A B2B Buyer’s Guide to Conveyor Table: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for conveyor table

In an increasingly interconnected world, sourcing the right conveyor table can present significant challenges for businesses striving to optimize their material handling processes. Whether you’re managing a warehouse in Nigeria, a manufacturing facility in Saudi Arabia, or a distribution center in Europe, selecting the appropriate conveyor system is crucial for enhancing operational efficiency and reducing downtime. This guide aims to navigate the complexities of the global conveyor table market, equipping international B2B buyers with the knowledge needed to make informed purchasing decisions.

Throughout this comprehensive resource, you will explore various types of conveyor tables, including gravity roller, powered, and flexible systems, along with their specific applications across industries such as food processing, manufacturing, and logistics. We delve into essential considerations for supplier vetting, ensuring that you choose reputable vendors who meet quality standards and provide reliable support. Additionally, we analyze cost factors, helping you understand pricing structures and potential savings from both new and used equipment.

By empowering you with actionable insights and expert recommendations, this guide will facilitate your journey towards finding the ideal conveyor table solution tailored to your unique operational needs. Whether you are in Africa, South America, the Middle East, or Europe, the knowledge gained here will enable you to enhance productivity and streamline your material handling processes effectively.

Understanding conveyor table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Roller Conveyor | Uses gravity for product movement; adjustable height options | Package sorting, assembly lines, truck unloading | Pros: Cost-effective, easy to install. Cons: Limited to flat surfaces, slower than powered options. |

| Power Roller Conveyor | Motorized system for consistent product movement | Heavy-duty applications, manufacturing processes | Pros: Suitable for heavy loads, faster operation. Cons: Higher initial investment, requires electrical setup. |

| Flexible Conveyor | Easily adjustable length and configuration for variable layouts | Warehousing, temporary setups, trade shows | Pros: Versatile, quick to set up. Cons: May lack stability under heavy loads. |

| Accumulation Conveyor | Designed to hold products in place, allowing for pauses in movement | Order fulfillment, packaging lines | Pros: Prevents product damage, improves efficiency. Cons: More complex, higher maintenance. |

| Stainless Steel Conveyor | Durable construction, ideal for hygiene-sensitive environments | Food processing, pharmaceutical industries | Pros: Easy to clean, resistant to corrosion. Cons: Higher cost, may not be necessary for all applications. |

What Are the Key Characteristics of Gravity Roller Conveyors?

Gravity roller conveyors are a staple in material handling, relying on gravity to facilitate the movement of products. Typically adjustable in height, they are easy to install and configure, making them ideal for applications like package sorting and assembly lines. Buyers should consider the surface conditions since these conveyors are only effective on flat surfaces. While they are cost-effective and require minimal maintenance, their speed is limited compared to powered options.

How Do Power Roller Conveyors Enhance Efficiency in Heavy-Duty Applications?

Power roller conveyors are motorized systems that provide consistent and reliable product movement, making them suitable for heavy-duty applications such as manufacturing processes. They can handle larger loads and longer distances, improving operational efficiency. However, buyers must account for the higher initial investment and the need for electrical setup. These conveyors are designed for durability and can significantly reduce labor costs in environments where heavy items are frequently moved.

What Advantages Do Flexible Conveyors Offer for Dynamic Layouts?

Flexible conveyors are designed for adaptability, allowing businesses to modify their layout quickly in response to changing operational needs. This type of conveyor can be easily adjusted in length and configuration, making it ideal for warehousing and temporary setups like trade shows. Although they offer versatility, buyers should be cautious about their stability under heavy loads, as this can limit their effectiveness in certain applications.

Why Choose Accumulation Conveyors for Order Fulfillment?

Accumulation conveyors are engineered to hold products in place, facilitating pauses in movement that are essential in order fulfillment and packaging lines. This feature helps prevent product damage and enhances overall efficiency by allowing for better organization. However, the complexity of these systems can lead to higher maintenance costs. Buyers should evaluate their specific operational needs to determine if the benefits outweigh the potential drawbacks.

