How to Source Mechanical Terms Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for mechanical terms

In the complex landscape of international B2B transactions, sourcing accurate mechanical terms can present a significant challenge for buyers, particularly when navigating diverse industries and markets. Understanding terms related to mechanical engineering is essential for making informed decisions about equipment, materials, and processes that are crucial to operations. This guide serves as a comprehensive resource, detailing a wide array of mechanical terms, their applications, and the nuances of supplier vetting, pricing strategies, and cost considerations.

As global markets expand, buyers from regions such as Africa, South America, the Middle East, and Europe—including key players like Saudi Arabia and Germany—face the necessity of aligning their procurement strategies with local and international standards. This guide empowers B2B buyers by providing not only definitions and explanations of essential mechanical terms but also actionable insights into how these terms apply to their specific purchasing needs. By leveraging this knowledge, buyers can enhance their negotiation capabilities, streamline their supply chain processes, and ultimately drive their business success in an increasingly competitive environment.

By demystifying the lexicon of mechanical engineering, this guide equips buyers with the tools needed to make educated choices that align with their operational goals, fostering confidence in every purchase decision.

Understanding mechanical terms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Components | Physical parts that perform specific functions in machines | Manufacturing, Automotive, Aerospace | Pros: Essential for machine function; Cons: May require regular maintenance and replacement. |

| Mechanical Systems | Assemblies of components working together | Robotics, HVAC, Industrial Automation | Pros: Integrated solutions; Cons: Complexity can lead to higher initial costs. |

| Mechanical Processes | Methods for transforming materials or energy | Metalworking, Fabrication, Energy Production | Pros: Increases efficiency; Cons: Requires skilled labor and precise control. |

| Mechanical Properties | Characteristics that define material behavior under stress | Construction, Manufacturing, Material Science | Pros: Critical for material selection; Cons: Testing and analysis can be time-consuming. |

| Mechanical Tools | Instruments used for shaping, cutting, or assembling | Manufacturing, Construction, Maintenance | Pros: Improves precision and efficiency; Cons: Initial investment can be high. |

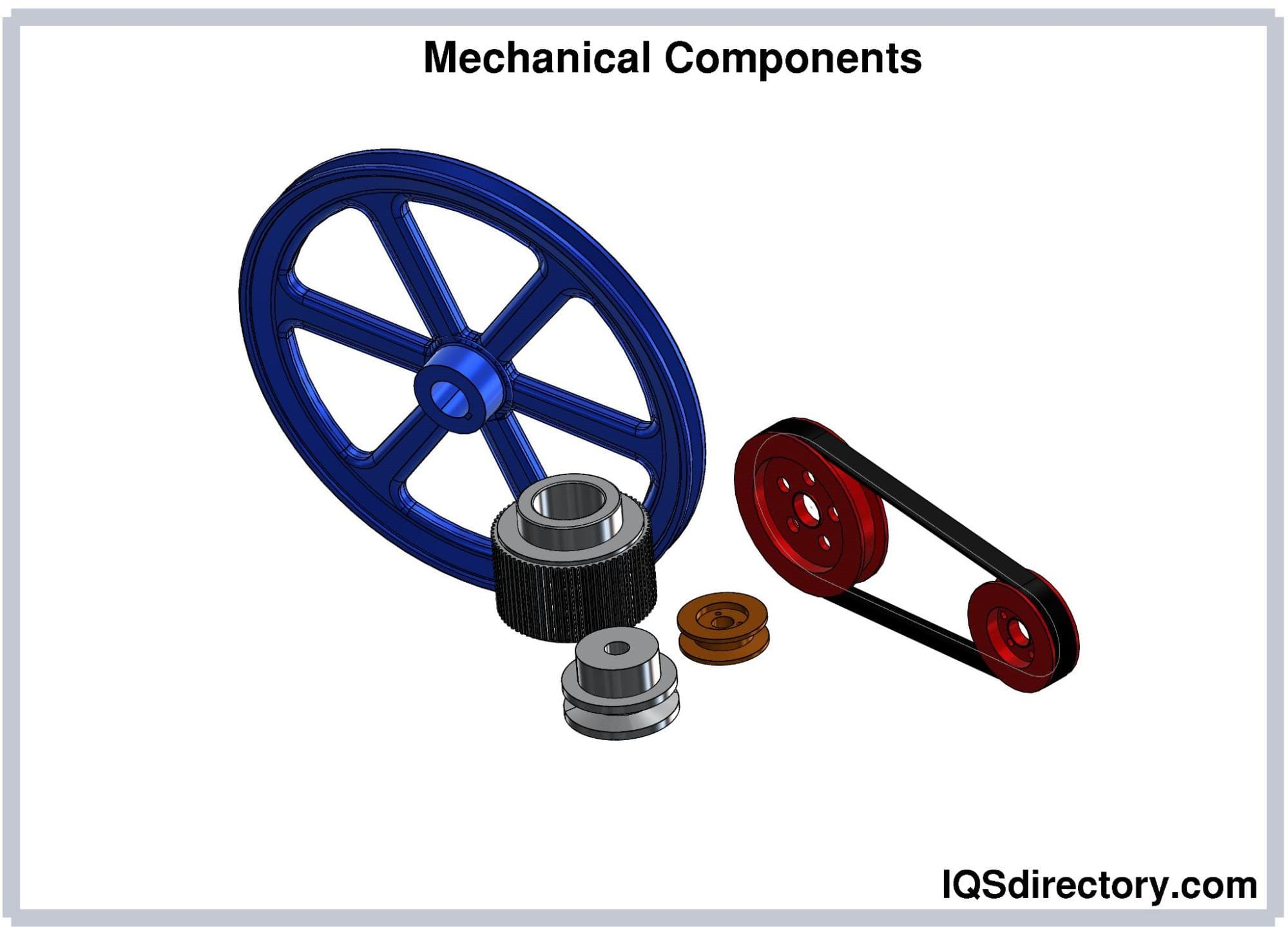

What are the Characteristics of Mechanical Components and Their Suitability for B2B Buyers?

Mechanical components are the building blocks of machinery and equipment, including items like gears, bearings, and pistons. They are characterized by their specific functions, such as transmitting motion or supporting loads. For B2B buyers, the suitability of these components hinges on their application, durability, and compatibility with existing systems. When purchasing, buyers should consider factors such as material quality, maintenance requirements, and the supplier’s ability to provide timely support.

How Do Mechanical Systems Integrate Components for Enhanced Functionality?

Mechanical systems consist of interconnected components designed to perform a collective function, such as a robotic arm or an HVAC system. These systems are distinguished by their complexity and the need for precise engineering to ensure seamless operation. B2B buyers should evaluate the scalability and reliability of these systems, considering factors like ease of integration and the availability of technical support. Investing in a well-designed mechanical system can lead to increased productivity and reduced operational costs.

