A Deep Dive into Data Aire Orange Ca Solution

Introduction: Navigating the Global Market for data aire orange ca

In an increasingly interconnected world, sourcing reliable climate control solutions like those offered by Data Aire in Orange, CA, is crucial for businesses aiming to maintain optimal performance in critical environments. As international B2B buyers navigate the complexities of the global market, they face the challenge of ensuring that their data centers and sensitive equipment are supported by top-tier cooling systems. This guide serves as a comprehensive resource, detailing the diverse range of products available from Data Aire, including computer room air conditioning (CRAC) units, in-row cooling solutions, and advanced humidity control systems.

Understanding the nuances of equipment types, their specific applications, and the importance of supplier vetting can empower businesses to make informed purchasing decisions. Additionally, insights into cost considerations and energy efficiency regulations will help buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in emerging markets like Saudi Arabia and Brazil—identify the best solutions tailored to their unique operational needs.

By equipping B2B decision-makers with actionable knowledge, this guide not only highlights the innovative technologies offered by Data Aire but also provides strategic insights that can enhance operational reliability and efficiency. Embrace the opportunity to optimize your climate control systems and ensure your business thrives in today’s competitive landscape.

Understanding data aire orange ca Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ceiling Mounted Units | Compact design, energy-efficient, and versatile installation. | Data centers, server rooms, and labs. | Pros: Space-saving, efficient cooling. Cons: Limited cooling capacity compared to larger units. |

| Floor Mounted Units | High capacity cooling, suitable for larger spaces. | Large data centers and industrial facilities. | Pros: High performance, customizable. Cons: Requires more floor space, installation complexity. |

| In-Row Cooling Solutions | Direct cooling for server racks, reduces energy consumption. | Data centers with high-density racks. | Pros: Enhanced efficiency, targeted cooling. Cons: Higher upfront costs. |

| Chilled Water Units | Utilizes chilled water for cooling, scalable for large setups. | Large enterprises and institutional buildings. | Pros: Energy-efficient for large loads. Cons: Requires water supply and management. |

| gForce Ultra Series | Advanced technology with variable speed fans and economizers. | Mission-critical applications and grow facilities. | Pros: Superior energy savings, flexible configurations. Cons: Higher initial investment. |

What Are the Key Features of Ceiling Mounted Units in Data Aire’s Offerings?

Ceiling mounted units are designed to provide efficient cooling in compact environments. They are ideal for data centers, server rooms, and laboratories where space is at a premium. These units are equipped with energy-efficient technology, making them a cost-effective solution for businesses looking to maintain optimal temperature and humidity levels. When considering these units, buyers should evaluate the cooling capacity needed for their specific application and the installation requirements, as these units typically require professional setup.

How Do Floor Mounted Units Meet the Needs of Larger Facilities?

Floor mounted units are characterized by their ability to deliver high-capacity cooling, making them suitable for larger data centers and industrial facilities. These units can be customized to meet specific cooling demands, which is particularly beneficial for businesses with varying heat loads. However, they require more floor space and can be more complex to install compared to ceiling-mounted options. B2B buyers should consider their facility layout and the potential need for additional infrastructure when investing in these systems.

Why Choose In-Row Cooling Solutions for High-Density Racks?

In-row cooling solutions are specifically designed for high-density server environments, providing direct cooling to racks to enhance energy efficiency. These systems reduce the risk of hot spots and allow for better temperature management in data centers. While they offer significant energy savings and improved cooling performance, buyers should be prepared for higher initial costs and ensure that their facilities can accommodate the installation of such systems.

What Advantages Do Chilled Water Units Offer for Large Enterprises?

Chilled water units are a scalable cooling option ideal for large enterprises and institutional buildings. They leverage chilled water systems to provide efficient cooling across expansive facilities. While these units are energy-efficient for handling large loads, they do require a reliable water supply and proper management to maintain performance. B2B buyers must assess their infrastructure to ensure compatibility with chilled water systems before making a purchase.

How Does the gForce Ultra Series Stand Out in the Market?

The gForce Ultra series represents the pinnacle of cooling technology within Data Aire’s offerings. Featuring variable speed fans and economizers, these units are engineered for mission-critical applications and specialized environments, such as grow facilities. The energy savings and flexibility they provide can justify the higher initial investment for businesses focused on long-term operational costs. Buyers should weigh the benefits of advanced technology against their budget constraints when considering this option.

Key Industrial Applications of data aire orange ca

| Industry/Sector | Specific Application of Data Aire Orange CA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Data Centers | Precision cooling systems for server rooms | Maintains optimal temperature and humidity, enhancing equipment longevity and performance. | Consider energy efficiency, capacity, and reliability. |

| Telecommunications | Cooling solutions for telecom equipment | Ensures uninterrupted service and protects sensitive equipment from overheating. | Evaluate compatibility with existing systems and scalability. |

| Manufacturing Facilities | Climate control in production areas | Improves product quality and operational efficiency by controlling environmental conditions. | Assess customization options for specific manufacturing processes. |

| Medical Facilities | HVAC solutions for critical care environments | Ensures patient safety and comfort by maintaining strict temperature and humidity levels. | Focus on compliance with health regulations and energy efficiency. |

| Agricultural Operations | Climate control for indoor growing facilities | Enhances crop yield and quality through optimized environmental conditions. | Investigate integration with automated systems for monitoring. |

How is Data Aire Used in Data Centers and What Problems Does It Solve?

In data centers, Data Aire’s precision cooling systems are vital for maintaining the optimal temperature and humidity levels necessary for high-performance servers. As equipment generates heat, inadequate cooling can lead to failures and data loss. Data Aire’s solutions, which include advanced cooling units with variable speed fans and economizers, help mitigate these risks. International buyers, particularly those in regions with extreme temperatures, should prioritize energy efficiency and capacity to ensure reliable operations.

