Everything You Need to Know About Brackets Metalicos Sourcing in 2025

Introduction: Navigating the Global Market for brackets metalicos

Navigating the intricate landscape of sourcing brackets metálicos can be a daunting challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany. As the demand for effective orthodontic solutions grows, understanding the nuances of different bracket types—ranging from traditional to self-ligating—becomes imperative. This comprehensive guide delves into various aspects of brackets metálicos, including their applications in orthodontics, the advantages and disadvantages of each type, and essential factors for vetting suppliers.

In addition to examining the effectiveness and affordability of brackets metálicos, this guide provides insights into cost considerations, market trends, and best practices for ensuring product quality. By leveraging this information, B2B buyers can make informed purchasing decisions that align with their operational needs and customer expectations. Whether you are a dental clinic looking to enhance your treatment offerings or a distributor aiming to expand your product portfolio, this guide serves as an essential resource. Empower your business with the knowledge to navigate the global market for brackets metálicos confidently, ensuring that you are well-equipped to meet the demands of an evolving orthodontic landscape.

Understanding brackets metalicos Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Metal Brackets | Requires ligatures; widely recognized | General orthodontics for children and adults | Pros: Cost-effective, versatile; Cons: Highly visible, may require more maintenance. |

| Self-Ligating Metal Brackets | Built-in clips eliminate ligatures; less friction | Advanced orthodontics, especially for adults | Pros: Shorter treatment times, easier maintenance; Cons: Higher initial costs. |

| Aesthetic Metal Brackets | Coated with tooth-colored materials | Targeted at image-conscious patients | Pros: Less visible than traditional; Cons: Slightly higher price, potential for staining. |

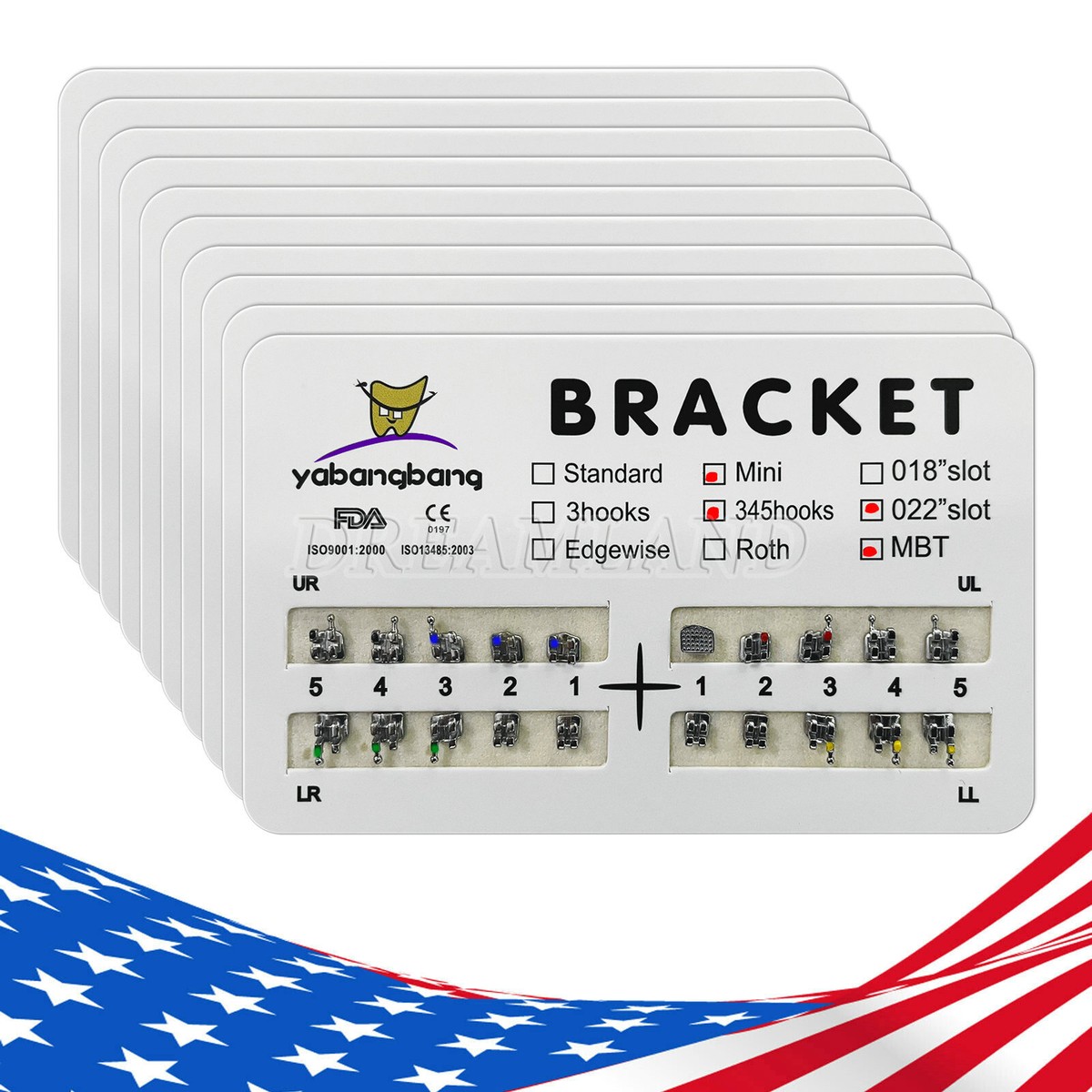

| Mini-Metal Brackets | Smaller size allows for more comfort and aesthetics | Pediatric and adult orthodontics | Pros: More discreet, less discomfort; Cons: May be less durable than larger brackets. |

| Lingual Metal Brackets | Placed on the inner surface of teeth | Discreet treatment for adults and professionals | Pros: Completely hidden; Cons: More complex to clean, potentially uncomfortable initially. |

What Are the Characteristics of Traditional Metal Brackets?

Traditional metal brackets are the most established type of orthodontic treatment, utilizing small metal pieces bonded to the teeth with ligatures to hold the archwire in place. These brackets are suitable for a wide demographic, including children, teenagers, and adults. When considering a purchase, B2B buyers should evaluate the cost-effectiveness and reliability of these brackets, as they are typically more affordable than newer options. However, their visibility can be a drawback for patients concerned about aesthetics.

