Everything You Need to Know About Cow Milking Machine Sourcing in 2025

Introduction: Navigating the Global Market for cow milking machine

In the ever-evolving landscape of dairy farming, sourcing an efficient cow milking machine is a critical challenge for international B2B buyers. With the global demand for high-quality dairy products on the rise, selecting the right milking equipment can significantly impact productivity, hygiene, and overall profitability. This comprehensive guide aims to equip buyers from diverse regions—including Africa, South America, the Middle East, and Europe, with specific insights for markets like Saudi Arabia and Germany—by exploring various types of milking machines, their applications, and supplier vetting processes.

Navigating the myriad options available in the marketplace can be daunting, given the wide array of machines designed for different herd sizes and operational needs. This guide delves into essential factors such as cost considerations, capacity requirements, and maintenance needs, ensuring that buyers make informed decisions tailored to their specific operational contexts. Additionally, we will provide insights into the latest technological advancements in milking equipment and highlight the importance of hygiene and durability in maintaining livestock health.

By empowering B2B buyers with actionable insights and practical recommendations, this guide will facilitate smarter sourcing strategies for milking machines, ultimately leading to enhanced operational efficiency and increased profitability in the dairy sector.

Understanding cow milking machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Milking Machine | Lightweight, mobile design, suitable for small herds. | Small farms, organic producers, remote locations. | Pros: Easy to transport, flexible usage. Cons: Limited capacity for large operations. |

| Fixed Milking System | Stationary setup with dedicated milking stations. | Large-scale dairy farms, automated operations. | Pros: High efficiency, suitable for large herds. Cons: Higher initial investment, less flexibility. |

| Bucket Milker | Utilizes a bucket to collect milk, often portable. | Small to medium-sized dairy operations. | Pros: Affordable, easy to clean. Cons: Manual operation may be labor-intensive. |

| Automatic Milking System | Fully automated process, often integrated with herd management systems. | Large dairy operations, high-volume production. | Pros: Labor-saving, consistent milk quality. Cons: High cost, complex maintenance. |

| Vacuum Milking Machine | Uses vacuum technology for efficient milk extraction. | Various dairy farms, including specialty producers. | Pros: Effective milk extraction, reduces udder stress. Cons: Requires regular maintenance, potential noise issues. |

What Are the Key Characteristics of Portable Milking Machines?

Portable milking machines are designed for mobility, allowing farmers to milk cows in various locations. They are ideal for small farms or organic producers who may not have fixed milking stations. These machines typically have a lightweight construction and are easy to transport. When considering a portable milking machine, buyers should evaluate their herd size and the frequency of movement required, as these factors will influence the machine’s efficiency and practicality.

How Do Fixed Milking Systems Benefit Large-Scale Dairy Operations?

Fixed milking systems are designed for larger dairy farms where efficiency and throughput are critical. These systems consist of permanent milking stations that streamline the milking process, allowing multiple cows to be milked simultaneously. They are often integrated with automated processes for herd management. Buyers should consider the infrastructure of their farm and whether the initial investment aligns with their long-term production goals, as these systems can be costly but offer significant operational efficiencies.

What Are the Advantages of Using Bucket Milkers?

Bucket milkers are simple and effective devices commonly used in small to medium-sized dairy operations. They collect milk in a bucket and are often portable, making them suitable for farmers who may need to move them between locations. While they are generally more affordable than larger systems, buyers should be aware that they may require more manual labor and can be labor-intensive compared to automated solutions. Assessing the trade-off between cost and labor is essential for potential buyers.

Why Choose Automatic Milking Systems for High-Volume Production?

Automatic milking systems represent the pinnacle of milking technology, offering full automation that minimizes labor costs and maximizes consistency in milk quality. These systems are ideal for large dairy operations with high-volume production needs. They often integrate with herd management software, providing valuable data insights. However, the high initial investment and the complexity of maintenance are crucial considerations for buyers. Understanding the total cost of ownership will help in making informed purchasing decisions.

How Do Vacuum Milking Machines Enhance Efficiency?

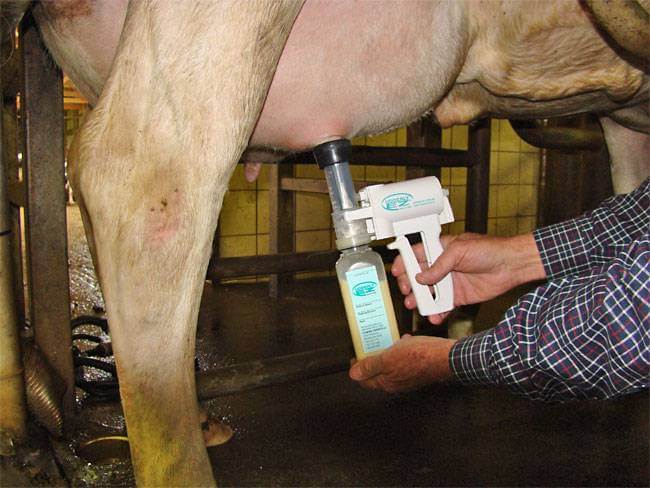

Vacuum milking machines leverage vacuum technology to extract milk efficiently while minimizing stress on the cow’s udder. They are versatile and can be used in various dairy farming contexts, including specialty operations. Buyers should consider the machine’s maintenance requirements and potential noise levels, as these factors can affect both the farm environment and the health of the livestock. Evaluating the balance between efficiency and operational comfort is critical when selecting vacuum milking equipment.

