How to Source Jib Crane And Hoist Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for jib crane and hoist

In today’s competitive industrial landscape, sourcing the right jib crane and hoist solutions can be a daunting challenge for international B2B buyers. The complexity of navigating various options, from wall-mounted to portable models, requires a thorough understanding of each type’s unique applications and benefits. This guide serves as an essential resource, illuminating the diverse landscape of jib cranes and hoists, including their functionalities, applications across different sectors, and strategies for effective supplier vetting.

Buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Saudi Arabia and Germany—face specific challenges such as varying compliance standards, logistical considerations, and the need for tailored solutions that fit unique operational requirements. By delving into aspects such as cost analysis, installation requirements, and maintenance needs, this guide empowers decision-makers to make informed purchasing choices that align with their business objectives.

With a focus on actionable insights, you will gain the tools necessary to assess the right jib crane and hoist for your operational demands. Whether you are looking to enhance productivity in a manufacturing plant or streamline operations in a warehouse, understanding the intricacies of these lifting solutions is vital for optimizing your material handling processes. Let this guide be your compass in the global market for jib cranes and hoists, ensuring that you select the most effective solutions tailored to your needs.

Understanding jib crane and hoist Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall Mounted Jib Crane | Fixed to a wall, saving floor space; suitable for light to moderate loads. | Warehouses, assembly lines, and small workshops. | Pros: Space-efficient, easy installation. Cons: Limited mobility and reach. |

| Floor Mounted Jib Crane | Base-mounted, allowing 360-degree rotation; ideal for heavy loads. | Manufacturing plants, shipping docks, and large warehouses. | Pros: Versatile movement, robust capacity. Cons: Requires floor space and installation. |

| Articulating Jib Crane | Features a jointed arm for enhanced maneuverability; suitable for tight spaces. | Automotive assembly, repair shops, and confined workspaces. | Pros: Flexible positioning, ideal for repetitive tasks. Cons: Generally higher cost and complexity. |

| Portable Jib Crane | Easily movable; lightweight design for temporary applications. | Construction sites, maintenance tasks, and outdoor activities. | Pros: Flexibility and ease of transport. Cons: Limited load capacity and stability. |

| Stainless Steel Jib Crane | Corrosion-resistant materials; ideal for sanitary environments. | Food processing, pharmaceuticals, and chemical handling. | Pros: Durable, hygienic, and long-lasting. Cons: Higher initial investment compared to standard models. |

What Are Wall Mounted Jib Cranes and Their Applications?

Wall mounted jib cranes are anchored to walls, offering an efficient lifting solution without occupying valuable floor space. They are particularly effective in environments where space is constrained, such as warehouses and small workshops. B2B buyers should consider the load capacity and the reach of the jib arm, as well as the wall’s structural integrity. While they are easy to install and cost-effective, their fixed nature may limit operational flexibility.

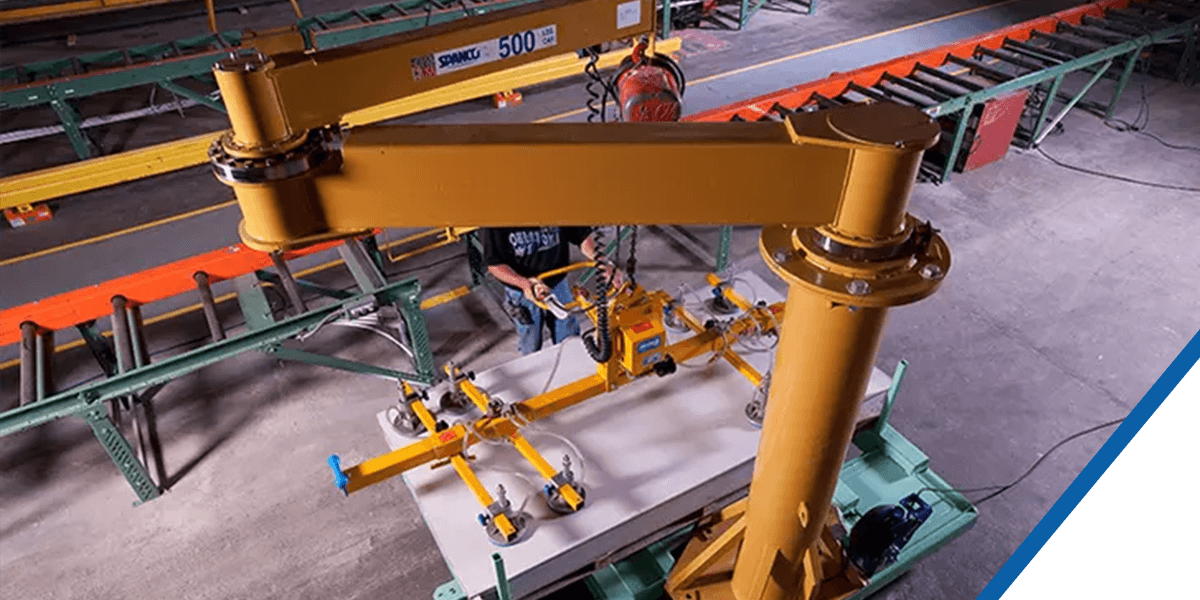

Illustrative image related to jib crane and hoist

How Do Floor Mounted Jib Cranes Enhance Operational Efficiency?

Floor mounted jib cranes provide a robust lifting solution with the ability to rotate 360 degrees, making them ideal for heavy loads in manufacturing plants and shipping docks. Their base-mounted design allows for extensive reach and versatility, accommodating various material handling tasks. Buyers should evaluate the required load capacity and the space available for installation. While these cranes excel in operational efficiency, they require more floor space and a proper foundation.

What Advantages Do Articulating Jib Cranes Offer in Tight Spaces?

Articulating jib cranes feature a jointed arm that allows for enhanced maneuverability, making them perfect for tight spaces in automotive assembly and repair shops. Their flexibility enables precise positioning of loads, which is essential for repetitive manufacturing tasks. When purchasing, consider the range of motion and load capacity. Although they offer significant advantages in maneuverability, articulating jibs may come at a higher cost and require more maintenance.

Why Choose Portable Jib Cranes for Temporary Applications?