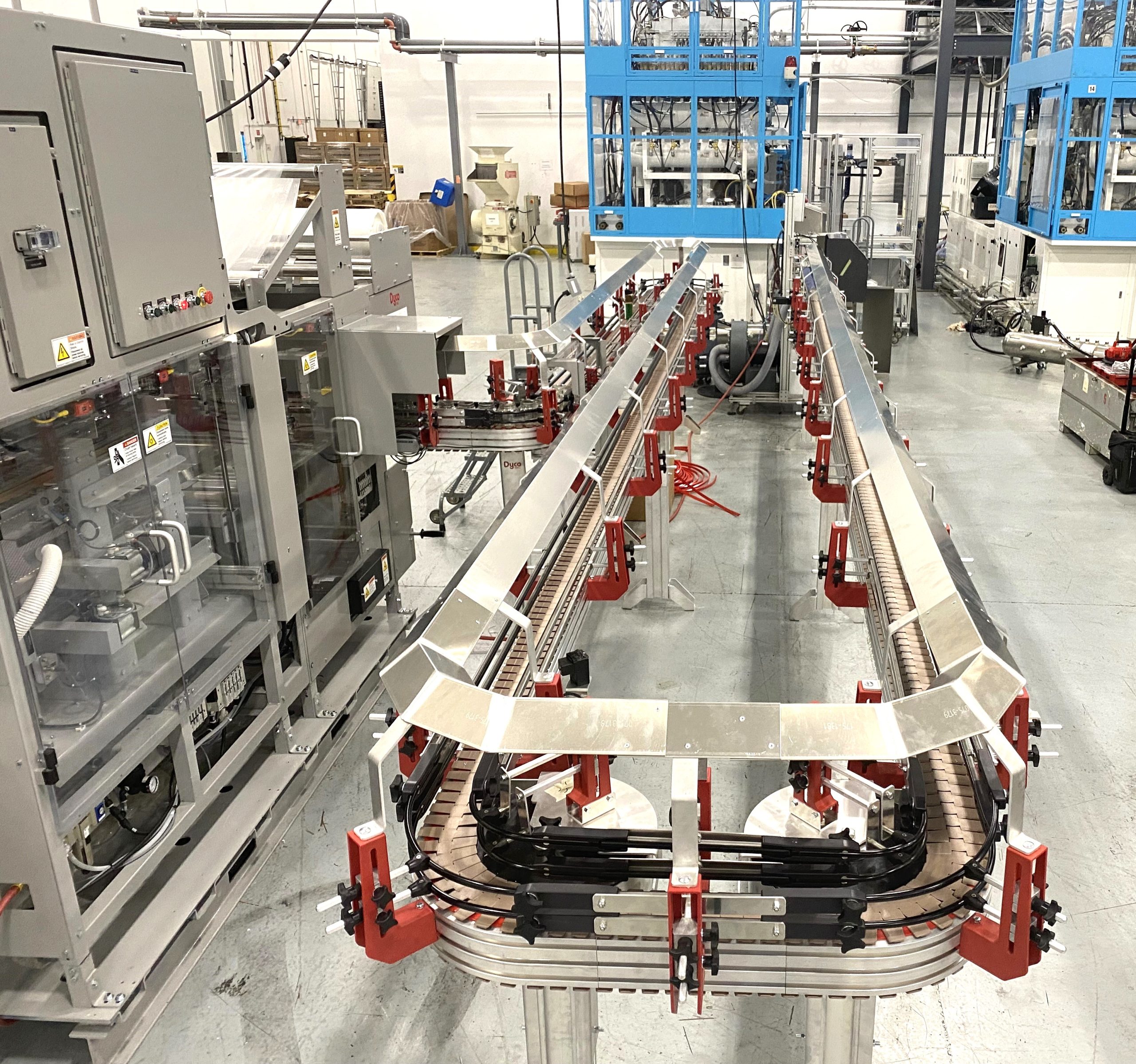

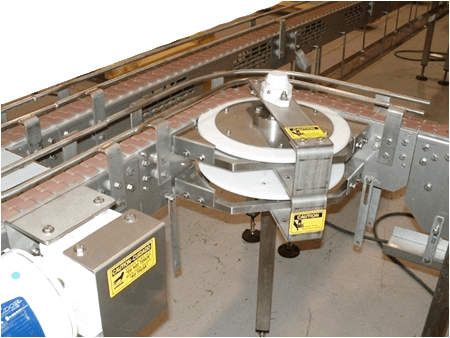

Illustrative image related to conveyor table

What Makes Stainless Steel Conveyors Ideal for Hygienic Applications?

Stainless steel conveyors are particularly valuable in industries where hygiene is paramount, such as food processing and pharmaceuticals. Their durable construction resists corrosion and is easy to clean, ensuring compliance with stringent sanitation regulations. While these conveyors come with a higher price tag, their longevity and reliability often justify the investment. Buyers in hygiene-sensitive sectors should prioritize stainless steel options to maintain high standards of cleanliness and safety.

Key Industrial Applications of conveyor table

| Industry/Sector | Specific Application of conveyor table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Sorting and packaging of food products | Enhances efficiency, reduces manual handling, and ensures hygiene | Compliance with food safety regulations, material durability |

| Pharmaceutical | Transporting and accumulating pharmaceutical products | Increases productivity and minimizes contamination risk | Need for sanitation, adjustable speed settings, and reliability |

| Manufacturing | Assembly line for parts and machinery | Streamlines production processes and improves workflow | Load capacity, customization options, and integration capabilities |

| E-commerce | Sorting and dispatching packages | Accelerates order fulfillment and improves accuracy | Flexibility in design, space optimization, and scalability |

| Construction Materials | Movement of heavy materials and tools | Reduces labor costs and enhances safety on job sites | Robust construction, load specifications, and mobility features |

How Are Conveyor Tables Used in the Food and Beverage Sector?

In the food and beverage industry, conveyor tables are essential for sorting, packaging, and transporting products. They facilitate the smooth movement of items through various stages of processing, ensuring that products are handled efficiently and hygienically. B2B buyers in this sector should prioritize materials that comply with food safety regulations, such as stainless steel or food-grade plastics, to maintain hygiene standards. Additionally, adjustable height features can enhance ergonomic handling for workers, reducing the risk of injuries.

What Role Do Conveyor Tables Play in the Pharmaceutical Industry?

Conveyor tables in the pharmaceutical sector are primarily used for the transportation and accumulation of sensitive products, such as tablets and vials. These systems help streamline production while minimizing contamination risks associated with manual handling. International buyers should consider sourcing conveyor tables that offer easy cleaning features and adjustable speed settings to accommodate different production rates. Reliability is also crucial, as any downtime can significantly impact production schedules and regulatory compliance.

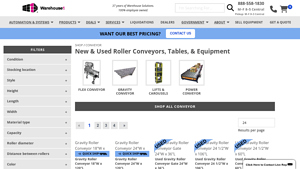

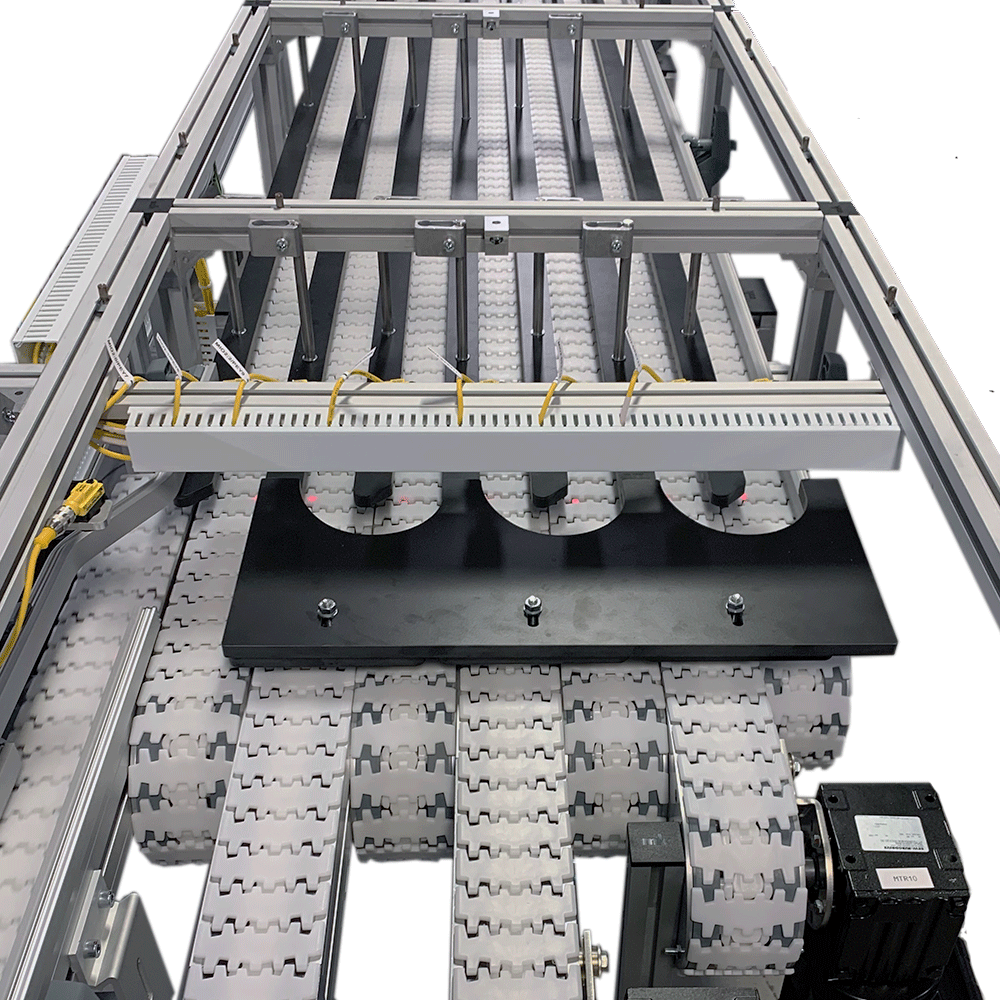

Illustrative image related to conveyor table

How Are Conveyor Tables Beneficial in Manufacturing?

