The Definitive Guide to Komatsu 7861-93-4520: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for komatsu 7861-93-4520

In today’s competitive landscape, sourcing essential components like the Komatsu 7861-93-4520 oil pressure switch can pose significant challenges for international B2B buyers. Factors such as varying quality standards, regional supplier reliability, and fluctuating shipping costs can complicate the procurement process, particularly for businesses operating across diverse markets in Africa, South America, the Middle East, and Europe. This guide aims to simplify these complexities by providing comprehensive insights into the Komatsu 7861-93-4520, detailing its applications, compatibility with various machinery, and key specifications that buyers need to consider.

Throughout this guide, we will explore the different types of oil pressure switches, their critical roles in monitoring hydraulic and engine oil pressure, and how they contribute to the overall efficiency and safety of heavy equipment. Additionally, we will cover essential aspects of supplier vetting, helping you identify reputable sources that meet your operational standards and budgetary constraints. With insights into pricing trends and shipping logistics, this guide empowers B2B buyers to make informed purchasing decisions, ensuring they can secure high-quality parts without unnecessary delays or costs. By equipping you with the necessary knowledge and tools, we aim to enhance your sourcing strategy for the Komatsu 7861-93-4520, ultimately driving operational success and reliability in your heavy machinery fleet.

Understanding komatsu 7861-93-4520 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrical Oil Pressure Switch | Monitors hydraulic or engine oil pressure; OEM standard fitting | Komatsu wheel loaders, excavators (e.g., PC400-7) | Pros: Reliable performance; Cons: Higher initial cost |

| Pressure Sensor | Calibrated to OEM specifications; corrosion-resistant housing | Heavy machinery monitoring (e.g., PC2000-8) | Pros: Accurate readings; Cons: Installation complexity |

| Hydraulic Pressure Switch | Designed for hydraulic systems; real-time signal transmission | Excavators and bulldozers (e.g., D155AX) | Pros: Critical for machinery safety; Cons: Limited lifespan |

| Engine Oil Pressure Sensor | Integrated into engine systems; alerts for abnormal pressure | Construction and mining equipment | Pros: Protects engine health; Cons: May require frequent checks |

| Multi-Compatibility Sensor | Fits various Komatsu models; adaptable connector types | Diverse machinery applications | Pros: Versatile use; Cons: Potential compatibility issues |

What Are the Key Features of the Electrical Oil Pressure Switch 7861-93-4520?

The Electrical Oil Pressure Switch 7861-93-4520 is essential for monitoring hydraulic or engine oil pressure in Komatsu machinery. Its OEM-standard fitting ensures compatibility with a variety of models, including popular wheel loaders and excavators. This switch provides reliable performance, crucial for maintaining operational efficiency. However, the higher initial cost may deter some budget-conscious buyers.

How Does the Pressure Sensor Support Heavy Machinery?

The Pressure Sensor variant of the 7861-93-4520 is specifically calibrated to meet OEM specifications, featuring a corrosion-resistant metal housing that enhances durability in harsh environments. It is widely used in heavy machinery, particularly excavators like the PC2000-8. While it delivers accurate pressure readings that are vital for performance, the installation process can be complex, necessitating skilled technicians.

Why Choose the Hydraulic Pressure Switch for Your Equipment?

Designed primarily for hydraulic systems, the Hydraulic Pressure Switch variant provides real-time signals to alert operators of low or abnormal pressure. This feature is critical for preventing potential failures in excavators and bulldozers, such as the D155AX. While it plays a significant role in maintaining machinery safety, its limited lifespan can be a concern for operators seeking long-term reliability.

What Role Does the Engine Oil Pressure Sensor Play?

The Engine Oil Pressure Sensor integrated into the Komatsu systems is responsible for monitoring oil pressure and alerting operators to any abnormalities. This sensor is integral to protecting the engine’s health, making it indispensable in construction and mining equipment. Although it is essential for operational safety, it may require frequent checks to ensure optimal functionality.

How Does the Multi-Compatibility Sensor Benefit B2B Buyers?

The Multi-Compatibility Sensor version of the 7861-93-4520 is designed to fit various Komatsu models, offering adaptability with different connector types. This versatility makes it an attractive option for businesses that operate a diverse fleet of machinery. While it provides broad applicability, potential compatibility issues may arise, necessitating careful verification before purchase.

Key Industrial Applications of komatsu 7861-93-4520

| Industry/Sector | Specific Application of komatsu 7861-93-4520 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Monitoring hydraulic pressure in excavators and loaders | Enhances operational safety and equipment longevity | OEM compatibility, warranty options, and lead times |

| Mining | Engine oil pressure monitoring in heavy machinery | Prevents costly breakdowns and operational delays | Quality assurance, availability of parts, and shipping |

| Agriculture | Hydraulic system pressure monitoring in tractors | Improves efficiency and reduces maintenance costs | Supplier reliability, international shipping capabilities |

| Infrastructure Development | Oil pressure monitoring in road construction equipment | Ensures optimal performance and reduces downtime | Compliance with local regulations and certifications |

| Waste Management | Monitoring pressure in waste handling machinery | Increases reliability and operational efficiency | After-sales support and ease of part replacement |

In the construction industry, the komatsu 7861-93-4520 plays a critical role in monitoring hydraulic pressure in excavators and loaders. By providing real-time feedback on hydraulic systems, this oil pressure switch helps operators avoid unsafe operating conditions, thereby enhancing the safety of the equipment and extending its service life. For international buyers, ensuring OEM compatibility and understanding warranty options are essential for maintaining equipment reliability.