How Do Self-Ligating Metal Brackets Differ from Traditional Options?

Self-ligating metal brackets feature a unique mechanism that allows the archwire to slide freely without the need for traditional ligatures. This design reduces friction and can lead to shorter treatment times, making them appealing for B2B buyers targeting efficiency in orthodontic practices. They are particularly suitable for adult patients who may prioritize quicker results. While the initial investment is higher, the long-term benefits in treatment duration and ease of maintenance may justify the cost for many practices.

What Makes Aesthetic Metal Brackets a Preferred Choice?

Aesthetic metal brackets are designed with a tooth-colored coating, making them less visible than traditional options. This type is ideal for image-conscious patients, including adults and teens who may be sensitive about their appearance during treatment. B2B buyers should consider the balance between aesthetics and price, as these brackets often come at a premium. Their potential for staining over time is another factor to weigh, particularly in regions with dietary habits that could affect bracket appearance.

Why Choose Mini-Metal Brackets for Comfort?

Mini-metal brackets are smaller than traditional brackets, offering a more discreet appearance and enhanced comfort. They are suitable for both children and adults, making them versatile in various orthodontic settings. B2B buyers should assess the market demand for comfort-focused orthodontic solutions, as these brackets can attract patients seeking less noticeable options. However, their smaller size may compromise durability, which is an essential consideration for long-term treatment success.

How Do Lingual Metal Brackets Provide Discreet Treatment?

Lingual metal brackets are attached to the inner surfaces of the teeth, rendering them virtually invisible from the outside. This makes them an excellent choice for adults and professionals who prefer a discreet orthodontic option. B2B buyers should consider the specialized training required for orthodontists to install and adjust these brackets, as well as the potential for higher patient satisfaction due to their invisibility. However, the cleaning process can be more challenging, which may impact patient compliance.

Key Industrial Applications of brackets metalicos

| Industry/Sector | Specific Application of brackets metalicos | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Orthodontics | Use in traditional orthodontic treatments | Proven efficacy in aligning teeth across demographics | Quality of materials, compliance with health regulations, supplier reliability |

| Automotive Manufacturing | Support structures for vehicle assembly | Enhances structural integrity and safety of vehicles | Durability under stress, weight specifications, customization options |

| Construction | Structural support in buildings | Provides strength and stability in architectural designs | Load-bearing capacity, corrosion resistance, local availability |

| Electronics | Mounting components for devices | Ensures secure assembly and operation of electronic devices | Precision manufacturing, compatibility with various devices, cost-effectiveness |

| Furniture Design | Brackets for modular furniture systems | Facilitates easy assembly and disassembly, enhancing customer satisfaction | Aesthetic finishes, load capacity, customization for design trends |

How Are Brackets Metálicos Used in Dental Orthodontics?

In dental orthodontics, brackets metálicos are essential for traditional braces, which are widely used to correct malocclusions and improve oral health. These metallic brackets are bonded to the teeth and connected with wires, enabling orthodontists to apply pressure and guide teeth into the desired position. For international buyers, particularly from regions like Africa and South America, sourcing high-quality brackets is crucial. They must ensure that the materials comply with local health regulations and are durable enough to withstand the rigors of orthodontic treatment.

What Role Do Brackets Metálicos Play in Automotive Manufacturing?

In the automotive sector, brackets metálicos are utilized as support structures during vehicle assembly. These brackets enhance the overall structural integrity of vehicles, ensuring safety and performance standards are met. For businesses in this industry, sourcing brackets that can withstand high stress and provide customization options is vital. International buyers should also consider the weight specifications and durability of the materials used, especially in markets like Europe and the Middle East, where regulatory standards are stringent.

How Are Brackets Metálicos Applied in Construction Projects?

In construction, brackets metálicos are employed for structural support in various building applications. They provide essential strength and stability, which are crucial for architectural designs and safety. Buyers in this sector should prioritize the load-bearing capacity and corrosion resistance of these brackets, particularly in regions with harsh climates. Additionally, local availability and compliance with building codes are significant considerations for international B2B buyers, especially in developing markets across Africa and South America.

Why Are Brackets Metálicos Important in Electronics?

Brackets metálicos are integral in the electronics industry for securely mounting components within devices. They ensure that parts are held in place during operation, which is critical for device functionality and longevity. When sourcing these brackets, businesses must focus on precision manufacturing to ensure compatibility with various electronic devices. Cost-effectiveness also plays a role, particularly for international buyers looking to optimize their supply chains in competitive markets like Germany and Vietnam.

How Do Brackets Metálicos Enhance Furniture Design?

In furniture design, brackets metálicos are used in modular systems to facilitate easy assembly and disassembly, enhancing customer satisfaction. These brackets allow for versatile designs that can adapt to different spaces and needs. Buyers should consider aesthetic finishes that align with current design trends, as well as the load capacity to ensure the furniture’s durability. For international buyers, understanding local consumer preferences and sourcing customization options can be key to successful market penetration in diverse regions.

3 Common User Pain Points for ‘brackets metalicos’ & Their Solutions

Scenario 1: Navigating the Aesthetic Concerns of Metal Brackets

The Problem: B2B buyers often face challenges when dealing with the aesthetic concerns associated with metal brackets. Many patients, particularly adults, are hesitant to opt for traditional metal braces due to their visibility, which can affect their confidence and social interactions. This is especially true in markets where appearance is highly valued, such as in Africa and parts of Europe. As a result, dental practices may struggle to convince potential clients of the benefits of metal brackets, leading to lost sales opportunities.

The Solution: To address aesthetic concerns, dental suppliers should consider offering a range of customizable options for metal brackets. This includes colored ligatures or decorative brackets that can make the braces more appealing, especially to younger patients. Dental practices can also promote the effectiveness and efficiency of metal braces in treatment plans, highlighting how they can lead to quicker results compared to other options. Additionally, marketing strategies should focus on testimonials and case studies demonstrating the successful outcomes of treatment with metal brackets, which can help reassure potential clients about their choice.

