The Definitive Guide to Dc To Dc Regulated Power Supply: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for dc to dc regulated power supply

Navigating the complexities of sourcing a DC to DC regulated power supply can present significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With diverse applications ranging from telecommunications to renewable energy systems, the need for reliable and efficient power solutions is paramount. Buyers often grapple with ensuring compatibility, efficiency, and regulatory compliance while seeking the best value for their investments.

This comprehensive guide addresses these challenges by providing a thorough exploration of the various types of DC to DC regulated power supplies available in the market. We delve into key applications, performance metrics, and essential features to consider, such as voltage stability and efficiency ratings. Additionally, we outline effective supplier vetting strategies to help you identify reputable manufacturers and distributors, ensuring that your sourcing decisions are informed and strategic.

Moreover, we discuss cost factors, including upfront investments and long-term operational savings, empowering you to make sound financial choices. By leveraging this guide, B2B buyers will gain the insights needed to navigate the global market confidently, ensuring they select the most suitable power supply solutions tailored to their specific operational needs. Whether you are based in Saudi Arabia, Brazil, or elsewhere, this resource will equip you with the knowledge to enhance your purchasing strategy and optimize your power supply systems.

Understanding dc to dc regulated power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear DC-DC Regulators | Simple design, low noise, and stable output voltage | Audio equipment, medical devices, and precision instruments | Pros: Low noise, high precision. Cons: Less efficient, larger size. |

| Switching DC-DC Converters | High efficiency, compact size, and versatile output | Telecom, automotive, and industrial applications | Pros: High efficiency, lightweight. Cons: More complex, can introduce noise. |

| Isolated DC-DC Converters | Electrical isolation between input and output | Renewable energy systems, data centers | Pros: Safety in sensitive applications. Cons: Generally higher cost. |

| Modular DC-DC Power Supplies | Flexible configurations, easily scalable | Industrial automation, robotics | Pros: Customizable, easy to expand. Cons: Potentially higher initial investment. |

| Buck and Boost Converters | Step-down (buck) or step-up (boost) voltage capabilities | Battery management systems, electric vehicles | Pros: Versatile voltage management. Cons: Complexity in design and implementation. |

What Are the Characteristics and Suitability of Linear DC-DC Regulators?

Linear DC-DC regulators are known for their straightforward design and low output noise, making them ideal for applications requiring high precision, such as audio equipment and medical devices. They provide a stable output voltage but are less efficient than other types, particularly in high-power applications. Buyers should consider the trade-off between noise levels and efficiency when selecting linear regulators, especially in environments where power conservation is critical.

How Do Switching DC-DC Converters Stand Out in Performance?

Switching DC-DC converters are characterized by their high efficiency and compact size, making them suitable for a wide range of applications, including telecommunications and automotive systems. They convert voltage levels with minimal power loss and can handle varying input voltages effectively. However, their complexity can introduce electromagnetic interference, which buyers need to mitigate in sensitive applications. Understanding the specific requirements of the project will aid in selecting the right converter.

Why Are Isolated DC-DC Converters Important for Safety?

Isolated DC-DC converters provide electrical isolation between the input and output, enhancing safety in applications like renewable energy systems and data centers. This feature protects sensitive equipment from voltage spikes and ground loops. While they tend to be more expensive than non-isolated options, the added safety and reliability make them a worthwhile investment for critical systems where downtime can be costly.

