Choosing Your Magnet Door Latches: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for magnet door latches

In today’s dynamic global market, sourcing magnet door latches presents unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With an increasing demand for efficient, secure, and low-maintenance access hardware, understanding the various types of magnetic latches and their applications is crucial for making informed purchasing decisions. This guide delves into the essential aspects of magnet door latches, including their specifications, applications across different industries, and critical supplier vetting processes.

Buyers will gain insights into the various models available, from concealed magnetic catches to heavy-duty options designed for rigorous environments. Additionally, the guide covers factors influencing cost, helping businesses budget effectively while ensuring they receive quality products that meet their operational needs. By equipping international buyers with actionable knowledge, this resource empowers them to navigate the complexities of the magnet door latch market confidently.

Whether you are a manufacturer in Nigeria seeking reliable components or a distributor in Germany looking to expand your product offerings, this guide is tailored to enhance your understanding of magnet door latches, facilitating smarter procurement strategies. With comprehensive insights and expert guidance, you can streamline your sourcing process and ensure the long-term success of your projects.

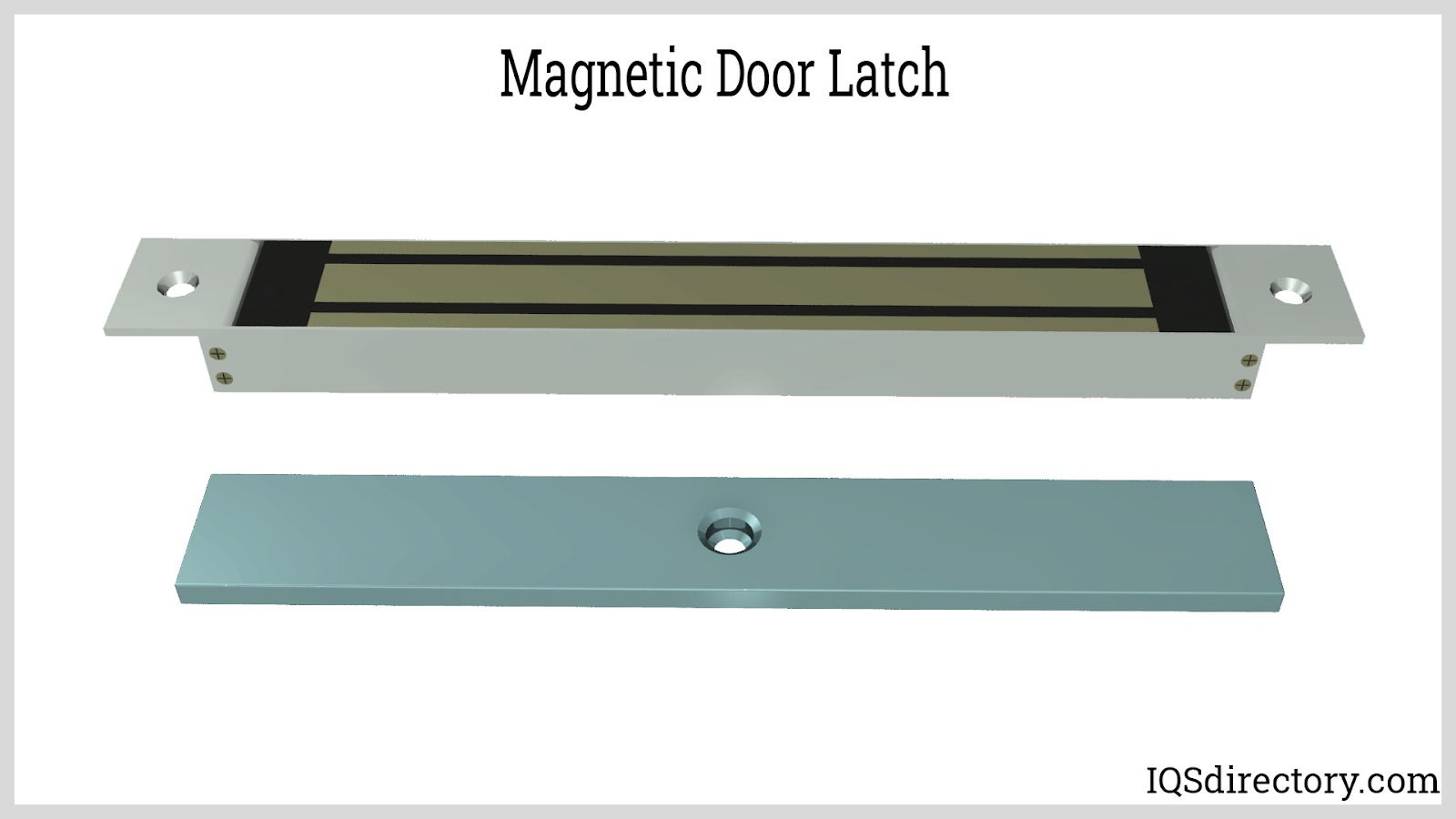

Understanding magnet door latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rare Earth Magnetic Latches | High holding strength, thin profile, corrosion-resistant materials | Cabinet doors, display mounting | Pros: Compact design, robust performance. Cons: Higher cost due to advanced materials. |

| Concealed Magnetic Door Catches | Invisible installation, lifetime guaranteed magnetism, noise-free operation | Full-size doors, sliding doors | Pros: Aesthetic appeal, reduced wear. Cons: Requires precise installation. |

| Heavy-Duty Magnetic Catches | Designed for rigorous use, adjustable holding strength, industrial-grade materials | Industrial doors, equipment enclosures | Pros: Durable under stress, customizable. Cons: Bulkier than standard options. |

| Adjustable Magnetic Latches | Power adjustment spacer rings for enhanced holding strength, easy installation | Commercial and residential applications | Pros: Versatile, adaptable to various needs. Cons: Additional components may complicate installation. |

| Standard Magnetic Latches | Simple design, cost-effective, suitable for light to moderate use | Furniture manufacturing, home use | Pros: Affordable, easy to source. Cons: Limited holding strength compared to specialized types. |

What are the Characteristics of Rare Earth Magnetic Latches?

Rare Earth Magnetic Latches utilize powerful neodymium magnets, which provide exceptional holding strength in a compact design. These latches are ideal for applications where space is limited, such as in cabinet doors or display mounts. B2B buyers should consider their durability and corrosion-resistant properties, making them suitable for various industries, including automotive and appliance manufacturing. However, the advanced materials used can lead to a higher price point, so businesses must evaluate their budget against performance needs.

