Unlocking Value: A Strategic Analysis of the Jib Crane Components Market

Introduction: Navigating the Global Market for jib crane components

In an increasingly interconnected world, sourcing reliable jib crane components presents a significant challenge for international B2B buyers, especially those in emerging markets such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil. The complexity of navigating diverse supplier landscapes, varying quality standards, and fluctuating costs can complicate procurement processes. This guide aims to streamline your sourcing efforts by offering a comprehensive overview of jib crane components, including their types, applications, and critical considerations for supplier vetting.

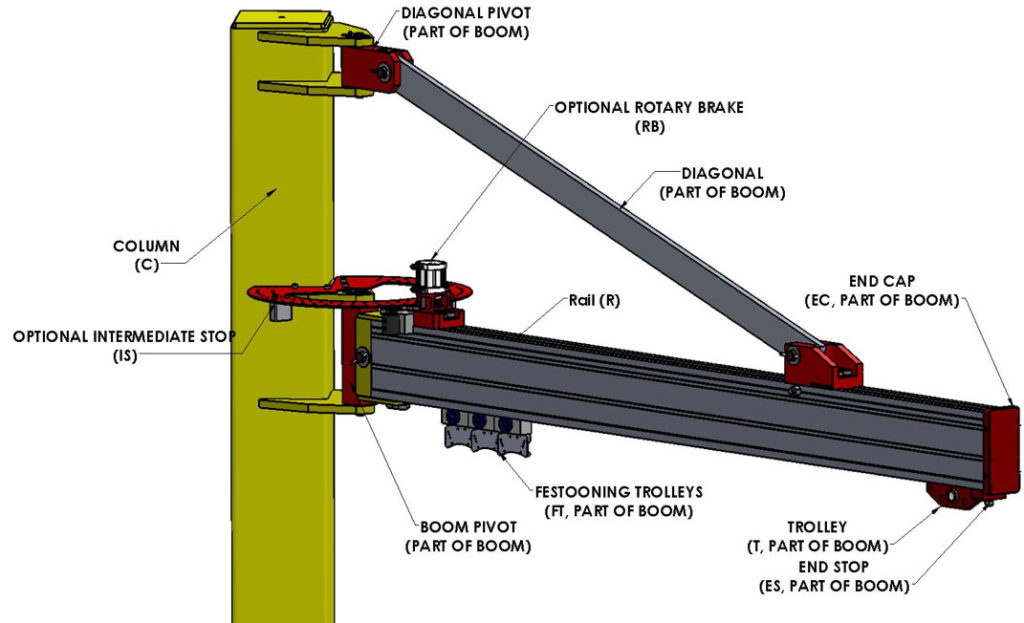

Throughout this guide, you will find detailed insights into the various components that make up jib cranes, such as the horizontal jib, mast, hoist, and control systems, along with their specific applications across different industries. We will also delve into the nuances of cost structures, enabling you to make informed purchasing decisions that align with your operational needs and budget constraints.

By providing actionable strategies and expert advice tailored to the unique challenges faced by B2B buyers in diverse regions, this guide empowers you to confidently navigate the global market for jib crane components. Whether you are looking to enhance your supply chain efficiency or ensure compliance with international standards, the insights offered here will be invaluable in optimizing your procurement strategy.

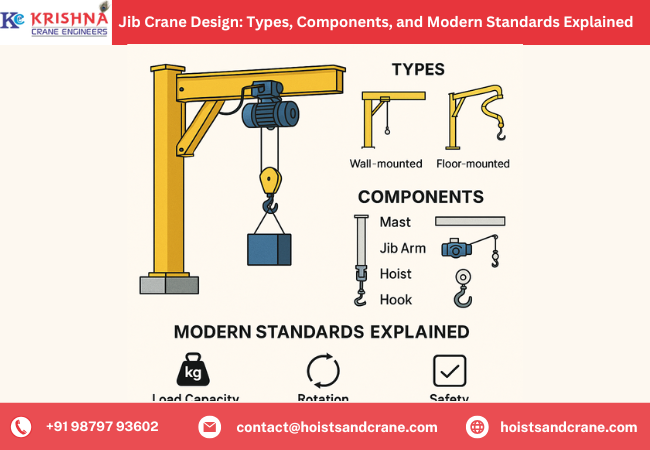

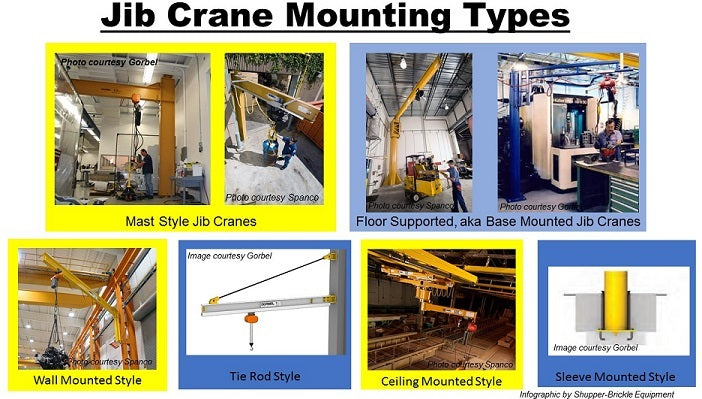

Understanding jib crane components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Articulating Jib Crane | Features a flexible arm that can pivot and extend; versatile in tight spaces. | Warehouses, manufacturing plants. | Pros: Flexible operation; ideal for confined areas. Cons: May have a lower weight capacity than fixed options. |

| Fixed Jib Crane | Mounted permanently to a structure; offers stable lifting capabilities. | Construction sites, docks. | Pros: High stability and load capacity. Cons: Limited range of motion; less adaptable to different tasks. |

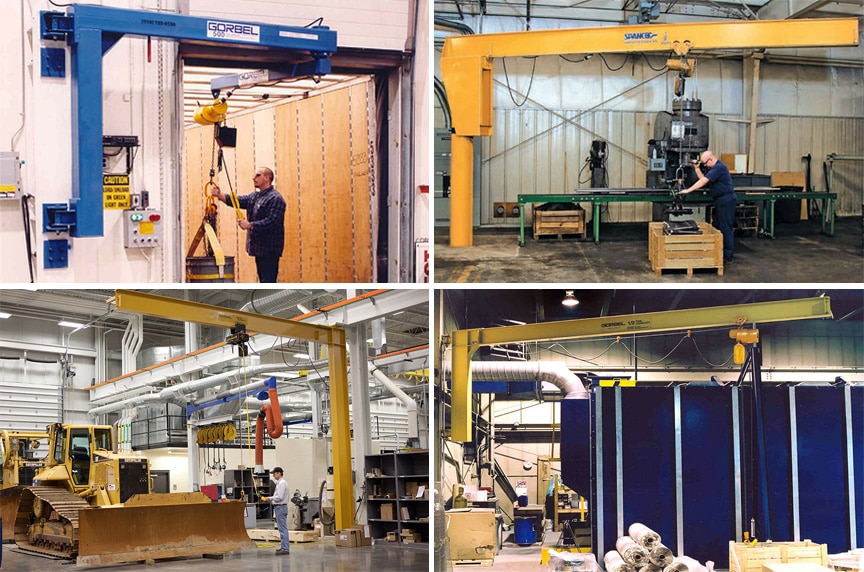

| Wall-Mounted Jib Crane | Attaches directly to walls; saves floor space and allows for efficient load handling. | Factories, workshops. | Pros: Space-efficient; easy to install. Cons: Limited reach compared to freestanding models. |

| Floor-Mounted Jib Crane | Standalone unit with a robust base; can rotate 360 degrees for maximum coverage. | Heavy-duty manufacturing, shipping. | Pros: High load capacity; extensive range of motion. Cons: Requires significant floor space; installation can be complex. |

| Portable Jib Crane | Lightweight and easy to relocate; often on wheels for mobility. | Construction sites, outdoor events. | Pros: Highly versatile; can be used in various locations. Cons: Generally lower lifting capacity; not suitable for heavy industrial applications. |

What Are the Key Characteristics of Articulating Jib Cranes?

