Unlocking Value: A Strategic Analysis of the Linak Actuator Market

Introduction: Navigating the Global Market for linak actuator

In today’s rapidly evolving industrial landscape, sourcing reliable electric linear actuators, such as those offered by LINAK, presents a significant challenge for B2B buyers. With applications spanning healthcare, agriculture, marine, and office environments, the demand for versatile, high-performance actuators continues to rise. Buyers must navigate a complex global market, making informed decisions about product specifications, supplier capabilities, and cost-effectiveness to ensure they select the right actuator for their specific needs.

This comprehensive guide aims to equip international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with essential insights into the world of LINAK actuators. We will explore the various types of actuators available, their diverse applications, and the importance of thorough supplier vetting. Additionally, we’ll provide a detailed analysis of pricing structures and factors influencing costs, empowering buyers to make educated purchasing decisions.

By delving into the intricacies of actuator technology, applications, and market dynamics, this guide serves as a valuable resource for businesses seeking to enhance operational efficiency and product innovation. Understanding these elements will not only streamline the sourcing process but also lead to more strategic investments in electric linear actuators, ultimately driving success in competitive markets.

Understanding linak actuator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LA20 | Compact design, lightweight, versatile voltage options | Office furniture, small medical devices | Pros: Space-saving, easy integration. Cons: Limited load capacity. |

| LA36 | High load capacity, robust construction, customizable strokes | Industrial machinery, healthcare equipment | Pros: Handles heavy loads, durable. Cons: Bulkier design may limit installation options. |

| LA40 | High-speed performance, integrated control options | Agricultural equipment, marine applications | Pros: Fast operation, advanced control. Cons: Higher complexity may require more technical support. |

| LA43 | Advanced safety features, low noise operation | Comfort furniture, adjustable beds | Pros: Enhanced user comfort, quiet operation. Cons: May be pricier than standard models. |

| LA45 | Designed for harsh environments, IP-rated protection | Construction, outdoor applications | Pros: Resistant to environmental factors, reliable. Cons: May require specialized installation. |

What Are the Key Characteristics of the LA20 Actuator?

The LA20 actuator is recognized for its compact and lightweight design, making it ideal for applications where space is at a premium. It operates on multiple voltage options (12V, 24V, 48V) and is particularly suited for office furniture and small medical devices. When considering the LA20, buyers should note its ease of integration into existing systems, although its limited load capacity may not meet the demands of heavier applications.

How Does the LA36 Stand Out in Heavy-Duty Applications?

The LA36 actuator is engineered for high load capacities, supporting up to 1,500 kg, making it suitable for industrial machinery and healthcare equipment. Its robust construction and customizable stroke lengths cater to diverse operational needs. While the LA36 excels in durability and performance, potential buyers should be mindful that its bulkier design could limit installation flexibility in tighter spaces.

What Advantages Does the LA40 Offer for Speed and Control?

The LA40 actuator is designed for applications requiring high-speed performance and integrated control options. It is often used in agricultural equipment and marine applications where rapid adjustments are necessary. Buyers should appreciate the actuator’s fast operational capabilities; however, its complexity may necessitate additional technical support during installation and maintenance.

Why Choose the LA43 for Comfort Furniture?

The LA43 actuator features advanced safety mechanisms and operates quietly, making it an excellent choice for comfort furniture and adjustable beds. Its design prioritizes user comfort, promoting a peaceful environment. While it offers significant advantages in terms of noise reduction and user experience, the LA43 may come with a higher price tag compared to standard models, which could impact budget considerations.

What Makes the LA45 Ideal for Harsh Environments?

The LA45 actuator is specifically designed to withstand harsh environmental conditions, featuring IP-rated protection that ensures reliability in construction and outdoor applications. Its resistance to environmental factors makes it a dependable choice for rugged use. Buyers should consider the LA45’s durability and performance, but should also be prepared for potential specialized installation requirements due to its robust design.

Key Industrial Applications of linak actuator

| Industry/Sector | Specific Application of linak actuator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Adjustable hospital beds | Enhances patient comfort and care efficiency | Compliance with medical standards, reliability, and safety features |

| Agriculture | Automated feeding systems | Increases efficiency and reduces labor costs | Durability in harsh environments, customizable stroke lengths |

| Industrial Automation | Robotic assembly lines | Improves precision in manufacturing processes | Compatibility with existing systems, load capacity, and speed |

| Marine | Adjustable yacht components | Enhances usability and comfort on marine vessels | Resistance to marine conditions, ease of installation |

| Office Furniture | Height-adjustable desks | Promotes ergonomic workspaces, reducing employee fatigue | Customization options, ease of integration with existing furniture |

How are LINAK Actuators Revolutionizing Healthcare Applications?

In healthcare, LINAK actuators are integral to the operation of adjustable hospital beds. These actuators enable smooth adjustments for patient comfort, which is crucial for recovery and care. They also contribute to enhanced efficiency in healthcare settings, allowing caregivers to easily reposition patients. For international buyers, especially in regions like Africa and the Middle East, sourcing actuators that comply with stringent medical standards is vital. Reliability and safety features are paramount, ensuring that the equipment can withstand continuous use in critical environments.

What Role Do LINAK Actuators Play in Modern Agriculture?

