Top 4 Gypsum Board 4 X 8 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for gypsum board 4 x 8

Navigating the global market for gypsum board 4 x 8 presents a unique set of challenges for international B2B buyers. From understanding regional demand to sourcing high-quality products at competitive prices, the complexity can be daunting. This guide aims to demystify the process of procuring gypsum board by providing an in-depth exploration of various types, applications, and supplier vetting strategies. It addresses critical considerations, including cost factors and quality assurance, ensuring that buyers can make informed decisions tailored to their specific markets.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, such as Vietnam and Brazil, will find this guide indispensable. It not only highlights the diverse applications of gypsum board—from residential construction to commercial projects—but also emphasizes the importance of choosing suppliers who adhere to international standards. By offering actionable insights and a clear framework for evaluating potential partners, this guide empowers businesses to enhance their procurement strategies. Whether you are looking for moisture-resistant, fire-rated, or lightweight options, understanding the nuances of gypsum board will lead to smarter purchasing decisions that align with your operational goals.

In an ever-evolving construction landscape, having the right information can set your business apart and lead to successful project outcomes.

Understanding gypsum board 4 x 8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gypsum Board | Basic fire-resistant properties, 1/2 inch thickness | Interior walls and ceilings in dry areas | Pros: Cost-effective, easy to install. Cons: Limited moisture and mold resistance. |

| Moisture-Resistant Board | Enhanced moisture resistance, suitable for high humidity areas | Bathrooms, kitchens, and other wet areas | Pros: Reduces mold growth, durable. Cons: Higher cost than standard boards. |

| Mold-Resistant Board | Specially treated paper and core to inhibit mold growth | Areas prone to moisture, such as basements | Pros: Excellent mold resistance. Cons: More expensive and may require specialized handling. |

| Fire-Resistant Board | Increased thickness (typically 5/8 inch) for fire safety | Commercial buildings, schools, and hospitals | Pros: Improved safety, insurance benefits. Cons: Heavier and more costly. |

| Eco-Friendly Gypsum Board | Made from recycled materials, lower VOC emissions | Green building projects and sustainable designs | Pros: Environmentally friendly, supports LEED credits. Cons: May have limited availability. |

What Are the Characteristics and Applications of Standard Gypsum Board?

Standard gypsum board, typically 1/2 inch thick, is the most commonly used type in construction. It offers basic fire resistance and is suitable for interior walls and ceilings in dry environments. B2B buyers often choose this option for its cost-effectiveness and ease of installation, making it ideal for large-scale projects where budget constraints are a priority. However, its limited moisture and mold resistance may not be suitable for areas prone to high humidity.

How Does Moisture-Resistant Gypsum Board Differ from Standard Options?

Moisture-resistant gypsum board is specially designed to withstand high humidity levels, making it an excellent choice for bathrooms, kitchens, and other wet areas. Its enhanced features help reduce the risk of mold growth, which is a significant concern in regions with high moisture levels. While it tends to be more expensive than standard gypsum board, its durability and protection against mold make it a worthwhile investment for B2B buyers focused on long-term performance in challenging environments.

What Are the Advantages of Using Mold-Resistant Gypsum Board?

Mold-resistant gypsum board is treated to inhibit mold growth, making it particularly suitable for basements and areas with limited ventilation. Its unique paper and core composition provide superior protection against moisture-related issues. For B2B purchasers, investing in mold-resistant options can lead to reduced maintenance costs and improved indoor air quality. However, buyers should be prepared for a higher upfront cost and ensure proper installation to maximize its benefits.

Why Consider Fire-Resistant Gypsum Board in Commercial Projects?

Fire-resistant gypsum board, usually 5/8 inch thick, is essential for commercial applications where safety is a priority, such as schools and hospitals. Its increased thickness provides enhanced fire protection, potentially lowering insurance premiums for businesses. While it offers significant safety advantages, B2B buyers must consider its heavier weight and higher price point, which could affect transportation and installation logistics.

What Makes Eco-Friendly Gypsum Board a Sustainable Choice?

Eco-friendly gypsum board is manufactured from recycled materials and is designed to emit lower levels of volatile organic compounds (VOCs). This makes it an attractive option for green building projects and those seeking to meet sustainability goals. B2B buyers involved in environmentally conscious construction can benefit from potential LEED credits. However, availability may vary, and this option may come at a premium compared to traditional boards.

Key Industrial Applications of gypsum board 4 x 8

| Industry/Sector | Specific Application of gypsum board 4 x 8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Interior wall and ceiling installations | Quick installation and reduced labor costs | Compliance with local building codes and regulations |

| Hospitality | Soundproofing in hotels and restaurants | Enhanced guest experience through noise reduction | Availability of fire and moisture-resistant options |

| Healthcare | Wall partitions in clinics and hospitals | Improved hygiene and mold resistance | Certifications for health and safety standards |

| Education | Classroom partitions and ceilings | Flexible space management and improved acoustics | Sustainable sourcing and environmental impact |

| Residential | Home renovations and DIY projects | Cost-effective solutions for interior design | Local availability and transportation logistics |

How is gypsum board 4 x 8 used in the construction industry?

In the construction sector, gypsum board 4 x 8 is primarily employed for interior wall and ceiling installations. Its lightweight nature allows for quick handling and installation, significantly reducing labor costs and project timelines. Buyers in this industry must ensure that the gypsum board complies with local building codes, particularly regarding fire resistance and moisture control, to prevent future structural issues and maintain safety standards.

What role does gypsum board 4 x 8 play in the hospitality sector?

