How to Source Pallet Stack Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pallet stack

In today’s competitive landscape, effectively sourcing pallet stacks presents a significant challenge for international B2B buyers. Whether you are in Nigeria, Vietnam, or anywhere across Africa, South America, the Middle East, or Europe, the complexity of selecting the right pallet stacks—considering factors like material, size, durability, and cost—can impact your operational efficiency and bottom line. This comprehensive guide aims to demystify the global market for pallet stacks by providing insights into various types, applications, and best practices for supplier vetting.

We will explore the advantages of different pallet materials, such as plastic versus wood, and highlight the importance of selecting pallets that align with your specific operational needs, including weight capacity and hygiene standards. Additionally, this guide will address cost considerations, helping you navigate pricing structures and identify potential savings. By equipping you with the knowledge to make informed purchasing decisions, this resource empowers businesses to optimize their supply chain processes and enhance productivity.

As you navigate through this guide, expect to gain actionable insights and strategies that will enable you to confidently select the right pallet stacks tailored to your business requirements, ultimately facilitating smoother logistics and improved profitability.

Understanding pallet stack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stackable Plastic Pallets | Durable, lightweight, easy to clean | Food, pharmaceuticals, and retail | Pros: Long-lasting, hygienic, customizable. Cons: Higher upfront cost than wood. |

| Wooden Pallets | Traditional, readily available, often heavier | General manufacturing and shipping | Pros: Cost-effective, easy to repair. Cons: Less durable, harder to clean. |

| Euro Pallets | Standardized size (1200mm x 800mm), robust design | European logistics and warehousing | Pros: Compatible with automated systems, high load capacity. Cons: Limited availability outside Europe. |

| Half Pallets | Smaller size (40” x 24” or 800mm x 600mm) | Retail displays, smaller shipments | Pros: Ideal for limited space, reduces waste. Cons: Lower load capacity. |

| Custom Pallets | Tailored dimensions and materials to specific needs | Specialized industries, custom loads | Pros: Optimized for unique requirements. Cons: Longer lead times, often more expensive. |

What Are the Key Characteristics of Stackable Plastic Pallets?

Stackable plastic pallets are designed for durability and longevity, often outperforming wood in both lifespan and cleanliness. They are lightweight, making them easy to handle and transport. Their non-porous surfaces prevent contamination, making them ideal for industries like food and pharmaceuticals. When purchasing, consider their higher initial cost, which can be offset by their longer lifespan and reduced maintenance needs.

How Do Wooden Pallets Compare in the Market?

Wooden pallets remain a staple in logistics due to their availability and lower cost. They are easy to repair and can be sourced locally, which is beneficial for businesses looking to minimize expenses. However, they are less durable than their plastic counterparts and can harbor bacteria if not properly cleaned. Buyers should evaluate their specific needs, including load types and hygiene requirements, before opting for wood.

What Are the Advantages of Using Euro Pallets?

Euro pallets, with their standardized dimensions, are widely recognized and utilized across Europe. Their robust design allows for high load capacity, making them suitable for heavy and bulk shipments. They are also compatible with automated warehousing systems, enhancing operational efficiency. Businesses outside Europe should ensure compatibility with local transport and storage systems, as availability may vary.

Illustrative image related to pallet stack

Why Choose Half Pallets for Your Business?

Half pallets are an excellent choice for businesses with limited space or those requiring smaller shipments. Their compact size makes them ideal for retail displays and environments where space is at a premium. While they offer lower load capacity, they help reduce waste and can be more cost-effective for smaller loads. Companies should assess their shipping volumes to determine if half pallets meet their operational needs.

What Benefits Do Custom Pallets Provide to Specialized Industries?

Custom pallets are designed to meet the unique specifications of various industries, from pharmaceuticals to automotive. Tailored dimensions and materials can optimize load stability and safety during transport. While they may come with longer lead times and higher costs, the benefits of increased efficiency and reduced damage during shipping can be significant. Businesses should clearly define their requirements to ensure they receive the most suitable pallet solution.

Key Industrial Applications of pallet stack

| Industry/Sector | Specific Application of pallet stack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Stacking and transporting packaged goods | Ensures hygiene, compliance with safety standards | Durability, ease of cleaning, and food safety certifications |

| Pharmaceuticals | Storage and distribution of medicinal products | Maintains product integrity and prevents contamination | Material specifications, regulatory compliance, and traceability |

| Retail and E-commerce | Efficient inventory management and shipping | Enhances operational efficiency and reduces costs | Pallet size standardization and compatibility with automation |

| Manufacturing | Component handling and assembly line support | Improves workflow efficiency and minimizes damage | Load capacity, material strength, and customization options |

| Construction and Building | Transporting building materials | Reduces handling time and improves site organization | Weight tolerance, weather resistance, and stacking stability |

How is ‘pallet stack’ utilized in the food and beverage industry?

In the food and beverage sector, pallet stacks are essential for the efficient storage and transportation of packaged goods. These pallets facilitate compliance with stringent hygiene and safety standards by allowing for easy cleaning and sanitization. Buyers in this industry must prioritize sourcing durable plastic pallets that meet food safety certifications and can withstand various environmental conditions, ensuring that products remain uncontaminated throughout the supply chain.