Key Industrial Applications of cow milking machine

| Industry/Sector | Specific Application of Cow Milking Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dairy Farming | Automated milking for large herds | Increases efficiency and reduces labor costs | Capacity, durability, and maintenance support |

| Livestock Cooperatives | Shared milking facilities for smallholder farmers | Enhances collective productivity and income | Portability, ease of use, and hygiene features |

| Organic Farming | Compliance with organic standards | Ensures high-quality milk with minimal environmental impact | Hygiene, material quality, and certification compliance |

| Agricultural Research | Research and development of milking techniques | Facilitates innovation in dairy practices | Customization options, data collection capabilities |

| Export Markets | Meeting international dairy standards | Expands market access and enhances competitiveness | Compliance with export regulations, quality assurance |

How Are Cow Milking Machines Used in Dairy Farming?

In large-scale dairy farming, cow milking machines are essential for automating the milking process, significantly enhancing efficiency. These machines allow farmers to milk multiple cows simultaneously, reducing labor costs and time spent on milking. For international buyers, especially from regions like Africa and South America, it is crucial to consider the machine’s capacity to handle their herd size and ensure durability for long-term use in varying climates.

What Role Do Cow Milking Machines Play in Livestock Cooperatives?

Livestock cooperatives often provide shared resources for smallholder farmers, and cow milking machines are central to this model. By using these machines collectively, farmers can improve their productivity and milk quality, leading to better income. Buyers from the Middle East and Africa should prioritize features like portability and ease of operation, as these factors can significantly affect their cooperative’s efficiency and success.

How Do Cow Milking Machines Support Organic Farming?

In organic farming, cow milking machines help maintain compliance with strict organic standards. These machines ensure hygienic milking processes that preserve milk quality and safety. Buyers in Europe, particularly Germany, should focus on machines that offer high hygiene standards, made from organic-certified materials, and easy cleaning mechanisms to align with their operational requirements and market expectations.

Why Are Cow Milking Machines Important for Agricultural Research?

Agricultural research institutions utilize cow milking machines to study and develop innovative milking techniques and improve dairy practices. These machines facilitate controlled environments for data collection and experimentation. Buyers in this sector should look for customizable options that allow for modifications based on research needs, as well as machines equipped with data collection capabilities to enhance their research effectiveness.

How Do Cow Milking Machines Help in Export Markets?

For businesses aiming to enter export markets, cow milking machines play a critical role in meeting international dairy standards. These machines help ensure that the milk produced adheres to quality regulations necessary for export. Buyers should consider compliance with export regulations, the quality of materials used, and the machine’s reliability to ensure that their products can compete effectively in global markets.

3 Common User Pain Points for ‘cow milking machine’ & Their Solutions

Scenario 1: Inconsistent Milk Yield Due to Machine Inefficiency

The Problem: Many B2B buyers, particularly in regions like Africa and South America, encounter challenges with the efficiency of their cow milking machines. An inefficient machine can lead to inconsistent milk yield, which directly affects profitability. Buyers often struggle with understanding the specifications of the machines, leading to a mismatch between their herd’s needs and the equipment’s capabilities. For instance, if a milking machine cannot accommodate the volume produced by a larger herd or is not designed for the specific breed of cows, it can result in reduced output and increased stress on both the cows and the operators.

The Solution: To address these challenges, buyers should conduct a thorough assessment of their herd’s size, breed, and average milk production before selecting a milking machine. It is crucial to opt for machines that have adjustable settings to cater to different sizes and capacities. Buyers should also consider investing in machines that feature advanced technology, such as variable speed controls and optimized pulsation rates, which are designed to maximize milk extraction without compromising animal comfort. Furthermore, establishing a relationship with reputable suppliers who can provide detailed product specifications and customer support is essential for making informed decisions that align with production goals.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Maintenance issues are a common concern for B2B buyers of cow milking machines, especially in regions with limited access to spare parts and technical support. Frequent breakdowns can lead to significant downtime, affecting overall milk production and incurring high repair costs. Buyers often find themselves in a cycle of reactive maintenance, leading to frustration and financial strain. This is particularly evident in emerging markets where the infrastructure for timely repairs is lacking.