Illustrative image related to magnet door latches

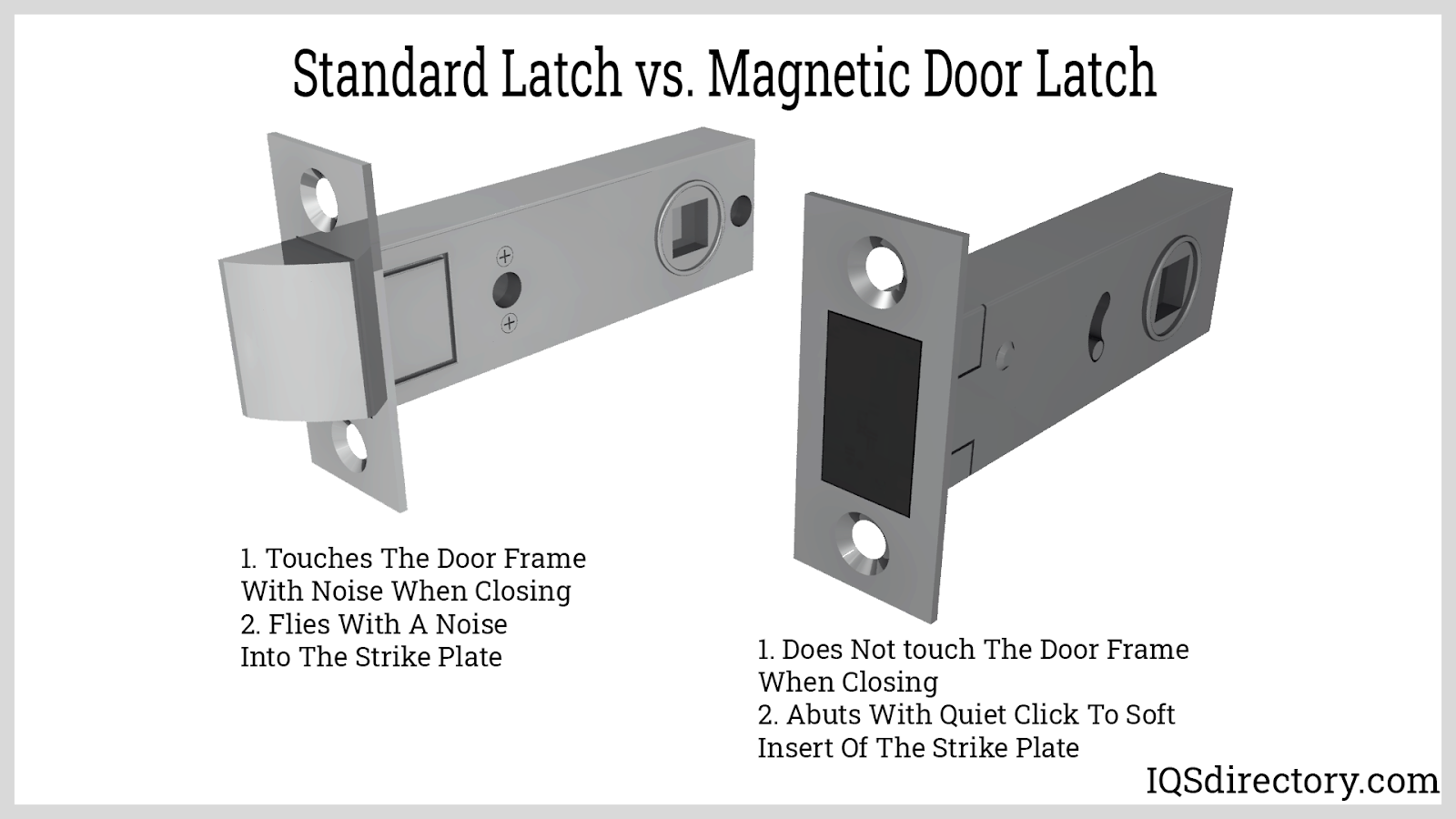

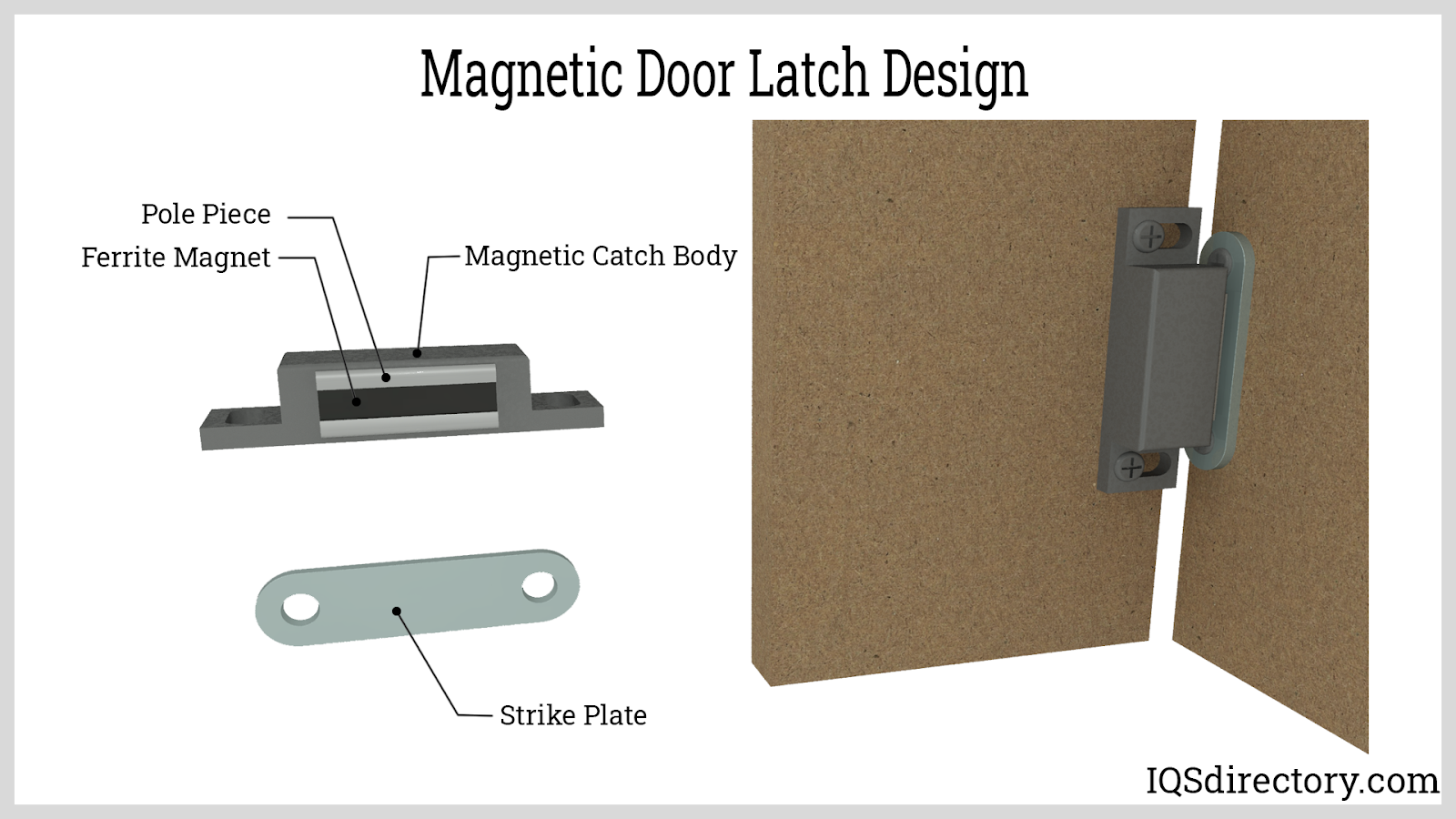

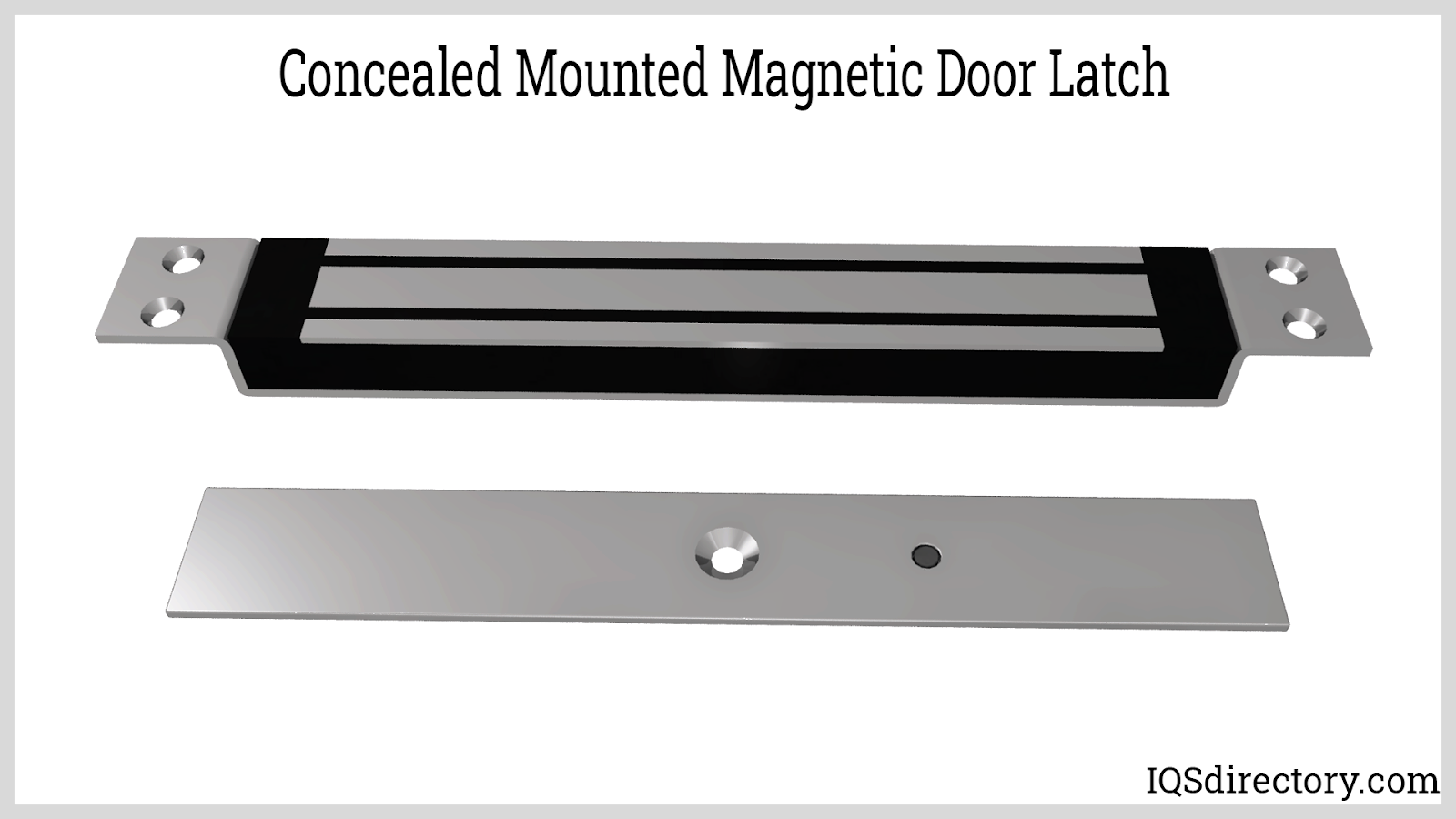

How Do Concealed Magnetic Door Catches Function?

Concealed Magnetic Door Catches are designed to remain hidden when doors are closed, offering a clean aesthetic that is particularly appealing in commercial settings. These catches operate silently, as the magnets do not touch post-installation, significantly reducing wear over time. They are commonly used in full-sized and sliding doors, making them a versatile option for both residential and commercial projects. Buyers must ensure precise installation to maximize performance, as misalignment can compromise functionality.

What Makes Heavy-Duty Magnetic Catches Suitable for Industrial Use?

Heavy-Duty Magnetic Catches are crafted from robust materials designed to withstand rigorous daily use and harsh environmental conditions. They often feature adjustable holding strength, allowing customization for specific applications such as industrial doors and equipment enclosures. B2B buyers in sectors like manufacturing and logistics will find these catches particularly beneficial due to their durability and reliability. However, they tend to be bulkier, which may not suit all applications, especially where space is constrained.

Why Choose Adjustable Magnetic Latches?

Adjustable Magnetic Latches come equipped with power adjustment spacer rings that enhance their holding strength, making them adaptable for various door types and weights. Their easy installation process makes them an attractive option for both commercial and residential applications. B2B buyers should consider their versatility and ability to meet diverse needs, though the inclusion of additional components may complicate the installation process for some users.