In hotels and restaurants, gypsum board 4 x 8 serves as an effective soundproofing material. By creating acoustic barriers, it enhances the guest experience by minimizing noise from surrounding areas. For B2B buyers in this sector, sourcing options that provide fire and moisture resistance are crucial, as these features not only protect the property but also align with health and safety regulations.

Why is gypsum board 4 x 8 essential for healthcare facilities?

Gypsum board is increasingly utilized in healthcare settings for wall partitions in clinics and hospitals. Its mold-resistant properties make it a safe choice for environments that require stringent hygiene standards. Buyers must prioritize products with relevant health certifications and ensure compliance with safety standards, as these factors significantly impact patient care and facility management.

How does gypsum board 4 x 8 benefit educational institutions?

In educational environments, gypsum board 4 x 8 is frequently used for classroom partitions and ceilings. This application allows for flexible space management, catering to various teaching methods while providing improved acoustics for better learning conditions. B2B buyers in this sector should focus on sourcing sustainable products that minimize environmental impact, as educational institutions increasingly prioritize eco-friendly materials.

What advantages does gypsum board 4 x 8 offer for residential projects?

In residential renovations and DIY projects, gypsum board 4 x 8 is a cost-effective solution for interior design. Its versatility allows homeowners to create customized spaces without significant financial investment. For international buyers, understanding local market dynamics and ensuring the availability of gypsum board products can facilitate smoother procurement processes and successful project outcomes.

3 Common User Pain Points for ‘gypsum board 4 x 8’ & Their Solutions

Scenario 1: Challenges with Moisture Resistance in Humid Climates

The Problem:

B2B buyers in regions with high humidity, such as parts of Africa and South America, often face significant challenges when selecting gypsum board products. Standard gypsum board can be susceptible to moisture damage, leading to mold growth, deterioration, and ultimately, costly repairs or replacements. This concern is amplified in construction projects where the longevity and durability of materials are paramount. Buyers may find themselves in a difficult position, trying to balance budget constraints with the need for high-performance materials that can withstand environmental conditions.

The Solution:

To combat moisture-related issues, buyers should consider sourcing moisture-resistant gypsum board products specifically designed for humid environments. Products like Gold Bond® XP® Gypsum Board, which features a mold-resistant core and moisture-repellent paper, are excellent choices. When specifying materials, buyers should look for boards that are clearly labeled for moisture resistance and inquire about their performance ratings. Additionally, proper installation is crucial; ensure that joints are sealed and that the boards are installed in accordance with manufacturer guidelines. Investing in quality materials upfront can save businesses from the long-term costs associated with repairs and replacements due to moisture damage.