In agriculture, LINAK actuators are commonly used in automated feeding systems for livestock. This technology increases operational efficiency and significantly reduces the labor required for feeding, thus lowering overall costs. For buyers in South America, where agriculture is a major industry, it’s essential to consider the durability of these actuators in harsh outdoor conditions. Customizable stroke lengths are also a key factor, allowing for tailored solutions that meet specific farming needs.

How Are LINAK Actuators Enhancing Industrial Automation?

Within industrial automation, LINAK actuators are utilized in robotic assembly lines, where precision and reliability are critical. These actuators facilitate accurate movements, improving the overall efficiency of manufacturing processes. Buyers in Europe, particularly in Germany, should focus on sourcing actuators that are compatible with existing systems and can handle high load capacities and speeds. This ensures seamless integration and maximizes productivity on the production floor.

Why Are LINAK Actuators Essential for Marine Applications?

For the marine industry, LINAK actuators are employed to adjust various yacht components, such as engine hatches and seating arrangements. This application enhances usability and comfort for yacht owners and passengers alike. Buyers in regions with significant marine activities should prioritize sourcing actuators that can withstand harsh marine conditions, such as humidity and saltwater exposure. Additionally, ease of installation is crucial for ensuring quick upgrades and maintenance.

How Do LINAK Actuators Improve Office Furniture Solutions?

In the office furniture sector, LINAK actuators are used to create height-adjustable desks that promote ergonomic work environments. By allowing users to switch between sitting and standing, these desks help reduce fatigue and improve overall productivity. For international buyers, especially in regions like Europe and Africa where workplace ergonomics is gaining traction, it is important to consider customization options that align with existing furniture designs. The ease of integration and operational smoothness are also key factors in the sourcing decision.

3 Common User Pain Points for ‘linak actuator’ & Their Solutions

Scenario 1: Difficulty in Customizing Actuator Specifications for Unique Applications

The Problem: Many B2B buyers struggle with finding linear actuators that fit their specific application requirements. In sectors like healthcare, agriculture, or industrial automation, the need for precise specifications such as stroke length, force capacity, and speed is critical. A buyer may find that the standard models available do not meet their unique operational needs, leading to inefficiencies, increased costs, or even project delays. This situation is particularly prevalent in regions where customization options may not be readily communicated or understood.

The Solution: To address this challenge, buyers should engage directly with manufacturers like LINAK that offer a wide range of customizable options. The first step is to clearly define the application’s requirements, including load capacities, required speeds, and operational environments. Once these specifications are established, buyers can utilize LINAK’s 3D configurator tool to visualize and refine actuator designs that meet their criteria. Additionally, leveraging the expertise of LINAK’s sales and application engineers can provide valuable insights into optimizing actuator selection. This proactive approach ensures that the selected actuators are tailored precisely to the application, minimizing the risk of operational setbacks.

Scenario 2: Concerns Over Actuator Reliability in Harsh Environments

The Problem: Buyers in industries such as marine, agriculture, and construction often face significant challenges regarding the reliability of linear actuators in harsh conditions. Factors like extreme temperatures, moisture, and dust can lead to actuator failure, resulting in costly downtimes and repair expenses. These concerns are amplified for businesses in regions with challenging climates, where equipment reliability is paramount to maintaining operational efficiency.

The Solution: To mitigate reliability issues, buyers should prioritize sourcing actuators designed for robust performance in challenging environments. LINAK offers actuators that have been rigorously tested for durability and environmental resistance. When selecting an actuator, it is essential to inquire about the specific environmental ratings (such as IP ratings) and to understand the testing processes that the actuators have undergone. Additionally, considering options like corrosion-resistant coatings and advanced sealing technologies can further enhance longevity. By investing in high-quality, purpose-built actuators, buyers can significantly reduce the risk of failure and associated costs, ensuring smooth operations even in the toughest conditions.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Many B2B buyers encounter difficulties when integrating new linear actuators into their existing systems, whether in manufacturing lines or healthcare facilities. The challenge often lies in ensuring compatibility with current controls, software, and power supplies. In some cases, buyers may invest in actuators only to discover that additional modifications or adapters are required, leading to increased costs and project delays.

The Solution: To streamline integration, buyers should conduct thorough compatibility assessments before purchasing actuators. This involves reviewing existing system specifications, including control interfaces and power supply requirements. LINAK provides detailed data sheets and manuals that outline compatibility features and integration guidelines. Furthermore, buyers can benefit from consulting with LINAK’s technical support team to clarify any integration concerns prior to making a purchase. Utilizing LINAK’s Plug & Play options can also simplify the process, as these systems are designed for easy installation and minimal configuration. By taking these proactive steps, buyers can ensure seamless integration, reducing the potential for costly delays and disruptions.

Strategic Material Selection Guide for linak actuator

What Are the Key Materials Used in LINAK Actuators?

When selecting materials for LINAK actuators, it is crucial to consider their properties, performance, and suitability for specific applications. Below is an analysis of four common materials used in the construction of LINAK actuators: aluminum, stainless steel, plastic, and composite materials.

How Does Aluminum Perform in LINAK Actuators?

Aluminum is frequently used in actuator housings due to its lightweight and excellent strength-to-weight ratio. Key properties include a temperature rating of up to 150°C and good corrosion resistance, particularly when anodized.

