipment damage, or even safety hazards. In some cases, local power supply variations and grid instability exacerbate these issues, making it difficult to ensure consistent operation across multiple devices.

The Solution: To address voltage compatibility, it’s crucial to conduct a thorough assessment of all equipment that will interface with the power supply transformer. Start by clearly defining the voltage requirements of each device and compare these to the transformer specifications. Utilizing a transformer that offers adjustable output voltage can be a practical solution; this flexibility allows for better alignment with varying equipment needs. Additionally, consider working with suppliers who offer transformers designed specifically for the regional grid conditions. Investing in high-quality, regulated transformers that accommodate input fluctuations can significantly enhance reliability and safety, ensuring that all equipment operates efficiently.

Scenario 2: Overheating and Performance Degradation

The Problem: Overheating is a common concern for B2B buyers, especially in high-demand environments like manufacturing and industrial plants. Transformers can generate excess heat due to factors such as overloading, poor ventilation, or inadequate cooling systems. This overheating not only reduces the lifespan of the transformer but can also lead to costly downtimes and repairs, affecting overall productivity and profitability.

The Solution: To mitigate overheating risks, ensure that the selected power supply transformer is appropriately rated for the specific load it will handle. Implement regular maintenance schedules that include inspections of cooling systems and ventilation pathways. Additionally, using transformers with built-in thermal protection features can help prevent overheating issues. If heat buildup is a recurrent problem, consider upgrading to a dry-type transformer, which is less prone to overheating and more suitable for environments where fire hazards are a concern. Lastly, integrating temperature monitoring systems can provide real-time data, allowing for proactive measures before overheating leads to equipment failure.

Scenario 3: Sourcing Reliable Transformers Amid Supply Chain Disruptions

The Problem: B2B buyers often struggle with sourcing reliable power supply transformers, particularly in regions prone to supply chain disruptions. Factors such as geopolitical issues, shipping delays, and fluctuating material costs can lead to inconsistent availability of quality transformers. This unpredictability complicates project planning and can result in stalled operations or increased project costs.

The Solution: To navigate sourcing challenges, establish relationships with multiple suppliers and manufacturers to diversify your supply chain. Look for suppliers with a strong reputation for reliability and quality assurance, and consider sourcing locally when possible to reduce shipping times and costs. Additionally, it’s beneficial to engage in forward planning by ordering transformers in bulk to cover future needs, thereby mitigating the risk of sudden shortages. Collaborating with suppliers who can provide real-time inventory updates and production timelines will also help in maintaining operational continuity. Finally, consider leveraging local partnerships that may offer alternative solutions or substitute products in times of scarcity, ensuring that your operations remain unaffected by external supply chain challenges.

Strategic Material Selection Guide for power supply transformer

What Are the Common Materials Used in Power Supply Transformers?

Selecting the right materials for power supply transformers is crucial for optimizing performance, durability, and cost-effectiveness. Below, we analyze four common materials used in power supply transformers, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

Illustrative image related to power supply transformer

1. Silicon Steel

Key Properties: Silicon steel is known for its high magnetic permeability and low hysteresis loss. It typically operates well within temperature ratings of up to 150°C, making it suitable for various electrical applications.

Pros & Cons: The primary advantage of silicon steel is its excellent magnetic properties, which enhance energy efficiency. However, it can be more expensive than other materials and may require complex manufacturing processes, such as lamination, to reduce eddy current losses.

Impact on Application: Silicon steel is compatible with AC applications, making it ideal for transformers that operate on alternating current. Its efficiency in magnetic flux conduction significantly impacts the transformer’s overall performance.

Considerations for International Buyers: Compliance with international standards such as ASTM A677 and DIN EN 10106 is essential. Buyers in regions like Europe and the Middle East may prefer silicon steel due to its established performance metrics.

Illustrative image related to power supply transformer

2. Copper

Key Properties: Copper has excellent electrical conductivity, with a conductivity rating of 59.6 S/m at 20°C. It also offers good thermal conductivity and corrosion resistance, making it a popular choice for windings in transformers.

Pros & Cons: The main advantage of copper is its superior conductivity, which allows for smaller wire sizes and reduced energy losses. However, copper is relatively expensive compared to alternatives like aluminum, and its weight can be a drawback in applications where weight is a concern.

Impact on Application: Copper’s conductivity makes it suitable for high-performance transformers, ensuring minimal energy loss during operation. Its resistance to corrosion also extends the lifespan of the transformer in harsh environments.

