How to Source Quartz Glassware Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for quartz glassware

In today’s competitive landscape, sourcing high-quality quartz glassware presents a unique challenge for international B2B buyers. The demand for durable, chemically resistant, and thermally stable glassware is growing, particularly in industries such as pharmaceuticals, electronics, and laboratory research. This guide serves as a comprehensive resource, addressing key elements such as types of quartz glassware, their various applications, supplier vetting processes, and cost considerations.

By navigating this guide, buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will gain valuable insights into making informed purchasing decisions. We delve into the specific needs of markets like Nigeria and Brazil, where the right glassware can significantly enhance operational efficiency and product reliability.

Understanding the intricacies of quartz glassware is essential for ensuring compliance with industry standards and optimizing supply chains. This guide not only highlights the critical factors to consider when selecting suppliers but also provides actionable strategies to mitigate risks and maximize value. Empowered with this knowledge, B2B buyers can confidently source the right quartz glassware tailored to their unique requirements, thereby enhancing their competitive edge in the global market.

Understanding quartz glassware Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Quartz Flasks | High thermal stability, chemical resistance | Chemical synthesis, laboratory analysis | Pros: Durable, excellent heat resistance. Cons: Higher cost than standard glass. |

| Quartz Crucibles | Designed for high-temperature applications | Material testing, metallurgy | Pros: Can withstand extreme temperatures. Cons: Fragile, requires careful handling. |

| Quartz Beakers | Transparent, uniform thickness | General lab use, mixing solutions | Pros: Clear visibility, easy to clean. Cons: Limited to lower temperature applications. |

| Quartz Ground Joints | Precise fit for secure connections | Vacuum and pressure systems | Pros: Reliable seals, reduces leakage. Cons: Requires precise alignment during assembly. |

| Quartz Microscope Slides | Thin, optically clear material | Biological research, microscopy | Pros: High clarity, minimal distortion. Cons: Can be expensive compared to plastic slides. |

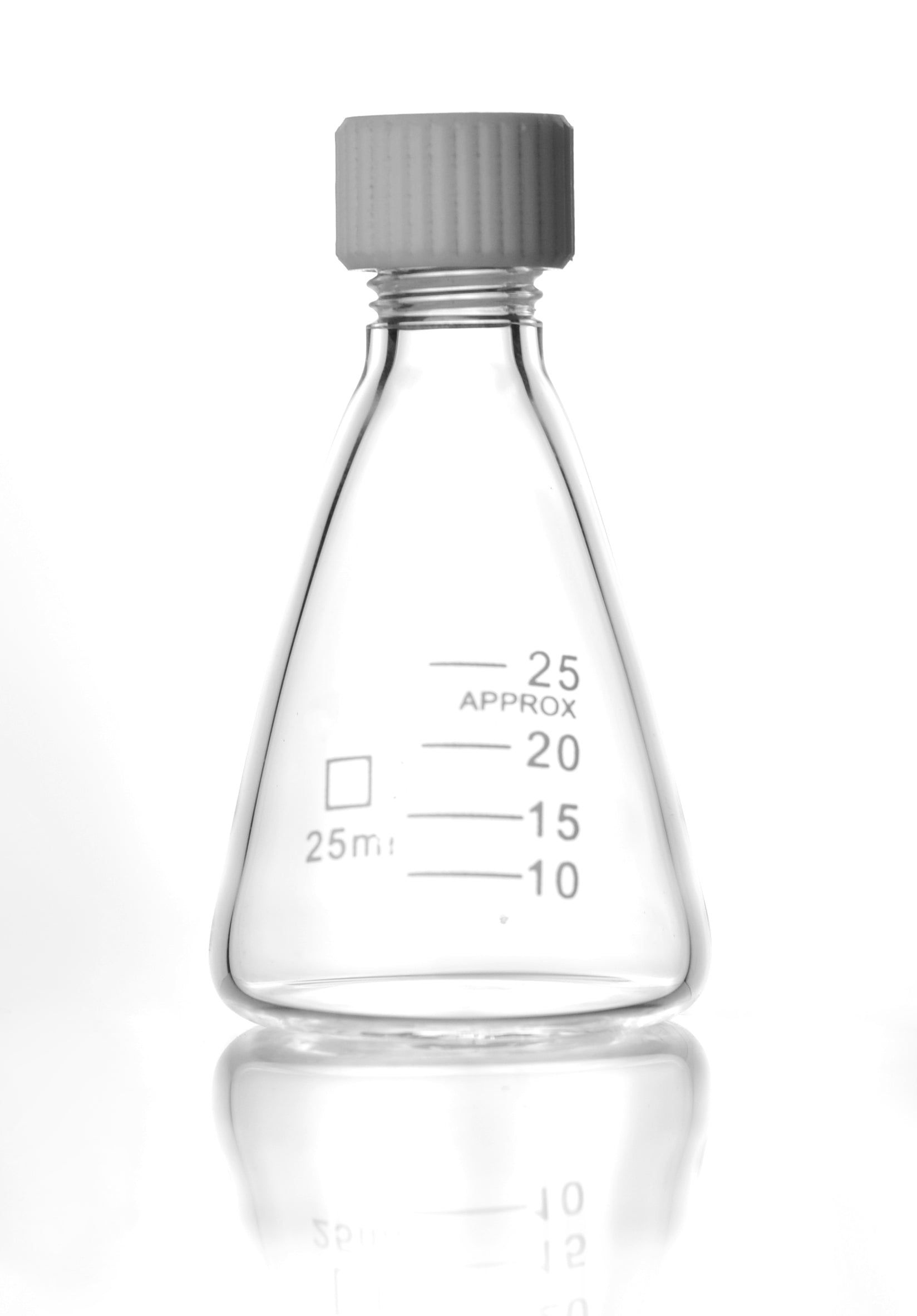

What Are the Key Characteristics of Quartz Flasks?

Quartz flasks are renowned for their exceptional thermal stability and chemical resistance, making them ideal for demanding laboratory environments. These flasks can withstand high temperatures without deforming, which is crucial for processes that involve heating. When purchasing quartz flasks, buyers should consider the specific volume and neck size required for their applications. While they tend to be more expensive than traditional glass options, their durability often justifies the investment, especially in high-stakes research settings.

How Do Quartz Crucibles Stand Out in High-Temperature Applications?

