Leak Detection Tools: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for leak detection tools

In an increasingly interconnected world, sourcing reliable leak detection tools can be a daunting challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Nigeria. The complexities of various technologies, pricing models, and supplier reliability can hinder effective purchasing decisions. This guide aims to demystify the global market for leak detection tools by providing a comprehensive overview of the types available, their diverse applications across industries, and practical insights into supplier vetting and cost considerations.

As international buyers navigate this landscape, they will find valuable information on the latest advancements in leak detection technology, from acoustic sensors to advanced video inspection tools. Understanding the specific needs of different sectors—from plumbing and irrigation to industrial applications—will empower decision-makers to select the most suitable equipment for their operations. Furthermore, insights into pricing structures and tips on evaluating supplier credentials will enhance the ability to make informed choices.

By equipping B2B buyers with actionable knowledge, this guide not only facilitates better purchasing decisions but also fosters long-term partnerships with trusted suppliers. As the demand for efficient leak detection tools continues to rise, leveraging this resource will be crucial for businesses aiming to enhance operational efficiency and reduce costs associated with undetected leaks.

Understanding leak detection tools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acoustic Leak Detection Tools | Utilize sound amplification to detect leaks through pipes. | Plumbing, HVAC, and irrigation systems. | Pros: Highly effective for underground leaks; Cons: May require trained personnel for optimal use. |

| Video Inspection Systems | Employ cameras to visually inspect pipes and identify leaks. | Plumbing, construction, and maintenance. | Pros: Provides visual confirmation of issues; Cons: High initial investment and maintenance costs. |

| Pressure Testing Equipment | Measures pressure changes in pipes to identify leaks. | Plumbing, industrial piping, and pools. | Pros: Quick leak identification; Cons: Requires specific conditions to be effective. |

| Electronic Leak Detection Kits | Combine multiple technologies (acoustic, pressure, visual) in one kit. | Comprehensive plumbing and facility maintenance. | Pros: Versatile and efficient; Cons: Can be expensive and complex to operate. |

| Infrared Thermography | Uses thermal imaging to detect temperature variations indicating leaks. | Building inspections and energy audits. | Pros: Non-invasive and quick; Cons: Limited to specific types of leaks and requires skilled operators. |

What Are the Characteristics of Acoustic Leak Detection Tools?

Acoustic leak detection tools are designed to amplify the sounds of leaks in pipes, allowing professionals to locate them without invasive digging. These tools often utilize specialized microphones and headphones to enhance sound quality, making them particularly effective in detecting underground leaks. They are widely used in plumbing, HVAC, and irrigation systems, making them essential for contractors seeking efficient leak detection methods. When purchasing, consider the skill level required for operation and whether the tool can handle the specific conditions of your projects.

How Do Video Inspection Systems Work for Leak Detection?

Video inspection systems consist of high-resolution cameras mounted on flexible cables that can navigate through pipes. This technology allows for real-time visual assessment of pipe conditions, enabling professionals to identify not only leaks but also blockages and structural issues. They are commonly used in plumbing and construction, where visual confirmation of pipe integrity is crucial. Buyers should evaluate the camera’s resolution, cable length, and compatibility with existing systems, as these factors greatly influence the effectiveness of the inspection.

What Are the Benefits of Using Pressure Testing Equipment?

Pressure testing equipment is essential for detecting leaks in pressurized systems. By measuring pressure changes, these tools can quickly identify leaks in plumbing, industrial piping, and swimming pools. This method is particularly useful in environments where other detection methods may be impractical. When considering a purchase, buyers should assess the equipment’s pressure range, ease of use, and whether it includes necessary accessories for comprehensive testing.

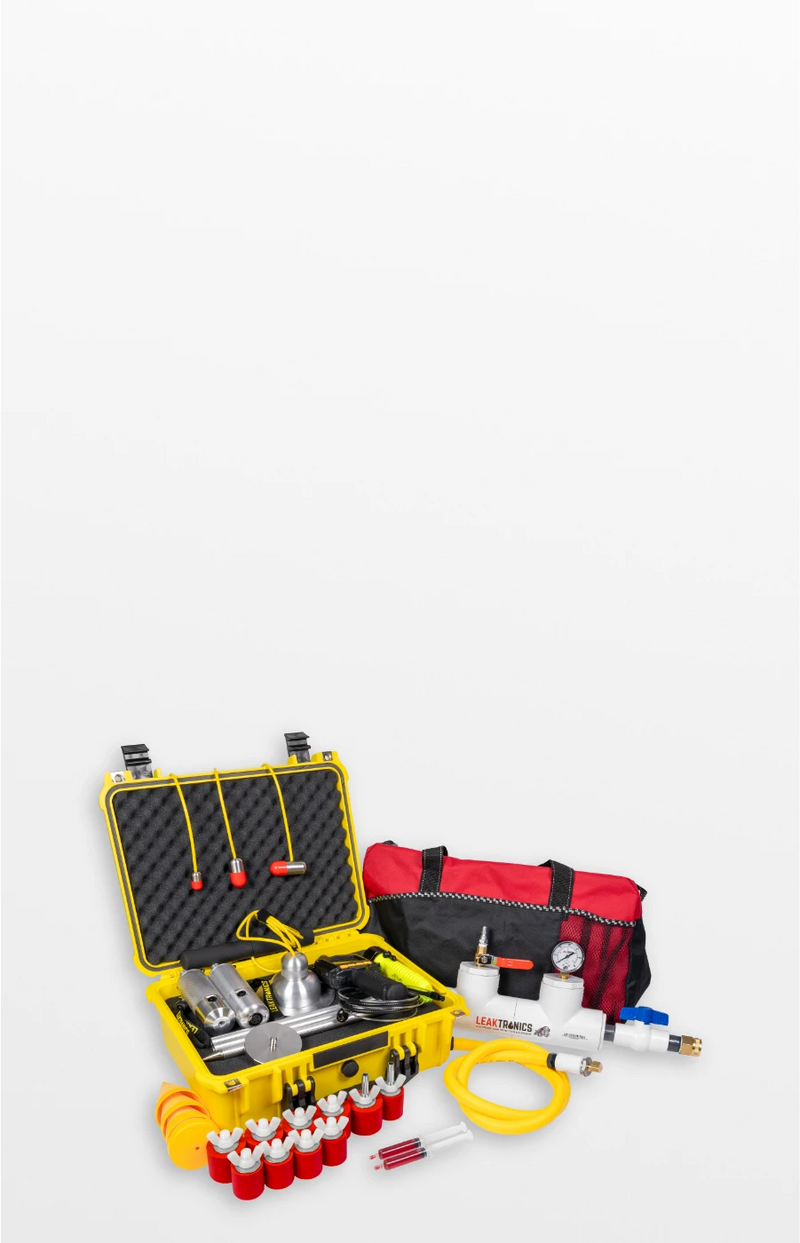

Why Choose Electronic Leak Detection Kits?

