A Deep Dive into Membrane Keypad Solution

Introduction: Navigating the Global Market for membrane keypad

In today’s rapidly evolving technological landscape, sourcing high-quality membrane keypads can pose a significant challenge for international B2B buyers. These crucial components serve as the interface between users and machinery, impacting both functionality and user experience. This comprehensive guide delves into the diverse types of membrane keypads, their myriad applications across industries, and essential considerations for supplier vetting. Additionally, we explore cost factors and the latest innovations in membrane technology, ensuring that you are equipped with the necessary knowledge to make informed purchasing decisions.

As businesses in regions such as Africa, South America, the Middle East, and Europe (including markets like Vietnam and Nigeria) seek to enhance their product offerings, understanding the global market dynamics for membrane keypads becomes imperative. This guide empowers buyers by providing actionable insights into selecting the right keypad solutions tailored to specific operational needs and environmental conditions. By navigating the complexities of product specifications, supplier capabilities, and pricing strategies, you can mitigate risks and streamline your procurement process.

In an era where user interface technology is pivotal to product success, this guide stands as an essential resource, helping you make confident, strategic choices in your membrane keypad sourcing journey.

Understanding membrane keypad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Keypads | Provides tactile feedback with metal dome switches | Medical devices, industrial controls | Pros: Enhanced user experience, reliable. Cons: Higher cost, limited design flexibility. |

| Non-Tactile Membrane Keypads | Flat surface without tactile feedback, usually thinner | Consumer electronics, home appliances | Pros: Cost-effective, slim design. Cons: Less user feedback, may not suit all applications. |

| Backlit Membrane Keypads | Integrated LED or EL backlighting for visibility | Automotive, military equipment | Pros: Improved visibility in low light, customizable. Cons: Higher complexity and cost. |

| Custom Membrane Keypads | Tailored designs with specific graphics and features | Specialized machinery, custom devices | Pros: Fully customizable, meets specific needs. Cons: Longer lead times, potentially higher costs. |

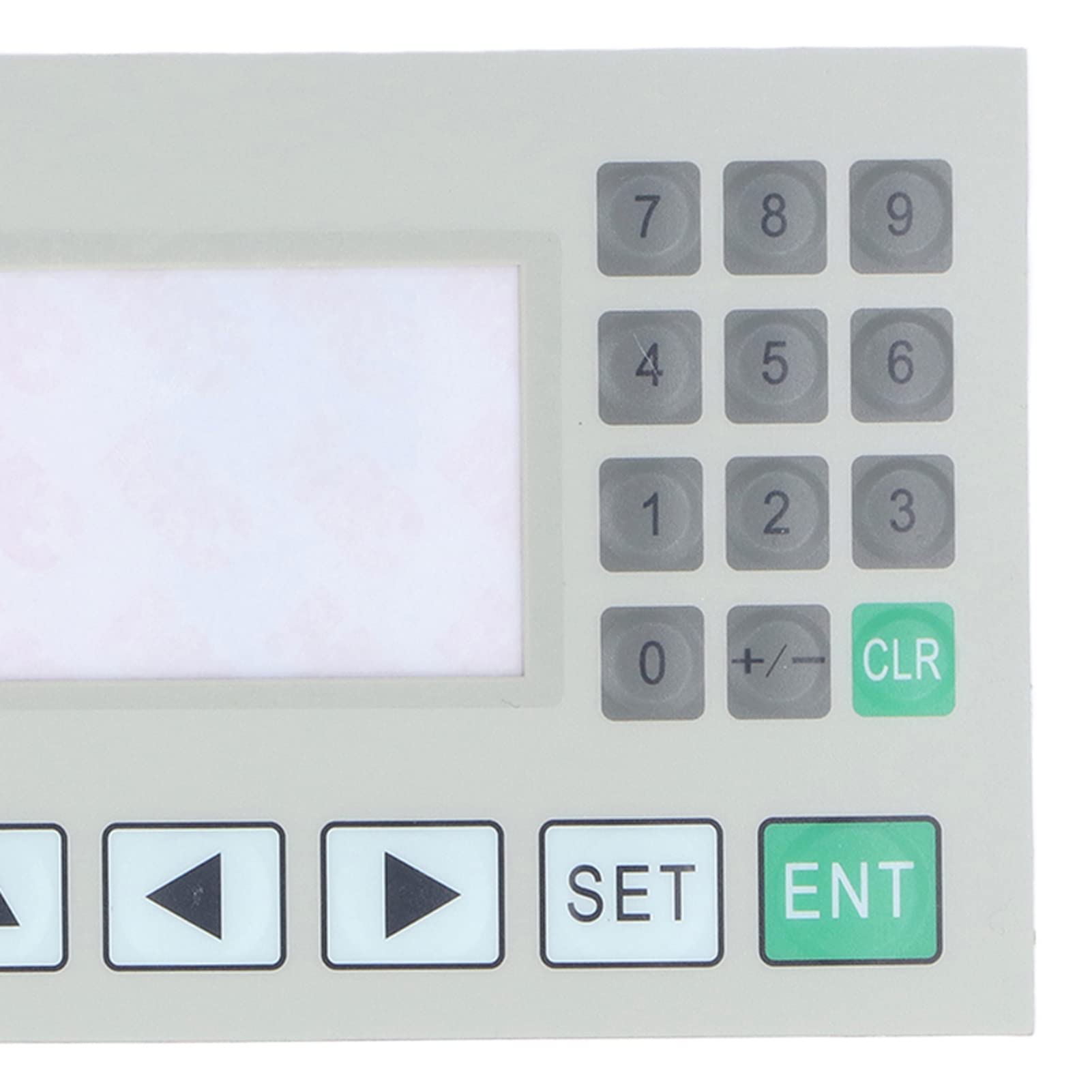

| Matrix Membrane Keypads | Arranged in rows and columns, allowing multiple key presses | Point of sale systems, control panels | Pros: Space-efficient, versatile input options. Cons: More complex wiring, potential for ghosting issues. |

What Are the Characteristics of Tactile Membrane Keypads?