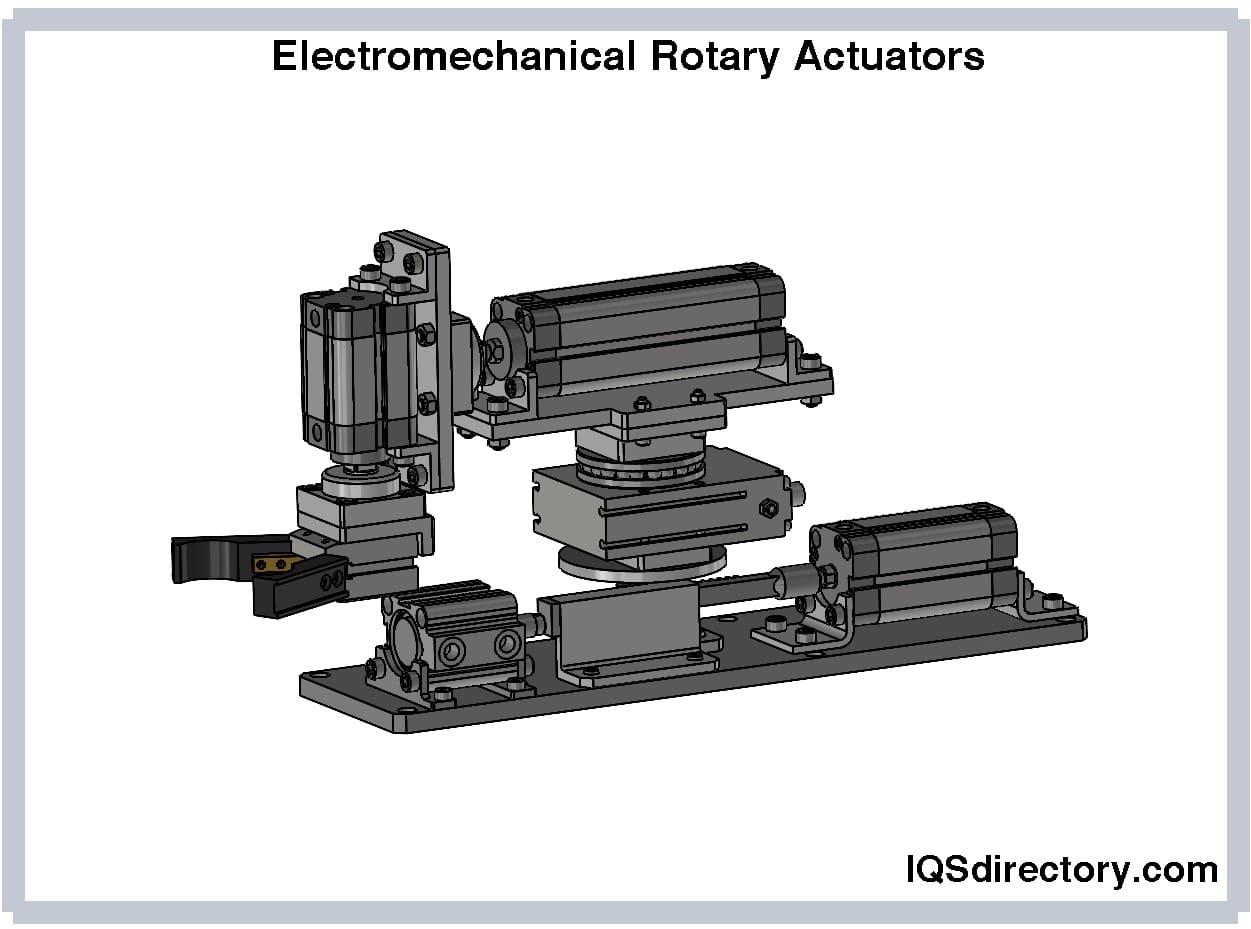

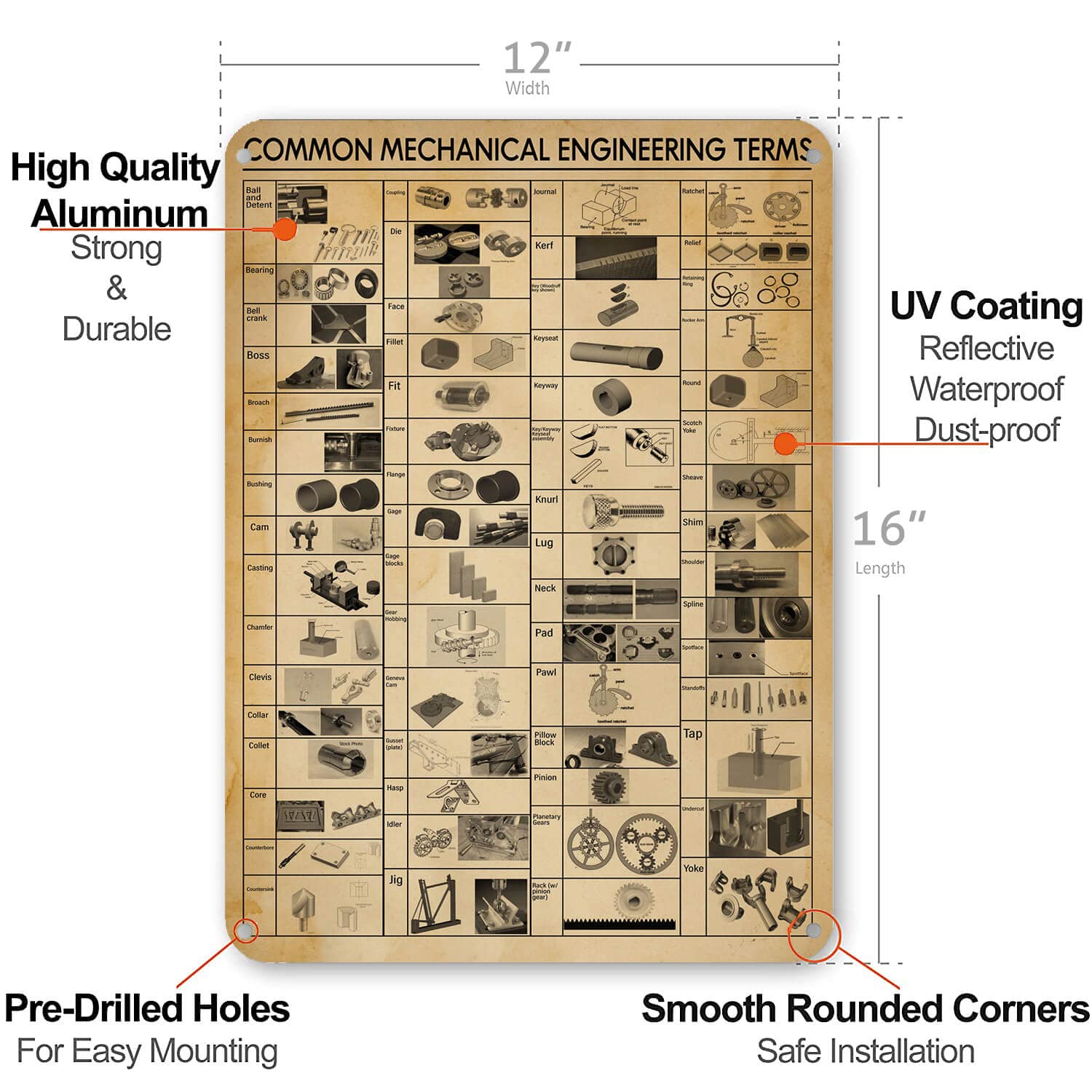

Illustrative image related to mechanical terms

What Are the Key Considerations for Mechanical Processes in B2B Applications?

Mechanical processes refer to the various methods used to manipulate materials or energy, such as machining, welding, and assembly. These processes are essential in industries like manufacturing and energy production, where efficiency and precision are paramount. B2B buyers must assess the suitability of a process for their specific needs, including the required skill level and potential for automation. Understanding the pros and cons of different processes can help in making informed purchasing decisions that align with operational goals.

How Do Mechanical Properties Impact Material Selection for B2B Buyers?

Mechanical properties define how materials respond to applied forces, including tensile strength, elasticity, and hardness. These properties are critical in industries like construction and manufacturing, where the performance of materials directly affects safety and functionality. B2B buyers should prioritize thorough testing and analysis to ensure that the materials chosen meet the required specifications. Knowledge of mechanical properties can lead to better material selection, enhancing the overall quality and longevity of products.

What Role Do Mechanical Tools Play in Improving Manufacturing Efficiency?

Mechanical tools encompass a range of instruments designed for tasks such as cutting, shaping, and assembling materials. These tools are essential in manufacturing and construction, providing the precision needed for high-quality outputs. B2B buyers must weigh the initial investment against the long-term benefits, including productivity gains and reduced labor costs. Selecting the right tools can significantly enhance operational efficiency, making it a crucial consideration in the purchasing process.

Key Industrial Applications of mechanical terms

| Industry/Sector | Specific Application of mechanical terms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machining processes | Increases precision and efficiency in production | Quality of cutting tools, material compatibility, lead times |

| Automotive | Internal Combustion Engines | Enhances performance and fuel efficiency | Engine specifications, compliance with emission standards |

| Aerospace | Aerospace Engineering | Ensures safety and reliability in flight operations | Certification requirements, materials for weight reduction |

| Energy | Turbines and Generators | Maximizes energy output and operational efficiency | Maintenance schedules, parts availability, energy regulations |

| Construction | Hydraulic Systems | Improves lifting and moving capabilities in projects | Equipment durability, hydraulic fluid specifications |

How Are Mechanical Terms Applied in Manufacturing?

In the manufacturing sector, machining processes utilize mechanical terms such as “machining,” “cutting tools,” and “tolerance” to achieve high precision and efficiency in production. By implementing advanced machining techniques, manufacturers can reduce waste, optimize material usage, and enhance product quality. For international buyers, especially from regions like Africa and South America, sourcing high-quality cutting tools and ensuring compatibility with local materials are critical to maintaining production standards and reducing downtime.

What Role Do Mechanical Terms Play in the Automotive Industry?

In the automotive industry, mechanical terms are fundamental in the design and operation of internal combustion engines. Terms like “compression ratio” and “fuel injector” are crucial for enhancing engine performance and fuel efficiency. For B2B buyers, particularly in the Middle East and Europe, understanding engine specifications and compliance with stringent emission standards is essential when sourcing components. This ensures that the vehicles produced meet both performance expectations and regulatory requirements.

How Are Mechanical Terms Essential in Aerospace Engineering?

