The Definitive Guide to Thermoplastic Moulding: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for thermoplastic moulding

In the ever-evolving landscape of global manufacturing, sourcing high-quality thermoplastic moulding solutions presents a formidable challenge for B2B buyers. With applications spanning automotive, consumer goods, and industrial components, understanding the nuances of thermoplastic injection moulding is essential for making informed purchasing decisions. This comprehensive guide serves as a roadmap, detailing various thermoplastic types, their applications, and the intricacies of the moulding process. It also offers insights into effective supplier vetting, cost considerations, and market trends that are critical for businesses operating in diverse regions, including Africa, South America, the Middle East, and Europe.

As international buyers navigate the complexities of thermoplastic moulding, they face the dual pressures of quality and cost-efficiency. This guide empowers decision-makers with actionable insights, equipping them to identify the right materials and suppliers that align with their specific needs. By demystifying the thermoplastic moulding process and highlighting best practices, we aim to enhance your procurement strategy and streamline your operations. Whether you are a seasoned professional or new to the industry, this resource is designed to facilitate a deeper understanding of thermoplastic moulding, enabling you to harness its potential for your business.

Understanding thermoplastic moulding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermoplastic Injection Molding | High precision, complex geometries, mass production capabilities | Automotive parts, consumer goods, medical devices | Pros: High efficiency, versatility; Cons: Initial tooling costs can be high. |

| Thermoforming | Uses heat to form sheets into shapes, less complex molds | Packaging, disposable cups, trays | Pros: Lower tooling costs; Cons: Limited to simpler shapes. |

| Blow Molding | Forms hollow parts by inflating heated plastic | Bottles, containers, automotive fuel tanks | Pros: Efficient for large volumes; Cons: Less suitable for complex designs. |

| Rotational Molding | Rotates mold to distribute material evenly | Large tanks, playground equipment | Pros: Good for large, hollow parts; Cons: Slower production rates. |

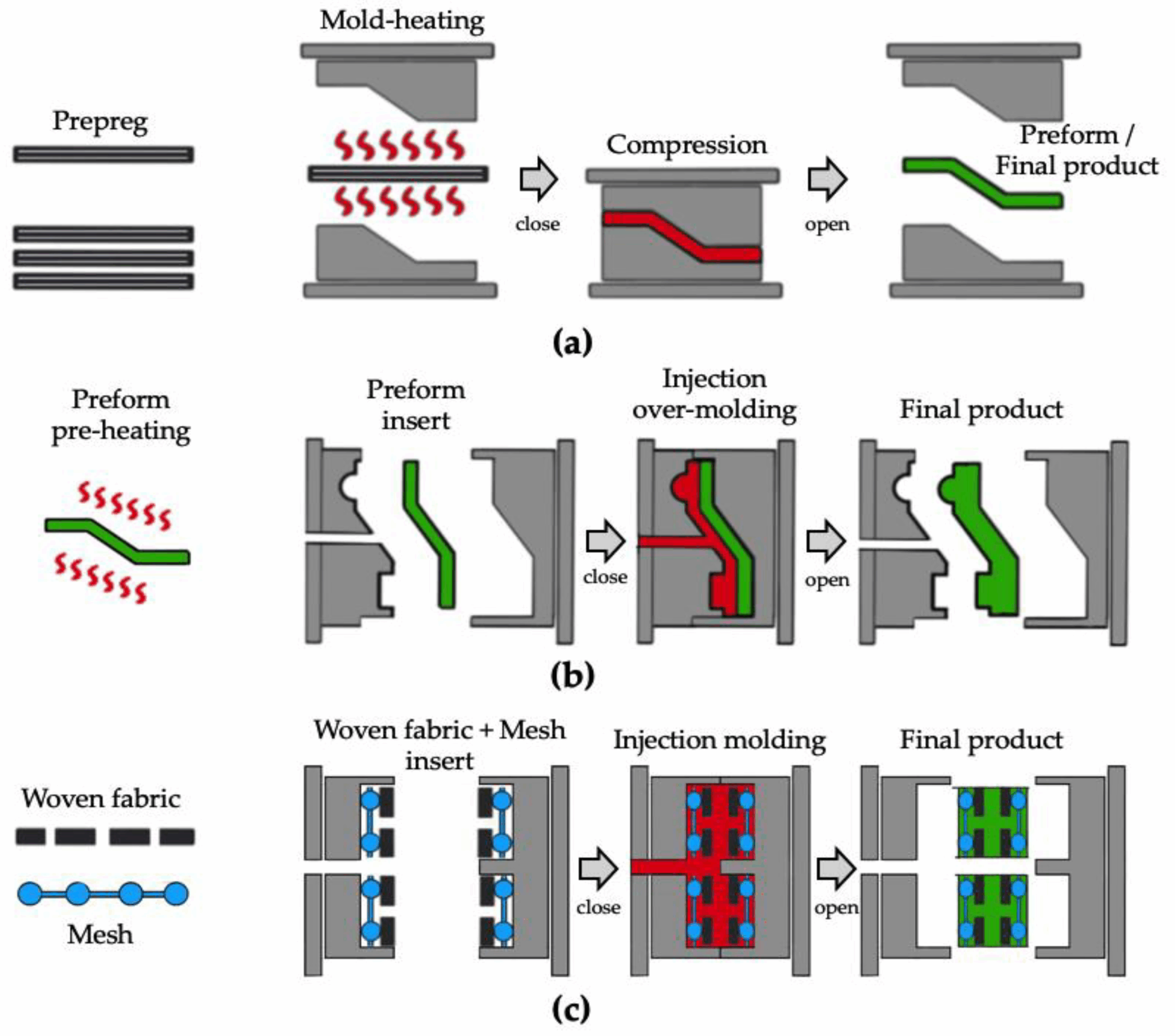

| Compression Molding | Uses heat and pressure to shape materials | Electrical components, automotive parts | Pros: Suitable for high-viscosity materials; Cons: Longer cycle times. |

What are the Characteristics of Thermoplastic Injection Molding?

Thermoplastic injection molding is renowned for its ability to produce high-precision parts with intricate geometries. This method is ideal for mass production, making it a go-to for industries such as automotive, consumer goods, and medical devices. Buyers should consider the initial investment in tooling, which can be significant, but the efficiency and scalability of production often justify these costs. Material selection is crucial as it directly impacts the final product’s performance and compliance with industry standards.

How Does Thermoforming Differ from Other Molding Techniques?

