A B2B Buyer’s Guide to Desktop Dyno: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for desktop dyno

In the rapidly evolving landscape of automotive performance, sourcing a reliable desktop dyno has become a pivotal challenge for businesses looking to enhance engine simulation capabilities. This guide serves as a comprehensive resource for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe, including nations such as Nigeria and Germany. As the demand for precise engine performance analysis continues to rise, understanding the nuances of desktop dyno options, applications, and supplier vetting becomes essential.

Within these pages, you will find an in-depth exploration of various types of desktop dynos, their applications in both racing and street performance, and critical factors to consider when evaluating suppliers. The guide will also address cost considerations, ensuring that you can make informed financial decisions while maximizing your investment in engine simulation technology. By equipping you with actionable insights and a clear framework for comparison, this guide empowers you to navigate the global market effectively, enabling you to select the right desktop dyno that aligns with your specific business needs. Whether you are a seasoned automotive engineer or a new entrant in the performance sector, understanding these elements will position you for success in a competitive environment.

Understanding desktop dyno Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DeskTop Dyno 5 | Comprehensive engine simulation for 1-12 cylinder engines; includes QuickIterator™ for automated testing. | Performance tuning, engine design, R&D for automotive companies. | Pros: High accuracy, user-friendly interface. Cons: Requires Windows OS; may have a learning curve for beginners. |

| DeskTop Dyno Basic | Simplified version with essential features for basic engine simulation. | Entry-level users, small workshops, educational purposes. | Pros: Cost-effective, easy to use. Cons: Limited features compared to advanced versions. |

| DeskTop Dyno 2000 | Older version with basic functionalities; suitable for legacy systems. | Hobbyists, budget-conscious users, basic engine simulations. | Pros: Low cost, compatible with older systems. Cons: Outdated technology; lacks advanced features of newer models. |

| Custom Engine Simulators | Tailored software solutions designed for specific engine types or industries. | Specialized automotive manufacturers, racing teams. | Pros: Highly customizable, meets specific needs. Cons: Potentially higher costs; longer setup times. |

| Online Dyno Simulators | Cloud-based solutions allowing remote access and collaboration. | Global teams, remote R&D, engineering firms. | Pros: Accessible from anywhere, often includes collaboration tools. Cons: Requires stable internet; may have subscription fees. |

What are the Key Features of DeskTop Dyno 5 for B2B Buyers?

DeskTop Dyno 5 is a powerful simulation tool ideal for businesses engaged in automotive performance tuning and engine design. Its ability to model engines from 1 to 12 cylinders, coupled with the QuickIterator™ feature for automated testing, makes it a versatile choice for R&D departments. Companies looking to optimize engine performance can leverage its predictive accuracy and extensive component library, ensuring they get the most from their designs. However, it is essential to consider the software’s compatibility with Windows OS and the potential learning curve for new users.

How Does DeskTop Dyno Basic Cater to Entry-Level Users?

DeskTop Dyno Basic serves as an entry-level solution for smaller workshops or educational institutions. It provides essential features for basic engine simulations without the complexity of more advanced versions. This software is particularly appealing for businesses that need a cost-effective solution for training or basic performance analysis. While it lacks the comprehensive features of DeskTop Dyno 5, its simplicity makes it an excellent option for those who are new to engine simulations or operate on a tight budget.

Why Consider DeskTop Dyno 2000 for Budget-Conscious Projects?

For businesses operating on limited budgets or those needing compatibility with older systems, DeskTop Dyno 2000 offers a viable solution. While it provides basic functionalities suitable for hobbyists and budget-conscious users, it lacks many advanced features found in newer models. Companies should weigh the pros of low costs against the cons of outdated technology, as it may not meet the needs of more sophisticated engine simulations.

What Advantages Do Custom Engine Simulators Offer to Specialized Manufacturers?

Custom engine simulators are designed to cater to the specific needs of specialized automotive manufacturers and racing teams. These tailored solutions can provide in-depth analysis and modeling capabilities for unique engine types or applications. Although they may come at a higher cost and require longer setup times, the advantage of customization can lead to significant performance gains and competitive advantages in the marketplace.

How Do Online Dyno Simulators Enhance Collaboration for Global Teams?

Online dyno simulators present a modern approach to engine simulation, enabling global teams to collaborate effectively. These cloud-based solutions offer remote access, allowing engineers to work together on projects from different locations. While they provide accessibility and often include collaboration tools, businesses must ensure they have a stable internet connection and be prepared for potential subscription fees. This model is particularly beneficial for companies with distributed teams or those looking to streamline their R&D processes.

Key Industrial Applications of desktop dyno

| Industry/Sector | Specific Application of desktop dyno | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Engineering | Engine design and performance optimization | Reduces costs by simulating engine performance before manufacturing | Compatibility with local regulations and fuel types |

| Motorsports | Race engine development and tuning | Enhances competitive edge through precise performance predictions | Access to detailed engine specifications and performance data |

| Manufacturing | Prototyping and testing of custom engines | Minimizes trial-and-error in production, saving time and resources | Ability to model various engine configurations efficiently |

| Agricultural Equipment | Engine efficiency analysis for farming machinery | Improves fuel efficiency and performance, leading to cost savings | Understanding of agricultural practices and machinery needs |

| Marine Engineering | Simulation of marine engines for boats and vessels | Optimizes engine performance for better fuel efficiency and reliability | Need for marine-grade components and environmental conditions |

How Is Desktop Dyno Used in Automotive Engineering?