In the mining sector, the sensor is utilized to monitor engine oil pressure in heavy machinery, such as haul trucks and excavators. This application is vital for preventing costly breakdowns and unplanned operational delays, which can significantly impact productivity. Buyers should prioritize sourcing high-quality, OEM-standard products to ensure optimal performance in demanding environments.

In agriculture, the komatsu 7861-93-4520 is crucial for monitoring hydraulic system pressure in tractors and other farm equipment. By ensuring that the hydraulic systems operate within the appropriate pressure range, farmers can enhance the efficiency of their machinery while reducing maintenance costs. Buyers from regions with large agricultural sectors should consider supplier reliability and the availability of parts for seamless operations.

For infrastructure development, this sensor is essential for monitoring oil pressure in road construction equipment. Accurate pressure readings help ensure that machinery operates at peak performance, reducing the risk of equipment failure and downtime. Buyers must be aware of local regulations and certifications that may affect sourcing decisions, especially in regions with stringent compliance requirements.

Lastly, in the waste management sector, the komatsu 7861-93-4520 assists in monitoring pressure in waste handling machinery. This application increases the reliability of equipment, ensuring that waste collection and processing operations run smoothly. Businesses should look for suppliers that offer robust after-sales support and easy part replacement options to minimize operational disruptions.

3 Common User Pain Points for ‘komatsu 7861-93-4520’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine Parts for Komatsu Equipment

The Problem: B2B buyers, especially in regions like Africa and South America, often struggle to find authentic parts for their Komatsu machinery. The challenge is compounded by the prevalence of counterfeit products in the market, which can lead to operational inefficiencies and increased maintenance costs. Buyers may feel overwhelmed by the options available online, unsure which suppliers are reliable and which parts will meet OEM specifications. This uncertainty can cause delays in equipment repairs, leading to downtime and loss of productivity.

The Solution: To ensure the authenticity of the Komatsu 7861-93-4520 oil pressure switch, buyers should prioritize sourcing from established dealers or authorized distributors. Utilizing platforms like My Komatsu can streamline the purchasing process, as they are directly linked to the manufacturer and guarantee OEM quality. It’s advisable to request documentation or certifications that verify the authenticity of the parts. Additionally, forming relationships with trusted local suppliers who have a proven track record can offer peace of mind and faster access to parts when needed. Conducting thorough research on suppliers, including checking customer reviews and ratings, can further mitigate risks.

Scenario 2: Challenges with Installation and Compatibility Issues

The Problem: Another common pain point for buyers is the installation of the Komatsu 7861-93-4520 switch, especially when it comes to compatibility with existing machinery. Buyers may face difficulties ensuring that the part fits their specific model, such as various excavators or wheel loaders. Incorrect installation or compatibility can lead to malfunctioning systems, which not only affects equipment performance but also poses safety risks on job sites.

The Solution: To address these concerns, buyers should meticulously cross-reference the part number 7861-93-4520 with their equipment’s specifications before purchasing. Consulting the machinery’s manual can provide insights into compatibility and installation requirements. For those unfamiliar with installation processes, seeking assistance from certified technicians or consulting with the supplier’s technical support can be invaluable. Many suppliers also offer installation guides or videos, which can simplify the process. Moreover, leveraging the expertise of local Komatsu service centers can ensure the part is installed correctly, thus enhancing equipment reliability and safety.

Scenario 3: Uncertainty Over Warranty and Post-Purchase Support

The Problem: After investing in critical components like the Komatsu 7861-93-4520, buyers may experience anxiety regarding the warranty and post-purchase support. Questions often arise about the length of the warranty, coverage specifics, and how to handle potential issues that may arise after installation. This uncertainty can be particularly troubling for companies operating on tight budgets, as unexpected failures can lead to costly repairs and operational delays.

The Solution: Buyers should take the initiative to clarify warranty terms before completing a purchase. Engaging with the supplier to understand the warranty coverage on the 7861-93-4520 can provide reassurance. It’s important to document all communications and save purchase receipts, as they are crucial for warranty claims. Additionally, establishing a relationship with the supplier for ongoing support can facilitate quicker resolutions should issues arise. Many suppliers, such as IMARA Engineering Supplies, offer comprehensive customer service and support, making it easier for buyers to address concerns post-purchase. Regular maintenance and periodic checks can also preemptively identify issues, ensuring that the equipment continues to operate efficiently.

Strategic Material Selection Guide for komatsu 7861-93-4520

What Are the Key Materials Used in the Komatsu 7861-93-4520 Oil Pressure Switch?