Designed for extreme conditions, quartz crucibles are perfect for applications requiring high-temperature resistance, such as metallurgy and material testing. Their ability to endure intense heat without compromising structural integrity makes them a preferred choice in laboratories. However, buyers should be cautious as these crucibles are fragile and require careful handling to prevent breakage. When sourcing, it’s essential to assess the crucible’s size and compatibility with existing equipment to ensure optimal performance.

In What Situations Are Quartz Beakers Most Effective?

Quartz beakers are widely utilized in various laboratory settings due to their uniform thickness and transparency, which allows for easy monitoring of contents. They are suitable for mixing solutions and general lab use, providing a clear view of the sample. However, they are best suited for lower temperature applications, as extreme heat can lead to thermal shock. Buyers should evaluate their specific use cases and consider the beaker’s capacity and shape to ensure it meets their laboratory needs.

What Advantages Do Quartz Ground Joints Offer for B2B Buyers?

Quartz ground joints are essential for creating secure connections in vacuum and pressure systems. Their precise fit ensures reliable seals that minimize the risk of leakage, which is critical in applications involving hazardous materials. When purchasing, buyers should focus on the compatibility of joint sizes and types with their existing setups. While quartz ground joints provide excellent performance, they require careful alignment during assembly to avoid issues, making proper training for laboratory personnel a key consideration.

Why Choose Quartz Microscope Slides for Research?

Quartz microscope slides are favored in biological research due to their high optical clarity and minimal distortion. This makes them ideal for detailed imaging and analysis in microscopy. While they are more costly than plastic alternatives, their durability and performance can enhance research outcomes. Buyers should consider the specific dimensions and thickness required for their applications, ensuring that the slides fit their microscopes and meet laboratory standards.

Key Industrial Applications of quartz glassware

| Industry/Sector | Specific Application of quartz glassware | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Reaction vessels for drug synthesis | High chemical resistance and purity | Compliance with international standards (e.g., USP) |

| Semiconductor Manufacturing | Quartz tubes for thermal processing | Excellent thermal stability and low contamination risk | Precision sourcing for specifications and dimensions |

| Laboratory Research | Quartz cuvettes for spectrophotometry | Superior optical clarity for accurate measurements | Availability of various sizes and compatibility |

| Biotechnology | Bioreactor components made from quartz | Enhanced durability and resistance to sterilization | Customization options for specific bioprocess needs |

| Environmental Testing | Sample containers for volatile organic compounds | Minimization of leaching and contamination | Robust supply chain to ensure consistent quality |

How is Quartz Glassware Used in Pharmaceuticals?

In the pharmaceutical industry, quartz glassware serves as essential reaction vessels for drug synthesis. Its high chemical resistance ensures that reactive substances do not degrade the container, maintaining the purity of the compounds being synthesized. Buyers from regions like Africa and South America should prioritize suppliers that adhere to international standards, such as the United States Pharmacopeia (USP), to ensure compliance and safety in drug production. The ability to withstand high temperatures and pressures also makes quartz glassware ideal for complex reactions, reducing the risk of contamination.

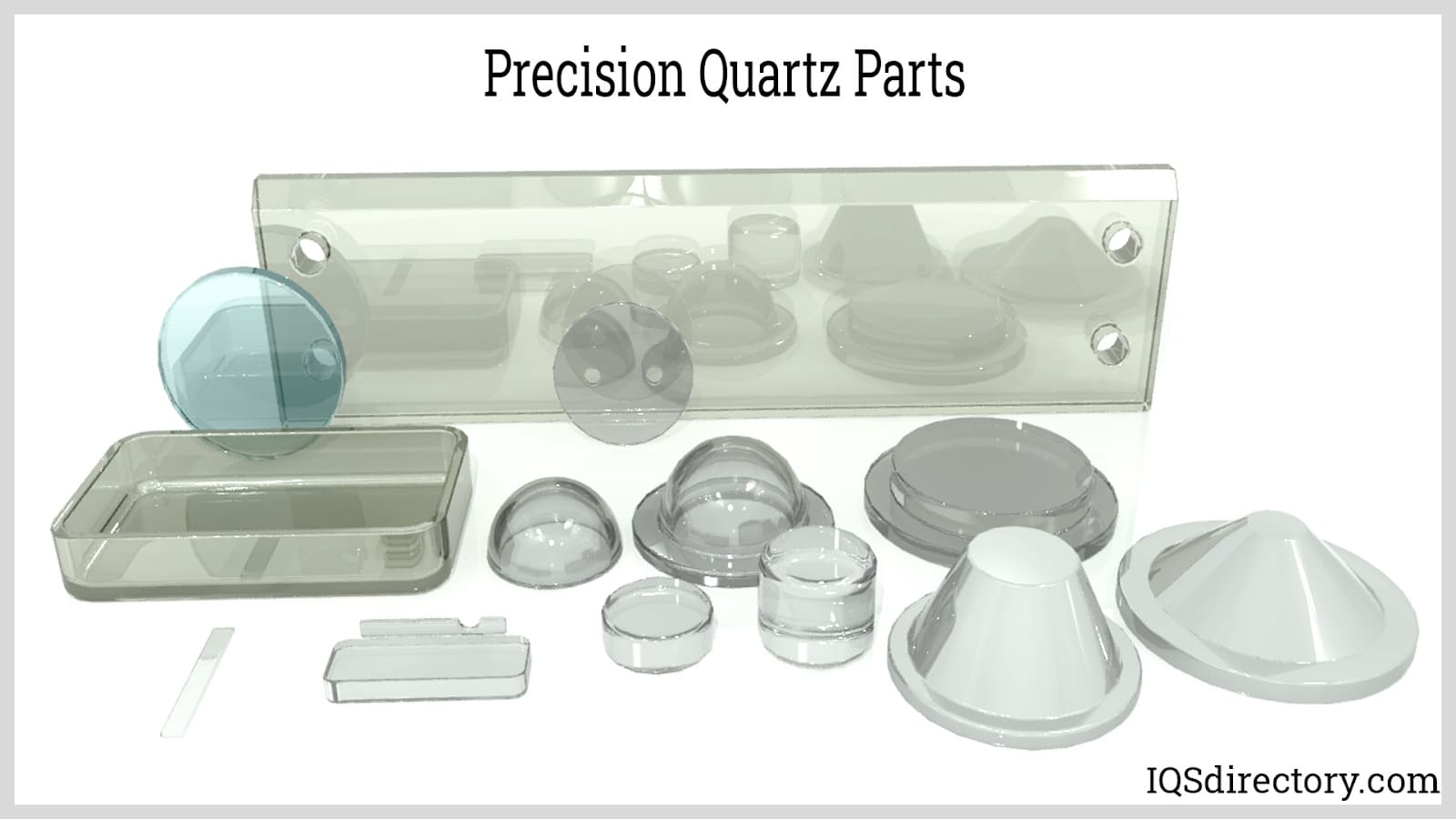

Illustrative image related to quartz glassware

What Role Does Quartz Glassware Play in Semiconductor Manufacturing?