What Role Does Data Aire Play in Telecommunications?

Telecommunications companies rely on Data Aire’s cooling solutions to protect sensitive equipment from overheating. These systems ensure that critical infrastructure remains operational, preventing service disruptions that could affect customer satisfaction. Buyers must consider the compatibility of these cooling solutions with existing telecom systems, as well as their scalability to accommodate future growth, especially in rapidly developing markets in Africa and South America.

How Does Data Aire Enhance Manufacturing Facilities?

In manufacturing environments, Data Aire’s climate control systems are essential for maintaining the quality of products and processes. By regulating temperature and humidity, these systems minimize defects and ensure optimal conditions for production. For B2B buyers, especially those in developing regions, understanding the customization options available for specific manufacturing processes is crucial to achieving operational efficiency and product consistency.

What Are the Applications of Data Aire in Medical Facilities?

Medical facilities require precise climate control to ensure patient safety and comfort. Data Aire provides HVAC solutions that maintain strict temperature and humidity levels in critical care environments, such as operating rooms and intensive care units. Buyers in the healthcare sector must focus on compliance with health regulations and energy efficiency, as these factors significantly impact operational costs and patient care quality.

How is Data Aire Utilized in Agricultural Operations?

Data Aire’s cooling and climate control systems are increasingly used in agricultural operations, particularly in indoor growing facilities. These systems optimize environmental conditions, enhancing crop yield and quality. For international buyers, especially in regions with variable climates, investigating integration with automated monitoring systems can provide significant advantages in managing resources and ensuring consistent crop production.

3 Common User Pain Points for ‘data aire orange ca’ & Their Solutions

Scenario 1: Ensuring Optimal Cooling in High-Density Data Centers

The Problem: Many businesses are investing heavily in high-density data centers to handle growing data demands, yet they often face the challenge of maintaining optimal temperature and humidity levels. Inadequate cooling solutions can lead to equipment overheating, system failures, and ultimately, costly downtimes. B2B buyers may struggle to identify the right cooling system that balances efficiency with performance in these critical environments.

The Solution: To address this challenge, buyers should consider Data Aire’s specialized Computer Room Air Conditioning (CRAC) units, designed for high-density applications. Start by conducting a comprehensive cooling load analysis to determine your specific requirements, including the heat output of your equipment and the desired temperature and humidity levels. Data Aire offers a variety of customizable solutions, including the gForce Ultra series, which features variable frequency drives (VFD) for precise airflow control.

Additionally, incorporating advanced monitoring systems can provide real-time data on temperature and humidity, enabling proactive adjustments. Engage with Data Aire’s team to ensure that your cooling system is tailored to your data center’s unique needs, maximizing both performance and energy efficiency.

Scenario 2: Navigating Regulatory Compliance for Energy Efficiency

The Problem: International buyers, particularly from regions with strict energy regulations, often encounter challenges in ensuring their cooling systems comply with local and international energy efficiency standards. Non-compliance can lead to fines and increased operational costs, making it crucial for businesses to source equipment that meets these criteria.

The Solution: Data Aire is proactive in addressing energy regulations, offering products that are compliant with both U.S. Department of Energy (DOE) and California Energy Commission (CEC) standards. When sourcing cooling solutions, buyers should prioritize manufacturers who demonstrate a commitment to energy efficiency.

Conduct thorough research on Data Aire’s product line, focusing on energy-saving features such as economizers and electronic expansion valves. These technologies optimize cooling performance while minimizing energy consumption. Engage with local representatives to discuss how Data Aire’s offerings can be integrated into your existing systems, ensuring compliance and cost-effectiveness.

Scenario 3: Overcoming Installation and Maintenance Complexities

The Problem: Installing and maintaining specialized cooling equipment can be daunting for B2B buyers, especially those unfamiliar with the technical aspects of CRAC systems. Complications during installation or maintenance can lead to disruptions in service, additional costs, and even equipment damage.

The Solution: To mitigate these challenges, buyers should work closely with Data Aire’s experienced team throughout the installation and maintenance process. Start by requesting detailed installation guides and technical support during setup. Data Aire’s documentation includes comprehensive manuals and wiring diagrams, which can be invaluable for your technical team.

For ongoing maintenance, consider implementing a service contract with Data Aire or a certified technician to ensure regular checks and timely repairs. This proactive approach will help maintain optimal performance and extend the lifespan of your cooling systems. Additionally, participating in training sessions offered by Data Aire can equip your team with the necessary skills to handle minor troubleshooting and maintenance tasks, reducing reliance on external services.

Strategic Material Selection Guide for data aire orange ca

What Are the Common Materials Used in Data Aire Products?

When selecting materials for products from Data Aire in Orange, CA, it is critical to consider their properties, advantages, disadvantages, and suitability for specific applications. The following analysis covers four common materials used in their computer room air conditioning (CRAC) systems.

1. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, making it ideal for heat exchangers and structural components in cooling systems. It can withstand moderate temperature and pressure ratings, typically up to 200°F and 150 psi.

Pros & Cons:

Aluminum is durable and cost-effective, allowing for easier manufacturing and assembly. However, its lower strength compared to steel can be a limitation in high-stress applications. Additionally, while it is generally resistant to corrosion, it can be susceptible to galvanic corrosion when in contact with other metals.

Impact on Application:

Aluminum’s thermal properties make it suitable for applications requiring efficient heat transfer, such as evaporators and condensers in CRAC units. Its lightweight nature also facilitates easier installation.

Considerations for International Buyers:

Buyers from regions with high humidity, like parts of Africa and South America, should ensure that aluminum components are properly treated to prevent corrosion. Compliance with international standards such as ASTM for material specifications is crucial.

2. Stainless Steel

Key Properties:

Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand high temperatures and pressures (up to 1000°F and 300 psi). It is often used in environments where hygiene is critical.

