A Deep Dive into Conveyor Motor Solution

Introduction: Navigating the Global Market for conveyor motor

In an increasingly interconnected global marketplace, sourcing the right conveyor motor can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding the diverse range of conveyor motor options available is crucial for optimizing efficiency and productivity in your operations. This guide aims to demystify the conveyor motor landscape by providing a comprehensive overview of various types, applications, and key considerations for selecting the ideal motor for your needs.

From AC induction motors suited for continuous operation to advanced brushless DC motors that offer precise speed control, the options are vast and varied. Additionally, we will delve into supplier vetting processes, helping you identify reliable manufacturers and distributors who align with your operational requirements. Pricing insights will also be provided, enabling you to make informed decisions that balance cost and quality effectively.

By empowering international B2B buyers with actionable insights and detailed information, this guide serves as a valuable resource for navigating the complexities of the conveyor motor market. Whether you are looking to enhance your existing systems or implement new solutions, understanding these dynamics will enable you to make confident purchasing decisions that drive your business forward.

Understanding conveyor motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motors | Continuous operation in one direction, robust design | Material handling, assembly lines | Pros: Durable, low maintenance; Cons: Limited speed control. |

| Brushless DC Motors | High speed stability, energy-efficient, precise speed control | Packaging, robotics, conveyor systems | Pros: Efficient, low noise; Cons: Higher initial cost. |

| Stepper Motors | High torque at low speeds, excellent for precise positioning | CNC machinery, automated assembly | Pros: Accurate positioning; Cons: Limited speed range. |

| Servo Motors | Smooth operation, high precision, suitable for variable loads | Robotics, automated guided vehicles (AGVs) | Pros: High accuracy, adaptable; Cons: More complex control systems. |

| Reversible AC Motors | Ability to reverse direction easily, suitable for varied loads | Loading docks, material transfer systems | Pros: Versatile, easy to integrate; Cons: May require more maintenance. |

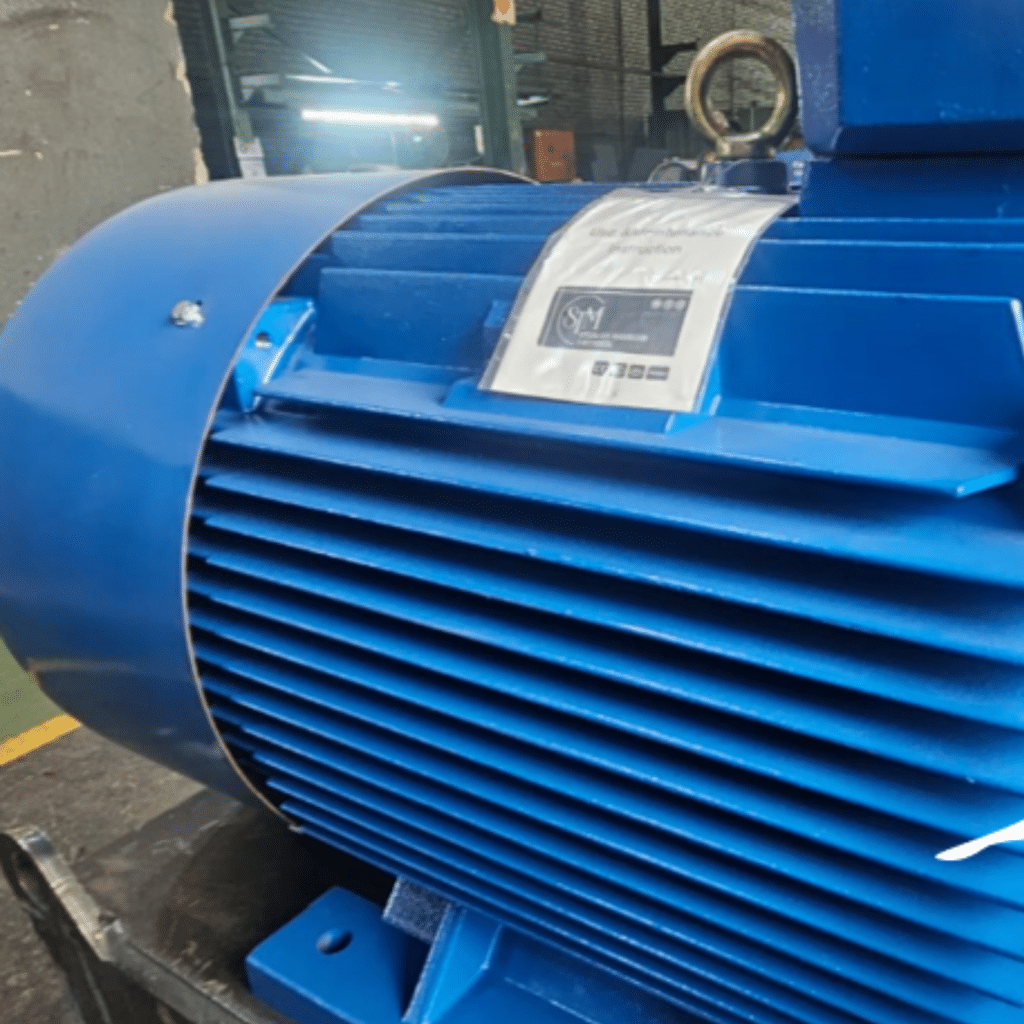

What Are the Key Characteristics of AC Induction Motors for Conveyor Systems?

AC Induction Motors are widely used in conveyor systems due to their reliability and ability to operate continuously in one direction. They are designed for high durability, making them ideal for heavy-duty applications like material handling and assembly lines. When considering AC Induction Motors, B2B buyers should evaluate their operational efficiency, maintenance requirements, and compatibility with existing systems.

Illustrative image related to conveyor motor

How Do Brushless DC Motors Enhance Conveyor System Performance?

Brushless DC Motors offer significant advantages in terms of speed stability and energy efficiency, making them suitable for applications that require precise speed control, such as packaging and robotics. These motors operate quietly and have a longer lifespan than traditional motors. B2B buyers should assess the initial investment against the long-term savings in energy and maintenance when considering these motors.

Why Are Stepper Motors Ideal for High Precision Applications?

Stepper Motors are characterized by their ability to provide high torque even at low speeds, which is essential for applications requiring accurate positioning, such as CNC machinery and automated assembly lines. Their design minimizes vibration, enhancing performance in sensitive tasks. Buyers should consider the specific torque requirements and the motor’s speed range to ensure optimal application fit.

What Advantages Do Servo Motors Offer in Conveyor Systems?

Servo Motors are known for their smooth operation and high precision, making them suitable for applications that involve variable loads, like robotics and automated guided vehicles (AGVs). Their closed-loop control systems allow for accurate positioning over long distances. B2B purchasers should evaluate the complexity of the control systems and the motor’s adaptability to different operational demands.

