Top 4 Circular Outlet Suppliers (And How to Choose)

Introduction: Navigating the Global Market for circular outlet

In today’s rapidly evolving global market, the challenge of sourcing reliable and innovative circular outlets is paramount for businesses across diverse sectors. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—navigate this complex landscape, understanding the nuances of circular outlet options can significantly impact operational efficiency. This guide delves into the various types of circular outlets available, their unique applications in both residential and commercial settings, and the essential criteria for vetting suppliers.

From the compact in-cabinet outlets that enhance kitchen designs to recessed floor boxes that seamlessly integrate power sources in modern office spaces, the scope of this guide encompasses a comprehensive overview of product specifications, installation considerations, and market trends. Additionally, we will address cost structures, potential savings, and the importance of sustainability in your purchasing decisions.

By equipping buyers with actionable insights and strategic considerations, this guide empowers informed purchasing decisions that can lead to enhanced functionality and aesthetic appeal in any project. Understanding the intricate details of circular outlets not only helps in meeting immediate needs but also positions businesses to leverage future opportunities in an increasingly competitive market.

Understanding circular outlet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| In-Cabinet Round Power Outlet | Compact size (2” diameter), paintable cover, easy installation | Kitchen islands, cabinetry, workspace setups | Pros: Space-saving, aesthetic integration; Cons: Limited power capacity. |

| Recessed In-Floor Outlet | Flush design, available in various materials (brass, aluminum) | Commercial offices, conference rooms, residential spaces | Pros: Sleek appearance, protects outlets from damage; Cons: Requires floor modification for installation. |

| Flush Mounted Round Floor Box | Offers power and data connections, customizable configurations | Retail spaces, trade shows, exhibition areas | Pros: Versatile for multiple uses; Cons: Installation complexity may deter some buyers. |

| Surface-Mounted Round Outlet | Easily accessible, surface-mounted design, often available in multiple colors | Industrial settings, workshops, garages | Pros: Quick installation, high visibility; Cons: Can be less aesthetically pleasing. |

| Outdoor Round Power Outlet | Weather-resistant, often includes GFCI protection | Construction sites, outdoor events, landscaping | Pros: Durable for outdoor use; Cons: Limited to external applications. |

What Are the Key Characteristics of In-Cabinet Round Power Outlets?

In-cabinet round power outlets are designed for discreet installation in tight spaces, such as kitchen islands and cabinetry. Measuring only 2 inches in diameter, they come with a paintable cover that allows for seamless integration into various surfaces. These outlets are particularly appealing for B2B buyers in the hospitality and furniture industries, where aesthetic design is crucial. When purchasing, consider factors such as installation ease and compatibility with existing electrical systems.

How Do Recessed In-Floor Outlets Function in Commercial Spaces?

Recessed in-floor outlets are characterized by their flush-mounted design, which allows them to sit level with the floor surface. Available in materials like brass and aluminum, they provide a clean, professional look ideal for commercial settings such as offices and conference rooms. B2B buyers should evaluate the outlet’s capacity to handle electrical and data connections, as well as installation requirements, which may involve significant floor modifications.

What Makes Flush Mounted Round Floor Boxes Versatile?

Flush mounted round floor boxes are designed to accommodate both power and data connections, making them highly versatile for various applications. Their customizable configurations are particularly beneficial in retail spaces and trade shows, where adaptability is key. Buyers should consider the potential for multi-use functionality and the ease of installation, as these factors can significantly influence overall project timelines and costs.

Why Choose Surface-Mounted Round Outlets in Industrial Settings?

Surface-mounted round outlets are ideal for environments where quick access to power is essential, such as workshops and industrial settings. Their visible design allows for easy identification and accessibility, making them a practical choice for high-traffic areas. However, B2B buyers should weigh the aesthetic implications against the functional benefits, as these outlets may not blend well into more refined environments.

What Should Buyers Know About Outdoor Round Power Outlets?

Outdoor round power outlets are specifically designed to withstand weather conditions, often featuring GFCI protection for safety. These outlets are crucial for applications in construction sites and outdoor events, where reliable power access is needed. When considering an outdoor outlet, buyers should focus on durability, weather resistance, and the outlet’s ability to handle specific electrical loads relevant to their operations.

Key Industrial Applications of circular outlet

| Industry/Sector | Specific Application of circular outlet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Integration in hotel room designs for convenience | Enhances guest experience and improves room aesthetics | Ensure compliance with local electrical standards and safety codes |

| Retail | Installation in display fixtures for power accessibility | Facilitates customer interaction and enhances product displays | Evaluate durability and ease of maintenance for high-traffic areas |

| Office Spaces | Recessed outlets in conference rooms and workstations | Maximizes space efficiency while maintaining a clean look | Consider configurations for power and data to support technology needs |

| Residential Construction | Use in modern kitchen designs for hidden power access | Increases functionality without compromising design | Assess compatibility with existing cabinetry and materials |

| Educational Institutions | Installation in classrooms and lecture halls | Supports technology use in teaching and learning environments | Focus on robust designs to withstand heavy usage and frequent movement |

How is the circular outlet utilized in the hospitality industry?

In the hospitality sector, circular outlets are often integrated into hotel room designs, particularly in areas like bedside tables and desks. These outlets provide convenient access to power for guests who need to charge devices. By offering aesthetically pleasing and easy-to-use solutions, hotels can significantly enhance the guest experience. International buyers should ensure these outlets comply with local electrical codes and standards to avoid safety issues.