Pros: Aluminum is durable and offers a cost-effective solution for many applications. Its lightweight nature makes it ideal for portable or mobile devices, such as adjustable furniture and medical equipment.

Cons: While generally resistant to corrosion, aluminum can be susceptible to galvanic corrosion when in contact with dissimilar metals. Additionally, it may not withstand high-pressure environments as effectively as some other materials.

Impact on Application: Aluminum is suitable for environments where weight savings are crucial, such as in healthcare applications where mobility is essential. However, buyers must ensure compatibility with specific media, especially if the actuator will be exposed to corrosive substances.

What Advantages Does Stainless Steel Offer for LINAK Actuators?

Stainless steel is renowned for its high strength and exceptional corrosion resistance, making it an ideal choice for harsh environments. It can handle temperatures exceeding 300°C, which is beneficial for industrial applications.

Pros: The durability and longevity of stainless steel components make them suitable for heavy-duty applications, including agriculture and marine environments. Its resistance to rust and corrosion ensures reliable performance over time.

Cons: The primary drawback is the higher cost compared to aluminum and plastic. Additionally, stainless steel is heavier, which may not be suitable for all applications.

Impact on Application: Stainless steel is particularly advantageous in environments with high humidity or exposure to chemicals, such as in food processing or marine applications. Buyers should consider local standards for stainless steel grades to ensure compliance.

How Do Plastics Fit into LINAK Actuator Designs?

Plastics, such as polyamide (nylon) and polycarbonate, are often used for actuator components due to their lightweight and versatility. They typically have a temperature rating of up to 80°C and offer good chemical resistance.

Pros: Plastics are generally low-cost and can be molded into complex shapes, allowing for design flexibility. Their lightweight nature makes them suitable for applications where weight is a concern.

Cons: Plastics may not be as durable as metals and can be susceptible to wear and tear over time. They also have lower temperature and pressure ratings, which may limit their use in high-stress environments.

Impact on Application: Plastics are ideal for applications in home and office furniture, where weight and design flexibility are critical. However, international buyers must ensure that the selected plastic meets relevant safety and environmental standards.

What Role Do Composite Materials Play in LINAK Actuators?

Composite materials combine the benefits of different materials, often pairing lightweight fibers with resins to create strong, durable components. They can handle temperatures up to 200°C and offer excellent corrosion resistance.

Pros: Composites are highly customizable, allowing for tailored properties such as increased strength or reduced weight. They are also resistant to corrosion and chemicals, making them suitable for various applications.

Cons: The manufacturing process for composites can be complex and costly, potentially leading to higher prices. Additionally, they may not be as widely available as traditional materials.

Impact on Application: Composites are particularly beneficial in specialized applications, such as aerospace or advanced medical devices, where performance is paramount. Buyers should consider the specific certifications required for composite materials in their region.

Summary Table of Material Selection for LINAK Actuators

| Material | Typical Use Case for LINAK Actuator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Adjustable furniture, medical devices | Lightweight and cost-effective | Susceptible to galvanic corrosion | Medium |

| Stainless Steel | Industrial, agricultural applications | High strength and corrosion resistance | Higher cost and heavier | High |

| Plastic | Home and office furniture | Low-cost and design flexibility | Less durable and lower temperature rating | Low |

| Composite | Aerospace, advanced medical devices | Customizable and corrosion-resistant | Complex manufacturing process | High |

This material selection guide provides valuable insights for B2B buyers looking to optimize the performance and suitability of LINAK actuators across various applications. Understanding the properties and implications of each material can help in making informed purchasing decisions that align with specific operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for linak actuator

What Are the Main Stages of Manufacturing LINAK Actuators?

The manufacturing process of LINAK actuators involves several critical stages that ensure both efficiency and quality. These stages include material preparation, forming, assembly, and finishing, each employing advanced techniques and technologies tailored to meet the specifications required for various applications.

How Is Material Prepared for LINAK Actuators?

Material preparation is the foundational step in the manufacturing of LINAK actuators. High-quality raw materials such as aluminum, steel, and polymers are sourced from trusted suppliers. These materials undergo rigorous inspections to ensure they meet predefined standards before they are accepted into the production line. Advanced cutting and machining processes are then employed to shape the materials according to the actuator design specifications, ensuring precision and durability.

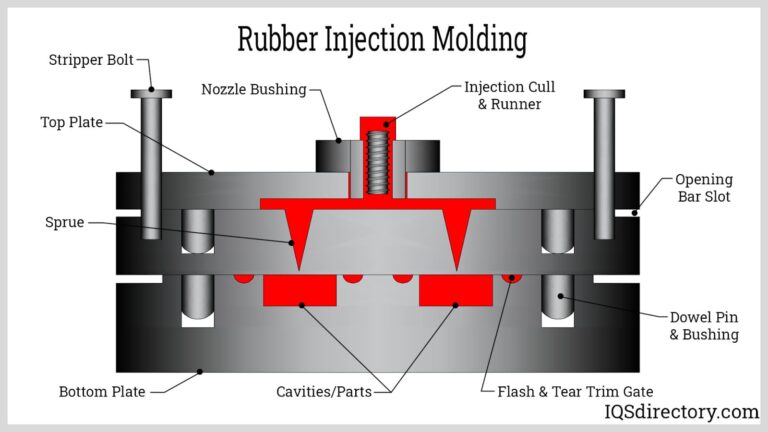

What Forming Techniques Are Used in LINAK Actuator Manufacturing?