Portable jib cranes are designed for easy transport and setup, making them ideal for temporary applications at construction sites or maintenance tasks. Their lightweight design allows for quick relocation, providing flexibility in various work environments. Buyers should assess the load capacity and stability during operation. While they offer unmatched mobility, portable jibs typically have lower load limits and may not be as stable as fixed models.

Illustrative image related to jib crane and hoist

What Are the Key Benefits of Stainless Steel Jib Cranes?

Stainless steel jib cranes are specifically designed for environments that require high levels of hygiene and corrosion resistance, such as food processing and pharmaceuticals. Their durable construction ensures long-lasting performance, even in harsh conditions. When considering a stainless steel option, buyers should evaluate the specific application requirements and the crane’s load capacity. While they provide excellent durability, the initial investment can be higher compared to standard steel models.

Key Industrial Applications of jib crane and hoist

| Industry/Sector | Specific Application of jib crane and hoist | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line support for heavy components | Increases productivity and reduces labor costs | Ensure the crane supports required load capacity and has suitable reach for the workspace. |

| Construction | Lifting and positioning materials on site | Enhances safety and efficiency in material handling | Consider portability and adaptability to various site conditions. |

| Automotive | Engine assembly and vehicle maintenance | Streamlines workflow and minimizes downtime | Look for models that allow for ergonomic lifting and easy maneuverability. |

| Warehousing & Logistics | Loading and unloading goods from trucks or shelves | Optimizes space utilization and improves workflow | Evaluate options for customization based on warehouse layout and specific lifting needs. |

| Food Processing | Handling bulk ingredients and packaging | Ensures hygiene standards and efficiency in operations | Stainless steel models are preferred for corrosion resistance and easy cleaning. |

How is Jib Crane and Hoist Used in Manufacturing?

In the manufacturing sector, jib cranes and hoists are essential for supporting assembly lines, particularly for heavy components. They facilitate the movement of parts within confined spaces, enhancing operational efficiency. By reducing manual lifting, businesses can decrease labor costs and minimize workplace injuries. Buyers in this sector should focus on cranes that meet their specific load capacities and reach requirements, ensuring they can effectively integrate them into their existing workflows.

What Role Do Jib Cranes Play in Construction?

In construction, jib cranes are utilized to lift and position materials on-site, improving both safety and efficiency. They can be used for various tasks, from hoisting steel beams to placing heavy equipment. The ability to maneuver loads in tight spaces makes them invaluable for construction projects. Buyers should consider the portability of jib cranes, as well as their adaptability to different site conditions, ensuring they can be deployed quickly and effectively.

How Do Jib Cranes Benefit the Automotive Industry?

The automotive industry leverages jib cranes and hoists for tasks such as engine assembly and vehicle maintenance. These systems streamline workflows by allowing workers to lift heavy components with ease, thus minimizing downtime. For international buyers, it is crucial to select jib cranes that offer ergonomic features and maneuverability, which can significantly enhance productivity and worker safety on the assembly line.

Why Are Jib Cranes Important in Warehousing and Logistics?

In the warehousing and logistics sectors, jib cranes facilitate the loading and unloading of goods from trucks or shelves, optimizing space utilization and improving overall workflow. Their ability to handle heavy loads in confined areas can lead to significant efficiency gains. When sourcing jib cranes for these applications, businesses should evaluate customization options that align with their specific warehouse layouts and lifting needs to maximize operational effectiveness.

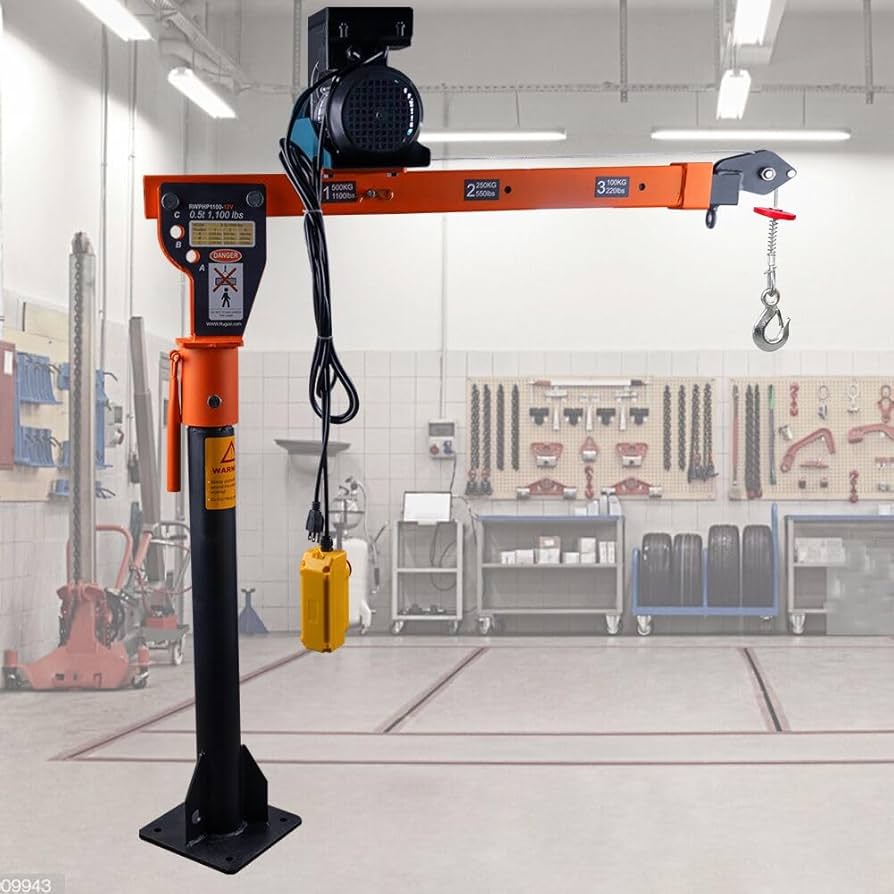

Illustrative image related to jib crane and hoist

How Are Jib Cranes Used in Food Processing?

In food processing, jib cranes are crucial for handling bulk ingredients and packaging products while adhering to hygiene standards. Stainless steel jib cranes are often preferred for their corrosion resistance and ease of cleaning, ensuring compliance with food safety regulations. Buyers in this sector should prioritize cranes that can withstand the demands of a food processing environment, focusing on materials and designs that support cleanliness and efficiency.