What role do circular outlets play in retail environments?

In retail, circular outlets are frequently installed in display fixtures, allowing customers to interact with products that require power, such as electronic displays or charging stations. This setup not only increases customer engagement but also enhances the visual appeal of the store. When sourcing these outlets, businesses should evaluate their durability, especially in high-traffic areas, to minimize maintenance costs and maximize uptime.

How do circular outlets improve functionality in office spaces?

In modern office environments, circular outlets are commonly recessed in conference rooms and workstations. This design choice maximizes space efficiency while maintaining a clean and organized appearance. They can be configured to provide both power and data connections, catering to the technological needs of today’s workplaces. Buyers should consider the specific configurations required to support their technology needs and ensure compatibility with existing office infrastructure.

In what ways are circular outlets beneficial for residential construction?

In residential construction, especially in contemporary kitchen designs, circular outlets offer a practical solution for hidden power access. They can be installed in cabinetry, providing power without compromising the kitchen’s aesthetic appeal. This design flexibility allows homeowners to maximize functionality while maintaining a sleek look. Buyers should assess the compatibility of these outlets with various materials and cabinetry designs to ensure seamless installation.

How do educational institutions utilize circular outlets?

Educational institutions leverage circular outlets in classrooms and lecture halls to support the use of technology in teaching and learning. These outlets provide power access for laptops, projectors, and other electronic devices, facilitating a more interactive and engaging learning environment. When sourcing outlets for educational settings, it is crucial to focus on robust designs that can withstand heavy usage and frequent movement, ensuring longevity and reliability.

3 Common User Pain Points for ‘circular outlet’ & Their Solutions

Scenario 1: Difficulty in Installation in Tight Spaces

The Problem: B2B buyers often face challenges when trying to install traditional power outlets in compact or awkwardly shaped areas, such as kitchen islands, cabinets, or corners. These installations can be frustrating, as standard outlets may not fit properly or may require extensive modifications to cabinetry or walls. This can lead to increased labor costs and project delays, especially in commercial settings where time is of the essence.

The Solution: To address these installation challenges, buyers should consider sourcing circular outlets, specifically designed for tight spaces. Products like the Sillites 2″ round power outlet are ideal, as they require only a 1.75″ hole for installation and do not necessitate a junction box. This not only simplifies the installation process but also reduces the need for extensive modifications. When specifying these outlets, ensure they come with paintable covers to match surrounding surfaces, enhancing aesthetic appeal. For contractors, stocking these outlets in various finishes can streamline project execution and reduce waiting times for custom orders.

Scenario 2: Aesthetic Incompatibility with Design

The Problem: In commercial and residential projects, maintaining a cohesive aesthetic is crucial. Buyers often struggle with traditional outlets that disrupt the overall design of a space. Standard outlets may clash with high-end finishes, modern furniture, or unique architectural elements, resulting in a visually unappealing outcome that can detract from the value of the project.

The Solution: Opting for circular outlets can significantly enhance the visual harmony of a space. These outlets can be installed flush with surfaces, minimizing their visibility while providing necessary functionality. When sourcing these products, it’s essential to choose options with customizable cover finishes that can blend seamlessly with the surrounding materials. For instance, selecting outlets with finishes that match cabinetry or flooring can create a unified look. Additionally, buyers should consider consulting with design professionals to identify the best placement for these outlets to ensure they do not disrupt the flow of the space.

Scenario 3: Safety and Compliance Concerns

The Problem: Safety and compliance with local electrical codes are paramount for B2B buyers, especially in commercial installations. Many traditional outlets can pose safety risks if not installed correctly or if they do not meet specific regulatory standards. The potential for electrical hazards can lead to liability issues and increased insurance costs, making it essential for buyers to choose the right products.

The Solution: To mitigate safety risks, buyers should prioritize sourcing circular outlets that are certified for compliance with relevant safety standards. Products like recessed in-floor outlets or flush-mounted options are designed to meet safety requirements while providing easy access to power without compromising safety. When selecting these outlets, ensure they are equipped with features such as tamper-resistant designs or weatherproof ratings for outdoor use. Collaborating with certified electricians during the installation process can also ensure that all local regulations are adhered to, providing peace of mind and protecting against potential liabilities. Investing in quality products from reputable suppliers can further enhance safety and compliance, ultimately safeguarding the project’s integrity.