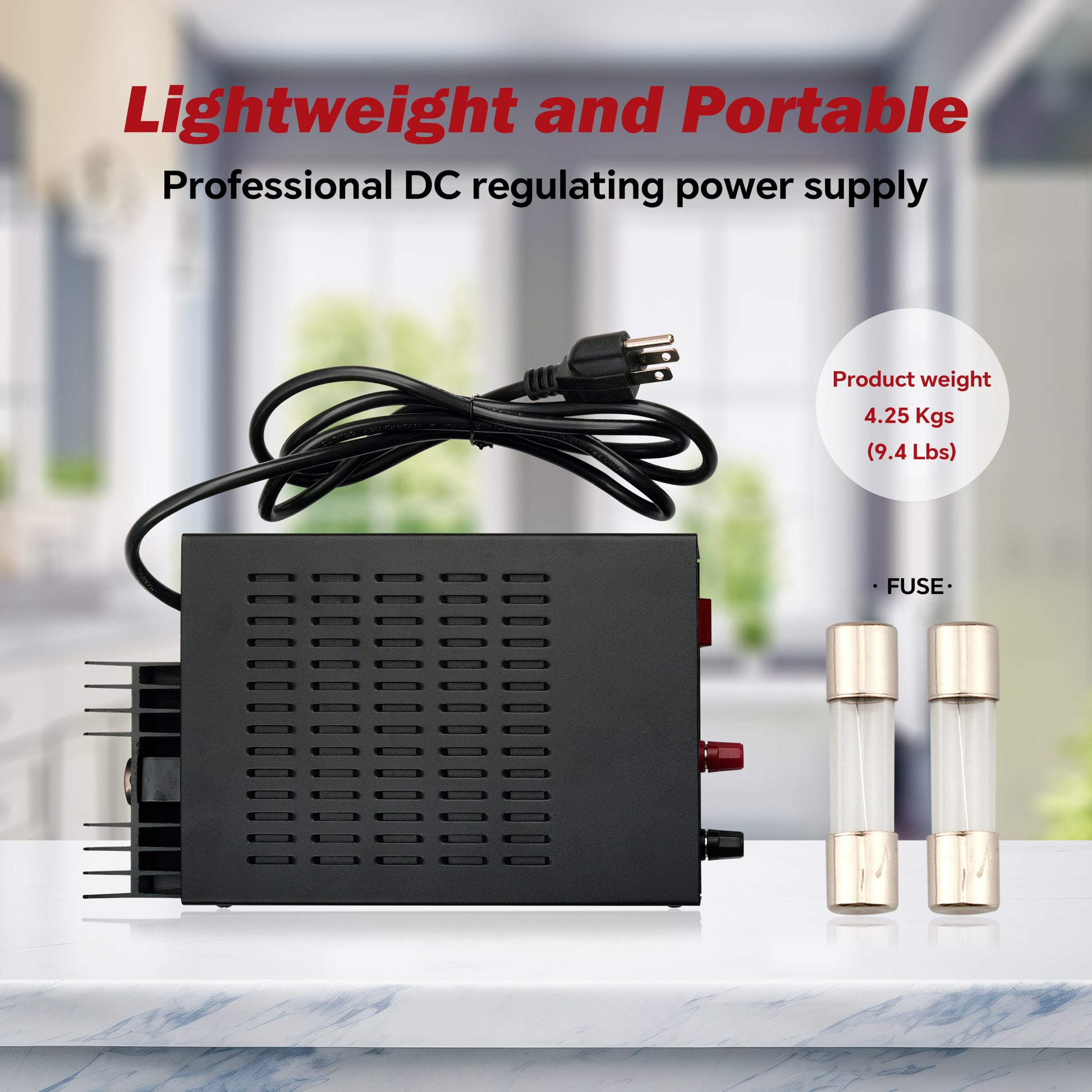

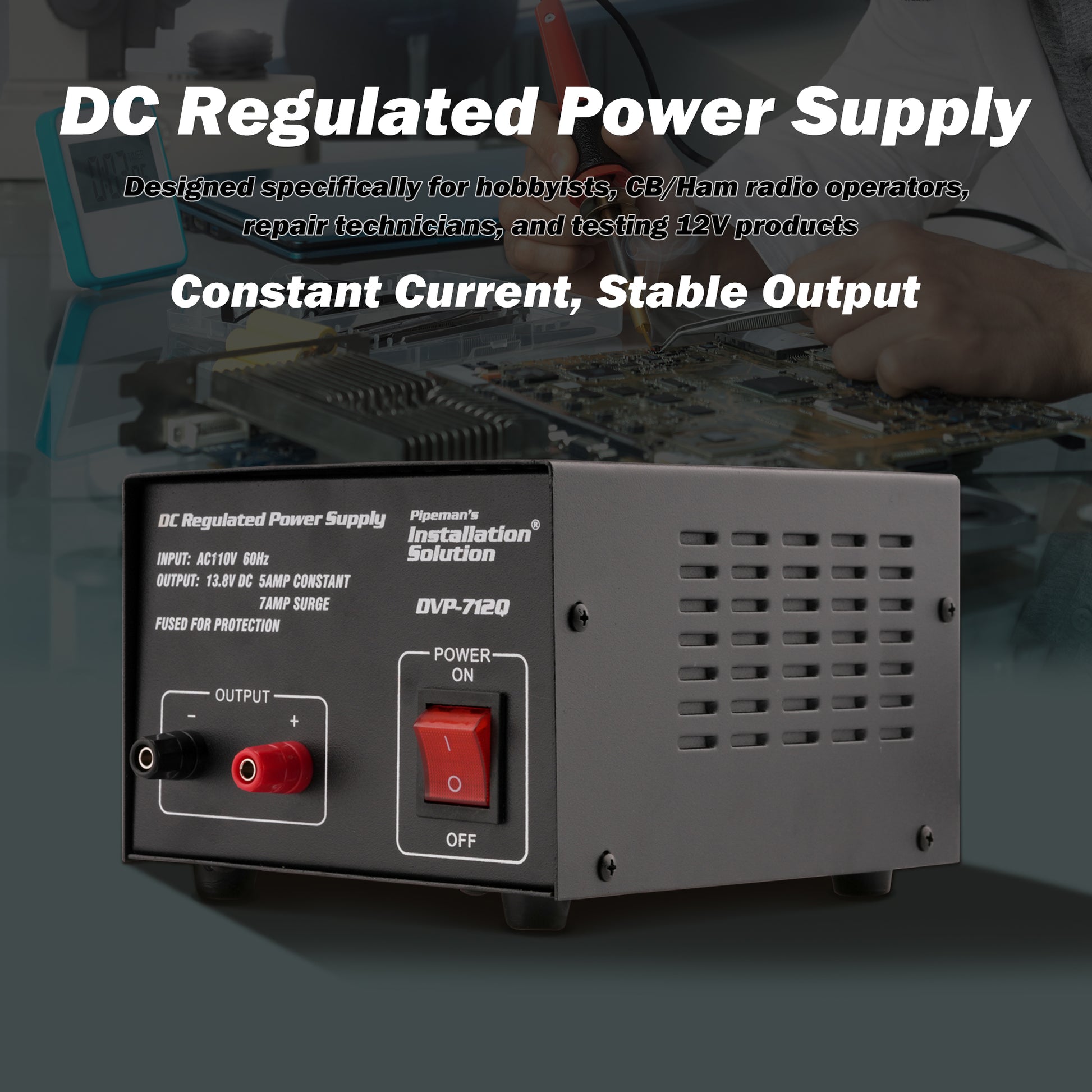

Illustrative image related to dc to dc regulated power supply

What Benefits Do Modular DC-DC Power Supplies Offer for Scalability?