Pros & Cons:

While stainless steel offers superior durability and resistance to corrosion, it comes at a higher cost compared to aluminum. Its manufacturing can also be more complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is ideal for components exposed to moisture and corrosive environments, such as humidifiers and condensate pans. Its robustness enhances the longevity of equipment in critical applications.

Considerations for International Buyers:

International buyers must consider local regulations regarding stainless steel grades (e.g., 304 vs. 316) based on environmental conditions. Compliance with standards such as DIN and JIS is essential for ensuring product quality.

3. Copper

Key Properties:

Copper is an excellent conductor of heat and electricity, with a high melting point (1981°F) and good resistance to corrosion when properly treated. It is often used in refrigeration and air conditioning applications.

Pros & Cons:

The primary advantage of copper is its superior thermal conductivity, which enhances energy efficiency. However, copper is more expensive than aluminum and can be prone to corrosion if exposed to certain environments, necessitating protective coatings.

Impact on Application:

Copper is commonly used in heat exchangers and piping systems within CRAC units, where its thermal efficiency is crucial. It is also compatible with refrigerants, making it a preferred choice for cooling systems.

Considerations for International Buyers:

Buyers should be aware of the copper market’s volatility, which can affect pricing. Compliance with international standards for copper tubing and fittings is important, especially in regions with specific material requirements.

4. Polycarbonate

Key Properties:

Polycarbonate is a lightweight, impact-resistant thermoplastic with good thermal stability and a high degree of transparency. It can operate effectively within a temperature range of -40°F to 240°F.