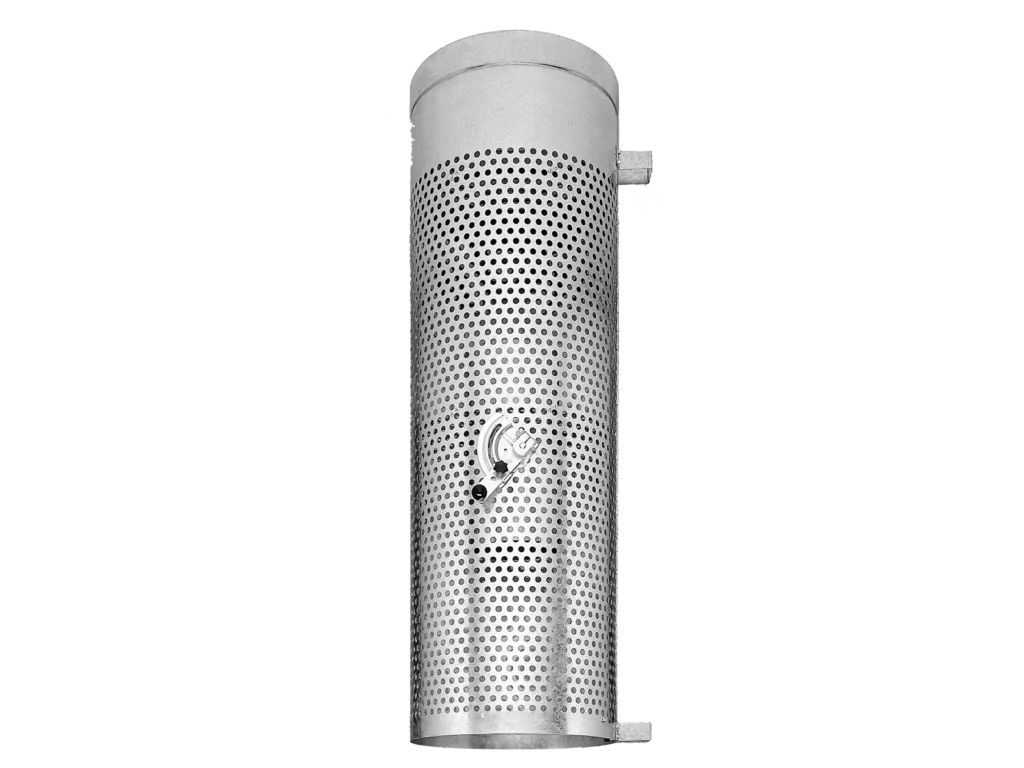

Illustrative image related to circular outlet

Strategic Material Selection Guide for circular outlet

What are the Key Properties of Common Materials for Circular Outlets?

When selecting materials for circular outlets, it is crucial to consider their properties, performance, and suitability for specific applications. Below is an analysis of four common materials used in the manufacturing of circular outlets, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Plastic (Polycarbonate or PVC)

Key Properties:

Plastic materials like polycarbonate and PVC are lightweight, corrosion-resistant, and can withstand moderate temperatures. Their electrical insulation properties make them ideal for electrical applications.

Pros & Cons:

Plastic is generally low-cost and easy to mold, which simplifies manufacturing processes. However, it may not withstand high temperatures or physical impacts as well as metals. Over time, UV exposure can lead to degradation.

Impact on Application:

Plastic circular outlets are suitable for indoor applications where moisture and temperature extremes are limited. They are not recommended for environments with high heat or exposure to chemicals.

Illustrative image related to circular outlet

Considerations for International Buyers:

Buyers should ensure compliance with local electrical standards (such as IEC in Europe or NEMA in the U.S.) and consider the availability of high-quality plastic materials in their region.

2. Aluminum

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and can handle a wide range of temperatures. It is also a good conductor of electricity.

Pros & Cons:

Aluminum is durable and can be anodized for additional protection, making it suitable for outdoor applications. However, it may be more expensive than plastic and can be prone to scratching.

Impact on Application:

Aluminum circular outlets are ideal for environments that require durability and resistance to corrosion, such as coastal areas. They are also suitable for high-traffic areas due to their strength.

Considerations for International Buyers:

Buyers should check for compliance with international standards like ASTM or DIN, especially in regions like Europe and the Middle East, where these standards are critical for safety and performance.

Illustrative image related to circular outlet

3. Stainless Steel

Key Properties:

Stainless steel is known for its high corrosion resistance and strength, able to withstand harsh environments and high temperatures.

Pros & Cons:

While stainless steel offers exceptional durability and a professional appearance, it is typically more expensive than both plastic and aluminum. Manufacturing processes can also be more complex due to the material’s hardness.

Impact on Application:

This material is perfect for industrial settings, kitchens, and laboratories where hygiene and durability are paramount. Its resistance to chemicals makes it suitable for various applications.

Considerations for International Buyers:

Compliance with food safety and electrical standards is essential, particularly in regions with stringent regulations like Europe. Buyers should also consider the availability of stainless steel options in their local markets.

4. Brass

Key Properties:

Brass is a copper-zinc alloy known for its excellent electrical conductivity and resistance to corrosion, particularly in marine environments.

Pros & Cons:

Brass is durable and offers an aesthetic appeal, making it suitable for decorative applications. However, it can be more expensive and may require regular maintenance to prevent tarnishing.

Impact on Application:

Brass circular outlets are often used in high-end residential and commercial projects where aesthetics and functionality are equally important. They are also suitable for outdoor applications due to their corrosion resistance.

Considerations for International Buyers:

Buyers should be aware of the environmental regulations concerning copper and brass materials, especially in regions like South America and Africa, where such regulations may vary significantly.

Summary Table of Material Selection for Circular Outlets

| Material | Typical Use Case for Circular Outlet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Indoor electrical applications | Lightweight and cost-effective | Limited heat resistance | Low |

| Aluminum | Outdoor and high-traffic areas | Durable and corrosion-resistant | Higher cost than plastic | Medium |

| Stainless Steel | Industrial and laboratory settings | High durability and hygiene | More expensive and complex to manufacture | High |

| Brass | Decorative and high-end applications | Excellent conductivity and aesthetics | Requires maintenance to prevent tarnishing | High |

This analysis provides a comprehensive understanding of the materials used in circular outlets, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for circular outlet

What Are the Key Stages in the Manufacturing Process of Circular Outlets?