In the forming stage, various techniques are utilized to create the components of the actuator. Techniques such as extrusion, injection molding, and stamping are commonly used depending on the specific part being produced. For example, aluminum profiles for the actuator housing may be extruded, while internal components like gears and housing parts may be produced using injection molding. These methods are selected based on their ability to produce high-volume parts with consistent quality, crucial for maintaining performance across LINAK’s product range.

How Is the Assembly Process Structured for LINAK Actuators?

Once the individual components are formed, they move into the assembly stage. This process is meticulously organized to ensure each actuator is assembled correctly and efficiently. Automated assembly lines and skilled technicians work in tandem to fit components together, integrating advanced technologies such as robotic arms for precision tasks. Each actuator is equipped with various control systems, including handsets and integrated controllers, which are also assembled during this stage. This integration is critical, as it directly impacts the actuator’s performance and reliability.

What Finishing Processes Are Employed for LINAK Actuators?

The finishing stage involves several processes designed to enhance the actuator’s durability and aesthetics. Surface treatments such as anodizing or powder coating are applied to prevent corrosion and wear, ensuring that the actuators can withstand harsh environmental conditions. Additionally, final inspections are conducted to ensure that all components meet the specified tolerances and quality standards before the products are packaged for shipment.

How Is Quality Assurance Ensured in LINAK Actuator Manufacturing?

Quality assurance is paramount in the manufacturing of LINAK actuators, ensuring that each product meets both international standards and industry-specific requirements. The quality control process is integrated throughout each stage of manufacturing, employing various checkpoints and testing methodologies.

Which International Standards Govern LINAK Actuator Quality?

LINAK adheres to international quality management standards such as ISO 9001, which outlines the criteria for a quality management system. This certification ensures that LINAK maintains a consistent level of quality in its products and services. Additionally, actuators may need to comply with industry-specific standards such as CE marking for European markets and API standards for certain industrial applications, ensuring safety and reliability in their use.

What Are the Key Quality Control Checkpoints in LINAK Manufacturing?

Quality control is implemented at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components before they enter the production line. Ensuring that materials meet specified criteria helps prevent defects later in the process.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the assembly process and ensure adherence to specifications. This includes checking tolerances and functionality at various stages of assembly.

-

Final Quality Control (FQC): Once assembly is complete, every actuator undergoes a thorough final inspection to assess functionality, performance, and aesthetic quality. This stage often includes functional testing under simulated conditions to guarantee reliability.

What Common Testing Methods Are Used for LINAK Actuators?

Testing methods play a crucial role in validating the performance and durability of LINAK actuators. Common testing techniques include:

-

Load Testing: Actuators are subjected to maximum load conditions to ensure they can handle specified weights without failure.

-

Cycle Testing: This involves operating the actuator through its full range of motion repeatedly to assess durability and performance over time.

-

Environmental Testing: Actuators may be exposed to extreme temperatures, humidity, and other environmental factors to ensure they perform reliably in various conditions.

How Can B2B Buyers Verify Quality Control in LINAK Actuator Suppliers?

For B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical. Here are several approaches to ensure that suppliers maintain high-quality standards:

What Role Do Audits and Reports Play in Supplier Quality Verification?

Conducting audits is one of the most effective methods for verifying supplier quality control. B2B buyers can request quality assurance audits from LINAK or conduct their own assessments to evaluate compliance with international standards and internal quality protocols. Additionally, suppliers should provide detailed quality control reports that outline testing results, compliance certifications, and any corrective actions taken in response to identified issues.

How Do Third-Party Inspections Enhance Quality Assurance for B2B Buyers?

Engaging third-party inspection agencies can further bolster confidence in a supplier’s quality control processes. These agencies conduct independent assessments and testing, providing unbiased evaluations of the supplier’s adherence to specified quality standards. This is particularly valuable for international buyers who may not have the resources to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control that can vary by region. For instance, different countries may have unique regulatory requirements or industry standards that affect product compliance. Understanding these regulations is essential for ensuring that purchased actuators meet local market requirements.

Additionally, cultural differences in business practices can influence quality perceptions. Buyers should establish clear communication with suppliers regarding quality expectations and standards, ensuring alignment throughout the procurement process.

Conclusion

In summary, the manufacturing and quality assurance processes for LINAK actuators are designed to ensure the highest levels of performance, safety, and reliability. By understanding these processes and verification methods, international B2B buyers can make informed decisions when selecting LINAK as their actuator supplier, ensuring that they receive products that meet their specific needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘linak actuator’

This guide is designed to help B2B buyers navigate the process of sourcing LINAK actuators effectively. By following these steps, you can ensure that you select the right actuator solutions tailored to your specific needs while establishing a reliable partnership with your supplier.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes understanding the force capacity, stroke length, speed, and voltage specifications that your application demands. Knowing these details will help you communicate effectively with potential suppliers and ensure that you receive the most suitable actuator for your needs.

- Key specifications to consider:

- Load capacity (e.g., 40 kg to 1,500 kg)

- Stroke length options

- Operating voltage (12V, 24V, 48V)

Step 2: Conduct Market Research on Suppliers

Investigate various suppliers to identify reputable manufacturers of LINAK actuators. Pay attention to their product offerings, industry experience, and geographical presence. A strong supplier network will ensure timely delivery and support, especially if you are sourcing from regions like Africa, South America, or the Middle East.