In manufacturing settings, conveyor tables are utilized on assembly lines to move parts and machinery efficiently. They play a critical role in streamlining production processes, reducing manual labor, and ensuring that materials are positioned correctly for assembly. When sourcing conveyor tables for manufacturing, buyers should evaluate load capacity to ensure that the systems can handle the specific weights of components. Customization options may also be necessary to fit unique assembly line layouts.

Why Are Conveyor Tables Important for E-commerce Operations?

In the fast-paced world of e-commerce, conveyor tables are integral to sorting and dispatching packages quickly and accurately. They enhance the order fulfillment process by allowing for the efficient movement of goods from storage to shipping areas. B2B buyers in this sector should focus on sourcing flexible conveyor designs that can be easily modified to accommodate changing inventory levels and order volumes. Space optimization and scalability are also critical considerations to ensure that the systems can grow with the business.

What Are the Advantages of Conveyor Tables in Construction Materials Handling?

Conveyor tables are invaluable in the construction sector for moving heavy materials and tools around job sites. By reducing the need for manual lifting, they help minimize labor costs and enhance workplace safety. Buyers looking for conveyor tables for construction should prioritize robust construction materials and features that allow for easy mobility, such as heavy-duty wheels or adjustable heights. Load specifications are crucial to ensure that the conveyor can handle the weight and type of materials being transported.

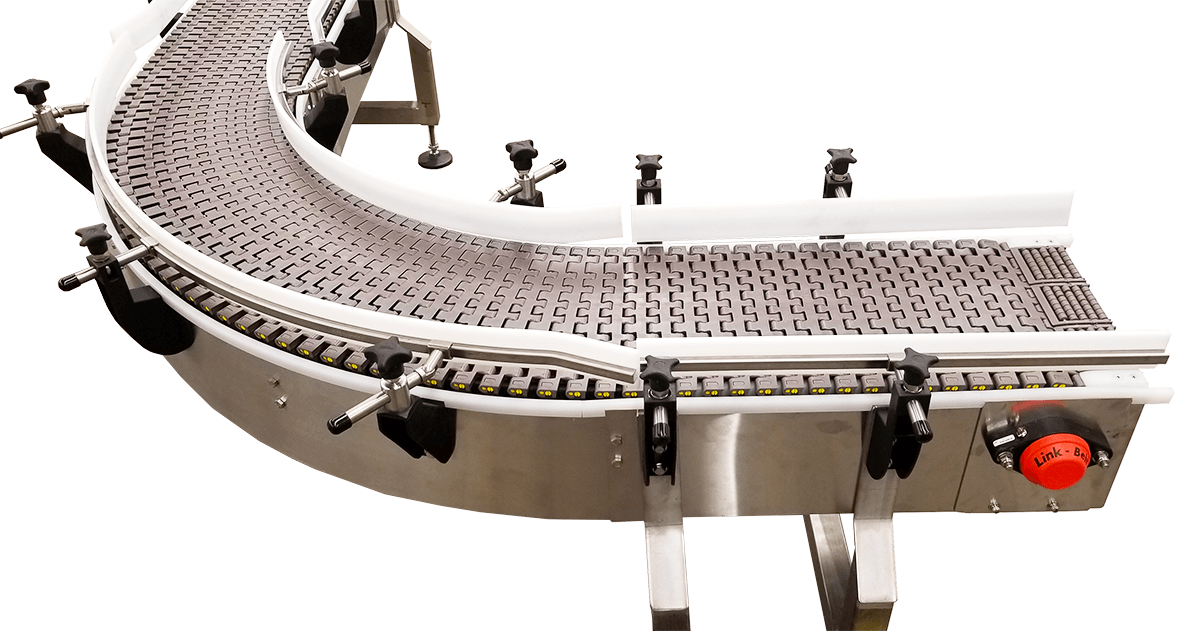

Illustrative image related to conveyor table

3 Common User Pain Points for ‘conveyor table’ & Their Solutions

Scenario 1: Inconsistent Load Handling Affects Productivity

The Problem: A common challenge faced by B2B buyers, particularly in manufacturing and warehousing sectors, is the inconsistent handling of loads on conveyor tables. This issue often arises when the specifications of the conveyor table do not match the types of products being moved. For example, if a conveyor table is designed for lighter items but is used to transport heavier products, it can lead to frequent jams, breakdowns, or even equipment failure. This not only hampers productivity but can also lead to costly downtime and increased maintenance expenses.

The Solution: To address this pain point, it’s crucial to conduct a thorough assessment of the products being transported before selecting a conveyor table. Buyers should evaluate the weight, dimensions, and fragility of the items. Choosing a conveyor table with adjustable height and load capacity features allows for flexibility in operations. Additionally, investing in a conveyor table with heavy-duty rollers or a motorized system can enhance performance. Consulting with suppliers who provide detailed specifications and load ratings can also help ensure that the chosen conveyor table is appropriate for the intended application, thus optimizing workflow and reducing the risk of operational disruptions.

Scenario 2: Limited Space for Conveyor Installation

The Problem: In many facilities, space constraints pose significant challenges when integrating conveyor tables into existing layouts. Buyers often find themselves in a situation where the designated area for installation is too small to accommodate standard conveyor systems, limiting their options and potentially leading to inefficient material handling processes. This can lead to delays in production and increased labor costs as workers struggle to navigate cramped spaces.