The manufacturing of circular outlets involves a series of systematic stages, each critical to ensuring the final product meets quality and performance standards. The main stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection and preparation of raw materials. Circular outlets are commonly made from high-grade plastics, metals, or composite materials. During this phase, suppliers must ensure that the materials meet the required specifications for electrical safety, durability, and aesthetic appeal. This often involves sourcing materials that comply with international standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

How Is the Forming Process for Circular Outlets Executed?

Once the materials are prepared, the forming stage takes place. This stage includes various manufacturing techniques such as injection molding for plastic components and stamping or die-casting for metal parts. For circular outlets, precision is crucial, as the dimensions must be exact to ensure compatibility with standard electrical systems.

Advanced technologies like CNC (Computer Numerical Control) machining may be employed to enhance accuracy. This level of precision is essential not only for aesthetic reasons but also for ensuring proper electrical connections and safety.

Illustrative image related to circular outlet

What Does the Assembly Process Entail for Circular Outlets?

After the forming process, the next step is assembly. This stage involves integrating various components, such as the electrical contacts, housing, and cover plates. Automated assembly lines are often utilized to enhance efficiency and reduce human error. Quality control checks during this stage ensure that all components fit together seamlessly, which is vital for maintaining the outlet’s functionality and safety.

Incorporating smart technology, such as surge protection or USB charging capabilities, may also occur during this phase. Manufacturers focusing on innovation can offer additional features that appeal to modern consumers and businesses.

What Finishing Techniques Are Used in Circular Outlet Manufacturing?

The final manufacturing stage is finishing, which includes surface treatments, painting, and quality inspections. Finishing processes may involve applying coatings to enhance corrosion resistance, durability, and aesthetics. For instance, a paintable cover allows the outlet to blend into its environment, an attractive feature for many commercial and residential applications.

Quality assurance during this stage is crucial. Manufacturers often conduct thorough inspections to ensure that the final product meets all specifications. This can include visual inspections for surface defects, as well as functional tests to confirm electrical performance.

How Is Quality Assurance Implemented in Circular Outlet Production?

Quality assurance (QA) is integral to the manufacturing process, ensuring that circular outlets meet the highest standards of safety and performance. The QA process typically adheres to both international standards, such as ISO 9001, and industry-specific certifications like CE marking for Europe and UL listing for North America.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 outlines a framework for quality management systems, emphasizing customer satisfaction and continuous improvement. Circular outlet manufacturers often seek ISO certification to demonstrate their commitment to quality. Additionally, compliance with CE marking indicates that the product meets European safety, health, and environmental protection requirements.

For buyers in regions such as Africa and South America, understanding local regulations and standards is essential. Different countries may have varying requirements for electrical safety and product certifications, which can affect importation and distribution.

What Are the Key Quality Control Checkpoints in Circular Outlet Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Ensuring materials meet specified standards prevents defects from occurring later in the process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections ensure that production adheres to established standards. This may include monitoring the forming and assembly processes to catch any discrepancies early.

-

Final Quality Control (FQC): At the completion of production, the final product undergoes comprehensive testing. This includes functional testing of electrical properties, visual inspections, and safety checks.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Buyers can take several steps to ensure they are sourcing from reputable manufacturers:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices. This can be conducted by the buyer or through third-party auditing services.

-

Request Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes and results from recent inspections. This transparency is vital for building trust.

-

Utilize Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This can be particularly beneficial for buyers unfamiliar with local manufacturing standards.

What Common Testing Methods Are Used for Circular Outlets?

Testing methods for circular outlets often include:

-

Electrical Testing: Ensures that the outlet can handle specified voltage and current levels without failure.

-

Durability Testing: Simulates wear and tear to assess the outlet’s lifespan under normal usage conditions.

-

Safety Testing: Checks for compliance with safety standards, such as resistance to fire and electrical hazards.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing circular outlets, ensuring they choose reliable products that meet their needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘circular outlet’

To assist international B2B buyers in sourcing circular outlets effectively, this guide provides a detailed checklist designed to streamline the procurement process. By following these steps, buyers can ensure they make informed decisions that align with their technical requirements, budget, and long-term operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing circular outlets. Consider factors such as voltage, amperage, and installation environment (e.g., residential vs. commercial). Specify additional features like waterproofing or data connectivity, as these will influence both the type of outlet and the suppliers you engage with.

Illustrative image related to circular outlet

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Utilize online platforms, trade shows, and industry contacts to compile a list of manufacturers and distributors specializing in circular outlets. Focus on suppliers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe, as they will be more familiar with local compliance and logistical challenges.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, it’s crucial to verify their certifications and compliance with international standards. Look for certifications such as ISO 9001 for quality management and UL or CE marks for safety compliance. These certifications not only ensure product safety but also signal the supplier’s commitment to quality.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request product samples to evaluate the quality of the circular outlets. Assess the materials used, build quality, and any additional features. This hands-on evaluation can prevent costly mistakes later in the procurement process and help establish trust with your supplier.

Illustrative image related to circular outlet

Step 5: Review Pricing Structures

Analyze the pricing offered by different suppliers, taking into account bulk purchase discounts, shipping costs, and payment terms. Ensure that the pricing aligns with your budget while also considering the total cost of ownership, including installation and maintenance costs. Transparent pricing will help you avoid unexpected expenses later.