Modular DC-DC power supplies allow for flexible configurations and scalability, catering to industries such as industrial automation and robotics. They can be tailored to meet specific power requirements and easily expanded as system needs grow. Buyers should evaluate the initial investment against long-term scalability benefits, as modular solutions can lead to cost savings and efficiency improvements in dynamic environments.

How Do Buck and Boost Converters Facilitate Voltage Management?

Buck and boost converters are designed to either step down (buck) or step up (boost) voltage levels, making them essential for battery management systems and electric vehicles. Their versatility allows for effective voltage regulation in fluctuating input conditions. However, the complexity in their design and implementation may require specialized knowledge, which buyers should consider when integrating these solutions into their systems.

Key Industrial Applications of dc to dc regulated power supply

| Industry/Sector | Specific Application of dc to dc regulated power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Integration in photovoltaic systems | Enhances energy efficiency and reduces costs | Voltage range compatibility, efficiency ratings |

| Telecommunications | Powering remote communication equipment | Ensures reliable operation in remote locations | Size, weight, and thermal management capabilities |

| Industrial Automation | Supplying sensors and control systems | Improves system reliability and performance | Input/output voltage specifications, protection features |

| Automotive | Electric vehicle charging systems | Supports faster charging and improves customer satisfaction | Compliance with safety standards, efficiency metrics |

| Medical Devices | Powering diagnostic and monitoring equipment | Increases accuracy and reliability of medical devices | Regulatory certifications, compact design |

How is ‘dc to dc regulated power supply’ utilized in Renewable Energy?

In the renewable energy sector, particularly in solar power applications, dc to dc regulated power supplies are essential for integrating photovoltaic systems. These power supplies convert varying input voltages from solar panels into stable output voltages suitable for battery charging and grid connection. This not only enhances energy efficiency but also reduces operational costs by optimizing power management. Buyers in this sector must consider voltage range compatibility and efficiency ratings to ensure optimal performance and compliance with local regulations, especially in regions like Africa and South America where solar energy is increasingly being harnessed.

What role does ‘dc to dc regulated power supply’ play in Telecommunications?

In telecommunications, dc to dc regulated power supplies are crucial for powering remote communication equipment, such as cellular base stations and satellite transceivers. These power supplies ensure reliable operation in environments where traditional power sources may be unavailable or unstable. By providing a stable voltage, they help maintain communication integrity, especially in rural or remote areas. Buyers should focus on size, weight, and thermal management capabilities to accommodate the often limited space and harsh conditions found in these applications, particularly in the Middle East and parts of Europe.

How does ‘dc to dc regulated power supply’ enhance Industrial Automation?

In industrial automation, dc to dc regulated power supplies are used to power sensors, control systems, and actuators. These supplies provide a regulated voltage that improves the reliability and performance of automation systems, which is critical in high-stakes environments like manufacturing and process control. They help mitigate issues related to voltage fluctuations that can lead to equipment failure or downtime. Buyers need to pay attention to input/output voltage specifications and protection features to ensure compatibility with existing systems and to enhance operational safety and efficiency.

What is the significance of ‘dc to dc regulated power supply’ in the Automotive industry?

In the automotive industry, especially with the rise of electric vehicles (EVs), dc to dc regulated power supplies are integral for charging systems. They facilitate faster charging by converting high-voltage battery outputs to the required lower voltages for vehicle systems and accessories. This not only enhances the overall user experience but also contributes to the efficiency of energy use in vehicles. Key considerations for buyers include compliance with safety standards and efficiency metrics, particularly in regions like Europe and Brazil, where stringent regulations are in place for automotive technologies.

How do ‘dc to dc regulated power supplies’ support Medical Devices?

In the medical sector, dc to dc regulated power supplies are vital for powering diagnostic and monitoring equipment. These supplies ensure that medical devices operate accurately and reliably, which is essential for patient safety and effective treatment. The stability provided by regulated power supplies minimizes the risk of errors due to voltage fluctuations, thereby improving the overall quality of care. Buyers should prioritize regulatory certifications and compact design to fit within the stringent requirements of medical environments, especially in regions with advanced healthcare systems in Europe and the Middle East.

3 Common User Pain Points for ‘dc to dc regulated power supply’ & Their Solutions

Scenario 1: Inconsistent Voltage Output Leading to Equipment Malfunction

The Problem: B2B buyers often face issues with inconsistent voltage output from DC to DC regulated power supplies, which can lead to operational disruptions and equipment malfunctions. This is particularly critical in industries such as telecommunications and medical devices, where precise voltage levels are essential for the functionality and safety of equipment. If the voltage fluctuates beyond acceptable limits, it can result in hardware damage, reduced efficiency, or even complete system failure, resulting in costly downtime and repairs.

The Solution: To combat this issue, buyers should prioritize sourcing high-quality DC to DC converters with built-in voltage regulation features. It is advisable to look for suppliers that offer products with advanced regulation capabilities, such as those that maintain a stable output under varying load conditions. Additionally, implementing a regular maintenance schedule for voltage regulation devices can help monitor performance and catch potential issues early. Investing in modular power supplies that allow for easy scalability and replacement of faulty components can also mitigate risks associated with voltage inconsistencies. Finally, conducting thorough testing of the power supply in real-world applications can help ensure it meets specific operational requirements before full-scale deployment.