Electronic leak detection kits combine various technologies, such as acoustic, pressure, and video inspection, into a single package. This versatility makes them ideal for comprehensive leak detection in plumbing and facility maintenance. While they offer efficiency and convenience, these kits can be more expensive and may require specialized training for effective operation. Buyers should weigh the benefits of having a multi-functional tool against the initial investment and ongoing training needs.

How Does Infrared Thermography Enhance Leak Detection?

Infrared thermography is a non-invasive method that uses thermal imaging to identify temperature discrepancies caused by leaks. This technology is particularly useful in building inspections and energy audits, as it can detect leaks in insulation and roofing systems. While it offers rapid results, its effectiveness is limited to specific types of leaks, and it typically requires skilled operators for accurate interpretation. Buyers should consider the application scope and necessary training when investing in infrared thermography tools.

Key Industrial Applications of leak detection tools

| Industry/Sector | Specific Application of leak detection tools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plumbing | Detecting leaks in residential and commercial plumbing systems | Reduces water waste, prevents structural damage | Consider the type of technology (e.g., acoustic, video) and ease of use for technicians. |

| Oil and Gas | Monitoring pipelines for leaks and integrity testing | Enhances safety, minimizes environmental impact | Look for tools that can operate in harsh conditions and provide real-time data. |

| Manufacturing | Identifying leaks in hydraulic and pneumatic systems | Increases operational efficiency, reduces downtime | Ensure compatibility with existing systems and availability of support services. |

| Agriculture | Detecting leaks in irrigation systems | Optimizes water usage, improves crop yield | Evaluate the durability of equipment for outdoor use and the need for portable solutions. |

| Construction | Leak detection during building inspections | Ensures compliance with safety standards, reduces rework | Focus on comprehensive kits that offer training and support for staff. |

How Are Leak Detection Tools Used in Plumbing?

In the plumbing sector, leak detection tools are essential for identifying leaks in both residential and commercial systems. These tools, which may include acoustic devices and video inspection cameras, allow plumbers to quickly locate leaks without invasive digging. The primary benefit is the reduction of water waste and prevention of costly structural damage. Buyers in this sector should prioritize tools that are user-friendly and compatible with various plumbing configurations to maximize efficiency.

What Role Do Leak Detection Tools Play in Oil and Gas?

In the oil and gas industry, leak detection tools are critical for monitoring pipelines and ensuring the integrity of operations. These tools help identify leaks that could lead to environmental disasters or safety hazards. By providing real-time data, businesses can respond swiftly to potential issues, thereby minimizing risks and costs associated with leaks. International buyers should consider tools designed for extreme conditions and those that offer robust data analytics capabilities.

How Do Leak Detection Tools Benefit Manufacturing?

Manufacturing facilities utilize leak detection tools to monitor hydraulic and pneumatic systems for leaks. By detecting leaks early, companies can significantly enhance operational efficiency and reduce downtime, which is crucial for maintaining production schedules. Buyers should ensure that the tools they select are compatible with existing machinery and offer reliable support services, particularly when sourcing internationally.

In What Ways Are Leak Detection Tools Used in Agriculture?

In agriculture, leak detection tools are vital for monitoring irrigation systems to prevent water loss. Efficient water management directly impacts crop yield and sustainability, making these tools indispensable for farmers. Buyers should consider the durability and portability of these tools, as they often need to be used in various outdoor conditions. Additionally, features that provide easy integration with existing irrigation systems are beneficial.

How Are Leak Detection Tools Applied in Construction?

During construction, leak detection tools are used for inspections to ensure that plumbing systems are installed correctly and comply with safety standards. These tools help in identifying leaks before walls are closed up, which can save time and reduce the need for costly rework. Buyers should focus on comprehensive leak detection kits that include training for staff, ensuring that they can effectively utilize the equipment for optimal results.

3 Common User Pain Points for ‘leak detection tools’ & Their Solutions

Scenario 1: Difficulty in Accurate Leak Location

The Problem:

Many B2B buyers, especially those in plumbing and facility management, often struggle with accurately locating leaks in extensive plumbing systems. Traditional methods, such as visual inspections or manual pressure testing, can be time-consuming and may lead to misdiagnosis. This not only prolongs repair times but also increases labor costs and may result in further damage to the infrastructure. In regions where plumbing systems are complex and buried, such as in urban areas of Nigeria or Saudi Arabia, pinpointing the exact location of a leak becomes even more challenging.

The Solution:

Investing in advanced leak detection tools, such as acoustic leak detectors or thermal imaging cameras, can significantly enhance accuracy. Acoustic devices use sound to identify leak locations, while thermal imaging can detect temperature differentials caused by leaks. Buyers should consider sourcing tools that offer a combination of these technologies for comprehensive detection capabilities. Additionally, training staff on the proper use of these tools is crucial. Ensuring that technicians are well-versed in interpreting the data from these devices can drastically reduce the time taken to locate leaks, thereby minimizing repair costs and downtime.

Scenario 2: High Costs Associated with Leak Repair

The Problem:

The financial implications of undetected leaks can be staggering for businesses, especially in industries reliant on water, such as manufacturing or agriculture. In regions experiencing water scarcity, like parts of South America and the Middle East, not only is there a cost associated with water wastage, but businesses may also face penalties or increased operational costs. The challenge lies in balancing the upfront investment in leak detection tools against the potential savings from avoiding extensive repairs and water loss.

The Solution:

B2B buyers should conduct a cost-benefit analysis to justify the investment in leak detection technology. Opting for comprehensive leak detection kits that include various tools tailored for specific applications can provide long-term savings. For instance, a complete leak detection kit that includes both acoustic and video inspection tools allows for a thorough examination of plumbing systems. Additionally, establishing a regular maintenance schedule using these tools can help detect leaks early, ultimately reducing the need for costly emergency repairs. Collaborating with suppliers that offer financing or leasing options can also alleviate the initial financial burden while still providing the necessary technology.

Scenario 3: Lack of Skilled Technicians for Leak Detection

The Problem:

A common pain point for B2B buyers is the shortage of skilled technicians who are proficient in using advanced leak detection tools. This skill gap can lead to ineffective use of equipment, resulting in inaccurate readings and unresolved leaks. In many regions, particularly in developing markets, there may be a limited pool of qualified professionals, hindering companies from efficiently addressing leak issues.