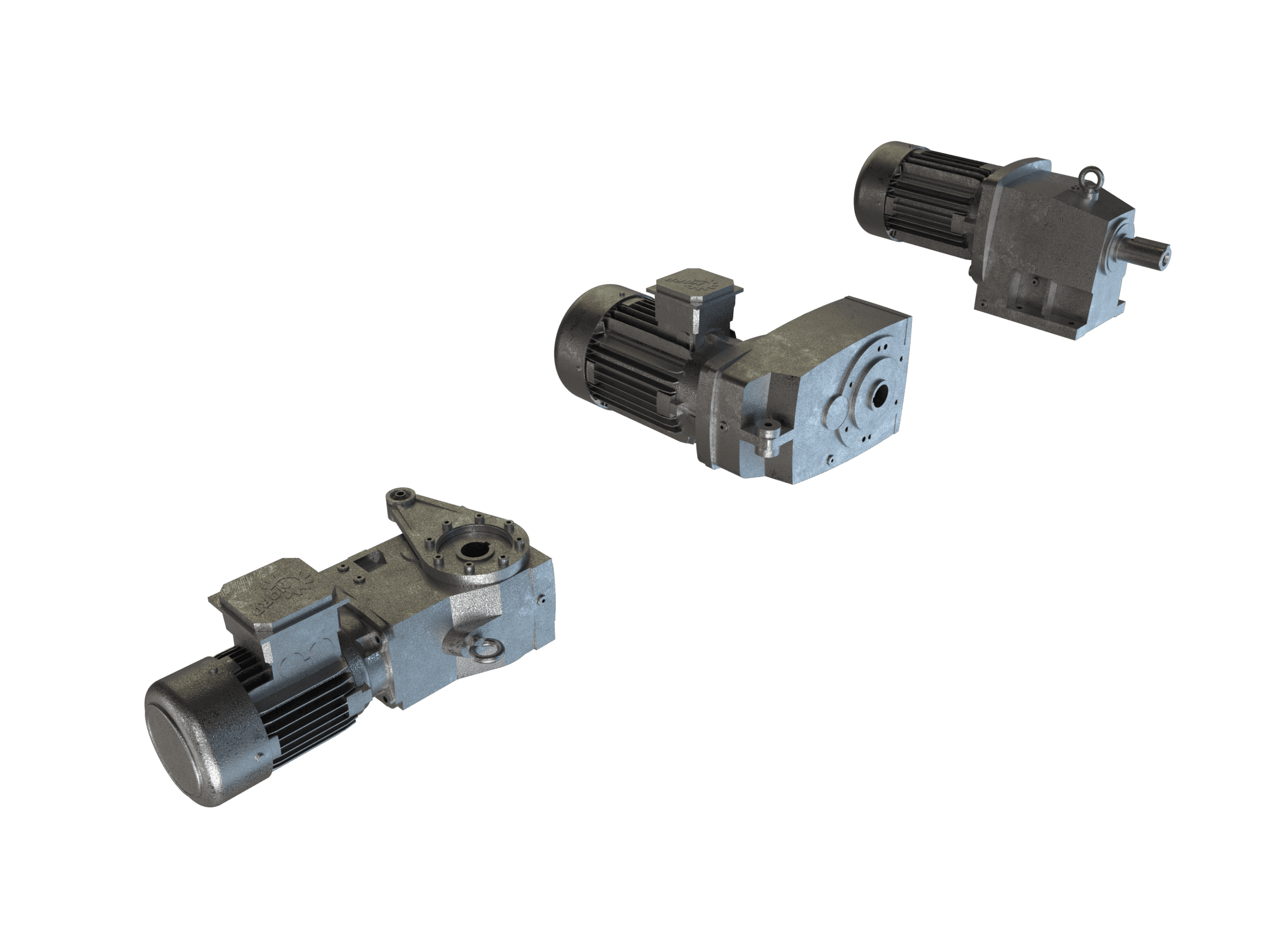

How Do Reversible AC Motors Provide Flexibility in Conveyor Operations?

Reversible AC Motors are designed to easily change direction, making them an excellent choice for applications in loading docks and material transfer systems. Their versatility allows for integration into a variety of conveyor setups. When purchasing, buyers should consider the motor’s responsiveness and maintenance needs to ensure reliable performance in dynamic environments.

Key Industrial Applications of conveyor motor

| Industry/Sector | Specific Application of Conveyor Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Automated food processing and packaging lines | Increased efficiency, reduced labor costs | Compliance with food safety standards, washdown ratings |

| Manufacturing | Material handling in assembly lines | Enhanced productivity, reduced manual handling | Motor torque capacity, compatibility with existing systems |

| Mining & Minerals | Bulk material transport | Improved safety, minimized downtime | Durability in harsh environments, power requirements |

| Logistics & Warehousing | Sorting and distribution systems | Faster order fulfillment, optimized inventory management | Speed control, energy efficiency, and maintenance support |

| Pharmaceuticals | Automated drug packaging and sorting | Precision in handling, compliance with regulations | Cleanroom compatibility, precision motor control |

How Are Conveyor Motors Used in the Food & Beverage Industry?

In the food and beverage sector, conveyor motors drive automated processing and packaging lines, ensuring products move smoothly through various stages, from preparation to packaging. The use of these motors enhances efficiency and reduces labor costs by minimizing manual handling. Buyers in this industry must prioritize compliance with food safety standards, including selecting motors with washdown ratings to withstand frequent cleaning.

What Role Do Conveyor Motors Play in Manufacturing?

Manufacturing facilities utilize conveyor motors for material handling on assembly lines, facilitating the seamless transport of components and finished goods. This integration boosts productivity and lowers the risk of workplace injuries associated with manual handling. When sourcing motors for manufacturing applications, businesses should consider torque capacity and compatibility with existing systems to ensure optimal performance.

How Are Conveyor Motors Essential in Mining & Minerals?

In the mining and minerals industry, conveyor motors are pivotal for transporting bulk materials, enabling efficient movement from extraction points to processing facilities. This application significantly enhances safety and reduces equipment downtime. Buyers must focus on the durability of motors, ensuring they can withstand harsh environmental conditions and meet the specific power requirements of their operations.

How Do Conveyor Motors Improve Logistics & Warehousing Operations?

In logistics and warehousing, conveyor motors are integral to sorting and distribution systems, which streamline the movement of goods and improve order fulfillment speeds. These systems optimize inventory management by ensuring that products are efficiently routed to their destinations. Key considerations for sourcing include speed control features, energy efficiency, and robust maintenance support to minimize operational disruptions.

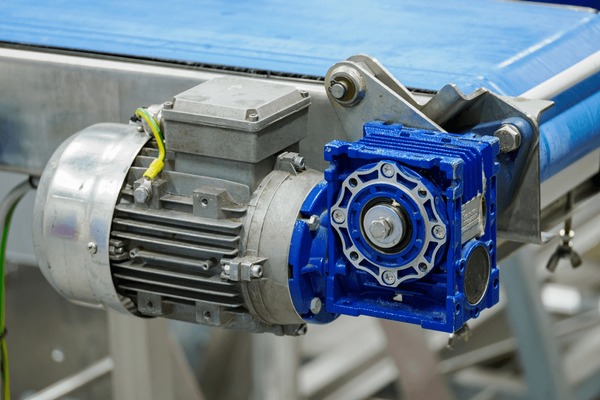

Illustrative image related to conveyor motor

Why Are Conveyor Motors Important in Pharmaceuticals?