Scenario 2: Difficulty in Sizing the Right Power Supply for Application Needs

The Problem: A common challenge for B2B buyers is accurately sizing the DC to DC power supply for their specific application needs. Many companies struggle to determine the correct voltage and current ratings required for their devices, leading to either underpowered systems that cannot perform adequately or over-specified units that waste energy and increase costs. This sizing issue can stem from a lack of understanding of the application’s load requirements or insufficient data on power supply specifications.

The Solution: To overcome this challenge, buyers should engage in a detailed analysis of their application’s power requirements. Utilizing tools such as load calculators can provide insights into the voltage and current needs of the system. Additionally, collaborating with manufacturers that offer consulting services can help identify the most suitable power supply options based on specific applications. When sourcing, look for suppliers who provide comprehensive technical documentation and support for their products. This enables buyers to make informed decisions and select appropriately sized DC to DC converters that optimize performance without overspending on unnecessary capacity.

Scenario 3: Navigating Compliance and Certification Challenges

The Problem: International B2B buyers often face hurdles in ensuring that their DC to DC regulated power supplies meet regional compliance and certification standards. Different markets, such as those in Europe, Africa, and the Middle East, have varying regulations that can complicate the purchasing process. Failure to comply with these standards can lead to regulatory fines, shipment delays, or even product recalls, which significantly impact business operations.

The Solution: To navigate these compliance challenges, it is crucial for buyers to conduct thorough research on the certification requirements in their target markets. Partnering with suppliers who are well-versed in international standards can provide an advantage; many reputable manufacturers offer documentation and guidance on compliance. When purchasing, ensure that the DC to DC power supply carries necessary certifications such as CE, UL, or IECEx, depending on the application and location. Furthermore, engaging legal or compliance experts can help clarify any uncertainties regarding regulations and ensure that the products being sourced are compliant. This proactive approach not only mitigates risks but also enhances the buyer’s credibility in the marketplace.

Strategic Material Selection Guide for dc to dc regulated power supply

What Are the Key Materials Used in dc to dc Regulated Power Supply?

When selecting materials for dc to dc regulated power supplies, several factors come into play, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in these applications: aluminum, copper, plastic, and silicon. Each material has unique properties and implications for product performance, durability, and market suitability.

How Does Aluminum Perform in dc to dc Regulated Power Supply Applications?

Aluminum is widely used in the housing and structural components of dc to dc power supplies due to its lightweight and excellent thermal conductivity. It typically has a temperature rating up to 150°C and offers good corrosion resistance when anodized.

Pros: Aluminum is relatively inexpensive and easy to manufacture, making it a popular choice for cost-effective solutions. Its lightweight nature also aids in reducing overall product weight, which is beneficial for portable applications.

Cons: While aluminum has good durability, it can be prone to corrosion in harsh environments unless properly treated. Additionally, it may not be suitable for high-pressure applications.

Impact on Application: Aluminum is compatible with most media and is often used in environments that do not expose the material to extreme conditions.

Illustrative image related to dc to dc regulated power supply

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that aluminum components meet local corrosion resistance standards, especially in coastal areas where saltwater exposure is a concern.

What Role Does Copper Play in dc to dc Regulated Power Supply Design?

Copper is primarily used for electrical connections and conductors in dc to dc power supplies due to its superior electrical conductivity. It can handle high temperatures and has a high melting point, making it suitable for demanding applications.

Pros: The high conductivity of copper ensures efficient power transmission, reducing energy losses. It is also highly durable and resistant to thermal expansion.

Illustrative image related to dc to dc regulated power supply

Cons: Copper is more expensive than aluminum and can be heavier, which may be a disadvantage in applications where weight is critical. It is also susceptible to corrosion unless coated or treated.

Impact on Application: Copper is ideal for applications requiring high reliability and efficiency, such as telecommunications and industrial equipment.

Considerations for International Buyers: Compliance with electrical standards such as IEC and UL is crucial for copper components, especially in regions like Europe and South America where stringent regulations apply.

Illustrative image related to dc to dc regulated power supply

How Do Plastics Contribute to dc to dc Regulated Power Supply Functionality?

Plastics are commonly used for insulation and housing in dc to dc power supplies. Materials like polycarbonate and ABS provide excellent electrical insulation and can withstand a range of temperatures.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for versatile design options. They also provide good resistance to moisture and chemicals.

Cons: Plastics generally have lower thermal conductivity compared to metals and may not perform well in high-temperature environments. They can also degrade over time when exposed to UV light.

Impact on Application: Plastics are suitable for applications where electrical insulation is critical, such as in consumer electronics.

Considerations for International Buyers: Buyers should verify that plastic materials comply with international standards for fire resistance and environmental impact, such as RoHS and REACH, particularly in Europe.

What Advantages Does Silicon Offer in dc to dc Regulated Power Supplies?

Silicon is a key material used in the semiconductor components of dc to dc power supplies. It is known for its excellent electrical properties and ability to function in a wide range of temperatures.

Pros: Silicon-based components are highly efficient and can operate at high frequencies, making them ideal for compact power supply designs. They also have a long lifespan and high reliability.

Cons: The manufacturing process for silicon can be complex and costly. Additionally, silicon components can be sensitive to temperature extremes, requiring careful thermal management.

Illustrative image related to dc to dc regulated power supply

Impact on Application: Silicon is essential for applications requiring precise voltage regulation and high efficiency, such as in renewable energy systems.