Articulating jib cranes are distinguished by their flexible arms that can pivot and extend, allowing for enhanced maneuverability in tight spaces. These cranes are particularly suitable for warehouses and manufacturing plants where space is limited but operational flexibility is crucial. When considering an articulating jib crane, buyers should evaluate their specific space constraints and the weight of the loads they intend to handle, as these cranes typically have lower weight capacities compared to fixed models.

How Do Fixed Jib Cranes Provide Stability?

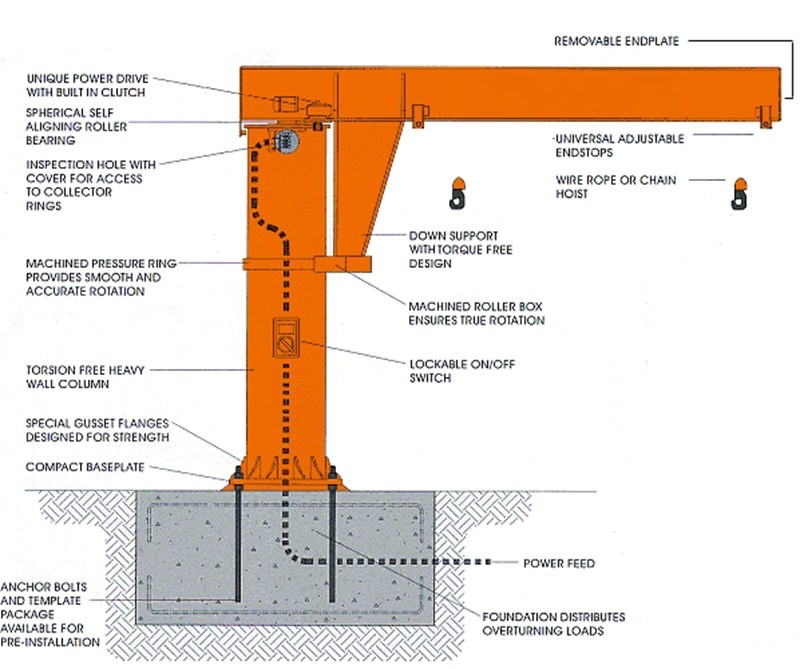

Fixed jib cranes are permanently mounted to a structure, offering exceptional stability and load-bearing capabilities. They are ideal for environments such as construction sites and docks where heavy lifting is a routine task. Buyers should consider the load requirements and the installation process, as fixed cranes require a secure foundation and may involve more complex setup procedures.

What Are the Advantages of Wall-Mounted Jib Cranes?

Wall-mounted jib cranes attach directly to walls, optimizing vertical space and enhancing operational efficiency in factories and workshops. Their design allows for easy installation and a straightforward approach to load handling. However, buyers should be aware of the limitations in reach compared to freestanding models, as these cranes are confined to the wall’s location.

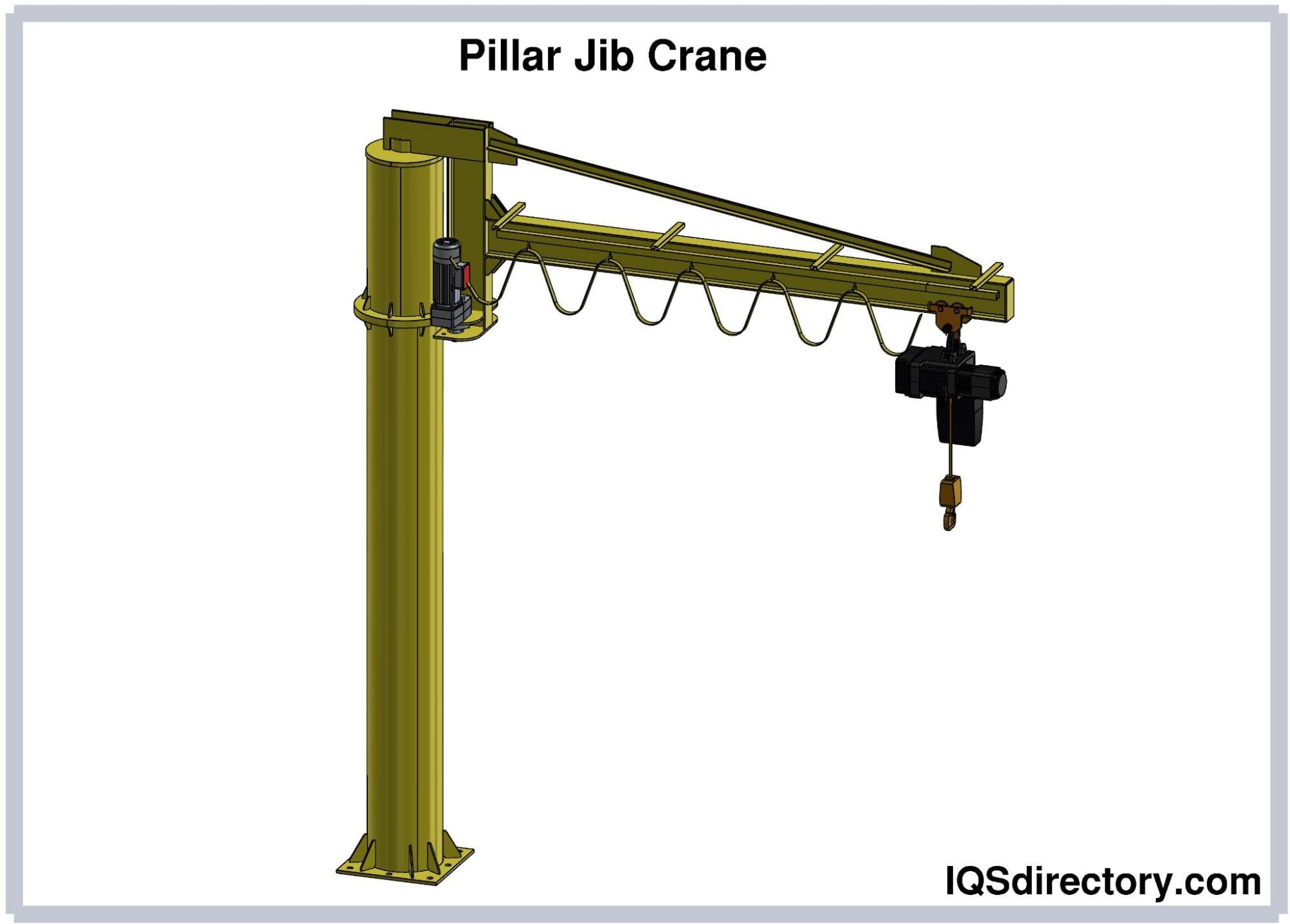

Why Choose Floor-Mounted Jib Cranes for Heavy-Duty Applications?