Illustrative image related to magnet door latches

What are the Benefits of Standard Magnetic Latches?

Standard Magnetic Latches offer a straightforward and cost-effective solution for light to moderate use. Their simple design makes them easy to source and install, making them suitable for furniture manufacturing and general home use. While they are more affordable than specialized options, buyers should note their limited holding strength, which may not be adequate for heavier applications. Evaluating the specific requirements of the intended use will be crucial for businesses considering these latches.

Key Industrial Applications of magnet door latches

| Industry/Sector | Specific Application of Magnet Door Latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Securing vehicle compartments and access panels | Enhanced safety and ease of access for maintenance | Durability, corrosion resistance, and holding strength |

| Furniture Manufacturing | Cabinet doors and drawer closures | Streamlined design and quiet operation | Aesthetics, load capacity, and ease of installation |

| Appliance Manufacturing | Refrigerator and oven door closures | Improved user experience with seamless operation | Temperature resistance, compliance with safety standards |

| Commercial Construction | Access doors in HVAC and electrical panels | Facilitates maintenance and reduces wear on mechanical parts | Size specifications, installation requirements, and durability |

| Retail Displays | Mounting signage and product displays | Flexibility in display configurations and easy updates | Strength of magnet, ease of use, and aesthetic considerations |

How Are Magnet Door Latches Utilized in Automotive Manufacturing?