Tactile membrane keypads incorporate metal dome switches, providing users with physical feedback when a key is pressed. This feature enhances the user experience, making them particularly suitable for applications in medical devices and industrial controls where reliability is paramount. When purchasing, consider the tactile response, durability, and potential cost implications, as these keypads typically have a higher price point due to their added functionality.

How Do Non-Tactile Membrane Keypads Differ?

Non-tactile membrane keypads feature a flat design without the tactile feedback of metal dome switches. They are often thinner and more cost-effective, making them ideal for consumer electronics and home appliances. Buyers should weigh the benefits of a sleek design against the reduced user feedback, which may not be suitable for all applications, particularly where user interaction is critical.

What Makes Backlit Membrane Keypads Valuable?

Backlit membrane keypads utilize integrated LED or electroluminescent (EL) technology, making them highly visible in low-light environments. This feature is particularly valuable in automotive and military applications where visibility is crucial. While they offer enhanced functionality and customization options, buyers should consider the increased complexity and cost associated with these keypads, as well as their specific lighting needs.

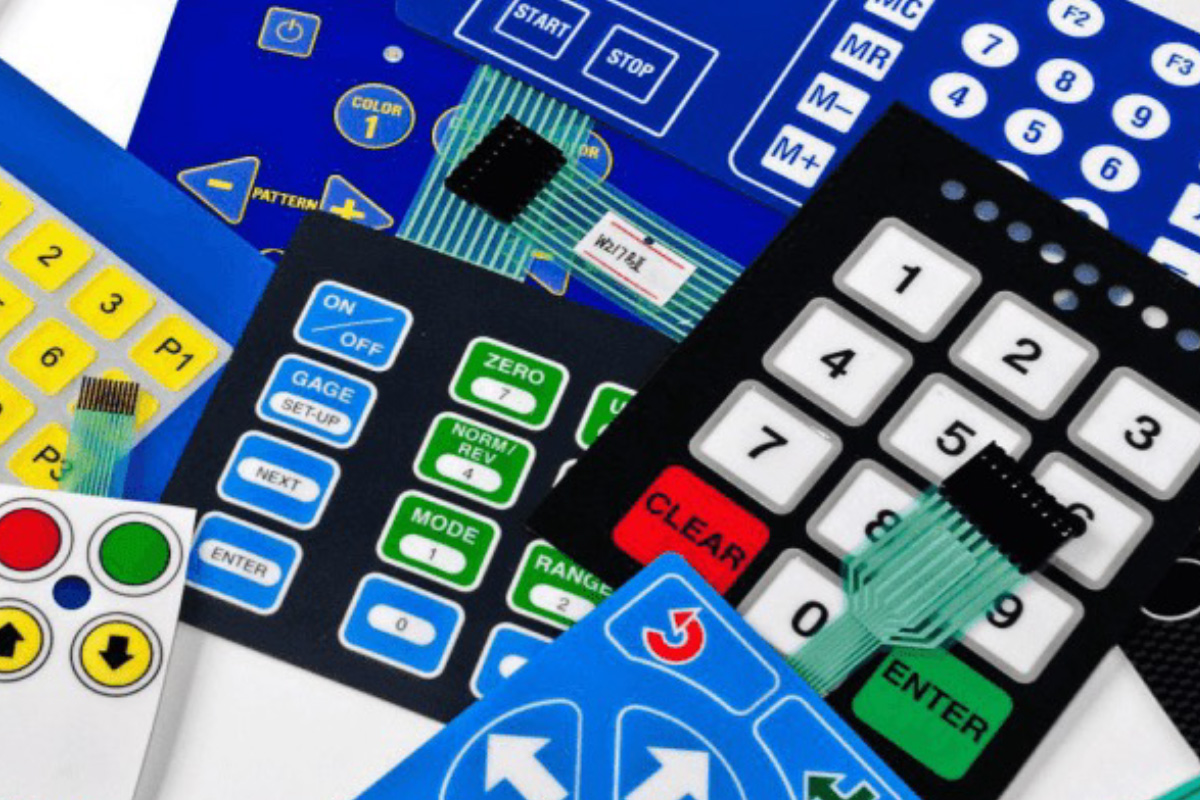

Illustrative image related to membrane keypad

Why Choose Custom Membrane Keypads?

Custom membrane keypads are designed to meet specific customer requirements, allowing for tailored graphics, features, and layouts. They are commonly used in specialized machinery and custom devices. While they offer the advantage of full customization, buyers should be aware of potentially longer lead times and higher costs associated with bespoke designs.

How Are Matrix Membrane Keypads Structured?

Matrix membrane keypads are arranged in a grid format, allowing multiple keys to be pressed simultaneously. This design is particularly effective for point of sale systems and control panels, where space efficiency and versatile input options are essential. Buyers should consider the wiring complexity and potential ghosting issues, which can arise from simultaneous key presses, when evaluating this type of keypad for their applications.

Key Industrial Applications of membrane keypad

| Industry/Sector | Specific Application of Membrane Keypad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | User interface for diagnostic equipment | Provides a reliable and hygienic interface for operators | Compliance with medical standards, durability, and ease of cleaning |

| Industrial Automation | Control panels for machinery and equipment | Enhances operational efficiency and user interaction | Customizability, resistance to environmental factors, and tactile feedback |

| Consumer Electronics | Remote controls for appliances and devices | Improves user experience and device functionality | Design aesthetics, integration capabilities, and cost-effectiveness |

| Automotive | Control interfaces for vehicle infotainment systems | Enhances user engagement and safety features | Temperature resistance, durability, and compatibility with vehicle designs |

| Military and Defense | User interfaces for tactical equipment | Ensures reliability and performance in critical situations | Environmental sealing, ruggedness, and compliance with military standards |

How is Membrane Keypad Used in Medical Devices?

In the medical sector, membrane keypads serve as critical user interfaces for diagnostic equipment, such as blood analyzers and imaging machines. These keypads are designed for high hygiene standards, often featuring antimicrobial coatings that prevent contamination. Buyers should prioritize suppliers who comply with medical regulations, ensuring the keypads are durable enough to withstand frequent cleaning and disinfection processes. The tactile feedback of these keypads also aids in precise operation during critical procedures.

What Role Does Membrane Keypad Play in Industrial Automation?