The Solution:

To overcome this challenge, companies should prioritize investing in training and development programs for their existing workforce. Partnering with manufacturers of leak detection tools to offer specialized training sessions can enhance technician skills and boost confidence in using advanced equipment. Furthermore, implementing a mentorship program where experienced technicians guide newcomers can foster knowledge sharing and improve overall team competency. Leveraging online training resources or virtual simulations can also make training more accessible, especially in remote areas. By cultivating a skilled workforce, businesses can ensure that they maximize the capabilities of their leak detection tools, leading to more effective leak management and resolution.

Strategic Material Selection Guide for leak detection tools

What Are the Key Materials Used in Leak Detection Tools?

When selecting leak detection tools, the choice of materials is critical for ensuring optimal performance and durability. Here, we analyze four common materials used in these tools, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Plastic Perform in Leak Detection Tools?

Key Properties: Plastics, especially high-density polyethylene (HDPE) and polyvinyl chloride (PVC), offer excellent resistance to chemicals and corrosion. They can typically withstand moderate temperatures and pressures, making them suitable for various leak detection applications.

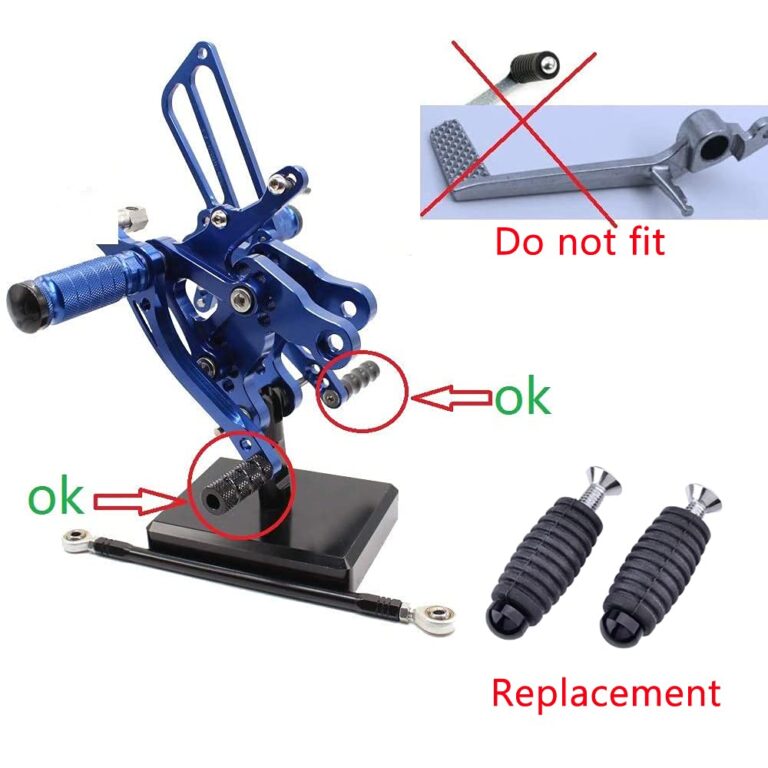

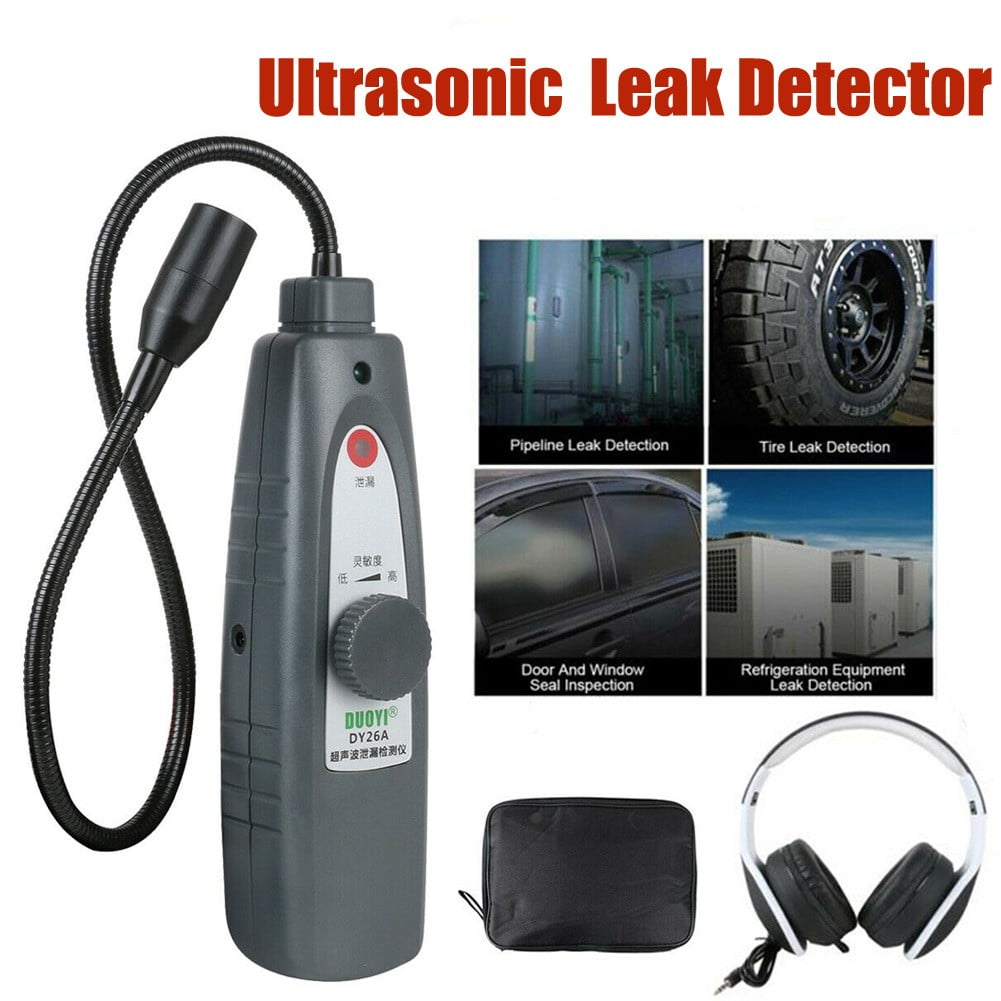

Illustrative image related to leak detection tools

Pros & Cons: The primary advantage of plastic is its lightweight nature, which enhances portability. Additionally, plastics are generally less expensive than metals, reducing manufacturing costs. However, they can be less durable under extreme conditions and may not perform well in high-pressure environments.