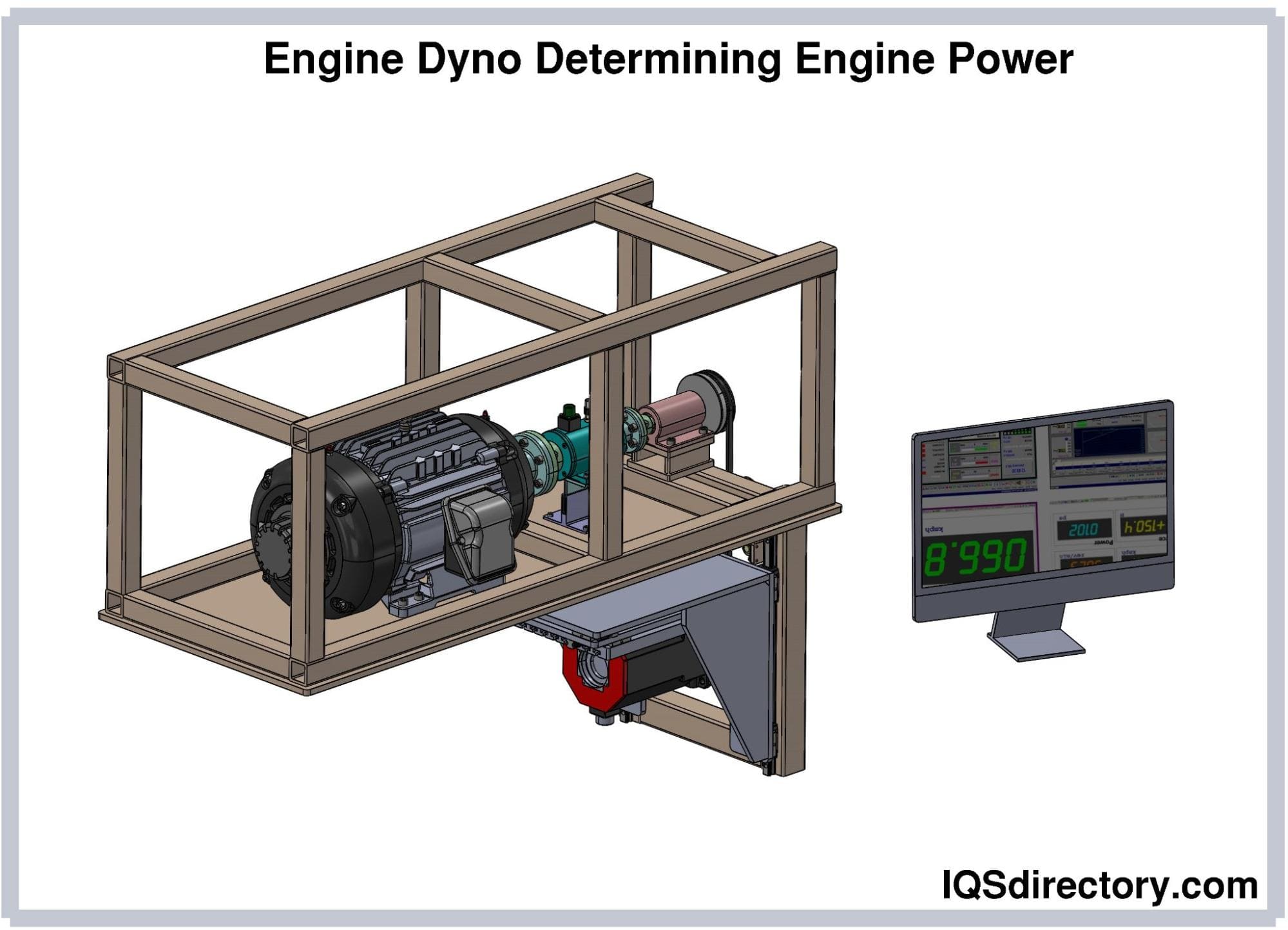

In the automotive engineering sector, Desktop Dyno is employed to design and optimize engine performance. Engineers can simulate various engine configurations, including different cylinder counts, bore and stroke sizes, and valve timing. This capability helps in identifying the most effective design before physical production, which significantly reduces costs associated with trial-and-error testing. For international buyers, especially in regions like Africa and Europe, it is crucial to ensure that the software aligns with local fuel standards and emission regulations.

What Role Does Desktop Dyno Play in Motorsports?

In motorsports, Desktop Dyno serves as a vital tool for developing and tuning race engines. Teams utilize the software to simulate engine performance under various racing conditions, allowing for precise adjustments to maximize horsepower and torque. The ability to quickly iterate on different configurations gives teams a competitive advantage. Buyers in this sector should consider the software’s compatibility with specific racing regulations and the ability to model high-performance fuel types.

How Does Desktop Dyno Assist in Manufacturing?

Manufacturers of engines and automotive components leverage Desktop Dyno for prototyping and testing custom engines. By simulating engine performance, manufacturers can streamline their production processes and reduce waste associated with faulty designs. This not only saves time but also conserves resources. Buyers should focus on the software’s capability to integrate with existing design tools and its adaptability to various manufacturing environments.

Why Is Desktop Dyno Important for Agricultural Equipment?

In agricultural equipment, Desktop Dyno is utilized to analyze engine efficiency for machinery such as tractors and harvesters. By simulating different engine setups, manufacturers can enhance fuel efficiency, thereby lowering operational costs for farmers. This is particularly relevant for international buyers who must consider local farming practices and the types of fuel available in their regions when sourcing the software.

How Is Desktop Dyno Beneficial for Marine Engineering?

Marine engineers use Desktop Dyno to simulate the performance of engines in boats and other vessels. This simulation aids in optimizing engine performance to ensure reliability and fuel efficiency, which are critical in marine applications. Buyers in this field must ensure that the software can model marine-specific conditions and that it complies with maritime regulations, which can vary significantly across different regions.

3 Common User Pain Points for ‘desktop dyno’ & Their Solutions

Scenario 1: Navigating Complex Engine Specifications

The Problem: B2B buyers often face the challenge of navigating complex engine specifications when trying to optimize performance using desktop dyno software. This includes selecting the right components and understanding how various factors such as bore size, stroke length, and compression ratios will influence engine performance. For businesses in regions with rapidly evolving automotive markets, like Africa or South America, the pressure to deliver high-performance engines quickly can lead to frustration when the software does not intuitively guide users through these technical specifications.

The Solution: To address this issue, buyers should leverage the software’s extensive component library and calculators, such as the QuickCalculator™ and QuickIterator™ features. Familiarize your team with the user manual available within the software, as it provides step-by-step guidance on component selection and adjustments. Additionally, consider conducting training sessions for your engineering team to enhance their understanding of engine dynamics and how to input custom specifications. By doing this, businesses can accurately simulate engine performance and make informed decisions that save time and resources in the design and testing phases.