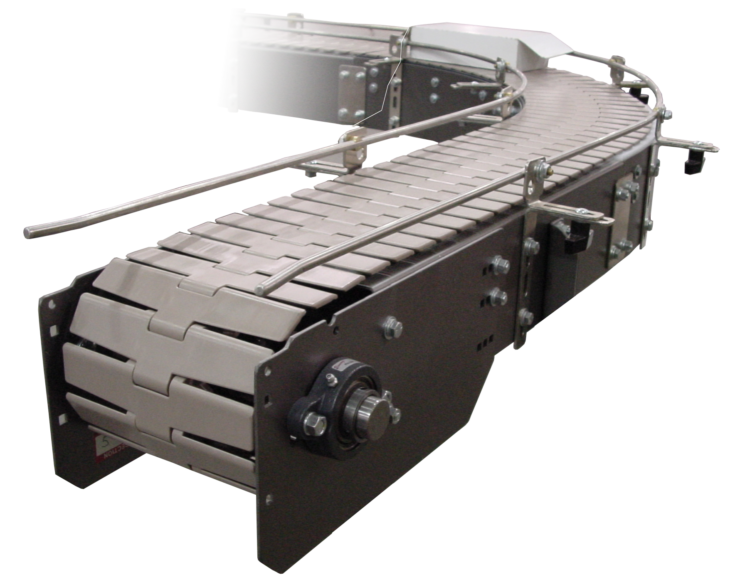

Illustrative image related to conveyor table

The Solution: To effectively tackle this issue, buyers should consider modular and flexible conveyor solutions that can be easily adjusted to fit specific spatial requirements. Investing in expandable conveyor tables that can be reconfigured as needed allows for greater versatility. Suppliers often offer customized solutions, so engaging with manufacturers who specialize in tailored conveyor systems can yield innovative designs that maximize available space. Additionally, leveraging vertical space through multi-level conveyor systems can help alleviate horizontal space limitations. It’s essential to involve layout planning early in the procurement process to ensure that the chosen conveyor table seamlessly integrates with existing operations.

Scenario 3: High Maintenance Costs and Equipment Lifespan

The Problem: Many B2B buyers experience rising maintenance costs associated with conveyor tables, particularly when they opt for lower-quality equipment to save on initial investments. Frequent breakdowns and repairs not only drain financial resources but also disrupt production schedules, leading to longer lead times and dissatisfied customers. Buyers may realize too late that choosing a conveyor table based solely on price, rather than quality, is a false economy.

The Solution: To mitigate maintenance costs and extend the lifespan of conveyor tables, it’s vital for buyers to prioritize quality over price. Investing in high-quality materials such as stainless steel or heavy-duty plastic can significantly reduce wear and tear. Additionally, regular maintenance schedules should be established, including inspections and timely replacements of worn-out components. Buyers should also consider investing in automated monitoring systems that can predict equipment failures before they occur, allowing for proactive maintenance. Engaging with reputable suppliers who provide warranties and customer support can further ensure that any issues are promptly addressed, ultimately leading to improved reliability and reduced total cost of ownership.

Strategic Material Selection Guide for conveyor table

What Are the Key Materials Used in Conveyor Tables?

When selecting materials for conveyor tables, it’s essential to consider their properties, advantages, and limitations in relation to specific applications. This analysis focuses on four common materials: steel, aluminum, stainless steel, and plastic. Each material has unique characteristics that can impact performance, durability, and cost-effectiveness, particularly for international B2B buyers.

How Does Steel Perform as a Material for Conveyor Tables?

Steel is a traditional choice for conveyor tables due to its strength and durability. It can handle heavy loads and is suitable for high-pressure applications. Steel conveyor tables can be treated for corrosion resistance, making them versatile for various environments. However, they may require additional coatings or treatments to prevent rust, especially in humid or corrosive settings.

Pros: High load capacity, cost-effective for heavy-duty applications, and readily available.

Cons: Heavier than other materials, potential for rusting without proper treatment, and more complex manufacturing processes.

For international buyers, compliance with standards such as ASTM for structural steel is crucial. In regions with high humidity, like parts of Africa and the Middle East, corrosion-resistant treatments are essential to ensure longevity.

Illustrative image related to conveyor table

What Advantages Does Aluminum Offer for Conveyor Tables?

Aluminum is known for its lightweight properties, making it easy to install and adjust. It is resistant to corrosion and typically requires little maintenance, which is advantageous in various industries, including food and beverage. Aluminum conveyor tables can also be anodized for additional protection and aesthetic appeal.

Pros: Lightweight, corrosion-resistant, and easy to work with.

Cons: Lower load capacity compared to steel, higher cost per unit, and less suitable for heavy-duty applications.

For buyers in Europe and South America, adherence to European Union regulations regarding material safety and environmental impact can influence purchasing decisions. Aluminum’s recyclability also aligns with sustainability goals in these markets.

Why Choose Stainless Steel for Conveyor Tables?

Stainless steel is the go-to material for applications requiring high sanitation standards, such as food processing and pharmaceuticals. It is highly resistant to corrosion, heat, and staining, making it ideal for environments where hygiene is paramount. Stainless steel conveyor tables can withstand rigorous cleaning processes without degrading.

Illustrative image related to conveyor table

Pros: Excellent corrosion resistance, high durability, and compliance with food safety standards.

Cons: Higher initial cost and potential for scratching, which can harbor bacteria if not maintained properly.

International buyers must consider compliance with standards such as FDA regulations in the U.S. or EU food safety regulations. In regions like Saudi Arabia, where strict hygiene standards are enforced, stainless steel is often the preferred choice.

When Is Plastic the Right Choice for Conveyor Tables?

Plastic conveyor tables are increasingly popular for lightweight applications, particularly in industries like packaging and assembly. They are resistant to chemicals and moisture, making them suitable for various environments. Additionally, plastic can be molded into complex shapes, allowing for customized solutions.

Pros: Lightweight, resistant to chemicals, and customizable.

Cons: Lower load capacity and potential for wear over time, especially in high-friction applications.

For international buyers, it’s important to ensure that the plastic used complies with local regulations regarding material safety and environmental impact. In regions like Africa and South America, where cost sensitivity is higher, plastic may offer a more economical solution for certain applications.

Illustrative image related to conveyor table

Summary Table of Material Selection for Conveyor Tables

| Material | Typical Use Case for conveyor table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty material handling | High load capacity | Potential for rust without treatment | Medium |

| Aluminum | Lightweight assembly lines | Corrosion-resistant | Lower load capacity | High |

| Stainless Steel | Food processing and pharmaceuticals | Excellent hygiene compliance | Higher initial cost | High |

| Plastic | Packaging and light assembly | Lightweight and customizable | Lower load capacity | Low |

This strategic material selection guide provides key insights for B2B buyers, helping them make informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor table

What Are the Key Manufacturing Processes for Conveyor Tables?

The manufacturing of conveyor tables involves several critical stages, each designed to ensure the final product meets industry standards and customer specifications. Understanding these processes can help B2B buyers make informed purchasing decisions and assess potential suppliers effectively.

How Are Materials Prepared for Conveyor Table Manufacturing?

The initial stage in manufacturing conveyor tables is material preparation. Common materials used include steel, aluminum, and sometimes plastic, depending on the application. The selection of materials is crucial as it influences the durability, weight, and overall performance of the conveyor.

Illustrative image related to conveyor table

Materials undergo quality inspections upon arrival, where suppliers check for compliance with specifications. Additionally, materials may be treated or coated to enhance corrosion resistance and improve longevity, especially for applications in harsh environments like food processing or chemical handling.

What Forming Techniques Are Used in Conveyor Table Production?

Once materials are prepared, they move to the forming stage. This phase typically includes processes such as cutting, bending, and welding. For example, steel sheets may be cut into specific dimensions using laser cutting or plasma cutting technologies.