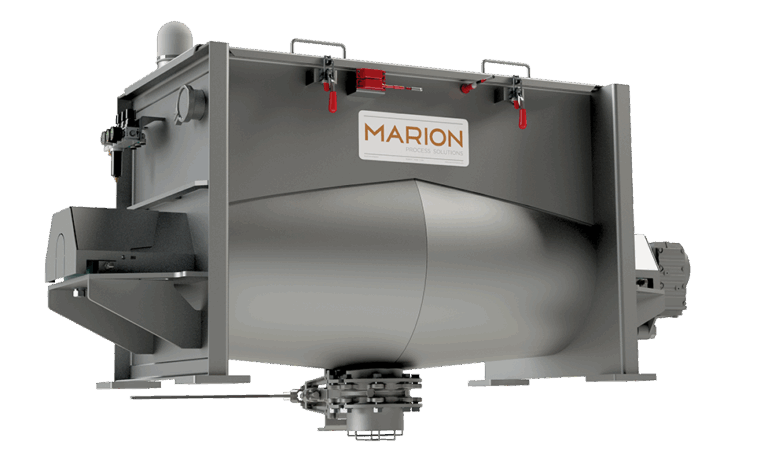

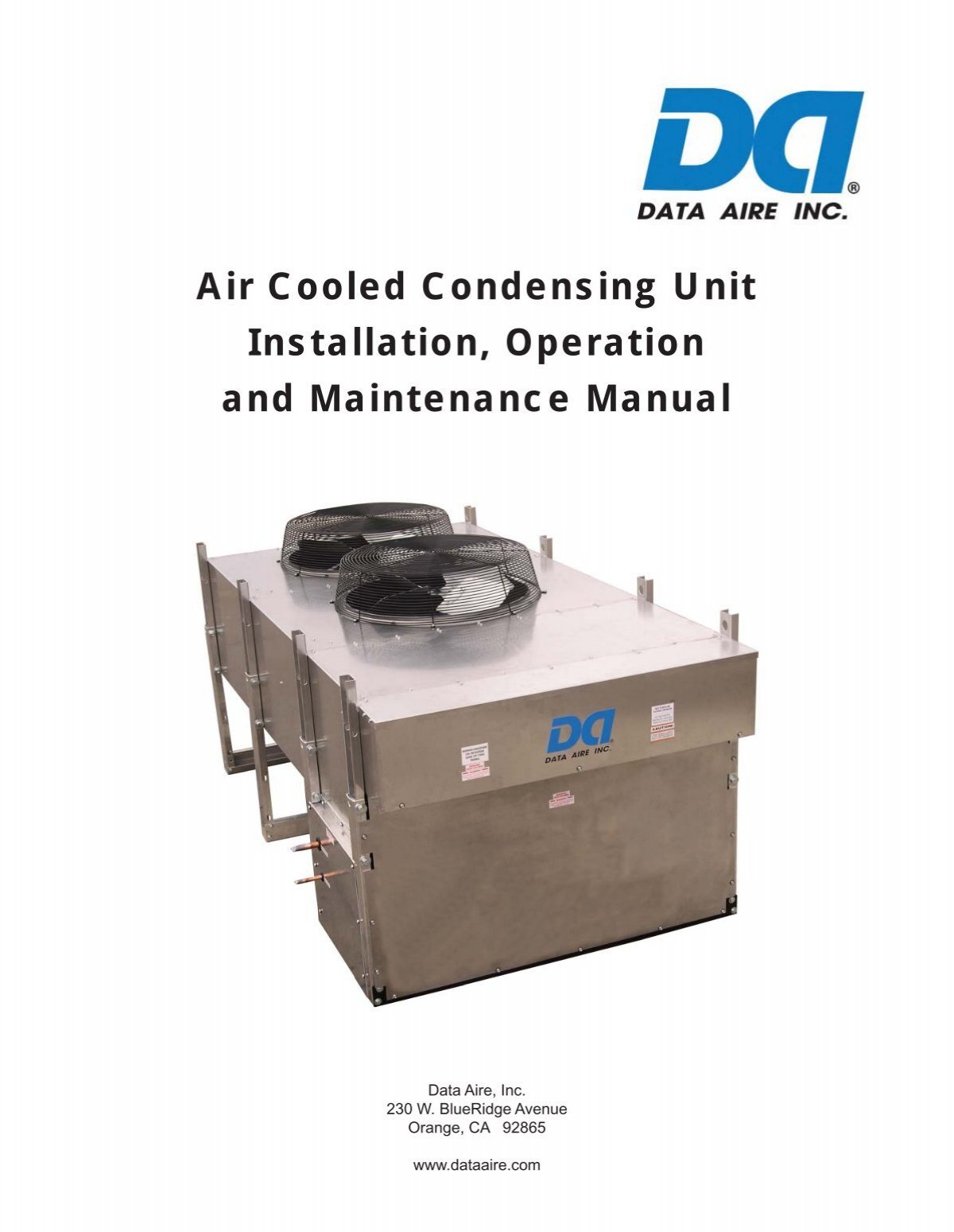

Illustrative image related to data aire orange ca

Pros & Cons:

Polycarbonate is cost-effective and offers excellent durability against impacts. However, it has lower thermal conductivity compared to metals, which may limit its use in certain applications. Additionally, it can be susceptible to UV degradation over time.

Impact on Application:

Polycarbonate is often used for protective covers and enclosures in CRAC systems, providing visibility while safeguarding internal components. Its lightweight nature aids in installation and maintenance.

Considerations for International Buyers:

International buyers should ensure that polycarbonate materials meet local fire safety standards, as regulations can vary significantly. Compliance with ASTM standards for plastics is also recommended.

Summary Table of Material Selection for Data Aire Products

| Material | Typical Use Case for data aire orange ca | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat exchangers, structural components | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Stainless Steel | Humidifiers, condensate pans | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Copper | Heat exchangers, piping systems | Superior thermal conductivity | Expensive and prone to corrosion | High |

| Polycarbonate | Protective covers, enclosures | Cost-effective and impact-resistant | Lower thermal conductivity | Low |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions when sourcing products from Data Aire in Orange, CA.

In-depth Look: Manufacturing Processes and Quality Assurance for data aire orange ca

What Are the Main Stages of the Manufacturing Process at Data Aire in Orange, CA?

Data Aire, a prominent manufacturer of Computer Room Air Conditioning (CRAC) equipment, follows a structured and efficient manufacturing process that emphasizes quality and performance. The manufacturing process typically includes several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection and preparation of high-quality raw materials. Data Aire sources materials that meet stringent industry standards for durability and performance. This stage may involve cutting, shaping, and treating materials to ensure they are ready for the next phase.

-

Forming: Once the materials are prepared, they undergo forming processes such as stamping, bending, and welding. Advanced machinery is used to ensure precision in creating components that fit together seamlessly. This stage is critical for maintaining the structural integrity and performance characteristics of the cooling systems.

-

Assembly: The assembly stage brings together various components to create the final product. Skilled technicians utilize both automated systems and manual assembly techniques to ensure each unit meets Data Aire’s specifications. This phase often involves integrating sophisticated controls and monitoring systems that enhance the equipment’s functionality.

-

Finishing: After assembly, the units undergo finishing processes that may include painting, coating, and quality checks. This stage not only improves the aesthetic appeal but also protects the units from environmental factors. Quality assurance checks are conducted to ensure that each unit meets the performance standards before leaving the manufacturing floor.

How Does Data Aire Ensure Quality Assurance Throughout the Manufacturing Process?

Quality assurance is integral to Data Aire’s manufacturing process, ensuring that each product meets international standards and customer expectations. The company adheres to several quality assurance protocols, including compliance with ISO 9001, which emphasizes a process-oriented approach to quality management.

-

International Standards Compliance: Data Aire’s commitment to quality is evident through its adherence to ISO 9001 standards. This certification ensures that the company’s processes are consistently monitored and improved, leading to high-quality products. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are pursued to align with global market requirements.

-

Quality Control Checkpoints: Throughout the manufacturing process, Data Aire implements several quality control checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards before entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After assembly, each unit undergoes rigorous testing to verify its performance and reliability. This includes functionality tests, leak tests, and environmental tests to ensure the units can operate effectively in critical environments.

- Testing Methods Employed: Data Aire employs various testing methods to validate the performance and safety of its products. Common testing protocols include:

- Thermal Performance Testing: Assessing the cooling efficiency under different load conditions.

- Durability Testing: Simulating long-term usage to evaluate the longevity and reliability of the units.

- Safety Testing: Ensuring compliance with safety regulations to protect end-users and equipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with local standards. Here are some actionable steps to undertake:

-

Supplier Audits: Conducting on-site audits of Data Aire’s facilities can provide insights into their manufacturing processes and quality control measures. Audits allow buyers to evaluate compliance with international standards and assess the effectiveness of quality management systems.

-

Requesting Quality Reports: Buyers should request documentation related to quality control practices, including inspection reports, testing results, and certifications. These documents can provide evidence of the supplier’s commitment to quality and adherence to relevant standards.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can conduct independent audits and tests, providing additional assurance to buyers regarding product quality.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their regions. Different countries may have varying requirements for compliance, and understanding these nuances can help in selecting a reliable supplier.

What Challenges Do International Buyers Face Regarding Quality Assurance?

International B2B buyers may encounter unique challenges when assessing the quality assurance practices of suppliers like Data Aire. These challenges include:

-

Language Barriers: Language differences can complicate communication regarding quality standards and specifications. Clear and effective communication is essential to ensure mutual understanding between buyers and suppliers.

-

Regulatory Differences: Buyers must navigate varying regulatory environments across different regions, which may affect product compliance. Understanding local regulations is crucial for ensuring that products meet necessary standards upon importation.

-

Cultural Differences in Business Practices: Different regions may have distinct business practices and expectations regarding quality assurance. Buyers should be aware of these cultural differences to foster effective collaboration with suppliers.