Scenario 2: Ensuring Accurate Simulations Across Diverse Environments

The Problem: Another significant pain point for B2B buyers is ensuring that simulations reflect real-world performance across diverse environmental conditions. Factors such as altitude, temperature, and humidity can dramatically affect engine performance, yet many users do not know how to adjust these variables in the desktop dyno software effectively. This oversight can lead to costly miscalculations when engines are tested under different conditions than those simulated.

The Solution: Buyers should take advantage of the built-in environmental adjustment features in the desktop dyno software. These allow users to simulate various conditions, which can be crucial for companies operating in different geographical markets. It is recommended to gather historical environmental data relevant to the target market and input this data into the simulation. This practice ensures that the performance predictions are realistic and reliable. Engaging with local experts or conducting field tests can further refine the accuracy of simulations, allowing for a more tailored approach to engine design that meets specific market demands.

Scenario 3: Maximizing ROI Through Effective Component Testing

The Problem: Many B2B buyers struggle with maximizing their return on investment (ROI) when it comes to engine components. The cost of experimenting with various parts can be prohibitive, especially for smaller businesses or startups in competitive markets. Without a clear strategy for testing and selecting components, companies may end up investing in parts that do not yield the desired performance improvements, resulting in wasted resources.

The Solution: To optimize ROI, buyers should utilize the QuickIterator™ feature to automate testing of different component combinations. This powerful tool allows users to run simulations quickly and efficiently, identifying the best-performing parts without the need for extensive trial and error. Furthermore, businesses should implement a systematic approach to component testing by setting clear performance benchmarks and using the software to compare results across various configurations. By documenting findings and leveraging data analytics, companies can make informed decisions that not only enhance engine performance but also lead to significant cost savings in the long run.

Strategic Material Selection Guide for desktop dyno

What Are the Key Properties of Common Materials Used in Desktop Dyno?

When selecting materials for desktop dyno applications, it is essential to consider their properties that directly influence performance, such as temperature and pressure ratings, as well as corrosion resistance. Here, we analyze four common materials: aluminum, steel, plastic, and composite materials.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is a popular choice for components in desktop dyno applications due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressure.

Pros: Aluminum is durable and easy to machine, making it suitable for intricate designs. Its lightweight characteristic also aids in reducing overall system weight, which can be beneficial in portable applications.

Cons: While aluminum is resistant to corrosion, it can be less durable than steel under high-stress conditions. Additionally, it may be more expensive than some alternatives, depending on the grade.

Impact on Application: Aluminum is compatible with various media, including oils and fuels, making it suitable for engine components.

Considerations for International Buyers: Buyers from regions like Germany and Nigeria should ensure compliance with European and Nigerian standards for aluminum alloys, such as EN 573 and ASTM B221, respectively.

Steel: Strength and Versatility

Steel is known for its exceptional strength and versatility, making it ideal for high-stress components in desktop dynos. With a temperature rating that can exceed 1,500°F (815°C) and high pressure resistance, steel is a reliable choice.

Pros: Steel offers high durability and is often more cost-effective than aluminum for large components. It can be easily welded and machined, allowing for complex designs.

Cons: Steel is heavier than aluminum, which can be a disadvantage in portable applications. It is also prone to corrosion if not properly treated or coated.

Impact on Application: Steel components can handle high-pressure environments, making them suitable for critical engine parts.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is crucial for buyers in South America and Europe to ensure material quality and performance.

Plastic: Lightweight and Cost-Effective

Plastic materials, particularly engineering plastics like nylon and polycarbonate, are increasingly used in desktop dyno applications due to their lightweight and cost-effective nature. They typically have a lower temperature rating, around 200°F (93°C), and moderate pressure resistance.

Pros: Plastics are generally less expensive than metals and can be molded into complex shapes, making them ideal for custom components. They also offer good chemical resistance.

Cons: Plastics may not withstand high temperatures or pressures as effectively as metals, limiting their use in high-performance applications. They can also degrade over time when exposed to UV light.

Impact on Application: Plastic components are suitable for non-structural parts, such as housings or covers, where weight savings are essential.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ISO 9001 for quality assurance in plastic manufacturing, particularly in regions like the Middle East.

Composite Materials: Advanced Performance

Composite materials, such as carbon fiber and fiberglass, are gaining popularity in high-performance applications due to their strength-to-weight ratio and resistance to environmental factors. They can handle temperatures up to 300°F (149°C) and moderate pressure.

Pros: Composites are incredibly lightweight and can be engineered for specific performance characteristics, making them ideal for high-performance dyno applications.

Illustrative image related to desktop dyno

Cons: The manufacturing process for composites can be complex and costly. They may also require specialized handling during production and assembly.

Impact on Application: Composites are particularly suitable for components that require high strength while minimizing weight, such as structural supports.

Considerations for International Buyers: Compliance with aerospace or automotive standards, such as ASTM D3039 for tensile properties, is essential for buyers in Europe and Africa to ensure product reliability.

Summary Table of Material Selection for Desktop Dyno

| Material | Typical Use Case for desktop dyno | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, housings | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Steel | Structural components, brackets | High strength and cost-effective | Heavier, prone to corrosion | Low |

| Plastic | Non-structural parts, covers | Cost-effective and easy to mold | Limited temperature and pressure resistance | Low |

| Composite Materials | High-performance structural components | High strength-to-weight ratio | Complex manufacturing process | High |

In-depth Look: Manufacturing Processes and Quality Assurance for desktop dyno

What Are the Main Stages of the Manufacturing Process for Desktop Dyno?

The manufacturing process for desktop dyno software involves several critical stages, ensuring that the end product is both functional and user-friendly.

Illustrative image related to desktop dyno

Material Preparation: What Inputs Are Needed for Development?

The first stage of production includes gathering the necessary software components and algorithms that will be utilized in the desktop dyno simulation. This involves sourcing high-quality programming languages, libraries, and frameworks that facilitate engine simulation. The development team must ensure that these materials are compatible with various operating systems, particularly Windows versions, as the software is designed to operate on PCs.

Forming: How Is the Software Engineered?