Step 6: Assess Supplier Support and Warranty

Investigate the level of customer support and warranty options provided by the supplier. Reliable support can be invaluable, especially in resolving installation issues or product defects. A robust warranty policy indicates the supplier’s confidence in their product and can safeguard your investment.

Step 7: Finalize Contract Terms

Before placing an order, ensure that all contract terms are clearly defined. This includes delivery timelines, payment terms, and return policies. Having a well-documented agreement will protect both parties and clarify expectations, reducing the likelihood of disputes.

By following this comprehensive checklist, B2B buyers can navigate the sourcing process for circular outlets with confidence, ensuring they select the right products and suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for circular outlet Sourcing

What Are the Key Cost Components for Sourcing Circular Outlets?

When evaluating the cost structure of circular outlets, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences costs. For example, outlets made from high-grade metals or specialized plastics may be more expensive than those made from standard materials. Buyers should consider the durability and application of the materials when assessing costs.

-

Labor: Labor costs vary by region and depend on the skill level required for production. In regions with lower labor costs, manufacturers might offer more competitive pricing, though this may come with trade-offs in quality or service.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, impacting the final price.

-

Tooling: Custom tooling for specific designs or specifications can increase initial costs. However, amortizing these costs over larger production runs can lead to lower per-unit prices.

-

Quality Control: Implementing robust QC processes ensures product reliability but can add to the cost. Certifications and compliance with international standards may also affect pricing, particularly for buyers in regulated markets.

-

Logistics: Transportation, warehousing, and customs duties are critical in the total cost calculation. Buyers should factor in the distance from the manufacturer and the chosen Incoterms, which dictate responsibilities for shipping and handling.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding industry standards for markup can help buyers gauge whether pricing is competitive.

How Do Price Influencers Affect Circular Outlet Sourcing?

Several factors can influence the pricing of circular outlets, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to significant discounts. Suppliers may offer better pricing for larger quantities, making it essential to assess whether MOQ aligns with your needs.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should balance the need for customization against budget constraints and explore standardized options that meet their requirements.

-

Material Quality and Certifications: Higher-quality materials or certified products tend to command higher prices. Buyers in regions with strict safety regulations may need to invest in certified products, which can affect overall costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their assurance of quality and service. Conducting due diligence on potential partners can yield better pricing negotiations.

-

Incoterms: Understanding shipping terms is crucial for total cost calculations. Different Incoterms can shift costs and responsibilities between buyer and seller, impacting the final price.

What Are Essential Tips for Negotiating Circular Outlet Prices?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Explore Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term operational costs, including maintenance and energy efficiency. A lower upfront cost may lead to higher overall expenses.

-

Leverage Market Research: Understanding market trends and competitor pricing can empower buyers during negotiations. Having data to support your position can encourage suppliers to offer better terms.

-

Build Relationships with Suppliers: Establishing a good rapport can lead to better pricing and terms. Long-term partnerships may encourage suppliers to provide discounts or favorable payment terms.

-

Be Clear About Specifications: Providing detailed specifications upfront can help suppliers tailor their quotes more accurately, reducing the likelihood of unexpected costs later.

-

Negotiate Payment Terms: Flexibility in payment terms can provide cash flow benefits. Discussing options like extended payment periods can improve financial management.

Conclusion

Navigating the cost and pricing landscape for circular outlets requires a comprehensive understanding of various cost components and price influencers. By employing effective negotiation strategies and considering the total cost of ownership, B2B buyers can achieve cost-efficient sourcing that meets their operational needs. Always remain vigilant about market conditions and supplier performance to ensure optimal purchasing decisions.

Alternatives Analysis: Comparing circular outlet With Other Solutions

Understanding Alternatives for Circular Outlets in Electrical Solutions

In the evolving landscape of electrical solutions, B2B buyers must assess various options available in the market. Circular outlets, known for their compact design and versatile applications, are a popular choice. However, understanding how they compare to alternative solutions such as recessed outlets and in-floor outlets can provide valuable insights for buyers, especially when considering factors like performance, cost, and implementation.

Comparison Table

| Comparison Aspect | Circular Outlet | Recessed Outlet | In-Floor Outlet |

|---|---|---|---|

| Performance | Compact, suitable for tight spaces | Provides unobtrusive access | Ideal for high-traffic areas |

| Cost | Moderate pricing ($21.29 each) | Slightly higher ($72.00 – $109.00) | Higher initial cost ($59.10 – $133.00) |

| Ease of Implementation | Easy installation (requires 1.75″ hole) | Moderate installation complexity | More complex, requires floor work |

| Maintenance | Low maintenance, durable | Low maintenance, durable | Moderate maintenance, accessible |

| Best Use Case | Kitchen islands, cabinets | Home and office spaces | Conference rooms, open offices |

Detailed Breakdown of Alternatives

Recessed Outlet

Recessed outlets are designed to be installed in walls or furniture, providing a clean and unobtrusive appearance. They are slightly more expensive than circular outlets, but their versatility makes them suitable for both commercial and residential applications. The installation process is moderate; it typically requires cutting into drywall or furniture, which may need professional assistance. Maintenance is minimal, as they are generally durable, but they can be less accessible for repairs if installed in difficult locations. Best used in settings where aesthetics and space-saving are priorities, such as modern offices or stylish homes.