In industrial automation, membrane keypads are integral to control panels for machinery and equipment. They facilitate user interaction, allowing operators to execute commands quickly and efficiently. The customizability of these keypads enables companies to tailor layouts and functions to specific operational needs. Buyers in this sector should consider the keypad’s resistance to environmental factors such as moisture, dust, and extreme temperatures, ensuring reliability in demanding conditions.

How are Membrane Keypads Enhancing Consumer Electronics?

In the realm of consumer electronics, membrane keypads are commonly used in remote controls for various devices, from televisions to smart home systems. These keypads enhance user experience by providing intuitive interfaces that simplify device interaction. When sourcing, businesses should focus on design aesthetics and integration capabilities to ensure the keypad aligns with the overall product design. Cost-effectiveness is also crucial, particularly for high-volume consumer products.

Illustrative image related to membrane keypad

Why are Membrane Keypads Important in the Automotive Industry?

Automotive applications increasingly rely on membrane keypads for control interfaces in infotainment systems and dashboard controls. These keypads improve user engagement by offering a sleek, modern interface that is easy to navigate. Buyers must consider factors such as temperature resistance and durability to ensure that the keypads perform reliably in the harsh automotive environment. Compatibility with existing vehicle designs is also essential for seamless integration.

How are Membrane Keypads Utilized in Military and Defense Applications?

In the military and defense sectors, membrane keypads are utilized for user interfaces in tactical equipment, where reliability and performance are paramount. These keypads often feature rugged designs that can withstand extreme conditions, including temperature fluctuations and exposure to moisture. When sourcing, businesses should look for keypads with environmental sealing and compliance with military standards to ensure functionality in critical situations. The ability to customize these keypads for specific applications can also provide a significant advantage in the field.

3 Common User Pain Points for ‘membrane keypad’ & Their Solutions

Scenario 1: Durability Concerns in Harsh Environments

The Problem: B2B buyers often encounter the challenge of ensuring that membrane keypads can withstand harsh environmental conditions. Industries such as manufacturing, food processing, and outdoor equipment rely on keypads that endure moisture, dust, and extreme temperatures. For instance, a keypad used in a factory setting may be exposed to oils and chemicals, leading to premature failure and costly downtime.

The Solution: To address durability concerns, buyers should prioritize sourcing membrane keypads with robust environmental sealing and chemical resistance features. Opt for keypads that utilize high-quality adhesives and materials, such as polyimide (Kapton) for circuit construction, which offers superior resistance to moisture and temperature fluctuations. Additionally, consider custom designs that include UV-resistant coatings and protective seal frames, which enhance longevity and reliability in challenging environments. When communicating with suppliers, clearly specify the environmental conditions the keypad will face, ensuring they can recommend appropriate materials and designs tailored to your specific operational needs.

Scenario 2: Customization Limitations Affecting User Experience

The Problem: A common pain point for B2B buyers is the lack of customization options available with off-the-shelf membrane keypads. Many buyers find that generic keypads do not meet the specific aesthetic or functional requirements of their products, leading to a subpar user experience. For example, in medical devices, the interface must be intuitive and visually appealing, as it directly impacts usability and safety.

The Solution: To overcome customization limitations, buyers should seek manufacturers that specialize in custom membrane keypads. Look for suppliers that offer extensive design capabilities, including options for tactile feedback, backlighting, and embossed graphics. Engage in discussions about your unique requirements, such as branding elements and specific user interface needs. Additionally, consider prototyping options to test the keypad’s functionality and design before full-scale production. This proactive approach ensures that the final product not only aligns with your brand identity but also enhances the overall user experience, ultimately leading to increased customer satisfaction.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Another significant challenge B2B buyers face is the integration of membrane keypads with existing electronic systems. Buyers often encounter compatibility issues when attempting to connect new keypads to legacy systems, resulting in delays and additional costs. For instance, a manufacturer trying to upgrade their equipment’s interface may find that the new keypad does not align with the existing circuit layout or connection types.

The Solution: To facilitate seamless integration, it is crucial for buyers to conduct a thorough assessment of their current systems before selecting a membrane keypad. Engage with suppliers who offer a variety of connection options and can provide technical support during the integration process. Clearly outline your existing system specifications and any required modifications. Additionally, consider investing in flexible membrane keypads that can be customized to fit various connector types and circuit layouts. This strategy not only reduces the risk of integration issues but also enhances the adaptability of your equipment, allowing for future upgrades with minimal disruption.

Strategic Material Selection Guide for membrane keypad

What Are the Key Materials Used in Membrane Keypads?

When selecting materials for membrane keypads, several factors must be considered, including performance, durability, and compatibility with specific applications. Below are analyses of four common materials used in membrane keypads, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Polyester (PET) – A Versatile Choice for Membrane Keypads

Key Properties: Polyester, commonly known as PET, exhibits excellent chemical resistance and durability. It can withstand temperatures ranging from -40°C to 125°C, making it suitable for various environments.

Illustrative image related to membrane keypad

Pros & Cons: The advantages of PET include its affordability, lightweight nature, and ease of printing for graphics. However, it can be less resistant to UV light over prolonged exposure, leading to potential fading of printed designs.

Impact on Application: PET is compatible with a wide range of media, including oils and solvents, making it ideal for industrial applications. However, its limitations in high UV exposure environments may affect its use in outdoor applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers in regions like Africa and South America should ensure that the material meets local environmental regulations, particularly regarding chemical resistance.

Illustrative image related to membrane keypad

Polycarbonate (PC) – Strength and Clarity Combined

Key Properties: Polycarbonate is known for its high impact resistance and optical clarity. It can endure temperatures from -40°C to 120°C and is resistant to many chemicals.

Pros & Cons: The key advantage of polycarbonate is its durability and resistance to breakage, making it suitable for high-traffic areas. However, it is generally more expensive than polyester and can be more challenging to print on.

Impact on Application: Polycarbonate’s robustness makes it ideal for applications in medical devices and military equipment, where reliability is paramount. Its clarity allows for backlit designs, enhancing user interface visibility.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with polycarbonate and ensure that suppliers can provide materials that comply with relevant safety standards, especially in regions with stringent regulations.

