Everything You Need to Know About Rubber Injection Molding Process Sourcing in 2025

Introduction: Navigating the Global Market for rubber injection molding process

In an increasingly competitive global landscape, effectively sourcing rubber injection molding processes can pose significant challenges for B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe. The complexities involved in selecting the right molding technique—be it transfer, compression, or injection molding—are compounded by the diverse applications and specifications required across various industries. This guide aims to demystify the rubber injection molding process, offering insights into the types of molding available, their specific applications, and critical factors to consider when vetting suppliers.

By understanding the nuances of each molding method, buyers can make informed decisions that align with their operational needs and budget constraints. This comprehensive resource not only covers the technical aspects of rubber molding but also delves into practical considerations such as cost analysis and supplier evaluation criteria. Whether you are seeking to produce high-volume parts with precision or exploring custom solutions for unique applications, this guide equips international B2B buyers with the knowledge needed to navigate the complexities of rubber injection molding. Ultimately, our goal is to empower your purchasing decisions, ensuring that you select the most suitable solutions to drive your business success in today’s dynamic market.

Understanding rubber injection molding process Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Transfer Molding | Utilizes a closed mold; suitable for intricate designs | Automotive parts, seals, gaskets | Pros: Good for complex shapes; reduced waste. Cons: More waste produced; longer cycle times. |

| Rubber Compression Molding | Traditional method; uses open molds for pre-formed shapes | Low to medium volume parts, O-rings, gaskets | Pros: Strong materials; cost-effective for low volumes. Cons: Longer curing times; larger molds required. |

| Rubber Injection Molding | High precision; uses a screw to inject pre-heated rubber | High-volume production, automotive, electronics | Pros: Short cycle times; less material waste; high consistency. Cons: Higher initial tooling costs; may not be cost-effective for low volumes. |

| Liquid Silicone Rubber (LSR) | Uses liquid silicone; closed system to minimize contamination | Medical devices, consumer goods | Pros: Quick cycle times; excellent for detailed parts. Cons: Higher material costs; specialized equipment needed. |

| Thermoplastic Rubber Injection | Processes elastomers like plastic; recyclable materials | Consumer products, automotive applications | Pros: Versatile; can be colored and reused. Cons: Limited to high-temperature applications; may lack rubber-like properties. |

What Are the Key Characteristics of Rubber Transfer Molding?

Rubber transfer molding is ideal for producing parts with multiple cavities or complex geometries. This method involves loading rubber into a pot, which is then forced through sprues into a closed mold. It is particularly beneficial for applications requiring dimensional tolerance and reduced viscosity. B2B buyers should consider this method for projects needing intricate designs, although they must also be aware of the potential for increased material waste and longer cycle times compared to other methods.

How Does Rubber Compression Molding Work for B2B Needs?

Rubber compression molding is a traditional technique that involves placing pre-formed rubber shapes into open molds. This method is well-suited for low to medium production volumes and is often used for items like O-rings and gaskets. The primary advantages for B2B buyers include cost-effectiveness and the strength of the materials used. However, it requires longer curing times and larger molds, which can be a drawback for businesses with tight timelines or space constraints.

Illustrative image related to rubber injection molding process

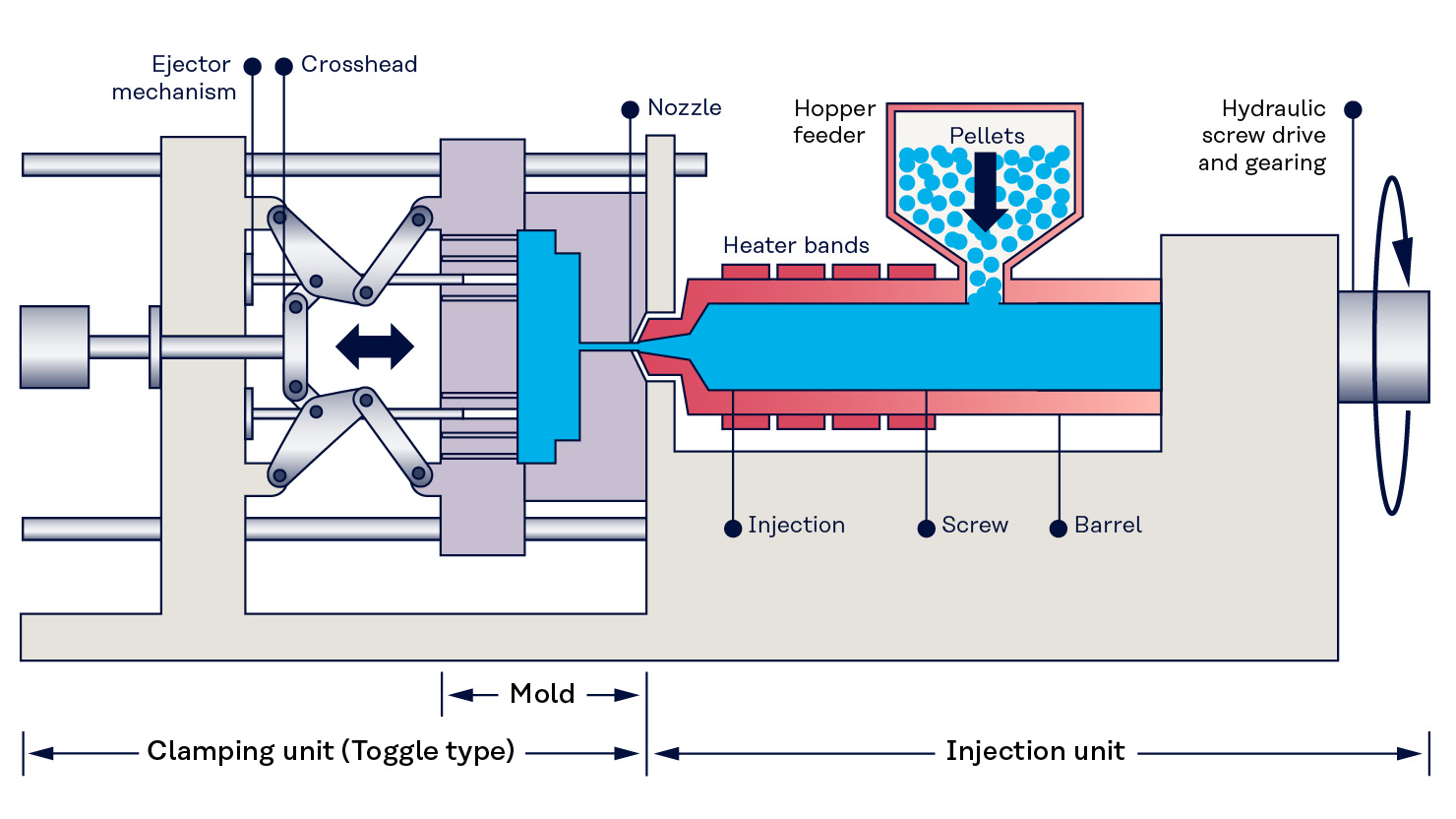

Why Choose Rubber Injection Molding for High-Volume Production?

Rubber injection molding is the most popular method due to its efficiency and precision. This process involves injecting pre-heated rubber into a mold under high pressure, making it suitable for high-volume production runs. Key applications include automotive and electronic components. B2B buyers benefit from shorter cycle times and reduced material waste, although the initial tooling costs can be higher. It is essential to evaluate the production volume to ensure that this method aligns with budget and operational goals.