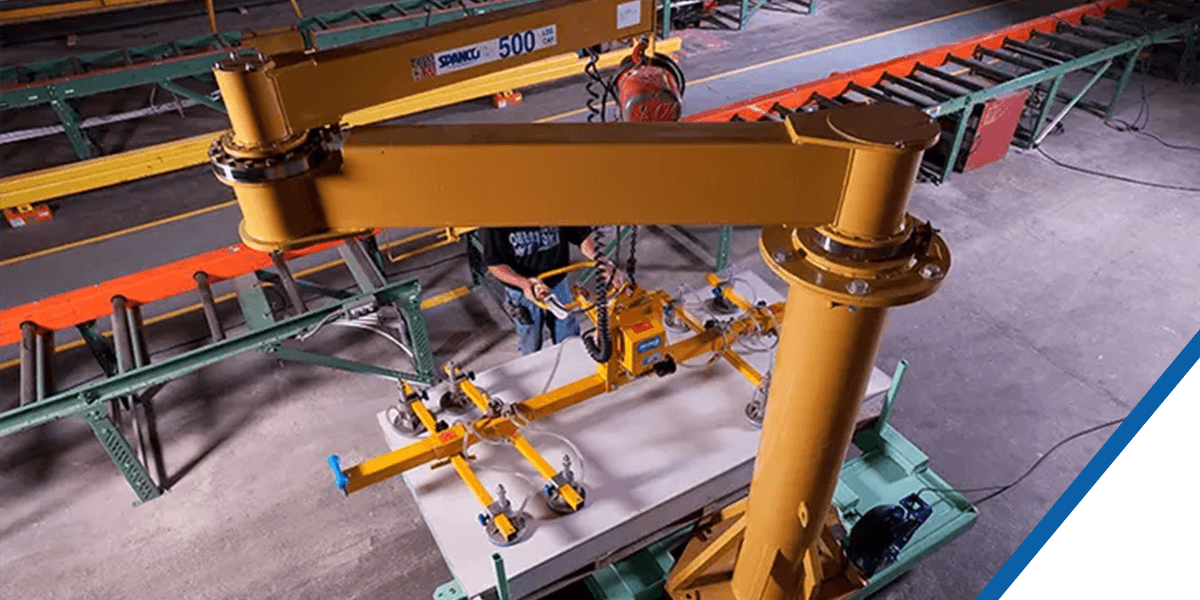

Floor-mounted jib cranes are robust units capable of rotating 360 degrees, making them suitable for heavy-duty manufacturing and shipping environments. Their extensive range of motion and high load capacity are significant advantages. However, these cranes require ample floor space and may involve a more intricate installation process, which buyers should factor into their procurement planning.

What Makes Portable Jib Cranes Ideal for Versatile Applications?

Portable jib cranes are designed for mobility and ease of relocation, making them perfect for construction sites and outdoor events. Their lightweight construction allows for quick setup and repositioning as needed. However, potential buyers should keep in mind that portable jib cranes usually have lower lifting capacities and may not be suitable for heavy industrial applications.

Key Industrial Applications of jib crane components

| Industry/Sector | Specific Application of jib crane components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Support | Increases efficiency and reduces manual labor costs | Quality certifications, load capacity, and durability |

| Construction | Material Handling on Job Sites | Enhances safety and streamlines workflow | Compliance with local regulations and safety standards |

| Warehousing | Inventory Management and Loading/Unloading Operations | Optimizes space utilization and improves productivity | Space requirements, hoist type, and maintenance services |

| Automotive | Engine Assembly and Heavy Component Lifting | Reduces downtime and improves assembly line flexibility | Compatibility with existing systems and ease of installation |

| Oil & Gas | Equipment Maintenance and Heavy Lifting | Increases operational efficiency and safety | Environmental resistance, load specifications, and service support |

How Are Jib Crane Components Utilized in Manufacturing?

In the manufacturing sector, jib crane components are essential for supporting assembly lines. These cranes facilitate the lifting and positioning of heavy parts, significantly improving workflow efficiency. By reducing the need for manual handling, companies can lower labor costs and minimize the risk of workplace injuries. Buyers in this industry should prioritize sourcing components that meet specific load capacities and durability standards to ensure long-term reliability.

What Role Do Jib Cranes Play in Construction?

Jib cranes are crucial on construction sites for material handling, offering flexibility in moving heavy materials across various elevations. Their ability to rotate up to 360 degrees allows for precise placement, reducing the time workers spend moving materials manually. For international buyers, especially in regions with stringent safety regulations, sourcing jib crane components that comply with local standards is vital to ensure safety and operational efficiency.

How Are Jib Cranes Beneficial in Warehousing?

In warehousing, jib crane components are utilized for efficient inventory management and loading/unloading operations. They enable quick access to products stored at height, optimizing space utilization and enhancing productivity. Buyers should consider the spatial constraints of their facilities and the type of hoisting mechanism that will best suit their operations to maximize efficiency.

Why Are Jib Cranes Important in the Automotive Industry?

In the automotive sector, jib cranes are frequently used for lifting heavy components such as engines during assembly. Their flexibility allows for quick adjustments in positioning, reducing downtime on the assembly line. International buyers should focus on compatibility with existing systems and the ease of installation, ensuring that the cranes integrate seamlessly into their production processes.

What Is the Significance of Jib Cranes in Oil & Gas?

In the oil and gas industry, jib cranes are vital for equipment maintenance and heavy lifting tasks. They enhance operational efficiency by allowing workers to lift and maneuver heavy equipment safely. Buyers in this sector should consider sourcing components designed to withstand harsh environmental conditions, ensuring reliability and safety in challenging operational settings.

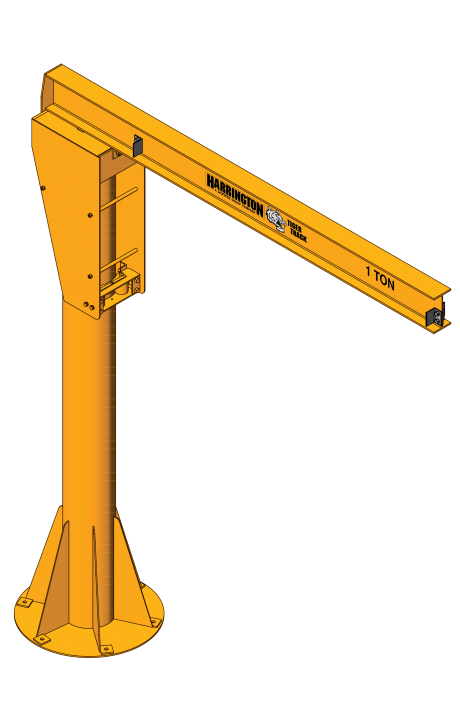

Illustrative image related to jib crane components

3 Common User Pain Points for ‘jib crane components’ & Their Solutions

Scenario 1: Inadequate Load Capacity for Heavy Applications

The Problem: Many B2B buyers find themselves in situations where their existing jib cranes cannot handle the weight of the loads they need to lift. This often occurs in industries like manufacturing, construction, or shipping, where the nature of the work frequently demands the movement of heavy materials. The inability to lift these loads not only hampers operational efficiency but can also lead to costly downtime and safety hazards. Buyers may also struggle with understanding the specifications of jib crane components, leading to the purchase of equipment that does not meet their lifting requirements.