Illustrative image related to power supply transformer

Considerations for International Buyers: Buyers should consider the price volatility of copper and ensure compliance with international standards such as IEC 60228. In regions like Africa and South America, where cost sensitivity is higher, alternative materials may be considered.

3. Aluminum

Key Properties: Aluminum offers good electrical conductivity (approximately 61% that of copper) and is lightweight, making it a favorable option for transformer windings. It also has a good resistance to corrosion.

Pros & Cons: The key advantage of aluminum is its lower cost and lighter weight compared to copper, which can significantly reduce shipping and installation costs. However, it has a lower conductivity than copper, requiring larger wire sizes to achieve the same performance level.

Impact on Application: Aluminum is often used in transformers where weight is a critical factor, such as in portable or mobile applications. However, its lower conductivity may lead to higher energy losses compared to copper.

Considerations for International Buyers: Buyers should be aware of the differing standards for aluminum conductors, such as ASTM B230. In regions like the Middle East, where environmental conditions may accelerate corrosion, proper coatings or treatments are essential.

4. Resin-Encapsulated Materials

Key Properties: Resin-encapsulated materials provide excellent insulation properties and are resistant to moisture and environmental contaminants. They can operate effectively in a wide temperature range, typically from -40°C to 130°C.

Pros & Cons: The primary advantage of resin encapsulation is its ability to protect internal components from environmental factors, enhancing reliability. However, the manufacturing process can be complex and costly, impacting overall transformer pricing.

Impact on Application: These materials are particularly suitable for transformers used in outdoor or harsh environments, where exposure to moisture and dust can be detrimental. Their insulation properties also contribute to improved safety.

Illustrative image related to power supply transformer

Considerations for International Buyers: Compliance with international insulation standards such as IEC 60085 is crucial. Buyers from Europe and South America may prefer resin-encapsulated transformers for their durability and reliability in challenging conditions.

Summary Table of Material Selection for Power Supply Transformers

| Material | Typical Use Case for power supply transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Core material in transformers | High magnetic permeability | Higher cost and complex manufacturing | High |

| Copper | Windings in high-performance transformers | Superior electrical conductivity | Expensive and heavy | High |

| Aluminum | Windings in lightweight transformers | Cost-effective and lightweight | Lower conductivity than copper | Medium |

| Resin-Encapsulated | Outdoor and harsh environment transformers | Excellent insulation and moisture resistance | Complex and costly manufacturing | Medium |

This guide provides actionable insights for B2B buyers looking to make informed decisions regarding material selection for power supply transformers, considering performance, cost, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for power supply transformer

What Are the Main Stages in the Manufacturing Process of Power Supply Transformers?

The manufacturing process for power supply transformers involves several key stages, each critical to ensuring the final product meets performance and safety standards. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in manufacturing power supply transformers involves selecting high-quality raw materials. Core materials, typically silicon steel, are chosen for their magnetic properties, while copper or aluminum is selected for windings. Proper handling and storage of these materials are crucial to prevent contamination and ensure quality.

Once selected, materials are cut and prepared to specified dimensions. This stage may also involve the treatment of the core materials to enhance their magnetic properties, including annealing processes that reduce internal stresses.

Illustrative image related to power supply transformer

2. Forming the Core

The core of the transformer is formed through processes like stacking and laminating. Stacking involves layering thin sheets of silicon steel to create a laminated core, reducing energy losses due to eddy currents. This is often done using automated machinery to ensure precision and consistency.

Following this, the core is assembled into its final shape, which can vary based on the transformer design—whether it’s a toroidal, EI, or other configurations. This step is critical, as the configuration of the core directly affects the efficiency and performance of the transformer.

3. Winding Assembly

In this stage, the prepared copper or aluminum wires are wound around the core to create the primary and secondary coils. This process requires precision, as the number of turns in each winding determines the voltage transformation ratio. Automated winding machines often assist in this process to maintain uniform tension and accuracy.

Illustrative image related to power supply transformer

After winding, the coils are insulated using high-quality materials to prevent short circuits and ensure safety during operation. The insulation must withstand high voltages and varying environmental conditions, which is especially important for international markets with diverse climates.

4. Finishing Processes

Once the winding assembly is complete, the transformer undergoes several finishing processes. This includes vacuum impregnation, where resin is used to enhance insulation and mechanical strength. The transformers are then tested for electrical integrity and insulation resistance before final assembly.