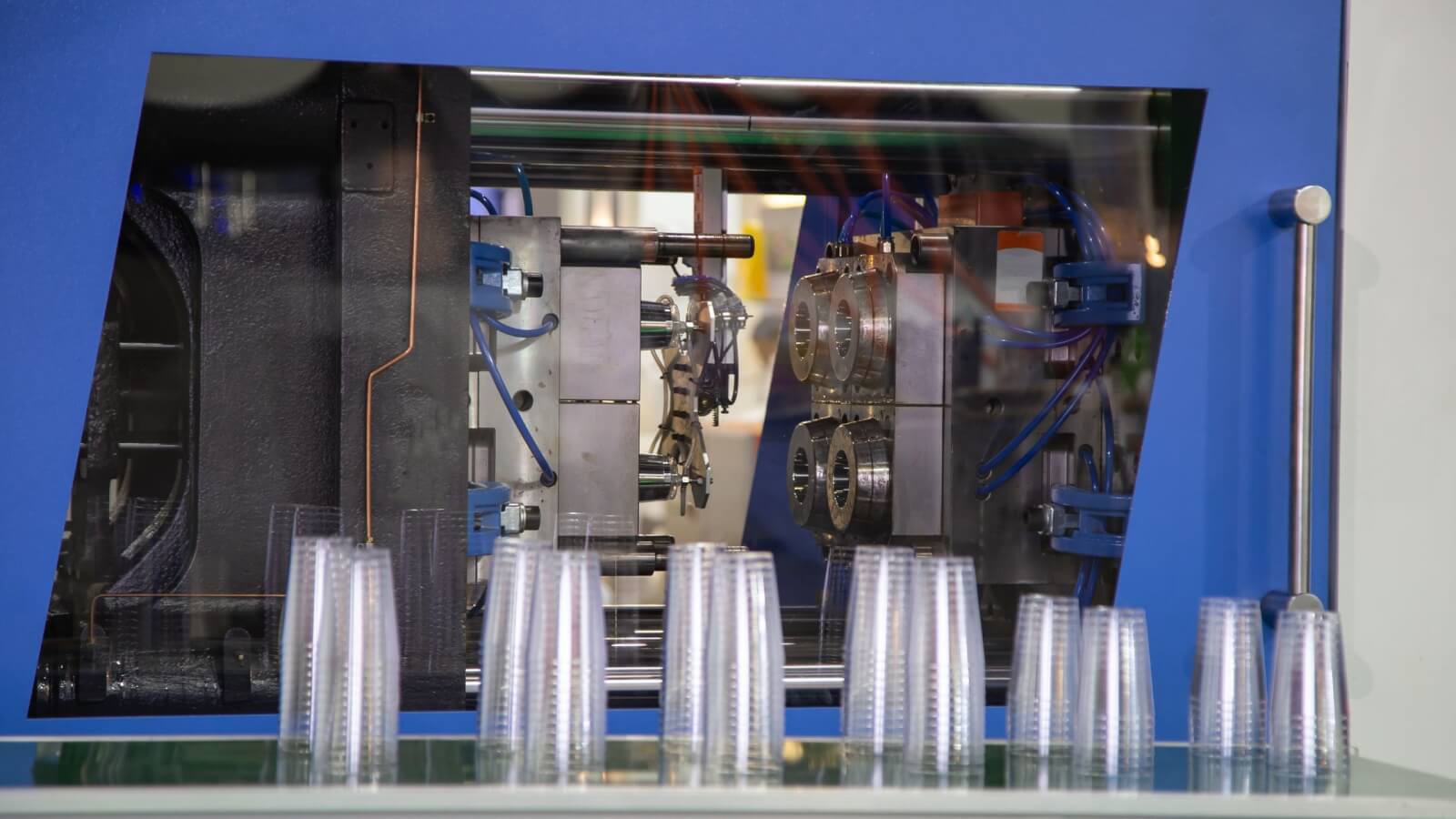

Thermoforming involves heating plastic sheets until pliable and then forming them into shapes using molds. This technique is particularly suited for applications requiring less complexity, such as packaging and disposable items. The tooling costs are generally lower than injection molding, making it an attractive option for businesses looking to prototype or produce smaller runs. However, the limitation lies in its inability to create intricate designs, which could restrict its applicability for certain B2B projects.

What are the Advantages of Blow Molding for B2B Buyers?

Blow molding is the preferred method for producing hollow plastic parts, such as bottles and containers. The process involves inflating heated plastic to shape it against the mold walls, allowing for rapid production of lightweight items. This technique is especially beneficial for high-volume manufacturing, offering cost efficiencies. However, it may not be suitable for parts requiring complex geometries, which could limit its use in specialized applications.

Why Choose Rotational Molding for Large Hollow Parts?

Rotational molding is characterized by its ability to create large, hollow products by rotating a mold filled with plastic material. This method is advantageous for producing items like tanks and playground equipment due to its uniform wall thickness and durability. While the production rate is slower compared to other molding techniques, the flexibility in design and material options makes it a compelling choice for businesses targeting specific markets. Buyers should weigh the trade-off between production speed and part size when considering this method.

What is the Role of Compression Molding in Manufacturing?

Compression molding is a process where plastic is heated and then compressed into molds under pressure. This technique is particularly effective for high-viscosity thermoplastics and is commonly used for manufacturing electrical components and automotive parts. While the cycle times can be longer compared to injection molding, the ability to work with a variety of materials can enhance product offerings. Buyers should evaluate the specific material requirements and production timelines when opting for this method.

Key Industrial Applications of thermoplastic moulding

| Industry/Sector | Specific Application of thermoplastic moulding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of interior components (dashboards, panels) | Lightweight, durable parts that enhance fuel efficiency | Material compatibility, weight specifications, and safety standards. |

| Consumer Electronics | Manufacturing of housings for electronic devices | Cost-effective production of complex shapes and designs | Precision requirements, thermal resistance, and aesthetic finishes. |

| Medical Devices | Creation of surgical instruments and components | High-quality, sterilizable parts that meet regulatory standards | Biocompatibility, stringent quality control, and compliance with health regulations. |

| Packaging | Development of custom containers and closures | Enhanced product protection and longer shelf life | Material sustainability, customization options, and sealing effectiveness. |

| Construction & Building | Fabrication of piping and fittings | Durable and corrosion-resistant materials for infrastructure | Material strength, temperature resistance, and compatibility with existing systems. |

How is Thermoplastic Moulding Applied in the Automotive Industry?

In the automotive sector, thermoplastic moulding is instrumental in producing lightweight interior components such as dashboards and panels. These parts not only contribute to the vehicle’s aesthetic but also enhance fuel efficiency by reducing overall weight. B2B buyers in this industry must focus on sourcing materials that comply with safety regulations and are compatible with various automotive applications, ensuring durability and performance under varying conditions.

What Role Does Thermoplastic Moulding Play in Consumer Electronics?

Thermoplastic moulding is widely used in the consumer electronics industry to manufacture housings for devices like smartphones, tablets, and laptops. The ability to create intricate designs at a lower cost makes it ideal for high-volume production. Buyers should prioritize precision in specifications, thermal resistance to protect sensitive components, and the availability of aesthetic finishes to align with brand requirements.

Why is Thermoplastic Moulding Essential for Medical Devices?

In the medical field, thermoplastic moulding is crucial for producing surgical instruments and components that require strict adherence to regulatory standards. The materials used must be high-quality, sterilizable, and biocompatible to ensure patient safety. B2B buyers must consider stringent quality control measures and compliance with health regulations when sourcing these components, as any deviation can have serious implications.

How is Thermoplastic Moulding Transforming Packaging Solutions?

The packaging industry benefits significantly from thermoplastic moulding, particularly in the development of custom containers and closures. These solutions provide enhanced product protection and contribute to longer shelf life, which is vital in competitive markets. Buyers should evaluate material sustainability and customization options, ensuring that the packaging meets specific product needs while maintaining cost-effectiveness.

What Advantages Does Thermoplastic Moulding Offer in Construction?

In construction and building, thermoplastic moulding is employed to fabricate piping and fittings that are durable and resistant to corrosion. This application is essential for maintaining infrastructure integrity. Buyers need to focus on sourcing materials with high strength and temperature resistance, ensuring compatibility with existing systems to avoid costly downtimes and repairs.

3 Common User Pain Points for ‘thermoplastic moulding’ & Their Solutions

Scenario 1: Challenges in Material Selection for Thermoplastic Moulding

The Problem:

B2B buyers often struggle with selecting the right thermoplastic material for their specific applications. With a myriad of options available, including polyethylene, polycarbonate, and ABS, the decision can be overwhelming. Choosing the wrong material not only impacts the functionality and durability of the final product but can also lead to increased costs due to waste and rework. This decision-making process can be particularly daunting for companies in regions with limited access to technical resources or expert advice.

The Solution:

To overcome material selection challenges, buyers should start by clearly defining the application requirements, such as mechanical properties, thermal resistance, and environmental conditions. Collaborating with material suppliers who provide comprehensive datasheets and technical support can significantly streamline this process. It’s beneficial to conduct sample testing with a few selected materials before making a bulk purchase. Suppliers often offer small-scale samples for this purpose. Additionally, engaging with industry forums or online communities can provide insights from other professionals who have faced similar challenges, aiding in more informed decision-making.