Semiconductor manufacturing relies heavily on quartz tubes used in thermal processing applications. These tubes provide excellent thermal stability, which is crucial during the heating and cooling phases of semiconductor fabrication. For international buyers, particularly in the Middle East and Europe, sourcing quartz glassware that meets precise specifications is critical. Variations in dimensions can lead to inefficiencies in production processes, thus necessitating a reliable supplier who can deliver consistent quality and performance.

How is Quartz Glassware Utilized in Laboratory Research?

In laboratory settings, quartz cuvettes are commonly used for spectrophotometry due to their superior optical clarity. This clarity allows for accurate absorption measurements in various experiments, which is vital for researchers aiming to achieve precise results. Buyers should consider the availability of various sizes and compatibility with existing laboratory equipment when sourcing quartz cuvettes. Suppliers must also provide transparent quality assurance processes to ensure that the optical properties are maintained throughout the product’s lifecycle.

What Benefits Does Quartz Glassware Provide in Biotechnology?

Biotechnology applications often utilize quartz glassware for bioreactor components due to its durability and resistance to sterilization processes. This resistance is essential for maintaining sterile environments during cell culture and fermentation processes. Buyers should look for suppliers that offer customization options tailored to specific bioprocess needs, ensuring that the equipment can handle the unique demands of their operations. Additionally, the longevity of quartz glassware minimizes replacement frequency, offering long-term cost savings.

Illustrative image related to quartz glassware

How is Quartz Glassware Essential for Environmental Testing?

In environmental testing, quartz glassware is used as sample containers for volatile organic compounds (VOCs). Its inert properties minimize the risk of leaching, which can compromise sample integrity. This characteristic is crucial for accurate environmental assessments, particularly in regions like Africa and South America, where regulatory compliance is increasingly stringent. Buyers should ensure that their suppliers maintain a robust supply chain to guarantee consistent quality and timely delivery, which is vital for maintaining testing schedules and regulatory compliance.

3 Common User Pain Points for ‘quartz glassware’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Quartz Glassware for Specialized Applications

The Problem: B2B buyers often face the challenge of selecting the appropriate quartz glassware that meets specific application requirements, such as high-temperature resistance, chemical compatibility, or optical clarity. This is particularly critical in industries like pharmaceuticals and research labs, where the wrong choice can lead to equipment failure, compromised results, or even safety hazards. With a plethora of options available in the market, distinguishing between various grades and specifications can be overwhelming and time-consuming.

The Solution: To effectively address this issue, buyers should begin by conducting a thorough needs assessment that outlines the specific requirements of their applications. This includes understanding the thermal properties, chemical exposure, and any optical needs. Once the requirements are established, they should engage with suppliers who can provide detailed technical data sheets and certification documentation for their quartz products. Furthermore, buyers can benefit from visiting industry trade shows or participating in webinars where they can engage directly with manufacturers to ask questions and clarify doubts. Additionally, establishing a relationship with a trusted supplier that offers custom solutions can facilitate tailored recommendations that align with unique operational needs.

Scenario 2: Budget Constraints Leading to Compromises on Quality

The Problem: Many companies, especially startups or those operating in developing markets, often face budget constraints that lead them to compromise on the quality of quartz glassware. This can result in purchasing lower-quality products that do not perform as expected, leading to frequent replacements and, ultimately, higher long-term costs. The pressure to minimize upfront expenses can also prevent businesses from investing in glassware that meets their performance standards.

The Solution: To tackle this issue, buyers should take a strategic approach to budgeting for quartz glassware. Instead of opting for the cheapest options, they should evaluate the total cost of ownership (TCO) over the product’s lifecycle. This includes considering factors such as durability, maintenance costs, and potential downtime due to equipment failure. Establishing a relationship with a reputable supplier who can provide bulk purchase discounts or financing options can also help alleviate budgetary pressures. Conducting a cost-benefit analysis to compare different suppliers and their offerings can highlight the value of investing in higher-quality products, ultimately leading to more reliable operations and better ROI.

Scenario 3: Challenges in Handling and Maintenance of Quartz Glassware

The Problem: Quartz glassware, while known for its durability and resistance to thermal shock, can still be prone to breakage if not handled properly. B2B buyers may find that their teams lack the training or protocols necessary to safely handle and maintain these products, resulting in increased risk of damage and costly downtime. This is particularly true in high-volume environments where glassware is frequently moved or cleaned.

The Solution: To mitigate these risks, organizations should implement comprehensive training programs that educate employees on the proper handling and maintenance of quartz glassware. This training should cover best practices for cleaning, storage, and transportation to minimize the risk of breakage. Additionally, investing in protective storage solutions, such as padded cases or racks designed for quartz glassware, can reduce the likelihood of accidents. Suppliers often provide maintenance guidelines and recommendations for compatible cleaning agents that are safe for quartz. Regular audits of handling procedures can also help ensure that the best practices are being followed, ultimately leading to reduced incidents of breakage and improved operational efficiency.

Strategic Material Selection Guide for quartz glassware

What Are the Key Properties of Common Materials Used in Quartz Glassware?

When selecting materials for quartz glassware, several options are prevalent, each with distinct properties that influence performance and suitability for various applications. This guide delves into four common materials: fused quartz, borosilicate glass, soda-lime glass, and quartz glass composites.

Fused Quartz: The Premium Choice for High-Performance Applications

Fused quartz is a high-purity, non-crystalline form of silica, known for its exceptional thermal stability and chemical resistance. It can withstand temperatures up to 1,200°C and is highly resistant to thermal shock, making it ideal for applications involving extreme heat or rapid temperature changes.

Illustrative image related to quartz glassware

Pros: Its durability and resistance to chemical corrosion make it suitable for demanding environments, such as laboratories and industrial processes. Additionally, fused quartz is transparent to UV light, which is beneficial for photochemical applications.