Aerospace engineering heavily relies on mechanical terms to ensure the safety and reliability of aircraft and spacecraft. Terms such as “aerospace engineering” and “dynamic balance” are vital in the design and testing phases of flight components. International buyers, especially from Europe and the Middle East, must consider certification requirements and the use of lightweight materials to enhance performance while adhering to strict safety regulations. This focus on quality and compliance is essential for successful procurement in this high-stakes industry.

How Do Mechanical Terms Enhance Energy Sector Efficiency?

In the energy sector, mechanical terms like “turbine” and “generator” are integral to maximizing energy output and operational efficiency. Understanding these terms allows businesses to select the right equipment for power generation, whether it be from renewable sources or traditional methods. For buyers in Africa and South America, factors such as maintenance schedules and parts availability are crucial for ensuring uninterrupted energy production and compliance with local energy regulations.

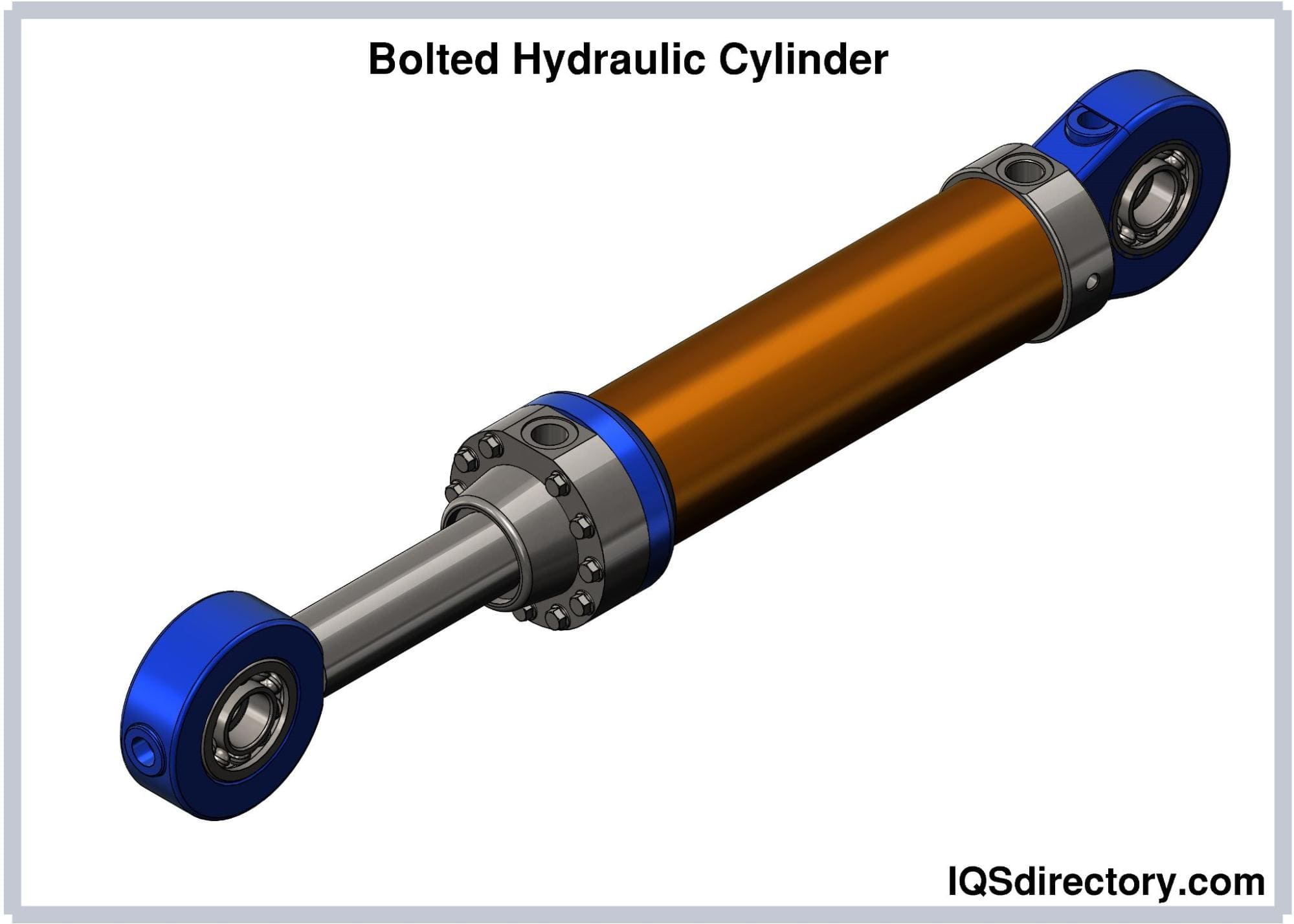

Illustrative image related to mechanical terms

What Importance Do Mechanical Terms Have in Construction?

In construction, hydraulic systems are vital for lifting and moving heavy materials, utilizing terms like “hydraulics” and “load” to ensure safe operations. By understanding these mechanical terms, construction companies can select the right equipment that meets project requirements. For international buyers, especially in emerging markets, sourcing durable equipment and adhering to hydraulic fluid specifications are key considerations that can significantly impact project efficiency and safety.

3 Common User Pain Points for ‘mechanical terms’ & Their Solutions

Scenario 1: Navigating Complex Terminology in Mechanical Engineering

The Problem:

B2B buyers in industries such as manufacturing or construction often encounter a significant challenge when trying to communicate technical specifications and requirements. Mechanical terms can be complex and varied across different regions and industries, leading to misunderstandings and errors in procurement. For instance, a buyer in South America may refer to a “bearings” specification differently than a supplier in Germany, causing misalignment in expectations and potentially resulting in costly delays or product failures.

The Solution:

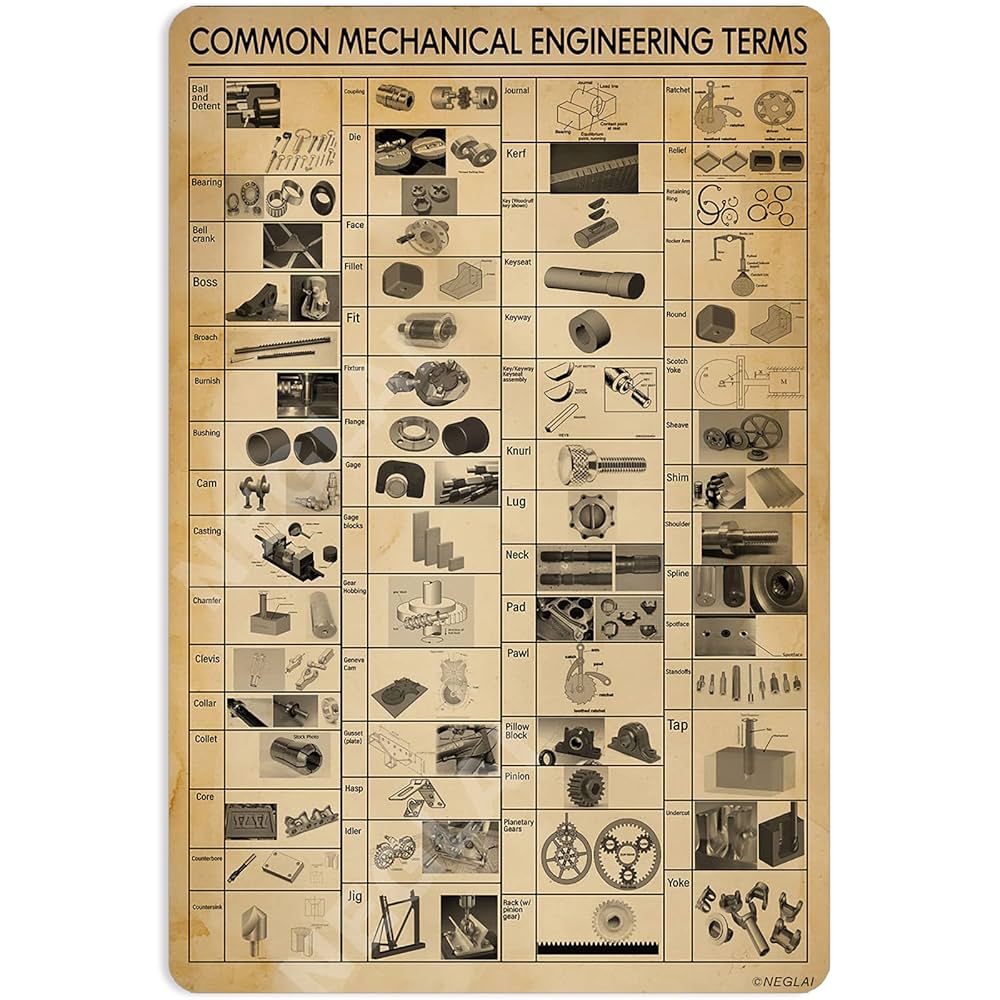

To mitigate this issue, B2B buyers should prioritize the creation of a standardized glossary of mechanical terms tailored to their specific industry and geographical context. This glossary should be developed in collaboration with both internal teams and suppliers, ensuring that everyone is on the same page. Additionally, utilizing visual aids such as diagrams or charts can help bridge language barriers and clarify complex concepts. Training sessions or workshops can also be beneficial in enhancing the team’s understanding of these terms, fostering better communication throughout the supply chain. By establishing a common language, buyers can ensure that specifications are accurately conveyed, reducing the risk of errors and enhancing operational efficiency.