Scenario 2: Overcoming Hygiene Challenges with Metal Brackets

The Problem: One significant concern for both dental practices and their clients is the hygiene challenges posed by metal brackets. The intricate design of braces can make it difficult for patients to maintain proper oral hygiene, leading to potential complications such as cavities or gum disease. For B2B buyers, this can translate into increased chair time for cleaning appointments and a higher risk of patient dissatisfaction, impacting the overall reputation of the practice.

The Solution: To mitigate hygiene concerns, dental suppliers should provide comprehensive patient education materials that emphasize proper care techniques for metal brackets. This can include instructional videos, brochures, and even in-office demonstrations on effective brushing and flossing techniques. Furthermore, recommending specialized dental hygiene products, such as orthodontic toothbrushes or interdental brushes, can significantly improve patients’ ability to maintain oral hygiene during treatment. Implementing follow-up appointments focused on hygiene checks can also reassure patients and provide additional value to their treatment experience.

Scenario 3: Addressing Treatment Duration and Patient Expectations

The Problem: B2B buyers often find that patients have misconceptions about the duration of orthodontic treatment with metal brackets. Many individuals expect quick results and may not understand the complexities involved in aligning teeth properly. This can lead to frustration and disengagement, particularly if patients are unaware that treatment timelines can vary based on their specific dental issues.

The Solution: To manage patient expectations effectively, dental practices should implement transparent communication strategies. This includes providing detailed consultations that outline the expected treatment timeline based on the patient’s unique circumstances. Creating visual aids, such as charts or timelines, can help patients better understand the process and what to expect at each stage. Additionally, utilizing digital tools like treatment simulations can enhance the patient’s understanding and engagement. Regular updates during the treatment process can keep patients informed and motivated, ultimately leading to higher satisfaction rates.

Strategic Material Selection Guide for brackets metalicos

What Materials Are Commonly Used for Brackets Metálicos?

When selecting materials for brackets metálicos, it is crucial to consider their properties, advantages, and limitations to ensure optimal performance in orthodontic applications. Here, we analyze four common materials used in the production of metal brackets, focusing on their suitability for international B2B buyers.

Stainless Steel: The Industry Standard

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and mechanical strength. It can withstand a wide range of temperatures and pressures, making it suitable for various orthodontic applications.

Pros & Cons: The durability of stainless steel brackets is one of their most significant advantages, as they can endure the forces exerted during orthodontic treatment without deforming. However, they can be relatively expensive compared to other materials. Manufacturing complexity is moderate, requiring specific processes to ensure the desired finish and performance.

Impact on Application: Stainless steel brackets are compatible with most orthodontic wires and elastics, facilitating effective tooth movement. Their resistance to corrosion also ensures longevity, which is vital for maintaining oral health.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is essential, particularly for buyers in Europe and the Middle East. The availability of stainless steel brackets is widespread, making them a reliable choice for orthodontists globally.

Titanium Alloys: A Lightweight Alternative

Key Properties: Titanium alloys are known for their high strength-to-weight ratio and excellent biocompatibility. They are resistant to corrosion and can withstand significant mechanical stress.

Pros & Cons: The primary advantage of titanium brackets is their lightweight nature, which can enhance patient comfort. However, they are generally more expensive than stainless steel and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Titanium brackets are particularly suitable for patients with metal allergies, as they are less likely to cause adverse reactions. Their compatibility with various orthodontic materials makes them versatile.

Considerations for International Buyers: Buyers from regions with stringent health regulations, such as Germany, should ensure that titanium alloys meet specific biocompatibility standards. Additionally, the cost may be a consideration for practices in developing markets.

Nickel-Titanium (NiTi): The Flexible Choice

Key Properties: Nickel-titanium alloys exhibit unique superelastic properties, allowing them to return to their original shape after deformation. This flexibility is beneficial in orthodontic applications.

Pros & Cons: NiTi brackets provide excellent performance in terms of tooth movement efficiency and patient comfort. However, they are more expensive than traditional stainless steel brackets and may require careful handling during manufacturing.

Impact on Application: The superelasticity of NiTi brackets allows for gentle continuous forces on teeth, making them ideal for specific orthodontic treatments. However, their compatibility with certain media must be assessed to avoid corrosion.

Considerations for International Buyers: Compliance with regulations regarding nickel content is vital, especially in Europe, where nickel allergies are common. Buyers should also consider the higher cost when budgeting for orthodontic supplies.

Ceramic Brackets: Aesthetic Appeal

Key Properties: Ceramic brackets are made from a composite material that is aesthetically pleasing and less visible than metal alternatives. They are generally resistant to staining and provide good mechanical strength.

Pros & Cons: The primary advantage of ceramic brackets is their cosmetic appeal, making them popular among adult patients. However, they are less durable than metal brackets and can be more expensive due to their manufacturing processes.

Impact on Application: Ceramic brackets are suitable for patients seeking a discreet orthodontic solution. However, they may not be as effective in severe cases of misalignment compared to metal brackets.

Illustrative image related to brackets metalicos

Considerations for International Buyers: Buyers should ensure that ceramic brackets comply with relevant aesthetic standards and consider the potential for increased costs in regions where metal brackets are the norm.

Summary Table of Material Selection for Brackets Metálicos

| Material | Typical Use Case for brackets metalicos | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Standard orthodontic treatments | High durability and corrosion resistance | Higher cost compared to alternatives | Medium |

| Titanium Alloys | Lightweight and biocompatible options | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

| Nickel-Titanium | Flexible orthodontic applications | Superelastic properties | More expensive and sensitive handling | High |

| Ceramic Brackets | Aesthetic orthodontic solutions | Discreet appearance | Less durable than metal options | Medium to High |

This analysis provides a comprehensive overview of the materials used in brackets metálicos, equipping international B2B buyers with the necessary insights to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for brackets metalicos

What Are the Key Stages in the Manufacturing Process of Brackets Metálicos?

The manufacturing process of brackets metálicos involves several critical stages, each designed to ensure the highest quality and functionality of the final product. Understanding these stages can help B2B buyers assess potential suppliers effectively.

1. Material Preparation: What Materials Are Used for Brackets Metálicos?

The first step in manufacturing brackets metálicos is the selection and preparation of raw materials. Typically, high-quality stainless steel is preferred due to its strength, durability, and resistance to corrosion. Some manufacturers may also use other alloys or materials that provide similar properties.