In the automotive sector, magnet door latches are employed to secure vehicle compartments and access panels. They provide a secure closure while allowing for quick access during maintenance. The robust design ensures that they can withstand the vibrations and environmental conditions typical in automotive applications. Buyers in this sector should prioritize durability and corrosion resistance, especially in regions with high humidity or variable climates, such as parts of Africa and South America.

What Role Do Magnet Door Latches Play in Furniture Manufacturing?

Furniture manufacturers utilize magnet door latches for cabinet doors and drawer closures, ensuring a clean aesthetic without visible hardware. These latches enable quiet operation, enhancing the user experience. For international buyers, particularly from Europe, the focus should be on aesthetics and load capacity to meet both functional and design requirements. Additionally, the ease of installation is crucial for manufacturers aiming to streamline production processes.

How Are Magnet Door Latches Beneficial in Appliance Manufacturing?

In appliance manufacturing, magnet door latches are critical for securing refrigerator and oven doors. They enhance user experience by providing a seamless and user-friendly operation. Manufacturers must consider temperature resistance and compliance with safety standards, especially in markets with stringent regulations, like Germany. Sourcing high-quality latches that meet these specifications can significantly reduce warranty claims and improve customer satisfaction.

Illustrative image related to magnet door latches

In What Ways Are Magnet Door Latches Used in Commercial Construction?

Magnet door latches are increasingly used in commercial construction for access doors in HVAC and electrical panels. They facilitate maintenance by providing easy access while reducing wear on mechanical parts. Buyers should evaluate size specifications and installation requirements, as well as durability to ensure long-term performance, particularly in harsh environments found in the Middle East.

How Do Retail Displays Benefit from Magnet Door Latches?

In retail, magnet door latches are essential for mounting signage and product displays. They allow for flexible display configurations and easy updates, which are vital in fast-paced retail environments. For B2B buyers, the strength of the magnet and ease of use are key considerations, as they directly impact the efficiency of display changes and the overall customer experience. Aesthetic considerations are also important, particularly in markets focused on design and branding.

3 Common User Pain Points for ‘magnet door latches’ & Their Solutions

Scenario 1: Inefficient Door Operation in High-Traffic Areas

The Problem: In environments such as manufacturing plants or commercial offices, doors are frequently used. B2B buyers often face the challenge of selecting door latches that can withstand heavy use while ensuring smooth operation. Magnetic door latches, while convenient, can sometimes fail to engage properly, leading to operational inefficiencies, increased wear and tear, and potential safety risks. Buyers are particularly concerned about the longevity and reliability of the latches in high-traffic areas where mechanical components can quickly wear out.

Illustrative image related to magnet door latches

The Solution: To address this challenge, B2B buyers should consider sourcing high-quality magnetic door latches specifically designed for heavy-duty applications. Selecting models with rare earth magnets, such as those from reputable manufacturers, will ensure superior holding strength and durability. It’s also essential to assess the latch’s design; concealed magnetic catches can provide a seamless look while minimizing wear since they do not make contact when the door is closed. Additionally, implementing regular maintenance checks can prevent latch failures. Buyers should keep spare latches on hand to facilitate quick replacements when needed, ensuring minimal disruption to operations.

Scenario 2: Environmental Challenges Affecting Latch Performance

The Problem: In regions with extreme weather conditions—such as high humidity, salt exposure, or temperature fluctuations—magnetic latches may corrode or lose their magnetic properties over time. This presents a significant issue for B2B buyers in industries like shipping or outdoor equipment manufacturing, where environmental durability is crucial for product longevity. Buyers may find that standard magnetic latches do not meet the demanding conditions of their operational environments, leading to frequent replacements and increased costs.

The Solution: Buyers should prioritize sourcing magnetic door latches that feature corrosion-resistant materials and coatings, such as stainless steel or specially plated finishes. Products designed for industrial applications often have enhanced durability and can withstand harsh conditions. Furthermore, buyers should assess the environmental ratings of the products, ensuring they are suitable for specific climates. Implementing a procurement strategy that includes suppliers offering warranties or guarantees on durability can also protect against premature failures and reduce long-term costs.

Scenario 3: Installation Complexity Leading to Increased Labor Costs

The Problem: The installation of magnetic door latches can often be more complicated than anticipated, especially when integrating them into existing door systems. Buyers may face challenges in ensuring that the latches align correctly with strike plates, leading to increased labor costs and project delays. Misalignment can result in improper latch engagement, which compromises security and functionality.

The Solution: To streamline installation and minimize labor costs, B2B buyers should seek magnetic latches that come with comprehensive installation kits, including templates and clear instructions. Selecting products that feature adjustable components, such as power adjustment spacer rings, can also simplify the installation process by allowing for fine-tuning after the latch is mounted. Engaging with suppliers who offer technical support or installation services can further alleviate concerns, ensuring that the latches are installed correctly the first time. Buyers can also consider training sessions for their teams on proper installation techniques, which can enhance overall efficiency and reduce future complications.

Strategic Material Selection Guide for magnet door latches

What Are the Best Materials for Magnet Door Latches?

When selecting materials for magnet door latches, several factors come into play, including durability, cost, and environmental resistance. Here, we analyze four common materials used in the manufacturing of magnet door latches: Stainless Steel, Plastic, Zinc Alloy, and Neodymium.

How Does Stainless Steel Perform in Magnet Door Latches?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it suitable for a variety of applications, including those exposed to harsh environments. With a temperature rating that can exceed 500°F (260°C), stainless steel latches can withstand significant heat without deforming.

Pros: The primary advantages of stainless steel include its strength, longevity, and aesthetic appeal. It is easy to clean and maintain, making it a preferred choice for high-traffic areas.

Cons: However, stainless steel can be more expensive than other materials, and its manufacturing process may be complex, leading to higher production costs.

Impact on Application: Stainless steel is compatible with various media, including water and chemicals, making it versatile for use in both industrial and commercial settings.

Considerations for International Buyers: Buyers from regions like Germany and South Africa should ensure compliance with relevant standards such as DIN and SANS. The higher cost may be justified by the longevity and performance of stainless steel latches.

What Role Does Plastic Play in Magnet Door Latches?

Plastic is often used in lighter-duty applications where cost is a primary concern. It is generally resistant to corrosion and can handle a range of temperatures, although it may not perform well in extreme conditions.

Pros: The main advantages of plastic include its low cost and lightweight nature, making it ideal for applications where weight is a concern.

Cons: However, plastic is less durable than metals and can degrade over time, especially when exposed to UV light or extreme temperatures.

Impact on Application: Plastic latches are suitable for indoor applications and environments where exposure to moisture is minimal.

Considerations for International Buyers: Buyers in developing regions may find plastic latches appealing due to their affordability, but they should consider the potential need for replacements in the long term.

How Do Zinc Alloys Compare for Magnet Door Latches?

Zinc alloy offers a balance between strength and cost, making it a popular choice for various applications. It has good corrosion resistance and can withstand moderate temperatures.