The Solution: To mitigate high maintenance costs, buyers should prioritize the purchase of machines known for their reliability and durability. Investing in milking systems with low maintenance requirements and readily available spare parts can significantly reduce downtime. Buyers should also explore machines that come with comprehensive maintenance kits and easy-to-follow service manuals. Establishing a proactive maintenance schedule, including regular inspections and cleaning, can further enhance the longevity of the equipment. Lastly, forming partnerships with local service providers or training in-house technicians can ensure quicker responses to maintenance issues, minimizing the impact on operations.

Scenario 3: Hygiene and Milk Quality Concerns

The Problem: Ensuring hygiene during the milking process is a critical concern for B2B buyers, as it directly impacts milk quality and safety. In regions where regulations are stringent, such as Europe and the Middle East, maintaining high hygiene standards is not just a matter of quality but also compliance. Buyers often struggle with machines that do not facilitate easy cleaning or that lack features to minimize contamination, leading to potential financial penalties and loss of customer trust.

The Solution: Buyers should seek out milking machines specifically designed with hygiene in mind. Features such as automated cleaning cycles, smooth internal surfaces to reduce bacterial buildup, and materials that are easy to sanitize can significantly improve hygiene practices. It is also beneficial to invest in training for staff on best practices for hygiene during milking and maintenance. Regular audits of the cleaning procedures and equipment can help identify areas for improvement. Additionally, maintaining a close relationship with suppliers who can provide ongoing training and resources on hygiene standards will ensure that operations remain compliant and that milk quality is consistently high.

Strategic Material Selection Guide for cow milking machine

What Are the Key Materials Used in Cow Milking Machines?

When selecting materials for cow milking machines, it is crucial to evaluate their properties and suitability for specific applications. The choice of material can significantly impact performance, durability, and compliance with international standards. Below are analyses of four common materials used in the construction of cow milking machines.

How Does Stainless Steel Perform in Cow Milking Machines?

Stainless steel is a popular choice for cow milking machines due to its excellent corrosion resistance and hygienic properties. It can withstand high temperatures and pressures, making it suitable for both cleaning and operational processes. The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements.

Pros: High resistance to corrosion, easy to clean, and durable.

Cons: Higher initial cost and potential for scratches if not properly maintained.

Impact on Application: Stainless steel is compatible with various cleaning agents and can handle the temperature and pressure requirements of milking processes.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets standards such as ASTM A240 or DIN 1.4301, particularly in regions like Europe where compliance is critical.

What Role Does Plastic Play in Cow Milking Machines?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are often used for components such as milk containers and tubing. These plastics are lightweight, resistant to impact, and provide good chemical resistance, making them suitable for milking applications.

Pros: Cost-effective, lightweight, and resistant to various chemicals.

Cons: Lower durability compared to metals and may degrade over time under UV exposure.

Impact on Application: Plastic components are generally suitable for lower-pressure applications and are often used in portable milking machines.

Considerations for International Buyers: Ensure compliance with food safety standards, such as FDA regulations in the U.S. or EU food contact regulations in Europe.

Why Is Rubber Important in Cow Milking Machines?

Rubber, particularly food-grade silicone and natural rubber, is commonly used for liners and seals in milking machines. Rubber materials are flexible and provide excellent sealing properties, which are essential for maintaining vacuum pressure during milking.

Pros: Good elasticity, excellent sealing capabilities, and relatively low cost.

Cons: Limited lifespan compared to metals and may require regular replacements.

Impact on Application: Rubber components must be compatible with milk and cleaning agents to prevent contamination.

Considerations for International Buyers: Buyers should look for rubber materials that comply with international standards such as FDA or EU regulations to ensure food safety.

How Does Aluminum Compare in Cow Milking Machines?

Aluminum is another material used in some cow milking machines, particularly for components that require lightweight yet durable materials. It offers good corrosion resistance and can be easily shaped into various forms.

Pros: Lightweight, good corrosion resistance, and lower cost compared to stainless steel.

Cons: Less durable than stainless steel and may not withstand high temperatures as effectively.

Impact on Application: Aluminum is suitable for components that do not require high-pressure handling.

Considerations for International Buyers: Ensure that aluminum components meet relevant standards like ASTM B221 or EN 573 for quality assurance.

Summary of Material Selection for Cow Milking Machines

| Material | Typical Use Case for cow milking machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Milk containers, pipelines, and frames | Excellent corrosion resistance and hygiene | Higher initial cost | High |

| Plastic | Milk containers and tubing | Lightweight and cost-effective | Lower durability under UV exposure | Low |

| Rubber | Liners and seals | Good sealing capabilities | Limited lifespan | Med |

| Aluminum | Lightweight components | Lightweight and good corrosion resistance | Less durable than stainless steel | Med |

This table encapsulates the essential insights into material selection for cow milking machines, guiding international B2B buyers in making informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cow milking machine

What Are the Key Stages in the Manufacturing Process of Cow Milking Machines?