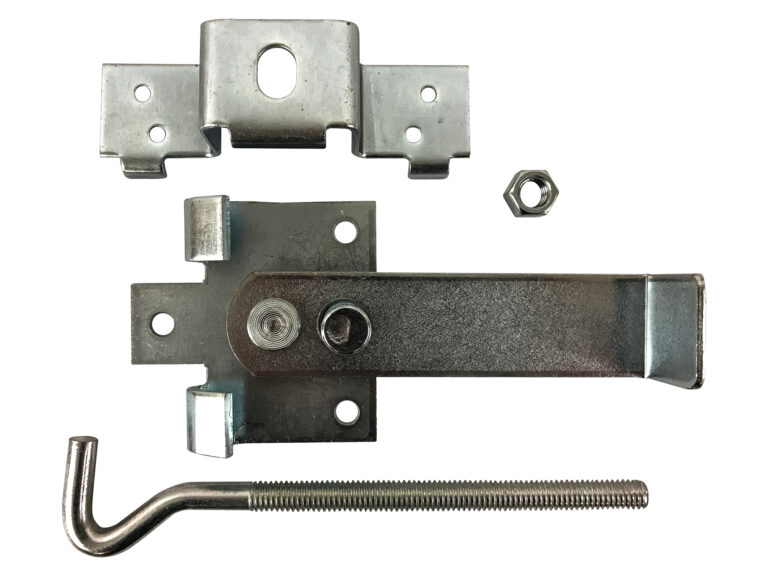

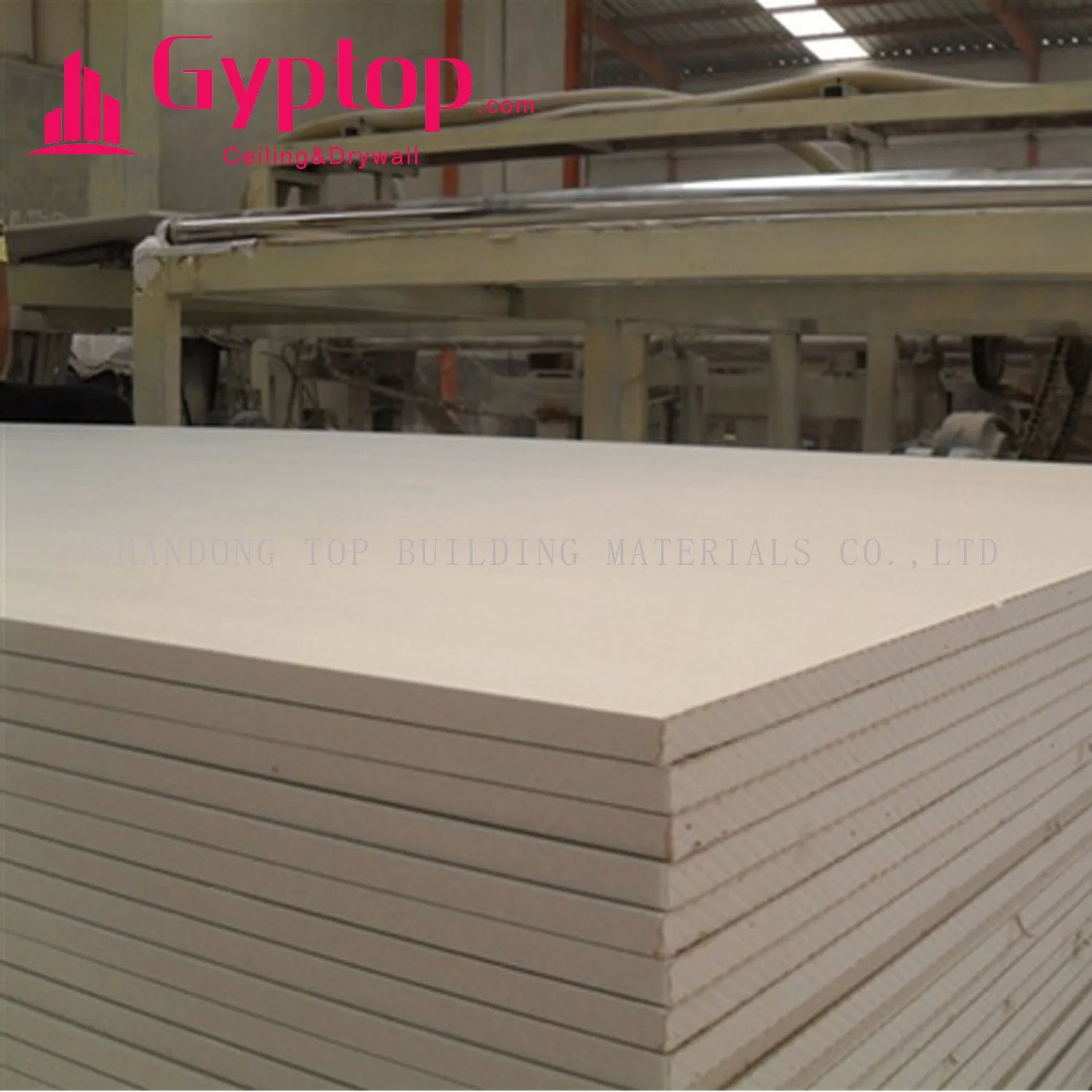

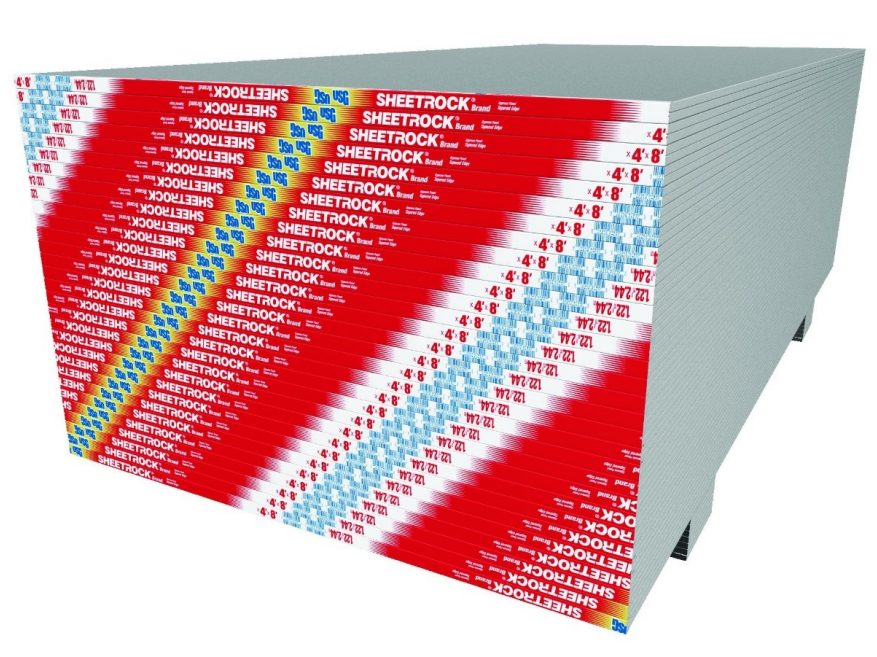

Illustrative image related to gypsum board 4 x 8

Scenario 2: Difficulty in Achieving Fire Safety Standards

The Problem:

In many regions, particularly in Europe and the Middle East, construction projects must adhere to stringent fire safety regulations. B2B buyers often struggle to find gypsum board that meets local fire resistance standards without significantly inflating project costs. The challenge lies in selecting products that not only comply with regulations but also fit within the overall budget while still providing quality performance.

The Solution:

Buyers should seek out fire-rated gypsum board options, such as the 5/8-inch Firecode X drywall, which is engineered to provide superior fire resistance. When evaluating products, it is essential to request documentation that verifies compliance with local fire safety codes. Buyers can also benefit from engaging with manufacturers or suppliers who offer guidance on regulatory requirements and product specifications. By carefully selecting fire-rated products and consulting with fire safety experts, buyers can ensure compliance while optimizing their budgets. Furthermore, consider using additional fire-resistant materials in conjunction with gypsum boards to enhance overall safety.

Scenario 3: Installation and Labor Costs Increasing Project Budgets

The Problem:

Many B2B buyers find that the labor costs associated with installing gypsum board can significantly impact their overall project budgets. Complexity in the installation process, including the need for specialized tools and skilled labor, can lead to unforeseen expenses. This is particularly problematic for projects with tight timelines or limited resources, where every dollar and hour counts.