Copper Flex – The Premium Option for High Performance

Key Properties: Copper flex materials offer excellent electrical conductivity and thermal stability, with a temperature rating of up to 150°C. They are typically used in conjunction with polyimide substrates.

Pros & Cons: The primary advantage of copper flex is its superior performance in terms of flexibility and reliability. However, the manufacturing process is complex, leading to higher costs.

Impact on Application: This material is ideal for environments requiring high durability and reliability, such as aerospace and automotive applications. Its compatibility with various media types enhances its versatility.

Considerations for International Buyers: International buyers should consider the complexity of sourcing copper flex materials and ensure that suppliers can meet the required standards for electrical performance and environmental compliance.

Silicone – The Flexible and Resilient Alternative

Key Properties: Silicone is known for its excellent temperature resistance (from -60°C to 200°C) and flexibility. It is also resistant to many chemicals and UV light.

Illustrative image related to membrane keypad

Pros & Cons: The key advantage of silicone is its durability and tactile feel, which enhances user experience. However, it can be more expensive and may require specialized manufacturing processes.

Impact on Application: Silicone is particularly well-suited for applications in harsh environments, such as outdoor equipment and medical devices, where flexibility and resilience are critical.

Considerations for International Buyers: Buyers should ensure that silicone materials meet international safety and environmental standards, particularly in regions with strict regulations regarding chemical exposure.

Summary Table of Material Selection for Membrane Keypads

| Material | Typical Use Case for membrane keypad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester (PET) | Industrial equipment, consumer devices | Affordable and easy to print | UV sensitivity | Low |

| Polycarbonate | Medical devices, military applications | High impact resistance and clarity | Higher cost and printing challenges | Med |

| Copper Flex | Aerospace, automotive applications | Superior flexibility and conductivity | Complex manufacturing process | High |

| Silicone | Outdoor equipment, medical devices | Excellent durability and tactile feel | Higher cost and specialized processes | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties and applications of various materials used in membrane keypads, enabling informed decisions that align with their specific industry needs.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane keypad

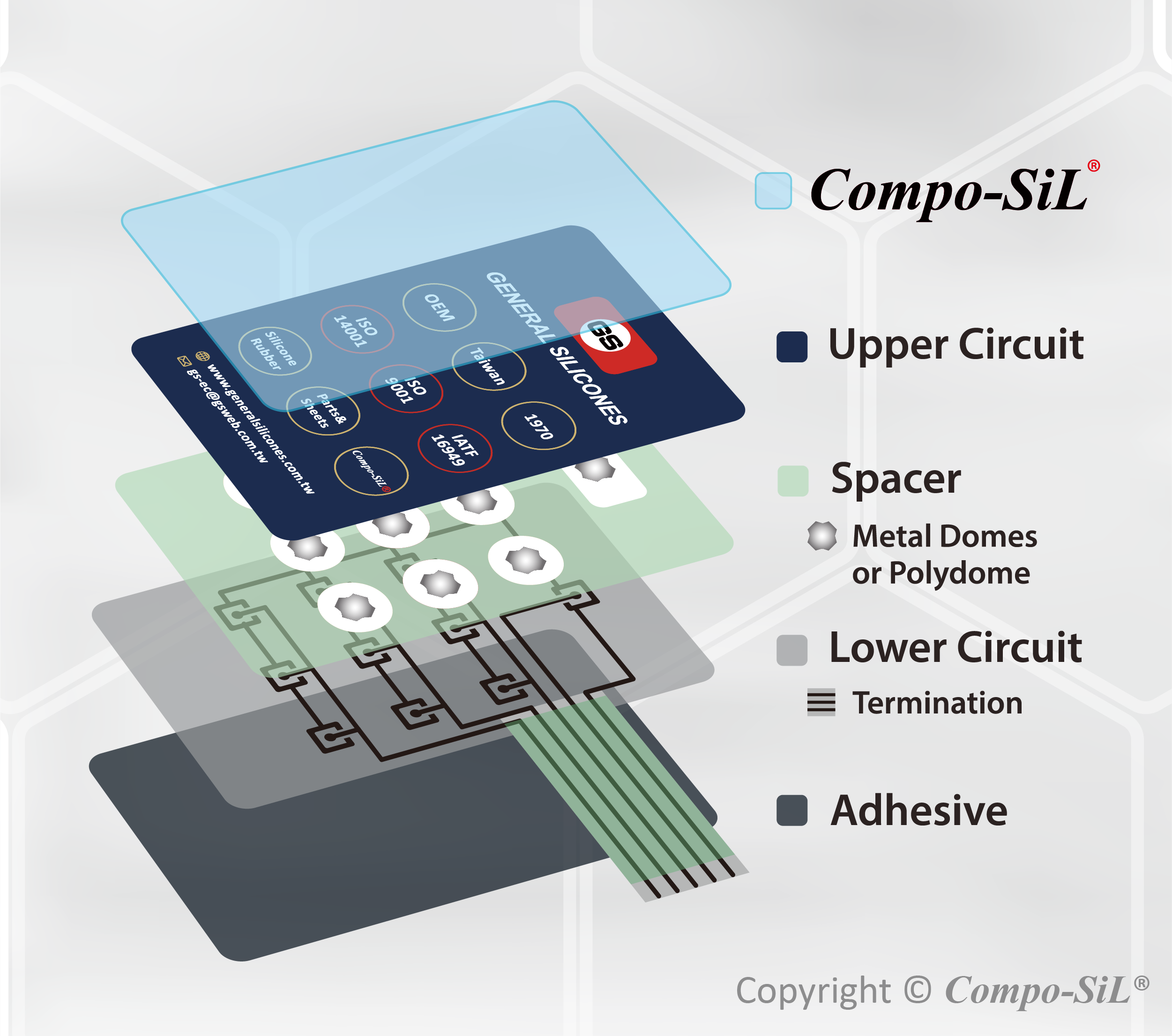

What Are the Key Stages in the Manufacturing Process of Membrane Keypads?

The manufacturing of membrane keypads is a meticulous process that ensures the final product meets both functional and aesthetic standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The choice of materials is crucial in determining the durability and functionality of membrane keypads. Common materials include:

- Overlay Films: Typically made from polyester or polycarbonate, these films serve as the outer layer and are often printed with graphics for user interfaces.