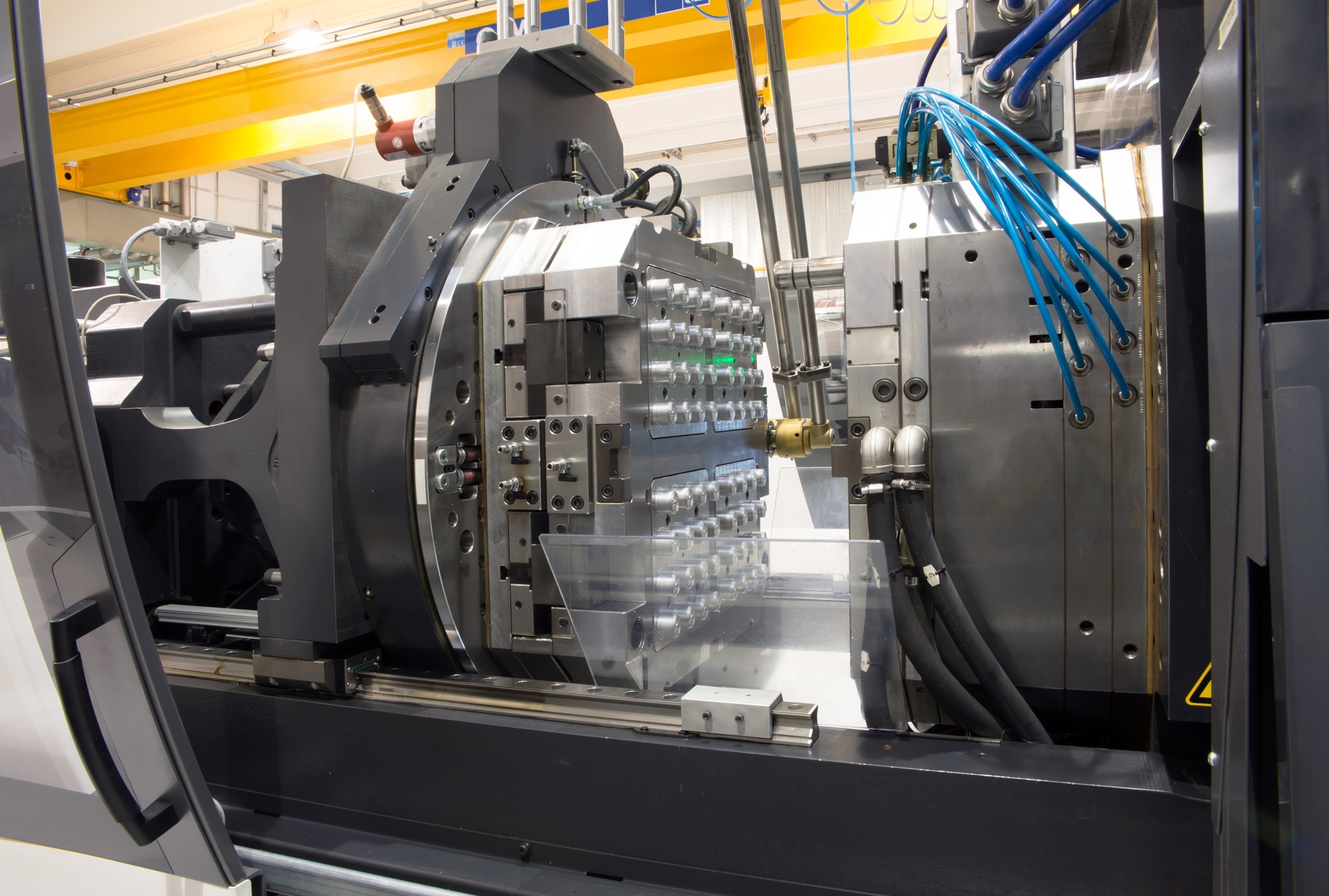

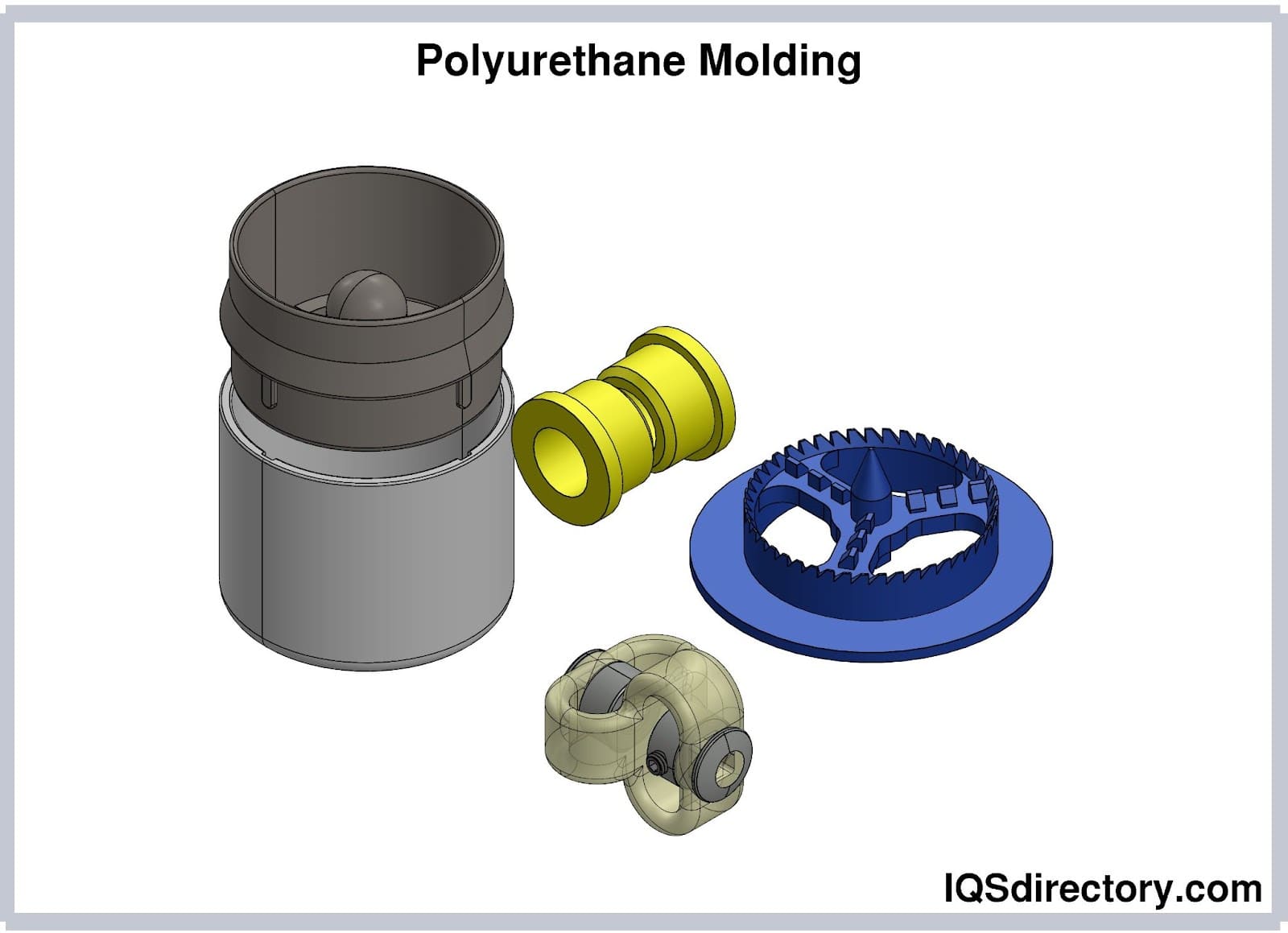

Illustrative image related to thermoplastic moulding

Scenario 2: High Production Costs and Inefficiencies

The Problem:

Many B2B buyers encounter high production costs and inefficiencies in the thermoplastic moulding process, particularly when scaling production. Factors such as long cycle times, excessive material waste, and equipment malfunctions contribute to inflated costs. In emerging markets, where margins can be tight, these inefficiencies can jeopardize competitiveness and profitability, making it essential for companies to find ways to optimize their processes.

The Solution:

To tackle production inefficiencies, buyers should invest in process optimization techniques. Conducting a thorough analysis of the injection moulding cycle can help identify bottlenecks. Implementing advanced machinery with improved energy efficiency and faster cycle times can yield significant savings. Additionally, applying lean manufacturing principles—such as minimizing waste and enhancing workflow—can help streamline operations. Regular maintenance of machinery is also crucial to prevent unexpected downtimes. Lastly, training operators on best practices in handling materials and running the machines can further boost efficiency and reduce costs.

Scenario 3: Quality Control Issues and Product Consistency

The Problem:

Quality control issues are a common concern for businesses engaged in thermoplastic moulding. Inconsistent product quality can result from various factors, such as variations in material properties, environmental conditions, or machinery settings. For international buyers, these inconsistencies can lead to customer dissatisfaction and potential loss of contracts, especially when dealing with strict regulatory requirements or high-quality standards in regions like Europe and North America.

The Solution:

To enhance quality control and ensure product consistency, implementing a robust quality management system (QMS) is essential. This system should include standardized operating procedures for every stage of the injection moulding process, from material handling to post-processing. Utilizing real-time monitoring technologies can help track critical parameters such as temperature, pressure, and injection speed, allowing for immediate adjustments when deviations occur. Regularly scheduled audits and quality assessments can also help maintain high standards. Furthermore, establishing strong partnerships with reliable suppliers ensures that the materials used meet necessary quality certifications, thereby reducing variability in the final product.

Strategic Material Selection Guide for thermoplastic moulding

What Are the Key Properties of Common Thermoplastics Used in Moulding?

When selecting materials for thermoplastic moulding, it’s essential to consider the unique properties of each type of thermoplastic. Here, we analyze four common thermoplastics: Polypropylene (PP), Polyethylene (PE), Polycarbonate (PC), and Acrylonitrile Butadiene Styrene (ABS). Each material offers distinct advantages and limitations that can significantly affect product performance and manufacturing processes.

Illustrative image related to thermoplastic moulding

How Does Polypropylene (PP) Perform in Thermoplastic Moulding?

Polypropylene is known for its excellent chemical resistance and low density, making it suitable for a wide range of applications, from automotive parts to consumer goods. It has a temperature resistance of up to 100°C and can withstand moderate pressure.

Pros: PP is lightweight, cost-effective, and offers good impact resistance. Its recyclability is another advantage, aligning with sustainability goals.

Cons: However, PP can be less durable than other materials under extreme temperatures and may have limited color options due to its inherent properties.

Impact on Application: PP is compatible with various media, including water and mild chemicals, making it ideal for packaging and automotive applications.