Cons: The primary drawback is its high cost compared to other materials, which may deter budget-conscious buyers. Manufacturing complexity can also increase costs, as specialized techniques are required to shape and form the material.

Impact on Application: Fused quartz is particularly compatible with aggressive solvents and high-purity applications, making it a preferred choice in the semiconductor and pharmaceutical industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and DIN, as well as consider local regulations regarding material safety and environmental impact.

Borosilicate Glass: The Versatile Workhorse

Borosilicate glass is a popular choice due to its excellent thermal and chemical resistance, withstanding temperatures up to 500°C. It is less prone to thermal shock than standard glass, making it suitable for laboratory settings.

Pros: Its affordability and versatility make it a staple in many laboratories. Borosilicate glass is also relatively easy to manufacture, allowing for a wide range of shapes and sizes.

Cons: While it is durable, it is not as resistant to extreme temperatures as fused quartz. Additionally, it may not be suitable for applications involving strong alkalis or hydrofluoric acid.

Impact on Application: Borosilicate glass is commonly used in laboratory glassware, such as beakers and flasks, where moderate thermal resistance is required.

Considerations for International Buyers: Buyers should look for products that meet common standards like ASTM E438 and JIS R 3202, especially when sourcing from different regions, to ensure quality and compatibility.

Illustrative image related to quartz glassware

Soda-Lime Glass: The Economical Option

Soda-lime glass is the most widely produced glass type, known for its low cost and ease of manufacturing. It typically withstands temperatures up to 300°C.

Pros: Its affordability makes it an attractive option for bulk purchases. Soda-lime glass is readily available and can be produced in various shapes and sizes.

Cons: However, it has lower thermal and chemical resistance compared to borosilicate and fused quartz, limiting its use in high-performance applications.

Impact on Application: Soda-lime glass is suitable for general-purpose applications but may not be ideal for environments involving extreme temperatures or corrosive substances.

Considerations for International Buyers: Buyers should be aware of the lower durability and performance standards of soda-lime glass, particularly in regions with strict quality regulations.

Quartz Glass Composites: The Innovative Solution

Quartz glass composites combine quartz with other materials to enhance performance characteristics. These composites can offer improved mechanical strength and thermal stability.

Pros: They can be tailored for specific applications, providing a balance between performance and cost. Their unique properties can make them suitable for specialized applications in various industries.

Cons: The complexity of manufacturing these composites can lead to higher costs and longer lead times. Additionally, the performance can vary significantly based on the specific formulation used.

Illustrative image related to quartz glassware

Impact on Application: Quartz composites are increasingly used in advanced applications, such as aerospace and high-tech manufacturing, where specific material properties are crucial.

Considerations for International Buyers: Buyers should ensure that the composites meet relevant international standards and specifications, as well as consider the implications of sourcing advanced materials from different regions.

Summary Table of Material Selection for Quartz Glassware

| Material | Typical Use Case for quartz glassware | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Quartz | Semiconductor and pharmaceutical labs | Exceptional thermal stability | High cost and manufacturing complexity | High |

| Borosilicate Glass | Laboratory glassware | Versatile and affordable | Limited thermal resistance | Medium |

| Soda-Lime Glass | General-purpose applications | Low cost and easy availability | Poor thermal and chemical resistance | Low |

| Quartz Glass Composites | Aerospace and high-tech industries | Tailored performance characteristics | Higher costs and variable performance | Medium to High |

This analysis provides a comprehensive overview of material selection for quartz glassware, highlighting the critical factors that B2B buyers should consider when making purchasing decisions.

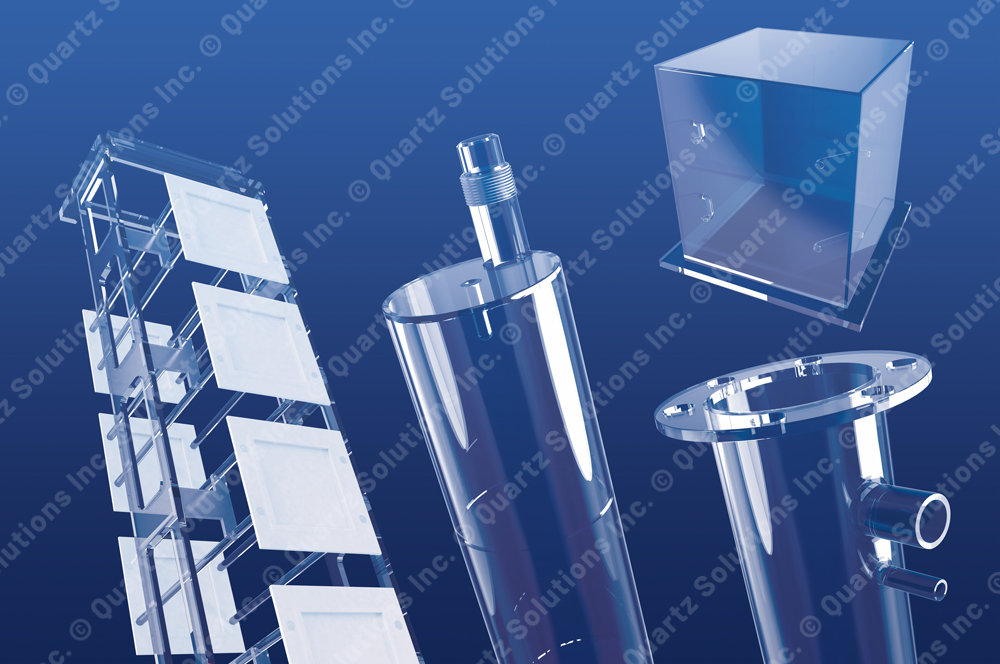

Illustrative image related to quartz glassware

In-depth Look: Manufacturing Processes and Quality Assurance for quartz glassware

What Are the Main Stages of Manufacturing Quartz Glassware?

The manufacturing process for quartz glassware is intricate and requires precision at each stage to ensure the final product meets the high standards expected in various industries. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality silica, which is the primary raw material for quartz glass. This silica is often processed to remove impurities that can affect the clarity and strength of the final product. Various techniques, including chemical treatments and high-temperature processing, are employed to achieve the desired purity levels. This stage is critical, as the quality of silica directly impacts the performance of the glassware.