The manufacturing of cow milking machines involves several critical stages, each essential for producing high-quality equipment that meets the demands of modern dairy farming. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-grade materials, including stainless steel, plastic, and rubber components. Stainless steel is often preferred due to its corrosion resistance and ease of cleaning, which are vital for maintaining hygiene in dairy operations. Suppliers should ensure that materials comply with international food safety standards.

-

Forming: During this phase, raw materials are shaped into components using various techniques such as stamping, molding, or machining. For instance, stainless steel parts may be welded or bent to create the necessary shapes for milking buckets and pipelines. Precision in this stage is crucial as it directly impacts the durability and performance of the milking machine.

-

Assembly: Once the components are formed, they are assembled into complete units. This process may involve integrating mechanical parts such as motors, pumps, and electronic controls. Skilled technicians often perform this assembly to ensure that all components fit correctly and function seamlessly together. Automated assembly lines may also be utilized for higher efficiency and consistency.

-

Finishing: The final stage includes surface treatments, such as polishing, painting, or applying anti-corrosive coatings. This not only enhances the aesthetic appeal of the machines but also provides additional protection against wear and tear. Quality checks are performed throughout this stage to ensure that all finishing meets the required standards.

How Is Quality Assurance Implemented in Cow Milking Machine Manufacturing?

Quality assurance (QA) in the manufacturing of cow milking machines is critical to ensure reliability, safety, and performance. This process involves adhering to international standards such as ISO 9001, as well as industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute).

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they are used in production. Suppliers should provide certificates of conformity to ensure that materials meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from quality standards are identified and corrected promptly. This may involve regular inspections and tests of components as they are produced.

– Final Quality Control (FQC): After assembly, each unit undergoes comprehensive testing to ensure it meets performance specifications. This includes functionality tests, safety checks, and hygiene inspections. -

Common Testing Methods for Cow Milking Machines: Various testing methods are employed to ensure the quality of milking machines. These may include:

– Pressure Testing: To verify that the vacuum systems operate correctly and do not leak.

– Performance Testing: To ensure that the machine can handle the expected milking volume without compromising efficiency.

– Durability Testing: Simulating extended use to ensure the machine can withstand the rigors of daily operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, it is crucial to verify the quality control practices of potential suppliers. Here are actionable steps to consider:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the operational standards and quality control measures in place. Buyers should request access to the supplier’s quality management system documentation and audit results.

-

Review Quality Assurance Reports: Suppliers should provide detailed reports on their quality assurance processes, including any certifications obtained and results from quality checks and tests. This transparency helps buyers assess the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These inspectors can conduct on-site evaluations and testing to ensure compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when it comes to quality control, particularly in diverse markets like Africa and the Middle East. Understanding these nuances can help in making informed purchasing decisions.

-

Compliance with Local Regulations: Different regions may have specific regulations governing the safety and quality of milking equipment. Buyers must ensure that suppliers are compliant with local standards, which may vary significantly from those in Europe or North America.

-

Understanding Certification Requirements: Certifications such as CE and ISO 9001 may be recognized globally, but buyers should also familiarize themselves with regional certifications that might be necessary for market entry. This is especially pertinent for buyers in Africa and South America, where local regulations may impose additional requirements.

-

Cultural and Economic Factors: The economic landscape and cultural practices in regions such as the Middle East and Africa can influence supply chain dynamics. Buyers should consider these factors when establishing relationships with suppliers, as they can impact lead times, reliability, and overall quality.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance measures for cow milking machines is essential for B2B buyers aiming to make informed purchasing decisions. By understanding the key stages of manufacturing, recognizing the importance of quality control, and verifying supplier practices, buyers can ensure they invest in reliable and efficient milking solutions that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cow milking machine’

To assist B2B buyers in sourcing cow milking machines effectively, this guide provides a practical checklist that outlines essential steps for a successful procurement process. By following these steps, buyers can ensure that they select a machine that meets their operational needs and enhances their productivity.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the milking machine. Consider factors such as the size of your herd, the type of milking system (portable vs. fixed), and the desired milking capacity. This step is crucial as it will guide your selection process and help you avoid purchasing a machine that does not meet your operational demands.

Step 2: Research Supplier Reputation

Investigate potential suppliers to gauge their reliability and quality of products. Look for reviews, ratings, and testimonials from other businesses, especially those in similar markets. A reputable supplier often has a track record of delivering high-quality equipment and excellent customer service.

- Check Industry Certifications: Ensure that suppliers have necessary certifications, which often indicate adherence to industry standards for safety and quality.

- Ask for References: Request references from other clients who have purchased similar machines to understand their experiences.

Step 3: Evaluate Machine Features and Benefits

Assess the specific features of the milking machines you are considering. Look for innovations that enhance efficiency, such as automated cleaning cycles, low noise levels, and durable materials.

- Hygiene Features: Prioritize machines designed with hygiene in mind to ensure safe milk production.

- Ease of Use: Consider machines that are user-friendly to minimize training time for your staff.