The Solution: To address this pain point, buyers should conduct a thorough assessment of their lifting needs before sourcing jib crane components. This includes determining the maximum weight to be lifted and the dimensions of the load, as well as the operational environment. When specifying a jib crane, consider selecting components like hoists and wire ropes that are rated for higher capacities than initially estimated. Collaborating with reputable suppliers who offer customizable solutions can also be beneficial. For example, opting for heavy-duty hoists that utilize electric or hydraulic systems can significantly increase lifting capabilities. Additionally, integrating load monitoring systems can provide real-time data on lifting conditions, allowing for informed operational decisions and improving safety.

Scenario 2: Frequent Wear and Tear on Crane Components

The Problem: Another common issue faced by B2B buyers is the rapid wear and tear of jib crane components, which can lead to frequent breakdowns and maintenance needs. This is particularly prevalent in environments with harsh operating conditions, such as high dust levels, extreme temperatures, or corrosive materials. Buyers often find themselves frustrated with the ongoing costs associated with repairs and the potential for accidents caused by equipment failure, which can also result in liability issues.

The Solution: To mitigate this issue, buyers should invest in high-quality, durable jib crane components designed for specific environmental conditions. For instance, selecting components made from corrosion-resistant materials or those rated for high-impact applications can extend the lifespan of the crane. Implementing a proactive maintenance schedule is also critical; regular inspections can identify wear early, allowing for timely replacements before a complete failure occurs. Additionally, suppliers who offer warranties or service contracts can provide peace of mind and reduce long-term maintenance costs. Establishing a relationship with a knowledgeable supplier who understands the specific challenges of the industry can lead to tailored solutions and better product recommendations.

Scenario 3: Complex Installation and Setup Processes

The Problem: B2B buyers often encounter challenges during the installation and setup of jib crane components, which can lead to delays and increased costs. The complexity of assembling various parts, such as the jib, mast, and hoist, coupled with the need for precise alignment and configuration, can overwhelm even seasoned professionals. Inadequate installation can not only delay operations but also compromise the safety and functionality of the crane, leading to further complications down the line.

The Solution: To streamline the installation process, buyers should seek comprehensive installation services from their suppliers. This may include on-site support from technicians who are familiar with the specific jib crane components being used. Additionally, detailed installation manuals and online resources, such as instructional videos, can guide teams through the process. Buyers can also benefit from investing in modular jib crane designs, which are easier to assemble and disassemble, reducing the complexity involved. Conducting pre-installation training for operators and maintenance staff can further enhance the efficiency and safety of the installation process. Lastly, leveraging advanced technology, such as 3D modeling, can help visualize the installation, ensuring all components fit correctly before physical assembly begins.

Strategic Material Selection Guide for jib crane components

What Materials are Commonly Used for Jib Crane Components?

When selecting materials for jib crane components, it is essential to consider the properties, advantages, and limitations of each material. The right choice can significantly impact performance, durability, and compliance with international standards. Below are analyses of four common materials used in jib crane construction.

Steel: The Backbone of Jib Crane Components

Key Properties: Steel is renowned for its high tensile strength, making it ideal for structural components like the mast and jib. It can withstand high loads and is available in various grades, each with specific temperature and pressure ratings.

Pros & Cons: The primary advantage of steel is its durability and load-bearing capacity. However, it is susceptible to corrosion if not treated, which can be a concern in humid or corrosive environments. The cost of steel can vary, but it is generally considered a medium-cost material, depending on the grade and treatment.

Impact on Application: Steel is compatible with various lifting applications and can be treated or coated for specific environments. Buyers in regions with high humidity or saline conditions should consider galvanized or stainless steel options to enhance corrosion resistance.

Considerations for International Buyers: Compliance with international standards such as ASTM or EN is crucial. Buyers from regions like Saudi Arabia and Brazil should ensure that the steel used meets local regulations regarding quality and safety.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It performs well in a variety of temperatures, making it suitable for diverse climates.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces the overall weight of the crane and increases ease of installation. However, it has a lower tensile strength compared to steel, which may limit its use in heavy-duty applications. Aluminum is generally more expensive than steel, categorizing it as a high-cost material.

Impact on Application: Aluminum is ideal for applications where weight reduction is critical, such as in portable cranes. Its corrosion resistance makes it suitable for outdoor use in coastal areas.

Illustrative image related to jib crane components

Considerations for International Buyers: Buyers should verify that aluminum components meet standards such as ASTM B221 for extruded aluminum. Additionally, understanding local market preferences for aluminum grades can help in making informed purchasing decisions.

Composite Materials: Innovative and Versatile

Key Properties: Composite materials, often a combination of fibers and resins, offer excellent strength-to-weight ratios and corrosion resistance. They can be engineered for specific applications, providing tailored mechanical properties.

Pros & Cons: The main advantage of composites is their lightweight nature and resistance to environmental degradation. However, they can be more expensive to manufacture and may require specialized handling during installation. Composites generally fall into the high-cost category.

Impact on Application: Composites are particularly beneficial in environments where traditional materials may fail due to corrosion or chemical exposure. Their versatility allows for innovative designs that can enhance the functionality of jib cranes.

Considerations for International Buyers: International buyers should consider the certifications required for composite materials, as standards can vary significantly between regions. Understanding local regulations regarding material safety and performance is essential.

Wire Rope: Essential for Lifting Mechanisms

Key Properties: Wire rope is made from multiple strands of steel wire twisted together, providing high tensile strength and flexibility. It is designed to withstand dynamic loads and has excellent fatigue resistance.

Pros & Cons: The key advantage of wire rope is its ability to handle heavy loads while maintaining flexibility, which is essential for lifting applications. However, it can be susceptible to wear and corrosion, requiring regular inspection and maintenance. Wire rope is generally considered a medium-cost material.

Impact on Application: Wire rope is critical for the hoisting mechanisms of jib cranes, making it suitable for various lifting tasks. Its compatibility with different hoisting systems allows for extensive application versatility.

Considerations for International Buyers: Buyers should ensure that wire rope complies with international standards such as ISO 2408. Understanding local standards and maintenance requirements is vital for ensuring safety and performance.