The Komatsu 7861-93-4520, an essential oil pressure switch for various Komatsu machinery, relies on specific materials that influence its performance, durability, and suitability for different applications. Understanding these materials is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, where operational conditions may vary significantly.

1. Corrosion-Resistant Metal Alloys

Key Properties:

Corrosion-resistant metal alloys, often stainless steel or specialized coatings, are employed in the construction of the 7861-93-4520. These materials can withstand high temperatures and pressures, making them ideal for hydraulic systems that operate under extreme conditions.

Pros & Cons:

The primary advantage of these alloys is their durability and resistance to rust and corrosion, extending the lifespan of the sensor. However, they can be more expensive than standard metals and may require complex manufacturing processes, impacting overall production costs.

Impact on Application:

The use of corrosion-resistant alloys ensures that the sensor remains functional in harsh environments, such as those found in mining or construction sites. This material choice is crucial for maintaining the integrity of the hydraulic system and preventing failures.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM or DIN for material specifications. In regions like Europe, adherence to REACH regulations regarding chemical safety is also important.

2. Plastic Components

Key Properties:

High-grade plastics, often thermoplastics, are utilized for the housing and insulation components of the switch. These materials provide excellent electrical insulation and can operate effectively within a wide temperature range.

Pros & Cons:

Plastics are lightweight and cost-effective, which can reduce shipping costs and overall product pricing. However, they may not offer the same level of durability as metal components, particularly in high-stress environments.

Impact on Application:

The insulation properties of plastics help prevent electrical failures, ensuring that the sensor accurately monitors oil pressure. However, in extreme temperatures or exposure to certain chemicals, plastic components may degrade faster than their metal counterparts.

Considerations for International Buyers:

Buyers should verify that the plastics used meet local regulations regarding environmental safety, especially in regions with stringent environmental laws, such as the EU.

3. Sealing Materials

Key Properties:

Sealing materials, such as rubber or silicone, are critical for maintaining the integrity of the sensor against leakage. These materials must withstand various temperatures and pressures while remaining flexible.

Pros & Cons:

The primary advantage of high-quality sealing materials is their ability to provide a reliable barrier against contaminants, which is essential for the sensor’s performance. However, they can wear out over time, especially in harsh operating conditions, necessitating regular maintenance or replacement.

Impact on Application:

Effective sealing ensures that the sensor operates correctly by preventing oil leaks, which could lead to inaccurate readings or sensor failure. This is particularly important in hydraulic systems where precise pressure monitoring is vital.

Considerations for International Buyers:

Buyers should consider the compatibility of sealing materials with the specific oils and fluids used in their machinery. Compliance with international standards for material safety and performance is also crucial.

Summary Table of Material Selection for Komatsu 7861-93-4520

| Material | Typical Use Case for komatsu 7861-93-4520 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Corrosion-Resistant Metal Alloys | Sensor housing and internal components | High durability and corrosion resistance | Higher manufacturing costs | High |

| Plastic Components | Housing and insulation | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Sealing Materials | Preventing leaks in the sensor | Reliable barrier against contaminants | Wear over time, requiring maintenance | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in the Komatsu 7861-93-4520 oil pressure switch. Understanding these materials can help buyers make informed decisions, ensuring compatibility and performance in their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for komatsu 7861-93-4520

What Are the Key Stages in the Manufacturing Process of Komatsu 7861-93-4520?

The manufacturing of the Komatsu 7861-93-4520, an essential electrical part used in various heavy machinery, typically involves several critical stages. Each stage is designed to ensure the final product meets rigorous quality and performance standards.

Material Preparation: What Materials Are Used?

The initial stage of manufacturing begins with the careful selection of materials. For the Komatsu 7861-93-4520, corrosion-resistant metals are often chosen for their durability and ability to withstand harsh operational environments. These materials are subjected to stringent quality checks upon arrival to ensure they meet the required specifications.

Forming: How Is the Component Shaped?

In the forming stage, advanced techniques such as precision machining and stamping are utilized. These processes allow for the accurate shaping of components to exact specifications. High-precision CNC (Computer Numerical Control) machines are commonly employed to create the intricate designs needed for components like the oil pressure switch. This ensures that all parts fit together seamlessly during assembly.

Assembly: What Are the Key Techniques Used?

Once the individual components are formed, the assembly process begins. Automated assembly lines are often used to enhance efficiency and consistency. Components are assembled under controlled conditions to minimize contamination and ensure the integrity of electrical connections. Specialized tools and fixtures are employed to guarantee the correct alignment and secure fitting of parts.

Finishing: How Is the Product Prepared for Delivery?

The finishing stage involves surface treatments and coatings that enhance corrosion resistance and improve the overall durability of the product. Techniques such as anodizing or powder coating may be applied to ensure that the product can withstand the environmental conditions it will face in the field. Additionally, final inspections are conducted to confirm that all aesthetic and functional aspects meet the established standards.

How Is Quality Assurance Implemented in the Production of Komatsu 7861-93-4520?

Quality assurance is a critical aspect of the manufacturing process for the Komatsu 7861-93-4520, ensuring that each part meets international and industry-specific standards.