Considerations for International Buyers: Buyers should ensure that silicon components meet relevant industry standards, such as those set by the IEEE or IEC, particularly in regions with advanced technological requirements like Europe.

Summary Table of Material Selection for dc to dc Regulated Power Supply

| Material | Typical Use Case for dc to dc regulated power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and good thermal conductivity | Prone to corrosion without treatment | Low |

| Copper | Electrical connections and conductors | Superior electrical conductivity | Higher cost and heavier | High |

| Plastic | Insulation and housing | Lightweight and versatile design | Lower thermal conductivity and UV degradation | Low |

| Silicon | Semiconductor components | High efficiency and reliability | Complex manufacturing process | Medium |

This guide provides a comprehensive overview of the strategic materials used in dc to dc regulated power supplies, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dc to dc regulated power supply

What Are the Main Stages in the Manufacturing Process of DC to DC Regulated Power Supplies?

The manufacturing process of DC to DC regulated power supplies is intricate, requiring precision and adherence to quality standards at every stage. Understanding these stages can help B2B buyers assess the reliability of potential suppliers.

Material Preparation: What Materials Are Used?

The first stage involves sourcing high-quality materials essential for the production of power supplies. This includes raw materials like copper for wiring, various metals for the chassis, and semiconductor components for the circuitry. Suppliers should be scrutinized for their material sourcing practices, as the quality of materials directly impacts the performance and longevity of the power supply. Additionally, materials must comply with international standards, such as RoHS (Restriction of Hazardous Substances), to ensure environmental safety.

How Is Forming Conducted in the Manufacturing Process?

Once materials are prepared, they undergo forming processes, which include stamping, machining, and molding. These processes shape the components of the power supply, such as the housing and circuit boards. Advanced techniques like CNC machining and laser cutting are often employed to ensure high precision. B2B buyers should look for manufacturers that utilize state-of-the-art technology, as this typically correlates with better quality and efficiency.

What Is Involved in the Assembly Phase?

The assembly phase is crucial, as it involves integrating various components into a functional unit. This can be done manually or through automated processes, depending on the scale of production. During this stage, components are soldered onto circuit boards, and units are tested for electrical integrity. Manufacturers that implement modular designs can offer flexibility for customizations, which is particularly advantageous for international buyers needing specific configurations.

How Is Finishing Achieved in the Manufacturing Process?

Finishing processes involve applying protective coatings, labeling, and packaging the power supplies. Protective coatings are critical for durability, especially in harsh environments. For example, conformal coatings can protect against moisture and dust. Proper labeling, including compliance marks such as CE or UL, ensures that the product meets international safety standards. B2B buyers should verify these certifications, as they indicate a commitment to quality and safety.

What Quality Assurance Measures Are Essential for DC to DC Regulated Power Supplies?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final product meets both customer expectations and regulatory requirements.

Which International Standards Should Manufacturers Adhere To?

Manufacturers of DC to DC regulated power supplies should comply with international standards like ISO 9001:2015, which outlines criteria for quality management systems. Additionally, industry-specific certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) are essential for products intended for markets in Europe and North America, respectively. These certifications provide assurance that the product has been tested for safety and performance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control (QC) checkpoints are integrated throughout the manufacturing process, typically categorized into three main stages:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials and components before they enter the production line. Suppliers should provide detailed reports on material specifications and test results.

-

In-Process Quality Control (IPQC): During assembly, regular inspections and tests are conducted to catch defects early. This may involve functional tests, visual inspections, and measurements to ensure specifications are met.

-

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive final inspection is conducted. This includes performance testing under various conditions, thermal cycling tests, and electrical safety checks. A failure at this stage can lead to significant costs, so rigorous testing is essential.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should employ several strategies to ensure the quality of their suppliers:

What Documentation Should Buyers Request?

Buyers should request documentation such as ISO certification, quality assurance reports, and test certificates. These documents provide insight into the supplier’s quality management processes and adherence to international standards.

How Can Audits and Inspections Enhance Supplier Reliability?

Conducting supplier audits can be an effective way to verify compliance with quality standards. Auditors can assess manufacturing practices, quality control measures, and adherence to regulations. Additionally, engaging third-party inspection services can offer an unbiased evaluation of the supplier’s capabilities.

What Are the Nuances of QC for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific compliance requirements in their markets. Understanding local regulations and quality expectations is essential to avoid costly delays or rejections. For example, products exported to the EU must meet stringent CE marking requirements, while products entering the U.S. market often require UL certification.

Conclusion: Why Is Quality Assurance Critical for DC to DC Regulated Power Supplies?

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for DC to DC regulated power supplies is crucial for B2B buyers. By focusing on suppliers who adhere to international standards and implement robust quality control practices, buyers can ensure they receive reliable, high-performance products that meet their specific needs.

Illustrative image related to dc to dc regulated power supply

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc to dc regulated power supply’

In today’s competitive landscape, sourcing a reliable DC to DC regulated power supply is essential for ensuring the efficiency and effectiveness of your operations. This guide provides a practical checklist to help B2B buyers navigate the procurement process, ensuring that they select the right products and suppliers for their needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as input and output voltage ranges, current ratings, efficiency levels, and environmental conditions where the power supply will operate. This clarity will not only streamline your search but also help in communicating your requirements effectively to potential suppliers.