Forming

Once the silica is prepared, it is subjected to high-temperature melting, typically around 1700°C (3090°F). At this temperature, the silica transforms into a molten state, allowing it to be shaped using several techniques. Common forming methods include blow molding, pressing, and casting. Each technique has its advantages; for instance, blow molding is ideal for producing complex shapes, while casting allows for larger components. The choice of technique depends on the specific requirements of the glassware being produced.

Assembly

After forming, the individual components may require assembly, especially for complex glassware like reactors or multi-part vessels. This stage involves precision joining techniques, such as fusing or using specialized adhesives designed for high-temperature applications. The assembly process must ensure that all joints are secure and capable of withstanding operational stresses.

Illustrative image related to quartz glassware

Finishing

The finishing stage encompasses several processes, including annealing, polishing, and surface treatment. Annealing is crucial as it reduces internal stresses developed during forming. Polishing enhances the optical clarity of the glassware, which is particularly important for laboratory applications where visibility is essential. Surface treatments may also be applied to enhance chemical resistance or reduce surface tension, depending on the intended use of the glassware.

How Is Quality Assurance Integrated into Quartz Glassware Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that quartz glassware meets international standards and customer expectations. Various international and industry-specific standards guide these QA processes.

International Standards and Certifications

Manufacturers often adhere to ISO 9001, a quality management standard that outlines criteria for an effective quality management system. This certification signifies a commitment to consistent quality and customer satisfaction. Additionally, other relevant certifications, such as CE marking for European markets or API standards for the oil and gas industry, may apply depending on the application of the glassware.

Quality Control Checkpoints

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not meet quality criteria are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, various parameters are monitored, including temperature, pressure, and dimensional accuracy. This ongoing inspection helps identify issues early, preventing defects in the final product.

-

Final Quality Control (FQC): After manufacturing, the finished products undergo rigorous testing. This includes visual inspections, dimensional checks, and functional tests to ensure they meet design specifications.

What Common Testing Methods Are Used for Quartz Glassware Quality Assurance?

Several testing methods are employed to ensure the quality and performance of quartz glassware. These methods help verify that the products meet the required standards and can withstand the conditions they will encounter in use.

Visual Inspection

A thorough visual inspection is conducted to identify any defects, such as bubbles, cracks, or surface imperfections. This is often the first step in the quality assurance process.

Dimensional Testing

Precision measuring tools are used to ensure that the dimensions of the glassware conform to specifications. This is essential for components that must fit together accurately.

Thermal Shock Testing

Given that quartz glassware is often subjected to extreme temperature changes, thermal shock testing is crucial. Samples are rapidly heated and cooled to simulate operational conditions, ensuring they can withstand thermal stress without cracking.

Chemical Resistance Testing

For laboratory applications, glassware must resist various chemicals. Manufacturers perform tests to determine the material’s compatibility with acids, bases, and solvents.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those sourcing quartz glassware from international suppliers, verifying quality control practices is essential to mitigate risks and ensure product reliability.

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Audits can be performed by the buyer’s quality assurance team or third-party inspectors, focusing on the manufacturing environment, equipment calibration, and adherence to quality standards.

Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their quality control processes. These reports should include information on raw material inspections, process controls, and final product testing results.

Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can provide unbiased evaluations of the supplier’s quality control systems and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing quartz glassware internationally, buyers must navigate various certification and quality control nuances specific to different regions.

Regional Compliance

Different regions may have unique regulatory requirements. For example, products sold in the European Union must comply with CE marking standards, while those in the United States may need to meet FDA regulations. Understanding these requirements is critical for compliance and market entry.

Cultural and Communication Barriers

Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, may face communication challenges with suppliers. Clear communication regarding quality expectations, standards, and certifications is essential to avoid misunderstandings.

Supply Chain Transparency

Ensuring transparency throughout the supply chain can help buyers verify the quality and origin of quartz glassware. Implementing a robust traceability system allows buyers to track materials from their source to the final product, enhancing confidence in quality claims.

Illustrative image related to quartz glassware

By understanding the manufacturing processes and quality assurance measures associated with quartz glassware, B2B buyers can make informed decisions, ensuring they procure products that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘quartz glassware’

Introduction:

This guide serves as a comprehensive checklist for B2B buyers looking to source quartz glassware. As the demand for high-quality quartz products increases in various sectors, including scientific research and manufacturing, it is essential to approach sourcing systematically. This checklist will help ensure that you make informed decisions, select reliable suppliers, and acquire products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical specifications required for your quartz glassware. This includes dimensions, tolerances, and any specific properties needed, such as thermal resistance or chemical compatibility. Having precise requirements will not only streamline communication with suppliers but also reduce the likelihood of receiving unsuitable products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of quartz glassware. Utilize online platforms, trade shows, and industry publications to compile a list of reputable manufacturers. Focus on suppliers that specialize in quartz products and have a proven track record in your industry. Pay attention to their geographical location, as proximity can influence shipping costs and delivery times.

Step 3: Evaluate Supplier Credentials

It’s crucial to verify the credentials and certifications of potential suppliers. Look for certifications that indicate adherence to industry standards, such as ISO or ASTM. These certifications can be a strong indicator of product quality and reliability. Additionally, check for any awards or recognitions that highlight the supplier’s commitment to excellence in manufacturing.

Step 4: Request Samples for Testing

Once you’ve narrowed down your list of suppliers, request samples of the quartz glassware you intend to purchase. Testing samples allows you to assess the quality, durability, and performance of the products firsthand. Ensure that the samples meet your predefined specifications and perform under the conditions they will be used in.

Step 5: Review Pricing and Payment Terms

After evaluating samples, review the pricing structures of your shortlisted suppliers. Compare quotes, but remember that the lowest price may not always be the best option. Consider the total cost of ownership, including shipping, taxes, and potential customs duties. Discuss payment terms to ensure they align with your budget and cash flow requirements.

Step 6: Assess Customer Support and After-Sales Service

Strong customer support and after-sales service are vital when sourcing quartz glassware. Evaluate how responsive suppliers are to inquiries and their willingness to provide technical assistance. A supplier that offers robust support can significantly reduce downtime and enhance your operational efficiency.

Step 7: Finalize Contracts and Place Orders

Once you have selected a supplier, finalize contracts that outline all agreed-upon terms, including pricing, delivery schedules, and warranty information. Ensure that all critical details are documented to avoid misunderstandings. Once the contract is signed, proceed with placing your order, keeping communication open throughout the process for updates and confirmations.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for quartz glassware, ensuring they select high-quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for quartz glassware Sourcing

What Are the Key Cost Components in Quartz Glassware Sourcing?