Impact on Application: Plastic materials are compatible with a wide range of media, including water and some chemicals. However, they may not be suitable for high-temperature applications or where mechanical stress is significant.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local regulations regarding plastic use, as some countries have stringent environmental standards. Compliance with ASTM or DIN standards may also be necessary.

What Are the Benefits of Metal in Leak Detection Tools?

Key Properties: Metals such as stainless steel and aluminum are known for their high strength, durability, and excellent resistance to corrosion. They can withstand high temperatures and pressures, making them ideal for demanding applications.

Pros & Cons: The key advantage of metal tools is their longevity and reliability, even in harsh environments. However, they tend to be heavier and more expensive than plastic alternatives, which can increase shipping costs and complicate manufacturing.

Impact on Application: Metal tools are particularly effective for applications involving high-pressure systems or where structural integrity is paramount. They are compatible with various media, including gases and corrosive liquids.

Illustrative image related to leak detection tools

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that metal products comply with relevant standards (e.g., JIS for Japan, EN for Europe). Additionally, the availability of materials may vary by region, impacting lead times.

How Do Composite Materials Enhance Leak Detection Tools?

Key Properties: Composite materials, often a combination of plastic and metal, offer a unique blend of properties, including high strength-to-weight ratios and enhanced resistance to corrosion and temperature extremes.

Pros & Cons: The primary advantage of composites is their versatility, allowing manufacturers to tailor products for specific applications. However, they can be more complex to manufacture, potentially leading to higher costs.

Illustrative image related to leak detection tools

Impact on Application: Composites are suitable for a variety of media and are often used in advanced leak detection systems that require both durability and lightweight characteristics.

Considerations for International Buyers: In regions like Saudi Arabia, where extreme temperatures are common, the thermal properties of composite materials should be carefully evaluated. Compliance with international standards is crucial for market acceptance.

What Role Does Rubber Play in Leak Detection Tools?

Key Properties: Rubber materials, particularly synthetic rubbers like neoprene and EPDM, provide excellent flexibility and resistance to various chemicals. They can operate effectively at moderate temperatures and pressures.

Pros & Cons: Rubber’s flexibility makes it ideal for seals and gaskets in leak detection tools, ensuring a tight fit. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures, leading to shorter lifespans.

Illustrative image related to leak detection tools

Impact on Application: Rubber is particularly effective in applications requiring sealing capabilities, such as in pressure testing and pipe inspection tools. However, its compatibility with certain chemicals should be assessed.

Considerations for International Buyers: Buyers from regions with high UV exposure, like parts of Africa, should consider the longevity of rubber materials. Compliance with local standards regarding chemical resistance is also essential.

Summary Table of Material Selection for Leak Detection Tools

| Material | Typical Use Case for leak detection tools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Water and chemical leak detection | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metal | High-pressure and high-temperature systems | High strength and durability | Heavier and more expensive | High |

| Composite | Advanced leak detection systems | Tailored properties for specific needs | Complex manufacturing | Medium |

| Rubber | Seals and gaskets in leak detection tools | Excellent flexibility and sealing | Degrades over time | Medium |

This comprehensive analysis of materials used in leak detection tools provides valuable insights for international B2B buyers, enabling informed decisions that align with their operational needs and regional standards.

Illustrative image related to leak detection tools

In-depth Look: Manufacturing Processes and Quality Assurance for leak detection tools

What Are the Main Stages of Manufacturing Leak Detection Tools?

The manufacturing process for leak detection tools involves several key stages that ensure the final product meets the rigorous demands of the plumbing and construction industries. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality materials that are durable and suitable for the specific application of the leak detection tools. Common materials include high-grade plastics, metals, and electronic components. The chosen materials undergo thorough inspections to ensure they meet the necessary specifications and performance standards.

-

Forming: Once the materials are prepared, they are shaped into the desired components using techniques such as injection molding, extrusion, or CNC machining. For instance, the production of plastic housings for electronic leak detectors often involves injection molding, which provides precision and consistency. Metal parts may be formed using CNC machines that create intricate designs and ensure tight tolerances.

-

Assembly: After forming, the individual components are assembled into the final product. This stage is crucial as it often involves integrating electronic systems with mechanical parts. Automated assembly lines may be used to enhance efficiency and reduce human error, while skilled technicians may perform complex assemblies that require a higher degree of precision.

-

Finishing: The final stage involves surface treatment and quality checks. Techniques such as powder coating, painting, or anodizing are used to enhance durability and aesthetics. Additionally, final inspections are conducted to ensure that all components function correctly and meet design specifications.

How Do Quality Assurance Processes Ensure Reliability in Leak Detection Tools?

Quality assurance (QA) is vital in the manufacturing of leak detection tools, ensuring that each product is reliable and performs effectively. The process typically adheres to international standards such as ISO 9001, which outlines quality management systems, and industry-specific certifications like CE marking for compliance with European health and safety regulations.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves the inspection of raw materials and components before they enter the manufacturing process. Any materials that do not meet specifications are rejected, preventing defects in the final product.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of the assembly and forming stages. This ensures that any issues are identified and rectified promptly.

– Final Quality Control (FQC): After assembly, the completed tools undergo rigorous testing to verify their performance and reliability. This can include functional tests, safety inspections, and performance evaluations under different conditions. -

Testing Methods Employed: Common testing methods for leak detection tools include pressure testing, acoustic testing, and functional testing. Pressure testing involves subjecting tools to high-pressure conditions to ensure they can withstand operational stresses. Acoustic testing assesses the sensitivity and accuracy of sound detection capabilities, while functional testing evaluates overall usability and performance.

What Certifications Should B2B Buyers Look for in Leak Detection Tools?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the certification landscape is crucial. Certifications not only affirm product quality but also enhance marketability.

-

ISO 9001: This certification indicates that the manufacturer adheres to internationally recognized quality management principles. Products bearing this certification have undergone rigorous quality checks throughout the manufacturing process.

-

CE Marking: This is essential for products sold within the European Economic Area (EEA). It signifies that the product meets EU safety, health, and environmental protection requirements.

-

API Standards: For tools used in the oil and gas sector, adherence to American Petroleum Institute (API) standards is critical. These standards ensure that the tools can operate safely and effectively in challenging environments.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that suppliers maintain high-quality standards is essential for B2B buyers. Here are some methods to verify supplier quality control practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control systems. Audits can be performed by the buying company or by third-party organizations specializing in quality assessments.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the steps taken to ensure product reliability. These reports often include information about testing methods, results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be conducted at various stages of the manufacturing process, from material selection to final product evaluation.