Pros: The key advantage of zinc alloy is its cost-effectiveness while still providing decent durability and aesthetic appeal.

Illustrative image related to magnet door latches

Cons: However, zinc alloys may not be suitable for high-stress applications or extreme environmental conditions, as they can corrode over time if not properly coated.

Impact on Application: Zinc alloy latches are often used in residential and light commercial applications where high strength is not a critical requirement.

Considerations for International Buyers: Buyers from regions like Nigeria should be aware of local environmental conditions that may affect the longevity of zinc alloy products.

Illustrative image related to magnet door latches

Why Is Neodymium a Game-Changer for Magnet Door Latches?

Neodymium is a type of rare earth magnet known for its exceptional strength and compact size. It is often used in applications where space is limited but strong magnetic force is required.

Pros: Neodymium magnets provide superior holding strength, allowing for thinner latch designs without sacrificing performance.

Cons: The primary downside is their susceptibility to corrosion, requiring protective coatings, and they can be more expensive than standard magnets.

Impact on Application: Neodymium latches are perfect for applications requiring compact designs and strong performance, such as in furniture or specialized equipment.

Illustrative image related to magnet door latches

Considerations for International Buyers: Buyers in Europe should ensure that neodymium magnets comply with safety regulations, as their strength can pose risks if not handled properly.

Summary Table of Material Selection for Magnet Door Latches

| Material | Typical Use Case for magnet door latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-traffic commercial applications | Exceptional durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Indoor applications | Low cost and lightweight | Less durable, can degrade over time | Low |

| Zinc Alloy | Residential and light commercial uses | Cost-effective with decent durability | Susceptible to corrosion over time | Medium |

| Neodymium | Compact applications requiring strong hold | Superior strength in small designs | Corrosion-prone, higher cost | High |

This guide provides actionable insights for B2B buyers considering the best materials for magnet door latches, ensuring informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for magnet door latches

What Are the Key Stages in the Manufacturing Process of Magnet Door Latches?

The manufacturing of magnet door latches involves several critical stages that ensure the final product meets both functional and quality standards. Understanding these stages helps B2B buyers evaluate potential suppliers and their capabilities effectively.

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is material preparation. Typically, magnet door latches are made from high-quality materials such as stainless steel, plastic, or rare earth magnets (neodymium). These materials are selected for their durability and resistance to corrosion, which is crucial for applications in various environments, especially in regions with high humidity or salt exposure.

The raw materials undergo rigorous checks to ensure they meet specified standards. For instance, stainless steel components must meet ASTM standards for corrosion resistance, while magnets must conform to specific magnetic properties outlined in industry standards.

How Are Magnet Door Latches Formed and Assembled?

Once the materials are prepared, the next stage involves forming and assembling the components. Key techniques employed in this phase include:

Illustrative image related to magnet door latches

- Casting and Machining: Metal parts are often cast and then machined to achieve precise dimensions. This includes the creation of the latch body, strike plates, and any other necessary components.

- Injection Molding: For plastic parts, injection molding is commonly used to produce consistent and intricate designs. This technique is particularly useful for producing the outer casing or covers of the latches.

- Magnet Placement: Rare earth magnets are strategically placed within the latch assembly. This requires precision to ensure that the magnetic force is optimal for the latch’s intended use.

After forming, the components are assembled using various methods, including screwing, riveting, or adhesive bonding. The choice of assembly method can depend on the design of the latch and the materials used.

What Finishing Processes Are Commonly Applied?

The finishing stage is essential for enhancing the performance and appearance of magnet door latches. Common finishing processes include:

- Plating and Coating: Many manufacturers apply a protective coating or plating (such as nickel or chrome) to metal parts to enhance corrosion resistance and aesthetic appeal.

- Surface Treatment: Processes like sandblasting or polishing may be employed to improve surface finish and reduce friction during operation.

- Quality Checks: After finishing, products undergo final quality checks to ensure they meet design specifications and aesthetic standards.

How Is Quality Assurance Implemented in Magnet Door Latch Manufacturing?

Quality assurance (QA) is crucial in ensuring that magnet door latches are reliable and perform as expected. The QA process involves adhering to international standards and implementing systematic checkpoints throughout the manufacturing cycle.

Illustrative image related to magnet door latches

Which International Standards Are Relevant for Quality Control?

For B2B buyers, understanding the certifications that suppliers hold is essential. Common international quality standards include:

- ISO 9001: This standard outlines the requirements for a quality management system and is widely recognized across industries. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European market, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: In industries like oil and gas, API standards may apply, ensuring that products meet specific performance and safety criteria.

What Are the Key Quality Control Checkpoints?

Quality control is integrated at various stages of the manufacturing process, with specific checkpoints that include:

- Incoming Quality Control (IQC): This initial inspection assesses raw materials and components before production begins. It ensures that only materials meeting quality standards enter the manufacturing process.

- In-Process Quality Control (IPQC): During production, continuous monitoring is essential. This includes checking dimensions, magnetic strength, and assembly integrity at different stages to catch defects early.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes comprehensive testing. This may include functional tests, durability tests, and inspections to ensure the latches meet all specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of potential suppliers is paramount. Here are several effective methods:

What Audits and Reports Should Buyers Request?

Buyers should request detailed quality audits and compliance reports from suppliers. These documents should outline the supplier’s adherence to international standards, along with any certifications they hold. Regular audits conducted by third-party organizations can provide an unbiased assessment of a supplier’s quality management system.

Illustrative image related to magnet door latches

How Do Third-Party Inspections Work?

Engaging third-party inspection services can offer additional assurance. These organizations conduct independent evaluations of the manufacturing process and final products, ensuring compliance with specified standards. Buyers can schedule these inspections at various stages, from IQC to FQC, to gain confidence in the supplier’s capabilities.

What Are the Nuances of Quality Control for International Buyers?

When dealing with suppliers in different regions, B2B buyers must consider several nuances in quality control:

- Regulatory Compliance: Different countries have varying regulations concerning product safety and quality. Buyers should ensure that suppliers are compliant with local regulations while also adhering to international standards.

- Cultural Differences in Quality Expectations: Quality perceptions can differ across cultures. Understanding the specific expectations of regions, such as stringent EU standards versus more lenient norms in some emerging markets, is vital for effective communication and partnership.

- Logistics and Supply Chain Considerations: International shipping may introduce additional risks. Buyers should work with suppliers who have robust logistics and supply chain management systems to mitigate potential quality issues during transport.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for magnet door latches is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions and ensure they partner with reliable suppliers who can meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘magnet door latches’

To help B2B buyers navigate the procurement of magnet door latches effectively, this practical sourcing guide outlines critical steps to ensure a successful purchasing process. By following this checklist, businesses can secure high-quality products that meet their operational needs.