What role does ‘pallet stack’ play in the pharmaceutical sector?

Pallet stacks are critical in the pharmaceutical industry for the storage and distribution of medicinal products. They help maintain the integrity of sensitive medications by preventing contamination and ensuring proper ventilation. B2B buyers should look for pallets that comply with regulatory standards, including material specifications and traceability, to guarantee that their products remain safe and effective throughout their lifecycle.

How do ‘pallet stacks’ enhance operations in retail and e-commerce?

In retail and e-commerce, pallet stacks are vital for efficient inventory management and shipping processes. They allow for the organized stacking of goods, which enhances operational efficiency and reduces shipping costs. Buyers in this sector should consider standard pallet sizes to ensure compatibility with automated systems and optimize storage space, ultimately leading to faster order fulfillment and improved customer satisfaction.

Illustrative image related to pallet stack

Why are ‘pallet stacks’ important for manufacturing?

In manufacturing, pallet stacks are used to handle components efficiently and support assembly lines. They streamline workflows by reducing handling time and minimizing the risk of damage to products during transit. Buyers should focus on the load capacity and material strength of pallets, as well as customization options that meet specific production needs, to enhance overall operational efficiency.

How do ‘pallet stacks’ support the construction and building industry?

In the construction and building industry, pallet stacks are used for the transport of heavy materials. They help to reduce handling time and improve site organization, which is crucial for maintaining productivity on job sites. When sourcing pallets for this application, buyers should prioritize weight tolerance, weather resistance, and stacking stability to ensure that materials are transported safely and efficiently, even in challenging conditions.

3 Common User Pain Points for ‘pallet stack’ & Their Solutions

Scenario 1: Inspection Oversights Leading to Costly Failures

The Problem: Many B2B buyers encounter significant challenges when receiving shipments of pallets, particularly plastic pallets. Upon delivery, buyers often neglect to conduct thorough inspections for damage, such as cracks or other signs of wear. This oversight can lead to using compromised pallets that may fail during transport or handling, resulting in product loss, safety hazards, and costly delays. In regions where logistics can be challenging, such as parts of Africa and South America, these issues can be exacerbated by limited access to quick replacement options.

The Solution: To mitigate this risk, it is crucial for buyers to implement a robust inspection protocol upon receiving pallets. This should include a checklist that outlines specific areas to examine, such as the corners, edges, and load-bearing surfaces for any structural damage. Additionally, buyers should consider establishing a relationship with reputable suppliers who provide quality guarantees and clear return policies for damaged products. Investing in training for warehouse staff on proper inspection techniques can further enhance safety and operational efficiency. This proactive approach ensures that only high-quality pallets are utilized, reducing the risk of failures and associated costs.

Scenario 2: Inefficient Pallet Configuration Causing Space Wastage

The Problem: B2B buyers often struggle with maximizing the efficiency of their pallet stacking configurations, especially when dealing with various product sizes and weights. Poorly configured pallets can lead to wasted space in transport and storage, which is a significant concern for businesses aiming to optimize logistics costs. This issue is particularly pronounced in regions with high shipping costs, where every inch of space counts.

The Solution: To address this problem, buyers should utilize advanced pallet configuration tools, such as 3D pallet calculators. These tools allow buyers to input specific dimensions and weights of their products to determine the optimal stacking arrangement. For instance, using a configurator can help identify the best alignment and layer configuration for stability and space efficiency. Moreover, buyers can engage with logistics experts to refine their stacking practices and ensure compliance with safety regulations. By adopting a data-driven approach to pallet configuration, businesses can significantly enhance their storage and transport efficiency, ultimately reducing costs and improving service delivery.

Scenario 3: Difficulty in Securing Loads for Safe Transport

The Problem: Another common issue faced by B2B buyers is the challenge of securing loads on pallets for safe transportation. Inconsistent load securing methods can lead to shifting during transit, resulting in product damage and increased liability. This concern is particularly pressing for businesses in the Middle East and Europe, where strict regulations regarding load safety are enforced.

The Solution: To overcome this challenge, buyers should adopt a multi-faceted approach to securing pallet loads. This includes employing appropriate securing methods such as stretch wrapping, strapping, or using corner boards to stabilize the loads. Buyers should also ensure that their staff is trained in best practices for load securing, as well as the maximum weight limits of the pallets being used. Furthermore, utilizing technology such as load monitoring systems can provide real-time feedback on load stability during transport. By prioritizing proper load securing techniques, businesses can enhance safety, reduce liability risks, and ensure that products arrive at their destination intact and on time.