The Solution:

To mitigate installation costs, buyers should consider opting for lightweight gypsum board options, such as UltraLight Drywall. These products are easier to handle, score, and install, potentially reducing labor time and costs. Additionally, buyers can invest in training sessions for their installation teams to improve efficiency and reduce errors during installation. Engaging with suppliers who provide comprehensive installation resources and support can also help streamline the process. By choosing user-friendly products and enhancing installation skills, businesses can achieve significant savings without compromising quality.

Strategic Material Selection Guide for gypsum board 4 x 8

When selecting gypsum board 4 x 8 for various applications, it’s essential to consider the specific materials used in their production. Different types of gypsum boards offer unique properties that can significantly impact performance, installation, and suitability for international markets. Below, we analyze four common materials used in gypsum board manufacturing, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Standard Gypsum Board?

Standard gypsum board, typically composed of a gypsum core encased in paper, is the most common type used in construction.

- Key Properties: It has a moderate temperature resistance and is not inherently moisture-resistant. It is designed for interior applications and is rated for normal use.

- Pros: This board is lightweight, easy to install, and cost-effective, making it suitable for a wide range of projects.

- Cons: Its susceptibility to moisture can lead to mold growth, limiting its use in humid environments.

- Impact on Application: In regions with high humidity, such as parts of Africa and South America, standard gypsum board may not be suitable without additional treatments.

- Considerations for International Buyers: Compliance with local building codes and standards, such as ASTM or DIN, is crucial. Buyers should also consider the availability of moisture-resistant options.

How Does Mold-Resistant Gypsum Board Perform?

Mold-resistant gypsum board is engineered to inhibit mold growth, making it ideal for areas prone to moisture.

- Key Properties: This board features a treated core and moisture-resistant paper, providing enhanced durability in humid conditions.

- Pros: It offers superior protection against mold and mildew, making it suitable for bathrooms, kitchens, and basements.

- Cons: The cost is typically higher than standard gypsum board, and installation may require specialized techniques.

- Impact on Application: In tropical climates or regions with high rainfall, this board is essential for maintaining indoor air quality and structural integrity.

- Considerations for International Buyers: Buyers should ensure compliance with local health and safety regulations regarding mold prevention and consider the board’s certification for moisture resistance.

What are the Benefits of Fire-Resistant Gypsum Board?

Fire-resistant gypsum board is designed to slow the spread of fire, making it a critical component in commercial and residential construction.

- Key Properties: It contains additives that enhance its fire-resistance rating, typically classified as Type X.

- Pros: This board provides increased safety and can reduce insurance costs due to its fire-resistant properties.

- Cons: It is generally heavier and more expensive than standard boards, which may impact shipping and handling costs.

- Impact on Application: In regions with strict fire safety regulations, such as parts of Europe and the Middle East, this board is often required in commercial buildings.

- Considerations for International Buyers: Buyers must verify compliance with local fire safety codes and standards, which can vary significantly across countries.

How Does Eco-Friendly Gypsum Board Compare?

Eco-friendly gypsum boards are made with sustainable materials, appealing to environmentally conscious buyers.

- Key Properties: These boards often use recycled materials and are free from harmful chemicals.

- Pros: They contribute to green building certifications, such as LEED, and can enhance a company’s sustainability profile.

- Cons: The availability may be limited in some regions, and costs can be higher due to sustainable sourcing.

- Impact on Application: In markets where sustainability is a priority, such as Europe, eco-friendly boards can provide a competitive advantage.

- Considerations for International Buyers: Buyers should assess the availability of these products in their region and ensure they meet local environmental regulations.

Summary Table of Gypsum Board Materials

| Material | Typical Use Case for gypsum board 4 x 8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Gypsum Board | General interior applications | Cost-effective and easy to install | Susceptible to moisture | Low |

| Mold-Resistant Gypsum Board | Bathrooms and kitchens | Superior mold resistance | Higher cost and specialized installation | Medium |

| Fire-Resistant Gypsum Board | Commercial buildings and high-rises | Enhanced fire safety | Heavier and more expensive | High |

| Eco-Friendly Gypsum Board | Sustainable construction projects | Supports green building certifications | Limited availability and higher cost | Medium to High |

This guide provides a comprehensive overview of the strategic material selection for gypsum board 4 x 8, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gypsum board 4 x 8

What Are the Key Stages in the Manufacturing Process of Gypsum Board 4 x 8?

The manufacturing of gypsum board, particularly the 4 x 8 size, involves several critical stages that ensure the final product meets industry standards for quality and performance. Understanding these stages is vital for B2B buyers looking to assess the reliability of their suppliers.

1. Material Preparation: How Is Gypsum Processed for Board Production?

The first step in the manufacturing process is the preparation of raw materials. Gypsum rock is mined and then crushed into a fine powder. This powder is mixed with water and other additives, such as starch and foaming agents, to enhance the board’s strength and performance. This slurry is then conditioned to ensure an even consistency, which is crucial for the subsequent forming stage.

2. Forming: What Techniques Are Used to Shape Gypsum Boards?

After preparing the gypsum slurry, the next step is forming the board. This is typically done using a continuous board machine. The slurry is poured onto a continuously moving sheet of paper, which serves as the board’s face. A second layer of paper is placed on top, and the mixture is spread out to the desired thickness. The edges are tapered to facilitate joint finishing during installation. This forming technique ensures a uniform product that meets the standard dimensions of 4 x 8 feet.

3. Assembly: How Are Gypsum Boards Constructed for Durability?

Once formed, the gypsum board undergoes a process called setting, where it is allowed to harden. This is achieved by passing the wet board through a series of heating zones in a dryer, which removes moisture and solidifies the gypsum core. The boards are then cut to size, and any necessary treatments, such as fire-resistant coatings, can be applied at this stage.