In this phase, materials are inspected for quality and compliance with specifications. This is crucial as the material’s integrity directly affects the performance and longevity of the brackets. B2B buyers should inquire about the source of materials and any certifications the supplier possesses to ensure compliance with international standards.

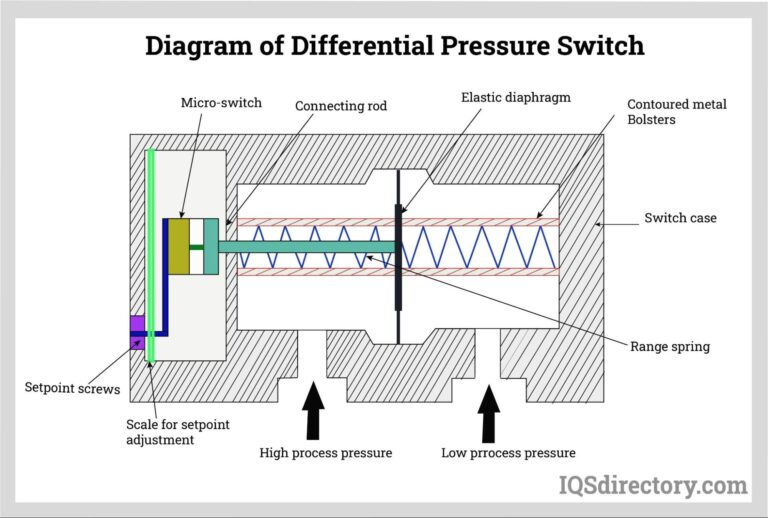

2. Forming: How Are Brackets Metálicos Shaped?

After material preparation, the next stage is forming. This process involves shaping the raw materials into the desired bracket design using techniques such as stamping, die casting, or CNC machining.

- Stamping: This technique is often used for mass production and involves using a die to cut and form the metal into the bracket shape.

- CNC Machining: This method offers higher precision and is commonly used for custom or complex designs. It can produce intricate details that enhance the bracket’s functionality.

During this stage, quality checks should be performed to ensure that the dimensions and shapes meet the specified tolerances.

Illustrative image related to brackets metalicos

3. Assembly: How Are Brackets Metálicos Assembled?

Once individual components are formed, the assembly process begins. This may include attaching various parts, such as ligatures or clips, depending on whether the brackets are traditional or self-ligating.

The assembly process must be executed under strict conditions to avoid contamination and defects. Automated assembly lines are often employed to enhance precision and efficiency. B2B buyers should look for suppliers who implement advanced assembly technologies, as this often correlates with higher quality products.

4. Finishing: What Finishing Techniques Are Used for Brackets Metálicos?

The finishing stage is crucial for ensuring that brackets are not only functional but also aesthetically pleasing. This may involve polishing, coating, or applying protective finishes to prevent corrosion and enhance durability.

Common finishing techniques include:

– Electropolishing: This process enhances the surface finish and reduces the risk of plaque accumulation.

– Coating: Some manufacturers apply a coating to improve aesthetics and corrosion resistance.

Buyers should inquire about the finishing processes employed by suppliers to ensure that the final products meet their expectations for quality and appearance.

Illustrative image related to brackets metalicos

What Quality Control Measures Are Essential for Brackets Metálicos?

Quality control (QC) is an integral part of the manufacturing process, ensuring that the final product adheres to required standards and specifications. For brackets metálicos, several international and industry-specific standards are relevant.

1. What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are fundamental for quality management systems. This certification indicates that a manufacturer has implemented a quality management system that consistently meets customer and regulatory requirements.

Additionally, specific certifications like CE marking in Europe signify that the product complies with health, safety, and environmental protection standards. B2B buyers should prioritize suppliers who hold these certifications, as they reflect a commitment to quality and regulatory compliance.

2. What Are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are crucial throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this ensures that each stage meets quality standards.

- Final Quality Control (FQC): After production, a final inspection is conducted to ensure the finished brackets meet all specifications before they are shipped.

B2B buyers should request documentation of these QC processes and results to verify that suppliers maintain high-quality standards.

3. What Testing Methods Are Common for Brackets Metálicos?

Testing methods are essential to confirm the performance and durability of brackets. Common tests include:

- Mechanical Testing: Assessing the strength and flexibility of the brackets under various conditions.

- Corrosion Resistance Testing: Evaluating how well the brackets withstand environmental factors that may lead to corrosion.

- Biocompatibility Testing: Ensuring that the materials used do not cause adverse reactions in patients.

Buyers should ask suppliers for details on their testing methods and the results of these tests to ensure the products’ reliability.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is critical for B2B buyers. Here are some methods to ensure that suppliers adhere to rigorous quality standards:

1. What Role Do Audits Play in Verifying Supplier QC?

Conducting audits is an effective way to assess a supplier’s manufacturing processes and quality control measures. These audits can be performed by the buying company or by third-party organizations specializing in quality assessments. Audits provide insights into the supplier’s compliance with international standards and their internal QC processes.

Illustrative image related to brackets metalicos

2. How Can Reports and Documentation Support QC Verification?

Requesting detailed reports and documentation from suppliers can provide further assurance of their quality control practices. This includes:

- Quality Assurance Plans: Outlining how the supplier intends to meet quality standards.

- Test Reports: Providing evidence of passed tests for mechanical strength, corrosion resistance, and biocompatibility.

- Certification Copies: Validating that the supplier meets international and industry-specific standards.

3. What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of the nuances in quality control and certification that may vary by region. For example, while CE marking is essential in Europe, other regions may have different regulatory requirements. Understanding these differences is vital for ensuring compliance and quality across markets.

In conclusion, the manufacturing processes and quality assurance protocols for brackets metálicos are critical for ensuring product effectiveness and safety. B2B buyers should focus on understanding these processes, verifying supplier certifications, and conducting thorough audits to ensure they partner with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brackets metalicos’

Introduction

In the competitive landscape of orthodontic supplies, procuring high-quality ‘brackets metalicos’ is essential for ensuring effective treatment outcomes. This guide serves as a practical checklist for international B2B buyers looking to source metal brackets, helping you navigate the procurement process efficiently and effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the brackets you need. Consider factors such as size, material composition (e.g., stainless steel), and design (traditional vs. self-ligating). Defining these parameters ensures that you target suppliers who can meet your specific requirements and maintain product consistency.