Bending processes often utilize CNC machines to achieve precise angles and shapes, ensuring that all components fit together seamlessly. Welding is critical in assembling the frame and structure of the conveyor table. Techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding are commonly employed, providing strong, durable joints that can withstand the stresses of operation.

Illustrative image related to conveyor table

How Is the Assembly Process Conducted for Conveyor Tables?

The assembly of conveyor tables involves integrating various components, including rollers, belts, motors, and structural frames. This stage often utilizes automated assembly lines to enhance efficiency and maintain consistency.

During assembly, quality assurance measures are implemented to verify that each component meets design specifications. For instance, the alignment of rollers is crucial to ensure smooth operation and prevent jams. Adjustable features, such as height or angle, are also tested to confirm they function correctly.

What Finishing Techniques Are Applied to Conveyor Tables?

After assembly, conveyor tables undergo finishing processes, which may include painting, powder coating, or polishing. These finishes not only enhance aesthetic appeal but also provide protective coatings that improve resistance to wear and corrosion.

Surface treatments, such as galvanization or anodizing, may be applied to enhance durability, particularly for conveyor tables used in environments with high humidity or exposure to chemicals. Quality control checks during this stage ensure that finishes are applied uniformly and meet the specified requirements.

How Is Quality Assurance Implemented in Conveyor Table Manufacturing?

Quality assurance is paramount in conveyor table manufacturing to ensure that products are reliable and safe for use. Various international and industry-specific standards guide these practices, enabling B2B buyers to assess the quality of potential suppliers.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a key international standard that outlines requirements for quality management systems. Suppliers adhering to ISO 9001 demonstrate their commitment to quality, customer satisfaction, and continuous improvement.

Illustrative image related to conveyor table

Additionally, CE marking is essential for products sold in the European market, indicating conformity with health, safety, and environmental protection standards. For industries such as oil and gas, API (American Petroleum Institute) certifications may also be relevant, ensuring that equipment meets industry-specific performance and safety requirements.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and ensure product integrity. These include:

- Incoming Quality Control (IQC): This phase inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify issues as they arise, such as dimensional inaccuracies or weld defects.

- Final Quality Control (FQC): Before shipment, a thorough inspection is conducted to verify that the finished product meets all specifications and quality standards.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to verify the quality and performance of conveyor tables. These may include:

- Load Testing: Ensures the conveyor can handle specified loads without failure.

- Operational Testing: Confirms that all moving parts function correctly and efficiently.

- Corrosion Resistance Testing: Assesses the durability of finishes and materials when exposed to corrosive environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some effective strategies:

What Steps Can Buyers Take to Audit Supplier QC Processes?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and compliance with industry standards. This provides firsthand insight into their operations.

-

Requesting Quality Reports: Buyers should request quality assurance reports that detail testing results, inspection findings, and adherence to relevant standards. These documents can help assess the supplier’s reliability and commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct thorough examinations and testing to ensure compliance with specifications.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of potential nuances in quality control practices across different regions. For instance, varying standards of materials and manufacturing processes can impact product quality. Understanding local regulations and market demands is essential for ensuring compliance and meeting customer expectations.

Furthermore, communication barriers may arise when dealing with suppliers from different cultural backgrounds. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings and ensure that quality requirements are consistently met.

In conclusion, understanding the manufacturing processes and quality assurance measures for conveyor tables equips B2B buyers with the knowledge needed to make informed purchasing decisions. By evaluating suppliers based on their adherence to international standards and robust quality control practices, buyers can ensure they invest in reliable, high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor table’

To facilitate an effective procurement process for conveyor tables, this guide provides a clear and actionable checklist tailored for international B2B buyers. Sourcing the right conveyor table is essential for enhancing operational efficiency and ensuring optimal material handling in your organization.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s critical to outline your specific requirements. This includes dimensions, weight capacity, material type (e.g., stainless steel for food-grade applications), and intended use (e.g., sorting, assembly). Clearly defined specifications will help streamline communications with suppliers and ensure you receive suitable options.

Illustrative image related to conveyor table

Step 2: Assess Your Space and Layout Needs

Understanding your facility’s layout is vital for selecting the appropriate conveyor table. Measure the available space, considering the flow of materials and the configuration of existing equipment. Look for options that offer flexibility, such as adjustable height or modular designs, to accommodate changing operational needs.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. It’s essential to confirm their experience in providing conveyor systems that meet your specifications and to assess their reliability and customer service.

- Check for Industry Certifications: Ensure that suppliers comply with relevant industry standards and certifications, particularly in sectors like food processing or pharmaceuticals where hygiene and safety are paramount.

Step 4: Compare Pricing and Total Cost of Ownership

While initial pricing is important, consider the total cost of ownership, which includes installation, maintenance, and potential downtime. Obtain quotes from multiple suppliers and inquire about warranties, after-sales support, and availability of replacement parts. This comprehensive view will help you understand the long-term value of your investment.

Illustrative image related to conveyor table

Step 5: Request Product Demonstrations or Samples

Whenever possible, request a demonstration or sample of the conveyor table. This allows you to assess the quality, functionality, and ease of use firsthand. Observe how the equipment operates with the types of materials you plan to handle, and evaluate its efficiency and reliability in real-world conditions.

Step 6: Review Delivery and Installation Options

Confirm the supplier’s delivery timelines and installation services. Timely delivery is crucial to minimize disruption in your operations, while professional installation ensures that the conveyor table is set up correctly and safely. Inquire about any additional costs associated with shipping and installation to avoid surprises later.

Step 7: Finalize Payment Terms and Contracts

Before finalizing your purchase, carefully review the payment terms and conditions outlined in the contract. Ensure that you understand the payment schedule, any upfront costs, and the terms for returns or exchanges. Clear contractual agreements will protect your interests and ensure a smooth transaction.

By following this structured checklist, B2B buyers can make informed decisions when sourcing conveyor tables, enhancing their operational efficiency and supporting their material handling needs effectively.

Comprehensive Cost and Pricing Analysis for conveyor table Sourcing

What Are the Key Cost Components for Sourcing Conveyor Tables?

When sourcing conveyor tables, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to conveyor table

-

Materials: The choice of materials significantly impacts the cost. Stainless steel, aluminum, and high-grade plastics tend to be more expensive but offer durability and corrosion resistance. Conversely, lower-cost materials may reduce initial expenses but could lead to higher maintenance costs over time.

-

Labor: Labor costs vary depending on the region and the complexity of the conveyor system. Skilled labor for assembly and installation is often required, which can add to the overall expense.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities and equipment maintenance. Suppliers with more efficient operations may offer better pricing.

-

Tooling: Custom conveyor systems may require specialized tooling, which can increase upfront costs. However, these costs can be offset by improved efficiency and productivity in the long run.