4. Finishing: What Quality Features Are Added to the Final Product?

The final stage involves finishing touches that enhance the board’s usability and performance. This may include applying moisture-resistant treatments or adding additional layers for fire resistance. Boards are also inspected for surface defects, and any boards that do not meet quality standards are removed from the production line.

What Are the International Quality Assurance Standards for Gypsum Board?

Quality assurance in gypsum board manufacturing is crucial for ensuring product reliability and safety. International standards play a significant role in this process.

Understanding ISO 9001: How Does It Apply to Gypsum Board Manufacturing?

ISO 9001 is a widely recognized international standard that focuses on quality management systems. Manufacturers of gypsum board need to implement this standard to ensure that their processes consistently produce high-quality products. Compliance with ISO 9001 involves regular audits, documentation, and continuous improvement practices.

What Other Industry-Specific Certifications Should B2B Buyers Look For?

In addition to ISO 9001, there are other certifications that may be relevant, depending on the market. For example, CE marking is important for products sold within the European Union, demonstrating compliance with EU safety, health, and environmental requirements. Additionally, certifications like API (American Petroleum Institute) may apply to specific applications of gypsum board in industrial settings.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integral to the manufacturing of gypsum board, with several checkpoints established to ensure product integrity.

What Are the Key QC Checkpoints in Gypsum Board Production?

-

Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials as they arrive at the manufacturing facility. Suppliers’ certifications, material properties, and compliance with standards are verified.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring occurs at various stages, including the mixing, forming, and drying phases. This ensures that any deviations from specifications are addressed promptly.

-

Final Quality Control (FQC): Once the boards are completed, they undergo a thorough inspection for defects such as surface imperfections, dimensional accuracy, and adherence to fire and moisture resistance standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, ensuring the quality of gypsum board products involves a proactive approach to supplier verification.

What Steps Can Buyers Take to Assess Supplier QC?

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC practices. This may include visiting their facilities and reviewing their quality management systems.

-

Request Quality Reports: Buyers should ask for detailed QC reports that outline testing methodologies and results. This documentation should align with international standards to verify compliance.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct tests and provide certification reports that validate a supplier’s claims.

What Are the Specific QC Considerations for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in QC standards that may affect their purchasing decisions.

Understanding Regional Compliance Requirements

Different countries have varying regulations and standards for building materials. Buyers need to be familiar with local building codes and standards, as well as any specific requirements for fire and moisture resistance. This knowledge will help ensure that the gypsum board products they source are compliant with local regulations.

How Do Trade Agreements Impact Quality Standards?

Trade agreements can also affect quality standards and certifications. Understanding these agreements can provide insights into the types of products that are permissible for import and the standards they must meet. B2B buyers should stay informed about changes in trade policies that could impact their supply chain.

Conclusion: How Can B2B Buyers Ensure They Source High-Quality Gypsum Boards?

In conclusion, B2B buyers looking to source gypsum board 4 x 8 products should have a thorough understanding of the manufacturing processes and quality assurance practices involved. By focusing on established international standards, conducting diligent supplier audits, and staying informed about regional compliance requirements, buyers can make informed decisions that ensure they acquire high-quality products for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gypsum board 4 x 8’

The following guide serves as a comprehensive checklist for B2B buyers looking to source 4 x 8 gypsum boards. It outlines essential steps to ensure a successful procurement process, maximizing value while minimizing risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the gypsum board meets your project requirements. Consider factors such as thickness (e.g., 1/2 inch or 5/8 inch), moisture resistance, fire ratings, and any specific certifications needed for your region. This clarity helps streamline the selection process and ensures that suppliers provide relevant products.

Illustrative image related to gypsum board 4 x 8

Step 2: Conduct Market Research

Understanding the market landscape allows you to identify potential suppliers and industry standards. Research different types of gypsum boards available, including specialty products like mold-resistant or fire-rated options. Additionally, analyze pricing trends in your target regions, as costs can vary significantly across different markets.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request company profiles, product samples, and references from other businesses within your industry. Look for suppliers with a solid reputation and experience in your geographical area, as local suppliers may better understand regional regulations and standards.

- Check Reviews and Ratings: Investigate online reviews and ratings on platforms relevant to your industry.

- Request Certifications: Ensure they hold necessary certifications (e.g., ISO, local building codes) that affirm their product quality.

Step 4: Assess Quality Assurance Processes

Quality assurance is paramount when sourcing building materials. Inquire about the supplier’s quality control measures, including testing protocols and material sourcing. A reliable supplier should be transparent about their processes and willing to share quality certifications that validate their claims.

Step 5: Negotiate Terms and Pricing

Once you have shortlisted suppliers, engage in discussions regarding pricing and payment terms. Be prepared to negotiate bulk discounts, payment schedules, and delivery timelines. Understanding the total cost of ownership, including shipping and handling, is vital for accurate budgeting.

- Consider Long-Term Partnerships: Establishing a long-term relationship may lead to better pricing and priority service in the future.

Step 6: Verify Logistics and Delivery Capabilities

Assess the supplier’s logistics and delivery capabilities to ensure timely receipt of materials. Inquire about their shipping methods, lead times, and how they handle potential delays. A supplier with a robust logistics network can significantly reduce project downtime.

Step 7: Finalize Contracts and Agreements

After selecting a supplier, finalize all contracts and agreements in writing. Ensure all terms discussed, including pricing, delivery schedules, and quality expectations, are clearly documented. This step protects both parties and provides a framework for accountability throughout the procurement process.

By following this checklist, B2B buyers can effectively navigate the sourcing of 4 x 8 gypsum boards, ensuring they meet their project requirements while fostering productive supplier relationships.