In the forming stage, developers create the core architecture of the software. This includes the design of the user interface (UI) and the user experience (UX) to ensure that the software is intuitive and accessible. The engine simulation algorithms are coded to handle various engine specifications, from cylinder configurations to torque and horsepower calculations. This stage often involves iterative testing and refinement to optimize performance and accuracy.

Assembly: How Are Features Integrated?

During the assembly phase, different modules of the software are integrated. This includes linking the simulation engine with the user interface and ensuring that various calculators—like the Cam-Math QuickCalculator™ and QuickIterator™—work seamlessly together. Extensive debugging is performed to identify and rectify any issues that may hinder the software’s performance.

Finishing: What Final Touches Are Applied?

The finishing stage includes final testing and quality assurance checks. This is where the software is subjected to rigorous performance evaluations to ensure it meets the claimed accuracy levels (within 5% of real dyno data). Additionally, the user manual, which serves as a guide for users, is prepared and incorporated into the final product.

What Are the Key Quality Control Measures for Desktop Dyno?

Quality assurance is paramount in the software development lifecycle, particularly for a product like desktop dyno that caters to a specialized audience.

Which International Standards Apply to Desktop Dyno Software?

Compliance with international standards such as ISO 9001 is essential for ensuring quality management throughout the development process. ISO 9001 provides a framework for improving processes, boosting efficiency, and enhancing customer satisfaction. Additionally, software specific certifications may include CE marking to indicate conformity with health, safety, and environmental protection standards within the European Economic Area.

What Quality Control Checkpoints Should Be Implemented?

To maintain high-quality standards, several quality control checkpoints should be integrated into the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of software components and libraries before they are integrated into the main system. Ensuring that all inputs meet predetermined specifications is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): During the development phase, periodic assessments are conducted to ensure that the software is being built according to specifications. This includes code reviews and functionality tests to catch issues early in the process.

-

Final Quality Control (FQC): Before the product is released, a comprehensive final quality check is performed. This includes performance testing, user experience assessments, and compliance verification with industry standards.

What Common Testing Methods Are Used?

Testing methods for desktop dyno software include:

- Unit Testing: Individual components or functions are tested to ensure they work correctly in isolation.

- Integration Testing: This checks that different modules of the software work together as intended.

- System Testing: The complete system is tested to verify that it meets the specified requirements.

- User Acceptance Testing (UAT): Real users test the software to confirm it meets their needs and expectations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their software suppliers adhere to stringent quality control measures. Here are several strategies for verification:

Illustrative image related to desktop dyno

What Role Do Audits and Reports Play?

Conducting supplier audits is a vital step in verifying the quality control processes of a software provider. These audits can be scheduled regularly or as needed, assessing compliance with both international standards and internal quality benchmarks. Buyers should request detailed reports that outline the results of these audits, providing insights into the supplier’s quality management practices.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can include software performance evaluations and compliance checks with international standards. A reputable third-party inspection can offer assurance that the supplier maintains high-quality standards throughout their manufacturing processes.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

Illustrative image related to desktop dyno

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations regarding software products. For example, European buyers will need to ensure that their software complies with GDPR regulations, which govern data protection and privacy. Similarly, buyers in Africa or South America should be aware of local compliance requirements that might affect software deployment.

What Cultural Considerations Should Be Taken Into Account?

Cultural differences can influence how quality assurance is perceived and implemented. Buyers should consider the supplier’s understanding of local market demands and their ability to adapt their quality control processes accordingly. This adaptability can be a significant factor in ensuring that the software meets the specific needs of various markets.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance practices for desktop dyno software is essential for B2B buyers. By focusing on the key stages of production, quality control measures, and verification strategies, buyers can make informed decisions and ensure they are partnering with reliable suppliers. This knowledge not only enhances the purchasing process but also contributes to the overall success of engine simulation projects in diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘desktop dyno’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure the DeskTop Dyno engine simulation software. With its extensive features and capabilities, making an informed purchasing decision is essential for maximizing your investment. This checklist will help you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Identify the specific features of DeskTop Dyno that align with your business needs, such as the ability to simulate various engine types or utilize advanced calculators. Understanding your technical specifications will streamline your search and ensure that the software meets your operational demands.

Step 2: Research Available Versions

DeskTop Dyno offers multiple versions, including DeskTop Dyno 5 and its basic iteration. Evaluate the differences in features, pricing, and compatibility with your systems. Focus on the version that provides the best value for your intended use—whether for casual testing or professional-grade simulations.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, conduct a thorough evaluation of potential suppliers. Request company profiles, customer testimonials, and case studies, particularly from businesses in similar industries or regions. This step is vital to ensure the supplier has a strong track record of reliability and customer support.

- Verify Supplier Certifications: Check if the supplier holds relevant certifications that demonstrate their credibility and adherence to industry standards.

Step 4: Assess Software Compatibility

Ensure that the DeskTop Dyno software is compatible with your existing hardware and operating systems. The software is designed for Windows environments, so confirm your systems meet the necessary specifications, including RAM, processor speed, and display resolution. Compatibility issues can lead to additional costs and operational disruptions.

Step 5: Request a Demonstration

Prior to purchase, request a live demonstration of the software. This allows you to see the software in action and evaluate its usability and functionality. Pay attention to the user interface, the ease of access to various features, and how intuitive the simulation process is for your team.

Step 6: Review Pricing and Warranty Options

Compare pricing structures among different suppliers to ensure you receive competitive rates. Inquire about warranty options and post-purchase support services, as these can significantly affect your total cost of ownership. A robust warranty and support framework can save you time and money in the long run.

Step 7: Consider Future Scalability

Finally, think about the future needs of your business. Will your operations expand to require additional features or capabilities? Choose a version of DeskTop Dyno that not only meets your current requirements but also allows for upgrades or additional modules as your needs evolve. This foresight will help you avoid costly replacements down the line.

By following this checklist, you can make a well-informed decision when sourcing DeskTop Dyno software that aligns with your business objectives and technical requirements.

Comprehensive Cost and Pricing Analysis for desktop dyno Sourcing

What Are the Key Cost Components of Desktop Dyno Sourcing?

When analyzing the cost structure for sourcing desktop dyno software, several components must be considered:

-

Materials: This primarily involves the software development costs, including licenses for third-party components, server hosting, and cloud storage solutions. Additionally, ongoing updates and maintenance require a steady investment in technology and resources.