-

Quality Control (QC): Investing in QC ensures that the conveyor tables meet industry standards, reducing the risk of defects. This may add to the cost but is essential for maintaining operational efficiency.

-

Logistics: Shipping and handling costs can vary significantly based on the distance, mode of transport, and weight of the equipment. International buyers must factor in customs duties and taxes as well.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins in your specific market can help in negotiating better prices.

How Do Price Influencers Affect Conveyor Table Sourcing?

Several factors influence the pricing of conveyor tables, making it essential for buyers to consider these when sourcing:

-

Volume/MOQ: Larger orders often qualify for discounts. Understanding the minimum order quantity (MOQ) can help in negotiating better rates.

-

Specifications and Customization: Custom designs or additional features (like adjustable heights) can increase costs. Buyers should assess whether these enhancements align with their operational needs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or CE) can increase prices. Buyers must weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record but can offer better service and support.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) play a significant role in total costs. Understanding these terms is critical for international transactions to avoid unexpected charges.

What Are the Best Buyer Tips for Sourcing Conveyor Tables Internationally?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, certain strategies can enhance cost-efficiency:

-

Negotiate Wisely: Use your understanding of cost components and price influencers to negotiate effectively. Suppliers may be willing to lower prices, especially for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, potential downtime, and energy consumption to determine the true cost over the product’s lifecycle.

-

Understand Pricing Nuances: Be aware of regional pricing variations due to local demand, competition, and currency fluctuations. This knowledge can empower better negotiation strategies.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and service. Suppliers are often more willing to accommodate loyal customers.

-

Consider Local Suppliers: Local manufacturers may offer competitive pricing without the added logistics costs of importing. This can be a viable option for buyers looking to minimize expenses.

Disclaimer on Indicative Prices

Prices for conveyor tables can vary widely based on the above factors. The indicative prices provided by suppliers should be viewed as starting points for negotiation rather than fixed costs. Always request detailed quotes and consider the total cost implications before making a decision.

Alternatives Analysis: Comparing conveyor table With Other Solutions

When considering the implementation of material handling solutions, businesses often seek alternatives to traditional conveyor tables. Understanding the various options available can aid in making informed decisions that align with operational needs and budget constraints. This analysis compares conveyor tables with two viable alternatives: powered belt conveyors and gravity roller conveyors, providing insights into their respective advantages and disadvantages.

Illustrative image related to conveyor table

| Comparison Aspect | Conveyor Table | Powered Belt Conveyor | Gravity Roller Conveyor |

|---|---|---|---|

| Performance | Efficient for steady product flow, ideal for assembly lines. | High flexibility; can handle various product types and sizes. | Best for light to medium loads; relies on gravity for movement. |

| Cost | Moderate upfront cost, with potential for savings in bulk orders. | Higher initial investment due to motor and controls. | Generally lower cost; used options available that can save 30-50%. |

| Ease of Implementation | Requires minimal setup; can be integrated into existing systems easily. | Installation may be complex due to electrical requirements. | Simple to install and adjust, especially in temporary setups. |

| Maintenance | Low maintenance; occasional cleaning and inspection needed. | Requires regular maintenance of motors and belts. | Very low maintenance; minimal moving parts reduce wear. |

| Best Use Case | Ideal for controlled environments where products require stable handling. | Excellent for diverse applications including packaging and sorting. | Best for assembly and loading areas where gravity can be utilized. |

What Are the Advantages and Disadvantages of Powered Belt Conveyors?

Powered belt conveyors are a robust alternative to conveyor tables, offering greater flexibility in handling a variety of products, including those with irregular shapes. They are particularly effective in high-speed operations and can easily transport heavier loads over longer distances. However, their higher initial investment and ongoing maintenance costs due to motorized components can be a drawback for some businesses. Moreover, they require a reliable power source and regular inspections to ensure optimal performance.

How Do Gravity Roller Conveyors Compare?

Gravity roller conveyors provide a cost-effective solution for transporting items without the need for powered systems. They are particularly useful in environments where items can be moved by gravity, such as sloped surfaces. The simplicity of their design means they are easy to set up and modify, making them ideal for temporary or flexible layouts. However, their effectiveness is limited to lighter loads, and they may not be suitable for all product types, especially those that are unstable or require specific handling.

Making the Right Choice for Your Business Needs

Choosing the right material handling solution requires careful consideration of various factors, including the specific requirements of your operations, budget constraints, and the types of products you handle. Conveyor tables are well-suited for steady, controlled environments, while powered belt conveyors offer versatility for diverse applications. On the other hand, gravity roller conveyors can be a cost-effective option for lighter loads. By evaluating the performance, cost, ease of implementation, and maintenance needs of each option, B2B buyers can select the solution that best aligns with their operational goals and enhances overall efficiency.

Illustrative image related to conveyor table

Essential Technical Properties and Trade Terminology for conveyor table

What Are the Key Technical Properties of Conveyor Tables?

When considering conveyor tables for material handling and logistics, understanding their technical specifications is crucial. Here are some essential properties to evaluate:

1. Material Grade

The material grade of a conveyor table significantly impacts its durability and suitability for specific applications. Common materials include stainless steel, aluminum, and carbon steel. Stainless steel is preferred for environments requiring high sanitation, like food processing, while aluminum is lightweight and corrosion-resistant, ideal for less demanding applications. Understanding the material grade helps buyers ensure the conveyor meets industry standards and operational needs.

2. Load Capacity

Load capacity refers to the maximum weight a conveyor table can safely handle. This specification is critical for B2B buyers as it dictates the types of products that can be moved without risking damage or failure. Typically, load capacities can range from a few hundred pounds for light-duty models to several thousand pounds for heavy-duty systems. Selecting a conveyor with the appropriate load capacity ensures efficiency and safety in operations.

Illustrative image related to conveyor table

3. Roller Diameter

The diameter of the rollers on a conveyor table affects its performance and load-bearing capabilities. Standard roller diameters range from 1.375 inches to 1.9 inches. Larger rollers can typically support heavier loads and reduce friction, leading to smoother operation. B2B buyers should consider roller diameter when assessing the conveyor’s suitability for their specific materials and operational requirements.

4. Conveyor Width

Conveyor width is determined by the size of the items being transported. A typical recommendation is to allow a 2-3 inch overhang on either side of the product for stability during transport. Choosing the right width is essential for preventing product jams and ensuring smooth operation, which can significantly affect productivity.

5. Speed Control

Many powered conveyor tables offer adjustable speed settings, allowing for greater flexibility in handling various products. Speed control is vital in applications requiring precise timing, such as assembly lines or packaging processes. Buyers should evaluate the need for speed adjustments based on their operational workflows.