Summary Table of Material Selection for Jib Crane Components

| Material | Typical Use Case for jib crane components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components (mast, jib) | High tensile strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight cranes | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Composite | Specialized applications | Excellent strength-to-weight ratio | Higher manufacturing costs | High |

| Wire Rope | Lifting mechanisms | High flexibility and tensile strength | Requires regular maintenance | Medium |

This strategic material selection guide serves as a comprehensive reference for international B2B buyers, helping them make informed decisions tailored to their specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for jib crane components

What Are the Key Stages in the Manufacturing Process of Jib Crane Components?

Manufacturing jib crane components involves several critical stages designed to ensure functionality, safety, and reliability. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with selecting appropriate materials such as high-strength steel, aluminum, or specialized alloys. Each material is chosen based on its mechanical properties, corrosion resistance, and cost-effectiveness. After selection, materials undergo cutting, shearing, or machining to achieve the required dimensions. This stage is crucial as it sets the foundation for the structural integrity of the jib crane.

-

Forming: Once materials are prepared, they undergo various forming processes. Techniques such as welding, bending, and forging are employed to shape components like the mast, jib, and hoist. Advanced methods like laser cutting and CNC machining are increasingly utilized for precision and efficiency. Forming must be done with great care to ensure that the components can withstand operational loads without deforming.

-

Assembly: After individual components are formed, the assembly process begins. This involves joining various parts, including the mast, jib, bearing systems, and hoists, using methods such as bolting, welding, or riveting. The assembly process is typically executed in a controlled environment to maintain quality. Attention to detail during assembly is vital, as misalignment can affect the crane’s performance and safety.

-

Finishing: The final stage of manufacturing includes finishing processes such as surface treatment, painting, and coating. These processes not only enhance the aesthetic appeal but also protect against corrosion and wear. Common treatments include galvanization, powder coating, and the application of anti-corrosive paints. Quality checks during this phase ensure that the components meet the required specifications before delivery.

What International Standards Guide Quality Assurance in Jib Crane Manufacturing?

Quality assurance in the manufacturing of jib crane components is governed by several international and industry-specific standards. These standards help ensure that products are safe, reliable, and meet customer expectations.

-

ISO 9001: This international standard outlines the criteria for a quality management system. Companies that comply with ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements. For B2B buyers, checking for ISO 9001 certification can be a strong indicator of a supplier’s commitment to quality.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. Jib cranes and their components must meet specific directives to carry this mark, ensuring they are safe for use in various applications.

-

API Standards: The American Petroleum Institute (API) sets standards relevant to cranes used in the oil and gas industry. Adherence to API standards can be crucial for buyers in sectors where operational safety is paramount.

What Are the Quality Control Checkpoints During the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not meet the criteria are rejected or sent back to suppliers.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring the production process at various stages. This includes checking the dimensions and tolerances of components to ensure they align with design specifications. Regular inspections help catch issues early, reducing the risk of costly rework.

-

Final Quality Control (FQC): The FQC stage involves comprehensive testing of the assembled jib crane components. This may include load testing, operational testing, and inspection of surface finishes. Components that pass these tests are deemed ready for shipment, while those that fail are reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers adhere to rigorous quality control processes to minimize risks. Here are effective ways to verify QC practices:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality management systems in place. This firsthand observation can provide insight into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers can ask for documentation of quality control processes, including IQC, IPQC, and FQC results. These reports should detail any issues encountered and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These inspections can verify compliance with international standards and provide detailed reports on product quality.

What Are the Unique QC Considerations for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider additional QC nuances when sourcing jib crane components:

-

Regulatory Compliance: Understanding local regulations and standards is essential. For example, while CE marking is crucial for European buyers, Middle Eastern buyers may need to adhere to specific regional standards.

-

Cultural and Communication Barriers: Different countries may have varying approaches to quality assurance. Buyers should be aware of cultural differences that may affect communication and expectations regarding quality.

-

Logistical Challenges: International shipping can introduce risks that affect product quality, such as damage during transit. Buyers should ensure that suppliers use appropriate packaging and handling procedures to mitigate these risks.

-

After-Sales Support: Assessing the supplier’s ability to provide after-sales support, including maintenance and spare parts availability, is crucial for ensuring long-term operational reliability.

By understanding the manufacturing processes and quality assurance practices for jib crane components, B2B buyers can make informed decisions and ensure that their investments are sound. Prioritizing suppliers with robust QC measures and compliance with international standards will not only enhance operational efficiency but also contribute to overall safety in lifting operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jib crane components’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure jib crane components. It aims to streamline the sourcing process by outlining essential steps that ensure quality, compatibility, and compliance with industry standards. By following this checklist, you can make informed purchasing decisions that enhance operational efficiency.

Illustrative image related to jib crane components

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your jib crane components. This includes load capacity, reach, and the type of hoist mechanism (electric, hydraulic, or manual). Understanding these parameters is crucial to ensure that the components will meet your operational needs and safety standards.

- Consider the environment: Assess whether components need to be weather-resistant or suitable for specific industrial conditions.

- Compatibility matters: Ensure that the components are compatible with existing equipment to avoid additional costs.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify potential suppliers specializing in jib crane components. Look for manufacturers and distributors with a proven track record in the industry.

- Use industry directories: Leverage platforms like IQS Directory and trade shows to find reputable suppliers.

- Check their experience: Prioritize suppliers with experience in your specific region, as they may have better insights into local regulations and market needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures that you are dealing with a reliable partner.

- Assess certifications: Verify that suppliers have necessary certifications (e.g., ISO, CE) that demonstrate compliance with quality and safety standards.

- Review customer feedback: Look for reviews and testimonials to gauge supplier reliability and customer service.

Step 4: Request and Compare Quotes

Once you have shortlisted suppliers, request detailed quotes for the required components. This will help you understand pricing structures and terms.

Illustrative image related to jib crane components

- Breakdown of costs: Ensure that the quotes include a breakdown of costs, including shipping and handling, to avoid hidden fees.

- Evaluate payment terms: Consider the payment terms offered by each supplier, as favorable terms can significantly impact cash flow.

Step 5: Conduct Quality Assurance Checks

Before finalizing your order, establish a quality assurance process. This includes inspecting samples and verifying that components meet your specifications.

- Request samples: If possible, obtain samples of critical components to test their performance and compatibility.

- Quality control processes: Inquire about the supplier’s quality control measures to ensure that their products consistently meet required standards.

Step 6: Negotiate Terms and Finalize Orders

Once you are satisfied with the quality and pricing, negotiate the terms of the purchase. Ensure that all aspects of the agreement are clear before proceeding.

- Clarify delivery timelines: Confirm lead times and delivery schedules to avoid operational disruptions.

- Document everything: Keep a written record of all agreements, including warranty terms and after-sales support.

Step 7: Plan for Installation and Maintenance

Finally, consider how the components will be installed and maintained. This includes training for your team on proper usage and maintenance protocols.

- Training programs: Check if the supplier offers training on installation and operation to ensure safe and effective use of the equipment.

- Maintenance schedules: Establish a maintenance schedule to prolong the lifespan of your jib crane components and ensure ongoing safety compliance.

By following these steps, B2B buyers can effectively navigate the procurement process for jib crane components, ensuring they select high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for jib crane components Sourcing

What Are the Key Cost Components in Sourcing Jib Crane Components?