-

Labor: Skilled labor, including software developers, engineers, and support staff, constitutes a significant portion of the cost. The complexity of the software demands expertise in engineering and computer science, which can elevate wage expectations, particularly in regions with high demand for tech talent.

-

Manufacturing Overhead: For companies that bundle software with hardware (e.g., specific dyno testing equipment), overhead costs such as utilities, rent, and administrative expenses must be factored in. Even for software-only products, overhead related to customer service and sales operations plays a role.

-

Tooling: While primarily associated with physical products, tooling in the software industry refers to development environments, testing platforms, and debugging tools. The investment in robust development tools can lead to increased initial costs but is essential for long-term quality and efficiency.

-

Quality Control (QC): Ensuring the software performs as expected involves rigorous testing and validation processes. This may include beta testing phases and user feedback integration, which can add to the overall cost but ultimately enhances product reliability.

-

Logistics: This involves the distribution of the software, including digital delivery systems and potential support systems for installation and troubleshooting. Although logistics costs are lower for digital products compared to physical goods, they still require investment in customer support infrastructure.

-

Margin: Finally, companies will include a profit margin, which can vary significantly based on market position, competition, and perceived value. Premium features or superior customer support can justify higher margins.

How Do Price Influencers Impact Desktop Dyno Software Costs?

Several factors influence the pricing of desktop dyno software, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should negotiate for better pricing structures when ordering multiple licenses or seeking long-term contracts.

-

Specs/Customization: Custom features tailored to specific needs can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses and explore off-the-shelf solutions that may meet their needs at a lower price.

-

Materials: The quality of the software, including the underlying algorithms and data accuracy, can affect pricing. Software that offers advanced simulation capabilities or extensive databases may command a premium.

-

Quality/Certifications: Certifications for quality assurance or industry standards can influence pricing. Software that meets rigorous quality benchmarks may be priced higher but could offer better long-term value.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to brand equity, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: For international buyers, understanding Incoterms is crucial. These terms dictate responsibilities for shipping, insurance, and tariffs, which can significantly impact the total landed cost of the software.

What Are Effective Buyer Tips for Negotiating Desktop Dyno Prices?

-

Leverage Negotiation: Engage in discussions with suppliers to negotiate better terms, especially for bulk purchases. Highlighting potential long-term partnerships can incentivize suppliers to offer favorable pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the initial purchase price but also maintenance, support, and potential upgrade costs. This holistic view can lead to better purchasing decisions.

-

Understand Pricing Nuances for International Buyers: Be aware of regional pricing strategies and the economic context of your market. Suppliers may have different pricing tiers based on regional demand and competition.

-

Seek Local Support: For international buyers, consider suppliers with a local presence or those who offer robust support systems. This can save time and money in the long run, enhancing your overall experience with the product.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and competitor offerings can provide leverage in negotiations. Knowledge of what similar products are priced at can inform your discussions with suppliers.

Disclaimer on Indicative Prices

Prices for desktop dyno software can vary widely based on the aforementioned factors and market conditions. It is advisable for buyers to request formal quotes and conduct thorough market research to ensure they are receiving competitive pricing tailored to their specific requirements.

Alternatives Analysis: Comparing desktop dyno With Other Solutions

When evaluating engine simulation solutions, it’s crucial to consider various alternatives that can offer similar functionalities to DeskTop Dyno. Each option has unique features and benefits tailored to different business needs and budget constraints. Here, we present a comparison of DeskTop Dyno against two alternative solutions: Engine Analyzer Pro and DynoSim.

Illustrative image related to desktop dyno

| Comparison Aspect | ‘Desktop Dyno’ | Engine Analyzer Pro | DynoSim |

|---|---|---|---|

| Performance | High accuracy with up to 5% variance | Very accurate, but requires fine-tuning | Good accuracy, more generalized results |

| Cost | Low-cost, typically under $70 | Mid-range, around $200 | Higher-end, approximately $300 |

| Ease of Implementation | User-friendly with intuitive interface | Moderate learning curve | Advanced features may complicate use |

| Maintenance | Minimal updates required | Regular updates with support | Requires more frequent updates |

| Best Use Case | DIY enthusiasts and small workshops | Professional tuning shops | Racing teams and high-performance shops |

What Are the Advantages and Disadvantages of Engine Analyzer Pro?

Engine Analyzer Pro is a robust alternative designed primarily for professional use. It offers a high level of accuracy and the ability to fine-tune engine parameters for precise simulations. However, the cost is significantly higher than DeskTop Dyno, making it less accessible for smaller workshops or individual users. While the software is feature-rich, it may require additional training to navigate effectively, which could be a barrier for some users.

How Does DynoSim Compare to DeskTop Dyno?

DynoSim provides a high-performance simulation environment tailored for racing teams and high-performance shops. Its advanced modeling capabilities allow for detailed analysis of engine performance under various conditions. However, it comes at a higher price point and may necessitate frequent updates to maintain accuracy. Additionally, the complexity of its features can lead to a steeper learning curve, which may deter less experienced users.

How Should B2B Buyers Choose the Right Engine Simulation Solution?

When selecting an engine simulation solution, B2B buyers should assess their specific needs, including budget, user experience, and the intended application. For smaller businesses or individual enthusiasts, DeskTop Dyno offers a cost-effective and user-friendly option that delivers reliable results. In contrast, professional tuning shops might find Engine Analyzer Pro more suitable due to its enhanced accuracy and advanced features. Racing teams looking for in-depth analysis may prefer DynoSim, despite its higher cost, for the detailed insights it provides.

Illustrative image related to desktop dyno

Ultimately, understanding the unique requirements of your business and the capabilities of each solution will ensure that you choose the right engine simulation software to optimize performance and drive success.

Essential Technical Properties and Trade Terminology for desktop dyno

What Are the Key Technical Properties of Desktop Dyno?