When sourcing quartz glassware, understanding the cost structure is critical. The primary cost components include:

-

Materials: Quartz glass is primarily made from high-purity silica, which can be subject to price fluctuations based on market demand and availability. The purity level required for specific applications can also affect material costs significantly.

-

Labor: Skilled labor is essential for manufacturing quartz glassware, especially in processes like glassblowing and precision machining. Labor costs can vary greatly depending on the region, with developed countries typically incurring higher wages than those in developing regions.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs, but they are often unavoidable.

-

Tooling: Custom tooling for specialized glassware can represent a significant upfront investment. Buyers should consider whether the tooling costs are justifiable based on expected order volumes.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes adds to the overall cost. Certifications such as ISO or ASTM can enhance product value but may also increase expenses.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping methods. International buyers should account for potential tariffs and customs duties that may apply.

-

Margin: Suppliers will typically mark up prices to cover their costs and ensure profitability. Understanding the typical margins in the quartz glassware industry can aid in negotiations.

How Do Price Influencers Affect Quartz Glassware Costs?

Several factors can influence the pricing of quartz glassware:

-

Volume/MOQ: Purchasing larger volumes or meeting minimum order quantities (MOQs) often results in lower per-unit costs. Buyers should assess their needs and consider bulk purchasing to maximize savings.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Standard products usually offer more competitive pricing, so buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials or additional certifications may command premium prices. Buyers should evaluate whether the additional costs align with their application needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding the shipping terms agreed upon between buyer and seller is crucial. Incoterms dictate who bears shipping costs and risks, which can significantly impact the total cost.

What Are the Best Negotiation Tips for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies:

-

Conduct Thorough Market Research: Understanding market rates for quartz glassware can provide leverage in negotiations. Researching competitor pricing and supplier options is essential.

-

Negotiate on Volume: As mentioned, higher volumes can lead to better pricing. Engaging suppliers with potential future orders can strengthen your negotiation position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront price but the total cost over the product’s lifecycle, including maintenance, shipping, and potential replacement costs.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local labor costs, material availability, or market demand. This knowledge can help you negotiate better terms.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to preferential pricing, better service, and improved responsiveness to your needs.

Disclaimer on Pricing

It is important to note that prices for quartz glassware can vary significantly based on the aforementioned factors. The indicative prices listed by suppliers may change due to market dynamics, and buyers should request quotes tailored to their specific requirements. Always conduct due diligence before making purchasing decisions to ensure the best value for your investment.

Alternatives Analysis: Comparing quartz glassware With Other Solutions

When evaluating quartz glassware for laboratory and industrial applications, it’s essential to consider various alternative solutions available in the market. This analysis aims to provide a comprehensive comparison of quartz glassware against two viable alternatives: borosilicate glassware and high-density polyethylene (HDPE) containers. Each option has its own set of advantages and disadvantages depending on specific use cases, materials handled, and operational requirements.

| Comparison Aspect | Quartz Glassware | Borosilicate Glassware | High-Density Polyethylene (HDPE) Containers |

|---|---|---|---|

| Performance | Excellent thermal and chemical resistance; ideal for high-temperature applications. | Good thermal resistance but less than quartz; suitable for a wide range of applications. | Moderate chemical resistance; not suitable for high-temperature applications. |

| Cost | Generally higher cost due to specialized manufacturing. | Moderate cost; widely available and less expensive than quartz. | Low cost; economical choice for bulk applications. |

| Ease of Implementation | Requires careful handling; fragile and needs specialized cleaning. | Easy to handle and clean; durable under normal lab conditions. | Very easy to implement; lightweight and shatterproof. |

| Maintenance | Requires careful maintenance to avoid scratches and breakage. | Relatively low maintenance; durable and resistant to breakage. | Minimal maintenance; resistant to many chemicals and easy to clean. |

| Best Use Case | Ideal for high-temperature reactions, spectroscopy, and applications requiring high purity. | Suitable for general lab use, chemical reactions, and heating applications. | Best for storage and transport of non-corrosive liquids and solids. |

What Are the Advantages and Disadvantages of Borosilicate Glassware?

Borosilicate glassware is a popular alternative to quartz due to its moderate cost and good thermal resistance. It is commonly used in laboratory settings for general applications, chemical reactions, and heating processes. The main advantages of borosilicate glass include its durability, ease of handling, and resistance to thermal shock. However, it does not perform well under extremely high temperatures or corrosive conditions compared to quartz glassware, making it less suitable for specialized applications that require strict purity and heat resistance.

How Does High-Density Polyethylene (HDPE) Compare?

High-density polyethylene (HDPE) containers offer a cost-effective and practical solution for many laboratory and industrial needs. They are lightweight, shatterproof, and resistant to various chemicals, making them ideal for storage and transport. HDPE is particularly advantageous in environments where breakage could pose safety risks. However, HDPE is not suitable for high-temperature applications and may not provide the same level of chemical resistance as quartz glassware, particularly with certain solvents and acids. Its longevity and performance under extreme conditions are also inferior to those of quartz.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate glassware or containers for laboratory and industrial applications, B2B buyers should carefully assess their specific requirements. Factors such as the nature of the materials being handled, temperature conditions, potential chemical interactions, and budget constraints play a critical role in this decision. For high-temperature and high-purity applications, quartz glassware stands out as the best option despite its higher cost. Conversely, for general laboratory use or cost-sensitive projects, borosilicate glassware or HDPE containers may provide a more practical solution. Ultimately, understanding the unique needs of each application will guide buyers in making informed choices that align with their operational goals.

Essential Technical Properties and Trade Terminology for quartz glassware

What Are the Key Technical Properties of Quartz Glassware for B2B Buyers?

When sourcing quartz glassware, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade: Quartz glassware is typically classified by its purity, with high-purity quartz (99.99% SiO2) being preferred for applications in pharmaceuticals, optics, and high-temperature processes. The material grade directly impacts the glassware’s chemical resistance, thermal stability, and optical clarity, essential for ensuring product integrity in sensitive applications.

-

Thermal Expansion Coefficient: This property indicates how much a material expands when heated. Quartz has a low thermal expansion coefficient (around 0.5 x 10^-6/K), making it ideal for high-temperature applications. This characteristic minimizes the risk of thermal shock, ensuring durability and longevity in laboratory settings.