3 Common User Pain Points for ‘jib crane and hoist’ & Their Solutions

Scenario 1: Limited Space for Heavy Lifting Operations

The Problem: In many industrial environments, especially in regions with high population densities or older facilities, space is often at a premium. B2B buyers frequently face the challenge of needing to implement lifting solutions that do not obstruct workflow or consume too much floor space. This is particularly true in sectors such as manufacturing or assembly where operational efficiency is crucial. The inability to effectively maneuver equipment can lead to safety concerns, reduced productivity, and ultimately, higher operational costs.

The Solution: To address space constraints, buyers should consider wall-mounted or articulating jib cranes, which are designed to maximize lifting capabilities while occupying minimal floor area. These models can be mounted directly to walls or ceilings, allowing for full utilization of vertical space without interfering with other operations. Buyers should collaborate closely with suppliers to assess the specific dimensions of their workspace and the load requirements to choose a jib crane that fits their needs. Investing in customizable jib crane kits that include hoists and trolleys tailored to their operational dimensions can also enhance efficiency. Additionally, conducting a thorough site assessment before installation can ensure optimal placement and functionality, thereby minimizing disruptions in the workflow.

Scenario 2: Safety Compliance and Operator Training Challenges

The Problem: Ensuring safety compliance is a critical concern for B2B buyers, especially in industries such as construction and manufacturing where heavy lifting is common. The complexity of operating jib cranes and hoists can pose significant risks if operators are not properly trained. Buyers often find themselves facing the dual challenge of meeting regulatory standards while also protecting their workforce from potential injuries, which can lead to costly downtime and liability issues.

The Solution: To mitigate safety risks, buyers should prioritize selecting jib cranes that come with comprehensive safety features such as overload protection, emergency stop buttons, and clearly marked operational guidelines. Furthermore, investing in training programs for operators is essential. Buyers can partner with equipment suppliers who offer training sessions as part of their sales package, ensuring that employees are well-versed in safe operating procedures. Regular refresher courses and safety drills can also reinforce best practices and keep safety top of mind. By fostering a culture of safety and compliance, businesses can enhance their operational reliability and reduce the risk of workplace accidents.

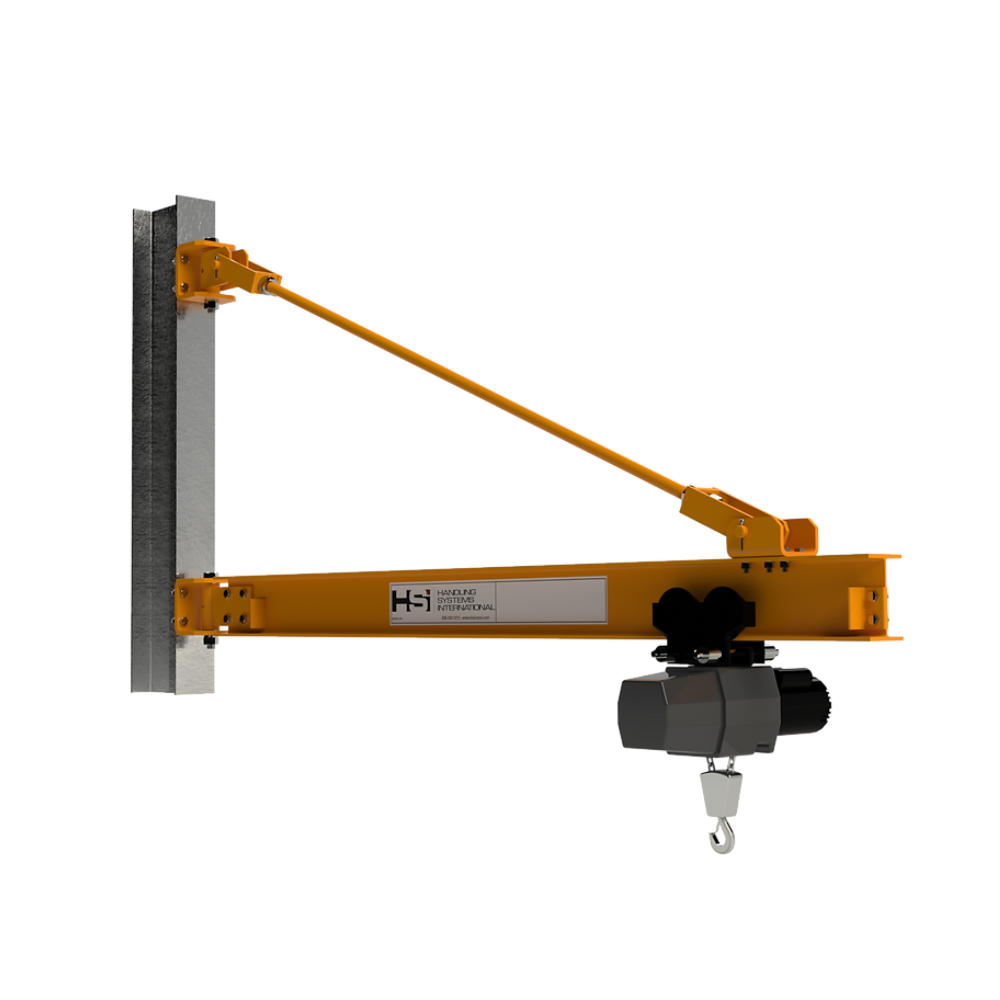

Illustrative image related to jib crane and hoist

Scenario 3: Cost Management and Equipment Longevity

The Problem: For many B2B buyers, the initial investment in jib cranes and hoists can be substantial, leading to concerns about cost management and the long-term viability of their equipment. Buyers often grapple with the challenge of balancing budget constraints with the need for high-quality, durable lifting solutions that can withstand the rigors of daily operations. This is particularly relevant in regions where economic fluctuations can affect procurement budgets.

The Solution: To optimize cost management, buyers should focus on sourcing high-quality jib cranes from reputable manufacturers known for their durability and reliability. Investing in cranes with longer warranties and proven performance records can significantly reduce maintenance costs over time. Additionally, buyers should consider regular maintenance programs that can extend the lifespan of their equipment. Suppliers often provide maintenance packages that include routine inspections and servicing, which can help identify issues before they become costly repairs. By establishing a preventative maintenance schedule and training staff on proper equipment care, buyers can ensure that their investments yield maximum returns and avoid unexpected downtime.