Additionally, painting or coating is applied to protect the outer surfaces from environmental factors. This step not only enhances durability but also improves the aesthetic appeal of the transformer, which can be an important consideration for B2B buyers in various regions.

How Is Quality Assurance Implemented in Power Supply Transformer Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for power supply transformers, ensuring that products meet both industry standards and customer expectations. Here are the key components of a robust quality assurance program:

International Standards and Compliance

Manufacturers must adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with regional standards, such as CE marking in Europe and UL certifications in the U.S., is also essential for market access. These standards help ensure that transformers are designed and manufactured to minimize risks and enhance reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify defects early. The main checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specified standards before they enter the production line. Any non-compliant materials are rejected or returned to suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to verify that processes are followed correctly and that products are being manufactured to specifications. This includes monitoring winding tension, insulation quality, and core assembly.

-

Final Quality Control (FQC): After assembly, each transformer undergoes final testing to assess electrical performance, insulation resistance, and mechanical integrity. These tests ensure that the transformers meet the required operational specifications.

What Testing Methods Are Commonly Used?

Manufacturers employ various testing methods to ensure the quality and performance of power supply transformers:

Illustrative image related to power supply transformer

-

Electrical Testing: This includes testing for voltage withstand, insulation resistance, and short-circuit performance.

-

Thermal Testing: Transformers are subjected to temperature rise tests to ensure they can operate safely under load conditions.

-

Load Testing: Full-load tests verify that the transformers can handle specified loads without performance degradation.

-

Environmental Testing: For regions with extreme weather, transformers may undergo environmental stress tests to ensure durability and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring product reliability. Here are actionable steps:

Conduct Audits and Assess Supplier Certifications

Engaging in regular audits of suppliers can provide insights into their manufacturing practices and quality assurance processes. Buyers should request copies of relevant certifications (e.g., ISO 9001, CE, UL) to ensure compliance with international standards.

Review Quality Control Reports

Requesting detailed quality control reports can help buyers understand the QC measures implemented by suppliers. These reports should outline the results of IQC, IPQC, and FQC processes, as well as any corrective actions taken in response to non-conformities.

Utilize Third-Party Inspections

Consider employing third-party inspection agencies that specialize in electrical equipment. These agencies can provide independent assessments of the manufacturing processes and the final products, ensuring that they meet both local and international standards.

What Are the Quality Control Nuances for International Markets?

B2B buyers operating in diverse markets should be aware of specific regional requirements and preferences that may influence quality assurance practices.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and reliability. Understanding local market conditions and customer expectations is vital for successful procurement.

-

Regulatory Compliance: Familiarize yourself with local regulations that may impose additional quality assurance requirements. For example, certain countries may have stricter standards for electrical safety, requiring additional certifications.

-

Logistical Challenges: When sourcing transformers internationally, consider the potential impact of shipping and handling on product integrity. Ensure that suppliers have protocols in place to protect products during transit, which is crucial for maintaining quality.

By understanding the manufacturing processes and quality assurance practices associated with power supply transformers, B2B buyers can make informed decisions and establish successful partnerships with reliable suppliers.

Illustrative image related to power supply transformer

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power supply transformer’

In the world of industrial equipment, sourcing a power supply transformer requires careful consideration of various factors to ensure optimal performance and reliability. This guide provides B2B buyers with a step-by-step checklist to facilitate a smooth procurement process.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is crucial when sourcing a power supply transformer. Consider factors such as voltage requirements, power ratings, and the type of load (resistive, inductive, etc.) the transformer will serve.

– Voltage Rating: Ensure the transformer can handle the input and output voltage levels needed for your equipment.

– Power Rating: Determine the VA (volt-ampere) rating necessary to meet your operational demands.

Step 2: Research Regulatory Compliance and Standards

Before selecting a supplier, verify that their products comply with international and regional standards. Compliance is essential for safety and reliability, especially in regions with strict regulations.

– Common Standards: Look for certifications such as UL, CE, or ISO to ensure the transformer meets safety and performance criteria.

– Local Regulations: Be aware of any specific regional compliance requirements, particularly if you are sourcing from or for markets in Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Potential Suppliers

A thorough evaluation of potential suppliers is vital for securing a trustworthy partner. Request comprehensive company profiles and assess their experience in the industry.