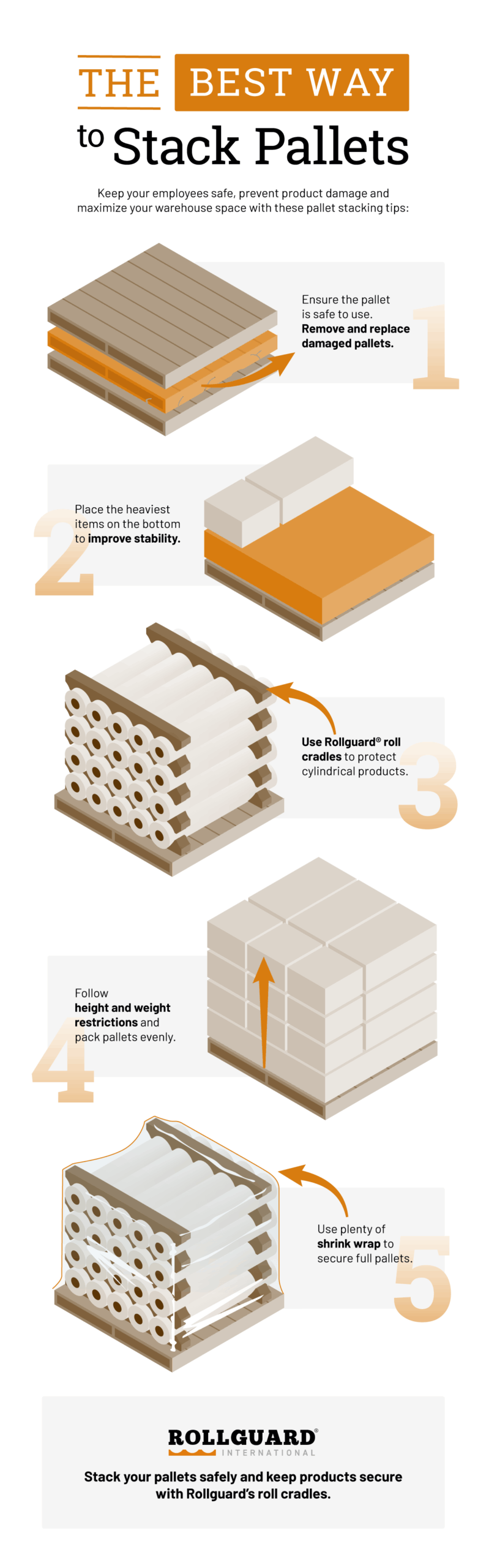

Illustrative image related to pallet stack

Strategic Material Selection Guide for pallet stack

When selecting materials for pallet stacks, it’s crucial for B2B buyers to consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in pallet stacks, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Wooden Pallets?

Wooden pallets are one of the most traditional and widely used materials in the pallet industry. They are typically made from softwoods like pine or hardwoods like oak.

- Key Properties: Wooden pallets have good load-bearing capacity and can withstand moderate temperature fluctuations. However, they are susceptible to moisture, which can lead to warping or mold growth.

- Pros & Cons: They are relatively inexpensive and easy to manufacture. However, their durability is lower compared to other materials, and they require regular maintenance to prevent decay. Additionally, wooden pallets may not be suitable for all types of media, especially those requiring high hygiene standards.

- Impact on Application: Wooden pallets are often used in industries like food and beverage, where they may come into contact with moisture. Their compatibility with various media is limited due to potential contamination risks.

- Considerations for International Buyers: Compliance with international standards such as ISPM 15 for pest control is essential. Buyers in regions like Africa and South America should be aware of local regulations regarding wood treatment.

How Do Plastic Pallets Compare in Terms of Performance?

Plastic pallets are becoming increasingly popular due to their durability and ease of maintenance.

- Key Properties: They are resistant to moisture, chemicals, and pests, making them suitable for a wide range of applications. Plastic pallets can also handle extreme temperatures without losing structural integrity.

- Pros & Cons: Their durability leads to a longer lifespan, reducing the need for frequent replacements. However, they tend to be more expensive upfront compared to wooden pallets, and manufacturing processes can be complex.

- Impact on Application: Plastic pallets are ideal for industries requiring high hygiene standards, such as pharmaceuticals and food processing, as they can be easily cleaned and sanitized.

- Considerations for International Buyers: Buyers should look for pallets that comply with food safety standards and certifications like FDA approval. In regions like the Middle East, where high temperatures are common, selecting UV-resistant plastic is advisable.

What Are the Benefits of Metal Pallets?

Metal pallets, often made from steel or aluminum, are known for their strength and durability.

- Key Properties: They can withstand high temperatures and heavy loads, making them suitable for industrial applications. Metal pallets are also resistant to corrosion when treated properly.

- Pros & Cons: Their strength and longevity make them a worthwhile investment for heavy-duty applications. However, they are significantly more expensive than wooden or plastic pallets and can be heavier, which may increase shipping costs.

- Impact on Application: Metal pallets are often used in manufacturing and automotive industries where heavy loads are common. They are less suitable for environments where weight is a concern.

- Considerations for International Buyers: Buyers must ensure compliance with relevant standards like ASTM for structural integrity. In regions with high humidity, corrosion-resistant coatings are essential.

What Advantages Do Composite Pallets Offer?

Composite pallets combine materials like plastic and wood, offering a balance of benefits from both.

- Key Properties: They are designed to provide the strength of wood with the moisture resistance of plastic. Composite pallets can withstand various environmental conditions without deteriorating.

- Pros & Cons: Their hybrid nature allows for versatility in applications, but they may not be as readily available as traditional pallets. Additionally, their manufacturing process can be complex, leading to higher costs.

- Impact on Application: Composite pallets are suitable for diverse industries, including retail and logistics, where both durability and hygiene are important.