What Are the Unique QC Considerations for International Buyers?

International buyers must be aware of specific quality control nuances when sourcing leak detection tools from global suppliers. Differences in regulatory standards, cultural practices, and logistical challenges can impact product quality and compliance.

-

Regulatory Compliance: Buyers should ensure that products meet the regulatory requirements of their respective markets. This may involve understanding local standards and obtaining necessary certifications.

-

Cultural Differences: Cultural attitudes towards quality and compliance may vary by region. Buyers should be prepared to navigate these differences and establish clear expectations with suppliers.

-

Logistical Challenges: Transportation and storage conditions can affect the quality of leak detection tools. Buyers should discuss with suppliers how products are handled during shipping to mitigate potential damage or degradation.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing leak detection tools, ensuring they invest in reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leak detection tools’

To help international B2B buyers effectively procure leak detection tools, this practical sourcing guide outlines essential steps to ensure a successful purchase. Each step is designed to streamline the process and enhance decision-making, ultimately leading to a more efficient leak detection operation.

Step 1: Define Your Technical Specifications

Before embarking on your sourcing journey, clearly outline the technical specifications your leak detection tools must meet. Consider factors such as the types of leaks you will be detecting (e.g., water, gas), the environments in which the tools will be used (commercial, residential, industrial), and any industry-specific regulations. This foundational step will guide your selection process and help you avoid investing in tools that do not meet your operational needs.

Illustrative image related to leak detection tools

Step 2: Identify Your Budget

Establishing a budget is crucial to ensure you remain financially viable throughout the procurement process. Take into account not just the initial purchase price but also ongoing costs such as maintenance, training, and possible upgrades. Categorize tools into essential and optional items to prioritize your spending effectively.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of reliability and quality, as these factors significantly impact the performance and longevity of your tools.

- Consider supplier certifications: Verify that suppliers hold relevant industry certifications, which can indicate adherence to quality standards.

- Check customer reviews: Reviews and testimonials can provide insight into the supplier’s reputation and customer service capabilities.

Step 4: Request Product Demonstrations

Whenever possible, request demonstrations of the tools you are considering. This hands-on experience can help you understand the functionality and ease of use of the tools, which is essential for training your staff. Pay attention to the responsiveness of the supplier during these demonstrations, as this reflects their commitment to customer support.

Step 5: Assess After-Sales Support and Training

Evaluate the level of after-sales support offered by your potential suppliers. Quality tools are only as good as the support that backs them. Look for suppliers who provide training sessions, technical support, and warranties, as these factors can significantly enhance the value of your purchase.

Illustrative image related to leak detection tools

- Inquire about training resources: Determine whether the supplier offers online tutorials, manuals, or on-site training.

- Understand warranty conditions: A robust warranty can save you costs associated with repairs and replacements.

Step 6: Review Terms and Conditions

Before finalizing your purchase, carefully review the terms and conditions associated with the sale. Pay close attention to return policies, delivery timelines, and payment terms. Understanding these details can prevent potential disputes and ensure a smoother transaction process.

Step 7: Plan for Integration

Once you have procured your leak detection tools, consider how they will integrate with your existing systems and processes. This may involve software compatibility, training staff on new procedures, and ensuring that maintenance protocols are established. Planning for integration will help you maximize the utility of your new tools and enhance operational efficiency.

By following these steps, B2B buyers can effectively navigate the procurement process for leak detection tools, ensuring they select the right solutions for their business needs.

Comprehensive Cost and Pricing Analysis for leak detection tools Sourcing

What Are the Key Cost Components in Leak Detection Tools?

Understanding the cost structure of leak detection tools is crucial for B2B buyers. The primary cost components include:

Illustrative image related to leak detection tools

-

Materials: The quality and type of materials significantly influence the overall cost. High-performance components, such as specialized sensors or durable casings, may elevate prices but provide better longevity and reliability.

-

Labor: Skilled labor is necessary for manufacturing sophisticated tools. Labor costs can vary significantly by region, impacting pricing structures. For instance, labor-intensive processes may be cheaper in regions with lower wage standards.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tools or molds required for specific products can lead to higher initial costs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Ensuring products meet industry standards incurs additional costs. Certifications from recognized bodies can add to the price but are essential for buyers seeking reliability.

-

Logistics: Transportation and warehousing costs fluctuate based on location and shipping methods. International buyers must account for these costs, especially in regions with underdeveloped infrastructure.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market demand and competition.

How Do Price Influencers Affect Leak Detection Tool Costs?

Several factors influence the pricing of leak detection tools, which buyers should consider:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Understanding a supplier’s minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Tailored solutions often command higher prices due to additional design and production efforts. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials: Premium materials enhance performance and durability but also elevate costs. Buyers should assess whether these materials align with their operational requirements.

-

Quality and Certifications: Tools with industry certifications may carry a premium. However, they often translate into fewer failures and reduced long-term costs, making them a wise investment.

-

Supplier Factors: Supplier reputation, reliability, and service levels can impact pricing. Established suppliers may offer higher quality but at a premium. Newer suppliers might provide lower prices but come with higher risks.

-

Incoterms: The terms of shipping can greatly affect the final cost. Understanding the responsibilities associated with different Incoterms (like FOB, CIF) can help buyers manage their total costs effectively.

What Are the Best Negotiation Strategies for Buyers?

When sourcing leak detection tools, buyers can adopt several strategies to enhance cost-efficiency:

-

Research and Comparison: Conducting thorough market research to compare different suppliers can reveal price discrepancies and provide leverage in negotiations.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to loyalty discounts and better payment terms.

-

Emphasizing Total Cost of Ownership (TCO): When negotiating, consider the TCO rather than just the upfront price. High-quality tools may have a higher initial cost but offer lower maintenance and replacement expenses.

-

Flexible Payment Terms: Negotiating favorable payment terms can help manage cash flow, especially for larger orders.

-

Understanding Local Market Dynamics: Buyers from regions like Africa, South America, and the Middle East should be aware of local market conditions and supplier capabilities, which can influence pricing and availability.

What Should International Buyers Consider When Sourcing Leak Detection Tools?

For international B2B buyers, particularly in regions like Saudi Arabia and Nigeria, several nuances exist:

-

Currency Fluctuations: Exchange rates can impact the total cost when purchasing from foreign suppliers. Buyers should monitor currency trends and consider hedging strategies.

-

Import Duties and Taxes: Understanding local import regulations and associated costs can prevent unexpected expenses.

-

Shipping and Delivery Times: Logistics can be complex; thus, factoring in shipping times and potential delays is essential for project planning.