Conveyor motors are critical in the pharmaceutical industry for automating drug packaging and sorting processes. They provide precision in handling sensitive materials, ensuring compliance with stringent regulatory requirements. Buyers in this sector should prioritize motors that are compatible with cleanroom environments and offer precise control to maintain the integrity of pharmaceutical products during processing.

3 Common User Pain Points for ‘conveyor motor’ & Their Solutions

Scenario 1: Inconsistent Performance and Downtime

The Problem: Many B2B buyers experience frustration when conveyor motors fail to deliver consistent performance, leading to unexpected downtime. This inconsistency can stem from inadequate motor selection based on load requirements, environmental conditions, or lack of proper maintenance. For instance, a manufacturer in South America might find that their conveyor system struggles under heavy loads, resulting in frequent shutdowns. The downtime not only affects production schedules but also incurs additional costs due to lost labor and delayed shipments.

The Solution: To mitigate this issue, buyers should conduct a thorough needs assessment before purchasing a conveyor motor. This includes analyzing the weight and type of materials being transported, the operational environment (such as temperature and humidity), and the specific performance requirements. Sourcing from reputable manufacturers that provide comprehensive technical support and detailed specifications is crucial. Additionally, implementing a regular maintenance schedule can significantly enhance motor longevity and performance. This involves periodic checks on motor alignment, lubrication, and electrical connections to ensure optimal operation. By selecting the right motor and committing to ongoing maintenance, businesses can reduce downtime and improve overall productivity.

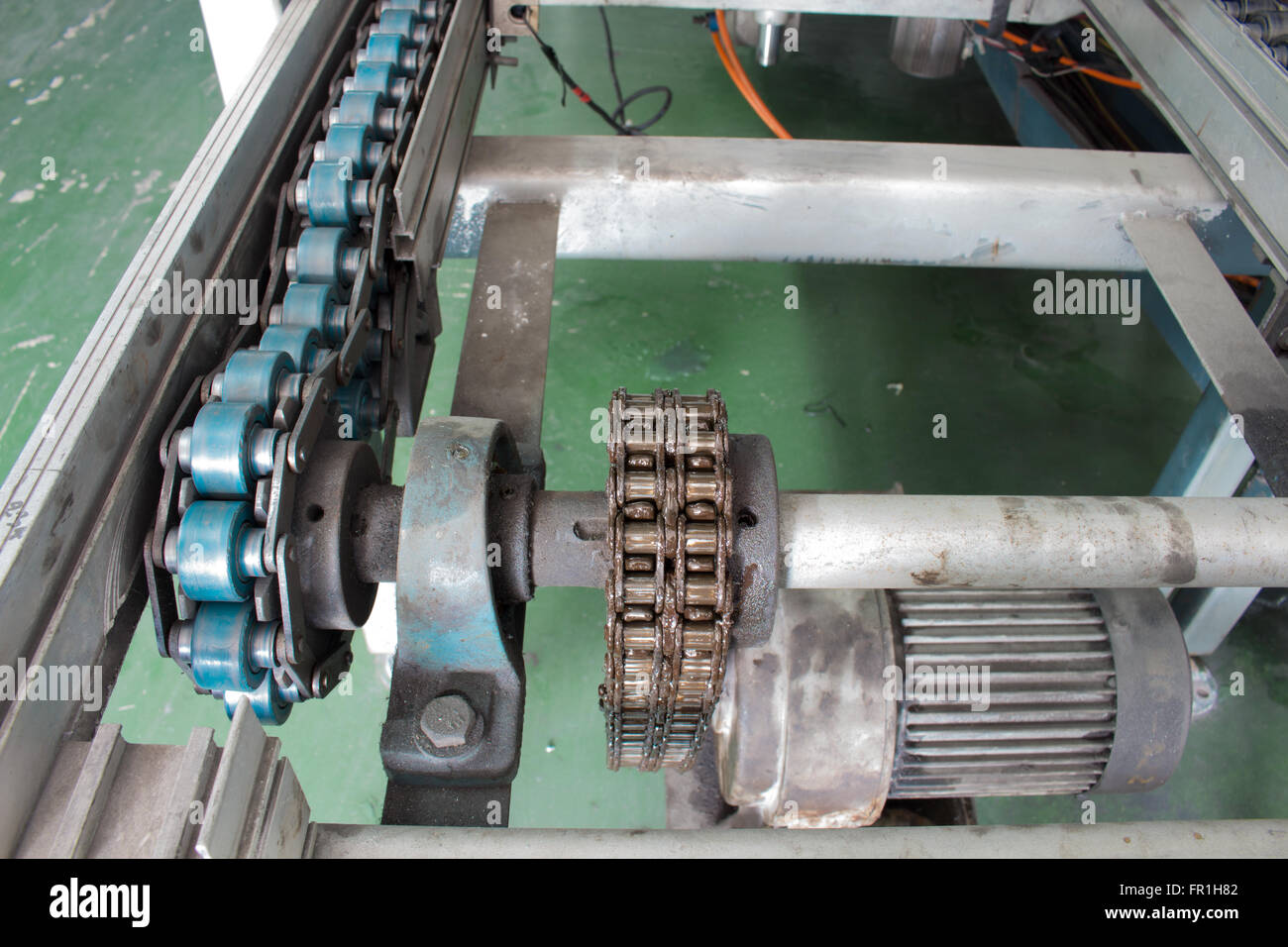

Illustrative image related to conveyor motor

Scenario 2: Energy Efficiency and High Operational Costs

The Problem: Energy costs are a significant concern for many international B2B buyers, especially in regions like Africa and Europe where energy prices can fluctuate dramatically. Many conveyor systems operate with outdated motors that consume excessive energy, leading to inflated operational costs. This can be particularly burdensome for businesses that rely heavily on conveyor systems for continuous production processes, such as in food processing or material handling industries.

The Solution: To address energy inefficiencies, buyers should consider investing in modern, energy-efficient conveyor motors. Motors with variable frequency drives (VFDs) allow for better control of motor speed and can adjust according to the load requirements, significantly reducing energy consumption. Additionally, opting for brushless DC motors or synchronous motors can provide better efficiency compared to traditional induction motors. It is also advisable to conduct an energy audit to identify specific areas of improvement within the conveyor system. By replacing outdated motors and implementing smart motor control strategies, businesses can lower their energy costs and contribute to sustainability initiatives.

Scenario 3: Complex Integration with Existing Systems

The Problem: Integration challenges often arise when businesses attempt to implement new conveyor motors into existing automation systems. This can be particularly daunting for companies in the Middle East and South America, where legacy systems may not be compatible with modern motor technologies. Buyers may face technical hurdles, such as communication issues between different motor types and control systems, leading to inefficiencies and operational disruptions.

The Solution: To overcome integration issues, it is essential for buyers to collaborate closely with motor suppliers who understand their existing systems. Choosing motors that offer compatibility with common communication protocols (such as Modbus or RS-485) can facilitate smoother integration. Additionally, investing in modular motor solutions can provide flexibility, allowing for easier upgrades in the future. Consulting with automation engineers during the planning phase can also ensure that the new conveyor motors align with existing operational workflows. By focusing on compatibility and engaging with knowledgeable suppliers, businesses can ensure a seamless transition and maintain operational efficiency.