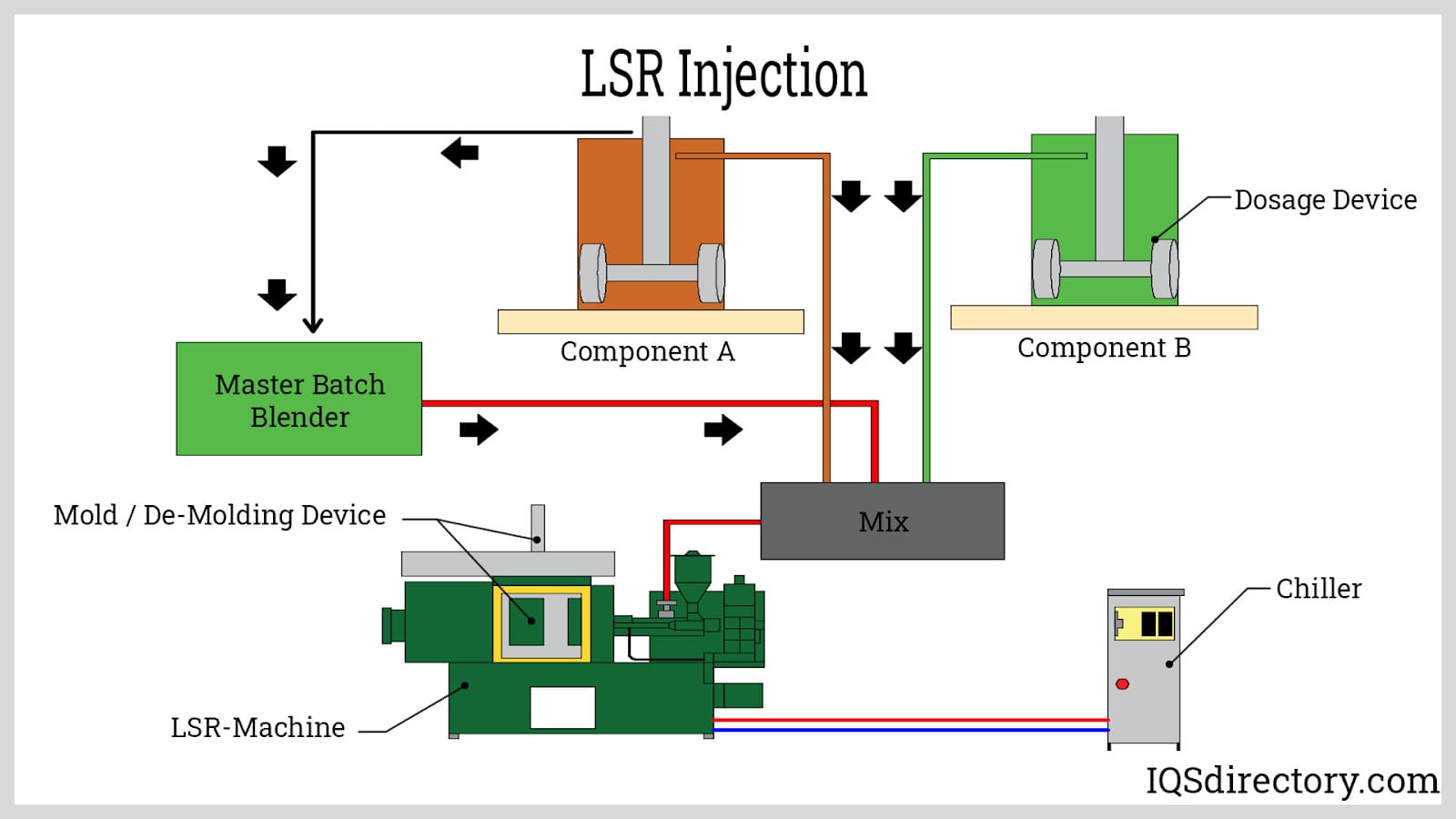

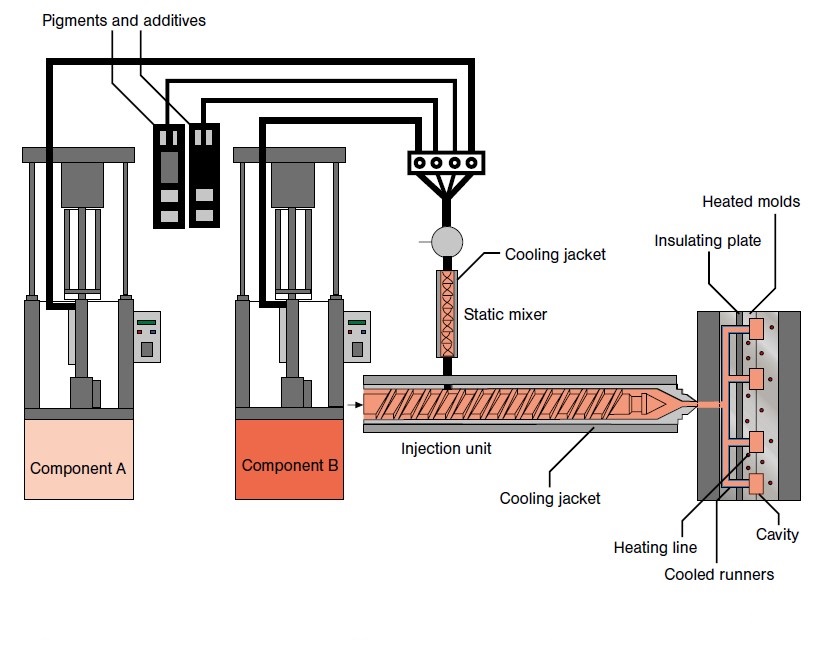

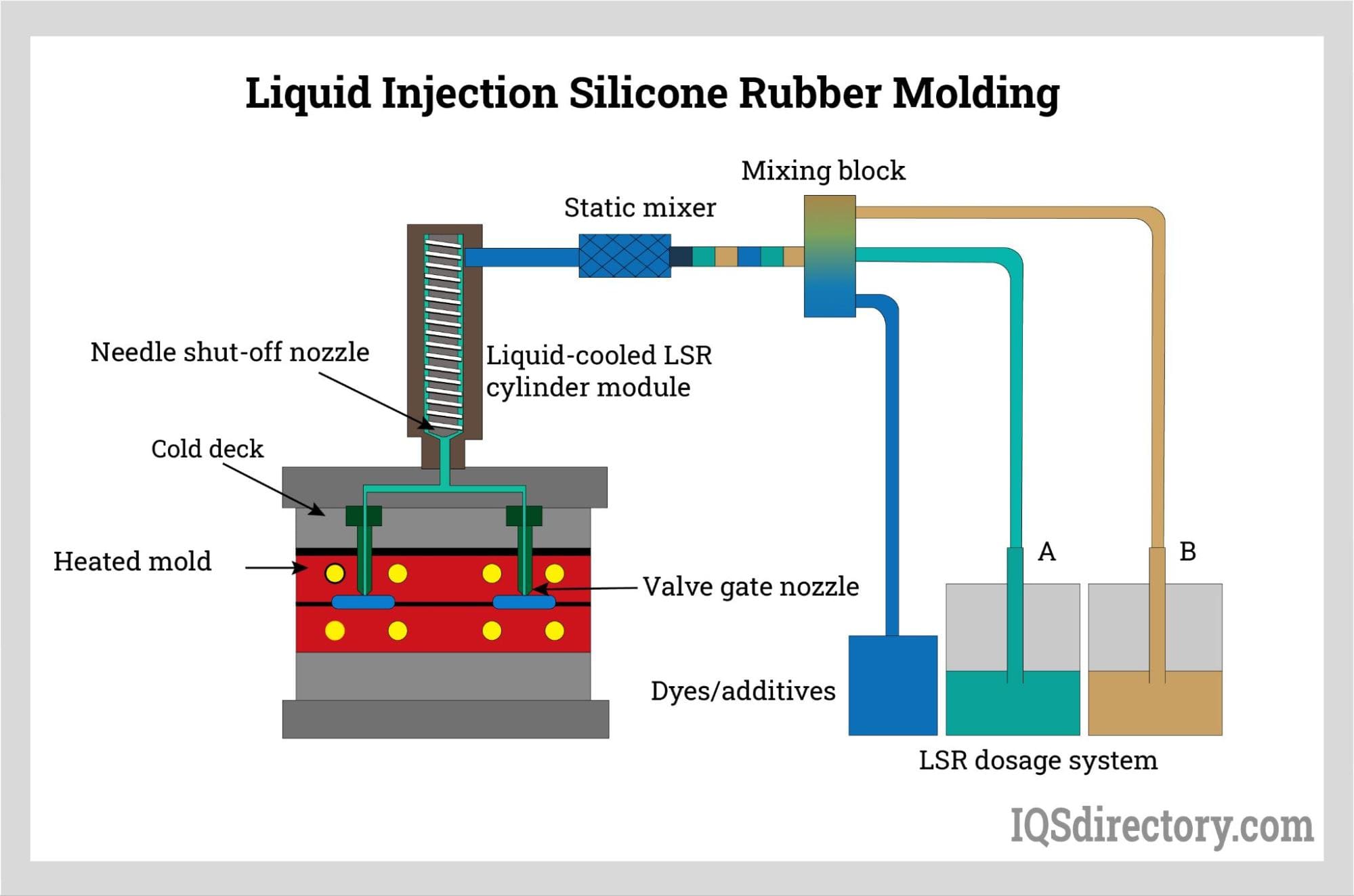

What Makes Liquid Silicone Rubber (LSR) Ideal for Specific Applications?