- What to look for:

- Industry certifications and compliance with international standards

- Customer reviews and testimonials

- A diverse product range to meet various applications

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, case studies, and references from clients in your industry. Assess their responsiveness and willingness to customize products based on your specific needs.

- Important considerations:

- Check for a robust support system, including technical assistance and after-sales service

- Explore their manufacturing capabilities and lead times for custom orders

Step 4: Request Quotes and Compare Pricing

Reach out to multiple suppliers for quotes on the actuators that fit your specifications. Comparing prices is crucial, but also consider the total cost of ownership, which includes shipping, installation, and maintenance.

- What to include in your request:

- Detailed specifications for the actuator

- Quantity needed and expected delivery timeline

- Inquiry about bulk pricing or discounts for long-term contracts

Step 5: Assess Customization Options

Many applications require actuators to be customized. Ensure that your chosen supplier can accommodate modifications in design or functionality. This could include unique stroke lengths, force requirements, or integration with existing systems.

- Customization considerations:

- Availability of tailored solutions to fit specific applications

- Flexibility in adapting to future changes in your operational needs

Step 6: Verify Supplier Certifications

Confirm that your selected suppliers have the necessary certifications, especially if you’re in regulated industries such as healthcare or automotive. This ensures compliance with safety and quality standards, minimizing risks associated with product failure.

- Key certifications to check:

- ISO standards relevant to actuator manufacturing

- Compliance with industry-specific regulations (e.g., medical device standards)

Step 7: Establish a Communication Plan

Once you’ve selected a supplier, establish a clear communication plan to facilitate smooth interactions throughout the procurement process. This includes defining points of contact for technical support, order updates, and any issues that may arise.

- Effective communication practices:

- Regular check-ins during the production phase

- Clear escalation paths for addressing concerns or delays

By following this structured approach, you can confidently source LINAK actuators that meet your operational requirements while building a strong partnership with your supplier.

Comprehensive Cost and Pricing Analysis for linak actuator Sourcing

What Are the Key Cost Components in LINAK Actuator Pricing?

When sourcing LINAK actuators, understanding the cost structure is crucial. The primary components contributing to the overall cost include:

-

Materials: The raw materials used in manufacturing LINAK actuators significantly affect pricing. High-quality components such as steel, plastics, and electronic parts can increase costs but ensure durability and performance.

-

Labor: Labor costs vary based on the region and the complexity of the actuator design. Skilled labor is essential for assembly and quality control, impacting the final price.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. These overhead costs can vary between manufacturers and regions, influencing the overall pricing strategy.

-

Tooling: Custom tooling for specific actuator designs can be expensive. If a buyer requires unique specifications, the tooling costs must be factored into the overall price.

-

Quality Control (QC): Rigorous testing and compliance with international standards, especially for medical applications, add to the manufacturing costs. Buyers should expect to pay a premium for actuators that meet stringent quality certifications.

-

Logistics: Shipping costs, including freight and insurance, are significant, particularly for international shipments. The choice of Incoterms can also affect the total cost, with options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) impacting pricing.

-

Margin: Suppliers will include their profit margin in the final price. This can vary widely based on the supplier’s market positioning and perceived value of their products.

How Do Volume and Customization Affect LINAK Actuator Prices?

Pricing for LINAK actuators is heavily influenced by order volume and customization requirements.

-

Volume/MOQ (Minimum Order Quantity): Bulk orders typically lead to lower per-unit costs. Suppliers often provide discounts for larger quantities, which can be a significant cost-saving opportunity for buyers.

-

Specifications and Customization: Custom features, such as specific stroke lengths, voltage options, or unique design requirements, can substantially increase costs. Buyers should carefully assess their needs against available standard options to optimize spending.

What Quality and Certification Factors Should Buyers Consider?

Quality and certification play pivotal roles in actuator sourcing.

-

Material Quality: Actuators made from higher-quality materials typically command higher prices but offer better performance and longevity. Buyers should evaluate the material specifications and lifecycle costs.

-

Certifications: Compliance with industry standards, particularly in healthcare and industrial applications, can influence price. Actuators that meet international standards may be priced higher due to the added testing and certification processes.

What Are the Best Negotiation Tips for B2B Buyers?

Negotiating effectively can yield significant savings. Here are some tips for international buyers:

-

Understand Total Cost of Ownership (TCO): Calculate the TCO, which includes purchase price, operational costs, maintenance, and potential downtime. A higher initial investment may lead to lower operational costs over time.

-

Leverage Volume Discounts: When possible, commit to larger orders to negotiate better pricing. Suppliers are often willing to offer lower prices for guaranteed business.

-

Discuss Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to better pricing and more favorable terms in the future.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, import tariffs, and shipping costs, as these can affect the overall price.

What Should International Buyers Keep in Mind Regarding Pricing?

For buyers from regions such as Africa, South America, the Middle East, and Europe, consider the following:

-

Local Supplier Options: Research local suppliers who may offer competitive pricing due to reduced shipping and logistics costs.

-

Cultural Negotiation Styles: Different regions have varying negotiation styles. Understanding these can help in achieving better deals.