Strategic Material Selection Guide for conveyor motor

What Are the Key Materials Used in Conveyor Motors?

When selecting materials for conveyor motors, B2B buyers must consider several factors, including the operational environment, performance requirements, and compliance with international standards. Here, we analyze four common materials used in conveyor motor construction: aluminum, stainless steel, cast iron, and plastic composites.

How Does Aluminum Benefit Conveyor Motor Applications?

Aluminum is a lightweight yet durable material, making it a popular choice for conveyor motors. Its excellent thermal conductivity allows for effective heat dissipation, which is crucial in high-speed applications. Additionally, aluminum has good corrosion resistance, especially when anodized, which enhances its longevity in humid or chemically aggressive environments.

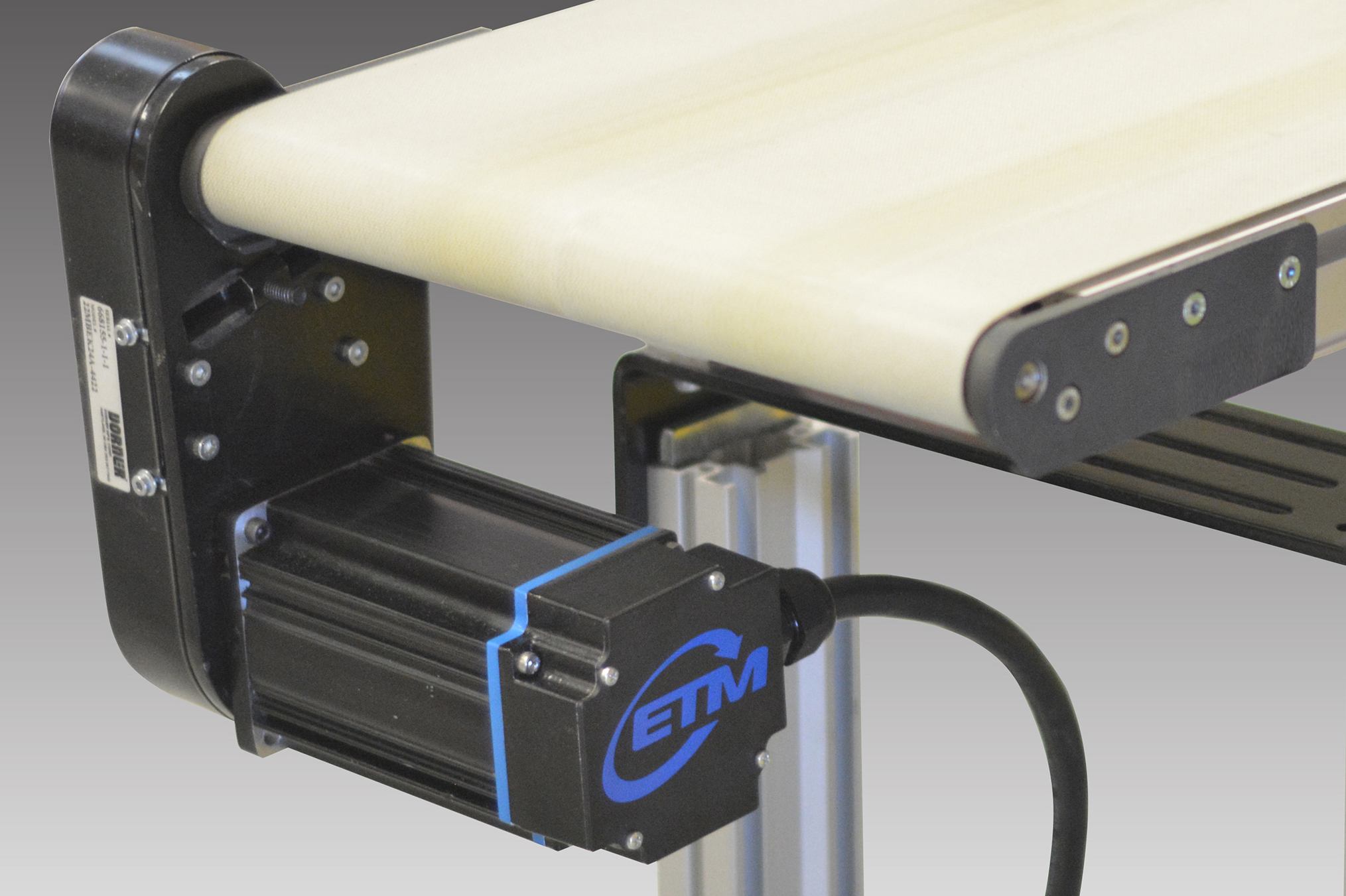

Illustrative image related to conveyor motor

Pros: Aluminum is relatively inexpensive compared to other metals, making it an attractive option for budget-conscious buyers. Its lightweight nature simplifies installation and reduces energy consumption during operation.

Cons: While aluminum is strong, it can be less durable than steel under high-impact conditions. It may also require additional coatings for specific applications, increasing manufacturing complexity.

Impact on Application: Aluminum is suitable for environments where weight reduction is critical, such as in mobile or portable conveyor systems. However, it may not be ideal for heavy-duty applications involving abrasive materials.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for material quality. In Africa and South America, local sourcing of aluminum may also affect pricing and availability.

What Role Does Stainless Steel Play in Conveyor Motor Design?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it ideal for conveyor motors used in food processing, pharmaceuticals, and other sanitary applications. Its high-temperature tolerance also allows it to perform well in extreme conditions.

Pros: The durability of stainless steel ensures a longer lifespan, reducing maintenance costs over time. Its resistance to rust and staining makes it suitable for environments where hygiene is paramount.

Cons: The primary drawback is the higher cost compared to aluminum and plastic materials. Additionally, stainless steel can be heavier, potentially affecting energy efficiency in some applications.

Impact on Application: Stainless steel is particularly advantageous in food and beverage industries where compliance with health regulations is critical. It can also withstand exposure to harsh cleaning agents.

Considerations for International Buyers: Buyers should verify compliance with international standards like ISO and FDA regulations for food-safe materials, especially in Europe and North America.

How Does Cast Iron Compare for Heavy-Duty Conveyor Motors?

Cast iron is often used in heavy-duty conveyor motors due to its strength and ability to absorb vibrations. This material is particularly effective in applications involving high torque and heavy loads.

Pros: Cast iron’s durability and rigidity make it an excellent choice for industrial environments. It also has good wear resistance, which is beneficial for long-term operation.

Cons: The main disadvantage of cast iron is its weight, which can complicate installation and increase energy consumption. Additionally, it is more susceptible to corrosion if not properly coated.

Impact on Application: Cast iron is best suited for heavy-duty applications where robustness is required, such as mining or large-scale manufacturing.

Considerations for International Buyers: Buyers should be aware of the need for corrosion-resistant coatings, especially in humid climates like those found in parts of Africa and South America.

What Are the Advantages of Plastic Composites in Conveyor Motors?

Plastic composites are increasingly being used in conveyor motors due to their lightweight and corrosion-resistant properties. They can be engineered to provide specific performance characteristics, such as electrical insulation or enhanced chemical resistance.