Step 2: Assess Application Requirements

Different applications may require distinct power supply characteristics. Determine whether your application needs isolation, specific form factors (like DIN rail or modular mounts), or unique features such as programmable outputs or redundancy. Understanding these requirements will enable you to shortlist products that align with your operational needs.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify reputable suppliers of DC to DC regulated power supplies. Look for manufacturers that have a strong track record, positive customer reviews, and industry certifications (e.g., ISO 9001). Create a shortlist of potential suppliers based on their product offerings and market reputation to facilitate further evaluation.

Step 4: Verify Supplier Certifications

Before finalizing a supplier, ensure they possess the necessary certifications and compliance with international standards. Check for certifications relevant to your region, such as CE for Europe or UL for North America. These certifications not only indicate product safety and reliability but also assure compliance with regulatory requirements.

Illustrative image related to dc to dc regulated power supply

Step 5: Request Samples and Technical Documentation

Engage with your shortlisted suppliers to request samples and comprehensive technical documentation. Evaluate the samples in your specific application environment to verify performance. Detailed documentation, including data sheets, installation guides, and application notes, will provide insights into the product’s capabilities and help mitigate future issues.

Step 6: Evaluate Total Cost of Ownership

Consider the total cost of ownership (TCO) rather than just the initial purchase price. Assess factors such as energy efficiency, maintenance requirements, warranty terms, and potential downtime costs. A power supply with a higher upfront cost may offer savings in operational efficiency and longevity, making it a more economical choice in the long run.

Step 7: Negotiate Terms and Place Your Order

Once you have selected a supplier, enter negotiations to secure favorable terms, including pricing, delivery timelines, and payment conditions. Clear communication at this stage is crucial to ensure all parties understand expectations. After finalizing the agreement, place your order and confirm the delivery schedule to align with your project timelines.

By following this checklist, B2B buyers can enhance their procurement strategy for DC to DC regulated power supplies, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for dc to dc regulated power supply Sourcing

When sourcing DC to DC regulated power supplies, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the various components of costs, the factors influencing pricing, and provides actionable insights for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in DC to DC Regulated Power Supplies?

-

Materials: The primary component of the cost structure includes the raw materials used in manufacturing, such as semiconductors, capacitors, and inductors. The quality and source of these materials can significantly affect the final price. For instance, high-grade materials may enhance performance and longevity but increase costs.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the manufacturing process. Regions with higher labor costs may reflect these in the pricing of power supplies. Automation in production can mitigate labor costs, but the initial investment in technology is also a factor.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and general administrative expenses. Efficient manufacturing processes can reduce overhead, thus lowering overall costs.

-

Tooling: Customization often requires specific tools and molds, which can be a significant upfront expense. Manufacturers may spread these costs over large production runs, making them more manageable per unit.

-

Quality Control (QC): Ensuring that power supplies meet industry standards involves rigorous testing and inspection. QC processes are essential, especially for applications in sensitive environments, and contribute to overall production costs.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination, weight, and volume of the product. For international buyers, understanding Incoterms is crucial as they define responsibilities for shipping, insurance, and tariffs.

-

Margin: Finally, the profit margin is added to the total cost to establish the selling price. This margin can vary based on market competition and perceived value.

What Influences Pricing for DC to DC Regulated Power Supplies?

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their needs and budget.

-

Specifications and Customization: Customized solutions tailored to specific applications can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Materials and Quality Certifications: Higher quality components and certifications (e.g., ISO, CE) can justify a higher price. Buyers should evaluate whether the added cost aligns with their application requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is essential for international sourcing. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) affect the total landed cost and should be carefully negotiated.

How Can Buyers Negotiate for Better Pricing?

-

Understand Total Cost of Ownership (TCO): Rather than focusing solely on the upfront price, consider the long-term costs associated with energy efficiency, durability, and maintenance. A slightly higher initial investment in quality may yield savings over time.

-

Leverage Volume Discounts: If your purchasing strategy allows, consolidate orders to negotiate better pricing based on volume. Suppliers are often willing to provide discounts for larger commitments.

-

Explore Alternative Suppliers: Diversifying your supplier base can create competition and drive down prices. However, ensure that alternative suppliers meet quality and reliability standards.

-

Negotiate Payment Terms: Flexible payment options can improve cash flow and might be leveraged to obtain better pricing or terms.

-

Stay Informed on Market Trends: Knowledge of market conditions, including material costs and technological advancements, can empower buyers to negotiate effectively.

Conclusion

In summary, understanding the comprehensive cost structure and pricing influences of DC to DC regulated power supplies is essential for B2B buyers. By focusing on the various cost components, negotiating strategically, and considering the total cost of ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Prices may vary significantly across suppliers and regions, so conducting thorough market research is crucial. Note that the prices discussed herein are indicative and subject to change based on market conditions and specific requirements.

Alternatives Analysis: Comparing dc to dc regulated power supply With Other Solutions

Introduction: Understanding Alternative Solutions for Power Supply Needs

When considering power supply solutions, B2B buyers often evaluate various technologies to meet their specific requirements. The choice of a DC to DC regulated power supply is popular due to its ability to provide stable output voltage and current. However, alternatives exist that may offer distinct advantages depending on the application and operational context. This analysis compares DC to DC regulated power supplies with two notable alternatives: linear power supplies and unregulated power supplies.