Illustrative image related to thermoplastic moulding

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding recycling and environmental standards, such as ASTM D638.

What Advantages Does Polyethylene (PE) Offer in Moulding Applications?

Polyethylene, particularly High-Density Polyethylene (HDPE), is widely used in thermoplastic moulding due to its excellent toughness and chemical resistance. It can withstand temperatures up to 120°C and is highly resistant to moisture and chemicals.

Pros: PE is durable, lightweight, and cost-effective, making it a popular choice for packaging, containers, and piping systems.

Cons: Its lower temperature tolerance compared to other materials can limit its use in high-heat applications.

Illustrative image related to thermoplastic moulding

Impact on Application: PE is suitable for applications involving food contact and chemical storage, given its non-toxic nature.

Considerations for International Buyers: Buyers should verify compliance with food safety standards, such as FDA regulations in the U.S. and similar standards in Europe and the Middle East.

How Does Polycarbonate (PC) Compare in Terms of Performance?

Polycarbonate is a high-performance thermoplastic known for its exceptional strength and transparency. It can withstand temperatures up to 135°C and offers high impact resistance, making it suitable for applications requiring durability.

Pros: PC is highly versatile, offering excellent optical clarity and resistance to UV light, making it ideal for lenses and safety glasses.

Illustrative image related to thermoplastic moulding

Cons: However, it can be more expensive than other thermoplastics and may be prone to scratching without proper coatings.

Impact on Application: PC is commonly used in applications where visibility and strength are critical, such as in safety equipment and automotive components.

Considerations for International Buyers: Buyers should consider the availability of UV-resistant grades for outdoor applications, particularly in regions with high sun exposure like the Middle East.

What Role Does Acrylonitrile Butadiene Styrene (ABS) Play in Thermoplastic Moulding?

ABS is a widely used thermoplastic known for its toughness and impact resistance. It operates effectively at temperatures up to 80°C and is often used in consumer products and automotive applications.

Pros: ABS is easy to process, offers good surface finish, and is relatively inexpensive, making it a go-to choice for many manufacturers.

Cons: Its lower heat resistance and susceptibility to environmental stress cracking can be limiting factors in specific applications.

Impact on Application: ABS is suitable for applications requiring aesthetic appeal and durability, such as electronic housings and toys.

Considerations for International Buyers: Compliance with safety standards, such as those for toys and consumer products, is crucial for buyers in Europe and North America.

Summary Table of Thermoplastic Materials

| Material | Typical Use Case for thermoplastic moulding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Automotive parts, consumer goods | Lightweight and cost-effective | Limited durability under extreme temperatures | Low |

| Polyethylene (PE) | Packaging, containers, piping systems | Excellent chemical resistance | Lower temperature tolerance | Low |

| Polycarbonate (PC) | Safety glasses, automotive components | High strength and optical clarity | Higher cost and prone to scratching | High |

| Acrylonitrile Butadiene Styrene (ABS) | Consumer products, electronic housings | Easy to process and good surface finish | Lower heat resistance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, assisting them in making informed decisions based on material properties, application suitability, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for thermoplastic moulding

What Are the Main Stages of the Manufacturing Process for Thermoplastic Moulding?

Thermoplastic moulding is a sophisticated manufacturing process that involves several key stages, each critical to producing high-quality plastic parts. Understanding these stages helps B2B buyers evaluate suppliers and ensure they meet industry standards.