Conclusion

Data Aire in Orange, CA, exemplifies a robust manufacturing process and a strong commitment to quality assurance. By understanding the manufacturing stages and quality control practices, international B2B buyers can make informed decisions when partnering with Data Aire for their cooling solutions. By leveraging audits, quality reports, and third-party inspections, buyers can ensure they are sourcing high-quality products that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘data aire orange ca’

In the quest to procure reliable cooling solutions, particularly from Data Aire in Orange, CA, international B2B buyers must navigate a series of critical steps. This guide serves as a practical checklist to streamline your sourcing process, ensuring you make informed decisions and select a supplier that aligns with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount before reaching out to potential suppliers. Identify the specific requirements of your facility, including cooling capacity, energy efficiency, and humidity control. This will help you communicate effectively with suppliers and ensure they can meet your unique needs.

Step 2: Conduct Market Research

A thorough market analysis will provide insights into the competitive landscape. Investigate various manufacturers and their offerings, focusing on product features, pricing, and customer reviews. This research will enable you to identify which suppliers are reputable and have a proven track record in your industry.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong history of reliability and innovation, as well as their ability to offer customized solutions tailored to your operational requirements.

Step 4: Verify Supplier Certifications

Confirm that your potential suppliers hold the necessary certifications and adhere to industry standards. This includes compliance with energy regulations and environmental guidelines. Certifications not only indicate a supplier’s credibility but also ensure that their products are safe and efficient for your operations.

Step 5: Request Proposals and Quotes

Once you have narrowed down your options, solicit detailed proposals and quotes from your shortlisted suppliers. Ensure that these documents outline all relevant costs, including installation, maintenance, and warranty options. Compare these proposals to assess which supplier provides the best value for your investment.

Step 6: Assess After-Sales Support and Services

Robust after-sales support is essential for the longevity of your cooling systems. Inquire about maintenance services, response times for repairs, and the availability of spare parts. Reliable support can significantly reduce downtime and enhance the overall performance of your cooling equipment.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, enter negotiations to finalize terms that are favorable for both parties. This should include payment terms, delivery schedules, and service level agreements. A well-structured contract will protect your interests and ensure a smooth procurement process.

By following this checklist, B2B buyers can streamline their sourcing of Data Aire’s cooling solutions, ensuring they select a supplier that meets their technical requirements and business goals effectively.

Comprehensive Cost and Pricing Analysis for data aire orange ca Sourcing

What Are the Key Cost Components in Sourcing from Data Aire, Orange CA?

When considering a partnership with Data Aire in Orange, CA for computer room air conditioning (CRAC) systems, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing CRAC units significantly impact costs. High-performance components such as Variable Frequency Drives (VFDs) and electronic expansion valves are integral to energy efficiency but can elevate material costs.

-

Labor: Skilled labor is required for both manufacturing and installation. As Data Aire emphasizes precision in their cooling solutions, labor costs can vary based on the complexity of the systems being produced or installed.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and facility expenses. Data Aire’s commitment to energy-efficient technologies may lead to higher upfront manufacturing costs but could result in long-term savings for clients.

-

Tooling: The need for specialized tools and equipment for production can add to the overall cost. Custom solutions often require unique tooling, which can be a significant expense.

-

Quality Control (QC): Rigorous quality assurance processes ensure that products meet industry standards. This is particularly important in critical environments where cooling failure is not an option.

-

Logistics: Shipping costs, especially for international buyers, can vary based on the delivery method and distance. Factors such as customs duties and tariffs should also be considered.

-

Margin: Data Aire’s pricing structure will also reflect their desired profit margin, influenced by the overall market demand and competition.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of Data Aire products, which can vary based on the buyer’s requirements:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders may qualify for discounts, making it essential for buyers to assess their needs accurately. Larger volumes often lead to lower per-unit costs.

-

Specifications and Customization: Custom solutions tailored to specific operational needs can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: The availability of high-quality materials and compliance with international standards can influence pricing. Buyers should verify that products meet relevant certifications for their regions.

-

Supplier Factors: The reputation and reliability of Data Aire as a manufacturer can affect price negotiations. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon in contracts is crucial for international buyers. These terms dictate responsibilities for shipping, insurance, and tariffs, impacting the overall cost.

What Are Effective Buyer Tips for Negotiating with Data Aire?

International B2B buyers from regions like Africa, South America, the Middle East, and Europe can optimize their sourcing strategy with the following tips:

-

Negotiation: Engage in open discussions regarding pricing and payment terms. Leverage potential bulk purchases or long-term contracts to negotiate better rates.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and operational costs over the product’s lifespan. Data Aire’s energy-efficient solutions could lead to significant savings in the long run.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and regional regulations that may affect the final pricing. Establish clear communication regarding payment methods to avoid complications.

-

Conduct Thorough Research: Investigate competitor offerings and market rates for similar products. This knowledge can empower buyers during negotiations, ensuring they receive a fair price.

Disclaimer for Indicative Prices

Prices can fluctuate based on market conditions, supply chain dynamics, and specific buyer requirements. It is advisable for buyers to obtain detailed quotes directly from Data Aire to ensure accurate and up-to-date pricing information tailored to their specific needs.