-

Tolerance: Precision in manufacturing is vital, especially for components that fit together, such as joints and flanges. Typical tolerances for quartz glassware range from ±0.1 mm to ±0.5 mm, depending on the application. Adhering to strict tolerances ensures compatibility with existing systems and reduces the likelihood of leaks or failures during operations.

-

Chemical Resistance: Quartz glass is renowned for its resistance to a wide range of chemicals, making it suitable for various laboratory environments. This property is critical for industries handling corrosive substances, as it ensures the longevity of the glassware and prevents contamination of samples.

-

UV Transparency: Quartz glassware is highly transparent to ultraviolet light, which is essential for applications involving UV spectroscopy or photochemical reactions. This property allows for accurate measurements and reactions that rely on UV light, providing a significant advantage in research and development settings.

What Are Common Trade Terms in the Quartz Glassware Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are several key terms you should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships can help buyers identify reliable suppliers who can provide tailored quartz glassware solutions for specific applications.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses that may not require large quantities but still need high-quality products.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It is an essential step in the procurement process, allowing buyers to compare prices and negotiate better terms.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for understanding shipping costs, risk transfer, and delivery responsibilities, which can significantly impact overall procurement strategy.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for effective inventory management and ensuring that production schedules are met.

-

Certification Standards: These are industry-specific guidelines that ensure products meet certain safety and quality criteria. Certifications such as ISO or ASTM can be critical for buyers in regulated industries, as they assure compliance and reliability of the quartz glassware being procured.

In conclusion, being knowledgeable about the technical properties and trade terminology related to quartz glassware enables B2B buyers to make informed decisions, streamline procurement processes, and foster productive supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the quartz glassware Sector

What are the Current Market Dynamics and Key Trends in the Quartz Glassware Sector?

The quartz glassware market is experiencing notable growth driven by several global factors, including increased demand for high-purity materials in industries such as pharmaceuticals, biotechnology, and electronics. The rise of advanced manufacturing technologies, like 3D printing and automation, is facilitating the production of customized quartz glassware, enhancing the ability to meet specific client requirements. Furthermore, the growing trend towards sustainable practices is prompting manufacturers to innovate in material sourcing and production methods, catering to environmentally conscious buyers.

Emerging sourcing trends indicate a shift towards digital procurement platforms, enabling international buyers from regions such as Africa, South America, the Middle East, and Europe to streamline their purchasing processes. These platforms provide enhanced transparency, allowing buyers to evaluate suppliers based on quality, delivery performance, and sustainability practices. Additionally, the integration of AI and data analytics in supply chain management is helping businesses forecast demand more accurately, optimize inventory levels, and reduce lead times.

International buyers should also be aware of the regulatory landscape affecting quartz glassware, particularly concerning quality and safety standards. Compliance with international certifications can open up new markets and build trust with stakeholders, making it crucial for B2B buyers to partner with suppliers who maintain rigorous quality control processes.

How Does Sustainability and Ethical Sourcing Impact the Quartz Glassware Sector?

Sustainability is becoming a cornerstone of the quartz glassware industry, with an increasing emphasis on minimizing environmental impact throughout the supply chain. The production of quartz glassware involves energy-intensive processes, and manufacturers are adopting cleaner technologies to reduce carbon emissions. This shift not only benefits the environment but also aligns with the growing demand from B2B buyers for products that meet sustainability criteria.

Ethical sourcing practices are equally important, as international buyers are increasingly scrutinizing the supply chains of their vendors. Ensuring that materials are sourced responsibly and that labor practices are ethical is vital for maintaining brand integrity and consumer trust. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

For buyers in Africa, South America, the Middle East, and Europe, partnering with suppliers who prioritize sustainable and ethical practices can enhance marketability and compliance with local regulations, which are often becoming more stringent regarding environmental responsibility.

What is the Brief Evolution of the Quartz Glassware Sector?

The evolution of quartz glassware has been marked by advancements in material science and manufacturing techniques over the past few decades. Initially, quartz glass was primarily used in scientific applications due to its superior thermal resistance and optical clarity. However, as industries such as electronics and pharmaceuticals began to recognize the benefits of quartz glass, demand surged.

The introduction of high-purity quartz materials and improvements in fabrication technologies have enabled the production of more complex and specialized glassware. Today, quartz glass is indispensable in various applications, ranging from laboratory equipment to high-tech components in semiconductor manufacturing. This evolution highlights the sector’s adaptability and responsiveness to changing market needs, making it a vital area for international B2B buyers to explore.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context of quartz glassware is essential for B2B buyers looking to make informed sourcing decisions that align with both their operational needs and ethical commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of quartz glassware

-

How do I ensure the quality of quartz glassware before purchasing?

To ensure the quality of quartz glassware, request certifications and specifications from the supplier. Look for ISO certifications or equivalent quality assurance standards that confirm their manufacturing processes. Additionally, ask for samples to evaluate the product’s durability, thermal resistance, and clarity. Engaging in a factory audit or visiting the production facility can provide deeper insights into their quality control measures. -

What is the best type of quartz glassware for laboratory use?

The best type of quartz glassware for laboratory use often includes items like flasks, beakers, and crucibles made from high-purity quartz. This type of glassware offers superior thermal stability and chemical resistance, making it suitable for high-temperature applications and reactive substances. For specific applications, consider customized solutions that meet your unique laboratory requirements. -

How can I customize quartz glassware for my specific needs?

Many suppliers offer customization options for quartz glassware, including specific dimensions, designs, and features tailored to your applications. To initiate this process, discuss your requirements directly with the supplier’s sales team. Providing detailed specifications and potential application scenarios will help them understand your needs better and propose suitable solutions. -

What are the minimum order quantities (MOQs) for quartz glassware?

Minimum order quantities for quartz glassware can vary significantly between suppliers and depend on the type of products you are ordering. Typically, MOQs can range from as low as 10 units to several hundred. It is advisable to inquire with your chosen supplier about their specific MOQs and whether they offer flexibility for smaller orders, especially for new clients or start-ups. -

What payment terms should I expect when purchasing quartz glassware internationally?

International suppliers often have varied payment terms, which may include options such as advance payment, letters of credit, or payment upon delivery. It’s essential to clarify these terms before placing an order. Ensure you understand any additional fees related to currency exchange or international transactions, and consider negotiating terms that align with your cash flow and procurement policies. -

How do I vet suppliers of quartz glassware for reliability?