Comparison Table

| Comparison Aspect | Dc To Dc Regulated Power Supply | Linear Power Supply | Unregulated Power Supply |

|---|---|---|---|

| Performance | High efficiency, stable output | Excellent regulation, low noise | Variable output, less stable |

| Cost | Moderate to high | Typically higher | Low to moderate |

| Ease of Implementation | Generally straightforward | Can be complex | Simple, minimal circuitry |

| Maintenance | Low, with occasional checks | Moderate, may require calibration | Low, few components |

| Best Use Case | Sensitive electronic devices | Audio and precision equipment | Simple applications, low cost |

Detailed Breakdown of Alternatives

Linear Power Supply: A Reliable but Costly Alternative

Linear power supplies operate by using a transformer to convert AC voltage to DC voltage, providing excellent regulation and low noise levels. This makes them ideal for sensitive applications, such as audio and precision equipment, where signal integrity is paramount. However, the cost of linear power supplies tends to be higher due to the need for additional components like transformers and heat sinks. Additionally, their size and weight can be considerable, making them less suitable for compact applications. While they require moderate maintenance, including occasional calibration, their performance in terms of output quality remains unmatched in certain scenarios.

Illustrative image related to dc to dc regulated power supply

Unregulated Power Supply: Cost-Effective but Limited

Unregulated power supplies provide a simpler solution by converting AC to DC without complex regulation mechanisms. This results in lower costs and easier implementation, making them an attractive option for applications where precise voltage is not critical. However, the trade-off is that their output can vary significantly with changes in load, leading to potential instability in sensitive applications. Maintenance is minimal due to fewer components, but the lack of regulation means they are best suited for less critical tasks where performance can be compromised. This makes unregulated supplies ideal for basic applications, such as powering lights or simple electronic devices.

Conclusion: Choosing the Right Power Supply Solution

Selecting the right power supply solution depends on the specific needs of your application, including performance requirements, budget constraints, and installation considerations. For businesses operating in industries where stability and precision are vital, a DC to DC regulated power supply is often the best choice, despite the higher cost. Conversely, for applications where cost is a primary concern and voltage stability is less critical, unregulated power supplies may suffice. Linear power supplies can serve well in niche applications requiring low noise and high regulation but come with increased costs and complexity. Understanding these alternatives empowers B2B buyers to make informed decisions tailored to their operational needs.

Essential Technical Properties and Trade Terminology for dc to dc regulated power supply

What Are the Key Technical Properties of DC to DC Regulated Power Supplies?

Understanding the essential specifications of DC to DC regulated power supplies is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical technical properties that should be considered:

Illustrative image related to dc to dc regulated power supply

-

Output Voltage Range

The output voltage range indicates the minimum and maximum voltage that the power supply can provide. It is vital to ensure that the converter can meet the voltage requirements of your specific application. Variability in output voltage can affect the performance of connected devices, making it essential for compatibility and efficiency. -

Efficiency Rating

Efficiency rating measures how much input power is converted to output power. High-efficiency ratings (typically above 85%) are crucial for reducing operational costs, especially in large-scale applications. A higher efficiency means less energy is wasted as heat, leading to lower cooling requirements and increased reliability. -

Load Regulation

Load regulation refers to the ability of the power supply to maintain a constant output voltage despite variations in load current. Good load regulation is essential for sensitive electronic devices that require stable power to function correctly. Inconsistent output can lead to performance issues or damage to equipment. -

Isolation Voltage

Isolation voltage is the maximum voltage that can exist between the input and output without causing failure. This property is vital for safety and protecting sensitive components from voltage spikes. For applications involving critical systems or potentially hazardous environments, high isolation voltage can significantly enhance operational safety. -

Operating Temperature Range

This specification indicates the temperature limits within which the power supply can operate effectively. Equipment designed to function in extreme temperatures ensures reliability in various environments, from industrial settings to outdoor applications. Understanding these limits is crucial for applications in regions with harsh climates. -

Form Factor and Mounting Options

The form factor defines the physical dimensions and design of the power supply, which can affect installation and integration into existing systems. Common mounting options include DIN rail, wall, or rack mounting. Choosing the right form factor ensures compatibility with your infrastructure, optimizing space and ease of installation.

What Common Trade Terms Should B2B Buyers Know in the DC to DC Power Supply Market?

Navigating the procurement landscape involves understanding specific terminology that can impact negotiations and purchasing decisions. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure that components meet required specifications and quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for budgeting and inventory management, particularly for small businesses or projects with limited funding. Knowing the MOQ can help buyers plan their purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. This process is essential for comparing different vendors and securing the best price and terms. Crafting a comprehensive RFQ can help ensure that all necessary specifications are communicated clearly. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international shipping terms that clarify the responsibilities of buyers and sellers in global transactions. Familiarity with these terms can prevent misunderstandings regarding shipping costs, insurance, and risk transfer, making them crucial for international buyers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and inventory management, as longer lead times can impact production schedules and operational efficiency. -

Warranty Terms

Warranty terms detail the conditions under which a product will be repaired or replaced if it fails. Awareness of warranty provisions is crucial for risk management, as it can significantly affect long-term operational costs and equipment reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions and foster successful supplier relationships in the DC to DC regulated power supply market.

Navigating Market Dynamics and Sourcing Trends in the dc to dc regulated power supply Sector

What Are the Current Market Dynamics and Key Trends in the DC to DC Regulated Power Supply Sector?

The global market for DC to DC regulated power supplies is experiencing significant growth, driven by the increasing demand for efficient power management solutions across various industries. Key drivers include the rise of renewable energy sources, such as solar and wind, which require reliable power conversion and management systems. Additionally, advancements in telecommunications and IoT applications are pushing the need for compact, high-efficiency DC to DC converters that can operate in diverse environments.