Liquid Silicone Rubber (LSR) is a specialized form of rubber injection molding that utilizes liquid silicone in a closed system. This method is particularly effective in minimizing contamination, making it ideal for medical devices and consumer goods. Buyers should consider LSR for its quick cycle times and ability to produce highly detailed parts. However, the higher material costs and need for specialized equipment may be a consideration for businesses looking to manage expenses.

How Do Thermoplastic Rubber Injection Processes Benefit B2B Buyers?

Thermoplastic rubber injection molding processes elastomers similarly to plastics, allowing for versatility in product design and recyclability. This method is suitable for various applications, including consumer products and automotive components. B2B buyers appreciate the ability to customize colors and reduce waste, but they should be cautious as this method is limited to high-temperature applications and may not provide the same properties as traditional rubber.

Key Industrial Applications of rubber injection molding process

| Industry/Sector | Specific Application of rubber injection molding process | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of seals, gaskets, and vibration dampers | Enhanced durability and performance of vehicle parts | Material specifications, volume requirements, lead times |

| Medical Devices | Manufacturing of silicone rubber components for devices | High precision and compliance with health standards | Regulatory certifications, material biocompatibility |

| Consumer Electronics | Creation of rubber casings and protective components | Improved product longevity and user experience | Customization options, design complexity, cost efficiency |

| Industrial Machinery | Production of rubber mounts and vibration isolators | Increased operational efficiency and reduced downtime | Durability standards, environmental resistance, volume |

| Construction Equipment | Fabrication of rubber seals and gaskets for machinery | Enhanced reliability and reduced maintenance costs | Material strength, compatibility with existing systems |

How is the Rubber Injection Molding Process Used in the Automotive Industry?

In the automotive sector, rubber injection molding is pivotal for producing seals, gaskets, and vibration dampers. These components are essential for maintaining vehicle integrity and performance. By utilizing this process, manufacturers can achieve high precision and consistency, which are critical for safety and functionality. International buyers should consider material specifications that meet automotive standards, as well as the required volume for production runs to optimize costs.

What Role Does Rubber Injection Molding Play in Medical Devices?

The medical industry relies heavily on rubber injection molding for creating silicone rubber components used in various devices, such as syringes, catheters, and seals. This process allows for high precision and the ability to meet stringent health regulations. For B2B buyers in this sector, sourcing materials with the necessary biocompatibility certifications is crucial. Additionally, understanding the lead times and production volumes can help streamline supply chains and ensure compliance with medical standards.

How is Rubber Injection Molding Applied in Consumer Electronics?

In consumer electronics, rubber injection molding is employed to manufacture protective casings and rubber components that enhance device durability. The process allows for intricate designs that cater to user experience, such as non-slip surfaces. For international buyers, customization options and the ability to scale production based on demand are key considerations. Cost efficiency and rapid prototyping can also significantly impact market entry and product development timelines.

Why is Rubber Injection Molding Important for Industrial Machinery?

Rubber injection molding is integral to the production of rubber mounts and vibration isolators used in industrial machinery. These components help reduce wear and tear on equipment, leading to increased operational efficiency and minimized downtime. Buyers in this sector should prioritize sourcing materials that meet durability standards and environmental resistance requirements. Understanding the specific needs of machinery compatibility is essential for ensuring optimal performance.

What are the Benefits of Rubber Injection Molding in Construction Equipment?

In the construction equipment industry, rubber injection molding is utilized to create seals and gaskets that enhance machinery reliability. These components are critical in preventing leaks and ensuring optimal operation under harsh conditions. For B2B buyers, it’s important to focus on material strength and compatibility with existing systems. Additionally, considering the volume of parts needed can help negotiate better pricing and lead times, which are vital for project timelines.

3 Common User Pain Points for ‘rubber injection molding process’ & Their Solutions

Scenario 1: Inconsistent Quality of Rubber Parts in Production

The Problem: B2B buyers often face the challenge of inconsistent quality in rubber parts produced through injection molding. This inconsistency can stem from various factors such as variations in material properties, improper mold design, or inadequate process control. For manufacturers in industries like automotive or medical devices, even minor discrepancies in part quality can lead to significant operational disruptions, increased costs, and potential safety risks. Buyers may find themselves dealing with parts that do not meet specifications, resulting in costly rework or even product recalls.

The Solution: To mitigate quality issues, it is crucial to implement a robust quality assurance process throughout the rubber injection molding stages. Begin by selecting a reputable supplier that utilizes advanced technologies and adheres to stringent quality standards. Request samples and conduct thorough testing to ensure that the materials used meet your specific requirements. Establish clear specifications for the parts, including dimensions, tolerances, and material properties. Additionally, consider investing in a quality management system that includes regular monitoring and testing of production processes. Engage in open communication with your supplier to address any quality concerns promptly, ensuring that corrective actions are taken before mass production.

Scenario 2: High Tooling Costs and Long Lead Times

The Problem: One of the most significant barriers for B2B buyers in rubber injection molding is the high upfront costs associated with tooling and the long lead times required to create molds. Custom molds can be expensive and take several weeks or even months to produce, which can delay product launches and strain budgets. For companies looking to bring innovative products to market quickly, these challenges can be particularly frustrating, especially in competitive industries where speed is crucial.

Illustrative image related to rubber injection molding process

The Solution: To effectively manage tooling costs and lead times, consider adopting a design-for-manufacturability approach early in the product development phase. Collaborate closely with your supplier during the design process to ensure that the mold can be manufactured efficiently without compromising quality. Explore options such as using modular tooling systems that allow for quicker adjustments and reduced costs. Additionally, utilizing 3D printing for prototype molds can significantly decrease lead times and costs, enabling rapid testing and iteration of designs before committing to full production tooling. Furthermore, discuss with your supplier about the potential for shared tooling arrangements, which can spread costs among multiple projects.

Scenario 3: Difficulty in Scaling Production Volumes

The Problem: As demand for rubber parts fluctuates, B2B buyers often find it challenging to scale production volumes efficiently. Companies may initially require low volumes for testing but later need to ramp up production to meet market demands. This scenario can create complications if the rubber injection molding process is not flexible enough to accommodate changing requirements, potentially leading to supply chain disruptions and lost sales opportunities.

The Solution: To address scalability issues, choose a rubber injection molding partner that offers a flexible production setup. Look for suppliers with capabilities for both low- and high-volume production runs. Implement a phased production strategy where initial small batches are produced to validate designs, followed by a smooth transition to larger volumes once requirements are confirmed. Additionally, consider leveraging technologies such as automation and data analytics, which can help streamline operations and enhance responsiveness to demand changes. Establishing a strong partnership with your supplier is also vital; maintain ongoing dialogues about potential market shifts to ensure that your production capacity can adapt quickly to changing needs.

Strategic Material Selection Guide for rubber injection molding process

What Are the Key Materials Used in Rubber Injection Molding?

When selecting materials for the rubber injection molding process, it is crucial to consider the properties and performance characteristics that align with specific applications. Below, we analyze four common materials used in rubber injection molding, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Natural Rubber: What Are Its Key Properties and Applications?

Natural rubber, derived from the sap of rubber trees, exhibits excellent elasticity, resilience, and tensile strength. Its temperature resistance typically ranges from -40°C to 80°C, making it suitable for various applications. However, it is less resistant to ozone and UV exposure, which can lead to degradation over time.