-

Cultural Considerations: Building rapport and understanding cultural nuances can facilitate smoother negotiations and foster long-term relationships.

Disclaimer on Indicative Prices

Prices for leak detection tools can vary widely based on the factors outlined above. The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and order specifics. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing leak detection tools With Other Solutions

Exploring Alternatives to Leak Detection Tools

In the quest for effective leak detection, businesses often explore various solutions beyond traditional leak detection tools. Understanding these alternatives is crucial for making informed decisions that align with operational needs and budget constraints. This analysis compares leak detection tools with two viable alternatives: thermal imaging cameras and acoustic leak detection methods.

Comparison Table

| Comparison Aspect | Leak Detection Tools | Thermal Imaging Cameras | Acoustic Leak Detection Methods |

|---|---|---|---|

| Performance | High accuracy in detecting leaks | Effective for surface leaks | Excellent for underground leaks |

| Cost | $2,000 – $21,500 (varies by kit) | $1,500 – $5,000 | $500 – $3,000 |

| Ease of Implementation | Requires training and expertise | User-friendly, minimal training needed | Requires specialized training |

| Maintenance | Regular calibration needed | Minimal maintenance | Requires occasional recalibration |

| Best Use Case | Plumbing, irrigation systems | Building inspections, energy audits | Water pipelines, underground systems |

Detailed Breakdown of Alternatives

Thermal Imaging Cameras

Thermal imaging cameras utilize infrared technology to detect temperature variations caused by leaks. They are particularly effective in identifying surface leaks, making them ideal for building inspections and energy audits. The main advantage of thermal cameras is their user-friendly operation, which typically requires minimal training. However, they can be costly, ranging from $1,500 to $5,000. Maintenance is low, but they may not detect leaks hidden beneath surfaces, limiting their effectiveness in certain scenarios.

Illustrative image related to leak detection tools

Acoustic Leak Detection Methods

Acoustic leak detection employs sound wave technology to identify leaks. This method is particularly effective for underground water pipelines, as it can detect the sound of water escaping from pipes. Acoustic detection systems are relatively affordable, ranging from $500 to $3,000, and while they require some training for effective use, they are generally straightforward. One downside is that they may not perform well in noisy environments, which can interfere with sound detection. Additionally, regular recalibration is necessary to ensure ongoing accuracy.

Conclusion: How to Choose the Right Leak Detection Solution

Selecting the appropriate leak detection solution hinges on several factors, including the specific use case, budget, and ease of implementation. For businesses focusing on plumbing and irrigation, specialized leak detection tools may provide the highest accuracy and functionality. In contrast, thermal imaging cameras offer a versatile solution for general building inspections, while acoustic methods excel in detecting underground leaks at a lower cost. Ultimately, a thorough assessment of operational needs, along with a consideration of the pros and cons of each alternative, will guide B2B buyers toward the most suitable leak detection solution for their circumstances.

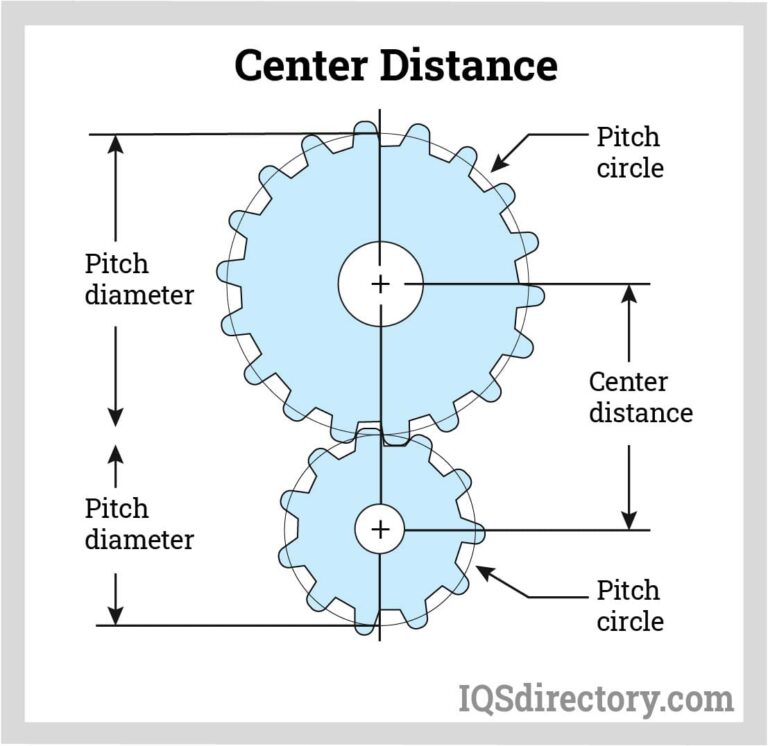

Essential Technical Properties and Trade Terminology for leak detection tools

What Are the Key Technical Properties of Leak Detection Tools?

When selecting leak detection tools for your business, understanding their technical specifications is crucial. Here are some essential properties to consider:

-

Material Grade

– The material used in leak detection tools often dictates their durability and performance. Tools made from high-grade materials such as stainless steel or reinforced plastics are more resistant to corrosion and wear. This is particularly important in environments prone to moisture and chemical exposure, ensuring longevity and reliability. -

Sensitivity Level

– Sensitivity refers to the tool’s ability to detect small leaks. High-sensitivity equipment can identify minute pressure changes or sound variations, allowing for early leak detection. In B2B contexts, this can lead to significant cost savings by preventing extensive water damage or loss of resources. -

Operating Range

– The operating range defines the conditions under which the tool can function effectively. For instance, some tools may work optimally in specific temperature ranges or with certain types of pipes. Understanding this property ensures that the tools you invest in will perform well in your specific operational environment. -

Calibration Requirements

– Calibration is essential for ensuring accuracy in leak detection. Some tools may require regular calibration to maintain their sensitivity and reliability. Knowing the calibration frequency and methods can help businesses plan maintenance schedules and avoid unexpected downtime. -

Weight and Portability

– The weight of the equipment can impact its usability in the field. Lighter tools are often more portable, which is beneficial for professionals who need to carry equipment to various job sites. Portability can enhance efficiency, making it easier to conduct inspections without the need for extensive setup. -

Data Output Formats

– Many modern leak detection tools provide data in various formats, such as digital readouts or integration with software systems. Understanding the data output formats can help businesses streamline reporting processes and improve data analysis, ultimately leading to better decision-making.

What Are Common Trade Terms in the Leak Detection Industry?