Illustrative image related to conveyor table

What Are Common Trade Terms Related to Conveyor Tables?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s product. Understanding OEM relationships is vital for B2B buyers as it can affect product quality, warranty, and service options. Partnering with reputable OEMs can ensure higher reliability in conveyor systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. This term is critical for businesses looking to manage inventory costs and optimize purchasing strategies. Understanding MOQ can help buyers negotiate better terms and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price proposals from suppliers for specific products or services. Submitting an RFQ can streamline the purchasing process, allowing companies to compare offers and choose the best supplier based on price, quality, and delivery terms.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, ensuring clarity in delivery and payment obligations.

Illustrative image related to conveyor table

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to effectively manage inventory and production schedules. Buyers should always inquire about lead times when negotiating with suppliers to avoid disruptions in operations.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions when selecting conveyor tables, optimizing their material handling processes and overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the conveyor table Sector

What Are the Current Market Dynamics and Key Trends in the Conveyor Table Sector?

The conveyor table sector is witnessing significant transformations driven by globalization, technological advancements, and evolving buyer preferences. As industries increasingly automate operations, the demand for efficient material handling solutions is surging. Key drivers include the rise of e-commerce, which necessitates faster and more efficient logistics systems, and the growing emphasis on automation in manufacturing processes. In regions such as Africa, South America, the Middle East, and Europe, companies are investing in conveyor systems to enhance productivity and reduce labor costs, leading to a robust market outlook.

Emerging trends include the adoption of smart conveyor systems integrated with IoT technology, enabling real-time monitoring and predictive maintenance. This shift towards smart automation facilitates enhanced operational efficiency and minimizes downtime. Additionally, there is a noticeable shift towards modular conveyor systems that offer flexibility and scalability, catering to diverse operational requirements. For international B2B buyers, understanding these trends is crucial for making informed sourcing decisions that align with their operational needs and long-term business goals.

How Is Sustainability Influencing Sourcing Decisions in the Conveyor Table Market?

Sustainability is becoming a pivotal factor in the sourcing of conveyor tables. As environmental concerns rise globally, buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and environmentally friendly practices. The conveyor sector is particularly impacted by initiatives aimed at reducing carbon footprints, with manufacturers exploring sustainable materials and production methods.

The importance of ethical supply chains cannot be overstated, as companies face growing scrutiny from consumers and regulatory bodies. Buyers are encouraged to seek conveyor systems made from recycled or eco-friendly materials, such as aluminum and stainless steel, which not only enhance durability but also reduce environmental impact. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability. By aligning sourcing strategies with sustainability goals, businesses can enhance their market reputation and cater to a growing demographic of eco-conscious consumers.

What Is the Historical Context of Conveyor Tables and Their Evolution in the B2B Sector?

The conveyor table has evolved significantly since its inception in the early 20th century. Initially designed for simple assembly line tasks, these systems have transformed into sophisticated solutions that integrate advanced technology and automation. Early models were primarily manual, requiring significant human labor, but advancements in engineering and materials science have led to the development of automated conveyor systems that enhance efficiency and reduce labor costs.

Over the decades, the introduction of powered conveyors, flexible designs, and smart technology has further revolutionized the sector. Today, conveyor tables are not only vital for manufacturing and logistics but also play a critical role in various industries, including food processing, pharmaceuticals, and packaging. This evolution reflects the changing landscape of industrial operations and highlights the importance of continuous innovation in meeting the demands of modern businesses. Understanding this historical context can help B2B buyers appreciate the capabilities and advancements in current conveyor table offerings, enabling them to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor table

-

How do I select the right conveyor table for my specific needs?

Selecting the right conveyor table involves assessing your material handling requirements, including the type of products being transported, weight, and dimensions. Consider factors such as the speed of operation, the layout of your workspace, and whether you need a powered or gravity system. Consulting with suppliers can provide insights into various models that suit your application, helping you avoid costly mistakes. It’s crucial to communicate your specific operational challenges to ensure the chosen conveyor table enhances productivity and efficiency. -

What are the key features to look for in a conveyor table?

When evaluating conveyor tables, look for features such as adjustable height, load capacity, and ease of integration with existing systems. Durability is essential, so materials like stainless steel or heavy-duty aluminum are preferable for demanding environments. Additionally, consider the design of the rollers or belts, as these can significantly affect the handling of different products. Safety features, such as emergency stop buttons and protective guards, are also important to minimize workplace accidents. -

What are the typical lead times for ordering conveyor tables internationally?

Lead times for international orders of conveyor tables can vary significantly depending on the supplier, customization options, and shipping logistics. Generally, expect a timeframe of 4-12 weeks from order placement to delivery. Factors such as manufacturing location, local regulations, and customs clearance can impact these timelines. It’s advisable to discuss lead times directly with your supplier and factor in any potential delays in your project planning. -

What are the common payment terms for purchasing conveyor tables?

Payment terms can vary widely among suppliers but typically include options such as net 30, net 60, or even upfront payments for custom orders. Some suppliers may accept letters of credit, especially for international transactions, which can offer additional security. It’s essential to clarify the payment structure before finalizing your order and to ensure it aligns with your cash flow capabilities. -

How can I vet suppliers for quality and reliability in conveyor tables?

To vet suppliers, start by checking their industry reputation, client testimonials, and case studies. Request references from previous clients, particularly those in your region or industry. It’s also beneficial to inquire about their manufacturing processes, quality assurance measures, and any certifications they hold. Engaging in direct communication can help gauge their responsiveness and willingness to address your specific needs. -

What customization options are available for conveyor tables?

Most suppliers offer a range of customization options, including size, load capacity, and specific features tailored to your operational needs. Common customizations may involve adjusting the height, adding side rails, or integrating power-driven components. Discussing your requirements with the supplier can lead to tailored solutions that enhance operational efficiency and address unique challenges in your workflow. -

What are the logistics considerations when importing conveyor tables?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Ensure that your supplier is knowledgeable about the logistics involved in international shipping, including handling duties, tariffs, and documentation. Working with freight forwarders can streamline the process, ensuring that your conveyor tables arrive safely and on time. Also, factor in the need for installation and setup once the equipment reaches your facility. -

How do I ensure the quality of the conveyor tables I purchase?

To ensure quality, request detailed specifications and certifications from the supplier, such as ISO standards. Consider asking for samples or visiting the manufacturing facility if feasible. Implementing a rigorous quality assurance process upon delivery, including inspections and testing, can help confirm that the conveyor tables meet your operational standards. Establishing a clear return and warranty policy with the supplier will also provide peace of mind regarding quality assurance.

Top 9 Conveyor Table Manufacturers & Suppliers List

1. WH1 – Conveyor Roller Tables

Domain: wh1.com

Registered: 1997 (28 years)

Introduction: New & Used Conveyor Roller Tables for Sale. Condition: New (74), Used (19). Stocking location: In Stock @ Wh1 in KC (23), Ships from Factory (70). Styles: Ball Transfer (6), Belt (2), Belt Driven (3), Chain Drive (2), Expanding Conveyors (23), Flat Motor (3), Gravity Roller (16), Gravity Skatewheel (6), Lineshaft Drive (3), Motorized Roller (3), Plastic Belt (3). Heights: 2.38″ (2), 3.50″ (6), 29….