Comprehensive Cost and Pricing Analysis for gypsum board 4 x 8 Sourcing

What Are the Key Cost Components for Gypsum Board 4 x 8 Sourcing?

When sourcing gypsum board (4 x 8), understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The raw materials used in gypsum board production significantly influence the overall cost. Gypsum, additives, and the face and back paper (which can be moisture or mold resistant) are primary inputs. Prices can fluctuate based on global supply chains and local availability.

-

Labor: Labor costs encompass wages for factory workers involved in the manufacturing process. This can vary by region; for instance, labor costs may be lower in developing countries compared to Europe or North America.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and factory management. Overhead can vary significantly depending on the efficiency of the production facility and local energy costs.

-

Tooling: Investment in machinery and equipment necessary for production is a significant factor. Advanced technology can improve efficiency and reduce long-term costs but may increase initial investment.

-

Quality Control (QC): Ensuring that products meet safety and performance standards incurs additional costs. This includes testing for fire resistance, moisture resistance, and mold growth prevention.

-

Logistics: Transportation of raw materials and finished products adds to overall costs. Factors influencing logistics costs include distance, mode of transport, and regional infrastructure.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market conditions and competition.

How Do Price Influencers Affect the Cost of Gypsum Board?

Several factors can influence the pricing of gypsum board, particularly for international buyers:

-

Volume/MOQ: Purchasing in bulk can lead to discounts. Suppliers often have minimum order quantities (MOQs), and negotiating favorable terms can lead to significant savings.

-

Specifications and Customization: Customized products (e.g., thicker boards, specialized coatings) typically cost more. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as fire ratings) may increase costs. Buyers should consider the long-term benefits of investing in quality products that meet safety regulations.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to perceived quality, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms define responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost of goods.

What Buyer Tips Should International B2B Buyers Consider for Cost Efficiency?

When navigating the sourcing of gypsum board internationally, buyers should consider the following strategies:

-

Negotiation: Build relationships with suppliers and negotiate terms. Leverage volume purchasing and long-term contracts to secure better pricing and payment terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the product’s lifecycle. This includes installation, maintenance, and potential disposal costs.

-

Pricing Nuances: Be aware of regional pricing variations. For example, logistics costs may be higher in remote areas of Africa compared to urban centers in Europe. Understanding local market conditions can lead to better purchasing decisions.

-

Local Regulations and Standards: Ensure that the chosen products comply with local building codes and standards. Non-compliance can lead to increased costs for rework or fines.

Conclusion

While sourcing gypsum board 4 x 8, a comprehensive understanding of cost components and pricing influencers is essential for making informed purchasing decisions. By focusing on negotiation strategies and total cost considerations, international buyers can optimize their sourcing processes and achieve significant cost efficiencies. Prices can vary widely based on local market conditions, specifications, and supplier relationships, so thorough research and strategic planning are paramount.

Alternatives Analysis: Comparing gypsum board 4 x 8 With Other Solutions

In the construction industry, selecting the right wall and ceiling material is crucial for ensuring optimal performance, durability, and cost-effectiveness. While gypsum board (commonly referred to as drywall) in the 4 x 8 size is a popular choice, several alternatives can meet similar needs. This section explores these alternatives, offering a detailed comparison to help B2B buyers make informed decisions.

| Comparison Aspect | Gypsum Board 4 x 8 | Alternative 1 Name: Plywood | Alternative 2 Name: Cement Board |

|---|---|---|---|

| Performance | Good fire resistance, sound absorption | Strong structural integrity, less fire resistant | Excellent moisture resistance, fire-resistant |

| Cost | Moderate cost per sheet | Higher initial cost per sheet | Higher cost but durable over time |

| Ease of Implementation | Easy to cut and install, lightweight | Requires more tools for cutting and installation | Heavier, may require specialized tools |

| Maintenance | Minimal maintenance needed | Requires sealing and regular maintenance | Low maintenance, resistant to mold and decay |

| Best Use Case | Interior walls and ceilings | Structural applications, cabinetry | High-moisture areas like bathrooms and kitchens |

What Are the Pros and Cons of Plywood as an Alternative to Gypsum Board?

Plywood offers a robust alternative to gypsum board, particularly in applications that require structural integrity. Its strength makes it ideal for areas needing additional support, such as cabinetry and wall sheathing. However, plywood is less fire-resistant than gypsum board and requires sealing to prevent moisture absorption. While it has a higher upfront cost, its durability can justify the investment over time. Plywood is best suited for projects where structural strength is paramount, but it may not be the best choice for standard interior walls.

How Does Cement Board Compare to Gypsum Board?

Cement board is an excellent choice for areas exposed to high moisture, such as bathrooms and kitchens. It offers superior resistance to mold and mildew, making it a preferred option in wet environments. While it is heavier and more challenging to install than gypsum board, its longevity and low maintenance requirements can make it a worthwhile investment. The initial cost is higher, but the durability and performance in moisture-rich areas can lead to savings in maintenance and replacement over time. Cement board is ideal for projects that prioritize moisture resistance, although its heavier weight may pose challenges during installation.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right wall and ceiling material, B2B buyers should consider the specific requirements of their projects, including performance needs, budget constraints, and installation capabilities. Gypsum board is a versatile option suitable for most interior applications, offering a balance of cost and performance. For projects requiring enhanced structural support or moisture resistance, plywood or cement board may be more appropriate. Ultimately, understanding the unique demands of each project will guide buyers in making the best choice, ensuring they select a solution that meets their operational and financial objectives.

Essential Technical Properties and Trade Terminology for gypsum board 4 x 8

What Are the Key Technical Properties of Gypsum Board 4 x 8?