- Material Standards: Look for brackets made from durable, corrosion-resistant materials.

- Compatibility: Ensure the brackets are compatible with existing orthodontic tools and techniques used in your practice.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors. A comprehensive understanding of the market landscape will allow you to compare offerings effectively.

- Supplier Reputation: Check online reviews and testimonials to gauge the reliability and quality of the suppliers.

- Product Range: Look for suppliers that offer a variety of brackets to ensure you have options for different patient needs.

Step 3: Evaluate Supplier Certifications

It is crucial to verify that suppliers possess the necessary certifications and compliance with international quality standards, such as ISO 13485 for medical devices. This step is vital to ensure that the brackets meet safety and efficacy requirements.

- Quality Assurance: Ask for documentation regarding their quality management systems and product testing procedures.

- Regulatory Compliance: Ensure that the products are compliant with the regulations in your target markets, especially if you are sourcing from different countries.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples from shortlisted suppliers. Testing samples allows you to evaluate the quality, functionality, and ease of use of the brackets. This hands-on assessment can significantly influence your final decision.

- Performance Evaluation: Assess the brackets for fit, comfort, and patient response during trials.

- Durability Testing: Consider how well the brackets hold up under typical orthodontic conditions.

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Establishing favorable terms can significantly impact your overall costs and inventory management.

- Volume Discounts: Inquire about pricing tiers based on order volume to maximize cost savings.

- Lead Times: Clarify delivery times to ensure that you can meet patient treatment timelines.

Step 6: Establish a Communication Plan

Effective communication is essential for a smooth procurement process. Establish clear channels of communication with your chosen suppliers to facilitate updates on order status, product availability, and any potential issues that may arise.

- Point of Contact: Designate a primary contact person for streamlined communication.

- Regular Updates: Schedule regular check-ins to discuss any ongoing needs or changes in your requirements.

Step 7: Review Post-Purchase Feedback

After receiving your order and implementing the brackets, gather feedback from your team and patients. This review process helps you assess the product’s effectiveness and the supplier’s performance, providing insights for future sourcing decisions.

- Performance Metrics: Track treatment outcomes associated with the brackets to determine effectiveness.

- Supplier Assessment: Evaluate the supplier’s responsiveness and quality of service for future reference.

By following these steps, B2B buyers can ensure a strategic and informed approach to sourcing ‘brackets metalicos’, ultimately enhancing their practice’s orthodontic offerings.

Illustrative image related to brackets metalicos

Comprehensive Cost and Pricing Analysis for brackets metalicos Sourcing

What Are the Key Cost Components in Sourcing Brackets Metálicos?

When sourcing brackets metálicos, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The type of metal used significantly affects cost. Stainless steel is commonly used due to its durability and resistance to corrosion, while other materials may vary in price and quality.

-

Labor: Labor costs can fluctuate based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can also impact quality and service.

-

Manufacturing Overhead: This includes costs related to the factory’s operational expenses, such as utilities, rent, and equipment maintenance. Efficient operations can help minimize these costs.

-

Tooling: Initial tooling costs for molds and dies can be high, especially for customized brackets. This is a fixed cost that should be amortized over the production volume.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability, which may add to costs but is essential for maintaining standards, especially in markets with strict regulatory requirements.

-

Logistics: Shipping and handling costs can vary widely depending on the Incoterms negotiated. Factors such as shipping distance, method (air vs. sea), and packaging can influence overall logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This can vary based on the supplier’s market position and competition.

How Do Price Influencers Affect the Cost of Brackets Metálicos?

Several factors influence the pricing of brackets metálicos:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts. Understanding the MOQ is essential for cost-effective sourcing.

-

Specifications and Customization: Customized brackets, designed for specific orthodontic needs, will generally incur higher costs than standard options. Ensure that your specifications are clear to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (ISO, CE marking) can impact pricing. Higher-quality materials and certifications typically lead to higher costs but can enhance product reliability.

-

Supplier Factors: The supplier’s reputation, production capabilities, and relationship with buyers can affect pricing. Building long-term relationships may yield better pricing and service terms.

-

Incoterms: The choice of Incoterms can significantly influence total costs. For example, terms like DDP (Delivered Duty Paid) may include additional fees compared to FOB (Free on Board), where the buyer assumes responsibility for shipping.

What Are Some Effective Buyer Tips for Negotiating Brackets Metálicos Pricing?

B2B buyers should consider the following strategies to enhance cost-efficiency in sourcing brackets metálicos:

-

Negotiate Pricing: Always engage in negotiations. Suppliers often have room for flexibility, especially when dealing with larger order volumes or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider maintenance, durability, and potential replacement costs. A lower upfront cost may lead to higher long-term expenses if the quality is compromised.

-

Research Local Market Trends: Understanding market dynamics in specific regions such as Africa, South America, the Middle East, and Europe can provide insights into pricing trends and potential cost-saving opportunities.

-

Leverage Multiple Quotes: Obtain quotes from multiple suppliers to compare pricing and terms. This not only helps in finding the best price but also offers leverage in negotiations.

-

Factor in Logistics Costs: Ensure that transportation costs are included in your pricing comparisons. Sometimes, a lower product price can be offset by higher shipping fees.

Disclaimer on Indicative Prices

Prices for brackets metálicos can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and request detailed quotes from multiple suppliers to ensure they receive competitive pricing tailored to their specific needs.