Strategic Material Selection Guide for jib crane and hoist

What Are the Most Common Materials Used in Jib Cranes and Hoists?

When selecting materials for jib cranes and hoists, several factors such as durability, weight, corrosion resistance, and cost must be considered. The choice of material directly impacts performance, maintenance, and overall lifecycle costs. Here, we analyze four common materials used in the construction of jib cranes and hoists: steel, aluminum, stainless steel, and composite materials.

Illustrative image related to jib crane and hoist

How Does Steel Perform in Jib Crane and Hoist Applications?

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for heavy-duty applications. It can withstand high temperatures and pressures, which is crucial in industrial settings.

Pros & Cons: Steel’s primary advantage is its strength, allowing for the construction of robust cranes capable of lifting heavy loads. However, it is susceptible to corrosion if not properly treated, which can lead to increased maintenance costs. Additionally, steel fabrication can be complex and may require specialized equipment.

Impact on Application: Steel is suitable for environments where heavy lifting is required, such as manufacturing and construction sites. However, in coastal or humid regions, additional protective measures may be necessary to prevent rust.

Considerations for International Buyers: Buyers from regions like the Middle East and coastal areas in South America should ensure compliance with local corrosion resistance standards. Common standards include ASTM A36 for structural steel, which is widely recognized.

What Are the Advantages of Using Aluminum in Jib Cranes and Hoists?

Key Properties: Aluminum is lightweight yet strong, offering good corrosion resistance and thermal conductivity. It is also non-magnetic, which can be beneficial in certain applications.

Pros & Cons: The primary advantage of aluminum is its reduced weight, making it easier to handle and install. However, it is generally less strong than steel, which may limit its use in heavy-duty applications. Additionally, aluminum can be more expensive than steel, which may affect budget considerations.

Impact on Application: Aluminum jib cranes are ideal for applications that require frequent repositioning or where weight is a concern, such as in aerospace or electronics manufacturing. Its corrosion resistance makes it suitable for environments with high humidity.

Illustrative image related to jib crane and hoist

Considerations for International Buyers: Buyers in Europe and Africa should be aware of the specific grades of aluminum that meet local standards, such as EN 573. Compliance with these standards ensures quality and safety in operations.

Why Choose Stainless Steel for Jib Cranes and Hoists?

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and durability. It can withstand extreme temperatures and is often used in food processing and pharmaceutical applications.

Pros & Cons: The main advantage of stainless steel is its resistance to rust and corrosion, making it ideal for harsh environments. However, it is more expensive than both carbon steel and aluminum, which can impact overall project budgets.

Impact on Application: Stainless steel jib cranes are particularly suited for industries such as food and beverage, pharmaceuticals, and marine applications where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should ensure that the stainless steel grades used comply with standards such as ASTM A240 or EN 10088, which define the requirements for corrosion resistance in various environments.

How Do Composite Materials Benefit Jib Crane and Hoist Design?

Key Properties: Composite materials, often made from a combination of plastics and fibers, offer lightweight and high-strength properties. They are resistant to corrosion and can be molded into complex shapes.

Pros & Cons: The lightweight nature of composites allows for easier handling and installation. However, they may not have the same load-bearing capacity as metals, which could limit their use in heavy-duty applications. Additionally, composites can be more expensive to manufacture.

Illustrative image related to jib crane and hoist

Impact on Application: Composites are suitable for specialized applications where weight reduction is critical, such as in aerospace or for portable jib cranes. Their resistance to environmental factors makes them ideal for outdoor use.

Considerations for International Buyers: Buyers should consider the specific composite materials that meet international standards for strength and durability, such as ISO 9001 for quality management.

Summary Table of Material Selection for Jib Cranes and Hoists

| Material | Typical Use Case for jib crane and hoist | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High tensile strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications, electronics | Lightweight and good corrosion resistance | Less strength than steel | High |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Composite | Aerospace, portable cranes | Lightweight and moldable | Limited load-bearing capacity | High |

This guide provides a comprehensive overview of material selection for jib cranes and hoists, helping international B2B buyers make informed decisions based on their specific operational needs and environmental conditions.

Illustrative image related to jib crane and hoist

In-depth Look: Manufacturing Processes and Quality Assurance for jib crane and hoist

What Are the Main Stages in the Manufacturing Process of Jib Cranes and Hoists?

The manufacturing process of jib cranes and hoists involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, such as steel and aluminum, which are essential for the structural integrity of jib cranes. Suppliers often use materials that meet international standards, such as ASTM or EN specifications, ensuring durability and safety. Material inspection is crucial at this stage; suppliers typically conduct tests to confirm the chemical composition and mechanical properties of the metals used.

-

Forming: Once the materials are prepared, they undergo various forming processes, including cutting, bending, and welding. Advanced techniques like laser cutting and CNC machining are frequently employed to achieve precise dimensions and shapes. These processes are vital for ensuring that components fit together correctly during assembly.

-

Assembly: The assembly stage involves the integration of all manufactured components, including the jib, hoist, trolley, and electrical systems. This stage often employs modular assembly techniques, which allow for flexibility and efficiency. Skilled technicians conduct assembly under stringent guidelines to ensure every component functions seamlessly. During this phase, it’s common to incorporate safety features, such as overload protection and emergency stop mechanisms.

-

Finishing: The final stage includes surface treatments like painting or galvanizing to enhance corrosion resistance and aesthetic appeal. This finishing process is particularly important for cranes used in harsh environments, such as those found in the Middle East or coastal regions. Quality checks during this phase often involve visual inspections and adhesion tests to ensure the finish meets industry standards.

How Is Quality Assurance Implemented in Jib Crane and Hoist Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for jib cranes and hoists, ensuring that products meet both customer expectations and regulatory standards. Key aspects of QA include adherence to international standards, quality control checkpoints, and testing methods.

-

International Standards and Certifications: Manufacturers often comply with international quality management standards such as ISO 9001, which outlines criteria for an effective quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific applications provide further assurance of quality and safety.