Alternatives Analysis: Comparing data aire orange ca With Other Solutions

Understanding Alternatives for Data Aire’s Cooling Solutions

In today’s competitive landscape, selecting the right cooling solution for data centers and critical environments is crucial for operational efficiency and reliability. Data Aire, based in Orange, CA, is renowned for its computer room air conditioning (CRAC) systems. However, businesses must consider various alternatives that can meet their specific cooling needs, especially as international B2B buyers look for tailored solutions. Below, we explore how Data Aire compares to other viable options.

| Comparison Aspect | Data Aire Orange CA | Alternative 1: Liebert (Emerson) | Alternative 2: Stulz |

|---|---|---|---|

| Performance | High precision in temperature and humidity control | Excellent for high-density environments | Optimized for energy efficiency and reliability |

| Cost | Moderate to high initial investment | Higher upfront costs | Competitive pricing with various models |

| Ease of Implementation | Requires professional installation | Professional installation needed | Flexible installation options |

| Maintenance | Regular maintenance recommended | Comprehensive service plans available | Low maintenance features available |

| Best Use Case | Data centers, telecom rooms | High-performance data centers | Mission-critical applications, server rooms |

What Are the Advantages and Disadvantages of Using Liebert (Emerson) Solutions?

Liebert, a brand under Emerson, is known for its high-performance cooling systems tailored for data centers. One of its key advantages is its ability to handle high-density environments effectively, making it a popular choice for businesses with significant cooling requirements. However, the initial investment for Liebert systems tends to be higher compared to Data Aire, which may deter smaller companies or those with limited budgets. Additionally, implementation requires professional installation, adding to the overall cost.

How Does Stulz Compare as an Alternative?

Stulz offers a range of cooling solutions designed for energy efficiency and reliability, making it a strong contender in the market. Its products are known for their flexible installation options, which can cater to various setups, including retrofitting existing systems. This flexibility can be a significant advantage for businesses looking to upgrade their cooling without extensive renovations. However, while Stulz solutions are competitively priced, they may not provide the same level of precision in humidity control as Data Aire or Liebert, which could be a drawback for critical applications.

Conclusion: How to Choose the Right Cooling Solution for Your Business

When selecting a cooling solution, B2B buyers must assess their specific requirements, including performance needs, budget constraints, and the complexity of installation. Data Aire is an excellent choice for environments demanding precise temperature and humidity control, while Liebert and Stulz provide robust alternatives with unique advantages. Ultimately, understanding your operational needs and evaluating each option’s strengths and weaknesses will guide you in making an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for data aire orange ca

What Are the Essential Technical Properties of Data Aire Products?

Understanding the technical specifications of Data Aire products is crucial for international B2B buyers who need reliable cooling solutions for critical environments. Here are some key properties to consider:

1. Cooling Capacity

Cooling capacity, measured in tons or BTUs (British Thermal Units), defines the amount of heat a cooling system can remove from a space. This is vital for ensuring that data centers maintain optimal temperatures to prevent equipment overheating. Buyers should select units that match their specific cooling requirements to ensure efficiency and reliability.

2. Energy Efficiency Ratio (EER)

The EER measures the cooling output of a unit per watt of electricity consumed. A higher EER indicates a more energy-efficient system, which translates to lower operational costs. For international buyers, especially in regions with high electricity costs, investing in high-EER units can lead to significant long-term savings.

3. Humidity Control

Humidity levels are crucial in data centers to prevent equipment damage and maintain optimal performance. Data Aire units often include advanced humidity control systems that can adjust moisture levels automatically. Understanding the specifications related to humidity control helps buyers ensure that their environments meet industry standards and safeguard their investments.

4. Construction Material

The materials used in manufacturing cooling equipment, such as galvanized steel or aluminum, affect durability and performance. Buyers should consider units built with corrosion-resistant materials, especially in environments with high humidity or corrosive agents. This ensures longevity and reduces maintenance costs.

5. Noise Level

Measured in decibels (dB), the noise level of cooling units can impact the work environment. Data Aire products often have specifications regarding sound output, which can be particularly important in office settings or facilities where noise reduction is a priority. Buyers should review these specifications to select units that align with their operational noise requirements.

6. Control Systems

Modern cooling units often come equipped with advanced control systems that allow for remote monitoring and management. Features such as programmable settings and integration with building management systems enhance operational efficiency. Understanding the capabilities of these control systems can help buyers choose products that offer greater flexibility and control over their cooling environments.