Pros: The lightweight nature of plastic composites allows for easier handling and installation. They are also resistant to many chemicals, making them suitable for various industrial applications.

Cons: While they can be durable, plastic composites may not withstand high temperatures or heavy loads as effectively as metals. Their longevity can also be a concern in high-wear applications.

Illustrative image related to conveyor motor

Impact on Application: Plastic composites are ideal for applications where weight savings and corrosion resistance are priorities, such as in the packaging or textile industries.

Considerations for International Buyers: Compliance with environmental regulations regarding plastic usage is crucial, particularly in Europe, where sustainability is a growing concern.

Summary Table of Material Selection for Conveyor Motors

| Material | Typical Use Case for conveyor motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight conveyor systems | Excellent thermal conductivity | Less durable under high impact | Low |

| Stainless Steel | Food processing and sanitary applications | Exceptional corrosion resistance | Higher cost and weight | High |

| Cast Iron | Heavy-duty industrial applications | High durability and vibration absorption | Heavy and prone to corrosion | Medium |

| Plastic Composites | Packaging and textile industries | Lightweight and chemical resistance | Limited high-temperature performance | Medium |

This guide aims to provide a comprehensive understanding of material selection for conveyor motors, enabling B2B buyers to make informed decisions based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor motor

What Are the Main Stages of Conveyor Motor Manufacturing?

The manufacturing process for conveyor motors involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets the required performance specifications and quality standards.

How Is Material Prepared for Conveyor Motors?

Material preparation begins with sourcing high-quality raw materials such as steel, copper, and plastic components. Suppliers must adhere to international standards to ensure the materials are suitable for industrial applications. Quality checks at this stage often include verifying material specifications and conducting chemical analyses to confirm properties like tensile strength and conductivity.

Illustrative image related to conveyor motor

Once materials are sourced, they undergo treatments such as annealing or surface hardening to enhance their durability and performance. This is particularly important for components like rotor and stator laminations, which require precise magnetic properties.

What Forming Techniques Are Commonly Used in Conveyor Motor Production?

The forming stage typically involves various machining processes such as cutting, stamping, and forging. For instance, stator and rotor cores are often stamped from laminated sheets to reduce eddy current losses, which improves motor efficiency.

CNC (Computer Numerical Control) machining is widely used for precision components, ensuring that parts are manufactured to exact specifications. Additionally, techniques like die-casting may be employed for housing components, providing strength while minimizing weight.

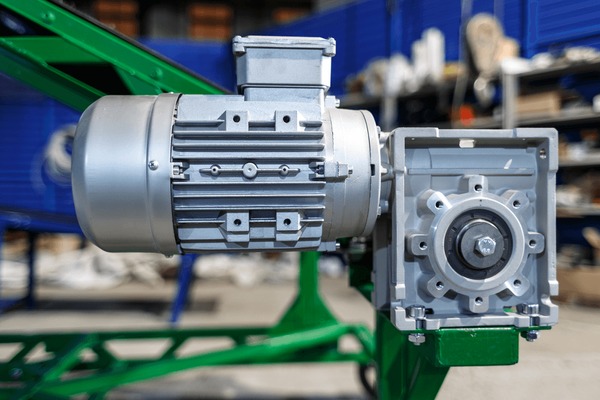

How Does the Assembly Process Work for Conveyor Motors?

The assembly process is where the prepared components come together to form the final product. This includes fitting the rotor within the stator, installing bearings, and securing the motor housing. During assembly, manufacturers often use automated systems to enhance efficiency and reduce human error.

Illustrative image related to conveyor motor

Quality Control (QC) checkpoints are integrated into the assembly line to ensure that each component fits correctly and operates as intended. This can include electrical testing of windings and functional tests to verify operational performance.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is vital for ensuring that conveyor motors are reliable and efficient. B2B buyers should be familiar with several international and industry-specific standards that govern manufacturing practices.

Which International Standards Are Relevant to Conveyor Motor Quality?

ISO 9001 is one of the most recognized quality management standards globally. It emphasizes continuous improvement and customer satisfaction, requiring manufacturers to implement systematic processes for quality control. Compliance with ISO 9001 indicates a commitment to quality and operational excellence.

In addition to ISO standards, certifications such as CE mark (for products sold in the European Economic Area) and API (American Petroleum Institute) standards for motors used in the oil and gas industry are essential. These certifications ensure that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Conveyor Motor Manufacturing?

Quality control (QC) is implemented at multiple stages throughout the manufacturing process to catch defects early and ensure that products meet specifications. The three primary QC checkpoints are:

Illustrative image related to conveyor motor

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet the specified standards. Testing may include visual inspections, dimensional checks, and material property analyses.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are performed to monitor processes and detect any deviations from established standards. This may involve sampling and testing components during machining and assembly.

-

Final Quality Control (FQC): After assembly, a comprehensive examination of the finished product is conducted. This includes functional testing, electrical testing, and performance assessments to ensure the motor operates according to specifications.

What Common Testing Methods Are Used to Validate Conveyor Motors?

Several testing methods are employed to validate the performance and safety of conveyor motors:

-

Electrical Testing: This includes checking insulation resistance, winding continuity, and phase balance to ensure the motor will operate safely and efficiently.

-

Thermal Imaging: Used to detect overheating issues that could lead to motor failure, thermal imaging can help identify hot spots during operation.

-

Vibration Analysis: This method assesses the mechanical integrity of the motor by monitoring vibration levels. Excessive vibrations can indicate misalignment or bearing wear.

-

Load Testing: Conducted to simulate actual operating conditions, load testing verifies that the motor can handle the specified load without overheating or failing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when selecting suppliers for conveyor motors. Here are several ways to verify the quality control practices of potential suppliers:

-

Supplier Audits: Perform on-site audits to assess manufacturing processes, quality control systems, and compliance with international standards. This provides insight into the supplier’s commitment to quality.

-

Reviewing Quality Control Reports: Request documentation that outlines the supplier’s QC procedures, testing results, and certifications. This transparency can help build trust and confidence in their capabilities.

-

Third-Party Inspections: Engage third-party inspection services to evaluate the manufacturing process and product quality independently. This is particularly useful for buyers in regions with specific regulatory requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of certain nuances when it comes to quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and performance. Understanding these can help ensure compliance and avoid legal issues.

-

Cultural Differences: Communication styles and business practices may differ across cultures. Establishing clear expectations and open lines of communication can mitigate misunderstandings.

-

Supply Chain Logistics: International shipping can introduce risks such as damage during transit or delays. Ensuring that suppliers have robust packaging and shipping practices is crucial for maintaining product integrity.

In conclusion, understanding the manufacturing processes and quality assurance standards for conveyor motors is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that ensure they source reliable and efficient products for their operations.

Illustrative image related to conveyor motor

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor motor’

Introduction

Navigating the procurement of conveyor motors can be a complex task for B2B buyers, particularly in diverse international markets. This guide offers a structured approach to ensure you make informed decisions, focusing on critical factors such as technical specifications, supplier evaluation, and compliance requirements. By following this checklist, you can streamline your sourcing process and secure the best solutions for your operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clarify the specific requirements for your conveyor motor. Consider factors such as power output, speed control options, and the operational environment (e.g., temperature, humidity, or exposure to water).