-

Quality Control Checkpoints: Quality control is typically implemented at several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials before they are used in production. Any substandard materials are rejected to prevent future complications.

– In-Process Quality Control (IPQC): During assembly, inspectors monitor processes to ensure adherence to specifications. This can include dimensional checks and functional tests of individual components.

– Final Quality Control (FQC): Before shipping, the completed jib cranes and hoists undergo comprehensive testing, including load testing and operational checks, to verify performance under expected conditions. -

Common Testing Methods for Jib Cranes and Hoists: Various testing methods are employed to ensure safety and functionality. Static and dynamic load tests simulate operational conditions, while fatigue testing assesses the equipment’s durability over time. Other testing methods may include electrical safety tests for hoists and functional tests for control systems.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring reliability and safety. Here are actionable steps to consider:

-

Supplier Audits: Conducting on-site audits of the manufacturer can provide invaluable insights into their quality assurance processes. Audits allow buyers to evaluate the production environment, equipment, and adherence to safety standards firsthand.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of various inspections and tests conducted throughout the manufacturing process. These reports can provide transparency and reassurance regarding product quality.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased assessment of the manufacturer’s quality control processes. These agencies can perform inspections at different stages of production and provide certifications that confirm compliance with international standards.

-

Understanding Certification Nuances: It’s essential for buyers to be aware of the specific certifications required in their regions. For instance, while CE certification may be mandatory in Europe, other regions may have different requirements. Understanding these nuances can help buyers make informed decisions and avoid potential compliance issues.

What Are the Challenges and Considerations for International B2B Buyers?

International B2B buyers face unique challenges when sourcing jib cranes and hoists, particularly concerning quality assurance. Factors such as varying regulatory standards, cultural differences in business practices, and logistical considerations can impact the procurement process.

-

Regulatory Compliance: Each region has distinct regulations governing the manufacturing and importation of lifting equipment. Buyers must ensure that their suppliers comply with these regulations to avoid legal complications and ensure safety.

-

Cultural Considerations: Understanding cultural nuances in business communication and negotiation can facilitate smoother transactions. Buyers should be aware of local customs and practices, which can influence supplier relationships.

-

Logistical Challenges: Importing heavy machinery like jib cranes involves complex logistics, including shipping, customs clearance, and transportation. Buyers should work closely with logistics providers to ensure timely delivery and compliance with shipping regulations.

By understanding the manufacturing processes and quality assurance measures in place for jib cranes and hoists, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements. This knowledge not only enhances their procurement strategy but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jib crane and hoist’

This guide aims to streamline the sourcing process for B2B buyers interested in procuring jib cranes and hoists. By following this step-by-step checklist, you can make informed decisions, ensuring that your investment meets your operational needs and compliance standards.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for your jib crane and hoist requirements. Consider factors such as load capacity, lift height, and the type of mounting (e.g., wall-mounted, floor-mounted, or portable). By defining these parameters upfront, you will narrow your options and ensure the equipment aligns with your operational environment.

- Load Capacity: Determine the maximum weight the crane must lift.

- Lift Height: Specify how high the loads need to be lifted.

- Mounting Type: Choose between wall-mounted, floor-mounted, or portable based on your space and usage.

Step 2: Research Supplier Credentials

Investigate the credentials of potential suppliers. Look for manufacturers with a proven track record in producing jib cranes and hoists. Verify their certifications, such as ISO standards, to ensure they meet safety and quality benchmarks.

- Company History: Review the supplier’s history and reputation in the industry.

- Certifications: Confirm compliance with international safety standards relevant to your region.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step will give you insights into their reliability and the quality of their products.

Illustrative image related to jib crane and hoist

- References: Ask for contact details of previous clients to discuss their experiences.

- Case Studies: Review relevant case studies that demonstrate the supplier’s capability to meet your specific needs.

Step 4: Compare Product Options and Customization

Evaluate the different models and configurations of jib cranes and hoists available from your shortlisted suppliers. Consider customization options that might be necessary for your application, such as motorized booms or additional safety features.

- Model Variants: Compare various models based on your defined specifications.

- Customization: Discuss potential modifications that can enhance efficiency and safety in your operations.

Step 5: Request Quotes and Analyze Costs

Once you have narrowed down your options, request detailed quotes from suppliers. Analyze the costs, including any additional fees for customization, delivery, and installation. Understanding the total cost of ownership will help you make an informed decision.

- Itemized Quotes: Ensure quotes include all costs associated with the purchase.

- Long-term Costs: Consider maintenance, warranty, and potential operational costs over time.

Step 6: Review Warranty and After-Sales Support

Examine the warranty terms and after-sales support offered by the supplier. A robust warranty and reliable customer service can significantly reduce operational risks and maintenance costs in the long run.

- Warranty Coverage: Understand what is covered under the warranty and the duration.

- Support Services: Confirm availability of technical support and service options post-purchase.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, finalize the purchase agreement. Ensure that all specifications, costs, delivery timelines, and terms of service are clearly outlined. This protects both parties and sets expectations for the delivery and installation process.

- Contract Clarity: Review the contract thoroughly to avoid misunderstandings.

- Delivery Terms: Specify delivery dates and conditions to ensure timely receipt of equipment.

By following these steps, you can confidently navigate the procurement process for jib cranes and hoists, ensuring that you select the right equipment for your operational needs.

Comprehensive Cost and Pricing Analysis for jib crane and hoist Sourcing

What Are the Key Cost Components for Jib Cranes and Hoists?

Understanding the cost structure of jib cranes and hoists is essential for B2B buyers. The primary components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to jib crane and hoist

-

Materials: The choice of materials significantly affects costs. Jib cranes are typically constructed from steel or aluminum, with variations in strength and weight impacting pricing. Stainless steel options, while more expensive, offer corrosion resistance for specialized applications.

-

Labor: Labor costs encompass both direct manufacturing labor and indirect costs associated with skilled personnel for assembly and installation. Higher labor costs are often observed in regions with stringent labor laws or higher wage standards.

-

Manufacturing Overhead: This includes costs related to the factory environment, utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Custom tooling requirements for specific designs or capacities can add to the initial investment. Buyers should consider whether the tooling costs are amortized over large production runs or if they will impact smaller orders significantly.