– References and Case Studies: Ask for references from other businesses in your sector to gauge their reliability and product quality.

– Supplier Capabilities: Consider the supplier’s ability to provide customization options, lead times, and after-sales support.

Step 4: Assess Quality Assurance Processes

Understanding the quality control measures of your potential suppliers can prevent future operational issues. Inquire about their manufacturing processes and quality assurance protocols.

– Testing Procedures: Ensure the transformers undergo rigorous testing, including load testing and insulation resistance tests.

– Warranty Policies: A robust warranty can be an indicator of a supplier’s confidence in their product quality.

Step 5: Review Pricing and Payment Terms

While cost shouldn’t be the sole factor, it is essential to understand the pricing structure and payment terms.

– Total Cost of Ownership: Consider installation, maintenance, and operational costs alongside the initial purchase price.

– Flexible Payment Options: Negotiate payment terms that align with your financial strategy, such as phased payments based on delivery milestones.

Step 6: Plan for Logistics and Delivery

Logistics can significantly impact your procurement timeline. Ensure you have a clear understanding of shipping methods, delivery times, and potential customs duties.

– Shipping Options: Discuss with suppliers about their shipping capabilities and timelines, particularly for international deliveries.

– Customs and Duties: Factor in any additional costs that may arise from importing transformers to your region.

Step 7: Establish a Communication Plan

Effective communication with your supplier is critical throughout the sourcing process. Set expectations for updates, milestones, and any potential issues that may arise.

– Regular Check-ins: Schedule periodic updates to stay informed about production status and any delays.

– Feedback Mechanism: Create a system for providing feedback on product performance post-delivery, fostering a strong supplier relationship.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing power supply transformers, ensuring they select the right products to meet their operational needs.

Comprehensive Cost and Pricing Analysis for power supply transformer Sourcing

What Are the Key Cost Components in Power Supply Transformer Sourcing?

When sourcing power supply transformers, understanding the cost structure is critical for effective budgeting and procurement. The primary cost components include:

-

Materials: This encompasses the raw materials used in manufacturing transformers, such as copper for windings, silicon steel for cores, and insulation materials. Fluctuations in the prices of these materials can significantly impact overall costs.

-

Labor: Labor costs vary based on geographical location, skill level, and the complexity of the transformer design. Skilled labor is essential for quality production, particularly in custom or high-spec transformers.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and facility maintenance. Efficient production processes can help minimize overhead.

-

Tooling: Investment in tooling is necessary for customized transformer designs. Tooling costs can be amortized over larger production runs, making it crucial to consider minimum order quantities (MOQs) when calculating total costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that transformers meet industry standards and specifications. These costs can vary based on the level of certification required (e.g., ISO, UL) and the testing procedures adopted.

-

Logistics: Transportation and shipping costs can be substantial, especially for international buyers. Factors such as distance, Incoterms, and shipping methods will affect overall logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Power Supply Transformer Costs?

Several factors can influence the pricing of power supply transformers, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger volumes often leads to reduced per-unit costs. Negotiating MOQs can help secure better pricing, especially if a buyer can commit to future orders.

-

Specifications and Customization: Custom-designed transformers tailored to specific applications may incur higher costs due to additional engineering and manufacturing complexity. Standard models generally offer more competitive pricing.

-

Material Quality and Certifications: Higher-quality materials and compliance with industry certifications can elevate costs. However, investing in quality can lead to lower failure rates and reduced Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers with proven track records may charge premium prices, reflecting their quality assurance processes and customer service.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. These terms can affect overall pricing and cost predictability.

What Are Some Buyer Tips for Cost-Efficient Power Supply Transformer Sourcing?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, strategic sourcing can lead to significant cost savings:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules with suppliers. Building a good relationship can lead to favorable terms and discounts on future orders.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider long-term factors such as maintenance, energy efficiency, and potential downtime. A slightly higher upfront cost for a more reliable transformer can result in lower overall expenses.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and transportation costs. Be aware of these factors when comparing suppliers from different countries.

-

Request Samples: Before committing to large orders, request samples to assess quality and performance. This can help avoid costly mistakes in bulk purchases.

-

Stay Informed: Keep abreast of market trends, material costs, and technological advancements in transformer manufacturing. This knowledge can empower buyers during negotiations and sourcing decisions.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on numerous factors, including market conditions and specific supplier quotes. Always conduct thorough market research and supplier evaluations to obtain the most accurate pricing for your needs.