Illustrative image related to brackets metalicos

Alternatives Analysis: Comparing brackets metalicos With Other Solutions

Understanding Alternatives to Brackets Metalicos

In the field of orthodontics, brackets metálicos (metal brackets) have long been a popular choice for aligning teeth and correcting bite issues. However, advancements in dental technology have introduced several alternative solutions that may better suit specific patient needs or preferences. This analysis will compare brackets metálicos with two viable alternatives: clear aligners and lingual brackets, providing B2B buyers with actionable insights to guide their purchasing decisions.

| Comparison Aspect | Brackets Metalicos | Clear Aligners | Lingual Brackets |

|---|---|---|---|

| Performance | Highly effective for various malocclusions; treatment duration typically 12-24 months. | Effective for mild to moderate cases; treatment duration varies based on case complexity. | Effective for a wide range of cases; similar treatment duration as metal brackets. |

| Cost | Generally lower cost; accessible for a wide demographic. | Higher cost; premium pricing for aesthetics and technology. | Mid to high cost; often more expensive due to custom fabrication. |

| Ease of Implementation | Straightforward application; requires regular adjustments. | Requires precise initial fitting; minimal follow-up adjustments needed. | Complex installation; requires skilled orthodontists for proper placement. |

| Maintenance | Regular hygiene needed; potential for food trapping. | Easy to maintain; removable for cleaning. | Similar hygiene challenges as metal brackets; hidden from view. |

| Best Use Case | Suitable for all ages and complex cases; effective for severe misalignments. | Ideal for patients seeking aesthetic options; best for mild to moderate cases. | Perfect for adults and professionals who prefer invisibility; effective for most cases. |

Exploring the Pros and Cons of Clear Aligners

Clear aligners, such as those offered by brands like Invisalign, are a popular alternative to brackets metálicos. Their primary advantage lies in aesthetics; they are virtually invisible, making them appealing to adults and teenagers. Additionally, clear aligners are removable, allowing patients to maintain their oral hygiene more effectively. However, they may not be suitable for all cases, particularly those requiring significant tooth movement or correction of complex bite issues. The cost of clear aligners is typically higher than that of metal brackets, which can be a limiting factor for some patients.

Understanding Lingual Brackets

Lingual brackets are another alternative that offers an aesthetic advantage similar to clear aligners. These brackets are placed on the back of the teeth, making them invisible from the front. This solution caters to adults and professionals who desire effective orthodontic treatment without compromising their appearance. However, lingual brackets can be more challenging to clean and may require a higher level of maintenance to prevent dental issues. Additionally, their installation demands a higher level of expertise from orthodontists, often leading to increased costs compared to metal brackets.

Making the Right Choice for Your Orthodontic Needs

When evaluating orthodontic solutions, B2B buyers must consider various factors, including the complexity of the cases they intend to address, patient demographics, and budget constraints. Brackets metálicos offer a reliable and cost-effective solution for a broad range of malocclusions, making them an excellent choice for practices serving diverse populations. However, if aesthetics and patient comfort are prioritized, clear aligners or lingual brackets may be more suitable alternatives despite their higher costs. Ultimately, the best choice will depend on the specific needs of the target patient population and the strategic goals of the dental practice.

Essential Technical Properties and Trade Terminology for brackets metalicos

What Are the Key Technical Properties of Brackets Metálicos?

In the realm of orthodontics, particularly regarding brackets metálicos, understanding the technical properties is vital for B2B buyers. Here are some essential specifications:

-

Material Composition

Brackets metálicos are primarily made from stainless steel, which is known for its strength, durability, and resistance to corrosion. The quality of the steel can significantly affect the longevity and performance of the brackets. High-grade stainless steel ensures that the brackets maintain their structural integrity throughout the treatment period, making it a critical factor for orthodontic professionals and suppliers alike. -

Bracket Size and Design

The dimensions and design of brackets can vary, impacting their effectiveness in treatment. Standard sizes are typically designed to fit a wide range of dental structures, but custom sizes may be required for specific patient needs. Understanding these variations is crucial for orthodontic practices aiming to provide tailored solutions to their patients. -

Bonding Strength

The adhesive used to attach brackets to the teeth is equally important. High bonding strength ensures that brackets remain securely in place throughout the treatment, reducing the need for frequent adjustments. This property is essential for B2B buyers who prioritize the efficiency of orthodontic treatments and patient satisfaction. -

Ligature Compatibility

Traditional brackets use ligatures (small rubber bands) to hold the archwire in place. The compatibility of brackets with various ligature types (colored, clear, or elastic) can influence aesthetic preferences, particularly among younger patients. B2B buyers should consider this aspect when selecting products for diverse clientele. -

Resistance to Wear and Tear

The durability of brackets is measured by their resistance to wear and tear, which is critical for maintaining performance over the treatment duration. Buyers should seek brackets that have undergone rigorous testing for wear resistance, ensuring that they do not compromise the treatment’s effectiveness. -

Thermal Sensitivity

Some brackets are designed with thermal sensitivity, allowing them to adapt slightly to body temperature, which can improve comfort for the patient. This feature can enhance the overall treatment experience, making it a valuable selling point for B2B suppliers.

What Are Common Trade Terms in the Brackets Metálicos Industry?

Navigating the trade landscape involves understanding specific jargon that is crucial for effective communication and transaction. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of brackets metálicos, OEMs are vital for orthodontic practices seeking reliable suppliers for high-quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For brackets metálicos, understanding MOQ is essential for B2B buyers to ensure they are meeting supplier requirements while managing inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products or services. For orthodontic practices, issuing an RFQ for brackets metálicos can help in comparing prices and securing the best deal. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that describe the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for B2B buyers in the brackets metálicos sector to understand shipping responsibilities, costs, and risks. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For orthodontic practices, understanding lead times for brackets metálicos is important for planning treatment schedules and managing patient expectations. -

Certification Standards

Certification standards, such as ISO or CE marking, ensure that products meet specific safety and quality requirements. B2B buyers should prioritize sourcing brackets metálicos that comply with these standards to ensure patient safety and regulatory compliance.

By familiarizing themselves with these technical properties and trade terms, B2B buyers in the orthodontic field can make informed purchasing decisions that enhance their practice and patient care.

Navigating Market Dynamics and Sourcing Trends in the brackets metalicos Sector

What Are the Current Market Dynamics and Key Trends in the Brackets Metalicos Sector?

The global brackets metalicos market is witnessing substantial growth, driven by rising demand for orthodontic treatments across diverse demographics. The increasing awareness of oral health, coupled with a growing aesthetic consciousness among adults, is propelling the market forward. In regions like Africa and South America, there is a notable increase in disposable income, enabling more individuals to seek orthodontic solutions. Meanwhile, in Europe and the Middle East, technological advancements in orthodontics are enhancing treatment options, improving patient outcomes, and stimulating market growth.