Step 4: Assess Maintenance and Spare Parts Availability

Understand the maintenance requirements of the machines and the availability of spare parts. A machine that is easy to maintain will reduce downtime and operational costs.

- Maintenance Kits: Ensure that the supplier offers maintenance kits and support services.

- Spare Parts: Verify that spare parts are readily available to avoid long wait times during repairs.

Step 5: Compare Pricing and Financing Options

Gather pricing information from multiple suppliers to compare costs. Look for machines that fit within your budget while also meeting your specifications.

- Consider Total Cost of Ownership: Evaluate not just the purchase price but also the long-term costs associated with maintenance, energy consumption, and potential repairs.

- Explore Financing Options: Some suppliers may offer financing or leasing options that can ease the initial investment burden.

Step 6: Negotiate Terms and Conditions

Before finalizing your purchase, negotiate the terms of the sale, including warranties, return policies, and delivery timelines.

- Warranty Coverage: Understand what is covered under warranty and for how long.

- Delivery and Setup: Confirm delivery timelines and whether the supplier provides installation services.

Step 7: Finalize Your Purchase and Train Staff

Once you’ve selected a machine and negotiated terms, finalize the purchase. Arrange for staff training on the new equipment to ensure smooth operations from the start.

- Training Programs: Check if the supplier offers training sessions or materials to help your team effectively use the machine.

- Feedback Mechanism: Establish a feedback loop to address any issues that arise during initial use, ensuring continuous improvement in operations.

By following this structured checklist, B2B buyers can make informed decisions when sourcing cow milking machines, ultimately leading to enhanced productivity and operational efficiency.

Comprehensive Cost and Pricing Analysis for cow milking machine Sourcing

What Are the Key Cost Components in Sourcing Cow Milking Machines?

When evaluating the cost structure of cow milking machines, several core components must be taken into account. The main cost components include:

-

Materials: The choice of materials significantly affects costs. High-quality stainless steel or durable plastics are common, but prices can vary. Materials must meet hygiene and durability standards, particularly in regions with stringent food safety regulations.

-

Labor: Labor costs can fluctuate based on the region of manufacture. For instance, sourcing from countries with lower labor costs may reduce overall expenses, but this can compromise quality or lead to longer lead times.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs, which is crucial for competitive pricing.

-

Tooling: Investment in specialized tooling can be a significant initial expense, particularly for custom machines. This cost must be amortized over production volume to maintain profitability.

-

Quality Control (QC): Ensuring that products meet specified standards incurs costs related to testing and inspection. High-quality standards may lead to higher upfront costs but can reduce long-term warranty claims and maintenance expenses.

-

Logistics: Shipping costs can vary significantly based on destination and method. International shipping may involve customs duties and tariffs, which need to be factored into the total cost.

-

Margin: Supplier profit margins can vary widely. Understanding the market landscape helps buyers negotiate better pricing by identifying suppliers with more competitive margins.

How Do Price Influencers Affect the Cost of Cow Milking Machines?

Several factors influence the pricing of cow milking machines, making it essential for buyers to consider these when sourcing:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower unit costs. Suppliers are more willing to negotiate favorable terms for larger orders, making it crucial to assess your operational needs and purchasing power.

-

Specifications and Customization: Customized machines tailored to specific operational requirements can incur additional costs. It’s important to balance customization needs with budget constraints.

-

Materials and Quality Certifications: Machines made from premium materials or those that meet specific quality certifications (like ISO or HACCP) can command higher prices. Buyers should assess the necessity of these certifications based on their market requirements.

-

Supplier Factors: Supplier reputation, reliability, and after-sales service can influence pricing. Established suppliers may charge a premium for their expertise and support.

-

Incoterms: The agreed terms of shipping can significantly impact costs. Understanding Incoterms can help buyers evaluate responsibilities for shipping, insurance, and customs clearance, thereby affecting the total cost.

What Buyer Tips Can Help Optimize Costs and Improve Value in Cow Milking Machine Purchases?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost efficiency:

-

Negotiate Wisely: Engage suppliers in negotiations to secure better pricing or added value, such as extended warranties or maintenance packages. Building a good relationship can lead to more favorable terms in the long run.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, repairs, and operational efficiency. A slightly higher initial investment in a more durable machine can lead to lower overall costs.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import tariffs, and local regulations can affect pricing. It’s crucial to factor these into your budget to avoid unforeseen expenses.

-

Research and Compare: Use industry benchmarks and supplier reviews to gauge fair pricing. Comparing multiple suppliers can reveal discrepancies and help justify your purchasing decision.