Alternatives Analysis: Comparing power supply transformer With Other Solutions

When considering power supply solutions for industrial applications, it’s essential to analyze different technologies available in the market. While power supply transformers are widely used for voltage regulation and power distribution, several alternatives can achieve similar goals. This section will explore and compare the power supply transformer with two viable alternatives: Switching Power Supplies and Uninterruptible Power Supplies (UPS).

Comparison Table

| Comparison Aspect | Power Supply Transformer | Switching Power Supply | Uninterruptible Power Supply (UPS) |

|---|---|---|---|

| Performance | High efficiency in voltage regulation | Highly efficient, compact, and lightweight | Provides backup power and power conditioning |

| Cost | Generally high initial investment | Lower initial cost, but may require more maintenance | Higher initial cost, but essential for critical systems |

| Ease of Implementation | Requires more space and installation expertise | Easy to install and integrate into systems | Straightforward installation but needs strategic placement |

| Maintenance | Low maintenance once installed | Moderate maintenance due to electronic components | Regular maintenance required for battery management |

| Best Use Case | Industrial applications needing voltage regulation | Electronic devices requiring stable DC output | Critical systems needing backup power during outages |

Detailed Breakdown of Alternatives

Switching Power Supplies

Switching Power Supplies (SPS) convert AC to DC power efficiently using high-frequency switching technology. They are compact and lightweight compared to traditional transformers, making them ideal for applications where space is limited. SPS can achieve high levels of efficiency, which is beneficial for energy conservation. However, they may introduce electrical noise, which can affect sensitive equipment. Additionally, while their initial cost is lower, they may require more frequent maintenance due to their electronic components.

Uninterruptible Power Supplies (UPS)

Uninterruptible Power Supplies (UPS) are designed to provide backup power during outages, ensuring that critical systems remain operational. They typically include batteries that kick in immediately when a power failure occurs. UPS systems also offer power conditioning features, protecting equipment from voltage spikes and fluctuations. The downside is that they tend to have a higher initial cost and require regular maintenance to ensure battery health. They are best suited for environments where downtime can lead to significant losses, such as data centers and hospitals.

Conclusion

When selecting the right power solution for specific industrial needs, B2B buyers should carefully evaluate the unique requirements of their operations. Power supply transformers are ideal for applications that require consistent voltage regulation across large systems. In contrast, Switching Power Supplies offer a compact solution for electronic devices needing stable DC output, while UPS systems are crucial for environments where power reliability is paramount. By assessing performance, cost, ease of implementation, maintenance needs, and best use cases, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for power supply transformer

What Are the Key Technical Properties of Power Supply Transformers?

When selecting power supply transformers, understanding their critical specifications is essential for ensuring compatibility, reliability, and efficiency in your applications. Here are several key properties that B2B buyers should consider:

1. Voltage Rating

The voltage rating indicates the maximum voltage the transformer can handle. Power supply transformers typically come with input and output voltage specifications, such as 120V AC input and 24V AC output. Understanding these ratings helps buyers select transformers that match their equipment requirements, ensuring optimal performance and safety.

2. Power Rating (VA)

Power rating, measured in Volt-Amperes (VA), specifies the transformer’s capacity to handle electrical loads. Selecting a transformer with the appropriate VA rating is crucial to prevent overheating and equipment failure. Buyers should assess the total power requirements of their systems to ensure they choose a transformer that can handle the load without compromising efficiency.

3. Efficiency

Efficiency is a measure of how much of the input power is effectively converted into output power. High-efficiency transformers reduce energy loss, which is particularly important for operations looking to minimize energy costs and environmental impact. Buyers should look for transformers with high efficiency ratings to maximize their investment.

4. Temperature Rating

The temperature rating indicates the maximum ambient temperature at which the transformer can operate safely. This is critical in environments with extreme temperatures, as exceeding this limit can lead to premature failure. Buyers should consider the operating environment when selecting transformers to ensure they can withstand local conditions.

5. Insulation Class

This specification refers to the type of insulation material used within the transformer, which determines its thermal endurance. Insulation classes range from A (maximum 105°C) to H (maximum 180°C). Selecting the appropriate insulation class is vital for ensuring the longevity and reliability of the transformer, especially in high-temperature applications.