Pros: Natural rubber is cost-effective and provides high durability and flexibility, making it ideal for applications such as seals, gaskets, and automotive parts.

Cons: Its susceptibility to environmental factors limits its use in outdoor applications. Additionally, the sourcing of natural rubber can be impacted by climate conditions, affecting supply chains.

Impact on Application: Natural rubber is compatible with a wide range of media, including water and certain oils, but it is not suitable for aggressive chemicals.

Considerations for International Buyers: Compliance with ASTM D2000 standards is essential for ensuring quality. Buyers from regions like Africa and South America should also consider the sustainability of sourcing practices.

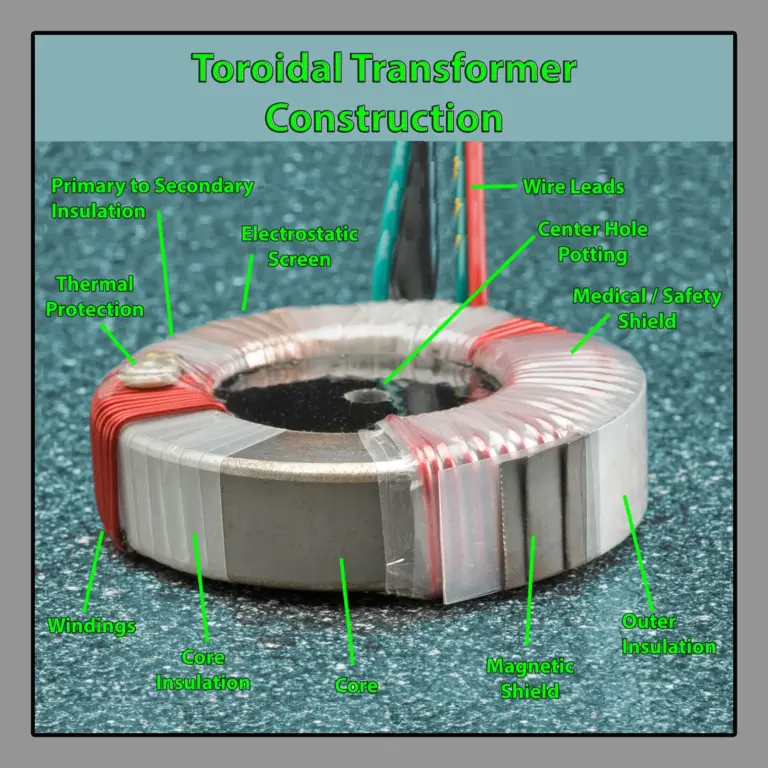

Silicone Rubber: How Does It Compare in Performance?

Silicone rubber offers exceptional temperature resistance, ranging from -60°C to 230°C, and is highly resistant to UV rays and ozone. Its flexibility and stability make it a preferred choice for applications requiring high performance in extreme conditions.

Illustrative image related to rubber injection molding process

Pros: Silicone rubber is chemically inert, making it suitable for food-grade applications and medical devices. Its durability and resistance to harsh environments enhance its appeal.

Cons: The manufacturing process can be more complex and costly compared to other rubber types, which may impact pricing for bulk orders.

Impact on Application: Its compatibility with a wide range of chemicals makes silicone rubber ideal for seals in the automotive and aerospace industries.

Illustrative image related to rubber injection molding process

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure compliance with food safety regulations (e.g., FDA, EU standards) when using silicone in food-related applications.

EPDM Rubber: What Are Its Advantages and Limitations?

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its excellent weather resistance and thermal stability, with a temperature range of -50°C to 150°C. It is also resistant to steam, ozone, and UV light, making it suitable for outdoor applications.

Pros: EPDM is highly durable and maintains its properties over time, making it ideal for roofing membranes, automotive seals, and weather stripping.

Cons: While it performs well in various environments, EPDM is not suitable for use with petroleum-based oils and solvents, which can limit its applications.

Impact on Application: Its resistance to various environmental factors ensures longevity in applications exposed to harsh weather conditions.

Considerations for International Buyers: Compliance with ASTM standards is critical, especially for construction and automotive applications. Buyers should also assess local sourcing options to mitigate supply chain risks.

Thermoplastic Elastomers (TPE): What Makes Them Unique?

Thermoplastic elastomers combine the properties of rubber and plastic, offering flexibility and ease of processing. They can withstand temperatures ranging from -30°C to 100°C and are recyclable, which is a significant advantage in sustainable manufacturing.

Pros: TPEs allow for faster production cycles and lower manufacturing costs due to their ease of processing. They are also available in various hardness levels, making them versatile for multiple applications.

Cons: While TPEs can mimic rubber properties, they may not match the performance of traditional rubber in high-stress applications.

Impact on Application: TPEs are suitable for consumer products, automotive components, and medical devices, where design flexibility is crucial.

Considerations for International Buyers: Buyers should ensure compliance with relevant international standards (e.g., JIS, DIN) and consider the environmental impact of sourcing TPE materials.

Summary Table of Material Selection for Rubber Injection Molding

| Material | Typical Use Case for rubber injection molding process | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Seals, gaskets, automotive parts | High durability and flexibility | Susceptible to environmental degradation | Low |

| Silicone Rubber | Food-grade applications, medical devices | Excellent temperature resistance | More complex and costly to manufacture | High |

| EPDM Rubber | Roofing membranes, weather stripping | Excellent weather resistance | Not suitable for petroleum-based oils | Medium |

| Thermoplastic Elastomers | Consumer products, automotive components | Fast production cycles | May not match traditional rubber performance | Medium |

This strategic material selection guide serves as a foundation for B2B buyers to make informed decisions regarding rubber injection molding materials, ensuring compatibility with their specific applications and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber injection molding process

What Are the Main Stages of the Rubber Injection Molding Manufacturing Process?

The rubber injection molding process consists of several critical stages that ensure the production of high-quality rubber components. Understanding these stages is essential for B2B buyers seeking reliable and efficient manufacturing solutions.