Emerging trends include the adoption of digital technologies in the sourcing process. B2B buyers are increasingly leveraging online platforms for procurement, enabling them to access a broader range of suppliers and products. Virtual consultations and AI-driven treatment planning are also gaining traction, facilitating personalized patient care and streamlining the workflow for orthodontic practices. Additionally, the shift towards self-ligating brackets is becoming prominent, as these offer reduced friction and shorter treatment times, appealing to both practitioners and patients.

As international buyers navigate these dynamics, it is crucial to prioritize suppliers that demonstrate reliability and innovation. Understanding local market conditions and regulations is essential for successful sourcing, especially in regions with distinct healthcare frameworks. This awareness can lead to more effective negotiations and partnerships, ultimately enhancing the overall business strategy in the brackets metalicos sector.

How Is Sustainability and Ethical Sourcing Shaping the Brackets Metalicos Market?

Sustainability is becoming a critical consideration in the brackets metalicos sector, as consumers and businesses alike prioritize environmentally friendly practices. The manufacturing process of brackets often involves materials that can have a significant environmental impact. Consequently, suppliers are increasingly adopting sustainable practices, including the use of recyclable materials and eco-friendly production methods.

Ethical sourcing is also gaining importance, with B2B buyers seeking suppliers who adhere to fair labor practices and responsible sourcing. Certifications such as ISO 14001, which outlines effective environmental management systems, are becoming essential for suppliers aiming to establish credibility in the market. These certifications not only help in mitigating environmental impact but also enhance brand reputation among conscientious consumers.

Moreover, the demand for green materials is rising. Buyers are encouraged to explore options for brackets made from sustainable metals or composites that reduce environmental footprints. By investing in suppliers committed to sustainability, B2B buyers can align their procurement strategies with broader environmental goals, contributing to a greener future while meeting market demands.

How Have Brackets Metalicos Evolved Over Time?

The evolution of brackets metalicos can be traced back to their introduction in orthodontics, where they were primarily used in traditional metal forms. Initially, these brackets were designed for children and adolescents, but advancements in orthodontic technology have broadened their appeal to adults seeking aesthetic and functional improvements in dental alignment.

Over the decades, innovation has led to the development of various types of brackets, including self-ligating options that enhance treatment efficiency. The integration of digital technologies has further transformed the landscape, allowing for precise treatment planning and monitoring. As the market continues to evolve, the focus is shifting toward improved materials, enhanced patient comfort, and greater effectiveness in treatment outcomes, all of which are critical considerations for B2B buyers looking to source the best products in the brackets metalicos sector.

Frequently Asked Questions (FAQs) for B2B Buyers of brackets metalicos

-

How do I ensure the quality of brackets metalicos when sourcing from suppliers?

To ensure the quality of brackets metalicos, start by requesting samples from potential suppliers to evaluate their materials and craftsmanship. Look for suppliers that comply with international standards, such as ISO certifications, and have a proven track record in the industry. Additionally, consider conducting factory audits or third-party inspections to assess their manufacturing processes. Establishing a robust quality assurance protocol, including regular audits and performance reviews, will help maintain consistent product quality. -

What is the best type of brackets metalicos for orthodontic treatments?

The best type of brackets metalicos generally depends on the specific needs of the orthodontic case. Traditional brackets are highly effective and versatile, suitable for a wide range of malocclusions and patient demographics. Autoligating brackets, which do not require elastic ligatures, offer benefits like reduced friction and shorter treatment times. It’s essential to consult with orthodontic professionals to determine the most appropriate type based on patient profiles and treatment goals. -

What are the minimum order quantities (MOQ) for brackets metalicos?

Minimum order quantities for brackets metalicos can vary significantly among suppliers, often ranging from 500 to 5,000 units. Factors influencing MOQ include the supplier’s production capacity, the complexity of the brackets, and the level of customization required. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you’re a smaller business or just starting. Some suppliers may offer lower MOQs for first-time orders or establish a tiered pricing structure based on order size. -

What payment terms should I expect when sourcing brackets metalicos internationally?

Payment terms for sourcing brackets metalicos typically range from 30% upfront and 70% upon delivery, to net 30 or net 60 days after receipt of goods. Some suppliers may offer more flexible terms depending on the buyer’s relationship or order volume. It’s crucial to discuss and finalize payment terms before placing an order, ensuring they align with your cash flow and business operations. Additionally, consider using secure payment methods, such as letters of credit, to mitigate financial risks. -

How can I customize brackets metalicos to meet my specific requirements?

Customization options for brackets metalicos may include variations in size, shape, color, and material. Discuss your specific needs with potential suppliers, who can often accommodate requests for tailored designs or unique features. Some manufacturers may also offer personalized branding options for your company. Make sure to communicate your specifications clearly and request prototypes to assess the final product before mass production. -

What logistics considerations should I keep in mind when importing brackets metalicos?

When importing brackets metalicos, consider shipping methods, customs clearance, and potential tariffs that may apply. Choose a reliable logistics partner experienced in handling medical devices to ensure compliance with international regulations. It’s also wise to plan for lead times that account for manufacturing, shipping, and customs processing. Establishing a clear communication channel with your supplier and logistics provider will help address any issues that arise during transit. -

How do I vet suppliers of brackets metalicos effectively?

Vetting suppliers involves assessing their credibility, experience, and reliability. Start by checking their business licenses and certifications, and look for reviews or testimonials from previous clients. Engage in direct communication to gauge their responsiveness and willingness to collaborate. Additionally, consider visiting the supplier’s facility if possible, or request references from other businesses that have sourced from them. This thorough process helps ensure that you partner with a trustworthy supplier capable of meeting your quality standards. -

What are the common challenges faced when sourcing brackets metalicos internationally?

Common challenges in sourcing brackets metalicos internationally include language barriers, cultural differences, and varying regulatory requirements across countries. Additionally, managing logistics and supply chain disruptions can pose risks to timely delivery. To mitigate these challenges, establish clear communication channels with your suppliers and consider working with local agents familiar with the market. Building strong relationships with suppliers and understanding the local business landscape can also enhance collaboration and reduce potential issues.