- Conductive Inks: Used to create the electrical pathways on the keypad, these inks are usually made from silver or carbon.

- Adhesives: High-performance adhesives are selected to ensure strong bonding between layers and resistance to environmental factors.

During this stage, materials are sourced from certified suppliers to guarantee quality, as the integrity of the materials directly impacts the performance of the keypad.

How Are Membrane Keypads Formed?

The forming stage involves several techniques to shape the keypads and establish the necessary circuitry. Key techniques include:

- Screen Printing: This is employed to apply the conductive inks onto the substrate, creating the electrical traces needed for the keypad to function.

- Lamination: Layers of materials are bonded together under heat and pressure, creating a durable assembly. This step is essential for ensuring that the keypad withstands wear and tear.

- Cutting: The laminated sheets are then cut to the desired dimensions using precision cutting tools, ensuring that the final product meets specifications.

The accuracy and precision of this stage are critical, as even minor deviations can lead to malfunctioning keypads.

What Does the Assembly Process Entail?

The assembly stage is where individual components come together to form the finished keypad. This includes:

- Layer Alignment: Each layer must be meticulously aligned to ensure that the graphical overlay matches the underlying circuitry.

- Adhesive Application: The application of adhesive is carefully controlled to prevent oozing, which can compromise the appearance and function of the keypad.

- Embedding Components: If applicable, components such as tactile switches or LED backlighting are integrated at this stage.

Attention to detail during assembly is vital, as this directly influences the keypad’s usability and longevity.

How Is the Finishing Touch Applied?

Finishing involves several steps that enhance the appearance and functionality of the keypad:

- Quality Inspection: Before the keypad is packaged, a thorough inspection is conducted to ensure that it meets quality standards.

- Protective Coatings: Depending on the application, keypads may receive protective coatings to enhance durability against chemicals and UV exposure.

- Packaging: Finally, the keypads are carefully packaged to prevent damage during transportation.

What Quality Assurance Measures Are Implemented in Membrane Keypad Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards and customer expectations. This involves adhering to various quality standards and implementing multiple checkpoints throughout the production cycle.

What International Standards Govern Membrane Keypad Quality?

Membrane keypads must comply with several international quality standards, including:

- ISO 9001: This standard outlines the requirements for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Particularly relevant for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For keypads used in specific industries, compliance with American Petroleum Institute (API) standards may be necessary, particularly for applications in oil and gas.

Understanding these standards is crucial for B2B buyers, as compliance often signifies a manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to identify any deviations from quality standards.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all design and functional requirements.

These checkpoints help minimize defects and ensure a consistent product output.

What Common Testing Methods Are Used for Membrane Keypads?

Several testing methods are employed to validate the performance and durability of membrane keypads:

Illustrative image related to membrane keypad

- Electrical Testing: This checks for proper circuit functionality and ensures that each key responds correctly.

- Environmental Testing: Keypads are subjected to temperature, humidity, and chemical exposure tests to evaluate their durability in various conditions.

- Mechanical Testing: This includes tests for abrasion resistance and tactile feedback to ensure that the keypad meets user expectations.

These tests not only verify the keypad’s functionality but also its long-term reliability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to high-quality standards, B2B buyers can take several steps to verify QC processes:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control practices, and overall compliance with standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes and any corrective actions taken for past issues.

- Third-Party Inspections: Engaging independent third-party inspectors can provide unbiased evaluations of the supplier’s quality practices and product reliability.

These steps are essential for mitigating risks associated with sourcing from international suppliers, particularly in regions where quality assurance practices may vary.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances when it comes to quality control:

- Cultural Differences: Understanding cultural attitudes towards quality can influence supplier relationships. Some regions may prioritize cost over quality, leading to potential conflicts.

- Regulatory Compliance: Different countries may have varying regulations that affect the quality standards applicable to membrane keypads. Buyers should ensure that suppliers are compliant with local regulations.

- Communication Barriers: Language differences can lead to misunderstandings regarding quality requirements. Clear communication and documentation are vital to ensure that expectations are met.

Navigating these nuances effectively can lead to successful partnerships and high-quality products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘membrane keypad’

In the fast-evolving world of technology, membrane keypads serve as critical user interfaces for various applications across industries. This guide aims to equip B2B buyers with a comprehensive checklist for sourcing membrane keypads, ensuring that your procurement process aligns with your technical and operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline your technical specifications. This includes understanding the dimensions, number of keys, and the type of circuitry (e.g., printed silver vs. copper flex) required for your application. Establishing these parameters upfront will streamline communication with suppliers and help avoid costly revisions later.

Step 2: Identify Your Application Needs

Different applications may require specific features in a membrane keypad. Assess whether your project necessitates tactile feedback, backlighting, or environmental sealing to protect against moisture and dust. Understanding your application will guide you in choosing a supplier who can meet these specialized requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request detailed company profiles, product samples, and case studies that highlight their experience in your industry. Look for references from buyers in similar sectors or regions to gain insight into their reliability and service quality.

- Check for Certifications: Ensure that the suppliers hold relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality and compliance with international standards.

Step 4: Assess Customization Capabilities

Customization is often a key factor in selecting a membrane keypad supplier. Inquire about their ability to create bespoke designs, including graphic overlays, key shapes, and tactile features. A supplier with robust customization capabilities can provide solutions tailored to your specific operational and aesthetic requirements.

Step 5: Understand Pricing Structures and Discounts

Pricing can vary significantly between suppliers, so it’s vital to understand their pricing structures. Look for tiered pricing models that reward larger orders with discounts. Be sure to clarify whether the quoted prices include additional features like backlighting or custom designs, as these can affect your overall budget.

Illustrative image related to membrane keypad

Step 6: Request Prototypes and Samples

Once you’ve narrowed down potential suppliers, request prototypes or samples of their membrane keypads. Testing these samples will provide insight into their quality, functionality, and ease of integration with your existing systems. Evaluate aspects such as tactile feedback, durability, and ease of installation.

Step 7: Review After-Sales Support and Warranty Policies

After securing a supplier, it’s important to understand their after-sales support and warranty policies. Ensure they offer adequate technical support and have a clear process for handling defective products. A supplier committed to excellent after-sales service can enhance your overall experience and mitigate risks associated with product failures.