1. Material Preparation: How Is Rubber Prepared for Molding?

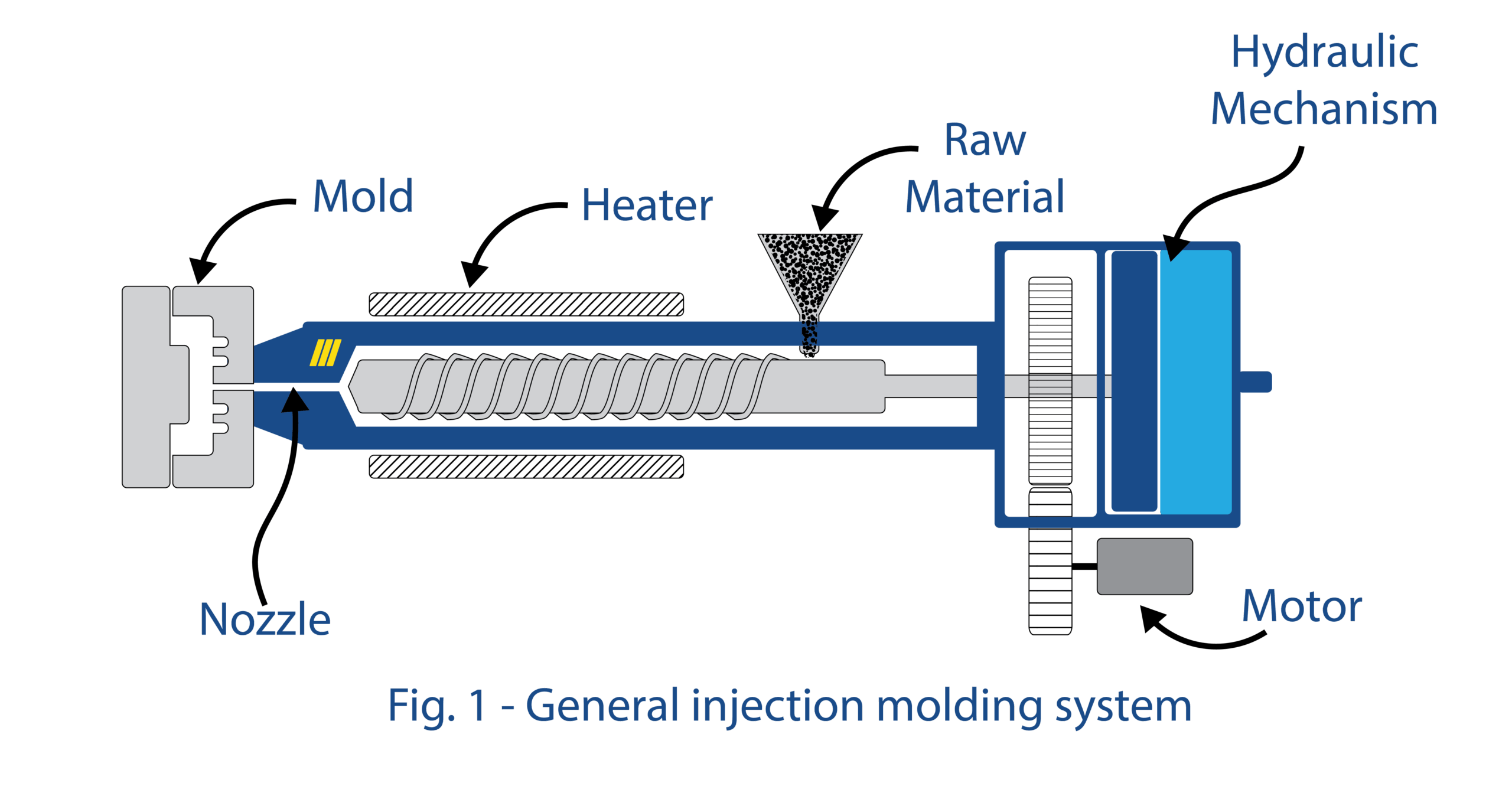

Material preparation is the first step in the rubber injection molding process. This involves selecting the appropriate type of rubber, whether organic, thermoplastic, or liquid silicone rubber (LSR), based on the intended application. The rubber is then mixed with various additives, such as curing agents, to achieve the desired properties.

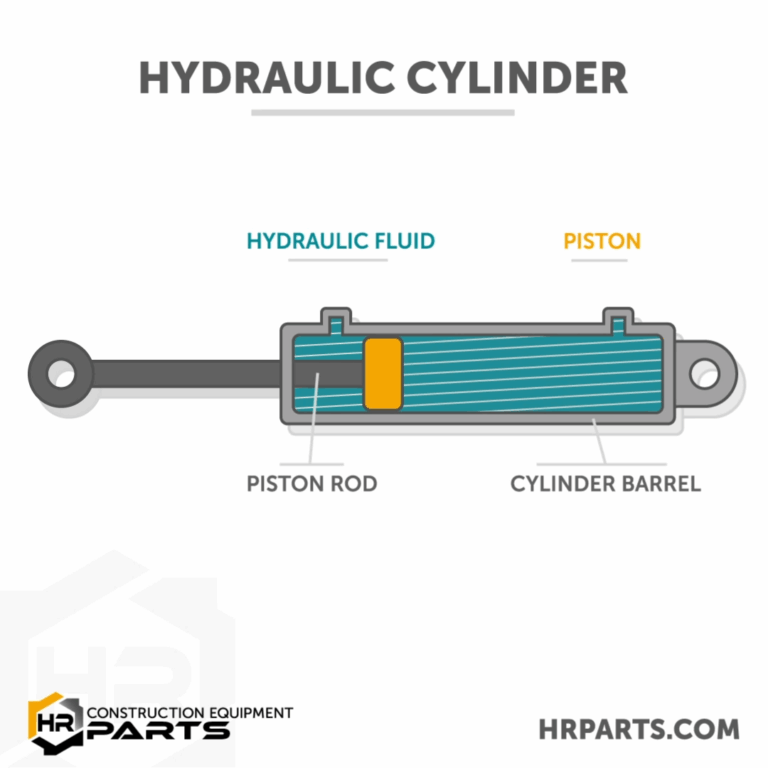

Once mixed, the rubber is fed into an injection unit, where it is preheated and plasticized to ensure optimal flow into the mold cavities. Proper material preparation is crucial for achieving consistent quality in the final product.

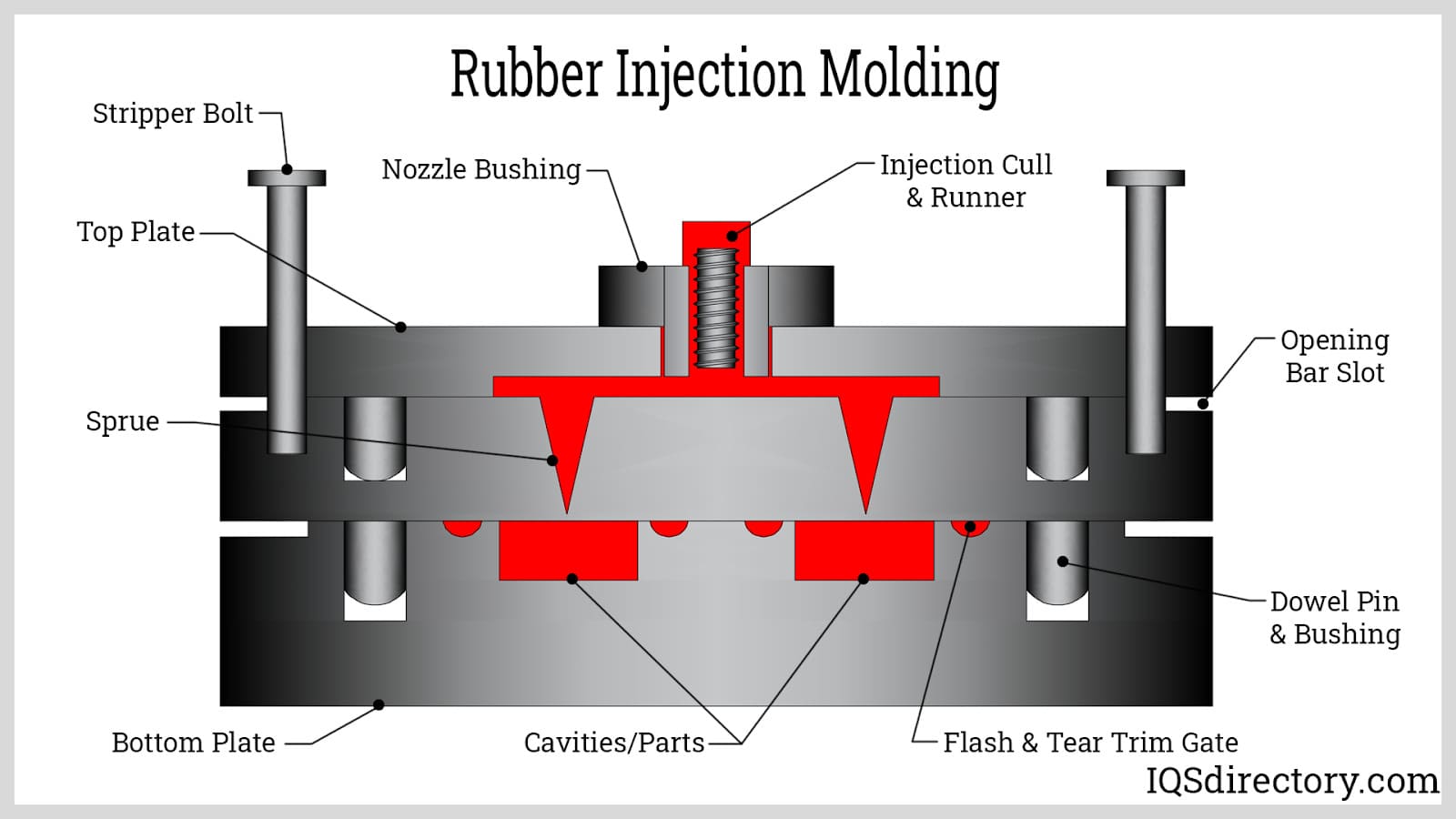

2. Forming: What Techniques Are Used for Shaping Rubber Parts?

The forming stage is where the actual shaping of rubber parts occurs. In rubber injection molding, the preheated rubber is injected into a mold cavity through a gate and runner system. This high-pressure process allows the rubber to fill intricate designs and complex geometries efficiently.