When selecting gypsum board, particularly the 4 x 8 size, understanding its technical specifications is crucial for ensuring it meets project requirements and performance expectations. Here are some essential properties:

-

Thickness

Gypsum boards typically come in various thicknesses, with 1/2 inch being standard for most applications. The thickness affects the board’s durability, soundproofing, and fire resistance. For B2B buyers, selecting the right thickness can influence installation costs and overall project timelines. -

Weight

The weight of gypsum board varies based on the type and additives used. For example, lightweight boards are designed for easier handling and reduced shipping costs. Understanding the weight specifications helps in planning labor requirements and transportation logistics. -

Fire Resistance Rating

Many gypsum boards are classified with fire resistance ratings, such as Type X, which is designed to withstand fire for a specified period. This property is critical for compliance with building codes, especially in commercial and residential constructions. B2B buyers must ensure that the selected board meets local fire safety regulations. -

Moisture and Mold Resistance

Certain gypsum boards, like those with a special coating or made from moisture-resistant materials, are ideal for humid environments. This property is particularly important for applications in kitchens, bathrooms, and coastal areas. By choosing moisture-resistant boards, buyers can minimize the risk of mold growth and subsequent damage. -

Edge Type

Gypsum boards feature different edge types, such as tapered or square edges. Tapered edges are designed for smooth joint finishing, which is essential for aesthetic appearances in drywall installations. Understanding edge types aids in selecting boards that fit specific installation methods and finishing requirements. -

Environmental Certifications

Many gypsum boards are made from recycled materials and come with environmental certifications, such as LEED. These certifications are increasingly important for companies looking to enhance their sustainability credentials and appeal to eco-conscious clients.

Which Trade Terms Should B2B Buyers Know About Gypsum Board?

Familiarity with industry jargon can streamline procurement processes and enhance negotiations. Here are some common terms relevant to gypsum board purchases:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that may be marketed under another company’s brand. Understanding OEM relationships can help buyers identify reliable manufacturers and negotiate better pricing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their orders and manage inventory effectively, ensuring they do not overcommit or underutilize their resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request price quotes from suppliers for specific products. This process is essential for comparing prices and terms, ensuring that buyers secure the best deal for gypsum board. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions that define the responsibilities of buyers and sellers. Familiarity with these terms helps in understanding shipping costs, risks, and insurance requirements when purchasing gypsum boards from overseas suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. For B2B buyers, understanding lead times is crucial for project scheduling and ensuring materials arrive when needed. -

Certification Standards

These are standards that products must meet to ensure quality and safety, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). Being aware of these certifications helps buyers ensure compliance with industry regulations and quality expectations.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their project needs and operational goals.

Navigating Market Dynamics and Sourcing Trends in the gypsum board 4 x 8 Sector

What Are the Key Market Dynamics and Trends in the Gypsum Board 4 x 8 Sector?

The gypsum board market, particularly the 4 x 8 variant, is currently experiencing significant growth, driven by various global factors. The construction industry is rebounding post-pandemic, with increased demand for residential and commercial buildings. Emerging economies in Africa and South America, such as Vietnam and Brazil, are seeing rapid urbanization, which fuels the need for efficient building materials like gypsum board. Technological advancements are also transforming sourcing practices, with B2B buyers increasingly adopting digital platforms for procurement, enhancing transparency and efficiency in the supply chain. Additionally, the rise of modular construction techniques is driving demand for lightweight and versatile materials, further emphasizing the role of gypsum board.

Key trends include the growing preference for moisture-resistant and fire-resistant gypsum boards, particularly in regions prone to humidity or wildfires. These product innovations cater to specific regional needs, offering international buyers the opportunity to tailor their purchases according to local requirements. The integration of Building Information Modeling (BIM) in construction projects is also influencing sourcing decisions, as it allows for better planning and material management, ultimately reducing waste and costs.

How Important Is Sustainability and Ethical Sourcing in the Gypsum Board Industry?

In today’s market, sustainability is no longer a choice but a necessity for B2B buyers in the gypsum board sector. The environmental impact of construction materials, including gypsum boards, has come under scrutiny. As a result, companies are increasingly prioritizing ethical supply chains, focusing on materials that are sustainably sourced and produced with minimal ecological footprint. Gypsum boards made from 100% recycled materials are gaining traction, offering a dual benefit of reducing waste while meeting industry standards for quality and performance.

Moreover, certifications such as LEED (Leadership in Energy and Environmental Design) and other green building standards are becoming critical for buyers, particularly in Europe and North America. These certifications not only enhance the marketability of products but also assure customers of their commitment to sustainability. B2B buyers are encouraged to engage with suppliers who can provide transparency about their sourcing practices and the environmental impact of their products, ensuring that they align with global sustainability goals.

What Is the Evolution of the Gypsum Board Industry Relevant to B2B Buyers?

The evolution of the gypsum board industry reflects broader trends in construction and material science. Initially, gypsum boards were primarily used for interior wall applications due to their ease of installation and cost-effectiveness. Over the years, advancements in technology have led to the development of specialized boards that offer enhanced performance characteristics, such as fire resistance, moisture resistance, and soundproofing capabilities.

This evolution has been particularly significant for international B2B buyers, who now have access to a diverse range of products tailored to specific regional needs and regulatory requirements. The introduction of eco-friendly gypsum boards made from recycled materials and those designed to minimize environmental impact has further expanded the market. As the industry continues to innovate, B2B buyers are presented with opportunities to enhance their offerings while aligning with sustainability initiatives and meeting the demands of modern construction practices.

Frequently Asked Questions (FAQs) for B2B Buyers of gypsum board 4 x 8

-

How do I choose the right gypsum board for my project?