-

Plan for Spare Parts Availability: Machines with readily available spare parts can reduce downtime and maintenance costs. Ensure the supplier has a reliable supply chain for essential components.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and consult suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing cow milking machine With Other Solutions

When evaluating the most effective solutions for milking cows, it’s essential to consider various alternatives to traditional cow milking machines. Each method presents its own set of advantages and challenges, making it crucial for B2B buyers to understand their options thoroughly. Below, we explore the differences between cow milking machines and two viable alternatives: manual milking and robotic milking systems.

| Comparison Aspect | Cow Milking Machine | Manual Milking | Robotic Milking System |

|---|---|---|---|

| Performance | High efficiency, can milk multiple cows simultaneously | Labor-intensive, slower process | Highly automated, consistent performance |

| Cost | Moderate to high initial investment; lower operational costs | Low initial cost; high labor costs | High initial investment; lower labor costs |

| Ease of Implementation | Requires some training; installation needed | Minimal training required | Requires significant setup and training |

| Maintenance | Regular maintenance needed; parts availability varies | Minimal maintenance; depends on the worker | High maintenance; specialized parts required |

| Best Use Case | Dairy farms with medium to large herds | Small farms or artisan dairies | Large-scale operations seeking efficiency |

What Are the Pros and Cons of Manual Milking as an Alternative?

Manual milking is a traditional method that involves hand-milking the cows. This approach is particularly beneficial for small farms or artisanal operations where the number of cows is limited. The primary advantage of manual milking is its low initial cost and minimal equipment needs. However, it is labor-intensive and can be time-consuming, which may limit scalability. Additionally, maintaining consistent hygiene standards can be challenging without proper training and practices.

How Does Robotic Milking System Compare to Cow Milking Machines?

Robotic milking systems represent the latest innovation in dairy farming, offering a fully automated solution for milking cows. These systems can milk cows at any time, allowing for more flexibility in managing herd health and milk production. While robotic systems provide consistent performance and can significantly reduce labor costs in the long run, they require a substantial initial investment and can be complex to implement. Maintenance can also be demanding, requiring specialized knowledge and parts, which may not be readily available in all regions.

Conclusion: How Should B2B Buyers Choose the Right Milking Solution?

When selecting the most suitable milking solution, B2B buyers should consider their specific operational needs, budget, and herd size. For smaller operations or those prioritizing low costs, manual milking may still be a viable option. Conversely, for larger dairy farms seeking efficiency and scalability, cow milking machines or robotic systems offer significant advantages. Ultimately, the decision should be based on a careful assessment of performance requirements, long-term operational costs, and the ability to maintain the chosen system effectively. By aligning these factors with their business objectives, buyers can make informed decisions that enhance productivity and profitability in their milking operations.

Essential Technical Properties and Trade Terminology for cow milking machine

What Are the Essential Technical Properties of Cow Milking Machines?

When evaluating cow milking machines for commercial use, understanding critical technical properties is paramount. These specifications not only impact the efficiency and effectiveness of the milking process but also influence operational costs and compliance with safety standards.

1. Material Grade: Why Is It Important?

The material used in the construction of milking machines, typically stainless steel or food-grade plastics, is crucial for durability and hygiene. Stainless steel is preferred due to its resistance to corrosion and ease of cleaning, which helps maintain milk quality and complies with health regulations. For B2B buyers, selecting machines made from high-grade materials can lead to long-term savings by reducing maintenance and replacement costs.

2. Milking Capacity: How Does It Affect Operations?

Milking capacity refers to the volume of milk a machine can process within a specific timeframe. Machines can range from single-cow models to larger systems capable of handling multiple cows simultaneously. Understanding your operational needs will help in selecting a machine that can efficiently meet production goals without causing bottlenecks. This is particularly important for larger farms aiming to maximize productivity.

3. Vacuum Pressure: What Role Does It Play?

Vacuum pressure is a vital specification that affects the efficiency of milk extraction. It is typically measured in inches of mercury (inHg) and should be adjustable to cater to different cow breeds and milking conditions. Proper vacuum levels ensure effective milking while minimizing discomfort for the cows. For B2B buyers, a machine with adjustable vacuum settings offers flexibility and adaptability to various operational scenarios.

4. Noise Level: Why Consider It?

Noise levels in milking machines can significantly impact the working environment for both operators and animals. Machines designed with noise-reduction features not only create a more pleasant milking experience but also help in maintaining animal welfare. Selecting quieter machines can lead to increased worker satisfaction and better cow comfort, which are essential for sustained productivity.

5. Hygiene Features: How Do They Enhance Safety?

Hygiene is a critical concern in the dairy industry. Milking machines equipped with automated cleaning systems or features that minimize bacterial growth play a significant role in ensuring food safety. For B2B buyers, investing in machines with advanced hygiene features can prevent costly contamination issues and enhance product quality, thereby complying with health standards.

What Are Common Trade Terminology and Jargon Related to Cow Milking Machines?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Understanding these terms can help buyers make informed decisions.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the milking machine industry, purchasing from an OEM ensures that buyers receive high-quality, compatible components, which can lead to improved machine reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when negotiating bulk purchases of milking machines or replacement parts, as it can significantly impact inventory management and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process, allowing for side-by-side comparisons of pricing, specifications, and delivery timelines from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is vital for B2B transactions, as they clarify who bears the risk and costs during transport, influencing pricing and logistics planning.