The choice of molding technique—whether organic rubber injection, liquid silicone injection, or thermoplastic rubber injection—depends on factors such as production volume, part complexity, and material characteristics. Each method has distinct advantages, such as reduced cycle times and lower material waste, making it essential for buyers to align their needs with the appropriate technique.

3. Assembly: How Are Rubber Components Assembled into Final Products?

In many cases, rubber parts may require assembly with other components, such as metal inserts or additional rubber pieces. This assembly can be done through over-molding, where a rubber part is molded around another component, ensuring a strong bond between materials.

B2B buyers should consider the assembly capabilities of their suppliers, as this can significantly impact lead times and overall product performance. Suppliers who can offer integrated assembly services may provide a competitive edge in terms of logistics and supply chain efficiency.

4. Finishing: What Processes Are Involved in the Final Touches?

The finishing stage involves processes such as trimming, surface treatment, and quality inspection. Trimming removes excess rubber from the molded parts, while surface treatments may enhance aesthetics or improve adhesion properties for subsequent coatings.

Final inspections at this stage ensure that the parts meet the required specifications and quality standards before they are shipped to clients. This is where quality assurance protocols come into play, ensuring that every product leaving the factory is fit for purpose.

What Quality Assurance Measures Are Essential for Rubber Injection Molding?

Quality assurance is a critical aspect of the rubber injection molding process, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

Relevant International Standards: Which Certifications Should B2B Buyers Look For?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality across their operations. Additionally, industry-specific certifications like CE (for European markets) and API (for oil and gas applications) indicate compliance with rigorous safety and performance standards.

Buyers should verify that their suppliers are certified and regularly undergo audits to maintain compliance with these standards. This certification not only assures product quality but also enhances the credibility of the supplier in the international market.

Quality Control Checkpoints: What Are the Key Stages of Quality Inspection?

Quality control (QC) in rubber injection molding typically involves several checkpoints, including:

-

Incoming Quality Control (IQC): This initial stage assesses raw materials to ensure they meet specified standards before production begins. This can involve testing for consistency in material properties and checking for contaminants.

-

In-Process Quality Control (IPQC): During production, IPQC monitors the molding process, checking parameters like temperature, pressure, and cycle times to ensure they remain within acceptable limits. This stage helps identify any deviations that may affect product quality.

-

Final Quality Control (FQC): After production, FQC involves rigorous testing of finished products against established specifications. Common testing methods include tensile strength tests, hardness testing, and visual inspections to identify defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to ensure that their suppliers maintain high-quality standards. Here are several strategies to consider:

1. Conducting Audits: What Should Buyers Look for During Supplier Audits?

Regular supplier audits can provide insight into a manufacturer’s quality management practices. Buyers should evaluate the supplier’s adherence to international standards, the effectiveness of their quality control processes, and their ability to respond to quality issues.

During audits, it’s essential to review documentation, such as inspection reports and compliance certificates, to verify that the supplier follows established protocols.

2. Reviewing Quality Reports: How Can Buyers Assess Quality Performance?

Requesting quality reports from suppliers can offer transparency into their manufacturing processes. These reports should include details on defect rates, corrective actions taken, and results from recent quality inspections.

Buyers should look for patterns in these reports to assess the reliability of the supplier over time. Consistent performance with minimal defects is a positive indicator of a supplier’s quality commitment.

3. Utilizing Third-Party Inspections: What Are the Benefits of Independent Verification?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be particularly valuable for international buyers, who may face challenges in verifying quality standards remotely.

Independent inspectors can conduct on-site evaluations and testing, ensuring that products meet the required specifications before shipment. This extra layer of verification can help mitigate risks associated with cross-border transactions.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their procurement processes.

1. Understanding Regional Standards: How Do Local Regulations Impact Quality?

Different regions may have varying regulations and standards governing product quality. Buyers should familiarize themselves with local requirements in their target markets to ensure compliance. For instance, products destined for the European market must adhere to CE marking requirements, while those for the Middle East may need to meet specific GSO standards.

2. Addressing Language Barriers: How Can Communication Be Enhanced?

Language differences can pose challenges in understanding quality documentation and specifications. Buyers should ensure that suppliers provide materials in a language they are comfortable with, or consider using professional translation services to facilitate clear communication.

Illustrative image related to rubber injection molding process

3. Navigating Supply Chain Challenges: What Considerations Are Important?

Supply chain complexities, such as transportation logistics and customs regulations, can impact the timely delivery of quality products. Buyers should work closely with suppliers to establish transparent supply chain practices, ensuring that quality is maintained throughout the delivery process.

By understanding the intricacies of the rubber injection molding manufacturing process and quality assurance measures, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber injection molding process’

Introduction

This practical sourcing guide is designed for international B2B buyers seeking to procure rubber injection molding services. With the diverse applications of rubber components across various industries, it’s critical to follow a structured approach to ensure you select the right suppliers and processes for your specific needs. This checklist will help streamline your procurement process and enhance your decision-making.

Illustrative image related to rubber injection molding process

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for successful procurement. Consider factors such as size, geometry, weight, material type, and production volume. This will not only guide your supplier search but also ensure that the final product meets your operational requirements.

- Material Requirements: Specify the type of rubber (e.g., organic, liquid silicone, thermoplastic) based on your application.

- Dimensional Tolerances: Identify any critical tolerances that must be met during the manufacturing process.

Step 2: Research and Identify Suppliers

Start by compiling a list of potential suppliers that specialize in rubber injection molding. Look for manufacturers with a strong reputation and experience in your industry sector.

- Geographical Considerations: Consider suppliers from regions known for quality rubber production, such as Europe and the Middle East.

- Supplier Capabilities: Ensure they offer the specific molding processes you require, such as transfer, compression, or injection molding.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from clients in similar industries.

- Quality Assurance: Inquire about their quality control processes and certifications, such as ISO 9001, to gauge their commitment to quality.

- Customer Feedback: Seek testimonials or feedback from existing customers to understand their reliability and service quality.

Step 4: Request Samples and Prototypes

Once you narrow down your options, request samples or prototypes of the rubber components you need. This step is critical to assess the quality and functionality of the products.

- Testing Procedures: Evaluate how the supplier conducts testing to ensure the components meet your specifications.

- Iterative Feedback: Use this opportunity to provide feedback on the samples, enabling adjustments before full-scale production.

Step 5: Assess Production Capabilities and Lead Times

Understand the supplier’s production capabilities and lead times to ensure they can meet your demands.

Illustrative image related to rubber injection molding process

- Production Volume: Confirm their capacity to handle your required production volumes, whether small batches or large-scale manufacturing.

- Delivery Timelines: Discuss expected lead times and their flexibility in responding to urgent orders.

Step 6: Negotiate Terms and Conditions

Once you are satisfied with the supplier’s capabilities and product quality, move forward with negotiating terms and conditions.

- Pricing Structure: Discuss pricing, including any volume discounts or payment terms that may apply.

- Contractual Obligations: Clearly outline responsibilities, including delivery schedules, warranties, and after-sales support.

Step 7: Finalize the Supplier Relationship

After negotiations, finalize your relationship with the selected supplier. Ensure all agreements are documented and clearly understood by both parties.

- Regular Communication: Establish communication protocols for ongoing updates and issue resolution during the production process.

- Performance Metrics: Define key performance indicators (KPIs) to evaluate the supplier’s performance post-contract.

By following these steps, B2B buyers can effectively navigate the procurement process for rubber injection molding, ensuring they choose suppliers that meet their specific needs while maintaining quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for rubber injection molding process Sourcing

What Are the Key Cost Components in Rubber Injection Molding?

When sourcing rubber injection molding, understanding the cost structure is crucial for effective budgeting and strategic decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type and quality of rubber used significantly impact costs. Common materials include natural rubber, synthetic rubber, and thermoplastic elastomers, each varying in price. Specialty materials, such as those with high-temperature resistance or specific certifications, will generally be more expensive.

-

Labor: Labor costs encompass both direct and indirect labor involved in the molding process. Skilled operators are essential for maintaining quality and efficiency, and their wages can vary based on geographic location and industry standards.