- Considerations for International Buyers: Buyers should verify compliance with both plastic and wood standards, especially in regions with strict import regulations.

Summary Table of Material Selection for Pallet Stacks

| Material | Typical Use Case for pallet stack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wooden | General storage and shipping | Cost-effective and easy to repair | Susceptible to moisture and decay | Low |

| Plastic | Food and pharmaceuticals | Durable, hygienic, and moisture-resistant | Higher initial cost | High |

| Metal | Heavy-duty industrial applications | Extremely strong and long-lasting | Expensive and heavier | High |

| Composite | Retail and logistics | Combines benefits of wood and plastic | Availability and manufacturing complexity | Medium |

This analysis provides a comprehensive overview of the materials used in pallet stacks, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pallet stack

What Are the Key Stages in the Manufacturing Process of Pallet Stacks?

The manufacturing process of pallet stacks typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets quality and performance standards.

Illustrative image related to pallet stack

-

Material Preparation

The first step in manufacturing pallets involves selecting the right materials. For plastic pallets, high-density polyethylene (HDPE) or polypropylene are common choices due to their durability and resistance to environmental factors. In the case of wooden pallets, selecting high-quality timber is essential to ensure strength and longevity. The materials undergo preprocessing, which may include shredding or granulating for plastics, and cutting or drying for wood. -

Forming

Once the materials are prepared, the next stage is forming. For plastic pallets, this often involves processes like injection molding or blow molding, where molten plastic is shaped into pallet forms. For wooden pallets, this involves assembling the cut pieces into a frame, typically using nails or staples. This stage is crucial as it determines the structural integrity of the pallet. -

Assembly

After forming, the pallets are assembled. This involves aligning the components and securing them together. Automated assembly lines are often employed to increase efficiency and ensure precision. For wooden pallets, this may involve adding blocks or runners to enhance stability. For plastic pallets, interlocking designs might be used for easy stacking. -

Finishing

The final stage involves finishing processes, which can include sanding, painting, or applying coatings to enhance durability. For plastic pallets, surface treatments may be applied to improve slip resistance or hygiene. Wooden pallets often receive a treatment to protect against pests and moisture. Finishing ensures that the pallets are ready for use and meet aesthetic standards.

How Is Quality Assurance Implemented in Pallet Manufacturing?

Quality assurance (QA) is vital in ensuring that pallet stacks are safe, durable, and meet international standards. Manufacturers typically follow a structured QA process that aligns with international standards like ISO 9001.

-

International Standards and Compliance

Adhering to international standards is crucial for B2B buyers. ISO 9001 provides a framework for quality management systems, ensuring that products consistently meet customer requirements. Additionally, specific certifications like CE marking for Europe or API standards for the oil and gas industry may be relevant, depending on the pallet’s intended use. -

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, various parameters such as dimensions, weight, and structural integrity are monitored. Regular sampling and testing are conducted to identify defects early.

– Final Quality Control (FQC): Once pallets are assembled, they undergo final inspections to ensure they meet all specifications and standards before shipment. -

Common Testing Methods for Pallet Stacks

Various testing methods are employed to validate the quality of pallets. Common tests include:

– Load Testing: Ensures that pallets can safely support specified loads without deformation.

– Impact Resistance Testing: Assesses the durability of pallets against drops or impacts.

– Environmental Testing: For plastic pallets, tests may include exposure to UV light or extreme temperatures to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is crucial to mitigate risks associated with poor-quality pallets. Here are several strategies:

-

Supplier Audits

Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. During an audit, buyers should assess the supplier’s adherence to international standards, review their QA documentation, and evaluate their production facilities. -

Quality Reports and Certifications

Requesting quality reports can provide detailed information on a supplier’s manufacturing processes and quality control measures. Certifications from recognized bodies can also serve as assurance that the supplier adheres to industry standards. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can include material checks, production monitoring, and final product evaluations, ensuring that the pallets meet specified standards before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control in pallet manufacturing.

Illustrative image related to pallet stack

-

Regional Standards and Regulations

Different regions may have varying standards and regulations concerning pallet specifications. Buyers must familiarize themselves with local requirements, such as phytosanitary regulations for wooden pallets, which are critical for international shipping. -

Cultural and Logistical Considerations

Cultural differences can impact communication and expectations regarding quality. Buyers should establish clear quality expectations and ensure that suppliers understand their requirements. Logistically, ensuring that pallets are manufactured and delivered in compliance with international shipping standards is crucial. -

Sustainability and Environmental Considerations

As global attention shifts towards sustainability, buyers should consider the environmental impact of their pallet choices. Suppliers who adhere to eco-friendly practices, such as using recycled materials or sustainable sourcing, can provide additional value and align with global sustainability goals.

In conclusion, understanding the manufacturing processes and quality assurance measures for pallet stacks is essential for B2B buyers. By focusing on these aspects, buyers can ensure they select high-quality, durable pallets that meet their specific needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pallet stack’

To effectively source pallet stacks for your business needs, follow this practical checklist designed for B2B buyers. This guide outlines essential steps to ensure you make informed decisions and procure high-quality pallets that meet your operational requirements.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications for the pallet stacks you require. Consider factors such as dimensions, weight capacity, and material type (e.g., plastic or wood). Establishing these criteria will help you filter suppliers and ensure that the pallets meet your specific handling and storage needs.