In-Floor Outlet

In-floor outlets are installed directly into the floor, making them ideal for high-traffic areas and open spaces. While they are more expensive than both circular and recessed outlets, their performance in busy environments is unmatched, allowing easy access to power without cluttering the space. The installation requires professional expertise, as it involves cutting into the floor and ensuring proper wiring, which can be a significant investment. Maintenance may be moderate; while durable, these outlets can accumulate dirt and debris, requiring periodic cleaning. They are best suited for conference rooms, auditoriums, and commercial spaces where mobility and accessibility to power are essential.

Illustrative image related to circular outlet

How to Choose the Right Solution for Your Needs

When selecting the best electrical outlet solution for your business, consider the specific needs of your environment. If space-saving and aesthetic appeal are crucial, circular outlets or recessed outlets may be the best fit. For high-traffic areas where accessibility and functionality are paramount, in-floor outlets could be more advantageous despite their higher cost and installation complexity. Assess your unique requirements, including the layout of your space, the volume of electrical devices to be used, and your budget to make an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for circular outlet

What Are the Essential Technical Properties of Circular Outlets?

Understanding the technical specifications of circular outlets is crucial for international B2B buyers, especially when sourcing products for varied applications such as residential, commercial, or industrial settings. Below are some critical specifications that buyers should consider:

-

Material Grade

Circular outlets are typically made from materials such as plastic, aluminum, brass, or stainless steel. Each material has different properties, including durability, corrosion resistance, and aesthetic appeal. For instance, brass offers excellent conductivity and a premium look, making it ideal for high-end installations, while plastic is cost-effective and suitable for lightweight applications. -

Electrical Ratings (Voltage and Amperage)

Buyers must assess the electrical ratings of circular outlets, which indicate the maximum voltage and current they can handle. Common ratings include 15A or 20A at 120V or 240V. Selecting an outlet with an appropriate rating ensures safety and compliance with local electrical codes, which is particularly important for large-scale projects. -

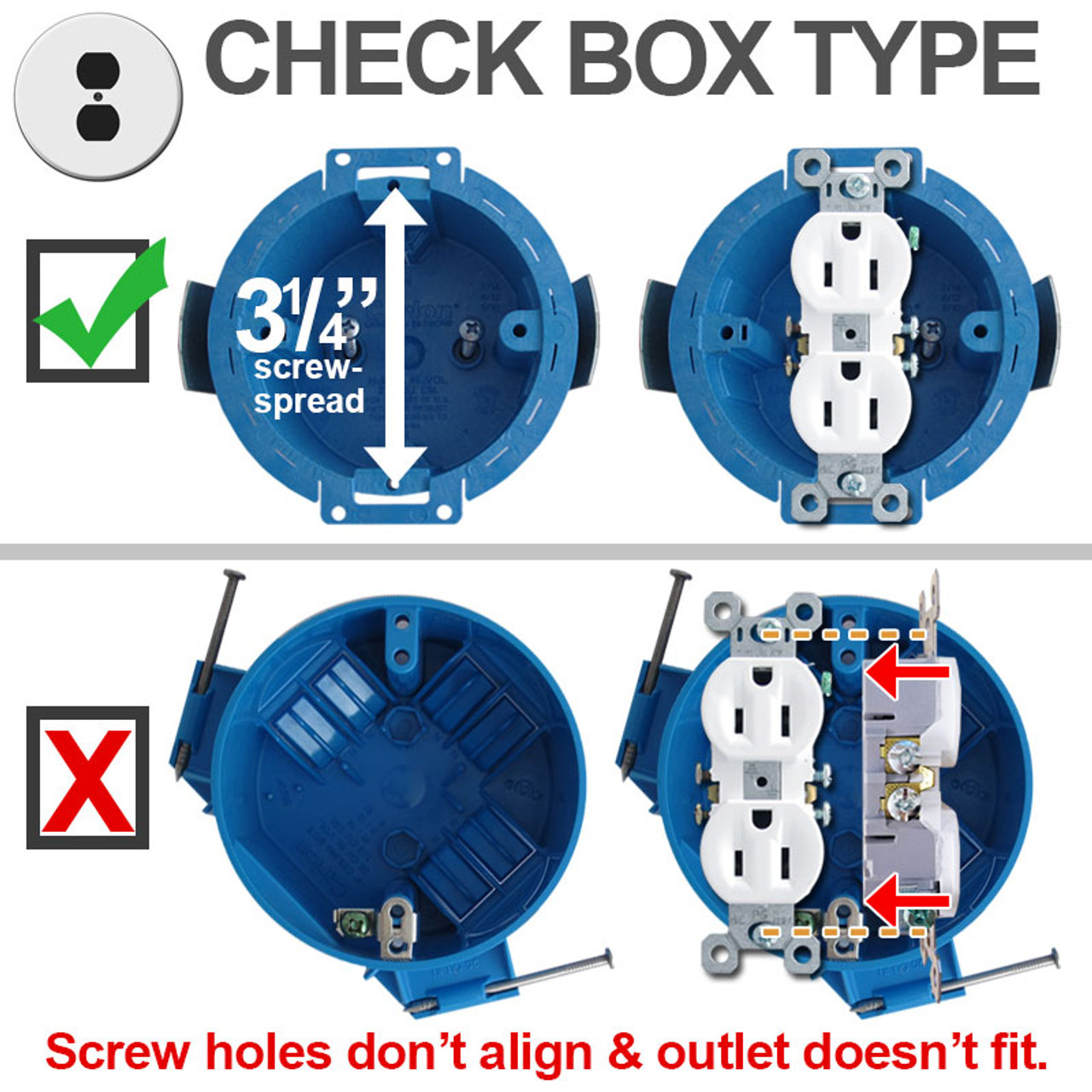

Installation Compatibility (Cutout Size)