Scenario 2: Overcoming Measurement Misinterpretations

The Problem:

Inaccurate measurements and specifications can lead to significant operational setbacks. For instance, a buyer may specify a “compression ratio” for an engine component without understanding how it varies across different engine types. This can result in sourcing parts that are incompatible, causing delays in production and additional costs in reworking or returning the incorrect items. Such misunderstandings are particularly problematic when dealing with international suppliers who may interpret these terms differently based on local standards and practices.

The Solution:

To address this pain point, buyers should implement a rigorous verification process for all technical specifications before finalizing orders. This includes cross-referencing measurements and terms with industry standards, such as those set by ISO or ASTM, which can provide a benchmark for accuracy. Leveraging digital tools, such as CAD software or measurement apps, can further enhance precision in specifications. Additionally, engaging in open dialogue with suppliers to confirm understanding of technical terms and specifications can preemptively resolve potential discrepancies. Establishing a culture of accuracy not only streamlines procurement but also strengthens supplier relationships, leading to more reliable partnerships.

Scenario 3: Managing Quality Control Standards Across Borders

The Problem:

Quality control is a critical aspect of mechanical engineering, yet B2B buyers often face challenges in ensuring that products meet their specific standards, especially when sourcing from international suppliers. The term “quality control” may encompass different practices and expectations in various regions, leading to inconsistency in product quality. For example, a buyer from the Middle East may have stringent quality requirements that are not communicated effectively to a supplier in Africa, resulting in the receipt of subpar products that do not meet operational standards.

The Solution:

To overcome this challenge, buyers should establish clear and detailed quality control guidelines that are agreed upon by both parties before any transactions occur. This involves outlining specific metrics, testing methods, and certification requirements that are aligned with international standards. Implementing regular audits and inspections can help ensure compliance and maintain quality over time. Additionally, fostering a collaborative relationship with suppliers, where feedback is continuously shared, can lead to improved quality outcomes. By taking proactive steps to align quality expectations, B2B buyers can significantly reduce the risk of receiving inferior products and enhance their operational success.

Strategic Material Selection Guide for mechanical terms

What Are the Key Properties of Common Materials Used in Mechanical Applications?

When selecting materials for mechanical applications, understanding their properties is crucial. Here, we analyze four common materials—steel, aluminum, brass, and plastics—focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Steel: A Versatile Choice for Mechanical Components

Steel is renowned for its strength and durability, making it a go-to material for various mechanical applications. It typically has a high tensile strength, excellent wear resistance, and can withstand high temperatures and pressures. However, its susceptibility to corrosion necessitates protective coatings or treatments.

Pros: Steel offers high strength and durability, making it suitable for heavy-duty applications. It is relatively cost-effective and widely available, which simplifies sourcing for international buyers.

Cons: The weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, its corrosion vulnerability may lead to increased maintenance costs.

Impact on Application: Steel is ideal for components like gears, shafts, and structural frameworks, particularly in environments where mechanical stress is high.

Considerations for Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM or DIN, particularly for structural steel applications.

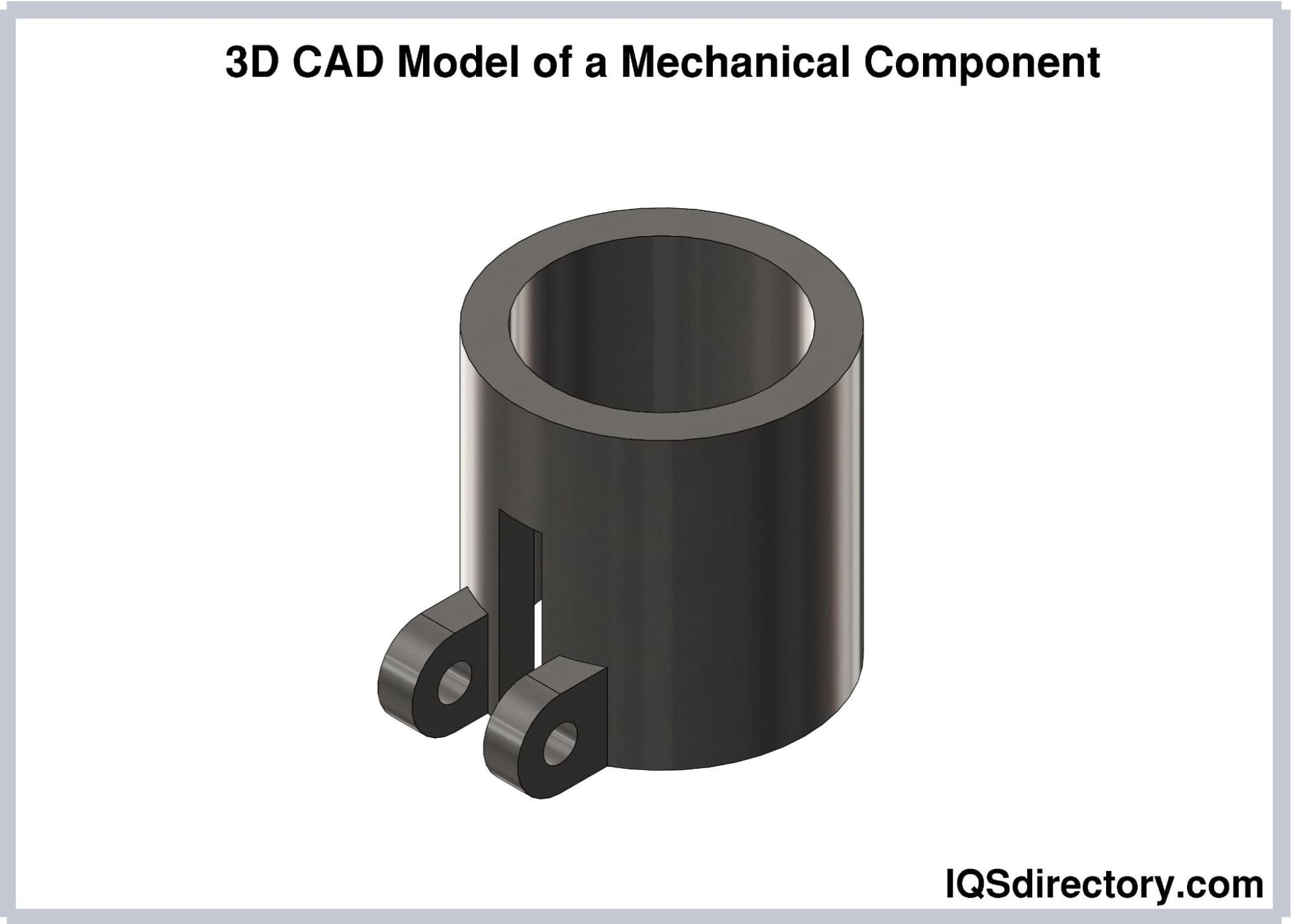

Illustrative image related to mechanical terms

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is favored for its lightweight properties and excellent corrosion resistance, making it ideal for applications where weight savings are essential, such as in aerospace and automotive industries. Its thermal and electrical conductivity is also noteworthy.

Pros: The lightweight nature of aluminum contributes to fuel efficiency in vehicles and aircraft. It also offers good machinability and is recyclable, aligning with sustainability goals.

Cons: Aluminum generally has lower tensile strength compared to steel, which may limit its use in heavy-duty applications. It can also be more expensive than steel.

Impact on Application: Aluminum is often used in components like brackets, housings, and heat exchangers, where weight and corrosion resistance are critical.

Considerations for Buyers: B2B buyers in Africa and South America should consider local availability and pricing fluctuations, as aluminum can be more costly in regions with limited supply chains.

Brass: A Durable Option for Precision Components

Brass, an alloy of copper and zinc, is commonly used for precision components due to its excellent machinability and resistance to corrosion. It also has good thermal and electrical conductivity, making it suitable for various mechanical applications.

Pros: Brass is durable and resistant to tarnishing, making it ideal for aesthetic applications like fittings and fixtures. Its machinability allows for intricate designs and precise tolerances.

Cons: Brass can be more expensive than steel and aluminum. Additionally, it is not as strong as steel, which may limit its use in high-stress applications.

Impact on Application: Brass is often used in applications such as valves, fittings, and electrical connectors, where corrosion resistance and precision are paramount.