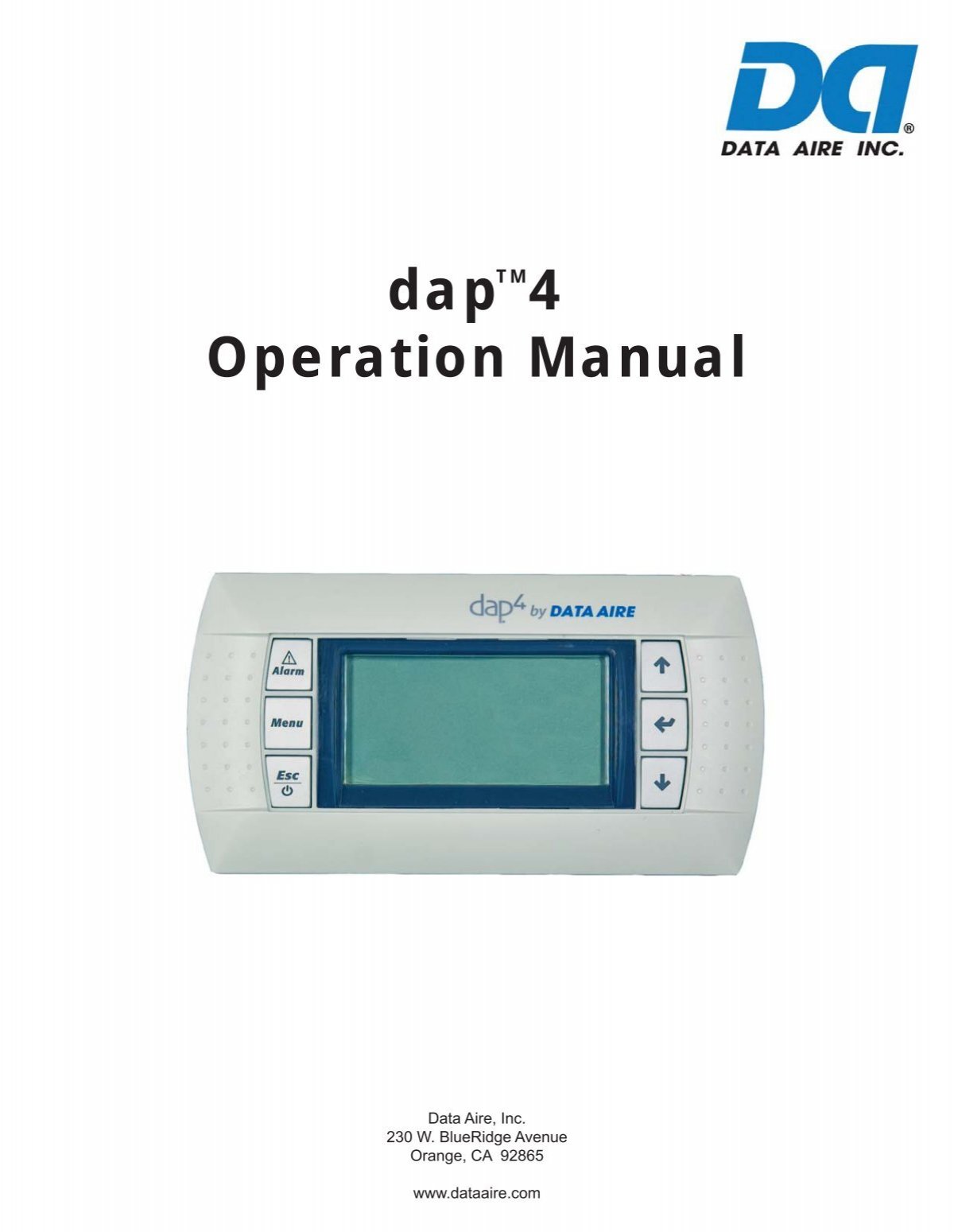

Illustrative image related to data aire orange ca

What Are Common Trade Terms Used in the Data Aire Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B sector. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of Data Aire, OEM parts may be necessary for maintenance and repair. Buyers should ensure they source OEM parts to maintain the integrity and performance of their cooling systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to plan their inventory and budget effectively. It can also impact negotiations, particularly when sourcing products from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It is a critical step in the procurement process, allowing buyers to compare prices and terms from various vendors. Crafting a clear RFQ can lead to better deals and more accurate proposals from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), helps buyers clarify shipping responsibilities and costs, reducing the risk of misunderstandings in transactions.

Illustrative image related to data aire orange ca

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses relying on cooling solutions, understanding lead times is essential for planning and minimizing downtime. Buyers should inquire about lead times during the procurement process to ensure timely delivery.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their operational efficiency and investment value when sourcing Data Aire products.

Navigating Market Dynamics and Sourcing Trends in the data aire orange ca Sector

What Are the Current Market Dynamics and Key Trends Affecting B2B Buyers in the Data Aire Sector?

The data center cooling solutions market is experiencing significant growth, driven by the increasing demand for efficient climate control systems in data-intensive environments. As businesses globally transition to digital platforms, the need for reliable cooling solutions has surged, particularly in regions with extreme temperatures, such as parts of Africa, the Middle East, and South America. For international B2B buyers, this presents an opportunity to invest in advanced cooling technologies that enhance operational efficiency and reduce energy costs.

Emerging trends include the adoption of energy-efficient systems, such as Data Aire’s gForce Ultra series, which utilize variable frequency drives (VFDs) and economizers. These technologies not only comply with stringent energy regulations but also significantly lower operational costs. Additionally, the integration of remote monitoring and control systems is becoming vital as businesses seek greater oversight over their cooling operations. Buyers from regions like Saudi Arabia and Brazil can leverage these innovations to ensure optimal performance in their data centers.

Illustrative image related to data aire orange ca

Furthermore, the market is witnessing a shift towards modular and scalable solutions that can adapt to fluctuating demands. This trend is particularly relevant for international buyers looking to future-proof their investments as data processing needs evolve.

How Does Sustainability and Ethical Sourcing Impact B2B Buyers in the Data Aire Sector?

Sustainability has become a crucial consideration for B2B buyers in the data center cooling market. As organizations strive to minimize their environmental impact, the importance of ethical supply chains and sustainable sourcing practices cannot be overstated. Data Aire is at the forefront of this movement, offering a range of products designed with energy efficiency in mind, which align with global sustainability goals.

The use of environmentally friendly refrigerants and energy-efficient technologies is becoming standard in the industry. Buyers should prioritize suppliers that hold certifications from recognized organizations, such as the Department of Energy (DOE) and the California Energy Commission (CEC), which signify adherence to rigorous environmental standards. By choosing suppliers committed to sustainable practices, businesses can significantly reduce their carbon footprint while also enhancing their corporate social responsibility (CSR) profile.

Moreover, the demand for ‘green’ certifications is rising, especially in regions like Europe, where regulatory frameworks encourage sustainable operations. International buyers can benefit from these trends by sourcing equipment that not only meets their operational needs but also contributes to their sustainability objectives.

What Is the Historical Evolution of Data Aire and Its Relevance to Today’s B2B Buyers?

Data Aire, established in Orange, California, has a rich history as a pioneer in the manufacturing of Computer Room Air Conditioning (CRAC) equipment. The company was the first to develop equipment designed for raised floor applications, setting the standard for cooling solutions in data centers. Over the years, Data Aire has evolved its product offerings to include innovative technologies like the in-row and gForce Ultra series, which cater to the ever-growing demands of modern data environments.