When sourcing jib crane components, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for jib cranes include high-strength steel for the structure and durable cables for lifting mechanisms. Prices can fluctuate based on market demand, availability, and quality specifications.

-

Labor: Labor costs encompass both direct and indirect labor involved in production. Skilled labor may be required for assembly and quality assurance, thus affecting the final pricing structure.

-

Manufacturing Overhead: This includes costs related to the factory operations, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The initial investment in tooling and machinery is essential for manufacturing jib crane components. This cost is often amortized over production runs, affecting the unit price based on order volume.

-

Quality Control (QC): Implementing stringent QC measures ensures that components meet safety and performance standards. While it may increase upfront costs, it ultimately reduces the risk of defects and associated warranty claims.

-

Logistics: Transportation and shipping costs can vary widely depending on the distance, mode of transport, and complexity of the delivery. For international buyers, understanding the logistics landscape is essential to avoid unexpected costs.

-

Margin: Suppliers typically apply a profit margin to cover risks and ensure sustainability. This margin can vary based on market competition, brand reputation, and the uniqueness of the offered components.

What Influences Prices for Jib Crane Components?

Several factors can influence the pricing of jib crane components, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit prices due to economies of scale. Negotiating favorable terms for higher volumes can significantly lower costs.

-

Specifications and Customization: Custom-designed components or those with specific specifications may incur additional costs. Buyers should assess the necessity of custom features against potential price increases.

-

Material Quality and Certifications: Higher quality materials or components that meet international standards (ISO, CE certifications) may command a premium price. Buyers should weigh the long-term benefits of investing in certified components.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Established suppliers with a track record of reliability may justify higher prices due to perceived value and service quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining who bears the cost and risk at each stage of the shipping process. This knowledge can lead to better negotiation outcomes and cost management.

What Are Essential Buyer Tips for Cost-Efficiency?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is important to adopt strategic purchasing practices:

-

Negotiation Strategies: Leverage volume commitments and long-term contracts to negotiate better pricing. Building relationships with suppliers can also lead to favorable terms and conditions.

-

Understanding Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the maintenance, operational efficiency, and potential downtime costs associated with the components. A lower initial price may lead to higher TCO over time.

-

Pricing Nuances in International Markets: Be aware of regional pricing differences influenced by local market dynamics, currency fluctuations, and economic conditions. Conduct thorough market research to make informed purchasing decisions.

-

Requesting Quotations: Always solicit multiple quotes from different suppliers to compare prices and terms. This practice not only provides a clearer view of the market but also strengthens negotiation positions.

-

Monitoring Market Trends: Keeping an eye on trends in material prices and demand can help buyers make timely purchasing decisions, potentially avoiding price hikes.

Disclaimer on Indicative Prices

Prices for jib crane components can vary widely based on the aforementioned factors. It is crucial for buyers to conduct thorough research and obtain specific quotes tailored to their needs to ensure accurate budgeting and planning.

Illustrative image related to jib crane components

Alternatives Analysis: Comparing jib crane components With Other Solutions

When considering lifting solutions in industrial settings, it’s crucial to evaluate various options to determine the best fit for specific operational needs. Jib crane components are a popular choice due to their versatility and efficiency in lifting heavy loads within confined spaces. However, there are alternative solutions available, such as gantry cranes and electric hoists, which may also meet the requirements of different applications. This analysis provides a comparative view of these options.

| Comparison Aspect | Jib Crane Components | Gantry Crane | Electric Hoist |

|---|---|---|---|

| Performance | High precision and range of motion; suitable for smaller spaces | Excellent for larger areas; capable of lifting heavier loads | Ideal for vertical lifting; limited horizontal movement |

| Cost | Moderate initial investment; low operational costs | Higher initial investment; variable operational costs depending on usage | Generally lower initial cost; maintenance can add up over time |

| Ease of Implementation | Requires proper foundation; quick setup in most cases | Requires more space and complex installation; may need extensive groundwork | Simple to install; can be mounted on existing structures |

| Maintenance | Low; periodic inspections required | Moderate; regular maintenance essential for moving parts | Low; minimal upkeep but requires checks on electrical components |

| Best Use Case | Ideal for workshops and assembly lines with limited floor space | Best for warehouses and large facilities needing high capacity | Effective for vertical lifts in various settings, including construction sites |

What Are the Benefits and Drawbacks of Gantry Cranes Compared to Jib Cranes?

Gantry cranes offer a robust alternative to jib cranes, particularly in environments requiring the lifting of heavy loads over larger areas. These cranes feature a bridge that spans a workspace and are supported by legs, allowing for significant lifting capacity. The primary advantage of gantry cranes is their ability to cover extensive areas and accommodate heavier weights. However, they require more floor space and a more complex installation process, which may not be feasible in smaller workshops. Their higher initial cost can also be a deterrent for smaller businesses.

How Do Electric Hoists Stack Up Against Jib Cranes?

Electric hoists are another viable alternative, particularly when the lifting requirement is primarily vertical. They are powered by electric motors and can easily be mounted on existing structures, making them a cost-effective and straightforward solution for lifting materials. While electric hoists are generally lower in cost compared to jib cranes, they lack the horizontal movement and precision offered by jib cranes, making them less suitable for tasks requiring maneuverability. Their maintenance needs are minimal, but regular checks on electrical components are essential to ensure safety and performance.

Illustrative image related to jib crane components

How Can B2B Buyers Choose the Right Lifting Solution?

When selecting the right lifting solution, B2B buyers should carefully evaluate their specific operational requirements. Factors such as load capacity, workspace dimensions, and the nature of lifting tasks should guide the decision-making process. For environments with confined spaces and the need for precision, jib cranes may be the best option. Conversely, if lifting heavier loads across larger areas is essential, gantry cranes could be more suitable. Electric hoists are ideal for straightforward vertical lifting tasks and offer a budget-friendly choice for businesses with limited space. Ultimately, the best solution will depend on balancing performance, cost, and operational needs.

Essential Technical Properties and Trade Terminology for jib crane components

What Are the Essential Technical Properties of Jib Crane Components?

When sourcing jib crane components, understanding key technical specifications is crucial for ensuring efficiency, safety, and compatibility with existing systems. Here are some critical specifications to consider:

-

Material Grade

The material grade of components such as the mast, jib, and hoist is fundamental for durability and load capacity. Common materials include structural steel grades like S235 and S275, which offer high tensile strength and resistance to deformation. Selecting the appropriate material is vital, as it directly impacts the crane’s ability to handle specific weights and withstand environmental conditions, especially in regions with extreme weather. -

Load Capacity

This specification defines the maximum weight the jib crane can safely lift. It is essential to match the load capacity with the operational needs of your facility. Choosing a crane with insufficient capacity can lead to equipment failure and safety hazards, while over-specifying can result in unnecessary costs. -

Tolerance Levels

Tolerances refer to the allowable deviations in dimensions for components. Precise tolerances ensure that parts fit together correctly, which is crucial for the crane’s overall functionality and safety. In manufacturing, tighter tolerances can lead to higher costs, so understanding the balance between cost and performance is essential for procurement decisions. -

Rotational Range

The rotational range of the jib, typically up to 360 degrees, determines the crane’s versatility in lifting and moving loads. A wider rotational range allows for greater maneuverability within a workspace, making it suitable for various applications. Buyers must evaluate their operational layout to ensure the selected crane can meet their spatial requirements. -

Control Systems

The type of control system—manual, pendant, or remote—affects operational efficiency and user safety. Advanced control systems can enhance precision in load handling and reduce the risk of accidents. It’s crucial for buyers to assess the ease of use and training requirements associated with each control option. -

Safety Features

Safety features such as overload protection, emergency stop buttons, and limit switches are critical for ensuring safe operation. Understanding the safety standards and certifications applicable to jib cranes in specific markets can influence purchasing decisions and compliance with local regulations.