– Key aspects to define:

– Motor type (AC, DC, stepper, servo)

– Required torque and speed ranges

Step 2: Assess Application Requirements

Evaluate the unique needs of your application to ensure the motor you select is suitable. This assessment includes understanding the load characteristics, cycle time, and frequency of operation.

– Consider the following:

– Will the motor operate continuously or intermittently?

– Are there specific load handling requirements (e.g., vertical lifting)?

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Look for:

– Established track records with similar projects

– Positive feedback from other customers regarding reliability and support

Step 4: Verify Supplier Certifications

Ensure that your potential suppliers comply with relevant industry standards and certifications. This step is vital for guaranteeing the quality and safety of the motors.

– Check for:

– ISO certifications and compliance with local regulations

– Environmental certifications, especially if operating in sensitive areas

Illustrative image related to conveyor motor

Step 5: Request Samples and Conduct Testing

Once you have shortlisted suppliers, request samples of the conveyor motors. Testing these samples in your operational environment can help validate their performance and compatibility.

– Focus on:

– Real-world performance metrics such as efficiency and noise levels

– Ease of installation and integration into existing systems

Step 6: Negotiate Terms and Conditions

Engage in discussions about pricing, delivery timelines, and warranty options. Clear negotiations can prevent misunderstandings later and ensure that you receive the best value for your investment.

– Important factors to negotiate:

– Payment terms and bulk order discounts

– Warranty duration and service agreements

Step 7: Finalize Purchase and Plan for Installation

After agreeing on terms, finalize your purchase while also planning for the installation and integration of the conveyor motors into your operations.

– Prepare for:

– Training for your staff on the new equipment

– Scheduling installation to minimize downtime

By following this checklist, B2B buyers can approach the procurement of conveyor motors with confidence, ensuring that they select the best solutions tailored to their operational needs.

Illustrative image related to conveyor motor

Comprehensive Cost and Pricing Analysis for conveyor motor Sourcing

What Are the Key Cost Components in Sourcing Conveyor Motors?

When sourcing conveyor motors, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality and type of materials used, such as metals for housing and copper for windings, significantly affect the price. Higher-quality materials typically enhance performance and longevity but also increase costs.

-

Labor: Labor costs can vary based on geographic location and the skill level required for manufacturing. Skilled labor may command higher wages, influencing overall production costs.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient production methods can help reduce these costs, impacting the final pricing of the motor.

-

Tooling: Custom tooling may be necessary for specialized motor designs, adding to initial costs. However, this can lead to cost savings in large production runs due to reduced per-unit costs.

-

Quality Control (QC): Rigorous QC processes ensure that motors meet specified performance standards. While this adds to costs, it can prevent costly failures and warranty claims in the long run.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the destination. Understanding these costs is crucial for accurate pricing.

-

Margin: Supplier margins can vary based on competition, brand reputation, and market demand. Recognizing these factors can help in negotiations.

How Do Price Influencers Impact Conveyor Motor Costs?

Several factors influence the pricing of conveyor motors, which can vary significantly across different markets:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk typically allows for better pricing. Suppliers often provide discounts for larger orders, making it advantageous for buyers with significant needs.

-

Specifications and Customization: Customized motors designed to meet specific operational requirements can lead to increased costs. Standard models are generally more affordable, so buyers should evaluate their actual needs carefully.

-

Materials: The choice of materials not only affects durability but also the cost. For instance, motors with higher protection ratings (like IP67) or those designed for harsh environments may carry a premium.

-

Quality and Certifications: Motors that meet international quality standards (such as ISO or CE certifications) may be priced higher due to the costs associated with compliance. However, investing in quality can lead to reduced maintenance costs and longer operational life.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and support services.

-

Incoterms: Understanding the shipping terms (like FOB, CIF) is vital for managing costs. These terms determine who bears the risk and costs during transit, impacting the total landed cost.

What Negotiation Tips Can Help Buyers Optimize Costs?

To maximize cost-efficiency in sourcing conveyor motors, buyers should consider the following strategies:

-

Leverage Volume Discounts: Buyers with large orders should negotiate for better pricing. Suppliers are often willing to offer discounts for high-volume commitments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and operational costs. A slightly higher upfront cost might be justified by lower long-term expenses.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. This knowledge can assist in making informed purchasing decisions.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better negotiation outcomes and potential long-term cost savings through loyalty discounts or favorable terms.

Conclusion: Why Are Indicative Prices Important?

While indicative prices can provide a baseline for budgeting, buyers should remember that actual costs may vary based on the factors discussed. Engaging with multiple suppliers for quotes and understanding the intricacies of pricing can empower buyers to make the best decisions for their operational needs.

Alternatives Analysis: Comparing conveyor motor With Other Solutions

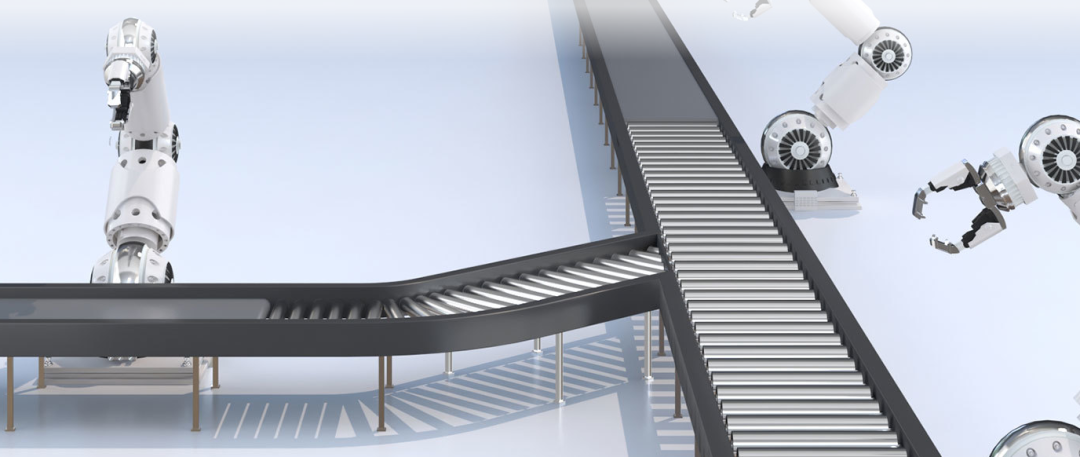

Exploring Alternatives to Conveyor Motors: A Comprehensive Comparison

In industrial applications, selecting the right drive system for material handling is crucial. Conveyor motors are a popular choice due to their efficiency and versatility. However, several alternative solutions can also achieve similar objectives, each with its unique benefits and limitations. This analysis will compare conveyor motors with two viable alternatives: pneumatic conveyor systems and linear actuators.

| Comparison Aspect | Conveyor Motor | Pneumatic Conveyor System | Linear Actuator |

|---|---|---|---|

| Performance | High torque, continuous operation | Good for lightweight materials; limited distance | Precise positioning; varying speeds |

| Cost | Moderate initial investment | Often higher due to compressed air setup | Variable; can be high for precision models |

| Ease of Implementation | Generally straightforward; requires electrical setup | Requires air compressor and piping; more complex | Installation can be simple or complex depending on design |

| Maintenance | Regular checks; manageable wear | Requires maintenance of air supply system | Low maintenance; durable components |

| Best Use Case | Heavy materials, continuous flow | Lightweight, bulk materials over short distances | Applications needing precision and control |

Understanding Pneumatic Conveyor Systems: Advantages and Disadvantages

Pneumatic conveyor systems utilize air pressure to move materials. They are particularly effective for transporting lightweight materials like powders and granules over short distances. One of the main advantages of pneumatic systems is their ability to handle delicate items without causing damage. However, they require a significant investment in air supply infrastructure, including compressors and piping, which can increase operational costs. Additionally, their effectiveness diminishes with heavier loads, making them less suitable for materials that conveyor motors handle efficiently.