Illustrative image related to power supply transformer

6. Mounting Options

Transformers come with various mounting configurations, including DIN rail, panel, and foot-mounted options. Understanding the installation requirements is essential for seamless integration into existing systems. Buyers should assess their setup to select a transformer that meets their mounting needs.

What Are Common Trade Terms in the Power Supply Transformer Industry?

In the B2B landscape, familiarity with industry jargon can enhance communication and decision-making. Here are several essential terms related to power supply transformers:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of transformers, buyers often work with OEMs to ensure that the transformers are compatible with their specific equipment, leading to better integration and performance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can affect purchasing decisions and inventory management. B2B buyers should negotiate MOQs to align with their project needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes specifications and quantities. Creating a detailed RFQ can help buyers receive accurate pricing and lead times, aiding in effective budget planning and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate international transactions, reducing risks associated with delivery and customs.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is essential for project planning and inventory management. Buyers should consider lead times when selecting suppliers to ensure timely project execution.

6. Certification Standards

Certification standards, such as ISO or UL, indicate that a product meets specific safety and performance criteria. Buyers should prioritize transformers that meet relevant certification standards to ensure compliance and reliability in their applications.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when selecting power supply transformers, ensuring they meet their operational needs while optimizing performance and costs.

Navigating Market Dynamics and Sourcing Trends in the power supply transformer Sector

What Are the Current Market Dynamics and Key Trends in the Power Supply Transformer Sector?

The global power supply transformer market is experiencing robust growth, driven by several key factors. The increasing demand for energy-efficient solutions across various industries, coupled with the expansion of renewable energy sources, is propelling the need for advanced power supply transformers. Particularly in regions such as Africa, South America, the Middle East, and Europe, there is a significant push for infrastructure development and modernization, which directly correlates with the demand for efficient power distribution systems.

Emerging technologies such as smart grid solutions and IoT integration are transforming the landscape of the power supply transformer sector. These innovations allow for better monitoring and management of energy consumption, thereby enhancing the overall efficiency of power systems. Additionally, the growing trend towards decentralization of power generation, particularly from renewable sources, is prompting a shift in sourcing strategies for international buyers. They are increasingly looking for suppliers who can offer customized solutions tailored to specific operational needs.

For B2B buyers, understanding regional market dynamics is crucial. In countries like Saudi Arabia and Brazil, government initiatives to enhance energy security and reduce carbon footprints are creating opportunities for partnerships with local manufacturers and technology providers. Buyers should focus on suppliers that not only meet technical specifications but also demonstrate an ability to adapt to evolving market demands and regulatory requirements.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in Power Supply Transformers?

Sustainability is no longer just a buzzword; it has become a significant factor influencing procurement decisions in the power supply transformer sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is a critical consideration for international B2B buyers. As industries strive to lower their carbon footprints, the demand for transformers made from sustainable materials and those that operate efficiently is rising.

Ethical sourcing is also gaining traction, with buyers increasingly prioritizing suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as indicators of a supplier’s commitment to sustainability. Buyers should seek partnerships with manufacturers who utilize recycled materials and demonstrate transparency in their supply chains. This not only enhances brand reputation but also ensures compliance with regulations in various markets.

Incorporating sustainability and ethical sourcing into procurement strategies can lead to long-term cost savings and improved operational efficiencies. B2B buyers who prioritize these factors are not only supporting global sustainability goals but also positioning themselves as leaders in their respective markets.

What Is the Brief Evolution and History of Power Supply Transformers?

The evolution of power supply transformers can be traced back to the late 19th century, with the development of the first practical transformers for electrical power distribution. Initially used for lighting applications, transformers became essential for stepping down high voltages generated by power plants to safer levels for residential and industrial use. The introduction of materials like silicon steel in the mid-20th century improved efficiency and performance, leading to widespread adoption across various sectors.

As technology advanced, the focus shifted towards enhancing energy efficiency and reliability. The rise of electronic devices in the late 20th century created a demand for specialized power supply transformers that could handle diverse voltage requirements. Today, with the integration of smart technologies and renewable energy sources, the sector is witnessing a new phase of innovation aimed at meeting the growing global energy demands sustainably. This historical context provides valuable insights for B2B buyers looking to understand the trajectory of the power supply transformer market and its implications for future sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of power supply transformer

-

How do I choose the right power supply transformer for my application?