Step 2: Research Available Pallet Types

Familiarize yourself with the various types of pallets available in the market, including standard, Euro, and industry-specific pallets. Each type has unique dimensions and load capacities, which can affect your supply chain efficiency. Understanding these differences will allow you to choose the most suitable pallet for your products.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from other businesses in your industry or region. Check for certifications that ensure compliance with international standards, as these can indicate reliability and quality.

Illustrative image related to pallet stack

Step 4: Inspect Pallets Upon Receipt

Once you receive your pallets, conduct a thorough inspection for any signs of damage or wear. Look for cracks, splits, or deformities that could compromise the pallet’s integrity during use. Ensuring the pallets are in good condition is crucial for safety and efficiency in your operations.

Step 5: Utilize Pallet Load Calculators

Take advantage of tools like pallet load calculators to optimize your pallet stacking configurations. These calculators can help you determine the ideal number of units per layer, total height, and weight distribution, ensuring that your pallets are stable and efficient for transport. This step is vital to maximize space and minimize transportation costs.

Step 6: Consider Additional Securing Methods

Evaluate methods for securing your pallet loads, such as stretch wrapping, strapping, or using pallet collars. Proper securing techniques are essential for protecting your products during transit and ensuring they arrive at their destination intact. Choose a method that aligns with the nature of your goods and shipping conditions.

Step 7: Review and Compare Pricing

After identifying potential suppliers, gather quotes and compare pricing. Be cautious of prices that seem too low; they may indicate lower quality or hidden costs. Look for a balance between cost and quality to ensure that you are making a sound investment in your pallet needs.

By following this checklist, B2B buyers can streamline the sourcing process for pallet stacks, ensuring they choose the right products and suppliers that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for pallet stack Sourcing

What Are the Key Cost Components for Sourcing Pallet Stacks?

When sourcing pallet stacks, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences costs. Plastic pallets, for instance, typically have a higher upfront cost compared to wooden pallets but offer durability and longevity that can lead to lower total ownership costs over time. The material’s sourcing location can also affect prices, especially for international buyers.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control. Regions with lower labor costs may provide competitive pricing, but it’s crucial to assess the trade-off between cost and quality.

-

Manufacturing Overhead: This includes costs related to the production facility, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in the final price.

-

Tooling: Custom tooling for specific pallet designs can lead to increased costs, particularly for unique specifications. Buyers should evaluate the necessity of custom designs against the potential cost savings from standardized options.

-

Quality Control (QC): Implementing robust QC processes ensures that the pallets meet required specifications and safety standards. This adds to the overall cost but can prevent expensive returns and liability issues.

-

Logistics: Transportation and handling costs can vary significantly based on the distance, mode of transport, and Incoterms agreed upon. For international buyers, understanding these logistics costs is crucial for budgeting.

-

Margin: Supplier margins can differ based on market conditions and competition. It’s advisable for buyers to research typical margins in their region to identify fair pricing.

What Influences Pricing for Pallet Stacks?

Several factors can influence the pricing of pallet stacks, particularly in the international B2B market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Customized pallets tailored to specific needs can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (e.g., food-grade, sustainable) will typically cost more. Buyers in industries with stringent regulations should prioritize certified products.

-

Supplier Factors: Relationships with suppliers can influence pricing. Long-term partnerships may result in better pricing and service.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can impact the total cost of procurement, influencing who bears shipping and insurance costs. Buyers should clarify these terms to avoid unexpected expenses.

How Can Buyers Negotiate for Better Pricing on Pallet Stacks?

Effective negotiation is key to obtaining favorable pricing. Here are some strategies:

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher volume thresholds, as suppliers often provide better rates for larger purchases.

-

Research Market Prices: Understanding market trends and competitor pricing can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also maintenance, longevity, and disposal costs. Presenting TCO findings can strengthen negotiation positions.

-

Consider Regional Suppliers: Engaging with local suppliers may reduce logistics costs and lead times, providing additional negotiation leverage.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of specific pricing nuances:

Illustrative image related to pallet stack

-

Currency Fluctuations: Be mindful of exchange rates when negotiating prices, as currency fluctuations can affect overall costs.

-

Import Duties and Tariffs: Understand any applicable import taxes that may increase the final cost of pallets.

-

Cultural Negotiation Styles: Adapt negotiation strategies to align with regional practices and expectations, which can vary significantly across cultures.

Conclusion

While the pricing of pallet stacks can vary widely based on multiple factors, a thorough understanding of cost components and pricing influencers can empower B2B buyers to make informed decisions. Always seek clarity in negotiations and be aware of the total cost implications to ensure optimal purchasing outcomes.