Evaluating Linear Actuators: Strengths and Weaknesses

Linear actuators convert rotational motion into linear movement, making them ideal for applications requiring precise positioning. They excel in environments where exact control of speed and distance is paramount, such as in automated assembly lines. One of the significant advantages of linear actuators is their low maintenance requirements due to fewer moving parts. However, they can be more expensive than conveyor motors, especially for high-precision models. Their performance may also be limited in applications requiring continuous movement over long distances, where conveyor motors shine.

Illustrative image related to conveyor motor

Making the Right Choice for Your Material Handling Needs

Choosing the right material handling solution depends on various factors, including the type of materials being transported, the required precision, and budget constraints. Conveyor motors are typically the best choice for heavy, continuous operations, while pneumatic systems are suited for lighter materials and short distances. Linear actuators should be considered for applications requiring high precision. By carefully assessing these aspects, B2B buyers can select the optimal solution that aligns with their operational requirements and enhances overall efficiency.

Essential Technical Properties and Trade Terminology for conveyor motor

What Are the Essential Technical Properties of Conveyor Motors?

Understanding the technical properties of conveyor motors is crucial for B2B buyers looking to optimize their material handling systems. Here are some key specifications to consider:

1. Power Output

Power output is typically measured in watts (W) or horsepower (HP). It indicates the motor’s ability to drive a conveyor system effectively. A higher power output enables the motor to handle heavier loads and maintain consistent speed, essential for productivity. For instance, motors with outputs ranging from 1 W to 3 HP are common in various applications. Selecting the appropriate power output is vital for ensuring operational efficiency and longevity.

2. Torque

Torque is a measure of rotational force, usually expressed in Newton-meters (Nm) or inch-pounds. It is critical for overcoming the resistance of the load being moved. Motors with high starting torque are especially beneficial for applications requiring rapid acceleration or frequent stops and starts. A thorough understanding of torque requirements helps buyers choose motors that can handle specific operational demands without risking mechanical failure.

3. Speed Control

Speed control refers to a motor’s ability to operate at variable speeds. This feature is especially important in applications where product handling rates may need adjustments. Motors equipped with speed control systems, such as brushless DC motors, offer flexibility and efficiency, allowing for both high-speed and low-speed operations. Ensuring that a motor has the right speed control capabilities can significantly impact throughput and product quality.

4. Protection Rating (IP Rating)

The Ingress Protection (IP) rating indicates how well a motor is protected against dust and moisture. For instance, an IP67 rating means the motor is dust-tight and can withstand immersion in water. This is particularly important in industries such as food processing or pharmaceuticals, where cleanliness and hygiene are paramount. Buyers should assess the environmental conditions in which the conveyor system will operate to select motors with appropriate protection ratings.

5. Material Grade

The material grade of a conveyor motor affects its durability and performance. Common materials include aluminum, stainless steel, and various plastics. Stainless steel motors are often preferred in corrosive environments due to their resistance to rust and degradation. Understanding material specifications helps buyers ensure they select motors that meet their operational and environmental needs.

What Are Common Trade Terms Related to Conveyor Motors?

Familiarity with industry terminology can streamline the purchasing process and facilitate better communication with suppliers.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor motors, OEMs often provide specialized products tailored to specific applications. Understanding OEM relationships can help buyers ensure they are sourcing quality components that meet their operational standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is essential for B2B buyers, as it affects inventory management and cash flow. Understanding the MOQ can help companies plan their purchasing strategy and negotiate better terms with suppliers.

Illustrative image related to conveyor motor

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price proposals from suppliers. It typically includes specifications, quantities, and delivery timelines. Crafting a clear RFQ can lead to more accurate quotes and better supplier relationships, allowing for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms can help B2B buyers navigate international transactions more effectively and mitigate risks associated with logistics and customs.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times is crucial for planning production schedules and inventory levels. Buyers should inquire about lead times when negotiating with suppliers to ensure they can meet their operational needs without delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their conveyor systems’ efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the conveyor motor Sector

What Are the Key Market Drivers and Trends Influencing the Conveyor Motor Sector?

The global conveyor motor market is experiencing dynamic growth driven by the rising demand for automation and efficiency across various industries, including manufacturing, logistics, and food processing. As international B2B buyers in regions like Africa, South America, the Middle East, and Europe seek to optimize their operations, the adoption of advanced conveyor systems is becoming essential. Key trends include the integration of IoT technology and smart motors that allow for real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime.

Additionally, the shift towards energy-efficient solutions is shaping sourcing strategies. Manufacturers are increasingly focusing on developing motors that offer higher energy efficiency ratings, which not only reduce operational costs but also align with global sustainability goals. As buyers look for reliable suppliers, understanding the technical specifications, such as torque ratings and speed control capabilities, becomes crucial. Furthermore, the emergence of modular conveyor systems is allowing for greater customization and scalability, catering to diverse industrial needs.

How Is Sustainability Shaping Sourcing Decisions in the Conveyor Motor Market?

Sustainability is no longer a secondary consideration; it has become a primary driver for sourcing decisions in the conveyor motor sector. The environmental impact of manufacturing processes and the end-use of products is under scrutiny, prompting buyers to seek out suppliers who prioritize ethical sourcing and sustainability. This includes sourcing materials that are recyclable or made from renewable resources, as well as ensuring that the manufacturing processes adhere to strict environmental standards.

Buyers are increasingly looking for suppliers that hold ‘green’ certifications, such as ISO 14001, which signifies a commitment to environmental management. Additionally, innovations in motor design, such as the use of brushless DC motors, can significantly reduce energy consumption and carbon footprints. By prioritizing sustainability in their supply chains, businesses not only comply with regulatory requirements but also enhance their brand reputation, appealing to environmentally-conscious customers and partners.

What Has Been the Evolution of Conveyor Motors and Their Market?

The evolution of conveyor motors has been marked by significant technological advancements and shifts in industrial needs. Initially, conveyor systems relied heavily on simple AC induction motors that provided basic functionality for material handling. However, as industries began to demand higher efficiency and versatility, the market saw the introduction of more sophisticated motor types, such as brushless DC and servo motors. These innovations offered improved speed control, energy efficiency, and reliability.