Illustrative image related to mechanical terms

Considerations for Buyers: Buyers in Europe should be aware of the regulations regarding lead content in brass, as compliance with local standards is essential.

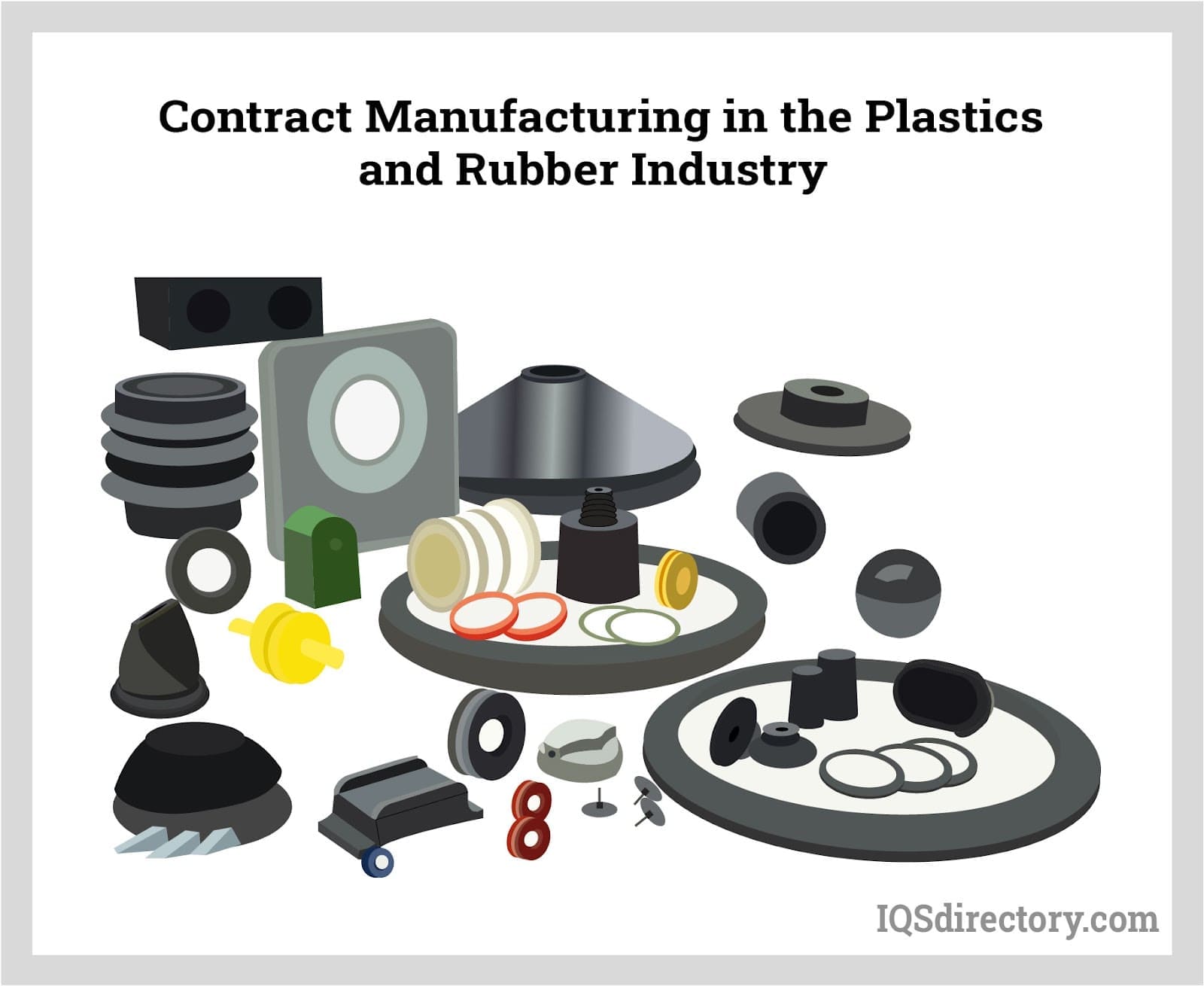

Plastics: Versatile and Cost-Effective

Plastics are increasingly used in mechanical applications due to their versatility, lightweight nature, and resistance to corrosion. Various types of plastics, such as nylon and polycarbonate, offer different properties suitable for specific applications.

Pros: Plastics are generally low-cost and can be molded into complex shapes, providing design flexibility. They are also resistant to chemicals and moisture.

Cons: Plastics may not withstand high temperatures or mechanical stresses as well as metals, which can limit their application scope. They can also degrade under UV exposure unless treated.

Impact on Application: Plastics are often used in components like housings, gears, and seals, particularly in environments where corrosion resistance is critical.

Considerations for Buyers: B2B buyers should evaluate the specific type of plastic and its compatibility with the intended application, considering factors like temperature and chemical exposure.

Summary Table of Material Selection for Mechanical Applications

| Material | Typical Use Case for mechanical terms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Gears, shafts, structural components | High strength and durability | Heavy and prone to corrosion | Medium |

| Aluminum | Aerospace parts, automotive components | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Brass | Valves, fittings, electrical connectors | Excellent machinability | More expensive, lower strength | Medium |

| Plastics | Housings, gears, seals | Low-cost and versatile | Limited temperature resistance | Low |

This analysis provides a comprehensive overview of material selection considerations for mechanical applications, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mechanical terms

What Are the Key Stages of Manufacturing Processes in Mechanical Engineering?

Manufacturing processes for mechanical components typically encompass several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers who want to ensure that their suppliers adhere to best practices and deliver high-quality products.

How Is Material Prepared for Mechanical Manufacturing?

Material preparation is the first step in the manufacturing process. This stage involves selecting the appropriate raw materials, which may include metals, alloys, or composites, based on the desired mechanical properties and application requirements. Materials undergo processes such as cutting, machining, and surface treatment to achieve the required dimensions and surface quality. Advanced techniques like laser cutting and waterjet cutting are often employed to enhance precision and reduce waste.

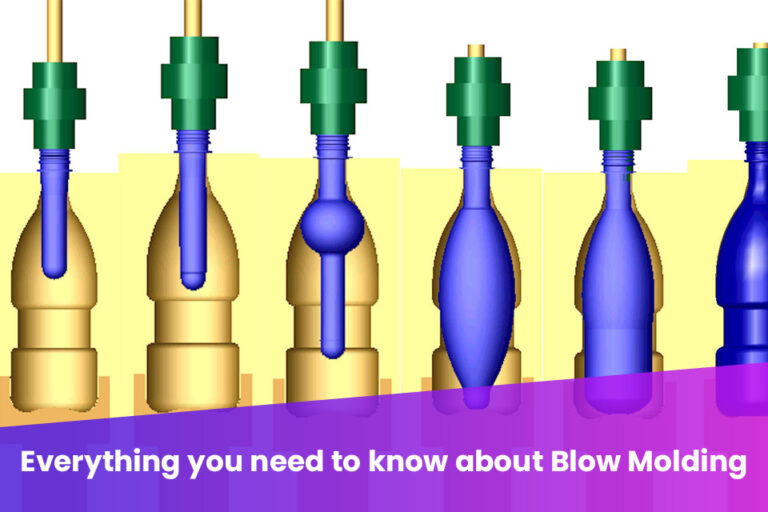

What Forming Techniques Are Commonly Used in Mechanical Manufacturing?

Once the materials are prepared, the next stage is forming. This involves shaping the materials into the desired forms using various techniques, including forging, casting, and machining.

- Forging involves deforming metal using compressive forces, which enhances its strength and toughness. This technique is particularly useful for components like gears and shafts.

- Casting allows for the creation of complex shapes by pouring molten metal into molds. This is commonly used for parts like engine blocks and housings.

- Machining includes processes such as turning, milling, and drilling, where material is removed from a workpiece to achieve precise dimensions.

Each of these techniques offers unique advantages, and the choice depends on factors such as the part’s geometry, material properties, and production volume.