-

Regulatory Compliance: Ensure that products meet local regulations, as non-compliance can lead to additional costs and delays.

Disclaimer on Indicative Prices

Prices for LINAK actuators can vary widely based on the factors discussed above. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing linak actuator With Other Solutions

Understanding Alternatives to Linak Actuators

When considering electric linear actuators for industrial, medical, or consumer applications, it’s essential to explore various alternatives that can meet similar needs. Evaluating these options helps buyers make informed decisions based on performance, cost, and other critical factors. Below is a comparison of Linak actuators against two viable alternatives: pneumatic actuators and hydraulic actuators.

| Comparison Aspect | Linak Actuator | Pneumatic Actuator | Hydraulic Actuator |

|---|---|---|---|

| Performance | High precision and reliability for various loads (40 kg to 1,500 kg). | Suitable for high-speed applications but less precise. | High force and torque, suitable for heavy loads but can be less precise. |

| Cost | Moderate initial investment; long-term savings due to low maintenance. | Generally lower initial costs but can incur higher operational costs due to air supply. | Higher initial investment and ongoing maintenance costs due to fluid management. |

| Ease of Implementation | Plug-and-play solutions with easy installation. | Requires air compressor and plumbing, complicating installation. | Requires hydraulic systems and can be complex to set up. |

| Maintenance | Low maintenance; minimal wear and tear. | Regular maintenance needed for air leaks and compressor upkeep. | High maintenance due to potential leaks and fluid management. |

| Best Use Case | Ideal for applications needing precise control and low noise, like medical devices. | Best for applications requiring rapid movement and moderate load, such as packaging. | Excellent for heavy-duty applications like construction machinery and industrial presses. |

In-Depth Analysis of Alternatives

Pneumatic Actuators

Pneumatic actuators operate using compressed air, making them suitable for applications that require fast actuation. They excel in environments where speed is critical, such as in packaging and assembly lines. However, their performance can be inconsistent due to variations in air pressure, which may lead to lower precision compared to electric actuators like Linak. Additionally, pneumatic systems require an air compressor and plumbing, making installation more complex and potentially increasing the overall cost of ownership.

Hydraulic Actuators

Hydraulic actuators utilize pressurized hydraulic fluid to generate motion, providing immense power and torque, ideal for heavy-duty applications. They are commonly used in industries such as construction and manufacturing, where high force is necessary. However, these systems come with a higher initial investment and ongoing maintenance costs. Hydraulic systems can also present challenges, such as leaks and the need for fluid management, which can complicate their implementation compared to the straightforward installation of Linak actuators.

Choosing the Right Solution for Your Needs

When selecting the appropriate actuator for your application, consider your specific requirements, including the necessary precision, load capacity, installation complexity, and long-term maintenance. Linak actuators offer a balanced solution with high precision, low noise, and minimal maintenance, making them suitable for various applications, especially in healthcare and comfort furniture. In contrast, pneumatic and hydraulic actuators may provide advantages in speed and power but come with higher maintenance needs and complexity. By understanding these differences, B2B buyers can make a well-informed choice that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for linak actuator

What Are the Key Technical Properties of LINAK Actuators?

When evaluating LINAK actuators for your business needs, understanding their technical properties is essential. Here are some critical specifications to consider:

Illustrative image related to linak actuator

-

Load Capacity (Force)

LINAK actuators are designed to handle a wide range of loads, from 400 N to 15,000 N (approximately 40 kg to 1,500 kg). This specification is crucial for B2B buyers as it determines the actuator’s suitability for various applications, such as healthcare equipment, industrial machinery, or agricultural tools. Selecting an actuator that can support the required load ensures safety and operational efficiency. -

Stroke Length

The stroke length refers to the distance the actuator can extend or retract, typically customized to meet specific application requirements. Common stroke lengths vary, and understanding this property allows buyers to select actuators that fit seamlessly into their designs, enhancing functionality and performance. -

Speed (mm/s)

Actuator speed is a vital property, with LINAK models offering speeds of up to 160 mm/s. This specification impacts the responsiveness of the actuator in real-time applications, such as adjustable hospital beds or automated industrial processes. Choosing the right speed ensures that equipment operates efficiently and meets user expectations. -

Voltage Options

LINAK actuators are available in various voltage options, including 12V, 24V, and 48V. This flexibility allows for compatibility with different power supply systems, making it easier for international buyers to integrate these actuators into existing infrastructure. Understanding voltage requirements is essential for ensuring reliable performance and compliance with local electrical standards. -

Customization Capabilities

LINAK offers extensive customization options, enabling buyers to tailor actuators to specific operational needs, including control systems, connectors, and other functionalities. This adaptability is particularly beneficial in B2B scenarios, where unique applications often require bespoke solutions for optimal performance.

What Are Common Trade Terminology and Jargon Related to LINAK Actuators?