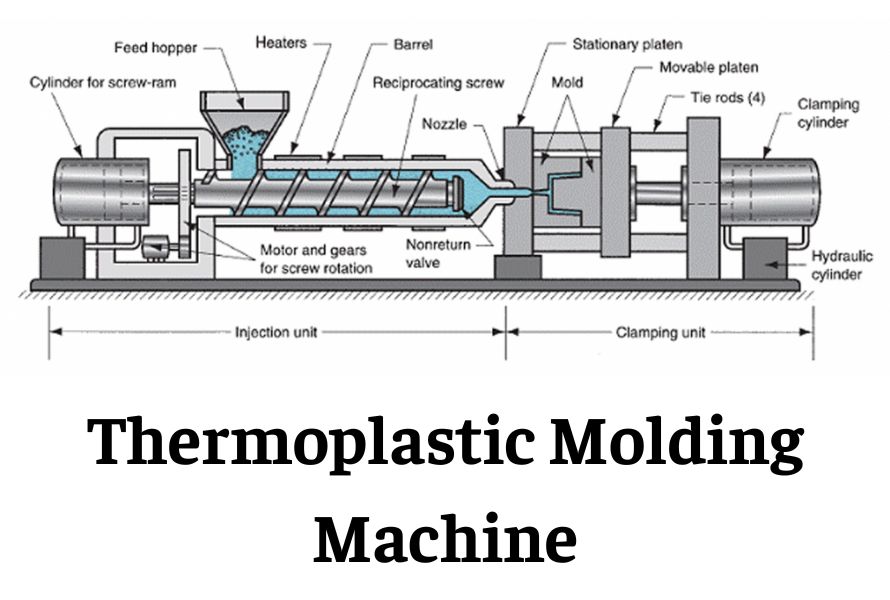

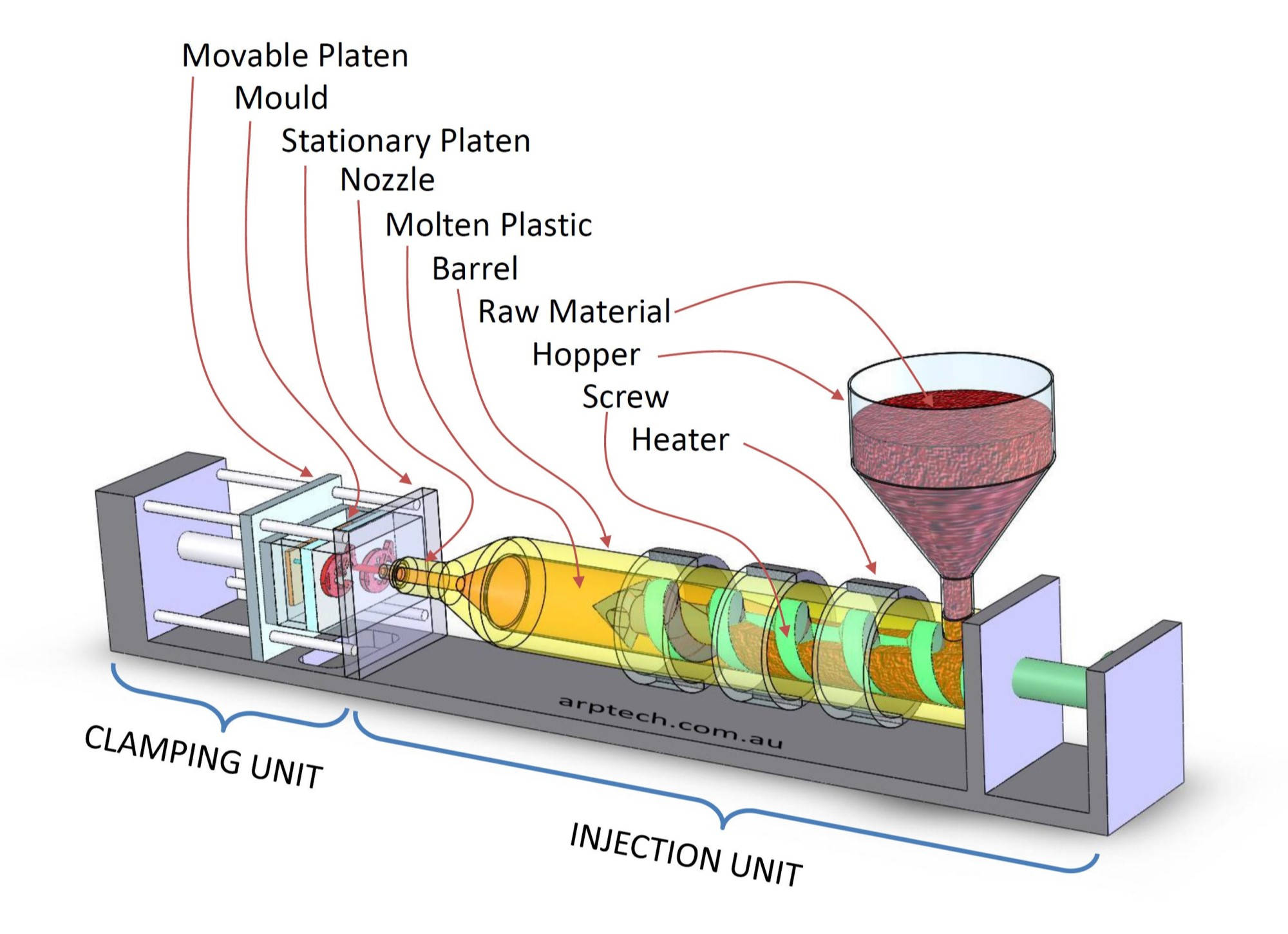

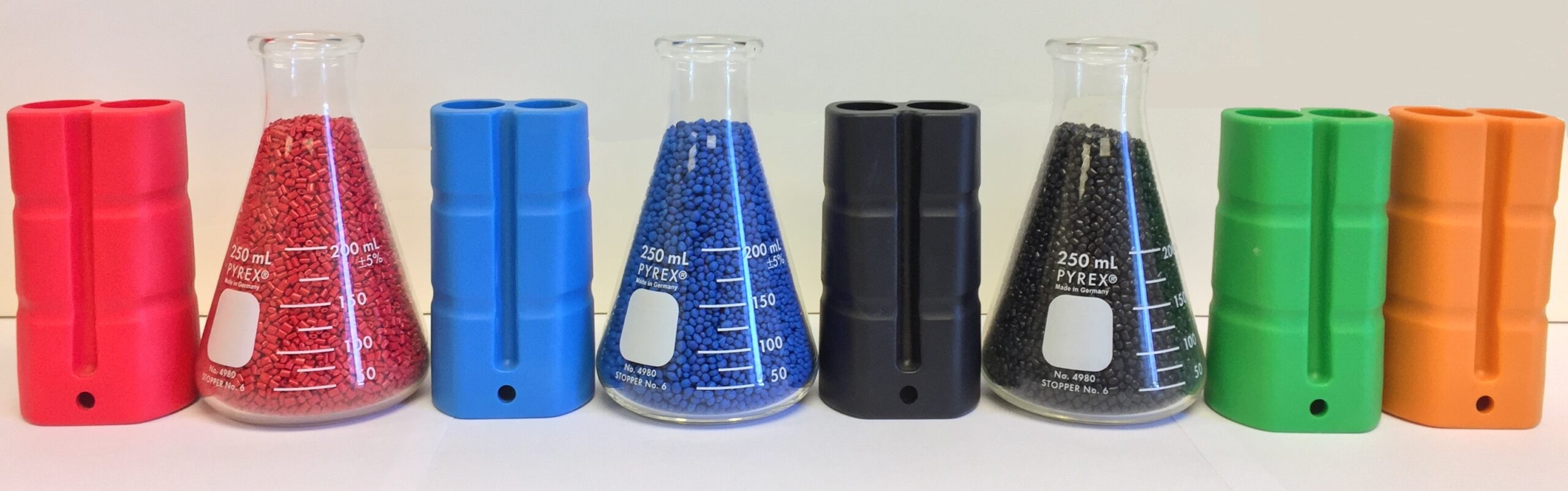

How Is Material Prepared for Thermoplastic Moulding?

The initial stage of thermoplastic moulding is material preparation. Raw thermoplastic materials, typically in pellet form, must be dried to eliminate moisture that can negatively affect the melting and moulding processes. This step often employs specialized drying equipment that maintains precise temperature and humidity levels.

Once dried, the pellets are transferred to the injection moulding machine’s hopper. The choice of thermoplastic material—such as polyethylene, polystyrene, or polycarbonate—depends on the desired mechanical properties, heat resistance, and application requirements. Buyers should verify that suppliers use high-quality materials that comply with international standards.

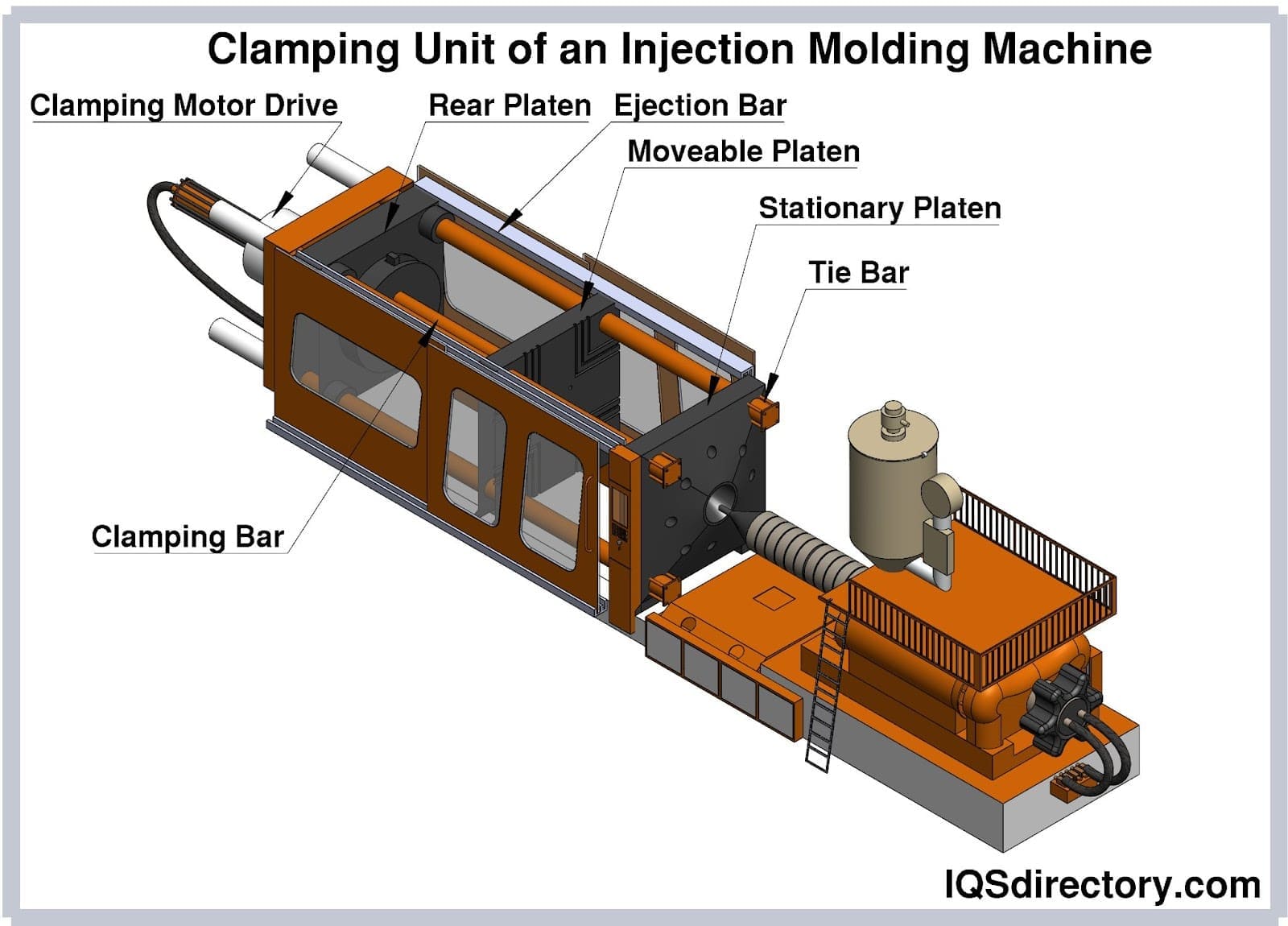

What Techniques Are Used in the Forming Stage of Thermoplastic Moulding?

The forming stage is where the real transformation occurs. The prepared thermoplastic pellets are heated in the injection unit, where they melt into a viscous state. This step is critical; maintaining the right melt temperature—typically between 200°C and 300°C—ensures optimal flow characteristics.

Once the material reaches the desired viscosity, it is injected into a meticulously designed mould under high pressure. This injection phase is essential for defining the part’s shape and surface quality. Buyers should inquire about the injection speed and pressure settings used by suppliers, as these parameters directly impact the dimensional accuracy and finish of the final product.

Illustrative image related to thermoplastic moulding

How Is Assembly and Finishing Handled in Thermoplastic Moulding?

After the molten plastic cools and solidifies within the mould, the part is ejected, often using ejector pins. The assembly process may involve additional components, depending on the final product requirements. Post-processing techniques, such as trimming, polishing, and surface finishing, are employed to enhance the part’s aesthetics and functionality.

B2B buyers should consider the post-processing capabilities of their suppliers, including the technologies used for finishing, as these can significantly affect the quality and appearance of the final product.

What Quality Assurance Measures Are Essential for Thermoplastic Moulding?

Quality assurance is crucial in thermoplastic moulding to ensure that products meet specified standards and customer expectations. Various international and industry-specific standards guide these quality measures, helping to establish credibility and reliability in the manufacturing process.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is the most recognized quality management standard, focusing on consistent quality in products and services. Companies engaged in thermoplastic moulding should have ISO 9001 certification, which demonstrates their commitment to quality management principles.

Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector may also be relevant, depending on the application of the thermoplastic parts. Buyers should confirm that their suppliers hold the necessary certifications, as this ensures compliance with regulatory requirements and market expectations.