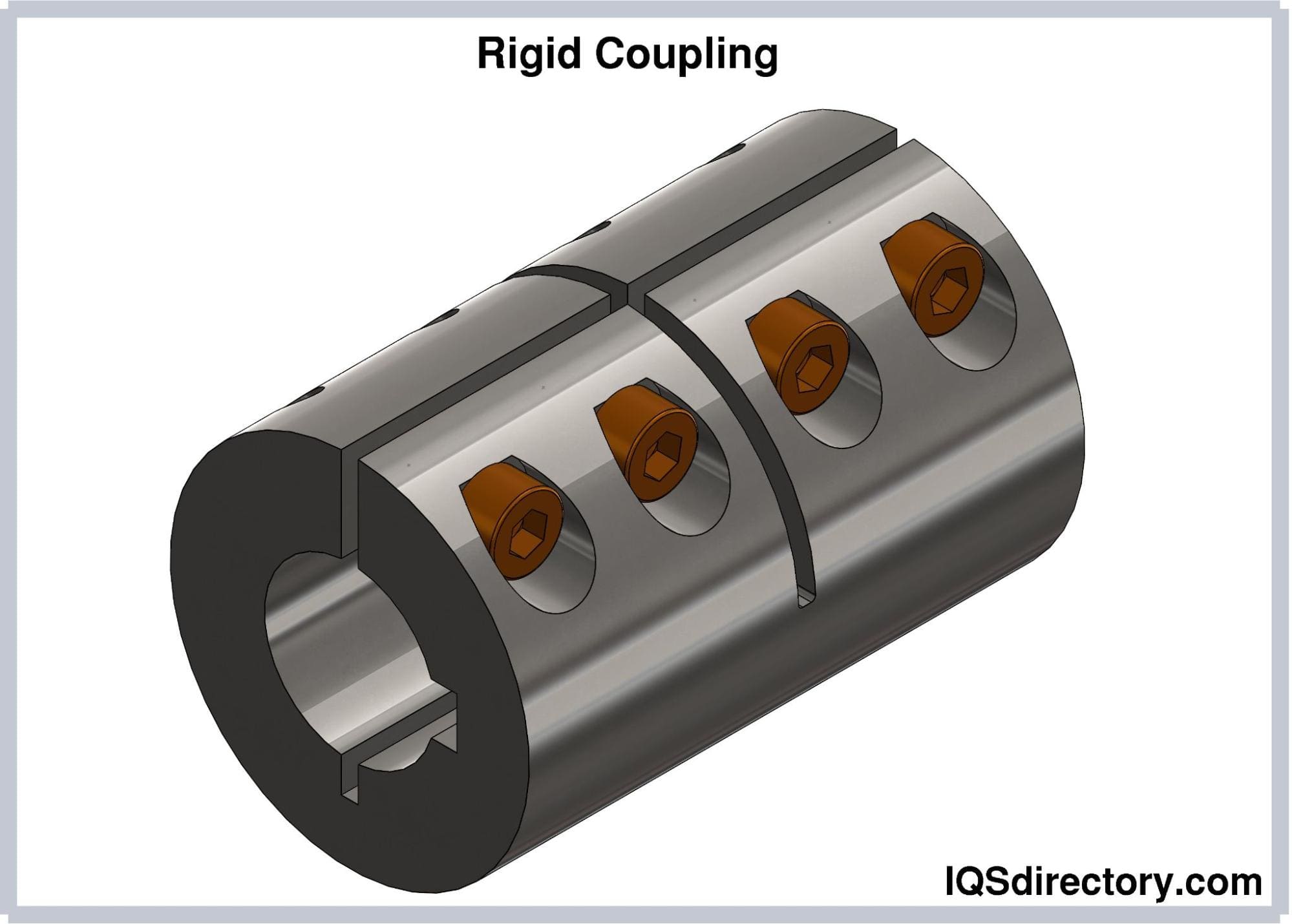

How Does the Assembly Stage Contribute to Quality in Mechanical Manufacturing?

The assembly stage is where individual components are put together to form the final product. This can involve manual assembly or automated processes using robotics. Quality during this stage is critical, as improper assembly can lead to functional failures. Techniques such as lean manufacturing and Six Sigma are often applied to optimize assembly processes and minimize errors. B2B buyers should look for suppliers who implement thorough assembly procedures and can demonstrate their effectiveness.

What Finishing Techniques Are Essential in Mechanical Manufacturing?

Finishing processes are applied after assembly to enhance the surface quality and performance of mechanical components. Common finishing techniques include:

- Surface treatment (e.g., anodizing, galvanizing) to improve corrosion resistance.

- Painting or coating for aesthetics and additional protection.

- Polishing to achieve a smooth finish, which is especially important for parts that require low friction.

These finishing steps not only enhance the appearance of the product but also play a significant role in its durability and functionality.

What Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance (QA) is critical in ensuring that manufactured mechanical components meet specified standards. B2B buyers should be familiar with international quality standards such as ISO 9001, which provides a framework for quality management systems. Additionally, industry-specific certifications like CE marking for products sold in Europe or API standards for oil and gas components can be significant indicators of quality.

What Are the Key Quality Control Checkpoints in Mechanical Manufacturing?

Quality control (QC) involves systematic inspections and tests at various checkpoints throughout the manufacturing process. The main QC checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to identify and rectify defects during manufacturing.

- Final Quality Control (FQC): Conducts thorough inspections and tests on finished products before they are shipped to customers.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defects and ensure that products meet quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the QC practices of potential suppliers. This can include:

- Conducting audits: Regular audits of suppliers can provide insights into their quality management systems and adherence to standards.

- Requesting quality reports: Suppliers should be able to provide documentation regarding their QC processes, inspection results, and any certifications they hold.

- Utilizing third-party inspection services: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s manufacturing and quality practices.

By taking these steps, buyers can ensure that their suppliers maintain high standards of quality and reliability.

Illustrative image related to mechanical terms

What Are the Nuances of Quality Control for International B2B Transactions?

When dealing with international suppliers, particularly in regions such as Africa, South America, the Middle East, and Europe, B2B buyers must be aware of specific QC nuances. Different countries may have varying regulations and standards, which can affect quality expectations. For instance, products exported to the European Union must comply with CE marking requirements, while those destined for the Middle East may need to meet GSO standards.

Additionally, cultural differences can influence business practices and communication. It is crucial for buyers to establish clear quality expectations and maintain open lines of communication with suppliers to mitigate potential misunderstandings.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Mechanical Engineering

In summary, a thorough understanding of manufacturing processes and quality assurance measures is essential for B2B buyers in the mechanical engineering sector. By familiarizing themselves with key stages in manufacturing, relevant quality standards, and verification techniques, buyers can make informed decisions when selecting suppliers. This proactive approach not only enhances the quality of the products they receive but also contributes to long-term business success.

Illustrative image related to mechanical terms

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mechanical terms’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure mechanical components and systems. Understanding mechanical terms is essential for effective communication and decision-making in sourcing processes. This checklist will help you navigate the complexities of mechanical terminology, ensuring you make informed purchasing decisions that align with your technical requirements.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in the sourcing process. This includes identifying the specific mechanical terms relevant to your project, such as “bearing,” “gearbox,” or “piston.” By having precise definitions, you can communicate your needs effectively to suppliers and avoid misunderstandings that could lead to costly errors.

- Consider the application: Think about how the mechanical components will be used in your operations.

- Document requirements: Create a detailed list of specifications, including dimensions, materials, and performance criteria.

Step 2: Research Supplier Expertise

Identifying suppliers with expertise in your specific mechanical terms is crucial. Not all suppliers may have the same level of knowledge or product range. Research potential suppliers to ensure they have a strong background in the relevant mechanical engineering fields.

- Check industry experience: Look for suppliers who have worked with similar applications or industries.

- Review certifications: Ensure suppliers hold relevant certifications that validate their expertise and quality standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. This step involves assessing their capabilities, reliability, and track record. Request company profiles, case studies, and references from clients in similar industries or regions to gauge their performance.

- Conduct site visits: If possible, visit the supplier’s facility to assess their operations and quality control processes.

- Review customer feedback: Seek testimonials and reviews from previous clients to understand their experiences.

Step 4: Request Samples or Prototypes

Obtaining samples or prototypes is an effective way to evaluate the quality of the mechanical components you intend to purchase. This step allows you to assess whether the products meet your specifications and performance standards.

- Conduct tests: Use the samples in practical scenarios to see how they perform under real-world conditions.

- Compare with competitors: Evaluate samples from multiple suppliers to ensure you’re choosing the best option.

Step 5: Verify Compliance with Standards

Ensuring that the mechanical components comply with relevant industry standards is critical for safety and performance. Different regions may have specific regulations, so it’s important to verify that your suppliers meet these standards.

- Request documentation: Ask for compliance certificates and quality assurance documentation from your suppliers.

- Stay updated on regulations: Familiarize yourself with the latest industry standards applicable in your region.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, it’s time to negotiate terms and conditions. This includes pricing, delivery schedules, payment terms, and warranty agreements. Clear agreements help prevent misunderstandings and ensure that both parties have aligned expectations.

- Be transparent: Clearly communicate your budget and requirements during negotiations.

- Consider long-term partnerships: Think about the potential for future collaboration when negotiating terms, which can lead to better deals.

Step 7: Establish a Quality Control Process

Implementing a quality control process is essential for maintaining product standards throughout the procurement lifecycle. Define inspection criteria and establish protocols for evaluating the mechanical components upon delivery.

- Set benchmarks: Determine quality benchmarks based on your technical specifications.

- Plan for feedback: Create a system for providing feedback to suppliers, which can help improve product quality in the future.