Alternatives Analysis: Comparing pallet stack With Other Solutions

Introduction: Exploring Alternatives to Pallet Stacking Solutions

In the dynamic landscape of logistics and warehousing, businesses are constantly seeking efficient and cost-effective methods for transporting and storing goods. While pallet stacking is a widely adopted solution, it is essential to consider alternative options that may better suit specific operational needs. This analysis compares pallet stacks with two viable alternatives: automated storage and retrieval systems (AS/RS) and mobile shelving systems, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Pallet Stack | Automated Storage and Retrieval Systems (AS/RS) | Mobile Shelving Systems |

|---|---|---|---|

| Performance | High load capacity; efficient space utilization | Very high efficiency; rapid retrieval times | Moderate efficiency; flexible storage |

| Cost | Generally low initial cost; potential for high long-term savings | High initial investment; lower operational costs over time | Moderate initial investment; ongoing costs for maintenance |

| Ease of Implementation | Simple setup; minimal training required | Complex installation; requires specialized training | Easy to install; low training needs |

| Maintenance | Low maintenance; requires periodic inspection | Higher maintenance; needs specialized technicians | Moderate maintenance; straightforward upkeep |

| Best Use Case | Bulk storage and transportation of heavy goods | High-volume operations needing quick access | Flexible storage needs in smaller spaces |

Detailed Breakdown of Alternatives

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems are designed to optimize warehouse space and increase efficiency by automating the retrieval and storage of goods. These systems consist of automated cranes or shuttles that can quickly locate and transport items, significantly reducing the time spent on manual handling.

Pros: AS/RS offers high speed and efficiency, especially beneficial for high-volume operations. It maximizes space utilization and can operate in smaller areas due to vertical storage capabilities.

Cons: The initial investment is substantial, which may deter small to medium enterprises. Additionally, the complexity of installation and the need for specialized training and maintenance can pose challenges.

Mobile Shelving Systems

Mobile shelving systems provide a flexible storage solution by allowing shelving units to move along tracks, maximizing the use of available space. This system is particularly useful in environments where the storage needs frequently change or where space is at a premium.

Pros: These systems are relatively easy to install and require minimal training for staff. They offer excellent flexibility and can adapt to changing inventory sizes and types.

Cons: While mobile shelving systems are efficient for moderate storage needs, they may not provide the same level of high-density storage as AS/RS. Additionally, ongoing maintenance is required to ensure the tracks and wheels function properly.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right storage solution, B2B buyers should assess their specific operational requirements, including the volume and type of goods handled, available space, and budget constraints. Pallet stacking remains a reliable choice for bulk storage and transportation of heavy goods, while AS/RS systems excel in high-volume environments needing rapid access. Mobile shelving systems offer a flexible alternative for businesses with changing storage needs. By carefully evaluating these alternatives against your operational goals, you can make an informed decision that enhances efficiency and supports your business growth.

Essential Technical Properties and Trade Terminology for pallet stack

What Are the Key Technical Properties of Pallet Stacks?

Understanding the essential technical properties of pallet stacks is crucial for B2B buyers who need to ensure the efficiency and safety of their logistics and supply chain operations. Below are some critical specifications to consider:

-

Material Grade

The material grade refers to the quality and type of material used in the construction of the pallet, which can include wood, plastic, or metal. For instance, high-density polyethylene (HDPE) is a popular choice for plastic pallets due to its durability and resistance to chemicals. Selecting the right material is vital as it impacts the pallet’s lifespan, load capacity, and suitability for specific applications, such as food safety requirements. -

Load Capacity

This specification denotes the maximum weight a pallet can safely support without structural failure. Standard load capacities vary by pallet type; for example, a standard North American pallet can typically handle up to 4,600 kg, while a Euro pallet generally has a safe working load of around 1,500 kg. Understanding load capacity is essential for optimizing shipping efficiency and preventing accidents during transport. -

Dimensions

Pallet dimensions, including length, width, and height, are critical for ensuring compatibility with storage systems and transportation vehicles. Common dimensions include the standard 48” x 40” size in North America and the 1200 mm x 800 mm Euro pallet. Proper dimensioning allows for efficient space utilization in warehouses and reduces handling costs. -

Tolerances

Tolerance refers to the allowable variation in the dimensions of a pallet. This is particularly important for automated systems that rely on precise measurements for stacking and unloading. High tolerance levels ensure that pallets fit seamlessly into racks or machinery, minimizing the risk of damage or operational delays. -

Stackability

The ability to stack pallets is a vital property for optimizing storage space. Stackability is influenced by the pallet design, including features such as corner posts and base structure. Efficient stackability allows businesses to maximize vertical space in warehouses, leading to reduced storage costs and improved organization.

Which Trade Terms Should B2B Buyers Understand for Pallet Stacks?

Navigating the pallet industry involves familiarizing oneself with various trade terminologies that can significantly impact purchasing decisions. Below are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the pallet industry, knowing the OEM can help buyers assess the quality and reliability of the pallets they are purchasing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can influence inventory costs and purchasing strategies. Buyers must evaluate whether they can meet the MOQ without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. Issuing an RFQ allows businesses to compare offers from multiple vendors, ensuring they receive competitive pricing and favorable terms for their pallet stack purchases. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and logistics responsibilities associated with pallet procurement. -

Palletization

This term refers to the process of loading goods onto pallets for transportation and storage. Efficient palletization is essential for optimizing space and ensuring the safety of products during shipping. Understanding this process can help buyers implement best practices in their logistics operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding pallet stacks, leading to enhanced efficiency and cost-effectiveness in their supply chain management.