-

Manufacturing Overhead: This includes costs associated with running the facility, such as utilities, maintenance, and administrative expenses. Overhead can be a substantial part of the total cost, particularly for smaller production runs.

-

Tooling: Tooling costs are often one of the largest upfront expenses. The design and fabrication of molds can vary widely depending on complexity and volume requirements. Custom molds are more expensive but may be necessary for specialized applications.

-

Quality Control (QC): Ensuring product quality involves testing and inspection processes, which add to the overall cost. Companies often invest in QC to comply with industry standards and certifications, particularly in regulated sectors such as automotive and medical.

-

Logistics: Shipping and handling costs can fluctuate based on destination, mode of transport, and volume. International buyers must also consider duties and tariffs, which can significantly affect the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers can help buyers negotiate better terms.

How Do Price Influencers Affect Rubber Injection Molding Costs?

Several factors influence the pricing of rubber injection molding services.

-

Volume/MOQ: Higher order volumes usually lead to lower per-unit costs due to economies of scale. Many suppliers have minimum order quantities (MOQ) that can affect pricing flexibility.

-

Specifications/Customization: Custom parts tailored to specific applications will incur additional costs. The complexity of the design, material requirements, and finishing processes all contribute to pricing.

-

Quality/Certifications: Parts that require specific quality standards or certifications (e.g., ISO, FDA) will typically have higher costs. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more but offer reliability and superior service, while new entrants may provide competitive pricing to gain market share.

-

Incoterms: Understanding the Incoterms used in the transaction can clarify responsibilities for shipping, insurance, and tariffs, ultimately affecting the total cost.

What Are the Best Practices for Negotiating Rubber Injection Molding Prices?

When negotiating prices for rubber injection molding, international B2B buyers should consider several strategies:

Illustrative image related to rubber injection molding process

-

Conduct Market Research: Understanding the market rates for various types of rubber and molding services can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on initial costs, consider the long-term implications, including maintenance, durability, and performance.

-

Leverage Volume Discounts: If possible, commit to larger orders or long-term contracts to secure better pricing. Suppliers often reward loyalty with discounts.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better terms and greater flexibility in negotiations.

-

Be Aware of Pricing Nuances: International buyers should be conscious of currency fluctuations, local economic conditions, and geopolitical factors that may affect pricing.

Conclusion

Sourcing rubber injection molding services involves a complex interplay of cost components and pricing influencers. By understanding these factors and employing effective negotiation strategies, B2B buyers can optimize their procurement processes and achieve cost-efficient solutions tailored to their specific needs. Always remember that indicative prices may vary based on market conditions, supplier capabilities, and specific project requirements.

Alternatives Analysis: Comparing rubber injection molding process With Other Solutions

Understanding Alternatives to the Rubber Injection Molding Process

In the competitive landscape of manufacturing, businesses often seek the most efficient and cost-effective methods for producing rubber components. While rubber injection molding is a popular choice due to its precision and speed, several alternatives may better suit specific production requirements. This analysis explores viable alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Rubber Injection Molding Process | Compression Molding | Transfer Molding |

|---|---|---|---|

| Performance | High precision and consistency | Moderate precision | High precision for complex parts |

| Cost | Higher initial tooling costs | Lower tooling costs | Moderate tooling costs |

| Ease of Implementation | Requires specialized equipment | Simple setup | More complex setup |

| Maintenance | Moderate, requires skilled labor | Low, simpler machinery | Moderate, more intricate machinery |

| Best Use Case | High-volume, complex designs | Low to medium volume, simpler parts | Multi-cavity, intricate designs |

What Are the Advantages and Disadvantages of Compression Molding?

Compression molding involves placing a pre-measured amount of rubber into an open mold. The mold is then closed, and heat and pressure are applied to cure the rubber.

Pros: This method is cost-effective for low to medium production volumes and is particularly suitable for larger parts like seals and gaskets. The tooling costs are generally lower than those of injection molding, making it a viable option for businesses looking to minimize initial investment.

Cons: However, compression molding has longer cycle times and is less suited for high-precision applications. It also requires specific mold designs, which can limit flexibility in production runs.

How Does Transfer Molding Compare?

Transfer molding is ideal for complex designs and multi-cavity molds. In this process, rubber is pre-heated and transferred into the mold under pressure, allowing for intricate shapes and tighter tolerances.

Pros: The main advantages of transfer molding include its ability to produce highly detailed parts and the capability to bond rubber to metal components effectively. This method is excellent for industries where precision is critical.

Cons: The downside lies in the higher material waste and complexity of the machinery involved. Additionally, transfer molding can incur moderate tooling costs, which may deter businesses with smaller budgets.

Conclusion: Which Rubber Molding Solution is Right for Your Business?

Choosing the right rubber molding process is crucial for achieving optimal production efficiency and product quality. While rubber injection molding excels in high-volume, precise applications, compression molding may be more cost-effective for simpler, larger parts with lower production requirements. Transfer molding stands out for its capability to handle complex designs but comes with increased complexity and potential waste.

B2B buyers should assess their specific needs, including production volume, part complexity, and budget constraints, to select the most suitable molding process. Engaging with experienced suppliers can further assist in navigating these options, ensuring that the chosen method aligns with operational goals and market demands.

Essential Technical Properties and Trade Terminology for rubber injection molding process

What Are the Key Technical Properties for Rubber Injection Molding?

Understanding the essential technical properties in rubber injection molding is crucial for B2B buyers seeking to optimize production and ensure product quality. Here are some of the most critical specifications:

1. Material Grade

The material grade refers to the specific type of rubber used in the injection molding process. Different grades offer varied chemical, thermal, and mechanical properties. For instance, silicone rubber is commonly used for medical applications due to its biocompatibility, while EPDM is suitable for automotive parts. Selecting the appropriate material grade impacts product performance, durability, and compliance with industry standards.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension. In rubber injection molding, tight tolerances (e.g., ±0.1 mm) are essential for applications requiring precise fits, such as in automotive or aerospace components. Understanding tolerance requirements helps B2B buyers ensure that the parts will function correctly within their assemblies, thereby minimizing costly rework or failures.

3. Cure Time

Cure time refers to the duration required for the rubber to undergo vulcanization and achieve its final properties. Shorter cure times enhance production efficiency and reduce cycle times. B2B buyers must consider cure time when planning production schedules and inventory management, as this affects lead times and overall operational efficiency.

4. Shore Hardness

Shore hardness measures the rubber’s resistance to indentation, typically on a scale from 0 (very soft) to 100 (very hard). This property is crucial for applications where flexibility or rigidity is required. For example, softer rubbers (30-60 Shore A) are often used in sealing applications, while harder rubbers (70-90 Shore A) may be employed in structural components. Understanding the necessary Shore hardness helps buyers select materials that align with their application needs.

5. Volume

Volume pertains to the quantity of parts produced during a single production run. Understanding the required volume is critical for selecting the appropriate molding process (injection vs. compression vs. transfer) and for cost estimation. Higher volumes often lead to lower per-unit costs, making it essential for buyers to evaluate their production needs accurately.

Illustrative image related to rubber injection molding process

What Are Common Trade Terms Used in Rubber Injection Molding?

Familiarizing yourself with industry terminology can facilitate better communication and decision-making in the rubber injection molding process. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that are used in another company’s end products. In rubber injection molding, understanding the OEM landscape is essential for B2B buyers to ensure compatibility and quality across the supply chain.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers as it affects initial investment and inventory management. Suppliers often set MOQs to balance production efficiency and costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing information from suppliers for specific products or services. Submitting an RFQ helps B2B buyers compare options, negotiate prices, and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in global transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and liability conditions, thus mitigating risks in international trade.

5. Lead Time

Lead time is the period between placing an order and receiving the product. In rubber injection molding, shorter lead times can enhance responsiveness to market demands. B2B buyers must assess lead times to ensure that production schedules align with customer expectations.

By grasping these essential properties and terminology, B2B buyers can make more informed decisions in the rubber injection molding process, ultimately leading to better product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the rubber injection molding process Sector

What Are the Current Market Dynamics and Key Trends in Rubber Injection Molding?