What International Standards Are Followed?

The manufacturing process adheres to recognized international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has established processes in place to ensure consistent quality. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the product’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages ensure that any deviations from standards are identified and corrected promptly.

- Final Quality Control (FQC): A comprehensive inspection of the finished product is conducted before packaging and shipment.

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the reliability and performance of the Komatsu 7861-93-4520. Common tests include:

- Functional Testing: Verifying that the sensor operates correctly under simulated conditions.

- Durability Testing: Assessing the product’s resistance to extreme temperatures, vibrations, and environmental factors.

- Electrical Testing: Ensuring proper electrical connectivity and signal transmission.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to ensure product reliability.

What Are the Key Steps in Supplier Audits?

Conducting supplier audits is a crucial step in assessing quality control measures. Buyers should:

- Request Documentation: Obtain quality management system certifications, inspection reports, and compliance documents.

- Conduct On-Site Audits: If feasible, visiting the manufacturing facility allows buyers to observe processes firsthand and assess compliance with quality standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

What Are the Nuances of Quality Certification for International Buyers?

B2B buyers should be aware of the nuances in quality certification when dealing with international suppliers. Different regions may have varying requirements and standards. For example, European buyers often prioritize CE certification, while buyers in the Middle East may look for compliance with local standards. Understanding these regional differences can help buyers make informed decisions.

Conclusion: Ensuring Quality and Reliability in Procurement

In summary, the manufacturing processes and quality assurance practices associated with the Komatsu 7861-93-4520 are designed to deliver high-quality, reliable components for heavy machinery. By understanding these processes and implementing thorough verification steps, B2B buyers can ensure they are sourcing products that meet their operational needs and standards. This diligence not only protects their investments but also enhances the performance and longevity of their machinery in the field.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘komatsu 7861-93-4520’

To assist B2B buyers in procuring the Komatsu 7861-93-4520, this guide outlines essential steps to ensure a successful sourcing process. By following this checklist, you can streamline your procurement efforts while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the Komatsu 7861-93-4520. This includes understanding its application in machinery such as excavators and wheel loaders, as well as its performance specifications. Having precise specifications helps in communicating your needs effectively to suppliers and ensures compatibility with your existing equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who offer the Komatsu 7861-93-4520. Look for companies that specialize in heavy machinery parts and have a solid reputation in the industry. Utilize online marketplaces, industry directories, and trade shows to gather a list of qualified suppliers.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your selected suppliers have the necessary certifications. Look for ISO certifications or other industry-specific credentials that demonstrate their commitment to quality and compliance with international standards. This step is crucial for ensuring you receive genuine parts that meet OEM specifications.

Step 4: Request Samples or Product Information

To assess the quality and compatibility of the Komatsu 7861-93-4520, request samples or detailed product information from your shortlisted suppliers. This may include technical datasheets, warranty details, and installation guides. Evaluating samples helps in making informed decisions about the quality and suitability of the parts.

Step 5: Inquire About Shipping and Delivery Options

Discuss shipping options with your suppliers to ensure timely delivery. Verify their capabilities for international shipping, especially if you are located in regions like Africa or South America. Understanding delivery timelines and costs upfront can help you plan your operations more effectively.

Step 6: Negotiate Payment Terms

Engage in discussions regarding payment terms and conditions. Look for suppliers that offer flexible payment options such as letters of credit, payment on delivery, or installment plans. Clear payment agreements can protect your financial interests and foster a trustworthy relationship with your supplier.

Step 7: Establish a Communication Plan

Set up a communication plan to maintain ongoing dialogue with your supplier throughout the procurement process. Regular check-ins can help address any issues that may arise and ensure that both parties are aligned on expectations. Effective communication is vital for a smooth transaction and successful partnership.

By following this practical sourcing guide, you can enhance your procurement process for the Komatsu 7861-93-4520, ensuring that you receive high-quality parts on time and at a competitive price.

Comprehensive Cost and Pricing Analysis for komatsu 7861-93-4520 Sourcing

What Are the Key Cost Components for Sourcing Komatsu 7861-93-4520?

When sourcing the Komatsu 7861-93-4520, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The sensor is typically constructed from corrosion-resistant materials to ensure durability in harsh operating conditions. Quality of materials directly influences both cost and performance.

-

Labor: Skilled labor is required for assembly and testing, affecting the overall cost. Labor costs can vary significantly based on the supplier’s location, impacting the final pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Initial tooling investments are necessary for the production of custom or high-volume orders. This one-time cost can be spread over larger order quantities, reducing the per-unit cost.

-

Quality Control: Ensuring the sensor meets OEM standards entails rigorous testing and inspection processes, which contribute to the overall cost.

-

Logistics: Shipping costs can vary based on distance, shipping method, and the chosen Incoterms. Understanding these factors can help in negotiating better shipping rates.

-

Supplier Margin: The profit margin charged by suppliers will vary based on their market positioning and the level of service provided.

How Do Price Influencers Affect the Cost of the Komatsu 7861-93-4520?

Several factors can influence the pricing of the Komatsu 7861-93-4520, especially for international B2B buyers.