What Are the Key Quality Control Checkpoints in Thermoplastic Moulding?

Quality control in thermoplastic moulding typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials for conformity to specifications before they enter the production line. Buyers should verify that suppliers conduct rigorous IQC to prevent defects early in the process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors critical parameters such as temperature, pressure, and cycle times. This proactive approach helps identify and rectify issues before they affect the final product.

-

Final Quality Control (FQC): At this stage, finished parts undergo comprehensive testing to ensure they meet design specifications and quality standards. Common testing methods include dimensional checks, visual inspections, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is vital for ensuring product reliability.

What Audit and Inspection Options Are Available?

Buyers can conduct audits to assess a supplier’s quality management system and production capabilities. This process can include on-site visits to review manufacturing processes, equipment, and compliance with quality standards.

In addition to audits, third-party inspections can provide an objective evaluation of a supplier’s quality control practices. Engaging independent inspection agencies can help verify that products are manufactured according to specified standards and requirements.

How Do Quality Control Certifications Affect International Trade?

Quality control certifications can significantly impact international trade dynamics. For instance, compliance with CE marking is essential for products sold within the European Union, while other markets may have different regulatory requirements. Understanding these nuances helps buyers navigate international supply chains and avoid costly compliance issues.

Conclusion

The manufacturing process and quality assurance practices in thermoplastic moulding are complex yet critical components for B2B buyers. By understanding the main stages of production, the importance of quality assurance standards, and how to verify supplier practices, buyers can make informed decisions and foster successful partnerships in the thermoplastic industry. Prioritizing quality and compliance will ultimately lead to better products and satisfied customers in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermoplastic moulding’

Introduction

Navigating the procurement of thermoplastic molding can be complex, especially for international B2B buyers. This practical sourcing guide offers a step-by-step checklist to help streamline the process, ensuring you select the right suppliers and materials for your production needs. By following these steps, you can make informed decisions that align with your business objectives and quality standards.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the thermoplastic parts you need. This includes dimensions, tolerances, and the specific thermoplastic materials to be used. Defining these specifications helps prevent misunderstandings with suppliers and ensures that the final products meet your operational needs.

- Consider the application: Different industries may have unique requirements, such as heat resistance for automotive parts or flexibility for consumer products.

- Document everything: Create a comprehensive specification sheet to share with potential suppliers.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in thermoplastic molding. Look for companies with a proven track record and expertise in your specific industry.

- Use online platforms: Leverage B2B marketplaces and industry-specific directories to find reputable suppliers.

- Check reviews and ratings: Look for testimonials or case studies that highlight the supplier’s experience and reliability.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of shortlisted suppliers to ensure they can meet your production requirements.

- Request samples: Ask for product samples to evaluate the quality of their thermoplastic parts.

- Inquire about technology: Ensure the supplier utilizes modern machinery and adheres to the latest manufacturing practices for thermoplastic molding.

Step 4: Verify Certifications and Compliance

It is crucial to ensure that your chosen suppliers comply with relevant industry standards and certifications. This helps mitigate risks associated with quality and safety.

- ISO Certifications: Look for suppliers with ISO 9001 certification, which indicates a commitment to quality management.

- Material Safety Data Sheets (MSDS): Ensure suppliers can provide MSDS for the thermoplastics they use to verify safety and compliance.

Step 5: Assess Production Capacity and Lead Times

Evaluate the production capacity of potential suppliers and their ability to meet your lead times.

- Discuss production schedules: Ensure that the supplier can handle your order volume within your required time frame.

- Understand their supply chain: A reliable supplier should have a robust supply chain to avoid delays due to material shortages.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to negotiate pricing and contractual terms. This step is vital to ensure you receive the best value for your investment.

- Consider bulk discounts: Inquire about pricing structures for larger orders or long-term partnerships.

- Clarify payment terms: Ensure that payment terms are mutually agreeable to avoid cash flow issues.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure that the thermoplastic parts produced meet your specifications consistently.

Illustrative image related to thermoplastic moulding

- Define inspection criteria: Establish clear criteria for quality checks at various stages of production.

- Set up regular reviews: Schedule regular meetings with the supplier to discuss quality performance and address any issues proactively.

By following this checklist, you can effectively navigate the sourcing process for thermoplastic molding, ensuring you partner with the right suppliers who meet your technical and quality requirements.

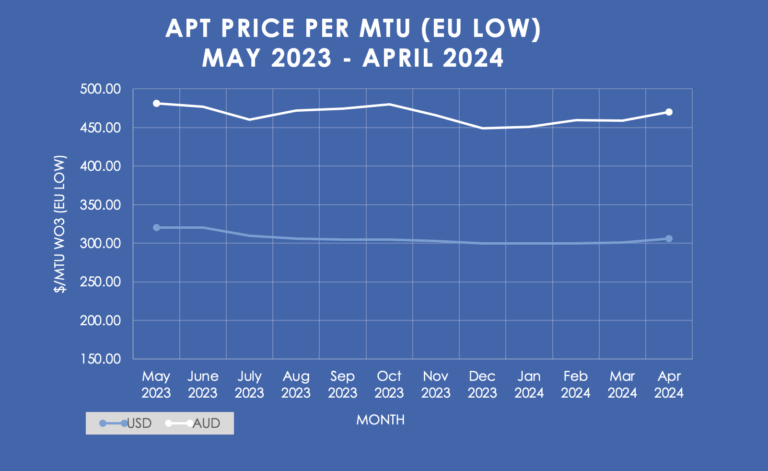

Comprehensive Cost and Pricing Analysis for thermoplastic moulding Sourcing

In the realm of thermoplastic molding, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will cover the various cost components, price influencers, and practical tips for negotiating effective deals, particularly for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Thermoplastic Molding?

-

Materials: The choice of thermoplastic resin significantly impacts the overall cost. Common materials such as polyethylene, polypropylene, and polycarbonate vary in price based on market demand and availability. High-performance materials or custom blends may incur additional costs, reflecting their specialized properties.

-

Labor: Labor costs encompass skilled workers for operating injection molding machines, quality control personnel, and maintenance staff. Labor costs can vary widely based on geographical location, local wage standards, and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, equipment depreciation, and administrative costs. Efficient manufacturing processes can help mitigate overhead, but it is essential for buyers to inquire about these costs when sourcing.

-

Tooling: The design and production of molds are significant upfront investments in thermoplastic molding. Tooling costs can vary based on the complexity of the mold, material used, and the expected lifespan of the mold. Buyers should consider these costs as part of the total investment.

-

Quality Control (QC): Ensuring product quality is crucial, especially for industries with strict regulatory requirements. QC processes may involve testing and inspection, which can add to overall costs but are necessary for maintaining product standards.

-

Logistics: Shipping and handling fees, including customs duties and insurance, contribute to the final cost. Buyers should factor in logistics costs, especially for international sourcing, as they can vary based on location and supplier agreements.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge the reasonableness of quotes received.

How Do Price Influencers Affect Thermoplastic Molding Costs?

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to reduced unit prices due to economies of scale. Buyers should negotiate for better pricing by exploring bulk purchasing options.

-

Specifications and Customization: Custom designs or specific tolerances can increase costs. Buyers should clearly communicate their requirements and seek standardized solutions where possible to optimize pricing.

-

Material Selection: The choice of material not only affects cost but also influences performance and application suitability. Buyers should evaluate material costs against their performance needs to ensure a balanced investment.

-

Quality and Certifications: Products requiring specific certifications or compliance with industry standards may incur higher costs. Buyers should assess whether these certifications are necessary for their market to avoid unnecessary expenditures.

-

Supplier Factors: Supplier reliability, production capacity, and reputation can influence pricing. Established suppliers may command higher prices due to their proven track record and quality assurance measures.

-

Incoterms: Understanding the agreed-upon Incoterms is vital, as they dictate the responsibilities of buyers and sellers in shipping arrangements. This can significantly affect total costs, especially in international transactions.

What Are Effective Buyer Tips for Sourcing Thermoplastic Molding?

-

Negotiation Strategies: Engage suppliers in open discussions about pricing and cost structures. Leverage your volume needs to negotiate favorable terms, and don’t hesitate to request quotes from multiple suppliers for comparison.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as durability, maintenance, and logistics when assessing the value of a supplier’s offer.

-

Understand Pricing Nuances for International Sourcing: Be aware of currency fluctuations, import tariffs, and regional economic conditions that may impact pricing. Establishing long-term relationships with suppliers can also lead to more stable pricing.

-

Request Detailed Quotations: Ensure that quotes include a breakdown of all costs involved, such as materials, labor, tooling, and logistics. This transparency will help in comparing offers and understanding the value being provided.

-

Stay Informed About Market Trends: Keeping abreast of market trends in thermoplastic materials and pricing can empower buyers to make informed decisions, ensuring they can negotiate effectively and capitalize on favorable conditions.