By following this checklist, B2B buyers can navigate the complexities of sourcing membrane keypads effectively, ensuring that the selected products meet both technical specifications and budgetary constraints.

Comprehensive Cost and Pricing Analysis for membrane keypad Sourcing

What Are the Key Cost Components in Membrane Keypad Sourcing?

Understanding the cost structure for membrane keypads is essential for B2B buyers to make informed decisions. The primary components include:

-

Materials: The choice of materials significantly impacts the cost. Membrane keypads are typically made from polyester or polycarbonate overlays, along with conductive inks like silver or carbon. Higher-quality materials can enhance durability and functionality but will also increase costs.

-

Labor: Labor costs can vary based on the complexity of the design and the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this may affect the quality and craftsmanship of the product.

-

Manufacturing Overhead: This includes costs related to equipment, utilities, and factory space. Efficient production processes can help minimize these costs, impacting the final price of the keypads.

-

Tooling: Custom designs often require specific tooling, which can be a significant upfront investment. This cost is usually amortized over the production run, so larger orders may benefit from lower per-unit tooling costs.

-

Quality Control (QC): Implementing rigorous QC processes can add to costs but is essential for ensuring product reliability. Certifications and quality standards might also come into play, affecting pricing.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. International shipping can introduce additional complexities, including tariffs and customs duties.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s pricing strategy and market conditions.

How Do Price Influencers Affect Membrane Keypad Costs?

Several factors can influence the pricing of membrane keypads:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volume orders generally lead to economies of scale, resulting in lower per-unit costs.

-

Specifications and Customization: Custom features such as tactile feedback, backlighting, and unique designs can increase costs. Buyers should carefully weigh the benefits of customization against the additional expense.

-

Materials and Quality Certifications: The choice of materials and the presence of certifications (e.g., ISO, RoHS) can influence pricing. Higher-quality materials usually command higher prices, but they may result in lower total costs over the product’s lifespan.

-

Supplier Factors: The reputation and reliability of the supplier can impact costs. Established suppliers may charge more for their products, reflecting their quality assurance and service levels.

-

Incoterms: The agreed terms of shipping and delivery can affect pricing. Understanding Incoterms (e.g., FOB, CIF) is crucial for assessing total costs and responsibilities.

What Tips Can B2B Buyers Use for Cost-Efficiency in Membrane Keypad Sourcing?

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing, especially if you can commit to larger orders. Leverage your negotiation power to secure better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the lifespan, maintenance, and potential replacements. A higher initial cost may be justified if the product lasts longer or requires less maintenance.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and trade agreements that may affect pricing.

-

Seek Multiple Quotes: Always obtain quotes from multiple suppliers to compare costs and services. This can provide insights into the market rates and help in identifying the best value.

-

Evaluate Long-Term Relationships: Establishing a long-term relationship with a reliable supplier can lead to better pricing and service in the future. Consider factors such as responsiveness and support when choosing a supplier.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and other external factors. Always verify current prices and terms directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing membrane keypad With Other Solutions

In the quest for effective user interfaces, membrane keypads have established themselves as a popular choice. However, businesses often seek alternatives that may better suit their specific operational needs, preferences, or budget constraints. This section evaluates membrane keypads against two viable alternatives: mechanical key switches and touch screen interfaces. The following comparison will help B2B buyers make informed decisions regarding their user interface solutions.

| Comparison Aspect | Membrane Keypad | Mechanical Key Switches | Touch Screen Interfaces |

|---|---|---|---|

| Performance | Reliable, low-profile, and moisture-resistant | High tactile feedback and durability | Highly interactive with multi-functionality |

| Cost | Low-cost, especially for mass production | Higher initial cost per unit | Variable costs, generally higher than keypads |

| Ease of Implementation | Simple installation with adhesive backing | More complex, requiring assembly | Requires software integration and calibration |

| Maintenance | Low maintenance, limited wear and tear | Moderate maintenance for mechanical parts | High maintenance due to screen exposure |

| Best Use Case | Medical devices, household appliances | Gaming consoles, computers | Smartphones, kiosks, and industrial controls |

What Are the Advantages and Disadvantages of Mechanical Key Switches as an Alternative to Membrane Keypads?

Mechanical key switches offer a tactile response that many users prefer, especially in applications like gaming and typing. They are known for their durability, often rated for millions of keystrokes, making them suitable for high-use environments. However, they come at a higher cost and are bulkier, which may not be ideal for compact designs. Additionally, installation can be more complex, requiring precise alignment and assembly.

How Do Touch Screen Interfaces Compare to Membrane Keypads?

Touch screen interfaces provide a modern and versatile alternative to membrane keypads. They allow for dynamic content and multi-functionality, making them suitable for applications where user interaction is crucial, such as in kiosks or smartphones. However, touch screens typically have higher upfront costs and can require extensive software integration. Maintenance can also be challenging, as screens are prone to scratches and require regular cleaning, especially in high-traffic areas.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate user interface solution hinges on several factors: performance needs, budget constraints, space considerations, and maintenance capabilities. For applications requiring durability and tactile feedback, mechanical key switches may be the best option. In contrast, if a low-cost and low-maintenance solution is paramount, membrane keypads excel. Touch screens stand out in environments demanding interactivity and versatility but require careful consideration of cost and maintenance. By assessing these factors, B2B buyers can align their choice with their operational goals and user expectations, ensuring they invest in a solution that enhances productivity and user satisfaction.

Essential Technical Properties and Trade Terminology for membrane keypad

What Are the Key Technical Properties of Membrane Keypads?