The rubber injection molding sector is experiencing significant evolution driven by technological advancements and shifting market demands. Global drivers such as the increasing demand for precision-engineered rubber parts across industries, including automotive, medical, and consumer goods, are pushing manufacturers to innovate. Emerging B2B technologies, such as automation and advanced data analytics, are streamlining production processes, enhancing quality control, and reducing lead times. This shift is particularly beneficial for international buyers from regions like Africa, South America, the Middle East, and Europe, where the need for efficient and reliable supply chains is paramount.

Additionally, the trend towards customization is gaining traction, as businesses seek tailored solutions that meet specific operational requirements. Manufacturers are increasingly investing in custom rubber injection molding capabilities, allowing them to cater to unique specifications without compromising on efficiency. Furthermore, the market is witnessing a rise in strategic partnerships and collaborations, as companies aim to leverage each other’s strengths for better product offerings and expanded market reach. This dynamic environment presents opportunities for B2B buyers to source high-quality, customized rubber parts that align with their operational needs.

How Is Sustainability and Ethical Sourcing Shaping the Rubber Injection Molding Industry?

Sustainability has become a critical focus in the rubber injection molding process, driven by increasing regulatory pressures and consumer demand for environmentally responsible products. The environmental impact of rubber manufacturing, particularly concerning waste generation and resource consumption, has prompted businesses to adopt greener practices. Ethical sourcing is paramount, as companies are now expected to ensure that their supply chains adhere to environmental standards and labor regulations.

B2B buyers are increasingly favoring suppliers that offer sustainable materials, such as bio-based or recycled rubber, and possess certifications like ISO 14001, which signifies effective environmental management systems. Companies that commit to transparent sourcing practices and demonstrate a proactive approach to sustainability not only enhance their brand reputation but also attract a growing segment of eco-conscious consumers. By prioritizing ethical supply chains and sustainable materials, businesses can ensure compliance with international standards while contributing positively to the environment.

What Is the Brief Evolution of the Rubber Injection Molding Process?

The rubber injection molding process has evolved significantly since its inception in the early 20th century. Initially, manufacturers relied on compression and transfer molding techniques to produce rubber parts, which were labor-intensive and limited in design flexibility. The introduction of rubber injection molding in the 1950s marked a turning point, allowing for more complex designs and higher precision in production.

As technology advanced, variations such as liquid silicone rubber (LSR) injection and thermoplastic rubber (TPR) injection emerged, expanding the applications and capabilities of rubber molding. Today, the process is characterized by automation, real-time data monitoring, and enhanced material formulations, enabling manufacturers to meet the diverse and evolving demands of global markets. This historical context underscores the importance of continuous innovation in the rubber injection molding industry, ensuring that businesses remain competitive in an increasingly complex landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber injection molding process

-

How do I choose the right rubber injection molding process for my application?

Choosing the appropriate rubber injection molding process hinges on factors such as the complexity of the part, production volume, material type, and design specifications. For intricate designs requiring multiple cavities, transfer molding may be ideal. Conversely, for high-volume production with strict dimensional tolerances, injection molding is typically preferred. Assess your project needs and consult with potential suppliers to identify the best fit, ensuring they have experience with your specific requirements. -

What are the advantages of rubber injection molding over other methods?

Rubber injection molding offers several advantages, including shorter cycle times, reduced material waste, and the ability to produce high volumes of parts with consistent quality. The process allows for precise control over the material’s temperature and pressure during curing, which enhances the final product’s integrity. Additionally, injection molding supports over-molding and multi-material applications, making it a versatile choice for complex projects. -

What is the minimum order quantity (MOQ) for rubber injection molding?

Minimum order quantities for rubber injection molding can vary widely depending on the supplier and the complexity of the mold. Generally, MOQs can range from a few hundred to several thousand units. It’s essential to discuss your specific needs with suppliers to determine their MOQ policies, which may also be influenced by the tooling costs associated with your project. -

What payment terms should I expect when sourcing rubber injection molding services?

Payment terms in the rubber injection molding industry typically include a deposit upon order confirmation, followed by the balance upon completion or before shipment. Terms can vary significantly by supplier and region, so it’s crucial to negotiate favorable terms that align with your cash flow and project timelines. Be prepared to discuss payment methods, such as wire transfers or letters of credit, particularly for international transactions. -

How can I ensure quality assurance (QA) in rubber injection molded parts?

To ensure quality assurance in rubber injection molded parts, select suppliers who adhere to recognized industry standards and have a robust QA process in place. Request documentation of their testing protocols, including material certifications and inspection reports. Additionally, consider conducting periodic audits or requesting samples before committing to larger orders to verify that the products meet your specifications. -

What should I consider when vetting suppliers for rubber injection molding?

When vetting suppliers for rubber injection molding, evaluate their experience, industry reputation, and technical capabilities. Review case studies or references from previous clients to gauge their reliability and service quality. Additionally, assess their production capabilities, including equipment, materials, and lead times, to ensure they can meet your specific requirements and adapt to any changes in demand. -

How do logistics and shipping impact the sourcing of rubber injection molded parts?

Logistics and shipping can significantly affect the overall cost and timeline of sourcing rubber injection molded parts. Consider factors such as shipping methods, customs clearance, and lead times when planning your procurement. Collaborate with suppliers who have experience in international shipping to mitigate potential delays and additional costs. Ensure that both you and the supplier agree on responsibilities regarding freight, insurance, and delivery timelines. -

Can I customize rubber injection molded parts to meet my specific needs?

Yes, customization is a key benefit of rubber injection molding. Suppliers often offer tailored solutions to meet unique design specifications, material requirements, and performance standards. Engage with your chosen supplier early in the design process to discuss your specific needs, including dimensions, material types, and any special features. This collaborative approach can lead to optimal solutions that enhance product performance and reduce production costs.

Top 3 Rubber Injection Molding Process Manufacturers & Suppliers List

1. Simtec – Liquid Silicone Rubber Injection Molding

Domain: simtec-silicone.com

Registered: 2002 (23 years)

Introduction: Liquid Silicone Rubber (LSR) injection molding is a process used to produce pliable, durable parts in high volumes. Key components of the process include an injector, metering unit, supply drum, mixer, nozzle, and mold clamp. LSR consists of two components, pigment, and additives, which are homogenized for desired properties. The process involves preparing the mixture, placing inserts in the mold,…

2. Timco Rubber – Rubber Injection Molding Solutions

Domain: timcorubber.com

Registered: 1997 (28 years)

Introduction: Rubber Injection Molding Process: Developed in the mid 1960s, it involves heating rubber and applying high pressure for molding. Key advantages include elimination of pre-forms, reduced cycle times, and minimal material waste. Transfer Molding: Involves placing pre-forms in a pot and using a plunger to transfer material into the cavity. Advantages include high cavity count and tighter dimensional …

3. IQS Directory – Rubber Injection Molding

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Rubber Injection Molding: A process of converting raw rubber into finished products by injecting it into pre-formed metal molds using pressure and heat. Key types of rubber used include: 1. Natural Rubber: High tensile strength, good friction and abrasion properties, used for seals, O-rings, diaphragms, dampers, and bumpers. 2. Nitrile (Buna-N): Excellent mechanical properties, resistant to oils, …

Strategic Sourcing Conclusion and Outlook for rubber injection molding process

In summary, the rubber injection molding process offers diverse solutions tailored to the unique needs of various industries. Understanding the three primary molding techniques—transfer, compression, and injection—is critical for B2B buyers aiming to optimize their production capabilities. Each method has distinct advantages, from cost efficiency to precision in complex designs. Strategic sourcing of rubber components can significantly enhance operational efficiency, reduce waste, and facilitate innovation in product development.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, the potential for growth in this sector is substantial. By leveraging custom rubber solutions and innovative molding techniques, businesses can meet their specific requirements while maintaining a competitive edge in the market.

As you consider your sourcing strategy, prioritize partnerships with experienced manufacturers who can provide tailored support and high-quality materials. Embrace the opportunities ahead by exploring advanced rubber molding processes that align with your operational goals. Take the next step in enhancing your production capabilities—connect with reliable suppliers today to ensure your business stays at the forefront of the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.