-

Volume/MOQ: Larger order quantities typically lead to lower prices per unit due to economies of scale. Suppliers are often willing to negotiate pricing based on minimum order quantities (MOQs).

-

Specifications and Customization: Custom specifications or alterations can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality materials or specific certifications (e.g., ISO) can lead to increased costs. However, investing in quality can reduce long-term operational costs.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can affect pricing. Suppliers with a proven track record may charge a premium for their products.

-

Incoterms: The chosen Incoterms can significantly impact logistics costs and risk management. Understanding these terms is crucial for international buyers to avoid hidden fees.

What Are Some Effective Buyer Tips for Cost-Efficient Sourcing?

International B2B buyers should adopt strategic approaches to ensure cost-effective sourcing of the Komatsu 7861-93-4520.

-

Negotiation: Engage in open negotiations with suppliers. Leverage potential order volume and long-term relationships to secure better pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operational costs, and maintenance expenses. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Familiarize yourself with local market conditions and currency fluctuations, especially when sourcing from regions like Africa, South America, the Middle East, and Europe. This knowledge can provide leverage in negotiations.

-

Supplier Research: Conduct thorough research on potential suppliers. Reviews, certifications, and past performance can help assess reliability and quality, which ultimately impacts cost.

Disclaimer on Indicative Prices

Prices for the Komatsu 7861-93-4520 can vary widely based on the factors mentioned above. It is essential for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and to understand the total cost implications of their sourcing decisions.

Alternatives Analysis: Comparing komatsu 7861-93-4520 With Other Solutions

Exploring Alternatives to the Komatsu 7861-93-4520: Key Comparisons for B2B Buyers

In the competitive landscape of heavy machinery parts, it’s essential for B2B buyers to evaluate not just one option but multiple alternatives to find the most suitable solution for their operational needs. The Komatsu 7861-93-4520, an oil pressure switch designed for various Komatsu machinery, serves a critical role in monitoring hydraulic and engine oil pressure. However, several alternatives exist that may offer different advantages depending on specific requirements.

| Comparison Aspect | Komatsu 7861-93-4520 | Alternative 1: Caterpillar 202-6486 | Alternative 2: Hitachi 452-4550 |

|---|---|---|---|

| Performance | Reliable monitoring of oil pressure; calibrated to OEM specifications | High precision in pressure readings; compatible with various Caterpillar models | Strong performance in extreme conditions; designed for durability |

| Cost | Approximately $60 | Approximately $55 | Approximately $50 |

| Ease of Implementation | Direct replacement with OEM fit | Requires slight adaptation for some models | Standardized fit, minimal adjustments needed |

| Maintenance | Low maintenance; robust design | Regular checks recommended; easy to access | Low maintenance; resistant to wear |

| Best Use Case | Ideal for Komatsu wheel loaders and excavators | Best for Caterpillar machinery users | Suitable for Hitachi equipment in tough environments |

What Are the Advantages and Disadvantages of Caterpillar 202-6486?

The Caterpillar 202-6486 is an alternative that offers high precision in oil pressure monitoring, making it a strong contender for users of Caterpillar machinery. Its compatibility with various models allows for flexibility in application. However, it may require slight adaptations during installation for some models, which could lead to increased labor costs. Overall, it is a reliable option for those already invested in the Caterpillar ecosystem.

How Does Hitachi 452-4550 Compare in Terms of Durability?

The Hitachi 452-4550 is designed to perform well in extreme operating conditions, making it an excellent choice for users who frequently operate heavy machinery in harsh environments. Its robust construction ensures durability and longevity, which can lead to lower replacement frequency and costs over time. While its initial price point is slightly lower, it may not be as widely compatible as the Komatsu 7861-93-4520, limiting its use to specific Hitachi models.

Making the Right Choice: What Should B2B Buyers Consider?

When choosing between the Komatsu 7861-93-4520 and its alternatives, B2B buyers should assess several factors: the specific machinery in use, the operational environment, and budget constraints. Each option presents unique advantages and potential drawbacks. Buyers should consider performance requirements, compatibility with existing equipment, and the long-term maintenance implications of their choice. Ultimately, the right solution will align closely with the operational goals and financial considerations of the business.

Essential Technical Properties and Trade Terminology for komatsu 7861-93-4520

What are the Essential Technical Properties of the Komatsu 7861-93-4520?

The Komatsu 7861-93-4520 is an electrical oil pressure switch crucial for monitoring hydraulic and engine oil pressure in various Komatsu heavy equipment models. Understanding its technical properties can aid in making informed purchasing decisions.

-

Material Composition: The housing of the 7861-93-4520 is made from corrosion-resistant metal, ensuring durability and longevity in harsh operating environments. This property is essential for minimizing maintenance costs and maximizing equipment uptime, particularly in regions with extreme weather conditions.

-

Operating Pressure Range: The sensor is calibrated to meet Komatsu’s OEM pressure specifications. This means it can accurately monitor the engine or hydraulic system pressure, providing real-time feedback to the control unit. Adhering to OEM specifications is critical for ensuring compatibility and reliability, which can prevent costly breakdowns and repairs.