By following this checklist, B2B buyers can effectively navigate the procurement of mechanical components, ensuring they meet their technical requirements while establishing strong supplier relationships.

Comprehensive Cost and Pricing Analysis for mechanical terms Sourcing

What Are the Key Cost Components in Mechanical Terms Sourcing?

When sourcing mechanical terms, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to mechanical terms

-

Materials: The choice of materials significantly impacts costs. High-quality alloys or specialized composites may increase prices but ensure durability and performance.

-

Labor: Skilled labor is essential in the manufacturing of mechanical components. Labor costs can vary widely depending on the region and expertise required.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: The initial investment in tools and machinery can be significant, especially for custom components. Consideration of tooling costs is essential for accurate pricing.

-

Quality Control (QC): Ensuring that mechanical components meet industry standards adds to the cost. Implementing robust QC processes can prevent costly errors down the line.

-

Logistics: Transportation and handling fees play a critical role in the overall cost. These can fluctuate based on distance and the chosen shipping methods.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

How Do Price Influencers Impact Mechanical Terms Sourcing?

Several factors can influence the pricing of mechanical components, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to achieve better pricing.

-

Specifications and Customization: Custom-engineered components will generally cost more than standard parts. Be clear about your requirements to avoid unexpected costs.

-

Materials: The choice of materials can significantly alter pricing. For example, using exotic materials will increase costs compared to standard options.

-

Quality and Certifications: Components that require specific certifications or high-quality standards may come at a premium. It’s essential to factor in these costs when evaluating suppliers.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate responsibilities for shipping costs, insurance, and customs duties, impacting total expenses.

What Are Effective Buyer Tips for Cost-Efficiency in Mechanical Terms Sourcing?

To maximize cost-efficiency when sourcing mechanical terms, consider the following tips:

-

Negotiation: Always negotiate pricing and terms with suppliers. Building long-term relationships can lead to better deals over time.

-

Total Cost of Ownership (TCO): Evaluate the TCO, not just the initial purchase price. Consider factors like maintenance, durability, and potential downtime to make informed decisions.

-

Pricing Nuances for International Buyers: B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import duties that may affect pricing. Understanding local market dynamics can provide a competitive edge.

-

Research and Comparison: Conduct thorough market research to compare prices and services from different suppliers. This can help identify the best value for your specific needs.

-

Seek Local Suppliers: Whenever possible, consider sourcing from local suppliers to reduce logistics costs and lead times, enhancing your supply chain efficiency.

Conclusion

Navigating the complexities of cost and pricing in mechanical terms sourcing requires careful analysis and strategic planning. By understanding the various cost components, recognizing price influencers, and employing effective buying strategies, B2B buyers can optimize their procurement processes and achieve significant savings. Always remember to check for indicative prices, as market conditions can lead to fluctuations in costs.

Alternatives Analysis: Comparing mechanical terms With Other Solutions

Understanding Alternative Solutions to Mechanical Terms

In the realm of mechanical engineering, understanding and utilizing specific mechanical terms is crucial for effective communication, design, and implementation. However, there are alternative solutions and methodologies that can also help achieve similar objectives. This analysis will compare mechanical terms against two viable alternatives: Computer-Aided Design (CAD) software and Simulation Software. These alternatives can enhance understanding and application in mechanical engineering, especially for B2B buyers looking for effective solutions.

Comparison Table

| Comparison Aspect | Mechanical Terms | CAD Software | Simulation Software |

|---|---|---|---|

| Performance | Essential for clear communication | High accuracy in design representation | Provides predictive insights |

| Cost | Generally low (knowledge-based) | High initial investment | Moderate to high, depending on complexity |

| Ease of Implementation | Requires basic knowledge | Requires training and expertise | Requires specialized knowledge |

| Maintenance | Minimal (knowledge updates needed) | Regular software updates needed | Continuous validation and updates |

| Best Use Case | Technical documentation and communication | Designing complex mechanical systems | Testing and optimizing designs |

Detailed Breakdown of Alternatives

CAD Software

Computer-Aided Design (CAD) software offers a digital platform for creating detailed drawings and models of mechanical components. Its primary advantage is the ability to visualize designs accurately and make real-time modifications. However, the initial investment can be significant, and users need to undergo training to effectively utilize the software. CAD is best suited for companies that require intricate designs and need to streamline their design processes, but it may not be as beneficial for smaller firms or those primarily focused on basic mechanical terms.

Simulation Software

Simulation software allows engineers to test and analyze the behavior of mechanical systems under various conditions without the need for physical prototypes. This capability can lead to significant cost savings and time efficiency in product development. While it provides valuable predictive insights, the complexity of these tools often requires specialized training and expertise, making them less accessible for smaller operations. This software is ideal for organizations looking to innovate and optimize their designs, particularly in industries where performance and safety are critical.

Conclusion: How to Choose the Right Solution

When evaluating the right solution for mechanical engineering needs, B2B buyers should consider their specific requirements, budget constraints, and the level of expertise available within their teams. If the focus is on effective communication and documentation, a solid understanding of mechanical terms may suffice. For organizations looking to enhance their design capabilities, investing in CAD software could be more advantageous. Conversely, those aiming for high-performance optimization should explore simulation software. Ultimately, the choice will hinge on aligning the selected solution with the company’s operational goals and available resources.

Illustrative image related to mechanical terms

Essential Technical Properties and Trade Terminology for mechanical terms

What Are the Key Technical Properties in Mechanical Engineering for B2B Buyers?

Understanding the critical specifications in mechanical engineering is essential for B2B buyers to ensure product quality, performance, and compliance with industry standards. Here are some of the most important technical properties:

-

Material Grade: The classification of materials based on their mechanical properties, such as strength, ductility, and hardness. For instance, steel grades like ASTM A36 or A992 define the material’s suitability for structural applications. Choosing the right material grade can affect the longevity and performance of mechanical components, directly impacting maintenance costs and operational efficiency.

-

Tolerance: This refers to the allowable deviation from a specified dimension. Tight tolerances ensure parts fit together correctly, which is crucial in high-precision applications like aerospace or automotive manufacturing. Understanding tolerance requirements helps buyers avoid costly reworks and ensure that components meet operational specifications.

-

Surface Finish: The texture and smoothness of a surface, which can influence wear resistance, friction, and aesthetic appeal. Different applications may require specific surface finishes, such as polished, anodized, or coated. Buyers must consider the surface finish to optimize performance and longevity in their applications.

-

Yield Strength: The maximum stress that a material can withstand while still being able to return to its original shape. In mechanical applications, knowing the yield strength helps buyers select materials that can endure operational stresses without permanent deformation, thus enhancing reliability and safety.

-

Fatigue Limit: The maximum stress level a material can withstand for an infinite number of cycles without failure. This property is critical for components subjected to repeated loading, such as gears and shafts. Understanding fatigue limits allows buyers to select materials that ensure longevity and reduce the risk of unexpected failures.

What Are Common Trade Terms Used in Mechanical Engineering?

Familiarity with industry jargon is crucial for effective communication and negotiations in B2B transactions. Here are several key terms that every buyer should know:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source high-quality components that meet specific performance standards.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget effectively, ensuring they do not overstock or run into supply chain issues.

-

RFQ (Request for Quotation): A standard business process where buyers invite suppliers to submit price quotes for specific products or services. An RFQ allows buyers to compare costs and terms from multiple vendors, enabling informed decision-making in procurement.

-

Incoterms (International Commercial Terms): A set of rules that define the responsibilities of buyers and sellers in international transactions, including shipping, risk, and insurance. Understanding Incoterms helps buyers manage logistics and costs more effectively, ensuring smooth cross-border transactions.

-

Lead Time: The amount of time from placing an order to receiving the goods. Knowing lead times is essential for buyers to coordinate production schedules and manage inventory levels, minimizing disruptions in their supply chain.

-

Certification: Documentation that verifies a product or service meets specific industry standards or regulations. Certifications can affect marketability and compliance, making it crucial for buyers to consider when sourcing components for regulated industries.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and product quality in their mechanical engineering projects.

Navigating Market Dynamics and Sourcing Trends in the mechanical terms Sector

What Are the Key Trends Shaping the Mechanical Terms Market for International B2B Buyers?

The mechanical terms sector is experiencing significant transformation driven by globalization, technological advancements, and evolving customer demands. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany) engage with this dynamic market, several key trends emerge. First, the integration of Industry 4.0 technologies, including IoT and AI, is reshaping how mechanical systems are designed, monitored, and maintained. Buyers are increasingly seeking suppliers who can provide smart solutions that enhance operational efficiency and predictive maintenance.

Moreover, the rise of e-commerce platforms tailored for B2B transactions is simplifying the procurement process. Buyers can now access a wider range of products and services, facilitating quicker decision-making and reducing lead times. The demand for customization is also on the rise, prompting suppliers to adopt agile manufacturing practices to meet specific client requirements. Additionally, as global supply chains become more interconnected, buyers are looking for suppliers who can provide transparent sourcing and logistics capabilities.