This historical context is vital for B2B buyers as it underscores Data Aire’s commitment to innovation and reliability. As the company continues to adapt to market trends and regulatory changes, international buyers can trust that Data Aire remains a dependable partner in achieving optimal climate control solutions for critical applications. The legacy of quality and innovation positions Data Aire as a leader in the industry, making it a valuable consideration for businesses seeking long-term cooling solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of data aire orange ca

-

How do I ensure that Data Aire products meet my specific cooling needs?

To ensure that Data Aire products meet your specific cooling needs, it’s essential to conduct a thorough assessment of your facility’s requirements, including the size of the data center, equipment heat output, and humidity levels. Engage with Data Aire’s technical sales team for a consultation. They can provide guidance on the most suitable CRAC (Computer Room Air Conditioning) units, such as the gForce Ultra series or other customized solutions that align with your operational demands. -

What are the energy efficiency features of Data Aire products?

Data Aire is committed to energy efficiency, offering products that incorporate state-of-the-art technology, such as VFD (Variable Frequency Drive) fans and economizers. Many units are compliant with DOE and CEC energy regulations, which can help lower operational costs. When sourcing, inquire about the specific energy ratings and certifications of the models you’re considering to maximize your energy savings and sustainability efforts. -

What customization options are available for Data Aire equipment?

Data Aire provides a variety of customization options, including tailored cooling capacities, humidity control settings, and integration with existing systems. For specialized environments like grow facilities, they offer specific configurations to manage CO2 levels and scheduling needs. Discuss your unique requirements with the Data Aire sales team to explore available custom solutions that fit your operational objectives. -

What is the minimum order quantity (MOQ) for Data Aire products?

The minimum order quantity (MOQ) for Data Aire products can vary based on the specific equipment and your location. Generally, larger orders may qualify for better pricing and terms. It’s advisable to reach out directly to their sales team or authorized distributors to inquire about MOQs relevant to your intended purchases, especially for international orders. -

What are the payment terms for international buyers sourcing from Data Aire?

Data Aire typically offers flexible payment terms for international buyers, including options for wire transfers, letters of credit, or other arrangements based on your creditworthiness and order size. It’s crucial to discuss these terms upfront to avoid any complications during the transaction. Ensure you understand any associated fees, currency exchange rates, and payment timelines. -

How does Data Aire handle quality assurance for their products?

Data Aire maintains rigorous quality assurance protocols throughout the manufacturing process, adhering to industry standards and regulations. Each product undergoes extensive testing to ensure performance and reliability. As a buyer, you can request documentation regarding quality certifications and testing results to ensure that the equipment meets your standards and expectations. -

What logistics support does Data Aire provide for international shipments?

Data Aire collaborates with various logistics partners to facilitate international shipping, ensuring timely and safe delivery of products. They can assist with customs documentation and provide shipping options that suit your timeline and budget. For seamless logistics, discuss your shipping requirements during the ordering process and ask about tracking and support for your shipment. -

What after-sales support can I expect from Data Aire?

After-sales support from Data Aire includes technical assistance, installation guidance, and access to a comprehensive library of manuals and service documentation. They offer ongoing maintenance and repair services to ensure optimal performance of your cooling systems. Establishing a relationship with their customer service team can provide you with the necessary resources to address any operational challenges post-purchase.

Top 6 Data Aire Orange Ca Manufacturers & Suppliers List

1. Data Aire – HVAC Solutions

Domain: hpac.com

Registered: 1995 (30 years)

Introduction: This company, Data Aire – HVAC Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Data Aire – Precision Cooling Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Data Aire – Precision Cooling Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Data Aire – CRAC Equipment

Domain: ksrassoc.com

Registered: 2009 (16 years)

Introduction: Data Aire is a division of Construction Specialties, located in Orange, CA, known for manufacturing CRAC (Computer Room Air Conditioning) equipment. Key products include:

– In-row and g-Force Ultra floor mounted series with VFD direct-driven plenum fans, electronic expansion valves, and economizers.

– A comprehensive ceiling series, customized for applications in grow facilities, focusing on CO2 i…

4. Data Aire – Precision Air Control Solutions

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Data Aire, Inc. provides precision air control for data processing centers and offers manufacturing of refrigeration and heating equipment. The company serves customers in the United States.

5. Data Aire – Computer Room AC Units

Domain: libraryresources.net

Registered: 2001 (24 years)

Introduction: DATA AIRE MECHANICAL: Computer Room AC Units, Air, Water, Glycol, Chilled Water Cooled, Energy Conservation, Computer Main Frame Chillers, Controls.

6. Data Aire, Inc. – Precision Air Conditioning Systems

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Data Aire, Inc. is a leading manufacturer of precision air conditioning and environmental control systems. Their product range includes precision air conditioning systems, environmental control units, air handlers, and computer room air conditioners. These products are designed for data centers, clean rooms, laboratories, medical facilities, and other critical environments, providing precise contr…

Strategic Sourcing Conclusion and Outlook for data aire orange ca

As international B2B buyers increasingly seek reliable cooling solutions, Data Aire in Orange, CA, stands out as a trusted partner. Their extensive range of computer room air conditioning (CRAC) systems is designed to meet the rigorous demands of critical environments, ensuring optimal temperature and humidity control. The incorporation of advanced energy-saving technologies aligns with global sustainability trends, offering buyers in regions such as Africa, South America, the Middle East, and Europe significant operational advantages.

Strategic sourcing from Data Aire not only facilitates access to high-quality equipment but also promotes long-term partnerships. By leveraging their expertise, businesses can enhance their operational efficiency, reduce downtime, and maintain compliance with evolving environmental regulations. The company’s commitment to innovation ensures that international clients receive state-of-the-art solutions tailored to their unique needs.

Looking ahead, the potential for collaboration with Data Aire presents a compelling opportunity for companies aiming to strengthen their infrastructure. Engage with Data Aire today to explore how their cutting-edge cooling solutions can optimize your operations and position your business for future success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.