When considering the purchase of a desktop dyno, understanding its technical specifications is crucial for making informed decisions. Here are some of the essential properties that B2B buyers should consider:

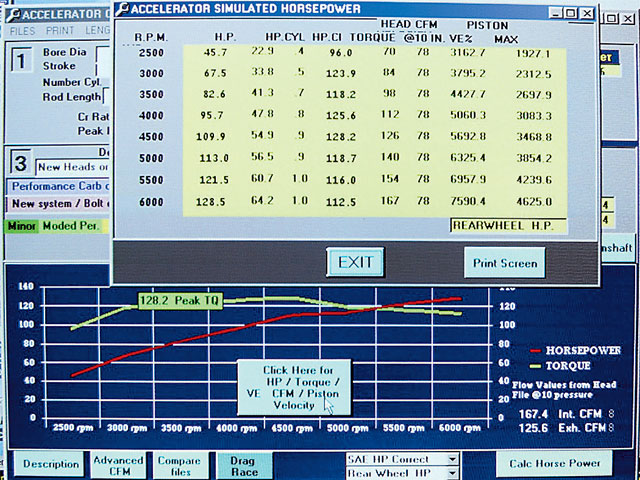

1. Simulation Accuracy

The accuracy of a desktop dyno is measured by how closely its simulated results align with actual dyno data. Typically, high-quality dynos can achieve an accuracy within 5% of real-world measurements. This precision is vital for businesses that rely on detailed engine performance data to make engineering decisions, as it can significantly reduce trial and error in product development.

2. Component Flexibility

Desktop dynos allow users to simulate a wide range of engine configurations, from 1 to 12 cylinders. This flexibility enables engineers and performance enthusiasts to test various engine setups, including different bore and stroke sizes, valve configurations, and fuel types. For B2B buyers, this means the ability to cater to diverse customer needs and preferences without the need for extensive physical prototyping.

Illustrative image related to desktop dyno

3. User Interface and Accessibility

The user interface of a desktop dyno is designed for ease of use, often featuring Direct-Click™ menus that simplify component selection. A well-designed interface enhances productivity by allowing quick modifications and simulations. This property is particularly important for teams with varying levels of technical expertise, ensuring that all members can efficiently utilize the software.

4. Built-in Calculators

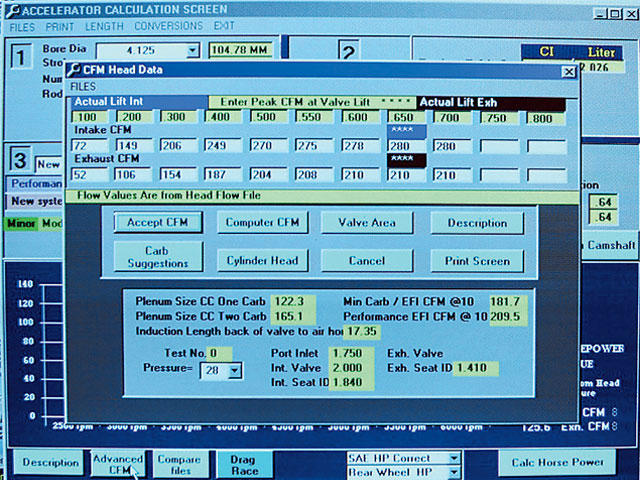

Advanced calculators, such as Cam-Math QuickCalculator™ and Induction-Flow calculators, are integrated into desktop dynos. These tools assist in detailed engine analysis, enabling users to evaluate various parameters quickly. For businesses, having these calculators at their disposal streamlines the design process, making it faster and more efficient to optimize engine performance.