Membrane keypads are essential components in various electronic devices, serving as the primary interface between users and machines. Understanding their technical properties can help B2B buyers make informed decisions. Here are some critical specifications to consider:

-

Material Composition

Membrane keypads are typically made from polyester or polycarbonate materials. Polyester offers excellent durability and resistance to moisture, while polycarbonate is known for its high impact resistance. For B2B buyers, selecting the right material is crucial for ensuring the longevity and reliability of the keypad in specific environments, especially in harsh conditions. -

Circuit Technology

The circuitry in membrane keypads can be made using printed conductive inks (like silver or carbon) or copper flex technology. Copper flex is particularly advantageous for outdoor applications due to its superior dielectric strength and thermal stability. Understanding the type of circuit technology helps buyers assess the keypad’s performance and suitability for their applications. -

Tactility and Feedback

Tactile feedback is an essential property for user interaction. Keypads can be designed with metal dome switches or non-tactile options. Tactile switches provide a noticeable click, enhancing user experience, especially in high-frequency applications. B2B buyers should consider how tactile feedback affects user satisfaction and productivity in their specific use cases. -

Environmental Sealing

Many membrane keypads come with sealing features that protect them from moisture, dust, and other contaminants. Sealing methods can include adhesive frames or epoxy coatings. For buyers, understanding the level of environmental protection is critical for applications in industries like medical or military, where reliability is paramount. -

Backlighting Options

Backlighting enhances visibility in low-light conditions and can be achieved through various technologies such as LEDs or electroluminescent (EL) layers. Buyers should evaluate the backlighting needs based on the operational environment and user requirements, as this can significantly impact usability. -

Customization Capabilities

The ability to customize membrane keypads in terms of layout, graphics, and additional features (like embossing or color options) is vital for branding and user experience. B2B buyers should explore customization options to ensure the keypad aligns with their product design and market positioning.

What Are Common Trade Terminologies Related to Membrane Keypads?

Familiarity with industry jargon can streamline communication and enhance negotiations for B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEMs are companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term is essential for buyers looking to integrate membrane keypads into their products, as it can impact pricing and branding. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This is crucial for buyers, especially startups or small businesses, as it can affect cash flow and inventory management. Knowing the MOQ helps in planning purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific quantities and specifications of products. B2B buyers should utilize RFQs to get competitive pricing and terms from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, which is crucial in global trade. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. Understanding lead times is vital for B2B buyers to manage project timelines and ensure timely product launches. -

Customization

This term refers to the ability to modify products to meet specific customer requirements. For membrane keypads, this might include design, size, or functionality adjustments. Buyers should leverage customization options to enhance product differentiation in the market.

By understanding these technical properties and trade terms, B2B buyers can navigate the membrane keypad landscape more effectively, ensuring they make strategic purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the membrane keypad Sector

What Are the Current Market Dynamics and Key Trends in the Membrane Keypad Sector?

The membrane keypad market is experiencing significant growth driven by the increasing demand for user-friendly interfaces in various sectors, including consumer electronics, automotive, and industrial automation. As global technology evolves, businesses across Africa, South America, the Middle East, and Europe are increasingly adopting membrane keypads for their versatility and cost-effectiveness. Key trends include the rise of customizable keypads, which allow manufacturers to tailor designs to specific applications, enhancing user experience and operational efficiency.

Moreover, the integration of advanced technologies such as backlighting and touch sensitivity is becoming commonplace. These features not only improve aesthetics but also enhance functionality, making them ideal for applications in challenging environments. Furthermore, the trend towards miniaturization in electronics is pushing manufacturers to develop smaller, more efficient keypads without compromising performance.

International B2B buyers should also note the growing importance of e-commerce platforms and digital sourcing tools, which facilitate better access to suppliers and enable comparative pricing. This shift is particularly relevant for buyers in emerging markets, where traditional sourcing methods may be less effective.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Membrane Keypads?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the membrane keypad sector. The environmental impact of production processes, particularly concerning waste and resource consumption, is under scrutiny. Buyers must prioritize suppliers who utilize sustainable materials and practices, such as recyclable substrates and eco-friendly inks.

Furthermore, certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances can serve as indicators of a supplier’s commitment to sustainability. These certifications not only reduce environmental footprints but also enhance brand reputation in an increasingly eco-conscious market.

Buyers should also consider the social aspects of sourcing, ensuring that suppliers adhere to ethical labor practices. This includes fair wages, safe working conditions, and the prohibition of child labor. Establishing a transparent supply chain fosters trust and loyalty among consumers who are increasingly favoring brands that demonstrate corporate social responsibility.

What Is the Brief Evolution and History of Membrane Keypads?

The evolution of membrane keypads dates back to the 1970s when they were first introduced as a cost-effective alternative to mechanical switches. Initially used in consumer electronics, their application quickly expanded into various industries, including automotive and medical devices.

Technological advancements have significantly enhanced the functionality and design of membrane keypads. The introduction of conductive inks and improved adhesive technologies has allowed for more durable and aesthetically pleasing products. Over the years, the integration of backlighting and touchscreen capabilities has transformed membrane keypads into sophisticated user interfaces, reflecting the ongoing demand for innovation in the B2B sector.

Today, membrane keypads are not just functional components; they are integral to the design and user experience of a wide range of products, making them essential for manufacturers looking to stay competitive in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of membrane keypad

1. How do I ensure the quality of membrane keypads from suppliers?

To ensure the quality of membrane keypads, conduct thorough supplier vetting. Look for manufacturers with certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples before placing large orders to assess the materials and manufacturing quality. Additionally, inquire about their quality assurance processes, including testing methods for durability, functionality, and environmental resistance. Establishing clear specifications and expectations in your purchase order can also help maintain quality throughout the production process.

2. What customization options are available for membrane keypads?

Membrane keypads can be highly customized to meet specific requirements. Options include different shapes, sizes, and button configurations, as well as various materials for overlays like polyester or polycarbonate. You can also incorporate features such as backlighting, tactile feedback, and unique graphic overlays. Discuss your design preferences with suppliers, who can provide mock-ups or prototypes to ensure the final product aligns with your vision. Customization can enhance user experience and improve the interface of your devices.

3. What is the typical minimum order quantity (MOQ) for membrane keypads?

Minimum order quantities (MOQ) for membrane keypads can vary widely among suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the complexity of the design and the manufacturer’s production capabilities. Smaller orders may be accepted, but they could come with higher per-unit costs. It’s essential to communicate your needs with potential suppliers to understand their specific MOQs and negotiate terms that suit your business requirements.

4. How can I effectively negotiate payment terms with suppliers?

When negotiating payment terms with suppliers, clarity and mutual understanding are key. Start by discussing preferred payment methods, such as letters of credit or bank transfers, which can provide security for both parties. Aim for terms that allow for partial payments upon order confirmation and the remainder upon delivery or acceptance of goods. Establishing a good relationship with suppliers can also facilitate more favorable terms, including discounts for early payment or flexible payment schedules.