Choosing the right power supply transformer involves evaluating your specific application requirements, including voltage ratings, power capacity, and physical space constraints. Start by identifying the input voltage and the desired output voltage. Consider the power rating (in VA) needed for your equipment and whether you require a step-up or step-down transformer. Additionally, ensure the transformer meets local regulations and compliance standards relevant to your region, which can vary significantly across Africa, South America, the Middle East, and Europe. -

What are the key specifications I should look for in a power supply transformer?

Key specifications include voltage ratings (input and output), power capacity (measured in VA), frequency ratings, and efficiency levels. Additionally, check for features such as overload protection, insulation type, and mounting options. Compliance with international standards (e.g., IEC or UL) is crucial for ensuring safety and reliability. Understanding these specifications will help you match the transformer to your operational needs and regulatory requirements, which is especially important for international procurement. -

What is the minimum order quantity (MOQ) when sourcing power supply transformers?

The minimum order quantity (MOQ) for power supply transformers can vary significantly between suppliers. Generally, MOQs can range from a few units to several hundred, depending on the manufacturer and the specific model. When sourcing internationally, it’s essential to communicate your needs clearly with potential suppliers and negotiate MOQs that align with your project requirements. Additionally, consider the potential for volume discounts if you plan for larger future orders. -

How can I ensure the quality of power supply transformers from international suppliers?

To ensure quality, verify that the supplier adheres to international manufacturing standards and has certifications such as ISO 9001. Request product samples to assess quality firsthand and inquire about their quality assurance processes. Additionally, seek references from other customers and consider third-party quality inspection services for larger orders. A rigorous vetting process will help mitigate risks associated with international sourcing, ensuring reliable performance in your applications. -

What payment terms are common when purchasing power supply transformers internationally?

Common payment terms in international trade can include letter of credit, advance payment, and open account terms. Each payment method has its pros and cons, with letters of credit offering security for both buyers and sellers. Discuss payment options with suppliers to find a mutually agreeable arrangement that protects your interests. It’s also advisable to clarify currency exchange rates and any additional fees that may apply during the transaction. -

What are the logistics considerations for importing power supply transformers?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure that the supplier provides proper documentation, including invoices, packing lists, and certificates of origin. Familiarize yourself with the import regulations of your country to avoid delays and additional costs during customs clearance. -

Can I customize power supply transformers to meet specific needs?

Yes, many manufacturers offer customization options for power supply transformers. You can request modifications in terms of voltage ratings, power capacity, and physical dimensions to fit your specific application. Discuss your requirements with potential suppliers early in the negotiation process to determine feasibility and any associated costs. Custom solutions can enhance efficiency and performance, making them a valuable option for specialized applications. -

What after-sales support should I expect from a power supply transformer supplier?

After-sales support can vary by supplier but typically includes warranty services, technical assistance, and replacement parts. Ensure that the supplier offers a clear warranty policy and support for troubleshooting and maintenance. Good after-sales service is crucial for addressing any operational issues that may arise post-installation, so inquire about the supplier’s responsiveness and support channels before finalizing your purchase.

Top 8 Power Supply Transformer Manufacturers & Suppliers List

1. Veris – 24 VDC Switching Power Supplies

Domain: veris.com

Registered: 1995 (30 years)

Introduction: {“Power Supplies”: [{“Brand”: “Veris”, “Part Number”: “PS24-S7.5W”, “Description”: “24 VDC Switching Power Supply, 7.5 W”}, {“Brand”: “Veris”, “Part Number”: “PS24-S15W”, “Description”: “24 VDC Switching Power Supply, 15 W”}, {“Brand”: “Veris”, “Part Number”: “PS24-S30W”, “Description”: “24 VDC Switching Power Supply, 30 W”}, {“Brand”: “Veris”, “Part Number”: “PS12-S7.5W”, “Description”: “12 VDC S…

2. DwyerOmega – Power Transformers

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: Power Transformers from DwyerOmega include various models with the following key details:

– Current Ratios: 20/5, 50/5, 60/5, 75/5, 100/5, 125/5, 150/5, 200/5, 250/5, 300/5, 400/5, 500/5, 600/5, 700/5, 750/5, 800/5, 1000/5, 1200/5, 1500/5, 2000/5, 2500/5, 3000/5.

– Window Sizes: 30.5 mm, 35 mm, 41.5 mm, 60 mm, 60.3 mm, 91 mm, 100 mm, 110 mm.