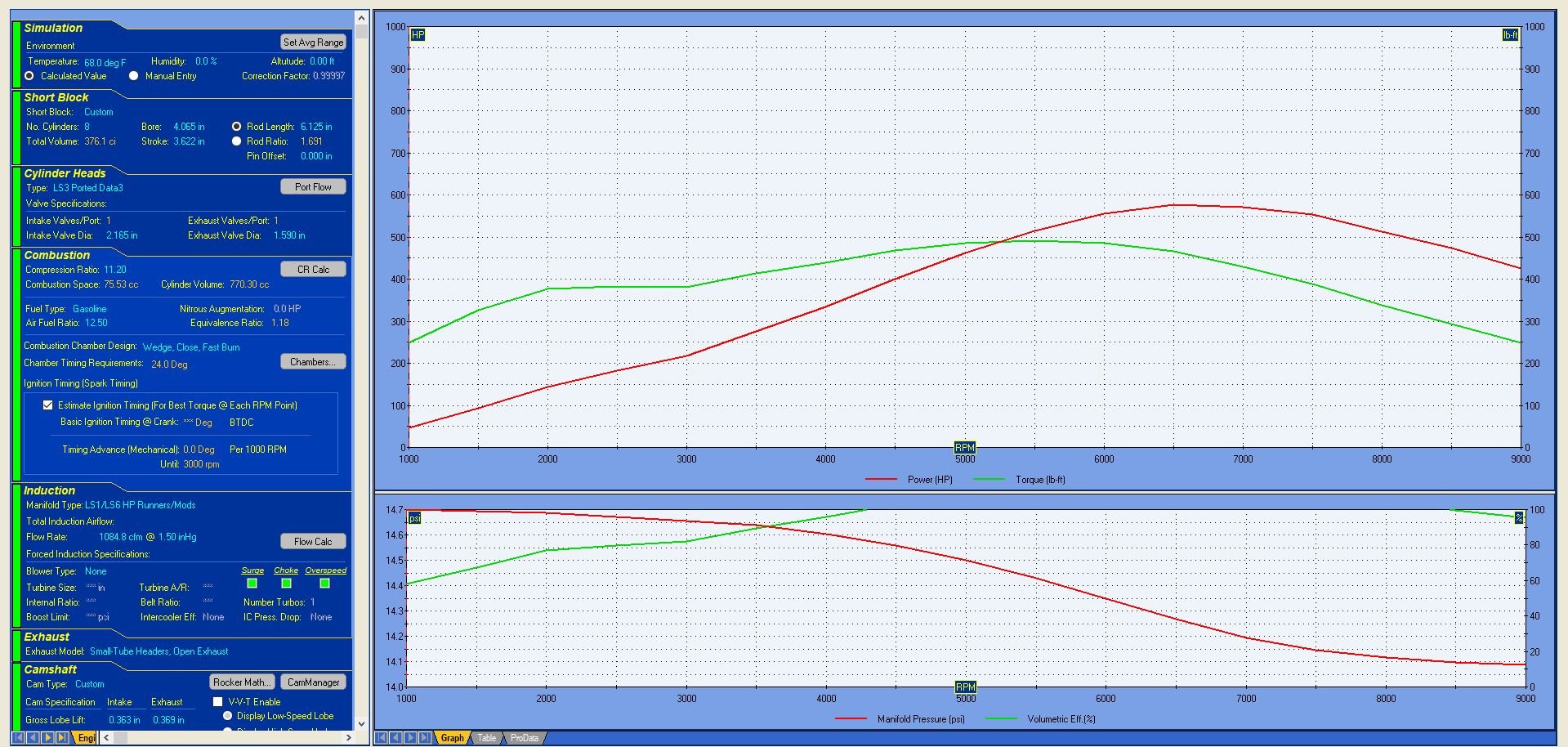

5. Data Visualization Capabilities

The ability to graphically represent engine performance data, such as horsepower and torque curves, is essential for analysis and presentation. Customizable graphs and tables allow for clearer communication of results to stakeholders. This feature can enhance decision-making processes and provide valuable insights during client presentations or internal reviews.

What Are Common Trade Terms Related to Desktop Dyno?

Familiarity with industry jargon is essential for effective communication in the B2B marketplace. Here are some common terms you may encounter when dealing with desktop dynos:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of desktop dynos, an OEM may provide specialized components or software that integrates with the dyno system, impacting performance and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is important for businesses looking to manage inventory costs effectively, especially when sourcing desktop dynos or related components in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers requesting pricing information for specific products or services. For desktop dynos, issuing an RFQ can help buyers compare costs and ensure they are getting the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Knowing these terms is crucial for businesses importing or exporting desktop dynos, as they outline who is responsible for shipping, insurance, and tariffs.

Illustrative image related to desktop dyno

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times for desktop dynos is essential for project planning and ensuring that product development timelines are met.

6. Technical Support

Technical support encompasses the assistance provided by manufacturers or suppliers to help users troubleshoot issues or optimize the use of their products. For B2B buyers, having reliable technical support can enhance the overall value of their investment in desktop dyno technology.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions, fostering better relationships with suppliers and ensuring their projects succeed.

Navigating Market Dynamics and Sourcing Trends in the desktop dyno Sector

What Are the Current Market Dynamics and Key Trends in the Desktop Dyno Sector?

The desktop dyno sector is witnessing significant transformation driven by technological advancements and increasing demand for precise engine simulations. Global drivers such as the rise in automotive performance tuning, the growing popularity of motorsports, and the need for cost-effective engine testing solutions are fueling market growth. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced simulation software that offers high accuracy at lower costs.

Emerging trends indicate a shift towards cloud-based solutions, enabling users to access powerful simulation tools without the need for extensive hardware investments. Additionally, the integration of artificial intelligence and machine learning into simulation software is enhancing predictive capabilities, allowing users to optimize engine configurations more efficiently. B2B buyers are also focusing on software that provides extensive databases of engine components and customizable features to cater to diverse automotive needs.

Market dynamics are influenced by competitive pricing, with many suppliers offering tiered packages to attract different buyer segments. As buyers from regions like Nigeria and Germany become more discerning, they prioritize software that combines functionality with user-friendly interfaces. This trend emphasizes the need for vendors to invest in customer support and training to facilitate smoother transitions to advanced simulation technologies.

How Does Sustainability and Ethical Sourcing Impact the Desktop Dyno Sector?

Sustainability is becoming a critical consideration for B2B buyers in the desktop dyno sector. As environmental concerns gain traction, the demand for software solutions that minimize waste and resource consumption is increasing. Buyers are now looking for vendors who adopt sustainable practices, including the use of ‘green’ certifications and materials in their product development.

In the context of desktop dyno software, this translates into sourcing practices that prioritize energy-efficient development processes and eco-friendly packaging. Companies are encouraged to showcase their commitment to sustainability through transparent supply chains and responsible sourcing practices. As buyers become more conscious of their environmental impact, they are likely to favor vendors who align with their values, thereby influencing purchasing decisions.

Moreover, the integration of sustainable practices can enhance a company’s brand reputation, making it more attractive to potential customers. B2B buyers are increasingly inclined to partner with organizations that prioritize ethical sourcing and sustainability, recognizing that these factors contribute to long-term business viability and corporate social responsibility.

What Is the Brief Evolution of Desktop Dyno Software?

The evolution of desktop dyno software began in the late 1990s when the need for affordable and accessible engine simulation tools emerged. Early iterations were limited in features but laid the groundwork for more advanced capabilities. Over the years, advancements in computing power and software development led to the introduction of more sophisticated versions like DeskTop Dyno 5, which boasts enhanced accuracy and a user-friendly interface.

The introduction of features such as the QuickIterator™ automated testing tool revolutionized the way engine configurations were optimized, allowing users to find the best parts combinations with minimal effort. As the software evolved, it began to cater to a broader audience, including both amateur enthusiasts and professional tuners, thereby expanding its market reach.

Today, desktop dyno software represents a crucial tool for performance engineers, enabling them to conduct detailed analyses and simulations that were once only possible on physical dynamometers. This evolution reflects the growing importance of precision in automotive engineering, driven by technological advancements and the increasing demand for high-performance vehicles.

Frequently Asked Questions (FAQs) for B2B Buyers of desktop dyno

-

How do I ensure the accuracy of simulations with DeskTop Dyno?

To ensure accurate simulations with DeskTop Dyno, it’s crucial to input precise specifications for the engine components you are testing. Familiarize yourself with the software’s extensive library of parts, or enter custom specs if necessary. Regularly update the software to leverage the latest features and improvements. Additionally, cross-reference the simulation results with real-world data when possible, as this will help validate the predictions made by the software, enhancing your confidence in the results. -

What is the best engine simulation software for performance testing?