-

Connector Type: The 7861-93-4520 features a standard 2-pin plug-style electrical connector. This design simplifies installation and replacement processes, allowing for quick and efficient service. For B2B buyers, ease of installation translates to reduced labor costs and minimized downtime.

-

Mounting Specifications: The sensor is designed for a threaded fitment, ensuring a secure installation that adheres to OEM standards. Proper mounting is vital for the sensor’s performance and accuracy, which impacts the overall efficiency of the machinery. This property is particularly important for heavy equipment operators looking to maintain high operational standards.

-

Weight and Dimensions: Weighing approximately 0.3 kg, the compact design of the 7861-93-4520 aids in efficient logistics and shipping. Understanding the weight and size is crucial for international buyers, as it affects shipping costs and handling procedures.

-

Warranty and Return Policy: Many suppliers offer warranties on the 7861-93-4520, providing buyers with peace of mind regarding product quality and performance. A solid warranty policy is an essential consideration for B2B transactions, as it reflects the manufacturer’s confidence in their product and protects the buyer’s investment.

What are the Key Trade Terminology and Concepts Related to the Komatsu 7861-93-4520?

Familiarity with industry terminology can enhance communication and negotiation during the purchasing process. Here are some common terms associated with the 7861-93-4520:

-

OEM (Original Equipment Manufacturer): This term refers to the company that originally manufactures the equipment. OEM parts, like the 7861-93-4520, are designed to meet the specific standards of the original machinery, ensuring compatibility and performance. B2B buyers should prioritize OEM parts to maintain warranty coverage and equipment integrity.

-

MOQ (Minimum Order Quantity): This is the smallest amount of product a supplier is willing to sell. Understanding the MOQ is crucial for budget management and inventory planning. B2B buyers should negotiate MOQs to ensure they can meet their operational needs without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a formal process in which a buyer requests price quotes from suppliers. This term is vital for B2B transactions, as it helps buyers compare costs and negotiate better deals. Including detailed specifications in an RFQ can lead to more accurate and favorable pricing.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping obligations, risk management, and costs associated with international purchases.

-

Lead Time: This refers to the time it takes from placing an order to receiving the product. For heavy equipment parts like the 7861-93-4520, understanding lead times is crucial for planning maintenance schedules and minimizing downtime.

-

Quality Assurance (QA): QA processes ensure that products meet specific standards of quality before they are shipped. For B2B buyers, understanding a supplier’s QA measures can provide confidence in the reliability and performance of parts, such as the Komatsu 7861-93-4520.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing the Komatsu 7861-93-4520, ultimately enhancing operational efficiency and minimizing costs.

Navigating Market Dynamics and Sourcing Trends in the komatsu 7861-93-4520 Sector

What Are the Current Market Dynamics and Key Trends Affecting the Komatsu 7861-93-4520 Sector?

The Komatsu 7861-93-4520, primarily an oil pressure switch used in various Komatsu machinery, is experiencing dynamic shifts influenced by global market drivers. Key factors include the increasing demand for construction and mining equipment, especially in emerging economies across Africa, South America, and parts of Europe. This demand is driven by urbanization, infrastructure development projects, and a growing emphasis on mechanization in agriculture and construction sectors.

B2B technology trends are also reshaping sourcing strategies. The rise of digital platforms for parts procurement allows international buyers to access a broader supplier base, ensuring competitive pricing and faster delivery options. Enhanced supply chain transparency through blockchain technology is gaining traction, enabling buyers to verify product authenticity and traceability. Additionally, the trend towards just-in-time inventory management is prompting buyers to seek reliable suppliers who can deliver quality components like the 7861-93-4520 quickly and efficiently.

Moreover, suppliers are increasingly adopting advanced manufacturing techniques, such as 3D printing, to create customized parts and reduce lead times. This shift is particularly relevant for buyers in regions where logistics can be challenging. Understanding these market dynamics will empower international B2B buyers to make informed sourcing decisions and optimize their supply chains.

How Can Sustainability and Ethical Sourcing Impact the Procurement of Komatsu 7861-93-4520 Parts?

Sustainability and ethical sourcing are becoming integral to the procurement strategies of international B2B buyers. As concerns over environmental impact grow, sourcing components like the Komatsu 7861-93-4520 from suppliers who prioritize eco-friendly practices is essential. This includes ensuring that materials used in manufacturing are sourced sustainably and that production processes minimize waste and energy consumption.

Buyers should also consider suppliers with recognized ‘green’ certifications, which demonstrate their commitment to environmental standards. Such certifications can include ISO 14001 for environmental management and other industry-specific sustainability labels. By choosing suppliers with these credentials, businesses can enhance their brand reputation and meet regulatory requirements that are increasingly being enforced across regions like Europe and North America.

Furthermore, ethical sourcing practices, such as ensuring fair labor conditions and responsible sourcing of raw materials, are becoming critical for companies looking to build resilient and responsible supply chains. International buyers from regions like Africa and South America, where labor practices can vary significantly, must conduct thorough due diligence to ensure that their suppliers adhere to ethical standards.