Disclaimer

The prices and cost structures discussed herein are indicative and subject to change based on market conditions, supplier pricing strategies, and individual project specifications. Buyers are encouraged to conduct thorough research and obtain tailored quotes to ensure accurate budgeting and sourcing decisions.

Alternatives Analysis: Comparing thermoplastic moulding With Other Solutions

Introduction to Alternative Manufacturing Solutions

In the quest for efficient and effective production methods, businesses often explore various manufacturing solutions to meet their needs. Thermoplastic moulding stands out for its versatility and efficiency in producing plastic components. However, it is essential to compare it with alternative technologies that can achieve similar results. This analysis will focus on two prominent alternatives: thermoset moulding and 3D printing, highlighting their performance, costs, and applicability to different scenarios.

Comparison Table

| Comparison Aspect | Thermoplastic Moulding | Thermoset Moulding | 3D Printing |

|---|---|---|---|

| Performance | High precision and repeatability; suitable for complex shapes | Excellent durability and heat resistance; limited to simpler designs | Highly flexible; ideal for prototyping and low-volume production |

| Cost | Moderate initial investment; cost-effective for large volumes | Higher material costs; cost-effective for high-performance applications | Low initial investment; higher cost per unit for mass production |

| Ease of Implementation | Requires specialized machinery and tooling; setup time can be significant | Similar to thermoplastic; requires specific molds and curing processes | Minimal setup; requires software for design and printing |

| Maintenance | Moderate; requires regular maintenance of machinery and molds | High; molds can wear out quickly and need replacements | Low; maintenance mainly involves printer upkeep and software updates |

| Best Use Case | High-volume production of intricate parts (e.g., automotive, consumer goods) | High-performance applications requiring durability (e.g., aerospace, electrical components) | Rapid prototyping and small-batch production with complex geometries |

Detailed Breakdown of Alternatives

Thermoset Moulding

Thermoset moulding involves the use of thermosetting polymers that undergo a chemical change when heated, resulting in a rigid and durable product. This method is particularly advantageous for applications requiring high heat resistance and structural integrity, such as aerospace and automotive components. However, the initial costs can be higher due to the materials and the need for specialized molds. Furthermore, once cured, thermoset materials cannot be remolded or recycled, which may limit their environmental appeal.

3D Printing

3D printing, or additive manufacturing, is a rapidly evolving technology that offers unparalleled design flexibility. It allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional methods. 3D printing is particularly suited for prototyping and low-volume production, enabling rapid iterations and adjustments. However, the cost per unit can be higher for mass production compared to thermoplastic moulding, making it less suitable for large-scale manufacturing. Additionally, while material options are expanding, they may not yet match the performance characteristics of thermoplastics or thermosets in all applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a manufacturing solution, B2B buyers should carefully evaluate their specific requirements, including production volume, material properties, and budget constraints. Thermoplastic moulding excels in high-volume production scenarios where precision and efficiency are paramount. In contrast, thermoset moulding is ideal for applications demanding superior durability and heat resistance, while 3D printing offers unmatched design flexibility for prototyping and small-scale production. By understanding the strengths and weaknesses of each method, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for thermoplastic moulding

What Are the Key Technical Properties of Thermoplastic Moulding?

In the realm of thermoplastic moulding, understanding the technical properties is crucial for making informed purchasing decisions. Here are some of the most significant specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the specific formulation of thermoplastic polymers, which dictates their mechanical and thermal properties. Common grades include ABS, PVC, and polycarbonate. Selecting the appropriate material grade is vital as it influences the part’s strength, flexibility, and overall suitability for the intended application, such as automotive or consumer products.

Illustrative image related to thermoplastic moulding

2. Tolerance

Tolerance defines the acceptable deviation from specified dimensions in the final product. In thermoplastic moulding, tighter tolerances (e.g., ±0.1 mm) may be necessary for precision components like medical devices. Understanding tolerance requirements is essential for ensuring that parts fit correctly and function as intended, thereby reducing the risk of costly reworks and enhancing customer satisfaction.

3. Surface Finish

Surface finish encompasses the texture and appearance of the molded part. It can range from smooth to textured, affecting both aesthetics and functionality. A high-quality surface finish may be crucial for consumer-facing products, while a functional finish may be sufficient for industrial applications. Buyers should specify surface finish requirements early in the design process to ensure alignment with market expectations.

4. Impact Resistance

Impact resistance measures a material’s ability to withstand sudden forces or shocks without fracturing. This property is particularly important in applications where durability is critical, such as automotive and aerospace components. Understanding the impact resistance of various thermoplastics helps buyers select materials that will endure operational stresses, ensuring longevity and reliability.

5. Heat Deflection Temperature (HDT)

HDT indicates the temperature at which a polymer deforms under a specified load. This property is crucial for applications exposed to high temperatures, such as automotive under-the-hood components. Buyers must consider HDT when selecting materials to prevent deformation and maintain the integrity of the part in its operational environment.

What Are Common Trade Terms in Thermoplastic Moulding?

Navigating the thermoplastic moulding industry involves familiarizing oneself with specific trade terminology. Here are several essential terms that B2B buyers should know:

Illustrative image related to thermoplastic moulding

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In thermoplastic moulding, an OEM might produce components for automotive manufacturers. Understanding the OEM landscape is crucial for buyers looking to partner with reputable manufacturers for their product needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers as it impacts inventory management and cost-effectiveness. Knowing the MOQ helps buyers plan their purchasing strategy, ensuring they meet production needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for a specific quantity of products. In thermoplastic moulding, an RFQ helps buyers compare offers from different manufacturers, allowing for informed decision-making based on cost, lead time, and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is vital for B2B buyers involved in cross-border transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thereby minimizing potential disputes.

5. Lead Time

Lead time is the duration from placing an order to receiving the goods. In thermoplastic moulding, understanding lead times is essential for effective supply chain management. Buyers should communicate their timelines clearly to ensure timely delivery and avoid production delays.

Illustrative image related to thermoplastic moulding

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of thermoplastic moulding with greater confidence, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the thermoplastic moulding Sector

What Are the Key Market Drivers and Trends Influencing Thermoplastic Moulding?

The thermoplastic moulding sector is experiencing robust growth driven by several global factors. Increasing demand for lightweight and durable materials in industries such as automotive, aerospace, and consumer goods is propelling the market forward. The surge in electric vehicle production, particularly in regions like Europe and the Middle East, is also a significant contributor, as manufacturers seek advanced materials for components that enhance performance and efficiency. Additionally, the rise of smart manufacturing technologies, including automation and IoT, is streamlining the thermoplastic injection moulding process, improving efficiency, and reducing costs for international buyers.

Emerging sourcing trends indicate a shift towards local suppliers, particularly in regions like Africa and South America, where manufacturers are exploring ways to shorten supply chains and mitigate risks associated with global disruptions. Furthermore, the demand for customization in product design is prompting suppliers to adopt more flexible manufacturing processes. This trend is particularly evident in regions like Vietnam, where manufacturers are increasingly investing in advanced moulding technologies to cater to diverse client requirements.

How Is Sustainability and Ethical Sourcing Impacting the Thermoplastic Moulding Industry?

Sustainability is becoming a critical focal point for B2B buyers in the thermoplastic moulding sector. The environmental impact of plastic production is under scrutiny, with buyers increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes utilizing recycled materials and adopting processes that minimize waste and energy consumption.

The importance of ethical supply chains cannot be overstated, as international buyers seek transparency in sourcing practices. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard (GRS) for recycled materials are becoming essential for suppliers aiming to position themselves competitively in the market. Buyers are also interested in bioplastics and other ‘green’ materials that offer similar performance characteristics to traditional thermoplastics but with a reduced environmental footprint. By prioritizing sustainable and ethical sourcing, companies not only enhance their brand reputation but also cater to a growing consumer demand for environmentally responsible products.

What Is the Evolution of Thermoplastic Moulding in the B2B Landscape?

The evolution of thermoplastic moulding has been marked by significant advancements in technology and materials. Initially, the process was limited to basic shapes and applications. However, the introduction of advanced polymers and sophisticated moulding techniques has transformed the industry, enabling the production of complex components with enhanced properties.

In recent years, the focus has shifted towards integrating smart technologies into the moulding process. The advent of Industry 4.0 has facilitated the adoption of automation, predictive maintenance, and data analytics, allowing manufacturers to optimize production efficiency and reduce downtime. This evolution is particularly relevant for B2B buyers who are seeking reliable and efficient suppliers capable of meeting the demands of an increasingly competitive marketplace. As the thermoplastic moulding sector continues to evolve, staying informed about these trends is crucial for making strategic sourcing decisions that align with business goals.