Familiarity with industry jargon can enhance communication and negotiation with suppliers and clients. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leak detection tools, working with OEMs can ensure that you receive high-quality, tested components that meet industry standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for businesses to manage inventory costs and ensure that they are not overcommitting to unnecessary stock. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. When sourcing leak detection tools, issuing an RFQ can help you compare different offerings and negotiate better deals. -

Incoterms (International Commercial Terms)

– Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Knowing the relevant Incoterms can help businesses avoid misunderstandings and ensure smoother logistics. -

Calibration Certificates

– Calibration certificates are documents issued by manufacturers or third-party services that verify the accuracy of measurement tools. When purchasing leak detection equipment, ensuring that the tools come with valid calibration certificates can enhance confidence in their reliability. -

Warranty Period

– The warranty period specifies the duration for which a manufacturer will repair or replace defective products. Understanding warranty terms is essential for B2B buyers to mitigate risks associated with equipment failures.

By grasping these technical properties and trade terminologies, businesses can make informed decisions that enhance their leak detection capabilities and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the leak detection tools Sector

What Are the Key Trends Shaping the Leak Detection Tools Market?

The leak detection tools sector is experiencing robust growth, driven by increasing infrastructure investment and heightened awareness of water conservation. Global demand for efficient leak detection technologies is fueled by the growing need to minimize water loss, especially in regions facing water scarcity, such as Africa and the Middle East. Innovations in technology, such as acoustic sensors, infrared thermography, and advanced data analytics, are transforming traditional leak detection methods, making them more effective and efficient.

Emerging trends include the integration of IoT (Internet of Things) technologies, allowing for real-time monitoring and data collection. This shift not only enhances detection capabilities but also improves predictive maintenance, enabling businesses to address leaks before they escalate into costly repairs. Furthermore, international buyers are increasingly seeking customizable solutions that can adapt to specific regional challenges, such as varying soil conditions or infrastructure types.

Illustrative image related to leak detection tools

The market dynamics are also influenced by regulatory frameworks promoting sustainable practices, compelling manufacturers to prioritize eco-friendly materials and production processes. As such, international buyers must stay abreast of these evolving technologies and sourcing trends to remain competitive in a rapidly changing marketplace.

How Does Sustainability Influence Sourcing in the Leak Detection Tools Sector?

Sustainability is a growing concern for B2B buyers in the leak detection tools market, particularly as environmental regulations become stricter across various regions. The environmental impact of leak detection tools is significant; water loss due to undetected leaks not only affects utility costs but also contributes to broader ecological challenges. Thus, the demand for tools that minimize waste and improve efficiency is on the rise.

Ethical sourcing is increasingly important, as companies strive to build transparent supply chains that prioritize social and environmental responsibility. Buyers should look for manufacturers that offer certifications such as ISO 14001, which indicates a commitment to environmental management, or products made from recycled materials. In addition, tools designed to be energy-efficient and durable contribute to a reduced carbon footprint, aligning with the sustainability goals of many organizations.

By prioritizing suppliers that adhere to sustainable practices, B2B buyers can not only enhance their brand reputation but also create value for their customers by offering solutions that support environmental stewardship.

What Is the Evolution of Leak Detection Tools and Its Impact on B2B Buyers?

The evolution of leak detection tools has been marked by significant technological advancements over the past few decades. Initially, leak detection relied heavily on manual inspections and rudimentary tools, which were often time-consuming and inefficient. However, the introduction of electronic leak detection systems in the late 20th century revolutionized the industry, allowing for more accurate and quicker identification of leaks.

The last decade has seen an acceleration in the adoption of smart technologies, including IoT-enabled devices that provide real-time data analytics and predictive maintenance capabilities. This evolution not only enhances the efficiency of leak detection but also allows B2B buyers to make informed decisions based on actionable insights. As the industry continues to innovate, international buyers must recognize the importance of investing in modern leak detection solutions to maintain competitive advantages in their respective markets.

By understanding these dynamics and sourcing trends, businesses can better navigate the complexities of the leak detection tools sector, ensuring they are equipped with the latest technologies and sustainable practices to meet the demands of today’s market.

Frequently Asked Questions (FAQs) for B2B Buyers of leak detection tools

-

How do I choose the right leak detection tool for my business needs?

Selecting the appropriate leak detection tool depends on various factors, including the specific application, the types of leaks you anticipate, and the environment in which you will operate. Assess the features of different kits, such as sensitivity, depth of detection, and the technology used (e.g., acoustic, thermal). For instance, if your business involves plumbing, a comprehensive kit with amplifiers and cameras may be ideal. Consult with suppliers and consider product demonstrations to understand the tool’s efficacy in real-world scenarios. -

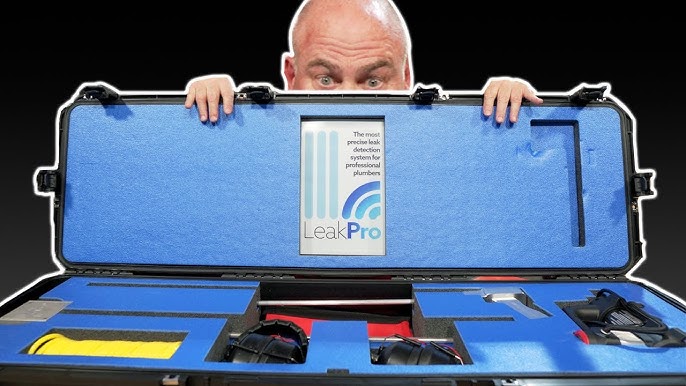

What is the best leak detection technology for commercial plumbing?

For commercial plumbing applications, acoustic leak detection technology is often the most effective. It allows for precise identification of leaks by amplifying the sounds of water escaping from pipes. Additionally, systems that incorporate video inspection capabilities provide visual verification, helping to pinpoint issues accurately. Evaluate solutions like the LeakTronics Plumbers Complete Leak Detection Kit, which combines multiple technologies for enhanced performance. -

What are the key factors to consider when vetting international suppliers of leak detection tools?

When vetting international suppliers, consider their industry reputation, product quality certifications, and customer reviews. Assess their ability to provide after-sales support, including training and maintenance. Additionally, examine their logistical capabilities, including shipping times and costs to your region. Request samples or demonstrations to evaluate product performance firsthand. Establishing clear communication channels is also crucial for addressing any queries during the procurement process. -

What are typical payment terms for purchasing leak detection tools internationally?

Payment terms can vary widely by supplier and region, but common arrangements include upfront payments, net 30 or net 60 days after delivery, or a letter of credit. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Ensure that payment methods are secure and provide buyer protection, especially for large orders. Discuss potential discounts for upfront payments or bulk purchases to optimize your procurement budget. -

Are there minimum order quantities (MOQ) for leak detection tools?