5. Tolerance Levels: What Do They Mean?

Tolerance levels refer to the permissible limits of variation in a product’s dimensions or performance. In milking machines, tighter tolerances can lead to better performance and reliability. B2B buyers should pay attention to these specifications to ensure that they meet operational standards and reduce the risk of equipment failure.

By understanding these technical properties and industry terms, B2B buyers can make more informed purchasing decisions, optimizing their operations and ensuring compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the cow milking machine Sector

What Are the Key Trends Influencing the Cow Milking Machine Market?

The cow milking machine market is experiencing significant transformation driven by technological advancements, changing consumer preferences, and evolving agricultural practices. Globally, the demand for efficient and hygienic milking solutions is on the rise. This is particularly true in regions such as Africa and South America, where dairy farming is expanding rapidly to meet growing domestic and international markets. In Europe and the Middle East, there is a strong emphasis on automation and precision farming, which is prompting the adoption of advanced milking systems that integrate IoT technology for real-time monitoring and data analytics.

Emerging trends include the shift towards portable milking machines, which offer flexibility and ease of use for smaller farms. Additionally, manufacturers are focusing on creating machines that are not only efficient but also environmentally friendly, utilizing sustainable materials and energy-efficient technologies. As international B2B buyers navigate these market dynamics, it’s essential to consider factors such as machine capacity, durability, and maintenance requirements. Buyers are increasingly seeking machines that offer a good balance between cost-effectiveness and advanced features, ensuring they can scale operations without compromising on quality.

How Is Sustainability Shaping the Cow Milking Machine Supply Chain?

Sustainability and ethical sourcing are becoming critical considerations for international B2B buyers in the cow milking machine sector. The environmental impact of dairy farming, particularly in terms of greenhouse gas emissions and resource consumption, is prompting a shift towards greener practices. This includes sourcing machines made from recyclable materials and those that minimize water and energy use during operation.

Ethical supply chains are gaining importance as buyers seek to partner with manufacturers who prioritize sustainable practices. Certifications such as ISO 14001 for environmental management systems and adherence to sustainable development goals (SDGs) are valuable indicators of a company’s commitment to reducing its ecological footprint. Moreover, transparency in the supply chain is essential, allowing buyers to verify the sustainability claims of their suppliers. As the market evolves, embracing sustainability not only enhances brand reputation but also aligns with consumer demands for ethically produced dairy products.

What Is the Historical Context of Cow Milking Machines in the B2B Sector?

The evolution of cow milking machines dates back to the late 19th century when the first mechanical milking devices were introduced. Initially, these machines aimed to reduce the labor intensity of milking, which was predominantly a manual process. Over the decades, advancements in technology have led to significant improvements in efficiency and hygiene, with the introduction of vacuum systems and automated milking parlors.

Today, the focus has shifted towards enhancing milk quality and animal welfare, with modern machines designed to be less stressful for cows while maximizing yield. This historical context is crucial for B2B buyers as it illustrates the continuous innovation within the industry, highlighting the importance of investing in cutting-edge technology to remain competitive in a rapidly changing market. Understanding this evolution helps buyers appreciate the value of modern milking machines and their role in promoting sustainable dairy farming practices.

Frequently Asked Questions (FAQs) for B2B Buyers of cow milking machine

-

How do I choose the right cow milking machine for my farm?

Selecting the appropriate cow milking machine involves evaluating several factors such as herd size, milking capacity, and available infrastructure. For smaller operations, a portable milking machine may suffice, while larger farms might benefit from fixed systems designed for higher volumes. Additionally, consider hygiene features, durability, and ease of maintenance. Assessing your specific needs against the machine’s capabilities will ensure you make an informed choice that enhances efficiency and productivity. -

What are the key features to look for in a cow milking machine?

When sourcing a cow milking machine, prioritize features like hygiene design, capacity, and noise levels. Machines that include automated cleaning cycles enhance hygiene, while those with higher capacities can process more milk simultaneously, increasing efficiency. Also, look for durable materials that ensure longevity and consider noise-reducing features for a more peaceful milking environment. Brands with a solid reputation for quality and service support should be favored to ensure reliability. -

What payment terms should I expect when purchasing cow milking machines?

Payment terms can vary significantly between suppliers and regions. Common arrangements include upfront payment, partial deposits, or payment upon delivery. For international transactions, it’s crucial to discuss currency exchange rates and payment methods, such as bank transfers or letters of credit. Establishing clear payment terms in advance can prevent misunderstandings and facilitate smoother transactions, especially when dealing with suppliers from different countries. -

How do I vet suppliers of cow milking machines?

To vet suppliers effectively, research their reputation through online reviews and industry references. Request information about their manufacturing processes, certifications, and warranty policies. Engaging with previous customers can provide insights into the supplier’s reliability and product quality. Additionally, consider suppliers who offer ongoing support, spare parts availability, and training for machine operation, as these factors contribute to long-term satisfaction. -

What is the minimum order quantity (MOQ) for cow milking machines?