Illustrative image related to thermoplastic moulding

Frequently Asked Questions (FAQs) for B2B Buyers of thermoplastic moulding

-

1. How do I choose the right thermoplastic material for my project?

Selecting the appropriate thermoplastic material is crucial to the success of your project. Consider the mechanical properties required, such as strength, flexibility, and heat resistance. Additionally, evaluate factors like the environmental conditions the part will face, regulatory requirements, and whether the material needs to be recyclable. Common thermoplastics include polyethylene for its durability, polycarbonate for impact resistance, and ABS for its ease of processing. Engaging with a material specialist or supplier can also provide insights tailored to your specific application needs. -

2. What are the key factors to consider when vetting a thermoplastic molding supplier?

When vetting suppliers, assess their experience in thermoplastic molding and their capability to handle your specific requirements. Check their certifications, such as ISO 9001, which indicates quality management systems. Investigate their production capacity, lead times, and flexibility for customization. Additionally, inquire about their quality assurance processes and past client references. A reliable supplier should be transparent about their operations and willing to provide samples or prototypes before finalizing contracts. -

3. What is the minimum order quantity (MOQ) for thermoplastic molded parts?

Minimum order quantities can vary significantly among suppliers based on their production capabilities and the complexity of the parts. Typically, MOQs may range from a few hundred to several thousand units. Smaller orders may be subject to higher per-unit costs due to setup and processing time. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that align with your project scale and budget. Some suppliers may also offer flexibility for first-time buyers or pilot runs. -

4. How can I ensure the quality of thermoplastic molded parts?

To ensure quality, implement a robust quality assurance (QA) process that includes defining specifications and conducting inspections at various stages of production. Request samples before full-scale production to evaluate the material properties and dimensional accuracy. Ask suppliers about their QA certifications and testing methods, such as dimensional checks, mechanical tests, and surface finish evaluations. Regular communication with the supplier throughout the production process can help address any issues promptly. -

5. What are common payment terms for international thermoplastic molding suppliers?

Payment terms can vary widely among suppliers, influenced by factors such as order size, relationship, and regional practices. Common terms may include a deposit upfront (typically 30-50%), with the balance due upon delivery or after inspection. Some suppliers may offer payment through letters of credit, especially for international transactions, to reduce risk. It’s essential to clarify and negotiate terms upfront to ensure mutual understanding and avoid disputes later in the process. -

6. How do I handle logistics and shipping for thermoplastic molded products?

Managing logistics effectively involves coordinating with your supplier to understand their shipping capabilities and timelines. Consider factors such as freight costs, customs regulations, and potential tariffs when shipping internationally. Work with logistics providers experienced in handling industrial products to ensure safe transport. Discuss with your supplier whether they can assist with shipping arrangements or if they have preferred logistics partners to streamline the process. -

7. Can thermoplastic molded parts be customized for specific applications?

Yes, thermoplastic molded parts can be highly customized to meet specific application requirements. Customization can include adjustments in design, material selection, color, and surface finish. Collaborating closely with your supplier during the design phase is critical to ensure that your specifications are feasible for production. Most suppliers will have design software and prototyping capabilities to assist in developing custom solutions tailored to your needs. -

8. What industries commonly use thermoplastic molding, and what are its applications?

Thermoplastic molding is widely used across various industries, including automotive, consumer goods, electronics, medical devices, and packaging. Applications range from automotive interior components and housings for electronic devices to medical instruments and packaging solutions. The versatility of thermoplastics allows manufacturers to create complex shapes and durable parts that meet diverse functional requirements. Understanding industry-specific needs can guide your material and design choices effectively.

Top 9 Thermoplastic Moulding Manufacturers & Suppliers List

1. IQS Directory – Thermoplastic Molding Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Thermoplastic molding involves forming plastic parts by injecting molten resin into a mold. Key features include:

– Thermoplastics can be reheated and reshaped, making them advantageous for recycling and reusability (up to 30% recycled content).

– Subdivisions include rapid injection molding for prototypes and production injection molding for full-scale manufacturing.

– Applications range from cel…

2. Injection Molded Plastics – Thermoplastic Molding Solutions

Domain: injection-molded-plastics.net

Registered: 2001 (24 years)

Introduction: Thermoplastic molding is a reversible molding process where plastic pellets are melted, pressed into a mold, and then fast-cooled to harden. It is characterized by high production rates, making it an economical and effective method for producing plastic components. Thermoplastics are easy to recycle and do not undergo chemical changes when heated or cooled repeatedly. This method can produce a wid…

3. Forged Acrylics – Thermoplastic Molding Techniques

Domain: forgedacrylics.com

Registered: 2020 (5 years)

Introduction: Thermoplastic molding is a versatile manufacturing process used to produce various plastic products. Key techniques include injection molding, blow molding, compression molding, and extrusion molding. Essential tools for beginners include an injection molding machine, CAD software for design, mold release agents, a drill press, an aluminum mold frame, a water bath for temperature control, and a bl…

4. Toray – TORAYCA™ Pellet

Domain: cf-composites.toray

Registered: 2021 (4 years)

Introduction: {‘short_fiber_pellet’: {‘name’: ‘TORAYCA™ Pellet’, ‘description’: ‘A carbon fiber reinforced thermoplastic (CFRTP) specially designed for injection molding.’, ‘features’: [‘light weight’, ‘excellent strength’, ‘stiffness’, ‘dimensional accuracy’, ‘sliding properties’], ‘base_resins’: [‘PP’, ‘PC’, ‘ABS’, ‘Nylon 6’, ‘Nylon 66’, ‘Nylon 610’, ‘PBT’, ‘PPS’], ‘applications’: [‘automotive’, ‘electric hom…

5. Accio – Key Product Details

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Key product details include: 1. Injection Pressure 2. Clamping Force 3. Cycle Time 4. Shot Weight 5. Ejector Stroke 6. Screw Diameter 7. Plasticizing Capacity 8. Tie Bar Distance 9. Mold Thickness 10. Injection Speed. Various suppliers offer customizable options such as model number, size, shape, cavity, color, mould base, surface finish, specifications, and mould material. Price range for product…

6. HLH Rapid – Thermoplastic Injection Molding

Domain: hlhrapid.com

Registered: 2020 (5 years)

Introduction: Thermoplastic Injection Molding Overview:

– Process: Involves injecting melted thermoplastic resin into a mold cavity, cooling and solidifying to form plastic parts.

– Benefits: Highly repeatable, cost-effective for high volumes (thousands to millions of parts), maintains original material properties with precision.

– Thermoplastics: Reheatable and reshaped, advantageous for recycling, intricat…

7. AccessArt – Thermoplastic Moulding Workshop

Domain: accessart.org.uk

Registered: 2000 (25 years)

Introduction: This module demonstrates simple thermoplastic moulding techniques to create brightly coloured, organic shapes out of plastic. It introduces a basic industrial process using coloured glue pellets, hot glue guns, aluminium strips, and moulds to cast plastic shapes. The workshop was part of Laura Kohler’s Kinetic Mobile Workshop, where teachers learned to make plastic shapes for kinetic mobiles inspi…

8. NTS Moulding – Thermoplastic Solutions

Domain: ntsmoulding.com

Registered: 2016 (9 years)

Introduction: Thermoplastic moulding involves the handling of thermoplastic materials, including technopolymers reinforced with glass and carbon. The thermoplastic department operates 12 injection presses with capacities up to 430 tons. The process is guided by high technology and lean principles, supported by an automated data collection system for production and performance, ensuring high-quality products del…

9. Nature – Regenerated Silk Moulding

Domain: nature.com

Registered: 1994 (31 years)

Introduction: Thermoplastic moulding of regenerated silk involves a thermal processing method for direct solid-state moulding of regenerated silk into bulk parts or devices. This process allows for tunable mechanical properties and utilizes regenerated amorphous silk nanomaterials with ultralow β-sheet content. The technique enables thermal fusion via molecular rearrangement and self-assembly, maintaining bioco…

Strategic Sourcing Conclusion and Outlook for thermoplastic moulding

As the thermoplastic molding landscape evolves, strategic sourcing remains a pivotal factor for international B2B buyers. By understanding the intricacies of thermoplastic injection molding—from material selection to machine capabilities—companies can enhance their production efficiency and product quality. The ability to source high-quality materials and advanced machinery enables businesses to innovate and respond swiftly to market demands, ensuring they stay ahead of the competition.

Moreover, leveraging relationships with reliable suppliers across Africa, South America, the Middle East, and Europe can significantly reduce lead times and costs. This interconnected approach not only fosters resilience in supply chains but also opens doors to new opportunities in diverse markets.

Looking ahead, businesses should prioritize ongoing education and collaboration within the thermoplastic industry. By embracing advancements in technology and sustainable practices, international buyers can position themselves as leaders in their respective sectors. Now is the time to act—evaluate your sourcing strategies, invest in quality materials, and partner with experts to unlock the full potential of thermoplastic molding. The future of manufacturing is here, and it’s time to seize it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.