Many suppliers establish a minimum order quantity to ensure efficient production and shipping. MOQs can vary significantly depending on the type of equipment and the supplier’s policies. It’s advisable to inquire about MOQs before placing orders, especially if you are a small business. Some suppliers may offer flexibility for first-time buyers or provide options to combine different products to meet MOQ requirements. -

How do I ensure quality assurance (QA) for leak detection tools?

To ensure quality assurance, request documentation regarding the manufacturing processes and quality control measures employed by the supplier. Look for compliance with international standards, such as ISO certifications. Additionally, consider conducting periodic audits or requesting third-party inspections for larger orders. Establishing a clear return policy can also provide peace of mind, allowing for replacements or repairs if products do not meet specified standards. -

What logistics considerations should I keep in mind when importing leak detection tools?

Logistics considerations include understanding shipping methods, customs duties, and import regulations specific to your country. Collaborate with a freight forwarder experienced in handling similar equipment to ensure compliance and timely delivery. Assess the total landed cost, including shipping, taxes, and potential tariffs, to accurately budget for your purchase. Additionally, factor in lead times for production and shipping to avoid disruptions in your operations. -

Can leak detection tools be customized for specific applications?

Many suppliers offer customization options for leak detection tools to better suit specific applications or environmental conditions. Customizations may include specialized sensors, tailored software features, or unique packaging solutions. Discuss your specific requirements with potential suppliers and request detailed proposals outlining customization capabilities. Be prepared to share insights about your operational challenges to help suppliers recommend the most effective solutions.

Top 7 Leak Detection Tools Manufacturers & Suppliers List

1. LeakTronics – Plumbing Leak Detection Kits

Domain: leaktronics.com

Registered: 2010 (15 years)

Introduction: LeakTronics offers a range of plumbing leak detection kits that utilize proprietary technology, including the LT-2000 Amplifier, DeckPlates, and Soil Probes. These tools are designed for plumbing professionals to detect leak sounds and pinpoint pipe breaks. Each kit provides different solutions tailored to specific needs. For assistance in selecting the right kit, customers can contact LeakTronics…

2. Anderson Manufacturing – Leak Detection Packages

Domain: leaktools.com

Registered: 1998 (27 years)

Introduction: Leak Detection Packages offered by Anderson Manufacturing Company, Inc. include various options tailored for the pool industry. Key packages include:

1. Starter Package – Price: $2,775.00, Part #: PKGST

2. Service Pro Package – Southern – Price: $4,715.00, Part #: PKGSPS

3. Service Pro Package – Northern – Price: $4,765.00, Part #: PKGSPN

4. First Responder Kit – Price: $115.00, Part #: DTKFR …

3. Tracer Electronics LLC – AquaTest T10

Domain: tracerelectronicsllc.com

Registered: 2007 (18 years)

Introduction: Tracer Electronics LLC offers a complete product line of professional water leak detection products, including:

1. **AquaTest T10**: A fully wireless acoustical water leak detector with integrated microphone and test rod technology, featuring an easy-to-read display and ergonomic design.

2. **Aquaphon A50**: A commercial-style acoustical water leak detector with wired microphone connections, ava…

4. Simply Leak Detection – Advanced Leak Detection Equipment

Domain: simplyleakdetection.biz

Registered: 2010 (15 years)

Introduction: Simply Leak Detection offers a range of advanced leak detection equipment, including: 1. Sonic Leak Detection: Utilizes sonic equipment from leading manufacturers to detect leaks by capturing vibrations caused by water escaping from pressurized pipes. 2. Metrotech HL 5000 + GM80 Ground Mic: Specialized sonic equipment for detecting leaks through structure-borne noise. 3. Leak-Pro Acoustic Systems:…

5. Water Leak Detection – Key Solutions

Domain: waterleakdetection.net.au

Introduction: 1. Acoustic Listening Devices: Amplify sounds of water escaping from pipes, pinpoint leak locations, reduce invasive searches. 2. Moisture Meters: Measure moisture levels in materials, easy to use, accurate readings, crucial for identifying hidden leaks. 3. Thermal Imaging Cameras: Detect temperature changes, visual representation of leaks, non-invasive, ideal for large areas. 4. Leak Detection Dy…

6. Alps Leak – FlexPitch® Multi-Moving Head Leak Tester

Domain: alpsleak.com

Registered: 1997 (28 years)

Introduction: Bottle Leak Detection Equipment includes various types of leak testers designed for high-speed testing of plastic bottles and containers. Key products include: 1. FlexPitch® Multi-Moving Head Leak Tester – Multi-station linear, moving head, speeds up to 250 BPM, container sizes up to 350 oz, features 2-4 multi-moving heads, no timing screw, fast changeover, mounts over existing conveyor. 2. NexGen…

7. Technoac – Water Leak Detection Equipment

Domain: technoac.com

Registered: 2005 (20 years)

Introduction: Water leak detection equipment includes various models:

1. Success AT-407N: Portable acoustic water leak detector with noise protection.

2. Success ATP-434N: Portable water leak detector with energized cables detection function.

3. Success ATG-435.15N: Portable set for underground utilities location and water leak detection, suitable for energized and non-energized cables, metal and non-metal pip…

Strategic Sourcing Conclusion and Outlook for leak detection tools

What Are the Key Takeaways for B2B Buyers of Leak Detection Tools?

In the ever-evolving landscape of leak detection technologies, strategic sourcing is paramount for B2B buyers seeking to enhance operational efficiency and reduce costs. Investing in advanced leak detection tools, such as the comprehensive kits offered by leading manufacturers, can significantly improve accuracy in identifying leaks, ultimately safeguarding infrastructure and minimizing water waste. As buyers navigate the complexities of selecting the right equipment, understanding the unique needs of their markets—especially in regions like Africa, South America, the Middle East, and Europe—will be crucial.

Illustrative image related to leak detection tools

How Can Strategic Sourcing Shape the Future of Leak Detection?

With a focus on quality and reliability, international buyers are encouraged to leverage strategic sourcing to identify suppliers that not only provide cutting-edge technology but also support training and ongoing service. This approach will ensure that their teams are well-equipped to utilize these tools effectively, maximizing return on investment.

As the demand for sustainable solutions grows, the future of leak detection tools looks promising. Now is the time for B2B buyers to engage with suppliers, explore innovative technologies, and take proactive steps toward building resilient operations. Your commitment to strategic sourcing today will pave the way for a more efficient and sustainable tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leak detection tools