-

Quality Control (QC): Investing in quality control measures ensures that the cranes and hoists meet safety and operational standards. This can include testing, certifications, and compliance checks, which can increase upfront costs but reduce long-term liabilities.

-

Logistics: Transportation costs vary significantly based on the distance between the manufacturer and the buyer, shipping methods, and the weight and size of the cranes. International buyers must consider customs duties and import taxes as additional expenses.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the margin structure can provide insights into negotiation opportunities.

How Do Price Influencers Impact Jib Crane and Hoist Costs?

Several factors influence the pricing of jib cranes and hoists, particularly for international B2B transactions.

-

Volume/MOQ: Manufacturers often have minimum order quantities (MOQs). Larger orders can lead to volume discounts, reducing the per-unit cost. Buyers should assess their needs and consider bulk purchasing when feasible.

-

Specifications and Customization: Custom designs or specific performance requirements can significantly affect pricing. Buyers should clearly define specifications to avoid unexpected costs and delays.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, CE) can impact pricing. Buyers in industries with strict compliance requirements may need to invest more upfront for certified products.

-

Supplier Factors: The reputation, location, and reliability of suppliers play crucial roles. Established suppliers with a history of delivering quality products may command higher prices, but they also reduce risks associated with defects and delivery delays.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks during transportation, affecting the overall cost structure.

What Are Essential Buyer Tips for Cost-Efficiency in Jib Crane and Hoist Procurement?

To maximize cost-efficiency, buyers should adopt several strategies:

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers may have flexibility in pricing that can lead to significant savings.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A lower-priced crane may incur higher costs over time due to maintenance or inefficiency.

-

Research Local Suppliers: For buyers in regions like Africa and South America, sourcing from local suppliers may reduce shipping costs and import duties. Additionally, local suppliers may offer tailored services and support.

-

Assess Long-term Needs: Evaluate future growth and operational needs. Investing in a slightly more expensive crane with higher capacity or advanced features may yield better ROI as operations expand.

-

Stay Informed About Market Trends: Keeping abreast of market trends, technological advancements, and pricing fluctuations can provide leverage in negotiations and strategic planning.

In conclusion, understanding the cost components and price influencers specific to jib cranes and hoists is vital for B2B buyers. By employing effective negotiation strategies and considering total ownership costs, buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing jib crane and hoist With Other Solutions

When evaluating material handling solutions, it’s essential to explore various alternatives to jib cranes and hoists. Each option has distinct advantages and disadvantages depending on the specific application, facility layout, and operational requirements. This analysis will compare jib cranes and hoists against two viable alternatives: overhead bridge cranes and gantry cranes.

| Comparison Aspect | Jib Crane And Hoist | Overhead Bridge Crane | Gantry Crane |

|---|---|---|---|

| Performance | High versatility; suited for small areas | Excellent for large spaces; continuous lifting | Good for outdoor and warehouse use; mobile |

| Cost | Moderate initial investment; low operating costs | High initial investment; high maintenance costs | Moderate to high initial investment; variable operating costs |

| Ease of Implementation | Quick setup; minimal structural changes | Requires significant installation effort; may need structural reinforcements | Easier to install; often requires less infrastructure |

| Maintenance | Low; few components; easy to service | High; complex systems with frequent checks | Moderate; simpler than overhead cranes but still requires regular maintenance |

| Best Use Case | Small workshops; assembly lines | Large manufacturing facilities; warehouses | Outdoor applications; large areas needing mobility |

What Are the Advantages and Disadvantages of Overhead Bridge Cranes?

Overhead bridge cranes are designed for heavy lifting and can cover large areas, making them ideal for extensive manufacturing environments. Their performance is superior for continuous lifting tasks, allowing for smooth movement of materials over long distances. However, the initial investment is significant, and installation may require extensive modifications to the building structure. Maintenance is also a concern, as these systems often necessitate regular inspections and repairs, increasing overall operational costs.

How Do Gantry Cranes Compare to Jib Cranes and Hoists?

Gantry cranes offer versatility and mobility, particularly in outdoor settings or warehouses where space configurations may change frequently. They are generally easier to set up than overhead bridge cranes, requiring less structural support. However, their lifting capacity may not match that of overhead cranes, and they can be less stable in windy conditions if used outdoors. The initial costs can vary widely based on the design and materials used, but overall, they represent a middle-ground solution between jib cranes and more extensive systems.

How Should B2B Buyers Choose the Right Solution?

When selecting the most suitable lifting solution, B2B buyers should consider several factors including the specific application, available space, and budget constraints. Jib cranes and hoists are ideal for small, confined areas where flexibility is paramount. In contrast, overhead bridge cranes are more appropriate for large-scale operations requiring continuous movement of heavy loads. Gantry cranes serve as a versatile alternative, particularly in dynamic environments. Ultimately, the decision should align with operational needs, facility design, and long-term maintenance capabilities to ensure optimal performance and ROI.

Essential Technical Properties and Trade Terminology for jib crane and hoist

What Are the Key Technical Properties of Jib Cranes and Hoists?

Understanding the technical specifications of jib cranes and hoists is crucial for making informed purchasing decisions. Here are several critical properties to consider:

-

Load Capacity

Load capacity refers to the maximum weight that a jib crane or hoist can safely lift and move. This specification is vital for B2B buyers to ensure that the equipment can handle the specific demands of their operations. Common capacities range from 300 lbs to over 5 tons. Selecting equipment with an appropriate load capacity prevents accidents and operational inefficiencies. -

Span Length

Span length is the distance between the crane’s support structure and the end of the jib. This measurement directly affects the area that can be serviced by the crane. Buyers must consider the layout of their work environment when selecting span lengths to ensure optimal coverage and efficiency in material handling. -

Material Grade

The material grade determines the strength and durability of the jib crane or hoist. Common materials include steel and stainless steel, with the latter being ideal for environments exposed to moisture or corrosive substances. Understanding material grades helps buyers assess the longevity and maintenance needs of their equipment, which is especially important in regions with extreme weather conditions. -

Rotation Angle

The rotation angle indicates how far the crane can pivot around its base. Full rotation (360 degrees) is advantageous for maximizing workspace efficiency, while limited rotation may be suitable for specific applications. Buyers should evaluate their operational needs to select a jib crane with the appropriate rotation capabilities. -

Ergonomics

Ergonomics refers to the design aspects that enhance user safety and comfort. Features such as adjustable heights and easy-to-use controls can reduce the risk of workplace injuries and improve productivity. B2B buyers should prioritize ergonomic designs, particularly in environments where operators will frequently use the equipment.