To vet suppliers, conduct thorough research on their reputation and experience in the quartz glassware market. Look for customer reviews, case studies, and references from other businesses, especially those in your industry. Additionally, assess their financial stability, response times, and willingness to provide documentation for quality assurance. Establishing a relationship with suppliers who have a proven track record can mitigate risks. -

What logistics considerations should I keep in mind when importing quartz glassware?

When importing quartz glassware, consider shipping methods, potential duties and tariffs, and the packaging required to protect fragile items. Collaborate with logistics partners experienced in handling sensitive materials to ensure safe transport. Also, be aware of customs regulations in your country, as they can impact delivery times and overall costs. -

How can I handle issues with damaged quartz glassware upon receipt?

If you receive damaged quartz glassware, document the condition with photographs and contact your supplier immediately. Most reputable suppliers have return and replacement policies in place for damaged goods. Ensure you report any issues within the specified timeframe outlined in your agreement to facilitate quick resolutions. Open communication and maintaining a record of correspondence will aid in resolving disputes efficiently.

Top 9 Quartz Glassware Manufacturers & Suppliers List

1. Chemglass – Quartz Products

Domain: chemglass.com

Registered: 1998 (27 years)

Introduction: Quartz Products include Quartz Ground Joints, Quartz O-Ring Joints, Quartz Spherical Joints, Quartz Plates and Discs, Quartz Tubing and Rod, Quartz Microscope Slides and Coverslips, Quartz Fritted Discs, Quartz Wool, Quartz Borosilicate Graded Seals, Quartz Flasks, Beakers, and Crucibles.

2. Mariposa – Fine Line Quartz Double Old-Fashioned Glass Set

Domain: mariposa.com

Registered: 1995 (30 years)

Introduction: Fine Line Quartz with White Rim Double Old-Fashioned Glass Set of 4 | SKU 8070QS4 | Price: $48.00 | Dimensions: 3.25″ L x 3.25″ W x 3.75″ H | Dishwasher safe | Color: Quartz | Sleek design with a subtle white rim.

3. Technical Glass Products – Quartz Distilling Flasks

Domain: technicalglass.com

Registered: 1997 (28 years)

Introduction: Technical Glass Products offers Quartz Distilling Flasks made from clear fused quartz, designed for even heat distribution and efficient vaporization in liquid mixtures. These flasks are ideal for separating or purifying components based on boiling points. The product line includes various sizes with specific capacities and dimensions. Custom sizes are available upon request.

Key Specifications:…

4. Luzchem – Quartz Glassware

Domain: luzchem.com

Registered: 2000 (25 years)

Introduction: Quartz Glassware from Luzchem Research includes lab grade glassware such as cuvettes and test tubes. The products are designed for use in photoreactors and other laboratory applications. Pricing starts from $130.00 USD.

5. Squall Quartz – High Purity Quartz Glass

Domain: squallquartz.com

Registered: 1999 (26 years)

Introduction: Quartz glass is made by melting natural quartz crystals with an SiO2 content of 99.9%. It has low iron, potassium, and sodium oxides, resulting in very low trace element content. Key properties include: very high purity, excellent elasticity, superior compressive strength, ability to withstand extremely high temperatures, extremely low thermal expansion, high thermal shock resistance, low thermal …

6. IQS Directory – Quartz Glass

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Quartz glass, also known as fused quartz or fused silica, is produced from high-purity silicon dioxide (SiO2) and is characterized by its exceptional purity and adaptability. Key properties include a low coefficient of thermal expansion, superior gas permeability, and a wide range of optical transmission. The production process involves several stages: washing and drying to remove contaminants, co…

7. MicQ Store – Lab Quartz Glassware

Domain: micqstore.com

Registered: 2020 (5 years)

Introduction: Lab Quartz Glassware including Quartz Crucibles, Quartz Pipettes, Quartz Weighing Bottles, Quartz Flasks, Quartz Evaporating Dishes, Quartz Sampling Bottles, Quartz Boats, Quartz Beakers, Quartz Test Tubes, High Purity Quartz Wool, and Custom Quartz Lab Glassware. Key products include: 1. Quartz Glass 96 Multiwell Plates – Dimensions: 2mm base thickness, 422µL well volume, outer size: 128*85*14.5m…

8. PGO Online – Fused Silica vs. Fused Quartz

Domain: pgo-online.com

Registered: 2000 (25 years)

Introduction: Fused Silica vs. Fused Quartz: Two distinct types of quartz glass with different properties and applications. Fused Quartz is made from natural quartz crystals, has moderate purity, and is suitable for sight glass applications. Fused Silica is made from high-purity synthetic silica powder, has superior optical properties, and is ideal for high-end optics requiring high imaging accuracy, low absorp…

9. Reddit – Identifying Quartz Lab Glass

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around identifying whether a piece of lab glass is quartz. Key methods mentioned include: 1. UV Vis Test: Quartz allows UV light to pass through, while borosilicate and flint glass do not. 2. Refractive Index Test: A solvent mixture (e.g., MeOH + CHCl3) can be used to match quartz’s refractive index, making it appear to ‘disappear’ in the solution, unlike borosilicate. 3. F…

Strategic Sourcing Conclusion and Outlook for quartz glassware

How Can Strategic Sourcing Enhance Your Quartz Glassware Procurement?

In conclusion, strategic sourcing of quartz glassware offers significant advantages for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. By prioritizing quality, reliability, and supplier relationships, companies can ensure they are not only acquiring high-performance products but also fostering partnerships that drive innovation and efficiency.

Illustrative image related to quartz glassware

As the demand for specialized quartz glassware continues to grow—spurred by advancements in industries like pharmaceuticals, electronics, and research—investing in a robust sourcing strategy becomes imperative. Buyers should leverage data-driven insights and market intelligence to identify the most suitable suppliers who can meet their unique requirements while maintaining competitive pricing.

Looking ahead, the landscape of quartz glassware sourcing is poised for transformation. Embrace this opportunity to refine your procurement processes and capitalize on emerging trends. Connect with reputable suppliers who can provide not only products but also expertise in application and customization. By doing so, you will position your business for success in a rapidly evolving market. Act now to secure your competitive edge and elevate your sourcing strategy in the quartz glassware domain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.