– Voltage Ratings: 20 VA, 40 VA, 50 VA, 75 VA, 96 VA, 1…

3. Encon Electronics – Gate Operators & Access Control Solutions

Domain: enconelectronics.com

Registered: 1997 (28 years)

Introduction: Gate Operators: Swing, Slide, Barrier, Overhead, Vertical, Pivot/Lift, Crash Rated; Pedestrian Access Control: Postal, Telephone Entry, Intercom, Door Controller, Card Access, Keypad Entry, Push Buttons, Keyswitch, Emergency Access; Traffic Control: Bollards, Speed Bumps, Spikes; Gate Hardware: Vehicle Gate, Pedestrian Gate; Safety Devices: Motion Sensor Receivers, Transmitters, Photo Eyes, Pneuma…

4. Acopian – Power Transformer

Domain: acopian.com

Registered: 1996 (29 years)

Introduction: Power Transformer: Converts input utility voltage to required output voltage (higher or lower). Isolates output voltage from input. Consists of an iron core and multiple wire windings. Voltage transformation is proportional to the number of turns in the windings. Current transformation is inversely proportional to the number of turns. Acopian manufactures a wide range of AC-DC and DC-DC power supp…

5. Markobakula – High Voltage ATX Transformer Solutions

Domain: markobakula.wordpress.com

Registered: 2000 (25 years)

Introduction: High voltage supply using PC power supply transformers, utilizing ATX form factor transformers typically operating at around 400W. The project involves running ATX transformers in reverse to generate high voltage, using a mains powered half bridge of MOSFETs or IGBTs. The configuration includes connecting two large ATX supply transformers in series for the primary and paralleled secondaries for th…

6. SE – Industrial Power Supplies

Domain: se.com

Registered: 1997 (28 years)

Introduction: This company, SE – Industrial Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. NSI Industries – Class 2 Signaling Transformers

Domain: nsiindustries.com

Registered: 2004 (21 years)

Introduction: {“products”:[{“name”:”Class 2 Signaling Transformer for Low-Voltage Power”,”model”:”#T-603″,”dimensions”:”2.34375 × 2.40625″},{“name”:”Class 2 Signaling Transformer for Low-Voltage Power”,”model”:”#T-604″,”dimensions”:”2.34375 × 2.40625 × 2.4063″},{“name”:”TORK TA1245Y-50 Heavy-Duty Signaling Device Transformer”,”power”:”50VA”,”input”:”120/208/240V”,”output”:”24V”,”dimensions”:”2.187 × 0.21 × 3.25…

8. Larson Electronics – DC to DC Power Converter

Domain: larsonelectronics.com

Registered: 2001 (24 years)

Introduction: [{‘name’: ‘DC to DC Power Converter’, ‘input’: ’16-40V DC’, ‘output’: ‘270V DC’, ‘current’: ‘3.7A’, ‘mounting’: ‘Surface Mount’, ‘features’: ‘Active Current Sharing’, ‘price’: ‘$2590.85’}, {‘name’: ‘Encapsulated DC to DC Step Up Transformer’, ‘input’: ’12V DC’, ‘output’: ’24V DC’, ‘current’: ’15 Amps’, ‘features’: ‘Flying Leads, Waterproof’, ‘price’: ‘$334.12’}, {‘name’: ‘Encapsulated DC to DC Ste…

Strategic Sourcing Conclusion and Outlook for power supply transformer

In the ever-evolving landscape of electrical infrastructure, strategic sourcing of power supply transformers is essential for optimizing efficiency and minimizing operational costs. By aligning procurement strategies with the specific needs of your business, international buyers can ensure they acquire high-quality transformers that meet local regulatory standards while addressing unique regional challenges.

Investing in reliable power transformers not only enhances the stability of electrical systems but also supports sustainable practices by reducing energy losses. This is particularly crucial for industries in Africa, South America, the Middle East, and Europe, where energy efficiency is increasingly tied to competitive advantage.

Looking ahead, the demand for innovative power solutions is set to rise as industries expand and modernize. Buyers should actively engage with suppliers to explore cutting-edge technologies, such as smart transformers and energy-efficient designs. By fostering strong partnerships and staying informed about market trends, businesses can secure a reliable supply of transformers that drive growth and sustainability.

Take the next step in your strategic sourcing journey today. Evaluate your current supplier relationships and explore new partnerships to ensure your power supply needs are met with the highest standards of quality and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.