The cutout size required for installation is another critical specification. Circular outlets often require specific diameters for proper fitting, commonly ranging from 2 inches to 4 inches. Understanding these dimensions helps avoid installation issues and ensures a seamless integration into existing structures. -

Ingress Protection (IP Rating)

The IP rating indicates the level of protection against dust and moisture. For instance, an IP54 rating means the outlet is protected against limited dust ingress and water splashes. This specification is essential for buyers in regions with high humidity or dust levels, ensuring the longevity and reliability of the outlet. -

Finish and Color Options

Aesthetic considerations can influence the choice of circular outlets. Various finishes (e.g., brushed nickel, matte black) and color options allow for customization to match the décor of a space. This aspect is increasingly important in commercial settings where design plays a key role in branding. -

Self-Contained Design

Many modern circular outlets feature a self-contained design that eliminates the need for a junction box. This design simplifies installation and reduces labor costs, making it an attractive option for contractors and builders.

What Are Common Trade Terms Related to Circular Outlets?

Navigating the landscape of B2B transactions involves familiarizing oneself with industry jargon. Here are some essential terms relevant to circular outlets:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. Understanding OEM relationships is vital for buyers looking for specific designs or customizations in circular outlets. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, particularly for businesses looking to scale operations in regions like Africa or South America. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. It typically includes specifications for the desired products, such as circular outlets. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms helps in managing logistics, costs, and risks involved in international transactions. -

Lead Time

Lead time refers to the time between placing an order and receiving it. For circular outlets, lead time can vary based on manufacturing processes and shipping. Knowing the lead time is essential for planning projects and ensuring timely delivery. -

Certification Standards

Certification standards indicate compliance with safety and quality regulations. Common standards include UL (Underwriters Laboratories) and CE (Conformité Européenne). Buyers should prioritize certified products to ensure reliability and adherence to international safety standards.

By grasping these technical properties and industry terms, B2B buyers can make informed purchasing decisions regarding circular outlets that align with their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the circular outlet Sector

What Are the Current Market Trends in the Circular Outlet Sector?

The global market for circular outlets is witnessing significant growth driven by several factors. First, the increasing demand for versatile and space-efficient electrical solutions in residential and commercial spaces is propelling innovation in outlet design. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Countries like Nigeria and Vietnam are experiencing urbanization and infrastructural development, leading to heightened demand for modern electrical solutions.

Emerging technologies such as smart home systems are also influencing sourcing trends. Circular outlets are being integrated into smart designs that allow for energy efficiency and enhanced user experience. Buyers are increasingly looking for products that support these technologies, as they align with the growing consumer preference for smart and sustainable living. Furthermore, the trend toward modular and customizable solutions is gaining traction, allowing buyers to adapt products to specific needs, enhancing their appeal in diverse markets.

How Does Sustainability Affect Sourcing in the Circular Outlet Sector?

Sustainability is becoming a critical consideration in the sourcing of circular outlets. The environmental impact of electrical components is under scrutiny, prompting businesses to adopt more sustainable practices. B2B buyers are now prioritizing suppliers who can demonstrate a commitment to ethical sourcing and environmental responsibility. This includes using recyclable materials and manufacturing processes that minimize waste.

Certifications such as ISO 14001 for environmental management and adherence to sustainable material standards are increasingly sought after. Buyers from regions like Europe, where regulatory frameworks are stringent, often require proof of compliance with these standards. Additionally, the use of ‘green’ materials, such as low-impact plastics and sustainable metals, can enhance a product’s marketability and appeal to eco-conscious consumers. Emphasizing these aspects not only aligns with global sustainability goals but also offers a competitive edge in the marketplace.

What Is the Historical Context of Circular Outlets in B2B Markets?

The circular outlet sector has evolved significantly over the past few decades. Initially, traditional square and rectangular outlets dominated the market, but as design aesthetics and functionality became more critical, the circular outlet emerged as a practical solution. This design allows for easier integration into various surfaces, from kitchen islands to office floors, meeting the needs of modern architecture and interior design.

The shift towards compact and versatile electrical solutions has been accelerated by technological advancements. The introduction of self-contained designs, which require no junction box, has simplified installation and broadened application possibilities. As urban centers grow and consumer preferences shift towards minimalism and efficiency, the circular outlet’s role in both residential and commercial environments continues to expand. This historical context is essential for B2B buyers to understand the product’s evolution and its potential for future applications.

By keeping abreast of these trends and historical shifts, international B2B buyers can make informed sourcing decisions that align with their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of circular outlet

-

How do I solve installation challenges with circular outlets?

To address installation challenges with circular outlets, ensure you have the correct tools and dimensions for your project. Most circular outlets require a specific hole size, typically around 1.75 inches in diameter. If you’re working with different materials, consider outlets designed for easy installation, like self-contained models that eliminate the need for junction boxes. Additionally, consult the manufacturer’s installation guidelines and consider hiring a qualified electrician if you encounter any complexities. -

What is the best circular outlet for compact spaces?