What Are Common Trade Terms Related to Jib Crane Components?

Navigating the procurement of jib crane components involves familiarizing oneself with industry-specific terminology. Here are some common terms that B2B buyers should know:

Illustrative image related to jib crane components

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. Understanding the OEM status of a supplier can help assess the quality and reliability of the components being sourced. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is critical for buyers to understand MOQ requirements to effectively manage inventory levels and avoid over-commitment to purchases that may not meet their operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services. It is an essential step in the procurement process, enabling buyers to compare options and negotiate better terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and duties. Familiarity with Incoterms helps buyers avoid misunderstandings related to shipping costs and risks. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for planning and ensuring that equipment is available when needed, especially in industries where operational downtime can be costly. -

Certifications

Certifications are official documents that verify a component meets specific industry standards. Common certifications for jib crane components include ISO 9001 for quality management and CE marking for compliance with European safety standards. Buyers should verify certifications to ensure compliance with local regulations and industry best practices.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing jib crane components, ultimately enhancing operational efficiency and safety in their workplaces.

Navigating Market Dynamics and Sourcing Trends in the jib crane components Sector

What Are the Current Market Dynamics and Key Trends Affecting Jib Crane Components?

The jib crane components market is experiencing significant growth, driven by the increasing demand for efficient material handling solutions across various industries. Key global drivers include the rise of automation in manufacturing, the expansion of e-commerce, and a growing emphasis on workplace safety. Emerging technologies such as IoT and AI are revolutionizing crane operations, enabling real-time monitoring and predictive maintenance, which enhances efficiency and reduces downtime. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

In terms of sourcing trends, buyers are increasingly looking for suppliers who can offer customized solutions that fit specific operational needs. This includes components such as hoists, control systems, and bearing mechanisms that can be tailored for different lifting capacities and operational environments. Additionally, there is a growing emphasis on transparent supply chains, where buyers seek out suppliers that provide detailed information about the origin and manufacturing processes of components. This shift reflects a broader trend toward accountability and quality assurance in procurement.

How Is Sustainability and Ethical Sourcing Influencing B2B Purchasing Decisions?

Sustainability has become a paramount concern for B2B buyers in the jib crane components sector. The environmental impact of manufacturing processes and materials used in crane components is under scrutiny, prompting companies to adopt greener practices. Buyers are increasingly favoring suppliers who utilize environmentally friendly materials and sustainable manufacturing processes. For example, the use of recycled metals and eco-friendly lubricants in components like hoists and bearings is becoming more common.

Moreover, ethical sourcing is gaining traction as companies recognize the importance of responsible supply chains. This encompasses fair labor practices, safe working conditions, and the reduction of waste throughout the supply chain. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are being prioritized by buyers looking to ensure that their suppliers adhere to high standards. By aligning procurement strategies with sustainability goals, B2B buyers not only fulfill corporate social responsibility mandates but also enhance their brand reputation and customer loyalty.

What Historical Developments Have Shaped the Jib Crane Components Market?

The evolution of jib cranes dates back to ancient times, with early designs utilizing simple mechanical principles to lift heavy objects. Over the centuries, advancements in materials science and engineering have led to the development of more sophisticated components, including electric hoists and automated control systems. The introduction of standardized components in the 20th century facilitated easier sourcing and replacement, paving the way for the global market we see today.

In recent decades, the integration of technology into crane systems has transformed operations, allowing for greater precision and efficiency. The focus has shifted from merely lifting loads to optimizing the entire material handling process. This historical context is vital for B2B buyers, as it highlights the ongoing innovation within the sector and the importance of staying updated on technological advancements that can enhance operational efficiency and safety.

Conclusion

Navigating the complexities of the jib crane components market requires an understanding of current trends, sustainability practices, and historical developments. By aligning procurement strategies with these insights, international B2B buyers can make informed decisions that not only enhance operational efficiency but also contribute to broader corporate sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of jib crane components

-

How do I choose the right jib crane components for my operation?

Selecting the appropriate jib crane components involves assessing your specific operational needs, including the weight and type of loads you will lift, the available space, and the required lifting height. Evaluate the jib length and rotation capacity, ensuring they align with your workspace dimensions. Consider the hoist type (electric, hydraulic, or manual) based on lifting frequency and load capacity. Additionally, consult with suppliers for customization options that can enhance efficiency and safety in your operations. -

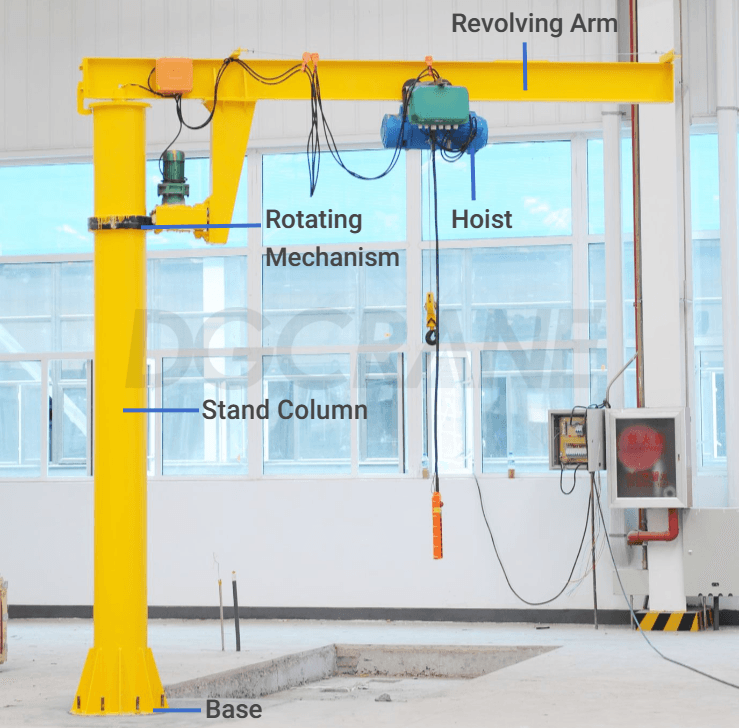

What are the key components of a jib crane I should be aware of?