Illustrative image related to magnet door latches

Step 1: Define Your Technical Specifications

Before approaching suppliers, it’s essential to outline your specific requirements for magnet door latches. Consider factors such as load capacity, environmental conditions, and installation space. This clarity will help you identify products that fit your application, reducing the risk of misalignment between your needs and the offered solutions.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in magnetic latch technology. Understanding current trends can enhance your sourcing strategy by enabling you to select products that offer improved performance, durability, or energy efficiency. Look for innovations such as concealed designs or enhanced magnetic strength, which may provide added value for your projects.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in manufacturing high-quality magnetic latches and those who can support your business with reliable service and product knowledge.

Illustrative image related to magnet door latches

- Supplier Certifications: Verify that suppliers hold relevant certifications, such as ISO 9001, which indicates adherence to quality management standards.

- Industry Experience: Choose suppliers with extensive experience in your industry to ensure they understand your specific needs and challenges.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of their magnetic latches. Testing these samples in real-world conditions will allow you to assess their performance, durability, and ease of installation. Pay attention to the latch’s holding strength and how well it integrates with your existing systems.

Step 5: Consider After-Sales Support and Warranty

Evaluate the after-sales support offered by suppliers, including installation assistance, maintenance services, and warranty terms. A strong support system is vital for resolving issues quickly and minimizing downtime. Ensure that the warranty covers defects and provides a clear process for claims.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations to secure favorable pricing and terms. Consider bulk purchase discounts or flexible payment options that align with your cash flow requirements. Ensure that you understand all costs involved, including shipping and handling, to avoid surprises later.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order and keep open lines of communication with your supplier regarding delivery schedules. Monitor the shipment to ensure it arrives on time and in good condition. Establish a process for inspecting the products upon receipt to confirm they meet your specifications before usage.

By following these steps, B2B buyers can ensure they select the right magnet door latches for their operational needs while minimizing risks and enhancing efficiency in their procurement processes.

Illustrative image related to magnet door latches

Comprehensive Cost and Pricing Analysis for magnet door latches Sourcing

What Are the Key Cost Components in Sourcing Magnet Door Latches?

Understanding the cost structure of magnet door latches is crucial for B2B buyers aiming to optimize their purchasing strategy. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. High-quality magnets, such as Rare Earth Neodymium, enhance performance but come at a premium. Additionally, corrosion-resistant coatings and durable plastics used in housing can elevate costs.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing; however, this can sometimes compromise quality. Buyers should assess the labor expertise in the manufacturing country to ensure quality standards are met.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can lower overhead, impacting the final pricing.

-

Tooling: Initial setup costs for specialized tools and machinery can be substantial, particularly for custom designs. Buyers ordering in large volumes may be able to amortize these costs over more units, reducing the per-unit price.

-

Quality Control (QC): Ensuring consistent quality is vital, especially for industrial applications. Rigorous QC processes add to manufacturing costs but can prevent costly returns and defects.

-

Logistics: Shipping costs vary based on distance, weight, and shipping methods. For international buyers, understanding Incoterms is essential to clarify responsibilities for shipping and customs duties.

-

Margin: Suppliers will typically add a margin to cover their risks and profits. This varies widely based on market dynamics and competition.

How Do Price Influencers Affect Magnet Door Latch Costs?

Several factors can influence the pricing of magnet door latches:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often attract discounts. Buyers should evaluate their needs carefully to take advantage of economies of scale.

-

Specifications and Customization: Tailored solutions often incur higher costs due to unique design requirements and additional manufacturing processes. Buyers should weigh the benefits of customization against the potential increase in price.

-

Material Quality and Certifications: High-grade materials and certifications (like ISO 9001) can elevate costs but assure buyers of reliability and longevity, which may reduce the Total Cost of Ownership (TCO) over time.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is critical for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final cost structure and logistical responsibilities.

What Are the Best Practices for Negotiating Prices on Magnet Door Latches?

To optimize procurement and achieve favorable pricing, buyers should consider the following tips:

-

Negotiate Volume Discounts: Leverage purchasing power by negotiating discounts for larger orders. Establishing long-term relationships with suppliers can also yield better terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial pricing, consider longevity, maintenance, and potential failure rates. A slightly higher upfront cost for a more reliable product can lead to savings in the long run.

-

Stay Informed on Market Trends: Understanding market fluctuations and trends can provide leverage during negotiations. Knowledge of competitor pricing and supplier availability can enhance bargaining power.

-

Assess Quality vs. Price: While lower prices are attractive, they should not compromise quality. Investing in high-quality latches can prevent costly replacements and ensure customer satisfaction.

-

Explore Diverse Suppliers: For international buyers, evaluating suppliers from different regions (e.g., Europe vs. Asia) can uncover competitive pricing and unique product offerings.

Conclusion

While sourcing magnet door latches involves various cost components and pricing influencers, informed decision-making can lead to better procurement strategies. By understanding these elements, B2B buyers from Africa, South America, the Middle East, and Europe can enhance their purchasing processes, ensuring they select the best products that meet their operational needs while maintaining cost efficiency.

Alternatives Analysis: Comparing magnet door latches With Other Solutions

Understanding Alternative Solutions to Magnet Door Latches

When selecting hardware for securing doors or cabinets, B2B buyers often consider a variety of options to ensure they choose the most effective solution. Magnet door latches are a popular choice due to their simplicity and low maintenance. However, it’s essential to compare them against other alternatives, such as traditional mechanical latches and electronic locks, to determine which option best fits specific operational needs.

Comparison Table

| Comparison Aspect | Magnet Door Latches | Traditional Mechanical Latches | Electronic Locks |

|---|---|---|---|

| Performance | High holding strength, silent operation | Reliable but may be noisy | Versatile, programmable access |

| Cost | Moderate pricing, low long-term costs | Generally lower initial cost | Higher upfront cost, potential savings in labor |

| Ease of Implementation | Simple installation with minimal tools | Requires precise alignment | Installation may require electrical expertise |

| Maintenance | Low maintenance, durable materials | Moderate, may need periodic adjustments | Higher maintenance, battery changes required |

| Best Use Case | Cabinets, light doors, indoor applications | General-purpose doors, cabinets | High-security areas, access control systems |

Detailed Breakdown of Alternatives

Traditional Mechanical Latches

Traditional mechanical latches, such as spring-loaded or bolt latches, have been used for decades. They offer a straightforward solution for securing doors and cabinets. One of the main advantages of mechanical latches is their lower initial cost and reliability in various environments. However, they can be noisy when engaging or disengaging, which may not be suitable for all applications. Additionally, they require precise installation to ensure proper functionality and may need periodic adjustments or maintenance.

Electronic Locks

Electronic locks provide advanced security features, allowing for programmable access codes and integration with security systems. These locks are particularly beneficial in high-security environments where access control is critical. Their versatility and ability to track access logs are significant advantages. However, they come with a higher upfront cost and may require specialized installation, which could lead to increased labor expenses. Maintenance is also a consideration, as electronic locks may need battery replacements and software updates.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right door latch solution involves considering various factors, including performance requirements, budget constraints, and maintenance capabilities. For businesses in industries requiring quick access and minimal maintenance, magnet door latches stand out as a robust option. However, if security is paramount, electronic locks may provide the necessary features despite their higher costs. Traditional mechanical latches could serve well for general purposes where cost-effectiveness and simplicity are prioritized. Ultimately, understanding the specific needs of your operations will guide you toward the most suitable solution.