The best circular outlet for compact spaces is the Sillites 2″ in-cabinet round power outlet. Measuring only 2 inches in diameter, this outlet is perfect for tight areas such as kitchen islands and cabinets. Its paintable cover allows it to seamlessly blend into various surfaces, enhancing aesthetics without sacrificing functionality. Moreover, its self-contained design simplifies installation, making it an ideal choice for limited space applications. -

What customization options are available for circular outlets?

Many suppliers offer customization options for circular outlets, including color choices, cover designs, and specific configurations for power or data connections. When sourcing, inquire about paintable finishes or unique designs to meet your project’s aesthetic requirements. Additionally, some manufacturers may provide options for customized packaging or branding, which can be beneficial for businesses looking to enhance their market presence. -

What are the minimum order quantities (MOQ) for circular outlets?

Minimum order quantities (MOQ) for circular outlets can vary significantly between suppliers. Generally, MOQs range from small quantities, such as 10 to 50 units, for standard models to larger orders for bulk purchases, often exceeding 250 units. It’s essential to discuss your project needs with potential suppliers to find a balance between your budget and their requirements, ensuring that you can meet both your operational and financial goals. -

How do I vet suppliers for circular outlets in international markets?

Vetting suppliers for circular outlets involves several steps. Start by researching their reputation through online reviews and industry ratings. Request references from previous clients to gauge their reliability and product quality. Verify their compliance with international standards and regulations relevant to your market. Additionally, consider visiting their facilities if feasible, or utilize third-party inspection services to ensure they meet your quality expectations before finalizing any agreements. -

What payment terms should I expect when sourcing circular outlets?

Payment terms for sourcing circular outlets can vary widely among suppliers. Common terms include net 30, 60, or even 90 days, allowing businesses time to manage cash flow. Some suppliers may require a deposit upfront, typically ranging from 20% to 50%, with the balance due upon delivery or after inspection. Always clarify payment methods accepted, such as wire transfers, letters of credit, or online payment platforms, to avoid any misunderstandings. -

How do I ensure quality assurance (QA) for imported circular outlets?

To ensure quality assurance (QA) for imported circular outlets, establish clear specifications and standards with your supplier before production begins. Request samples for testing to verify that the outlets meet your quality expectations. Implement a robust inspection process, either through third-party services or by conducting on-site inspections prior to shipment. Additionally, consider including quality clauses in your contract that outline penalties for non-compliance, ensuring that your supplier is held accountable. -

What logistics considerations should I keep in mind when sourcing circular outlets internationally?

When sourcing circular outlets internationally, logistics considerations include shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with customs procedures in your country to avoid delays and additional costs. Work closely with your supplier to determine the most efficient shipping options and ensure that all necessary documentation is prepared to facilitate smooth customs clearance.

Top 4 Circular Outlet Manufacturers & Suppliers List

1. Kitchen Power Popups – Sillites In-Cabinet Outlets

Domain: kitchenpowerpopups.com

Registered: 2017 (8 years)

Introduction: Sillites In-Cabinet Outlets are the smallest round power sockets on the market, measuring only 2″ in diameter. Available colors include brown, white, and black, with a matching paintable cover that allows it to blend into the surface behind it. They are easy to install in any wood location that can accommodate a 1.75″ hole and require no junction box. Ideal for unique applications such as the side…

2. Reddit – Outdoor Electrical Box Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Round electrical box for outdoor outlet, adapter plates for outlet cover available, not standard practice but not explicitly forbidden by code.

3. Legrand – ROUND FPC USB Power Outlet

Domain: legrand.us

Registered: 2004 (21 years)

Introduction: {“name”: “ROUND FPC, 1 OUTLET, USB, BLACK COMBO USB-A AND USB-C”, “category”: “In-Surface Furniture Power”, “type”: “Furniture Power and Table Boxes”, “color”: “Black”, “outlets”: “1”, “usb_type”: [“USB-A”, “USB-C”]}

4. TopGreener – 4-Inch Round Weatherproof Outlet Box

Domain: topgreener.com

Registered: 2011 (14 years)

Introduction: {“name”: “4-Inch Diameter Round Weatherproof Outlet Box with Five 1/2-Inch Threaded Outlets”, “SKU”: “EN4575”, “price”: “$7.29”, “availability”: “In stock”, “dimensions”: {“height”: “5.4 inches”, “length”: “4.2 inches”, “depth”: “1.6 inches”}, “material”: “Die-cast metal”, “features”: [“Designed for two-gang switch or receptacle configuration in moisture-prone and outdoor locations”, “Includes fiv…

Strategic Sourcing Conclusion and Outlook for circular outlet

As businesses increasingly prioritize sustainability and efficiency, the strategic sourcing of circular outlets presents a unique opportunity to enhance operational capabilities while adhering to eco-friendly practices. These innovative power solutions, such as the compact in-cabinet and recessed floor outlets, not only facilitate seamless integration into existing infrastructures but also cater to diverse aesthetic preferences across various markets.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, the ability to source high-quality, versatile electrical outlets can lead to significant cost savings and improved project timelines. Leveraging suppliers that offer customizable options and comprehensive support can further streamline procurement processes, ensuring that installations meet specific operational needs without compromising on design or functionality.

Looking ahead, international buyers are encouraged to explore partnerships with manufacturers that prioritize sustainability and product innovation. By investing in circular outlet solutions, businesses can not only enhance their own operational efficiency but also contribute to a broader commitment to environmental stewardship. Embrace this opportunity to future-proof your projects and elevate your competitive edge in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to circular outlet

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.