What Are Common Trade Terms Used in Jib Crane and Hoist Transactions?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are key trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and assess product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is crucial for budget planning and inventory management, especially for international buyers who may face shipping constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It allows buyers to compare offers and negotiate terms effectively, making it an essential tool in procurement processes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including delivery points and risk management. Familiarity with these terms helps buyers understand shipping costs and liability, which is especially important when sourcing from overseas manufacturers. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is critical for planning and can significantly impact project timelines. B2B buyers should consider lead times when scheduling projects to avoid delays. -

Tonnage

Tonnage refers to the weight-carrying capacity of cranes and hoists. It is often expressed in tons and is a critical factor for ensuring that the equipment matches operational needs. Buyers must ensure that the tonnage aligns with their lifting requirements to enhance safety and efficiency.

By understanding these technical properties and trade terminology, B2B buyers can make more informed decisions when investing in jib cranes and hoists, ultimately leading to improved operational efficiency and safety in their workplaces.

Navigating Market Dynamics and Sourcing Trends in the jib crane and hoist Sector

What Are the Current Market Dynamics and Key Trends in the Jib Crane and Hoist Sector?

The jib crane and hoist sector is witnessing significant transformations driven by a mix of technological advancements, economic factors, and changing buyer preferences. Globally, the demand for efficient material handling solutions is increasing, particularly in manufacturing, construction, and logistics. In regions like Africa, South America, the Middle East, and Europe, buyers are seeking cranes that offer versatility and compact designs, essential for operations in constrained spaces. The rise of automation in industrial processes is also influencing procurement decisions, with buyers increasingly looking for integrated systems that combine cranes and hoists with IoT capabilities for enhanced operational efficiency.

Emerging technologies such as advanced materials and smart sensors are becoming pivotal in the design and functionality of jib cranes and hoists. Buyers are increasingly interested in solutions that provide real-time data analytics for performance monitoring and predictive maintenance, which can significantly reduce downtime and operational costs. Additionally, the market is seeing a rise in customized solutions tailored to specific industry needs, as businesses strive for efficiency and safety in their operations.

Another key trend is the shift towards sourcing from local manufacturers to mitigate supply chain disruptions. This trend is particularly pronounced in Europe and the Middle East, where geopolitical factors and recent global events have made buyers wary of relying on distant suppliers. As a result, establishing partnerships with regional manufacturers can provide greater flexibility and responsiveness to changing market demands.

How Is Sustainability Influencing the Sourcing of Jib Cranes and Hoists?

Sustainability has become a crucial consideration in the sourcing of jib cranes and hoists. The environmental impact of industrial operations has prompted buyers to seek out suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials, energy-efficient manufacturing processes, and designs that minimize waste. For instance, cranes made from recycled steel or those that utilize energy-efficient motors are increasingly in demand.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more conscious of the social and environmental implications of their procurement decisions. They are looking for suppliers who not only comply with environmental regulations but also demonstrate a commitment to ethical labor practices. Certifications such as ISO 14001 for environmental management and the use of green materials can enhance a supplier’s appeal in the eyes of conscientious buyers.

Moreover, as the global push for sustainability intensifies, companies that adopt green certifications and transparent sourcing practices will likely gain a competitive edge. Buyers are encouraged to engage with suppliers who can provide clear information on their sustainability initiatives and the lifecycle impact of their products, ensuring that their investments align with their corporate social responsibility goals.

What Is the Historical Context of Jib Cranes and Hoists in B2B Operations?

The evolution of jib cranes and hoists can be traced back to ancient civilizations, where simple pulley systems were used to lift heavy loads. Over the centuries, advancements in engineering and materials science have transformed these tools into sophisticated equipment essential for modern industrial applications. The introduction of powered hoists in the 20th century marked a significant leap in efficiency and safety.

Illustrative image related to jib crane and hoist

In recent decades, the jib crane sector has seen a shift towards modular designs and customizable solutions, enabling businesses to adapt their lifting systems to specific operational needs. This evolution reflects broader trends in industrial automation and the increasing importance of ergonomic design in workplace safety. Today, jib cranes and hoists are indispensable in various sectors, from manufacturing to construction, underscoring their enduring relevance in B2B operations.

Frequently Asked Questions (FAQs) for B2B Buyers of jib crane and hoist

-

1. How do I choose the right jib crane for my industrial needs?

Selecting the appropriate jib crane involves evaluating your specific lifting requirements, workspace dimensions, and load capacities. Consider factors such as the maximum weight you need to lift, the height of your ceilings, and the available floor space. Wall-mounted, floor-mounted, and portable options each serve different environments. For example, wall-mounted jib cranes are excellent for maximizing vertical space, while floor-mounted cranes provide 360-degree movement. Consulting with a crane specialist can further refine your choices based on industry standards and safety regulations. -

2. What types of hoists are compatible with jib cranes?

Jib cranes can accommodate various hoist types, including electric, manual, and pneumatic hoists. The choice of hoist depends on your operational needs, load weight, and frequency of use. Electric hoists are ideal for heavy lifting and continuous operations, while manual hoists may be sufficient for lighter loads and less frequent use. Ensure that the hoist’s capacity matches the jib crane’s specifications to guarantee safe and efficient operation. -

3. What are the customization options available for jib cranes?

Many manufacturers offer customization options for jib cranes, allowing you to tailor the system to your specific requirements. Customizations can include variations in lifting capacity, boom length, and rotation angles. Additionally, you can opt for specific materials, such as stainless steel for corrosion resistance, or incorporate advanced features like motorized booms or specialized trolley systems. Discussing your needs with suppliers will help you identify the best options for your application. -

4. What are the minimum order quantities (MOQ) for jib cranes and hoists?

Minimum order quantities vary by supplier and can depend on factors like manufacturing capabilities and your location. Some manufacturers may have an MOQ of one unit for standard products, while custom orders might require larger quantities to justify production costs. It’s advisable to inquire directly with potential suppliers to understand their MOQs, especially if you are looking to purchase multiple units or a mix of products. -