The last two decades have witnessed a marked increase in automation within manufacturing and logistics, leading to the development of smart conveyor systems. These systems incorporate advanced controls and connectivity features, allowing for seamless integration with existing production lines. As the industry continues to evolve, the focus remains on delivering solutions that enhance productivity while minimizing environmental impact, highlighting the ongoing need for innovation and adaptation in the conveyor motor sector.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor motor

-

How do I solve issues with conveyor motor compatibility?

To resolve compatibility issues with conveyor motors, first assess your conveyor system’s specifications, including load capacity, speed requirements, and dimensions. Next, consult the motor manufacturer’s technical documentation to identify motors that meet these criteria. It’s also essential to consider the type of motor control required, such as fixed speed or variable speed. Engage with suppliers to discuss your specific needs and request recommendations for compatible motors, ensuring they have experience with similar applications. -

What is the best type of conveyor motor for heavy-duty applications?

For heavy-duty applications, AC induction motors are typically the best choice due to their robust design and ability to handle continuous operation. They provide high torque and are suitable for various load conditions. Additionally, consider options with electromagnetic brakes for vertical applications or those requiring load holding. It’s advisable to work with suppliers who can provide motors rated for higher horsepower and durability to withstand the demands of heavy-duty use. -

How can I ensure the quality of conveyor motors from international suppliers?

To ensure the quality of conveyor motors from international suppliers, start by vetting manufacturers through certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples or references from previous clients to assess product reliability. Conduct factory audits if possible, or utilize third-party inspection services to verify quality before shipment. Establish clear quality assurance protocols in your purchasing agreements, including warranty terms and return policies. -

What customization options are available for conveyor motors?

Customization options for conveyor motors can include modifications to size, power output, speed control features, and mounting configurations. Many manufacturers offer tailored solutions to meet specific operational requirements, such as integrating sensors or control systems for automation. When discussing customization, provide detailed specifications and requirements to the supplier to ensure they can accommodate your needs effectively. Additionally, inquire about lead times for custom orders to align with your project timelines. -

What are the typical minimum order quantities (MOQs) for conveyor motors?

Minimum order quantities (MOQs) for conveyor motors can vary widely depending on the supplier and the specific motor type. Commonly, MOQs may range from 10 to 100 units, but some manufacturers may offer lower MOQs for custom or specialized motors. When sourcing internationally, consider negotiating MOQs based on your project scale and future needs. Discussing bulk purchasing can also provide opportunities for reduced pricing and better terms. -

What payment terms should I expect when purchasing conveyor motors internationally?

Payment terms for international purchases of conveyor motors typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit upfront, especially for custom orders. It’s essential to clarify payment terms early in negotiations and ensure they are documented in the purchase agreement. Additionally, consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions. -

How can I manage logistics for importing conveyor motors?

To manage logistics for importing conveyor motors, start by selecting a reliable freight forwarder with experience in handling industrial equipment. Ensure they understand the specific requirements for transporting heavy machinery, including packaging and handling protocols. Develop a comprehensive shipping plan that includes timelines, customs documentation, and compliance with import regulations in your country. Regular communication with your supplier and logistics partner will help address any issues that arise during transit. -

What are the common certifications for conveyor motors that I should look for?

When sourcing conveyor motors, look for certifications that indicate compliance with international safety and performance standards. Common certifications include CE marking for European markets, UL certification for the U.S. and Canada, and IEC standards for international electrical safety. These certifications not only ensure that the motors meet quality and safety requirements but also facilitate smoother customs clearance and compliance with local regulations. Always request documentation of these certifications from suppliers before finalizing your purchase.

Top 6 Conveyor Motor Manufacturers & Suppliers List

1. McMaster – Conveyor Drives and Speed Controls

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Drives and Speed Controls, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Dayton – Electric Motor Conveyor Drive

Domain: eastey.com

Registered: 1997 (28 years)

Introduction: This company, Dayton – Electric Motor Conveyor Drive, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Oriental Motor – Conveyor Belt System Motors

Domain: orientalmotor.com

Registered: 1997 (28 years)

Introduction: Conveyor Belt System Products: 1. AC Induction Motors: Output Power: 1 W (1/750 HP) to 3 HP; Power Supply: Single-Phase 100-120 VAC, 200-240 VAC; Three-Phase 200-240 VAC. 2. AC Reversible Motors: Output Power: 1 W (1/750 HP) to 3 HP; Power Supply: Single-Phase 100-120 VAC, 200-240 VAC; Three-Phase 200-240 VAC. 3. AC Motors with Electromagnetic Brake: Output Power: 6 W (1/125 HP) to 3 HP; Power Sup…

4. Killion Industries – Powerroll Conveyor Belt Motors

Domain: parts.killionindustries.com

Registered: 1999 (26 years)

Introduction: Powerroll Conveyor Belt Motors are available in various sizes corresponding to the width of the belts they drive. Each motor comes with a new Starter Capacitor at no extra cost. To select the correct motor size, measure the width of the belt and round down to the nearest inch. For example, a 19″ belt requires an 18″ Powerroll motor. If the motor is removed, measure the length of the drum for addit…

5. Interroll – Conveyor Roller Checkstand Drum Motor

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Conveyor Motors for sale on eBay. Key products include: 1. Interroll Conveyor Roller Checkstand Drum Motor – Pre-Owned, $275.00 or Best Offer, $20.00 shipping. 2. Boston Gear F721B30KB5J Speed Reducer Leeson 114213.00 Conveyor Drive Motor – Pre-Owned, $202.49, Was: $224.99, $146.31 shipping. 3. MOL Belting Conveyor Roller Checkstand Drum Motor – Pre-Owned, $275.00 or Best Offer, $20.00 shipping. 4…

6. Redline Systems – Conveyor Motors and Drives

Domain: redlinesystems.com

Registered: 1998 (27 years)

Introduction: Different types of motors and drives for conveyor systems include: 1. Internal Drives: Motor lies within and connects with the drive pulley, often found in belt conveyors. 2. End Drives: Located at the end of the conveyor, providing power for one of the rollers, also known as head drives. 3. Center Drives: Positioned in the center of the conveyor’s frame, can be placed anywhere along the conveyor,…

Strategic Sourcing Conclusion and Outlook for conveyor motor

In today’s competitive landscape, strategic sourcing for conveyor motors presents a significant opportunity for businesses aiming to optimize their operations. By leveraging diverse motor technologies—such as AC, brushless DC, and servo motors—buyers can enhance efficiency, reduce downtime, and ensure precise control in their conveyor systems. Understanding the unique specifications and applications of each motor type allows companies to tailor solutions that meet their specific operational needs, ultimately driving productivity and profitability.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to adopt a proactive sourcing strategy. This involves not only evaluating suppliers based on price but also considering factors such as reliability, service support, and technological advancements. Engaging with manufacturers that offer comprehensive product ranges, including gear options and automation capabilities, can further streamline operations and foster innovation.

Illustrative image related to conveyor motor

As you look ahead, consider the evolving demands of your industry and the potential for integrating advanced conveyor motor solutions. Embrace the future of automation and efficiency by initiating conversations with reputable suppliers today. Your strategic sourcing decisions now can shape the operational success of your business for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to conveyor motor