Navigating the procurement process involves familiarizing yourself with industry-specific terminology. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of LINAK actuators, businesses often partner with OEMs to integrate actuators into their products, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ specifies the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it directly impacts inventory management and cost-effectiveness. Buyers should consider their project scale when negotiating MOQ with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing and other relevant information for specific products or services. In the case of LINAK actuators, issuing an RFQ can help buyers compare options, negotiate better terms, and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the delivery of goods. Familiarity with these terms is crucial for international transactions, as they clarify aspects such as shipping costs, risks, and responsibilities, ensuring smoother logistics in acquiring LINAK actuators. -

Integrated Controller (IC)

The Integrated Controller is a built-in component of LINAK actuators that enhances functionality by providing features such as position feedback, speed control, and safety limits. Understanding this term is essential for buyers looking for advanced actuator solutions that improve automation and operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when integrating LINAK actuators into their products or systems, ultimately enhancing their operational capabilities and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the linak actuator Sector

What Are the Current Market Dynamics in the Linak Actuator Sector?

The global market for linear actuators is witnessing significant growth, driven by the increasing demand for automation across various industries. Key drivers include advancements in technology, rising labor costs, and a growing emphasis on efficiency and precision in manufacturing processes. In regions such as Africa and South America, where industrialization is on the rise, there is a burgeoning demand for electric linear actuators in sectors like agriculture, construction, and healthcare. Meanwhile, Europe, particularly Germany, is leveraging its strong manufacturing base to adopt innovative actuator solutions, emphasizing automation in both industrial and consumer applications.

Emerging technologies, including IoT integration and AI-driven automation, are reshaping the actuator landscape. B2B buyers are increasingly seeking actuators that offer enhanced control features, such as real-time monitoring and adaptive performance. Additionally, the shift towards modular and customizable actuator systems is gaining traction, allowing businesses to tailor solutions to specific operational needs. Companies are also focusing on value-added services, such as comprehensive support and training, to differentiate themselves in a competitive market.

How Is Sustainability Impacting Sourcing Trends in the Linak Actuator Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the linear actuator sector. As businesses face growing scrutiny over their environmental impact, the demand for ethically sourced materials and processes is intensifying. Electric linear actuators, known for their energy efficiency compared to hydraulic or pneumatic systems, are being favored for their lower carbon footprint. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and implementing energy-efficient manufacturing processes.

Ethical supply chains are increasingly important, as they not only enhance brand reputation but also mitigate risks associated with regulatory compliance and consumer backlash. Buyers are looking for manufacturers with certifications that validate their environmental claims, such as ISO 14001 for effective environmental management. Additionally, sourcing from suppliers who adopt renewable energy sources in their production processes is becoming a key factor in decision-making. As a result, the linak actuator sector is evolving to meet these demands, ensuring that sustainability is integrated into product development and supply chain management.

What Is the Historical Context of the Linak Actuator Industry?

The evolution of the linear actuator industry traces back to the early 20th century, primarily driven by the need for automation in manufacturing and industrial applications. Initially dominated by hydraulic and pneumatic systems, the market began shifting towards electric solutions in the latter half of the century, as advancements in electric motor technology made electric actuators more viable and efficient. Companies like LINAK emerged as pioneers in developing electric linear actuator systems, focusing on precision and reliability.

Over the decades, the industry has seen significant technological advancements, such as the integration of smart controls and IoT capabilities, which have further enhanced the functionality and applicability of linear actuators. This evolution reflects a broader trend in manufacturing and automation, where the focus has shifted towards intelligent systems that improve operational efficiency while reducing environmental impact. As the industry continues to innovate, the future of linear actuators looks promising, with opportunities for further growth in diverse sectors, including healthcare, agriculture, and industrial automation.

Frequently Asked Questions (FAQs) for B2B Buyers of linak actuator

-

How do I select the right LINAK actuator for my application?

Choosing the right LINAK actuator involves assessing your specific application requirements, such as load capacity, speed, stroke length, and environment. Review the various models available, including compact and robust options, to find one that meets your needs. Consult with LINAK specialists for tailored advice based on your application, whether it’s in healthcare, industrial automation, or comfort furniture. You can also utilize LINAK’s 3D configurator to visualize your actuator selection, ensuring it aligns with your project specifications. -

What customization options are available for LINAK actuators?

LINAK offers extensive customization options to meet diverse application needs. You can specify stroke lengths, force requirements, voltage types (12V, 24V, or 48V), and even control features like integrated controllers. Discuss your unique requirements with LINAK’s engineers to develop a solution that fits your specifications. Customization can enhance performance, reliability, and integration into existing systems, making it an essential consideration for B2B buyers. -

What are the minimum order quantities (MOQ) for LINAK actuators?

Minimum order quantities (MOQ) for LINAK actuators can vary based on the specific model and customization options chosen. It is advisable to contact LINAK directly or your local distributor for precise MOQ details tailored to your requirements. Understanding the MOQ is crucial for budgeting and inventory planning, especially for international buyers looking to streamline their supply chain. -

What payment terms do LINAK offer for international orders?

Payment terms for international orders with LINAK typically vary based on the buyer’s location and the size of the order. Common terms include advance payment, letter of credit, or payment upon delivery. It’s essential to clarify payment options during negotiations to ensure smooth transactions. Always review terms and conditions thoroughly to avoid any unexpected costs or delays. -

How does LINAK ensure quality assurance for their actuators?

LINAK employs a rigorous quality assurance process that includes extensive testing to guarantee the performance and durability of their actuators. Each actuator undergoes full function tests before leaving the production line, ensuring compliance with international standards. This commitment to quality helps mitigate risks for B2B buyers, assuring that the actuators will perform reliably in their intended applications. -

What logistics support does LINAK provide for international shipping?