What Is the Evolution of the Komatsu 7861-93-4520 and Its Importance in the Heavy Equipment Sector?

The Komatsu 7861-93-4520 has evolved significantly since its introduction, reflecting advancements in technology and the increasing demands of the heavy equipment sector. Initially designed to monitor oil pressure in Komatsu machinery, its importance has grown as machinery has become more complex and reliant on electronic monitoring systems.

Today, the 7861-93-4520 is recognized for its critical role in ensuring optimal engine performance and safety by providing real-time feedback on oil pressure levels. This evolution has made it an essential component for various models, including excavators and wheel loaders, catering to the needs of a diverse global market. As machinery becomes more sophisticated, the demand for reliable components like the 7861-93-4520 continues to rise, underscoring its significance in maintaining operational efficiency and reducing downtime in heavy equipment applications.

Understanding the evolution of such components provides international B2B buyers with insights into their importance and the need for high-quality sourcing to ensure machinery reliability and performance.

Frequently Asked Questions (FAQs) for B2B Buyers of komatsu 7861-93-4520

-

How do I ensure the quality of the Komatsu 7861-93-4520 before purchasing?

To ensure the quality of the Komatsu 7861-93-4520, it’s crucial to source from reputable suppliers who provide OEM parts or certified replacements. Request documentation that verifies the part’s specifications, such as material quality, operational range, and compatibility with your equipment. Additionally, check for warranties and return policies, as these can indicate the supplier’s confidence in their products. Conducting a supplier audit or asking for customer references can also help assess their reliability. -

What are the common applications of the Komatsu 7861-93-4520?

The Komatsu 7861-93-4520 is primarily used as an oil pressure switch in various Komatsu heavy machinery, including wheel loaders and excavators like the PC400-7, PC450-7, WA380-6, WA470-6, and WA500-6. It monitors hydraulic or engine oil pressure, sending real-time alerts to the control panel to prevent damage from low or abnormal pressure. Understanding its application helps ensure you are purchasing the correct part for your machinery. -

What payment options are available for international orders of the Komatsu 7861-93-4520?

Payment options for international orders typically include bank transfers (T/T), PayPal, and credit cards (Visa, Mastercard). Some suppliers may also accept alternative payment methods like Western Union or letters of credit (L/C). When ordering, confirm the payment methods accepted by the supplier and ensure that the transaction is secure. Additionally, inquire about any upfront deposits that may be required for bulk orders. -

What is the minimum order quantity (MOQ) for the Komatsu 7861-93-4520?

The minimum order quantity (MOQ) for the Komatsu 7861-93-4520 can vary by supplier. Some suppliers may allow orders as low as one unit, while others may require a MOQ of 10 or more. It’s essential to discuss your purchasing needs with the supplier to understand their MOQ and any potential price breaks for larger orders. This can help you manage your inventory and budget more effectively. -

How can I vet a supplier for the Komatsu 7861-93-4520?

To vet a supplier, start by researching their reputation within the industry. Look for reviews and testimonials from other B2B buyers, and check for any certifications or affiliations with industry standards. It’s also beneficial to request samples or product specifications to assess quality. Establishing open lines of communication can help gauge their customer service and responsiveness, which are critical for ongoing partnerships. -

What shipping options are available for international buyers of the Komatsu 7861-93-4520?

International buyers can typically choose from various shipping options, including air freight for faster delivery and sea freight for cost-effectiveness. Some suppliers offer express shipping services through couriers like DHL, FedEx, or UPS. It’s important to discuss shipping terms with the supplier, including delivery times, tracking options, and whether shipping costs are included in the quoted price. Understanding these details can help you plan your logistics more efficiently. -

Can I customize the Komatsu 7861-93-4520 for specific machinery needs?

Customization options for the Komatsu 7861-93-4520 may be available depending on the supplier. If your machinery has unique requirements, discuss these with the supplier to see if they can provide tailored solutions. This may include modifications to the sensor’s calibration or connector type to ensure compatibility with your equipment. Be prepared to provide detailed specifications to facilitate the customization process. -

What is the warranty policy for the Komatsu 7861-93-4520?

Warranty policies for the Komatsu 7861-93-4520 vary by supplier, but many offer warranties that cover defects in materials and workmanship for a specified period, typically ranging from 30 days to one year. Always inquire about the warranty details before purchasing, including what is covered and the process for claims. A robust warranty policy can provide peace of mind and protect your investment in case of product failure.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Komatsu 7861-93-4520 Manufacturers & Suppliers List

1. Komatsu – Electrical Sensor

Domain: komatsu.com

Introduction: 7861-93-4520 – Electrical Sensor

2. KMP Brand – Sensor Coolant Level 7861-93-4520

Domain: store.kmpbrand.com

Registered: 2005 (20 years)

Introduction: Sensor Coolant Level 7861-93-4520

3. CTP – Komatsu Sensor 7861-93-4520

Domain: heavydutypros.com

Registered: 2019 (6 years)