5. How do I ensure quality assurance when sourcing jib cranes internationally?

To ensure quality assurance when sourcing jib cranes, start by vetting suppliers through their certifications, such as ISO standards, and checking their reputation through customer reviews. Request samples or detailed product specifications before committing to a purchase. Additionally, consider conducting factory audits or hiring third-party inspection services to evaluate manufacturing processes. Establishing clear quality standards and expectations in your contracts can also help maintain product quality. -

6. What payment terms should I expect when purchasing jib cranes?

Payment terms for jib cranes typically vary based on the supplier and the scale of the order. Common arrangements include upfront deposits (usually 30-50%) with the balance due upon delivery or prior to shipping. Some suppliers may offer financing options or letter-of-credit arrangements for larger purchases. Always clarify payment terms before finalizing a contract to avoid misunderstandings. -

7. What logistics considerations should I keep in mind when importing jib cranes?

When importing jib cranes, consider shipping methods, customs regulations, and delivery timelines. Ensure that your chosen supplier is familiar with international shipping and can provide necessary documentation for customs clearance. Factor in additional costs such as duties, taxes, and insurance. Collaborating with a logistics partner experienced in heavy equipment can streamline the process and help you navigate any challenges that may arise. -

8. How can I address maintenance needs for my jib crane and hoist?

Regular maintenance is crucial for the longevity and safe operation of jib cranes and hoists. Develop a maintenance schedule that includes routine inspections, lubrication of moving parts, and testing of safety features. It’s advisable to train your staff on proper usage and maintenance practices. Many suppliers offer maintenance services or can provide guidance on best practices, so do not hesitate to reach out for support.

Top 6 Jib Crane And Hoist Manufacturers & Suppliers List

1. Crane Depot – Jib Cranes

Domain: cranedepot.com

Registered: 2013 (12 years)

Introduction: Jib cranes are a subset of cranes featuring a jib or boom that supports a moveable hoist. They are versatile and ideal for small areas or large industrial facilities with limited space. Jib cranes are simple to operate, ergonomic, and require less maintenance due to fewer operational components. Crane Depot offers various types of industrial jib cranes including articulating, floor mounted, founda…

2. Hoists Direct – Jib Cranes

Domain: hoistsdirect.com

Registered: 2003 (22 years)

Introduction: Jib Cranes offered by Hoists Direct include various brands, capacities, types, sizes, and options for overhead lifting. Types include portable, wall-mounted, floor-mounted, and articulating jibs. Wall-mounted jibs come in full cantilever and wall bracketed options. Floor-mounted jibs provide full 360-degree movement, with accessories available for rotation stops. Articulating jibs are designed for…

3. Thern – 5PF5 Series Portable Davit Crane

Domain: liftingequipmentstore.us

Registered: 2018 (7 years)

Introduction: Jib Cranes: High-performance jib cranes for industrial, commercial, and warehouse environments. Features include fixed and articulating designs for reliability and efficiency. Product examples include:

– Thern 5PF5 Series 850lbs Portable Davit Crane with Winch – From $1,062.00

– Thern 5PT20 SERIES 2,000lbs Portable Davit Crane with Winch – From $3,360.00

– HSI Medium-Duty 500lbs Freestanding Fo…

4. TS Overhead Crane – Jib Cranes

Domain: tsoverheadcrane.com

Registered: 2013 (12 years)

Introduction: {“product_types”: [“Floor Mounted Jib Cranes”, “Wall Mounted Jib Cranes”, “Tool Solution Jibs”, “Articulated Jib Cranes”], “capacities”: [“50 lbs / 22.6 kg”, “100 lbs / 45.3 kg”, “150 lbs / 68.0 kg”, “1/8-ton / 113.3 kg”, “1/4-ton / 226.7 kg”, “1/2-ton / 453.5 kg”, “1-ton / 907.1 kg”, “2-ton / 1,814.3 kg”, “3-ton / 2,721 kg”, “5-ton / 4,535 kg”], “mounting_types”: [“Floor Mounted”, “Wall/Column Mo…

5. JibCranes.com – Jib Cranes and Hoists

Domain: jibcranes.com

Registered: 1998 (27 years)

Introduction: JibCranes.com offers a wide range of jib cranes, including floor mount, wall mount, and specialty jib cranes. They are a certified master distributor for Gorbel jib crane products and provide various hoists and accessories suitable for different applications. Featured products include electric chain hoists from Harrington with capacities ranging from 1/8 ton to 1 ton, available in different lift h…

6. Abell Howe – Custom Jib Cranes

Domain: abell-howe.com

Registered: 2019 (6 years)

Introduction: {“product_types”: [“Custom Jib Cranes”, “Motorized Rotation Jib Cranes”, “Runway Systems”, “Custom Runway Systems”, “Hoists”], “specific_models”: [{“model”: “J902”, “type”: “Mast Style Jib Crane”}, {“model”: “J900”, “type”: “Wall Mounted Tie Rod Jib Crane”}, {“model”: “J906FCT”, “type”: “Full Cantilever Wall Mounted Jib Crane”}, {“model”: “J950”, “type”: “Full Cantilever Wall Bracketed Enclosed Tr…

Strategic Sourcing Conclusion and Outlook for jib crane and hoist

In navigating the complexities of sourcing jib cranes and hoists, international B2B buyers are positioned to leverage a range of strategic advantages. Understanding the diverse applications and types of jib cranes—such as wall-mounted, floor-mounted, and articulating options—enables buyers to select the right equipment tailored to their operational needs. The ability to customize features, including capacity and rotation options, enhances efficiency in material handling processes, particularly in industries with limited space.

Strategic sourcing not only facilitates cost savings through competitive pricing but also ensures access to high-quality products that meet rigorous safety standards. Buyers are encouraged to engage with reputable suppliers who provide comprehensive support and expertise, fostering long-term partnerships that can adapt to evolving business requirements.

As we look toward the future, the demand for innovative lifting solutions will continue to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing strategic sourcing, businesses can enhance operational agility and drive productivity. We invite you to explore our extensive offerings and consult with our experts to identify the optimal jib crane and hoist solutions that align with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to jib crane and hoist