Minimum order quantities (MOQs) can differ based on the supplier and the type of machine. Some suppliers may have MOQs for bulk purchases to ensure cost-effectiveness, while others may allow single-unit purchases for smaller operations. It’s essential to clarify MOQs before placing an order, particularly for international buyers, as this may affect shipping costs and logistics planning. -

How can I ensure the quality of the cow milking machines I purchase?

To ensure quality, seek suppliers that adhere to international quality standards and certifications, such as ISO or CE marking. Request product samples or demonstrations before committing to a purchase. Additionally, inquire about the quality control processes in place at the manufacturing facility. Establishing a clear understanding of warranties and after-sales support can also safeguard against potential quality issues. -

What logistical considerations should I keep in mind when importing cow milking machines?

When importing cow milking machines, consider shipping methods, customs regulations, and potential tariffs. Ensure that your supplier provides necessary documentation, such as bills of lading and certificates of origin. Work with a reliable freight forwarder who can navigate international shipping complexities, and plan for delivery timelines to avoid disruptions. Understanding local import regulations in your country is crucial to ensure compliance and timely delivery. -

Can I customize the cow milking machine to fit my specific needs?

Many suppliers offer customization options for cow milking machines, allowing you to tailor features such as size, capacity, and additional functionalities. When negotiating with suppliers, clearly articulate your requirements and assess their willingness to accommodate your needs. Customization may involve additional costs and longer lead times, so be prepared to discuss these aspects during your procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Cow Milking Machine Manufacturers & Suppliers List

1. Homestead Supplier – Ultimate EZ Bucket Milker

Domain: homesteadsupplier.com

Registered: 2017 (8 years)

Introduction: Ultimate EZ Bucket Milker: Original price $899.00, current price $747.00. Features speed, comfort, and simplicity.

Udderly EZ Portable Cow Milking Machine: Original price $241.79, current price $189.95. Designed for easy and safe milking of cows.

Ultimate EZ Bottle Milker: Original price $799.00, current price $598.00. A vacuum milking solution for backyard farmers.

Udderly EZ Portable Goat …

2. Shenandoah Homestead Supply – Milkers & Pasturizers

Domain: shenandoahhomesteadsupply.com

Registered: 2011 (14 years)

Introduction: Collection: Milkers & Pasturizers

Availability: 12 products in stock, 2 products out of stock

Price Range: From $ to $1,599.97

Sort Options: Featured, Best selling, Alphabetically (A-Z), Alphabetically (Z-A), Price (low to high), Price (high to low), Date (old to new), Date (new to old

3. Family Cow – Top Milking Equipment

Domain: familycow.proboards.com

Registered: 1999 (26 years)

Introduction: 1. Hamby Improved Milker: Recommended for its easy cleaning and large bucket capacity. Price increased by $100 over two years.

2. Surge Belly Milker: Praised for its simplicity and ease of cleaning.

3. Nupulse Stainless Pump: Preferred for its design that keeps inflations clean and easy to scrub.

4. DeLaval Bucket Milker: Valued for its quiet operation and silicone inflations/hose.

5. Heavy-du…

4. Whirler – Milking Machines

Domain: dir.indiamart.com

Registered: 1996 (29 years)

Introduction: This company, Whirler – Milking Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. AHDB – Milking Machine Essentials

Domain: ahdb.org.uk

Registered: 2007 (18 years)

Introduction: The milking machine is the most important equipment on a dairy farm, harvesting all the milk sold. It comes into direct contact with cows’ udders daily, posing a risk for spreading mastitis-causing bacteria and potentially damaging blood vessels in the udder, leading to hyperkeratosis at the teat end. Regular maintenance is critical: minor service every 750 operating hours and significant service …

Strategic Sourcing Conclusion and Outlook for cow milking machine

In the evolving landscape of dairy farming, strategic sourcing of cow milking machines is paramount for enhancing operational efficiency and product quality. By focusing on key factors such as hygiene, capacity, durability, and spare parts availability, international B2B buyers can make informed decisions that align with their unique needs. The right milking machine not only optimizes the milking process but also significantly contributes to the overall health of livestock and the safety of milk production.

As the demand for high-quality dairy products continues to rise in regions like Africa, South America, the Middle East, and Europe, investing in advanced milking technologies becomes a competitive advantage. Buyers should prioritize reputable brands with proven track records to ensure reliability and performance. Additionally, exploring both portable and fixed systems can provide flexibility tailored to specific farm infrastructures.

Looking ahead, the integration of innovative milking solutions will further transform dairy farming practices. We encourage buyers to leverage this opportunity to enhance their operations and ensure they remain at the forefront of the dairy industry. Engage with suppliers today to explore the best options for your business and secure a sustainable, productive future in dairy farming.