LINAK has a well-established logistics network to support international shipping efficiently. They work closely with reliable freight forwarders to ensure timely delivery, regardless of the buyer’s location. Additionally, LINAK can assist with customs documentation and provide insights into import regulations specific to your region. Engaging with LINAK’s logistics team can help streamline your supply chain and minimize potential delays. -

What technical support does LINAK offer post-purchase?

Post-purchase, LINAK provides comprehensive technical support through a dedicated team of experts, including application engineers and customer service representatives. Buyers can access technical documentation, installation guides, and troubleshooting resources on LINAK’s website. For specific queries, direct communication with LINAK specialists can facilitate quick resolutions, ensuring your actuator operates effectively in your application. -

How can I stay updated on LINAK’s product innovations and industry trends?

To stay informed about LINAK’s latest innovations and industry trends, subscribe to their newsletter and follow them on social media platforms. Additionally, explore the LINAK Actuator Academy for educational resources, including videos and webinars that cover technology advancements and best practices. Engaging with LINAK’s community and resources will provide valuable insights to enhance your product offerings and competitive edge in the market.

Top 6 Linak Actuator Manufacturers & Suppliers List

1. LINAK – LA18 IC Standard Actuator System

Domain: linak.com

Registered: 1996 (29 years)

Introduction: LA18 IC Standard is a LINAK® actuator system designed for adjustable comfort beds. It consists of one primary actuator and one or more secondary actuators, capable of performing 6,000 N push. The system features a compact design with a click-on back fixture for easy installation. It includes integrated Bluetooth® technology and a green power indicator light. The system supports wireless control vi…

2. Linak – LA23 2 SET Linear Actuator

Domain: lineardirect.eu

Introduction: {“products”:[{“name”:”Linak LA23 2 SET linear actuator”,”stroke”:”150 mm”,”force”:”up to 5000 N”,”components”:[“2x Linak LA23 stroke 150 mm”,”2x motor cable 1 m”,”1x control unit CBD6S 2-fold”,”1x power cable”,”1x hand switch”],”price”:”€659.00*”},{“name”:”Linak LA23 DESKLINE® adjustment drive”,”stroke”:”150 mm”,”force”:”up to 2500 N”,”description”:”small and powerful push or pull actuator suitabl…

3. Linak – Linear Actuators

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Linak Linear Actuators for sale on eBay. Related searches include THK Industrial Linear Actuators, 200mm Stroke Linear Actuators, 150mm Linear Actuators, and 250mm Stroke Linear Actuators. Categories include Industrial Automation & Motion Controls, Rotary & Linear Motion, and specific items like Bearing Blocks & Supports, Lead, Ball & Roller Screws, and Linear Actuator Controls. The brand featured…

4. Linak – Positioning Drivers

Domain: linakthirdparty.com

Registered: 2014 (11 years)

Introduction: {“products”:[{“name”:”TR-EM-165 Positioning Driver”,”description”:”For controlling a DC-motor, suitable for slow and medium speed systems.”},{“name”:”TR-EM-167 Positioning Driver”,”description”:”Capable of driving a DC motor, suitable for slow and medium speed systems.”},{“name”:”TR-EM-208 Single Motor Control Unit”,”description”:”Protects against overload, features soft start/stop.”},{“name”:”TR-…

5. LinaK – Actuator 1

Domain: medproshop.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “LinaK Actuator 1”, “Price”: “$250.00”, “Max Load Push”: “6000 N”, “IP Rating”: “IPX1”, “Voltage”: “24Volt”, “Current”: “4.3AMP”, “Stock”: “2 in stock”, “Type”: “311100+0011500X”, “Item Number”: “310077-01”, “Tags”: [“Actuator”, “LinaK”, “Medical”, “medical equipment”]}

6. Airoil – High Quality Linear Actuator Solutions

Domain: airoil.com

Registered: 1996 (29 years)

Introduction: High Quality Linear Actuator Solutions: Linear actuators convert rotational motion in motors into linear push-and-pull movements, ideal for applications requiring tilting, lifting, pulling, or pushing with force. Electric linear actuators provide simple, safe, and clean movement with precise control. Available variants include 12V, 24V, 36V, and 48V. LINAK has led the industry since 1979, focusing…

Strategic Sourcing Conclusion and Outlook for linak actuator

In today’s competitive landscape, strategic sourcing of LINAK actuators can significantly enhance operational efficiency and product quality across diverse industries. By leveraging LINAK’s extensive range of electric linear actuators, businesses can benefit from tailored solutions that meet specific application requirements, whether in healthcare, industrial automation, or comfort furniture. The ability to customize actuators for various speeds, capacities, and functionalities underscores the importance of aligning sourcing strategies with operational needs.

Moreover, LINAK’s commitment to innovation and sustainability positions it as a reliable partner for businesses aiming to enhance productivity while adhering to environmental standards. International buyers from Africa, South America, the Middle East, and Europe can take advantage of LINAK’s global manufacturing capabilities and localized support, ensuring timely delivery and expert assistance.

As you consider your next sourcing decision, remember that investing in high-quality LINAK actuators not only meets immediate operational demands but also prepares your business for future advancements in automation and ergonomics. Embrace the potential of LINAK actuators to drive your projects forward—connect with a LINAK representative today to explore customized solutions that fit your unique requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.