Essential Technical Properties and Trade Terminology for magnet door latches

What Are the Key Technical Properties of Magnet Door Latches?

When selecting magnet door latches, understanding their technical specifications is crucial for ensuring product reliability and performance. Here are some essential properties to consider:

1. Material Grade

Magnet door latches are typically made from materials like stainless steel, plastic, or aluminum. The choice of material affects durability, corrosion resistance, and overall strength. For instance, stainless steel latches are ideal for environments exposed to moisture, as they resist rust and degradation over time. Selecting the right material ensures longevity and reduces maintenance costs for businesses.

2. Holding Force

The holding force, measured in pounds (lbs), indicates the amount of magnetic pull the latch can exert to keep a door securely closed. It is vital to choose a latch with an appropriate holding force based on the door’s size and usage. A higher holding force is essential for heavy doors or high-traffic areas, ensuring safety and functionality.

3. Tolerance

Tolerance refers to the allowable variation in the dimensions of the latch components. For instance, precise tolerances are necessary for ensuring that the latch and strike plate align correctly. This precision minimizes the risk of operational failure and enhances user experience. Manufacturers often specify tolerances to meet industry standards, making it easier for B2B buyers to match components.

4. Magnet Type

There are different types of magnets used in latches, such as neodymium (rare earth) and ceramic magnets. Neodymium magnets provide a stronger magnetic force in a smaller package, making them suitable for applications where space is limited. Understanding the type of magnet helps buyers select latches that best meet their specific requirements.

5. Strike Plate Dimensions

The strike plate’s dimensions, including inner and outer diameters and thickness, are critical for compatibility with the latch. A well-fitted strike plate ensures smooth operation and minimizes wear over time. Buyers should always check these dimensions to prevent installation issues and enhance the performance of the latch.

Illustrative image related to magnet door latches

What Common Trade Terms Should B2B Buyers Understand?

In the world of magnet door latches, several trade terms are essential for effective communication and transaction processes. Here are some key terms to be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of magnet door latches, businesses may source components from OEMs to integrate into their products. Understanding OEM relationships can help buyers negotiate better terms and ensure quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ helps buyers assess whether a supplier is a good fit based on their purchasing capacity and project needs.

3. RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. When sourcing magnet door latches, an RFQ allows buyers to gather pricing, terms, and specifications from multiple suppliers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. These terms govern aspects such as shipping costs, risks, and delivery points, which are vital for international transactions involving magnet door latches. Familiarity with Incoterms helps avoid misunderstandings in trade agreements.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For businesses relying on timely delivery of magnet door latches, understanding lead times is essential for planning and ensuring project timelines are met.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing magnet door latches, ultimately leading to improved project outcomes and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the magnet door latches Sector

What Are the Key Trends Shaping the Magnet Door Latches Market?

The magnet door latches market is experiencing robust growth, driven by several global factors. Firstly, the rise of automation in manufacturing processes across various sectors, including automotive, appliance, and furniture manufacturing, is increasing the demand for efficient and low-maintenance hardware solutions. Additionally, the trend towards minimalistic design in architecture and interior design is pushing businesses to adopt sleek, concealed magnetic latches that offer both functionality and aesthetic appeal.

Emerging technologies, such as smart home systems and IoT integration, are also influencing the market. As consumers demand more sophisticated security and convenience features, manufacturers are developing magnetic latches that can seamlessly integrate with electronic locking systems. This trend is particularly relevant for international buyers in regions like Europe and the Middle East, where smart home technology adoption is rapidly increasing.

Illustrative image related to magnet door latches

Furthermore, supply chain dynamics are shifting due to the globalization of sourcing practices. B2B buyers from Africa and South America are now accessing a wider range of suppliers, including those from Asia and Europe. This global approach allows businesses to leverage competitive pricing, but it also necessitates a thorough evaluation of supplier reliability and product quality. As a result, buyers are increasingly focused on establishing long-term partnerships with manufacturers that can provide consistent quality and rapid response times.

How Can Sustainability and Ethical Sourcing Impact the Magnet Door Latches Sector?

Sustainability has become a crucial factor in the procurement process for B2B buyers, including those sourcing magnet door latches. Companies are increasingly aware of the environmental impact of their sourcing decisions, which includes the materials used in manufacturing and the energy consumed during production. Buyers are now looking for suppliers that prioritize eco-friendly materials, such as recycled metals and low-VOC finishes, which reduce the overall carbon footprint of their products.

Ethical sourcing is equally important, as businesses strive to uphold corporate social responsibility. B2B buyers are encouraged to seek manufacturers that adhere to ethical labor practices and possess certifications such as ISO 14001, which indicates a commitment to environmental management. These certifications not only ensure compliance with international standards but also enhance brand reputation in increasingly eco-conscious markets.

Additionally, the demand for ‘green’ certifications is on the rise. Products that are certified by recognized environmental standards can provide a competitive edge, particularly in markets like Germany, where consumers and businesses alike are increasingly prioritizing sustainability. By aligning sourcing strategies with sustainability goals, B2B buyers can foster stronger relationships with their customers and enhance their market position.

Illustrative image related to magnet door latches

How Has the Magnet Door Latches Industry Evolved Over Time?

The evolution of the magnet door latches industry reflects broader trends in manufacturing and design. Initially, door latches were primarily mechanical and required significant maintenance. The introduction of magnetic technology in the late 20th century revolutionized the industry by offering a more reliable and low-maintenance alternative. This shift was driven by advancements in magnet technology, particularly the development of Rare Earth magnets, which provided greater holding strength in a compact form.

Over the years, the application of magnetic latches has expanded beyond residential use to encompass industrial and commercial settings, where durability and performance are paramount. Today, manufacturers are continuously innovating to meet the demands of a diverse range of applications, from securing cabinet doors to integrating with smart home systems. This ongoing evolution positions magnetic door latches as a critical component in modern hardware solutions, catering to the diverse needs of B2B buyers across various sectors and regions.

Frequently Asked Questions (FAQs) for B2B Buyers of magnet door latches

-

How do I solve issues with magnetic door latches not holding securely?

If your magnetic door latches aren’t holding securely, first check the alignment of the latch and the strike plate. Misalignment can weaken the magnetic connection. Ensure that the surfaces are clean and free from debris that could interfere with the magnetic field. If the latch is still ineffective, consider whether the strength of the magnet is sufficient for your application; you may need to upgrade to a stronger model or adjust the installation to reduce the gap between the magnet and the strike plate. -

What is the best magnetic door latch for industrial applications?

For industrial applications, a heavy-duty concealed magnetic door catch is often the best choice. These latches are designed to handle rigorous daily use and can withstand harsh environmental conditions. Look for latches made from durable materials such as stainless steel, which not only ensures longevity but also minimizes maintenance needs. Additionally, consider options that allow for power adjustment to enhance holding strength, ensuring that they meet the demands of high-traffic environments. -

What factors should I consider when sourcing magnetic door latches internationally?