5. What logistics considerations should I keep in mind when sourcing membrane keypads internationally?

When sourcing membrane keypads internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with import/export procedures in your region. Assess whether air freight or sea freight is more suitable based on urgency and budget. Ensure that your supplier provides all necessary documentation for customs clearance to avoid delays. Additionally, factor in potential tariffs and duties that may apply to your shipments.

6. How do I handle potential disputes with membrane keypad suppliers?

To handle potential disputes with suppliers effectively, establish clear communication from the start. Document all agreements, specifications, and correspondence to provide a reference point if issues arise. If a dispute occurs, attempt to resolve it through direct communication, aiming for a mutually beneficial solution. Consider including arbitration or mediation clauses in your contracts to facilitate resolution without escalating to legal action. Building a good relationship with suppliers can also reduce the likelihood of disputes.

7. What are the environmental considerations for membrane keypads?

When sourcing membrane keypads, consider the environmental impact of materials used and manufacturing processes. Opt for suppliers who utilize eco-friendly materials and practices, such as recyclable overlays and low-impact adhesives. Additionally, inquire about the durability of the keypads, as longer-lasting products reduce waste. Understanding a supplier’s commitment to sustainability can also enhance your brand’s reputation in environmentally conscious markets.

Illustrative image related to membrane keypad

8. How can I assess the reliability of a membrane keypad supplier?

To assess the reliability of a membrane keypad supplier, research their track record and customer reviews. Look for references from other businesses, particularly those in your industry, to gain insights into their performance. Evaluate their production capabilities, including lead times and flexibility in meeting orders. Certifications and compliance with industry standards can also indicate a supplier’s reliability. Finally, establish open lines of communication to ensure responsiveness and support throughout the sourcing process.

Top 6 Membrane Keypad Manufacturers & Suppliers List

1. Adafruit – Membrane 1×4 Keypad

Domain: adafruit.com

Registered: 2005 (20 years)

Introduction: {‘product_name’: ‘Membrane 1×4 Keypad + Extras’, ‘product_id’: ‘1332’, ‘price’: ‘$2.95’, ‘discounted_prices’: {‘1-9’: ‘$2.95′, ’10-99’: ‘$2.66’, ‘100+’: ‘$2.36’}, ‘weight’: ‘2.83g’, ‘keypad_dimensions’: ‘69.14mm x 20.07mm’, ‘cable_length’: ‘87.31mm x 14.28mm’, ‘connector’: ‘5-pin 0.1″ pitch connector’, ‘features’: ‘4 buttons, no matrix code required, soft membrane, strong adhesive backing, include…

2. CSi Keyboards – Custom Membrane Switches and Keypads

Domain: csikeyboards.com

Registered: 1997 (28 years)

Introduction: Custom membrane switches and keypads designed for various industries including medical, military, industrial, aerospace, emergency vehicles, marine, and agricultural. Features include tactile feel, backlighting options (LED, Light Guide Film, Fiber Optic, EL), sealing (UV, chemical, temperature resistant), shielding (EMI, ESD, RFI), and various graphic overlay capabilities. Circuitry options inclu…

3. TigerStop – Keypad Membrane for Version 4 Controller

Domain: shop.tigerstop.com

Registered: 1997 (28 years)

Introduction: {“name”:”Keypad Membrane for Version 4 Controller”,”sku”:”SMTKPM”,”price”:”300.00″,”currency”:”USD”,”dimensions”:”9.25 by 5.0 inches (23.5 by 12.7 cm)”,”compatibility”:”for controller versions 3.0-4.7, incompatible with Version 5 Controller (CON5)”,”weight”:”454 grams”}

4. Instructables – Custom Membrane Matrix Keypad for Arduino

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Create your own membrane matrix keypad for Arduino projects. Benefits include cost-effectiveness, customization options, and durability. Materials needed: aluminum foil, paper or flat material, glue, spacers, and optionally a laminator. The keypad can be designed in a 3×3 configuration with numbers 1-9. The construction involves mapping out circuits using foil, applying spacers, and ensuring prope…

5. CCL Design – Membrane Keypads

Domain: ccldesign.com

Registered: 2017 (8 years)

Introduction: Membrane keypads are advanced, user-friendly interfaces used in automotive, consumer electronics, and industrial applications. They consist of multiple layers, including printed circuitry and tactile or capacitive touch interfaces, providing durable and customizable solutions. Key benefits include:

– Customisation: Designs tailored to exact specifications across various sectors.

– Reliability: En…

6. Parallax – 4×4 Matrix Membrane Keypad

Domain: parallax.com

Registered: 1999 (26 years)

Introduction: {“name”: “4×4 Matrix Membrane Keypad”, “SKU”: “27899”, “price”: “$9.95”, “stock”: “647 in stock”, “description”: “This slim, 16-button keypad provides a useful human interface component for microcontroller projects. Convenient adhesive backing provides a simple way to mount the keypad in a variety of applications. It is well-supported for use with the Propeller microcontroller by BlocklyProp block…

Strategic Sourcing Conclusion and Outlook for membrane keypad

In summary, the membrane keypad market presents significant opportunities for international B2B buyers seeking cost-effective, customizable solutions for user interfaces across various industries. Strategic sourcing of membrane keypads enables companies to leverage advanced technologies such as backlighting, tactile feedback, and environmental sealing, ensuring product reliability and enhanced user experience. Engaging with reputable manufacturers can provide access to innovative designs tailored to specific application needs, ultimately improving operational efficiency and customer satisfaction.

As you consider your sourcing strategies, focus on suppliers who offer flexibility in customization and demonstrate a commitment to quality and sustainability. With the increasing demand for sophisticated user interfaces in sectors such as healthcare, automotive, and industrial equipment, the future of membrane keypads looks promising.

Now is the time to explore partnerships that will drive your business forward. By investing in high-quality membrane keypads, you position your company to meet evolving market demands while maintaining a competitive edge. Embrace the potential of membrane keypads and seize the opportunity to enhance your product offerings today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.