DeskTop Dyno 5 is widely regarded as one of the best engine simulation software options for performance testing due to its high accuracy and extensive feature set. It allows users to simulate a wide range of engine configurations, offering tools to analyze horsepower, torque, and other critical performance metrics. With user-friendly interfaces and advanced calculators, it caters to both novice and expert engine builders, making it an ideal choice for those looking to optimize engine performance effectively. -

What are the key features of DeskTop Dyno that benefit B2B buyers?

B2B buyers will find several key features in DeskTop Dyno particularly beneficial. The software supports the simulation of 1- to 12-cylinder engines and offers customizable graphs and tables to visualize performance data. Its QuickIterator™ tool automates testing, identifying optimal component combinations quickly, which saves time and resources. Additionally, the software’s ability to model various fuels and conditions enhances its versatility, making it suitable for diverse applications across different markets. -

What are the payment terms typically available for purchasing DeskTop Dyno?

Payment terms for purchasing DeskTop Dyno may vary by supplier but generally include options for credit card payments, bank transfers, and sometimes installment plans for larger purchases. It’s advisable to inquire directly with the supplier regarding specific terms, including any discounts for bulk orders or long-term contracts. Ensure to clarify currency options and any additional fees associated with international transactions, particularly when dealing with buyers from Africa, South America, and the Middle East. -

How can I vet suppliers when sourcing DeskTop Dyno?

When vetting suppliers for DeskTop Dyno, consider their reputation in the industry, customer reviews, and their history of reliability. Request references from previous customers and check their experience with international shipping, especially if you are based in regions like Africa or South America. Additionally, verify that the supplier offers adequate customer support and warranty options, as this will be critical for troubleshooting and future assistance. -

What is the minimum order quantity (MOQ) for DeskTop Dyno licenses?

The minimum order quantity for DeskTop Dyno licenses can vary depending on the supplier and the specific licensing structure they offer. Some may allow single licenses for individual users, while others may have a MOQ for bulk purchases aimed at businesses or educational institutions. Always confirm the MOQ with the supplier before placing an order to ensure it aligns with your purchasing needs and budget. -

What logistics options are available for international shipping of DeskTop Dyno?

International shipping logistics for DeskTop Dyno typically include options such as standard air freight, express shipping, or sea freight for larger orders. It’s important to discuss shipping methods with your supplier, considering factors such as delivery time, cost, and tracking capabilities. Additionally, ensure that the supplier is experienced in handling customs clearance and provides necessary documentation to facilitate a smooth import process, especially for buyers in regions with strict customs regulations. -

What quality assurance measures should I expect from DeskTop Dyno suppliers?

Reputable DeskTop Dyno suppliers should implement stringent quality assurance measures, including software testing for bugs and performance issues before release. They should also provide a clear return policy and support for troubleshooting any problems that arise post-purchase. Requesting access to user manuals and documentation can also aid in understanding the software’s capabilities and ensure you are equipped to utilize it effectively in your business applications.

Top 5 Desktop Dyno Manufacturers & Suppliers List

1. Pro Racing Sim – DeskTop Dyno5

Domain: proracingsim.com

Registered: 2003 (22 years)

Introduction: DeskTop Dyno5 is an engine simulation software compatible with Windows 7, 8, 10 & 11 (32 and 64 bit). It allows users to build and test any 1- to 12-cylinder, 4-cycle engine. The software features a custom interface with parts selection on the left and test results on the right, using Direct-Click™ menus. It provides instant displays of horsepower, torque, VE, and other performance data with a 5% …

2. Motion Software – Dynomation-6

Domain: motionsoftware.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘Dynomation-6’, ‘description’: ‘Pro Engine Simulation, Highest Accuracy’, ‘features’: [‘Professional Engine Sim’, ‘Widely Used By Pro Racers’, ‘Design/Test Intake, Exhaust Runners’], ‘price’: ‘100% Money-Back Guarantee’}, {‘name’: ‘DynoSim-6’, ‘description’: ‘Wave-Assisted Simulation, Dynomation Power For 25% Of The Cost’, ‘features’: [‘Many Features of Dynomation at 25% Of The Cost’, ‘M…

3. COMP Cams – DeskTop Dyno 5

Domain: compcams.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “DeskTop Dyno 5”, “brand”: “COMP Cams”, “price”: “$64.95”, “sku”: “186011”, “availability”: “In stock”, “upc”: “036584197812”, “emissions_code”: “N/A”, “shipping_info”: “FREE Shipping on orders over $50”, “customer_support”: “800 999 0853”, “features”: [“Proper Procedure To Install And Degree A Camshaft”, “Easy Returns”, “Secure Payments”]}

4. Palmer Performance – Virtual Engine Dyno Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Virtual engine dyno options include free online or app-based tools. Users mentioned Palmer Performance for its features like gear ratios and weather adjustments, available in a lite or trial version for free. Another option is PipeMax, a relatively inexpensive software priced at around $100, which provides moderately accurate dyno numbers for different engine combinations.

5. Chevelles – FREE Desktop Dyno Software

Domain: chevelles.com

Registered: 1996 (29 years)

Introduction: FREE Desktop Dyno software available for download at http://carprogrammer.com/Z28/PCM/Too…0(selfzip).exe. The software is a tool for engine builders, providing performance estimates. Users are advised to reduce the output numbers by 13% for more realistic figures at the crank. The software supports various engine specifications, including bore, stroke, rod length, compression ratio, and cam spec…

Strategic Sourcing Conclusion and Outlook for desktop dyno

In today’s competitive landscape, strategic sourcing of software like DeskTop Dyno is essential for businesses looking to enhance engine performance and innovation. This powerful engine simulation tool allows users to accurately model engine components, optimize configurations, and significantly reduce costs by simulating outcomes before investing in physical parts. The QuickIterator™ feature stands out, enabling users to efficiently identify optimal combinations, thereby streamlining the design process and enhancing productivity.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, investing in DeskTop Dyno translates to not only immediate cost savings but also long-term gains in engine performance and reliability. The software’s compatibility with a wide range of systems makes it an accessible choice for diverse markets.

As you consider your sourcing strategy, prioritize tools that offer both accuracy and affordability. Embrace the potential of DeskTop Dyno to drive innovation in your projects. Now is the time to take the next step—explore how integrating this technology can elevate your business and meet the evolving demands of the automotive industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.