When sourcing magnetic door latches internationally, consider factors such as product quality, compliance with industry standards, and the reputation of the supplier. Verify if the supplier is ISO certified to ensure consistent quality. Additionally, assess their ability to meet your delivery timelines and whether they provide adequate support for product development. Communication capabilities, including language proficiency and responsiveness, are also crucial in navigating international transactions smoothly. -

What are the typical minimum order quantities (MOQs) for magnetic door latches?

Minimum order quantities for magnetic door latches can vary significantly based on the manufacturer and the specifics of the product. Generally, MOQs can range from 50 to several hundred units. It’s essential to discuss your needs directly with the supplier to negotiate terms that align with your business requirements. Some suppliers may offer flexibility for first-time orders or for established relationships, so it’s beneficial to communicate your purchasing plans clearly. -

How can I ensure the quality of magnetic door latches before making a bulk purchase?

To ensure the quality of magnetic door latches, request samples before placing a bulk order. Evaluate the materials, strength, and functionality of the samples in real-world applications. Additionally, inquire about the supplier’s quality assurance processes, including testing and certification. Reading reviews and case studies from other B2B clients can also provide insights into the product’s performance and reliability. Establishing a clear return policy can further safeguard your investment. -

What payment terms are typically offered by suppliers of magnetic door latches?

Payment terms can vary widely among suppliers, but most will offer options such as upfront payment, net 30, or net 60 days. Some suppliers may require a deposit before production, especially for custom orders. It’s important to clarify these terms upfront to avoid any misunderstandings. Additionally, inquire about payment methods accepted, such as bank transfers, letters of credit, or online payment platforms, to facilitate smooth transactions. -

What logistics considerations should I keep in mind when importing magnetic door latches?

When importing magnetic door latches, consider logistics aspects such as shipping costs, customs duties, and delivery timelines. Ensure you understand the regulatory requirements for importing hardware into your country, including any safety standards. Partnering with a reliable freight forwarder can help navigate these complexities. Additionally, confirm that the supplier provides appropriate packaging to prevent damage during transit, particularly for sensitive magnetic components. -

How can I customize magnetic door latches to meet specific requirements?

Most manufacturers offer customization options for magnetic door latches, allowing you to specify dimensions, materials, and finishes. When seeking customization, provide detailed specifications and any necessary design files to ensure accuracy. Discuss potential lead times for custom orders, as they can differ from standard products. Engaging in early communication with the supplier about your specific needs will help streamline the process and ensure that the final product aligns with your expectations.

Top 6 Magnet Door Latches Manufacturers & Suppliers List

1. Magnetics – Rare Earth Magnetic Latches

Domain: magnetics.com

Registered: 1995 (30 years)

Introduction: Magnetic Latches are extremely powerful Rare Earth magnetic latches designed for securing cabinet doors and mounting displays that can be easily changed. They feature a thin profile, making them ideal for door and cabinet applications, as well as for mounting panels, signs, and pictures. The latches are plated to reduce corrosion, and the washers are recessed to allow screw heads to sit below the …

2. Hardwaresource – Concealed Magnetic Door Catch

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Concealed Magnetic Door Catch, Heavy Duty’, ‘sku’: ‘935000’, ‘price’: {‘black’: ‘$59.95’, ‘silver’: ‘$52.95’}, ‘description’: ‘A heavy duty concealed magnetic catch suitable for full size doors. Can be used anywhere that a roller, ball, or other type of door catch would normally be installed. The magnets do not touch after installation, meaning: The catch will never wear out, no latch no…

3. Sierra Pacific Engineering – High-Quality Magnetic Catches

Domain: spep.com

Registered: 1997 (28 years)

Introduction: High-Quality Door Magnetic Catch from Sierra Pacific Engineering and Products (SPEP) designed for industrial and commercial applications. Magnetic latches provide simplicity, convenience, and low maintenance. SPEP’s magnetic latches withstand rigorous daily use and harsh environmental conditions. SPEP sells B2B only, focusing on OEM customers. Magnetic door catches consist of a magnetized latch an…

4. INOX – TL7 Magnetic Latch

Domain: inoxproducts.com

Registered: 2006 (19 years)

Introduction: TL7 Magnetic Latch for Tubular Interior Leversets; eliminates need for lip strikes and door frame lip cut-outs; applicable with all INOX decorative lever, knob, and escutcheon designs; available in 2-3/8″ (60mm) and 2-3/4″ (70mm) backset; incorporates neodymium rare earth magnets; meets ANSI A117.1 Accessibility (ADA Compliant); door thickness: 1-3/8″ (35mm) to 1-3/4″ (44mm); latch backset: 2-3/8″…

5. Lee Valley – Magnetic Touch Latches

Domain: leevalley.com

Introduction: [{‘name’: ‘Double Magnetic Touch Latch’, ‘price’: ‘$4.50’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Panel Magnet Cup’, ‘price’: ‘$4.50’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Magnetic Touch Latches’, ‘price’: ‘$3.20’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Latch Plates for Glass Doors’, ‘price’: ‘$2.00’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Brass Magnetic Catch…

6. First4Magnets – Magnetic Catches & Closures

Domain: first4magnets.com

Registered: 2007 (18 years)

Introduction: Magnetic catches and closures offer convenient aid for closing and holding applications for use within cupboards, drawers, and gate closures. The range includes discreet closures and secure door catches, providing high-quality solutions. There are 25 products available, categorized by type, shape, thickness, and material. Types include craft and model making magnets, DIY magnets, and super strong …

Strategic Sourcing Conclusion and Outlook for magnet door latches

How Can Strategic Sourcing Enhance Your Procurement of Magnet Door Latches?

In the competitive landscape of industrial hardware, particularly for magnet door latches, strategic sourcing emerges as a pivotal approach for international B2B buyers. By aligning procurement strategies with reputable manufacturers, buyers can ensure access to high-quality products that meet stringent performance standards. As seen with various models, including those featuring advanced materials like Rare Earth magnets, the durability and reliability of these latches are paramount for applications across sectors such as automotive and appliance manufacturing.

Buyers should prioritize partnerships that offer comprehensive support, from product development to efficient supply chain management. This not only enhances operational efficiency but also fosters innovation tailored to specific market needs. Furthermore, understanding local market dynamics in regions such as Africa, South America, the Middle East, and Europe will enable companies to make informed decisions that drive cost-effectiveness and sustainability.

Looking ahead, the demand for magnetic door latches is expected to grow, driven by advancements in technology and increased focus on safety and convenience. Now is the time for international buyers to engage with suppliers who can deliver not just products, but strategic value and insights tailored to their unique challenges. Embrace this opportunity to strengthen your supply chain and ensure your organization remains competitive in a rapidly evolving marketplace.

Illustrative image related to magnet door latches

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.