Navigating Market Dynamics and Sourcing Trends in the pallet stack Sector

What Are the Current Market Dynamics and Key Trends Affecting the Pallet Stack Sector?

The global pallet stack market is experiencing transformative dynamics driven by several factors, including globalization, e-commerce growth, and technological advancements. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly prioritizing efficiency and sustainability in their sourcing decisions. The rise of e-commerce has led to a heightened demand for efficient logistics solutions, prompting businesses to adopt stackable pallets that optimize space and reduce shipping costs.

Emerging technologies, such as automation and IoT (Internet of Things), are revolutionizing pallet management. Advanced tracking systems and automated palletizers are streamlining operations, enabling businesses to monitor inventory levels in real-time and improve supply chain transparency. Furthermore, as companies shift toward omnichannel retailing, the need for flexible and adaptable pallet solutions is more crucial than ever.

In addition, the current market is witnessing a trend toward customization. Buyers are looking for pallets tailored to specific load requirements and dimensions, which can enhance load stability and reduce the risk of damage during transport. This customization trend is supported by online tools, such as 3D pallet configurators, which allow users to visualize and optimize their pallet loads before procurement.

How Does Sustainability and Ethical Sourcing Influence the Pallet Stack Market?

Sustainability is no longer a mere buzzword; it has become a critical factor in B2B sourcing strategies. The environmental impact of pallet production and disposal is prompting buyers to seek sustainable alternatives. Plastic pallets, for instance, are often favored for their durability and recyclability, making them a more sustainable option compared to traditional wooden pallets.

Moreover, ethical sourcing practices are gaining traction among international buyers. Companies are increasingly evaluating their supply chains for compliance with environmental standards and ethical labor practices. Certifications such as FSC (Forest Stewardship Council) for wood products and various eco-labels for plastic materials are becoming essential in the decision-making process.

Illustrative image related to pallet stack

The importance of these certifications cannot be overstated; they not only enhance brand reputation but also provide assurance to consumers and business partners about the sustainability of sourcing practices. As markets become more interconnected, the demand for transparency in the supply chain is expected to grow, compelling businesses to adopt more responsible sourcing practices.

What Is the Brief Evolution and History of the Pallet Stack Sector?

The evolution of the pallet stack sector can be traced back to the early 20th century when pallets were first introduced to enhance the efficiency of material handling. Initially made from wood, pallets have evolved significantly over the decades, with the introduction of plastic and composite materials that offer superior durability and hygiene.

The 1960s marked a pivotal moment with the standardization of pallet sizes, which facilitated global trade and logistics. Over time, advancements in technology have led to the development of sophisticated pallet management systems, including automated palletizers and tracking solutions. Today, the pallet stack sector continues to adapt to the demands of an increasingly digital and environmentally conscious marketplace, positioning itself as a vital component of modern supply chains.

As B2B buyers navigate this dynamic landscape, understanding these trends and historical contexts can provide valuable insights for making informed sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of pallet stack

-

How do I solve issues with damaged pallets upon delivery?

When receiving pallets, conduct a thorough inspection immediately. Look for cracks, splits, or any other signs of wear. If you find damaged pallets, document the condition with photos and notify the supplier promptly. Most reputable suppliers will offer a replacement or credit for defective pallets. Implementing a quality control process upon delivery can help prevent future issues and ensure that your operations remain uninterrupted. -

What is the best material for pallets in humid environments?

For humid environments, plastic pallets are often superior to wood pallets. They are resistant to moisture, mold, and mildew, making them ideal for regions with high humidity, such as parts of Africa and South America. Additionally, plastic pallets are easier to clean and sanitize, which is crucial in industries like food and pharmaceuticals. Consider investing in high-quality plastic pallets to enhance durability and reduce maintenance costs over time. -

How can I ensure compliance with international shipping regulations for pallets?

To ensure compliance, familiarize yourself with the shipping regulations of both your country and the destination country. This includes understanding the ISPM 15 standard for wood pallets, which mandates treatment to prevent pest infestation. Work with suppliers who provide documentation proving compliance. Additionally, consider using plastic pallets, which typically do not require such treatments, simplifying the compliance process. -

What factors should I consider when customizing pallets for my business needs?

Customization should be based on the specific dimensions and weight of your goods, as well as the type of handling and transport methods you will use. Consider factors such as load capacity, stackability, and the type of material. Additionally, think about any branding requirements, such as color or logo placement. Collaborate closely with your supplier to ensure that the custom pallets meet both your functional and aesthetic needs. -

What is the minimum order quantity (MOQ) for pallet stacks, and how does it vary by supplier?

MOQ can vary significantly by supplier, typically ranging from a few dozen to several hundred pallets. Factors influencing MOQ include the type of pallet (wood, plastic, etc.), customization options, and the supplier’s production capabilities. It’s advisable to discuss your needs with multiple suppliers to find the best deal. Some may offer flexibility in MOQ, especially for repeat customers or bulk orders. -

What payment terms should I expect when sourcing pallets internationally?

Payment terms can vary widely, but most suppliers will offer options such as upfront payment, partial payment with the balance due upon delivery, or credit terms for established businesses. Be sure to clarify these terms before placing an order. Consider using secure payment methods and obtaining a written agreement to protect your interests. Additionally, verify the supplier’s reputation to mitigate risks associated with international transactions. -

How do I vet suppliers when sourcing pallets from different regions?