A jib crane typically consists of several essential components: the horizontal jib (arm), mast or support column, bearing system, hoist, and controls. The jib allows for horizontal movement, while the mast provides vertical support. The bearing system facilitates smooth rotation, and the hoist is responsible for lifting and lowering loads. Controls can vary from manual push-button systems to sophisticated automated solutions, enabling precise operation tailored to your lifting requirements. -

What factors should I consider when vetting suppliers for jib crane components?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and the range of components offered. Verify their compliance with international quality and safety standards, which is crucial for operational reliability. Request certifications, warranties, and references from previous clients. Additionally, assess their ability to provide after-sales support, such as installation and maintenance services, which can significantly impact your operational efficiency. -

Are there minimum order quantities (MOQs) for jib crane components?

Minimum order quantities can vary significantly between suppliers. Some manufacturers may set MOQs based on production costs or logistics considerations, while others may offer flexibility for smaller orders. It’s advisable to discuss your specific needs with potential suppliers and negotiate terms that suit your budget and operational requirements. Be prepared to explore options for bulk purchasing if you anticipate future expansion or require components for multiple cranes. -

What payment terms should I expect when sourcing jib crane components internationally?

Payment terms can vary by supplier and region, but common practices include upfront deposits (often 30% to 50%) followed by the balance upon delivery or installation. Some suppliers may offer credit terms, particularly for established clients. Always clarify payment methods accepted, including letters of credit, bank transfers, or online payment platforms. Ensure that the terms align with your financial planning and cash flow management strategies. -

How can I ensure quality assurance (QA) for jib crane components?

To ensure quality assurance, request detailed specifications and certifications from your suppliers regarding materials, manufacturing processes, and safety standards. Conduct factory visits or audits if possible, to observe the production practices firsthand. Implement a rigorous inspection process upon receipt of components, checking for compliance with agreed specifications. Establish clear communication with suppliers regarding your QA expectations to foster a proactive approach to quality management. -

What are the logistics considerations for importing jib crane components?

Logistics considerations include understanding shipping methods, customs regulations, and potential tariffs that may apply to your imports. Evaluate the lead times for production and shipping, and factor in any delays that could affect your project timelines. It’s advisable to work with a logistics partner experienced in international shipping to navigate customs efficiently. Additionally, consider warehousing options in your region to facilitate quicker access to components when needed. -

Can I customize jib crane components to fit my specific needs?

Yes, many manufacturers offer customization options for jib crane components. Customizations can include variations in size, lifting capacity, material choices, and control systems to match your operational requirements. Discuss your specific needs with potential suppliers, including any unique challenges your operations face. Be prepared to provide detailed specifications and possibly engage in a collaborative design process to ensure the final components meet your expectations.

Top 7 Jib Crane Components Manufacturers & Suppliers List

1. IQS Directory – Jib Cranes

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Jib cranes are lifting machinery characterized by an arm or boom that extends from a primary structure, designed for enhanced reach in smaller work environments. They can handle loads from 250 lbs to 15 tons and come in various configurations including freestanding, wall-mounted, ceiling-mounted, and articulating types. Freestanding jib cranes are the most versatile, allowing for 360° rotation and…

2. Ace Industries – Jib Crane Components

Domain: aceindustries.com

Registered: 1997 (28 years)

Introduction: A jib crane consists of several key components: the horizontal jib (the arm that extends from the mast and supports the hoist and load), the mast or support column (the vertical structure that supports the jib and bearing system), the bearing system (which allows the jib to rotate horizontally with smooth and precise movement), the hoist (the lifting mechanism powered by electricity, air, or hydra…

3. Abell-Howe – Crane Parts Components

Domain: abell-howe.com

Registered: 2019 (6 years)

Introduction: Abell-Howe Crane Parts include various components such as Axle Bearings, Bushings, Collectors, Couplings, End Stops, Fittings, Guide Rollers, Guides, Hardware, Pins, Pinions, Snap Rings, Spacers, Trolleys, Washers, and Wheels. Specific products listed are: 10″ Diameter Trolley Idler Wheel, 10″ Diameter Trolley Driver Wheel, 7″ Diameter UH Machined Driver Wheel, 7″ Diameter UH Machined Idler Wheel,…

4. Amquip Inc – Jib Cranes

Domain: amquipinc.com

Registered: 2002 (23 years)

Introduction: A jib crane is a type of crane that spans between two points and is used for moving heavy objects. It typically features an A-frame structure with a one-arm extension at an angle from the main beam. Jib cranes are commonly used in construction sites, warehouses, factories, power plants, and ports for lifting large machinery or equipment. Key components include: 1. Reach – a horizontal beam that sw…

5. Kessler Crane – Replacement Parts

Domain: kesslercrane.com

Registered: 2005 (20 years)

Introduction: Cranes & Jib – Replacement Parts include various items such as: 100mm Ball Relocator ($94.00), Tool-less Knob for Hercules 2.0 Head / Jib Mounting (set of two) ($7.00), 12 ft. Crane Upgrade (Mid Section) – Ultra Duty ($528.00), Tool-less Knob – Male Short (set of two) ($13.00), Fine Tuning Weights (1 LB) ($18.00), 18 ft. Crane Upgrade Kit ($1,018.00), Extended Weight Bar ($105.00), Replacement Wei…

6. Mazzella Companies – Jib Cranes

Domain: mazzellacompanies.com

Registered: 1998 (27 years)

Introduction: Jib cranes are overhead lifting devices designed for high-volume lifts in smaller work cell areas. They can handle capacities ranging from 250 lbs. to 15 tons. Key components include: Reach/Boom (horizontal beam), Mast/Pillar (vertical support), Movable Hoist (for lifting), Trolley (manual or motorized movement), and Rotation (360° for freestanding, 180-200° for wall-mounted). Types include: Frees…

7. American Crane – Jib Crane Accessories

Domain: store.americancrane.com

Registered: 1996 (29 years)

Introduction: Jib Crane Accessories include various components and kits for enhancing jib crane functionality. Key products listed are: 1. Manual Rotation Stop Kit for Free Standing Jib / Mast Type Jib (Price: Quote) 2. Free Standing Jib Crane Top Entry Collector (Price: $1,013.25) 3. Logistics Fee (Price: $105.00) 4. Blue Touch-Up Paint (spray paint) (Price: $15.00) 5. Yellow Touch-Up Paint (spray paint) (Pric…

Strategic Sourcing Conclusion and Outlook for jib crane components

How Can Strategic Sourcing Enhance Your Jib Crane Component Procurement?

In the competitive landscape of jib crane components, strategic sourcing emerges as a vital approach for international B2B buyers. By focusing on quality, reliability, and cost-effectiveness, organizations can optimize their procurement processes, ensuring they obtain high-performance components such as hoists, bearings, and control systems. Establishing strong relationships with reputable suppliers not only enhances supply chain resilience but also fosters innovation and responsiveness to market demands.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, buyers must remain proactive in identifying and engaging with suppliers who can meet their specific needs. This means considering factors such as local regulations, logistical challenges, and technological advancements.

Looking ahead, the demand for efficient lifting solutions is poised to grow, driven by industrial expansion and modernization projects. Now is the time for businesses to leverage strategic sourcing to position themselves advantageously within the market. By investing in robust sourcing strategies today, companies can ensure they are prepared for tomorrow’s challenges and opportunities in the jib crane sector. Engage with suppliers who align with your strategic goals and elevate your operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to jib crane components