Introduction: {‘product_name’: ‘Komatsu Sensor’, ‘part_number’: ‘7861-93-4520’, ‘price’: ‘$110.73’, ‘msrp’: ‘$132.88’, ‘savings’: ‘$22.15 (17%)’, ‘brand’: ‘CTP’, ‘manufacturer_part_no’: ‘7861-93-4520’, ‘warranty’: ‘Click for Info’, ‘description’: ‘Sensor replaces: 7861-93-4520. Made with premium OEM quality materials for strength and durability. Designed to withstand extreme conditions in heavy duty equipment.’…

4. OEM – Pressure Sensor

Domain: m.excavator-spareparts.com

Registered: 2017 (8 years)

Introduction: {“Part Number”:”7861-93-4520, 7861934520″,”Product Name”:”Pressure Sensor”,”Brand Name”:”OEM”,”Compatible Machine Models”:[“PC1800″,”PC2000″,”D155AX”,”D275A”,”D275AX”,”D375A”,”D475A”],”Category”:”Electric Wiring Harness, Radiator Guard”,”Price”:”33 USD / pcs”,”Place of Origin”:”China”,”Lead Time”:”1-3 DAYS”,”Quality”:”Brand new, OEM quality”,”Minimum Order Quantity (MOQ)”:”1 PCS”,”Shipping Methods…

5. Komatsu – Aftermarket Sensor

Domain: propelparts.us

Registered: 2012 (13 years)

Introduction: {“part_number”:”7861-93-4520″,”product_name”:”Komatsu Sensor”,”type”:”Aftermarket”,”compatible_models”:[“BR380JG”,”BR580JG”,”D155A”,”D155AX”,”D275A”,”D375A”,”D475A”,”D475ASD”,”D85EX”,”D85MS”,”D85PX”,”HD325″,”HD405″,”HD465″,”HD605″,”HD785″,”HM300″,”HM400″,”PC2000″],”price”:”$91.92″,”warranty”:”1 year unlimited mileage”,”shipping”:”Same Day (Weekdays) if ordered by 3pm ET”,”weight”:”0.9 lbs”,”dimens…

6. Komatsu – DP Sensor 7861-93-4520

Domain: stszcmparts.com

Registered: 2019 (6 years)

Introduction: DP Sensor 7861-93-4520 for Komatsu BR380JG

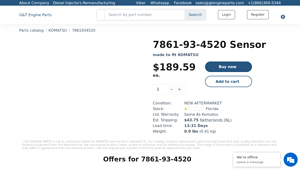

7. KOMATSU – Sensor 7861-93-4520

Domain: gtengineparts.com

Registered: 2012 (13 years)

Introduction: {“part_number”: “7861-93-4520”, “description”: “Sensor made to fit KOMATSU”, “price”: “$189.59”, “condition”: “NEW AFTERMARKET”, “stock_location”: “Florida”, “warranty”: “Same As Komatsu”, “estimated_shipping”: “$52.09”, “shipping_origin”: “Bangladesh (BD)”, “lead_time”: “13-31 Days”, “weight”: “0.9 lbs (0.41 kg)”, “brand”: “KOMATSU”, “OEM_code”: “7861-93-4520”}

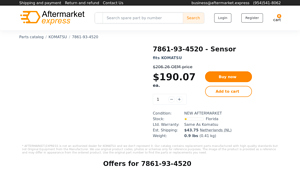

8. KOMATSU – Sensor

Domain: aftermarket.express

Introduction: {“part_number”:”7861-93-4520″,”description”:”Sensor fits KOMATSU”,”price”:”$190.07″,”OEM_price”:”$206.26″,”stock_location”:”Florida”,”contact_number”:”(954)541-8062″,”condition”:”NEW AFTERMARKET”,”warranty”:”Same As Komatsu”,”estimated_shipping”:”$52.09″,”weight”:”0.9 lbs (0.41 kg)”,”brand”:”KOMATSU”,”tags”:[“Electrical”,”Sensors”]}

Strategic Sourcing Conclusion and Outlook for komatsu 7861-93-4520

In conclusion, effective strategic sourcing for the Komatsu 7861-93-4520 oil pressure switch is vital for international B2B buyers seeking to enhance their operational efficiency and equipment reliability. This component plays a crucial role in monitoring hydraulic and engine oil pressure, thereby safeguarding critical machinery from potential damage. By partnering with reliable suppliers that offer OEM-quality parts, buyers can ensure not only the longevity of their equipment but also maintain a competitive edge in their respective markets.

The value of strategic sourcing extends beyond mere cost savings; it encompasses improved supplier relationships, enhanced product quality, and streamlined procurement processes. For businesses operating in regions such as Africa, South America, the Middle East, and Europe, leveraging local and international suppliers can open doors to better pricing, faster shipping, and tailored customer service.

Looking ahead, it is essential for B2B buyers to remain proactive in their sourcing strategies. Engaging with trusted suppliers, understanding market trends, and embracing technology for procurement can significantly impact operational success. Now is the time to invest in quality components like the 7861-93-4520 to ensure your machinery operates at peak performance. Explore your sourcing options today and position your business for future growth and resilience.