Start by researching potential suppliers online, focusing on their industry reputation, customer reviews, and certifications. Request references from previous clients and assess their responsiveness to inquiries. It can also be beneficial to visit the supplier’s facility if feasible, or to use third-party inspection services. Additionally, ensure that the supplier complies with local and international standards for quality and safety. -

What logistics considerations should I keep in mind when importing pallets?

When importing pallets, consider shipping costs, transit times, and the reliability of the logistics provider. Ensure that the pallets are packaged securely to prevent damage during transport. Additionally, be aware of customs regulations and potential tariffs that may apply to your shipment. Collaborating with a logistics expert can help streamline the process and avoid unexpected delays or costs.

Top 7 Pallet Stack Manufacturers & Suppliers List

1. PHS Inc. – Premier Stackable Pallets

Domain: phsinc.com

Registered: 2004 (21 years)

Introduction: This company, PHS Inc. – Premier Stackable Pallets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. PTChronos – 3D Pallet Calculator

Domain: ptchronos.com

Registered: 2009 (16 years)

Introduction: Free 3D pallet calculator to configure pallet loads and stacking patterns. Users can input unit dimensions (width, length, height, weight) and select from predefined pallet sizes or create custom dimensions. Common pallet sizes include Standard pallet (48″ x 40″, safe working load up to 4,600 kg), Euro pallet (1200 mm x 800 mm, safe working load up to 1,500 kg), Industry pallet (1200 mm x 1000 mm)…

3. PalletStacking – Pallet Optimization Software

Domain: palletstacking.com

Registered: 2008 (17 years)

Introduction: PalletStacking is a pallet optimization software designed for cargo transport optimization, freight optimization, pallet loading, packaging, and shipping strategy. Key features include:

– Optimize pallets and freight for cost reductions

– Evaluate mixed pallet and freight optimization

– Create shipping strategies for full packaging orders

– Calculate the best box arrangement

– Determine the b…

4. Onpallet – Free Online Pallet Calculator

Domain: onpallet.com

Registered: 2009 (16 years)

Introduction: Onpallet.com offers a free online pallet calculator that computes and optimizes pallet loads. Users can enter package dimensions (width, length, height) and weight in kg/lbs, as well as select from various pallet types including Europallet (1200 x 800 mm), Industrie (1200 x 1000 mm), Halfpallet (800 x 600 mm), Australian (1160 x 1160 mm), and custom options. The tool has served 18,898,689 pallets …

5. Gilmore Kramer – Pallet Stacking Frames

Domain: gilmorekramer.com

Registered: 2001 (24 years)

Introduction: Pallet Stacking Frames, Stacking Racks

– Converts ordinary warehouse pallets into racks

– Requires little storage space when not in use

– Stabilizes unsecured loads

– Supports thousands of pounds

– Standard color: BLUE

– Frames snap on pallets for easy assembly

Pricing Model:

– T484048L: 48″x40″, 48″ height, 52 lbs, $428.63

– T484060L: 48″x40″, 60″ height, 59 lbs, $458.27

– T484848L: 48″x48″, 48″…

6. CertifyMe – OSHA-Compliant Online Training

Domain: certifyme.net

Registered: 1999 (26 years)

Introduction: CertifyMe offers comprehensive online training programs covering pallet handling, forklift operation, and warehouse safety. The courses are OSHA-compliant, providing businesses with efficient training to prevent accidents and maintain a safe environment. Key features include 24/7 online access, instant certification, and free three-year renewals. The training can be completed in an hour or less, a…

7. Robopac USA – Advanced Palletizing Systems

Domain: robopacusa.com

Registered: 2017 (8 years)

Introduction: Robopac USA provides advanced palletizing and stretch wrapping systems that include features such as concurrent wrapping, end-of-line automation, and top-tier safety standards. Their systems optimize logistics by ensuring stability and efficiency in pallet stacking, addressing common misconceptions about pallet handling.

Strategic Sourcing Conclusion and Outlook for pallet stack

In the rapidly evolving landscape of logistics and supply chain management, strategic sourcing of pallet stacks is more critical than ever. By understanding the benefits of various pallet materials—such as the durability and hygiene advantages of plastic over wood—international B2B buyers can make informed decisions that enhance operational efficiency and reduce long-term costs. Furthermore, utilizing tools like 3D pallet calculators can optimize load configurations, ensuring that products are transported safely and effectively, minimizing waste and maximizing storage space.

Illustrative image related to pallet stack

For businesses operating in diverse markets across Africa, South America, the Middle East, and Europe, embracing innovative sourcing strategies will not only improve supply chain resilience but also foster sustainable practices. As global trade continues to expand, investing in high-quality pallet solutions will be key to maintaining competitive advantage.

Looking ahead, now is the opportune moment for B2B buyers to reevaluate their sourcing strategies and partnerships. Engage with suppliers who prioritize quality, sustainability, and advanced technology to future-proof your logistics operations. Take action today to ensure that your business is not just keeping pace but leading the way in efficient pallet management.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pallet stack

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.