2. Technopack Corp – Conveyors

Domain: technopackcorp.com

Registered: 2006 (19 years)

Introduction: Conveyors are essential for material handling across various industries such as food and beverage, building materials, general manufacturing, and parts and machinery manufacturing. The product offerings include Gravity Conveyors, Conveyor Tables, Motorized Conveyors, Accumulation Tables, and Elevators.

3. Wood-Mizer – Belted Sawdust Conveyor

Domain: woodmizer.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”Belted Sawdust Conveyor”,”price”:”$5,850.00″},{“name”:”Idle Roller Table”,”price”:”$1,395.00″},{“name”:”Green Chain”,”price”:”$10,995.00″},{“name”:”Transfer Table”,”price”:”$13,495.00″},{“name”:”Roll Case Conveyor”,”price”:”$12,995.00″},{“name”:”IC-2 Incline Conveyor”,”price”:””},{“name”:”IC-5 Incline Conveyor”,”price”:””},{“name”:”Cross Roller Table”,”price”:”$1,395.00″},{“n…

4. McMaster – Conveyor Tables

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Tables, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Ballymore – Expandable Conveyor 10′ to 60′

Domain: ballymore.com

Registered: 1997 (28 years)

Introduction: Ballymore Expandable Conveyor 10′ to 60′ w/ Steel Rollers, 24″W. 100 lbs per Ft. Price: $8,250.00, Model #: BEXCONV-60

6. Ashland Conveyor – Ball Transfer Tables

Domain: ashlandconveyor.com

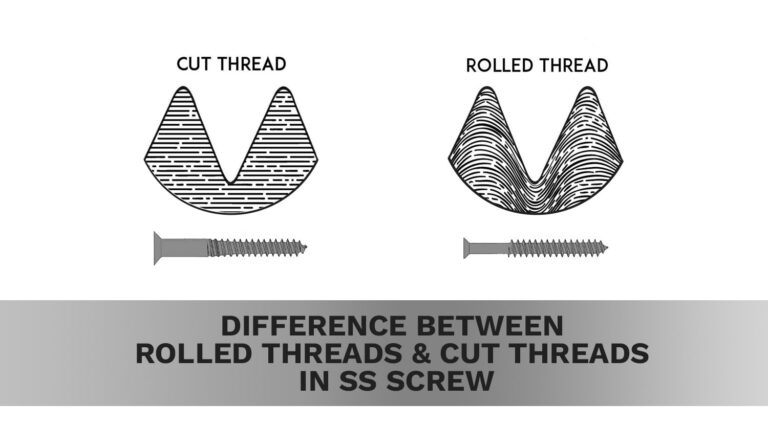

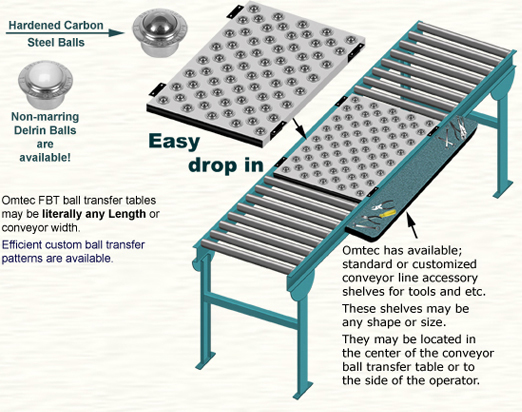

Registered: 1999 (26 years)

Introduction: Ball Transfer Tables consist of ball transfers attached to rigid frames or plates, allowing loads to be conveyed in multiple directions. They are typically used at the end of a conveyor system, packaging, and assembly stations where products need to be rotated or moved in various directions. Ball transfer tables are also utilized at conveyor intersections for horizontal movement of products. Avail…

7. Steel Storage – Heavy-Duty Roller Conveyor Tables

Domain: steelstorage.com

Registered: 1996 (29 years)

Introduction: Heavy-Duty Roller Conveyor Tables: Powered & Idler Conveyors. Modular design for easy shipping, assembly, and rearranging. Available in 10′ or less modular sections. Integrates with metal saw systems, cut-to-length lines, shot blasters, tube mill exit lines, order-filling, and packaging lines. Custom roller sizes, frames, and legs for extreme heavy-duty applications. Standard widths: 22″, 32″, and…

8. Omtec – PBT Ball Transfer Table Conveyor

Domain: omtec.com

Registered: 1997 (28 years)

Introduction: PBT Ball Transfer Table Conveyor Line Workstation designed for production and assembly lines to optimize workflow and reduce manual labor. Features include: 1. Dual Modes: Ball Transfer Mode for easy movement and positioning of items; Stabilized Mode for secure placement during precision tasks. 2. Easy Drop-In Installation: Quick replacement of existing rollers with the Ball Transfer Table. 3. Erg…

9. Cleveland Equipment – Gravity Roller Conveyor Tables

Domain: clevelandequipment.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”24\”W x 5’L Gravity Roller Conveyor Table”,”price”:”$578″,”rating”:”99%”,”reviews”:”7 Reviews”},{“name”:”24\”W x 10’L Gravity Roller Conveyor Table”,”price”:”$893″,”rating”:”98%”,”reviews”:”5 Reviews”},{“name”:”Flexible Conveyor”,”price”:”$1,695″,”rating”:””,”reviews”:””}]}

Strategic Sourcing Conclusion and Outlook for conveyor table

Why is Strategic Sourcing Essential for Conveyor Tables?

In the competitive landscape of material handling, strategic sourcing of conveyor tables is crucial for optimizing operational efficiency and cost-effectiveness. By evaluating both new and used options, international buyers can save significantly—often 30-50%—while ensuring they acquire systems that fit their specific operational needs. Understanding the nuances of different conveyor types—such as gravity, powered, and custom solutions—empowers businesses to enhance productivity and streamline workflows.

Illustrative image related to conveyor table

How Can Businesses Leverage Local and Global Suppliers?

Partnering with reliable suppliers from diverse regions, including Africa, South America, the Middle East, and Europe, allows companies to access innovative conveyor technologies tailored to their industries. Establishing strong relationships with suppliers can lead to favorable terms, reliable support, and access to cutting-edge solutions.

What is the Future Outlook for Conveyor Systems?

As industries continue to evolve, the demand for flexible, efficient conveyor systems will only increase. Investing in high-quality conveyor tables today positions businesses to adapt to future challenges and capitalize on new opportunities. For international B2B buyers, now is the time to assess your material handling needs and connect with suppliers who can provide the best solutions. Embrace the future of logistics and ensure your operations are equipped to meet the demands of tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.