Top 10 Brackets Metalicos Manufacturers & Suppliers List

1. Clínica Ferrus Bratos – Brackets Metálicos

Domain: clinicaferrusbratos.com

Registered: 2007 (18 years)

Introduction: Brackets metálicos: sistema de ortodoncia más utilizado y conocido, adecuado para niños, adolescentes y adultos. Ventajas: precio más bajo que otros tipos de brackets (zafiro, linguales, Invisalign), mayor resistencia que brackets de cerámica o plástico. Desventajas: escasa estética, muy visibles. Funcionan moviendo los dientes a la posición correcta para mejorar la masticación y la estética de la…

2. Sanitas – Brackets Metálicos

Domain: sanitas.es

Introduction: Brackets metálicos: tratamiento de ortodoncia, primera visita gratuita, disponibles para todos, sean o no de Sanitas.

3. Insmyle Dental – Brackets Metálicos

Domain: insmyledental.com

Registered: 2006 (19 years)

Introduction: Los brackets metálicos son considerados el estándar de oro en ortodoncia debido a su confiabilidad, asequibilidad y eficacia. Son efectivos para tratar una variedad de problemas de alineación dental, incluyendo apiñamiento extremo, espacios amplios, mordidas cruzadas y desalineaciones complejas. Están fabricados con acero inoxidable resistente, lo que les confiere durabilidad y resistencia al desg…

4. Bracket360 – Brackets y Kits de Ortodoncia

Domain: bracket360.com

Registered: 2010 (15 years)

Introduction: Brackets metálicos, Brackets autoligados, Brackets estéticos, Brackets cerámicos, Brackets zafiro, Brackets metálicos micro classic, Brackets metálicos precision, Kits de casos técnica MBT.022″, Kits de casos técnica ROTH.018″, Kits de casos técnica ROTH.022″, Reposiciones de brackets, Cemento para brackets y tubos, Adhesivos y composites ortodoncia, Componentes adhesivos, Alambres en varilla y bo…

5. Dentalia – Brackets Metálicos

Domain: dentalia.com

Registered: 1998 (27 years)

Introduction: Brackets Metálicos: Dispositivos de metal fijados a los dientes con adhesivo dental, conectados a un arco de alambre ajustable. Función: Alineación dental mediante presión constante y suave. Ventajas: Costo accesible, durabilidad, alta eficacia en corregir maloclusiones. Desventajas: Visibilidad, posible irritación en encías y boca, mantenimiento más complicado.

6. Adeslas Dental – Brackets Metálicos

Domain: adeslasdental.es

Introduction: Brackets metálicos son una técnica de ortodoncia común y efectiva, hechos de acero inoxidable de alto grado. Se utilizan para corregir la posición de los dientes y mejorar la mordida. Están compuestos por un arco, ligaduras (metálicas o de goma) y brackets. Existen varios tipos: brackets metálicos de ligado convencional, brackets metálicos autoligables y brackets metálicos linguales. Ventajas incl…

7. Clínica Dental Urbina – Brackets Metálicos y de Zafiro

Domain: clinicadentalurbina.com

Registered: 2013 (12 years)

Introduction: Brackets metálicos: Hechos de acero inoxidable, más visibles, duraderos, fáciles de reponer, económicos, eficaces para problemas graves, se pueden personalizar con ligas de colores. Brackets de zafiro: Hechos de zafiro sintético, casi imperceptibles, más estéticos, cómodos, producen menos molestias, requieren más cuidado, precio elevado, resistentes y no alteran su color.

8. Clínica Dental Seis – Brackets Metálicos

Domain: clinicadentalseis.cl

Introduction: Brackets metálicos son dispositivos que corrigen la alineación dental. Tipos: convencionales (acero inoxidable, económicos), autoligables (sin ligaduras elásticas), Damon (sistema de deslizamiento). Materiales: acero inoxidable (resistente), titanio (ligero, biocompatible). Ventajas: durabilidad, costo bajo, eficacia, variedad de tipos y colores. Desventajas: visibilidad, estética, requieren higie…

9. Clínica Dental Velázquez – Brackets Metálicos

Domain: clinicadentalvelazquez.com

Registered: 2008 (17 years)

Introduction: Brackets metálicos son piezas de metal que se adhieren a la superficie externa de los dientes para moverlos. Están hechos de una aleación metálica biocompatible y cada diente requiere un bracket específico. Se utilizan arcos metálicos y, a veces, gomas o muelles para completar el movimiento dental. Se fijan al esmalte con cemento que se elimina al finalizar el tratamiento. La clínica utiliza brack…

10. Clínica Dental Barrantes – Brackets Metálicos y de Porcelana

Domain: clinicadentalbarrantes.es

Introduction: Brackets metálicos: 1. Ventajas: Precio más bajo, fácil limpieza y mantenimiento, alta resistencia, buenos resultados. 2. Desventajas: Menos estéticos. 3. Usados comúnmente en tratamientos de ortodoncia. Brackets de porcelana: 1. Ventajas: Invisibles, más estéticos, menos molestias al colocarse, adecuados para pacientes con alergias a metales, más económicos que los de zafiro. 2. Desventajas: Meno…

Strategic Sourcing Conclusion and Outlook for brackets metalicos

In summary, the strategic sourcing of brackets metálicos offers significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The enduring popularity of metallic braces stems from their proven efficacy, versatility in treating various dental misalignments, and cost-effectiveness compared to alternative orthodontic solutions. Buyers should prioritize sourcing from manufacturers that adhere to high-quality standards, ensuring durability and compliance with international regulations.

As the demand for orthodontic solutions continues to grow, it’s essential for businesses to stay informed about the latest advancements in bracket technology and design. Engaging with suppliers who can provide innovative options, such as self-ligating brackets, can enhance treatment efficiency and patient satisfaction.

Looking ahead, the orthodontic market is poised for growth, driven by increasing awareness of dental aesthetics and health. B2B buyers are encouraged to leverage this momentum by forging strategic partnerships with reliable manufacturers. By doing so, they can ensure access to high-quality products that meet the evolving needs of their clientele, ultimately leading to enhanced business success and customer loyalty.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.