How Important Is Sustainability and Ethical Sourcing in the Mechanical Terms Sector?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the mechanical terms sector. The environmental impact of manufacturing processes and the sourcing of materials is under scrutiny, with a growing emphasis on reducing carbon footprints and waste. Buyers are increasingly favoring suppliers who adopt sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are gaining traction. These certifications not only signify a commitment to sustainability but also enhance a company’s reputation in the marketplace. Furthermore, ethical sourcing practices, including fair labor conditions and responsible sourcing of raw materials, are becoming critical factors in supplier selection. B2B buyers are now more informed and aware of the importance of selecting partners who align with their corporate social responsibility goals.

What is the Evolution of the Mechanical Terms Market and Its Significance for B2B Buyers?

The mechanical terms market has evolved significantly over the decades, transitioning from rudimentary mechanical systems to highly sophisticated, automated solutions. Historically, the industrial revolution marked a pivotal shift, introducing advanced machinery and engineering principles that laid the groundwork for modern mechanical engineering. This evolution continued through the 20th century with the introduction of computer-aided design (CAD) and simulation technologies, which revolutionized the design and testing of mechanical systems.

Illustrative image related to mechanical terms

Today, the integration of smart technologies and the focus on sustainability represent the latest phase of evolution. For B2B buyers, understanding this historical context is crucial as it informs current trends and future directions. Buyers who appreciate the evolution of mechanical terms can make more informed decisions regarding investments in technology, supplier partnerships, and sustainable practices, ultimately positioning themselves competitively in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of mechanical terms

-

How do I solve challenges in sourcing mechanical components internationally?

To address sourcing challenges, first, conduct thorough market research to identify reliable suppliers in your target regions. Utilize trade platforms and directories specific to mechanical engineering to find vetted suppliers. Establish clear communication channels to discuss specifications, certifications, and compliance with local regulations. Leverage technology such as video calls for virtual inspections and negotiations. Lastly, consider forming strategic partnerships with local distributors to navigate regional complexities effectively. -

What is the best way to evaluate suppliers for mechanical components?

Evaluating suppliers requires a multi-faceted approach. Start by assessing their experience in the industry, including years of operation and client testimonials. Request product samples to evaluate quality firsthand. Verify certifications such as ISO standards to ensure adherence to international quality benchmarks. Additionally, conduct background checks on their financial stability and capacity to meet your demand in terms of Minimum Order Quantities (MOQs) and delivery timelines. Regularly reviewing supplier performance can help maintain quality standards. -

How can I customize mechanical components for my specific needs?

Customization of mechanical components is often facilitated through direct communication with suppliers. Provide detailed specifications including dimensions, materials, and functionality to ensure accuracy. Many suppliers offer engineering support to help refine your designs. It’s crucial to discuss lead times and associated costs for customization upfront. Also, consider prototyping to test the designs before full-scale production, ensuring that the final product meets your requirements effectively. -

What are typical payment terms for international mechanical component purchases?

Payment terms can vary significantly depending on the supplier and the regions involved. Common options include upfront payments, partial payments upon order confirmation, and balance payments upon delivery. Letters of credit or escrow services can provide security for both parties in larger transactions. Always clarify payment methods accepted, such as wire transfers or credit terms, and ensure compliance with international trade regulations to avoid delays. -

How can I ensure quality assurance in mechanical components?

Implementing a robust quality assurance (QA) process is essential. Begin by specifying quality standards in your contracts, including certifications and testing methods. Regular audits and inspections at the supplier’s facility can help ensure compliance. Consider third-party inspection services to validate the quality before shipment. Additionally, establishing a feedback loop for continuous improvement can help maintain high standards throughout the supply chain. -

What logistics considerations should I keep in mind when importing mechanical components?

Logistics is critical in international trade, especially for mechanical components. Assess the best shipping methods based on delivery timelines and cost-efficiency, such as air freight for urgent needs or sea freight for bulk orders. Be aware of customs regulations and import duties in your country to avoid unexpected costs. Ensure that your supplier has a reliable logistics partner and that tracking options are available for real-time updates on shipment status. -

What are the common challenges faced when dealing with international suppliers?

International suppliers can present challenges such as language barriers, differing regulations, and cultural differences in business practices. To mitigate these issues, establish clear communication protocols and consider hiring local representatives if necessary. It’s also important to understand the legal and regulatory landscape of the supplier’s country, including labor laws and import/export restrictions. Building strong relationships with suppliers can help navigate these complexities effectively. -

How do I determine the right MOQ when sourcing mechanical components?

Minimum Order Quantities (MOQs) can vary widely depending on the supplier and the type of component. To determine the right MOQ for your needs, assess your project requirements and budget. Engage in discussions with suppliers to negotiate terms, as many are willing to accommodate smaller orders for first-time customers. Also, consider the potential for future orders; committing to a higher MOQ may lead to cost savings in the long run if you anticipate ongoing needs.

Top 6 Mechanical Terms Manufacturers & Suppliers List

1. GaugeHow – Mechanical Engineering Terminology

Domain: gaugehow.com

Registered: 2018 (7 years)

Introduction: A-Z Technical Terms in Mechanical Engineering: A comprehensive reference list covering various mechanical engineering terms, including definitions for terms such as Acceleration, Adiabatic Process, Aerospace Engineering, Alloy, Ammeter, Bearing, Bending Moment, Bolted Joint, Boiler, Brake, Camshaft, Compression Ratio, Centrifugal Force, Coolant, Crankshaft, Dynamics, Deformation, Design Engineerin…

2. TheAEMT – Actuator Solutions

Domain: theaemt.com

Registered: 2014 (11 years)

Introduction: This company, TheAEMT – Actuator Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Bartleby – Fundamental Concepts in Mechanics

Domain: bartleby.com

Registered: 1997 (28 years)

Introduction: Basic Terminology in Mechanics covers fundamental concepts in mechanics, including: 1. **Mechanics** – The study of motion and forces acting on objects. 2. **Classifications of Mechanics**: – **Statics**: Forces on bodies at rest. – **Kinematics**: Motion of bodies without considering forces. – **Kinetics**: Effects of forces on moving systems. 3. **Branches of Mechanics**: – **Classical Mecha…

4. Mechanical Engineering – Essential Resources

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Common Mechanical Engineering Components/Terms include references to resources such as the Encyclopedia of Mechanical Engineering, Oxford Dictionary of Mechanical Engineering, and Machinery Handbook. The original post seeks visual aids similar to the University of Michigan’s Visual Encyclopedia of Chemical Engineering to enhance understanding of mechanical components and terms.

5. Diequa – Gearboxes & Custom Solutions

Domain: diequa.com

Registered: 1998 (27 years)

Introduction: Complete Product Line, Spiral Bevel Gearboxes, Servo Gearheads, Speed Reducers, Shaft Phasing and Variable Speed Gearboxes, Cycloidal Reducers, Screw Jack Systems, Zero-Backlash Couplings and Line Shafts, Custom Products, Custom Designs.

6. Oxford Reference – Dictionary of Mechanical Engineering

Domain: oxfordreference.com

Registered: 2000 (25 years)

Introduction: Dictionary of Mechanical Engineering – Oxford Reference

– Authors: Tony Atkins, Marcel Escudier

– Publisher: Oxford University Press

– Print Publication Date: 2013

– Print ISBN-13: 9780199587438

– eISBN: 9780191752308

– Current Online Version: 2013

– DOI: 10.1093/acref/9780199587438.001.0001

– Number of Entries: Over 7,400

– Key Topics Covered: Design, stress analysis, dynamics and vibrations, the…

Strategic Sourcing Conclusion and Outlook for mechanical terms

How Can Strategic Sourcing Enhance Your Mechanical Engineering Needs?

In today’s competitive landscape, understanding mechanical terms is crucial for international B2B buyers. By leveraging strategic sourcing, businesses can optimize procurement processes, ensuring access to high-quality materials and components essential for mechanical engineering projects. Key takeaways from this guide emphasize the importance of familiarizing oneself with terminology such as “efficiency,” “torque,” and “lubrication,” which can influence purchasing decisions and project outcomes.

Investing in a robust strategic sourcing strategy not only reduces costs but also mitigates risks associated with supply chain disruptions. For buyers in regions like Africa, South America, the Middle East, and Europe, aligning with suppliers who understand the nuances of mechanical engineering can foster innovation and enhance product development.

As we look to the future, the integration of advanced technologies and sustainable practices in mechanical engineering will become increasingly important. We encourage you to engage with suppliers who prioritize these values, ensuring your business remains competitive and responsive to market demands. Take action today to refine your sourcing strategies and stay ahead in the ever-evolving mechanical landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to mechanical terms