When selecting gypsum board for your project, consider the specific application and environmental conditions. For interior walls, standard 1/2 inch boards are typically sufficient, while moisture-resistant boards are ideal for areas like kitchens and bathrooms. If mold resistance is a concern, look for products specifically designed to inhibit mold growth. Additionally, assess the weight and ease of installation, especially if labor costs are a factor. Always consult with suppliers to ensure the chosen product meets local building codes and project requirements. -

What are the key benefits of using 4 x 8 gypsum board?

The 4 x 8 gypsum board size offers a perfect balance of coverage and manageability. Its dimensions are convenient for both transportation and installation, making it a preferred choice for contractors. This size also minimizes seams in walls, leading to smoother finishes. Moreover, many 4 x 8 boards come with enhanced features such as fire resistance and moisture resistance, providing added safety and longevity in various applications. -

What factors should I consider when vetting suppliers for gypsum board?

When vetting suppliers, evaluate their reputation, experience, and product quality. Check for certifications that indicate compliance with international standards. Review their production capabilities to ensure they can meet your volume needs. It’s also essential to assess their logistics and delivery capabilities, particularly if you are importing from overseas. Request samples to evaluate the quality firsthand and inquire about customer service responsiveness and support for potential issues. -

What are the typical minimum order quantities (MOQ) for gypsum board?

Minimum order quantities for gypsum board can vary significantly based on the supplier and the specific product. Generally, MOQs can range from a few hundred to several thousand sheets. For international buyers, it’s crucial to clarify these terms before placing an order, as lower MOQs might be available for local markets. Additionally, consider the logistics of shipping large quantities, as this can affect cost and delivery times. -

How can I ensure quality assurance when sourcing gypsum board internationally?

To ensure quality assurance, establish clear specifications and standards with your supplier before production. Request certifications that demonstrate compliance with international quality standards, such as ISO or ASTM. Conduct regular quality checks and consider hiring third-party inspection services to verify product quality before shipment. Maintaining open communication with your supplier can help address any quality concerns promptly. -

What payment terms should I expect when purchasing gypsum board internationally?

Payment terms for international purchases can vary widely based on the supplier and the country of origin. Common terms include advance payment, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that provide you with adequate protection while ensuring the supplier’s confidence in fulfilling the order. Always review any associated fees, such as transaction fees or currency exchange rates, that may impact the overall cost. -

What are the logistics considerations for importing gypsum board?

Logistics considerations for importing gypsum board include shipping methods, customs regulations, and delivery timelines. Evaluate whether to use air or sea freight based on urgency and cost. Ensure that you understand the import duties and taxes applicable to your shipment. Working with a logistics provider familiar with building materials can streamline the process and help navigate any potential challenges with customs clearance. -

Can I customize gypsum board to meet specific project needs?

Yes, many manufacturers offer customization options for gypsum board. This can include variations in thickness, size, and additional features like enhanced fire or moisture resistance. Discuss your specific requirements with potential suppliers to determine the feasibility and any associated costs. Custom orders may have longer lead times, so it’s essential to plan accordingly to align with your project schedule.

Top 4 Gypsum Board 4 X 8 Manufacturers & Suppliers List

1. Gold Bond – XP Gypsum Board

Domain: cherbmi.com

Registered: 2005 (20 years)

Introduction: {“name”: “Gold Bond XP Gypsum Board”, “dimensions”: “1/2 in x 4 ft x 8 ft”, “part_number”: “12M08-N”, “features”: [“Extra protection against mold and mildew”, “Reinforced edges”, “Square-cut ends”, “Tapered long edges”, “PURPLE paper on face side”, “Heavy, mold- and moisture-resistant gray paper on back side”, “GridMarX for easy stud location identification”], “applications”: [“Interior wall and c…

2. Stine Home – Gypsum Board 4 ft. x 8 ft. x 1/2 in.

Domain: stinehome.com

Registered: 2010 (15 years)

Introduction: Gypsum Board 4 ft. x 8 ft. x 1/2 in.

3. KJ Drywall Supply – Gypsum Ultralight Regular ½ x 4′ x 8”

Domain: kjdrywallsupply.com

Registered: 2015 (10 years)

Introduction: Gypsum Ultralight Regular ½” x 4′ x 8′

4. GTS Interior Supply – High Flex Gypsum Board

Domain: gtsinteriorsupply.com

Registered: 2002 (23 years)

Introduction: 1/4 in x 4 ft x 8 ft High Flex Gypsum Board, Part Number: 14HF08, consists of a fire-resistive gypsum core encased in heavy natural-finish paper on the face side and strong liner paper on the back side. The face paper is folded around the long edges to reinforce and protect the core, and the ends are square-cut and finished smooth.

Strategic Sourcing Conclusion and Outlook for gypsum board 4 x 8

In the competitive landscape of construction materials, strategic sourcing of gypsum board 4 x 8 is pivotal for international buyers. By understanding the diverse offerings, such as moisture-resistant and mold-resistant boards, businesses can tailor their procurement strategies to meet specific project needs. Leveraging suppliers that prioritize sustainability and product innovation can yield not only cost savings but also enhanced project efficiency.

Furthermore, establishing strong relationships with manufacturers and distributors can facilitate access to the latest advancements in gypsum board technology, ensuring that your projects remain at the forefront of industry standards.

Looking ahead, the demand for high-quality gypsum board will continue to rise in emerging markets across Africa, South America, the Middle East, and Europe. As you navigate this evolving market, consider implementing a proactive sourcing strategy that emphasizes quality, sustainability, and supplier reliability. This approach will position your business for success as construction trends shift and evolve globally. Embrace the opportunity to enhance your supply chain and drive value in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.