Emerging B2B tech trends are increasingly focused on modular designs that offer customization and scalability, appealing to businesses looking for flexible solutions that can adapt to changing power requirements. For international B2B buyers, especially in regions like Africa and South America, sourcing products with high reliability and quick delivery times has become essential. Manufacturers are responding to this demand by streamlining their supply chains and investing in local partnerships to enhance service levels.

Moreover, a shift toward digitalization in procurement processes is influencing how companies engage with suppliers, with a growing preference for online platforms that provide easy access to product specifications and customer support. Buyers are also prioritizing vendors who demonstrate a commitment to innovation and customer-centric solutions, further shaping market dynamics.

Illustrative image related to dc to dc regulated power supply

How Important Is Sustainability and Ethical Sourcing in the DC to DC Regulated Power Supply Sector?

Sustainability and ethical sourcing are becoming increasingly critical in the DC to DC regulated power supply sector. As global awareness of environmental issues rises, businesses are under pressure to adopt greener practices and ensure that their supply chains are environmentally responsible. The impact of power supply manufacturing on the environment can be significant, with energy consumption and waste generation being key concerns.

To address these challenges, many manufacturers are investing in sustainable materials and production processes. Certifications such as ISO 14001 and RoHS compliance are becoming vital for suppliers aiming to attract international buyers who prioritize environmental responsibility. Furthermore, the use of recycled materials in manufacturing processes not only reduces waste but also appeals to environmentally conscious customers.

Ethical sourcing practices are equally important, as companies seek to ensure that their suppliers adhere to fair labor practices and contribute positively to their communities. This focus not only enhances brand reputation but also fosters loyalty among consumers who increasingly prefer to support businesses that align with their values. For B2B buyers, partnering with suppliers who prioritize sustainability can lead to long-term cost savings and a competitive edge in increasingly eco-conscious markets.

Illustrative image related to dc to dc regulated power supply

What Is the Brief Evolution and History of DC to DC Regulated Power Supplies?

The evolution of DC to DC regulated power supplies has been marked by rapid technological advancements and changing market demands. Initially, these power supplies were primarily linear converters, characterized by their simplicity and reliability. However, as electronic devices became more sophisticated, the need for more efficient and compact solutions led to the development of switching regulators in the late 20th century.

These switching power supplies offered higher efficiency and lower heat generation, making them ideal for a wide range of applications, from telecommunications to industrial automation. Over the years, the introduction of digital control technologies has further enhanced the performance and flexibility of DC to DC converters, allowing for greater precision and adaptability in power management.

Today, the market is witnessing a shift toward modular power supply solutions that cater to the diverse needs of various industries. This evolution has not only improved the functionality of DC to DC converters but has also paved the way for innovative designs that support the growing trend of renewable energy integration and smart grid technologies. As the demand for efficient power solutions continues to rise, the sector is poised for further growth and innovation.

Illustrative image related to dc to dc regulated power supply

Frequently Asked Questions (FAQs) for B2B Buyers of dc to dc regulated power supply

-

1. How do I choose the right DC to DC regulated power supply for my application?

Selecting the right DC to DC regulated power supply involves understanding your specific voltage and current requirements, as well as the application environment. Consider factors such as input voltage range, output voltage, and load current. Additionally, evaluate the efficiency, thermal performance, and form factor (e.g., DIN rail, wall mount) to ensure compatibility with your existing system. Consulting with manufacturers or suppliers can provide insights into suitable models tailored to your needs. -

2. What is the best type of DC to DC converter for industrial applications?

For industrial applications, high-efficiency switching DC to DC converters are typically recommended due to their compact size and ability to handle a wide range of input voltages. Look for converters with features like overvoltage protection, thermal shutdown, and high reliability ratings. Additionally, consider models with N+1 redundancy for critical systems to ensure continuous operation even in the event of a failure. -

3. Can I customize my DC to DC regulated power supply?

Yes, many manufacturers offer customization options for DC to DC regulated power supplies. This may include adjustments to output voltage, current ratings, and physical dimensions to fit specific applications. It’s advisable to discuss your requirements with the supplier early in the procurement process to ensure they can meet your unique specifications. -

4. What are the minimum order quantities (MOQs) for DC to DC power supplies?

Minimum order quantities can vary significantly between suppliers. Typically, MOQs may range from a single unit for standard models to several hundred for custom solutions. It’s essential to clarify MOQs with your supplier upfront, especially if you are considering a pilot project or need a small batch for testing. -

5. What payment terms should I expect when sourcing DC to DC power supplies internationally?

Payment terms for international purchases can vary, but common practices include upfront payment, a deposit with the balance upon delivery, or payment on credit terms, such as net 30 or net 60 days. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Always ensure that payment methods are secure and documented to protect both parties. -

6. How can I ensure quality assurance (QA) for my DC to DC power supply?

To ensure quality assurance, select suppliers that adhere to international quality standards such as ISO 9001. Request documentation of their QA processes, including testing and inspection protocols. Additionally, consider suppliers that offer warranties and after-sales support, as this indicates confidence in their product quality and reliability. -

7. What logistics considerations should I take into account when importing DC to DC power supplies?

When importing DC to DC power supplies, consider shipping methods, lead times, and customs regulations specific to your region. Work with logistics providers familiar with electronic components to ensure compliance with international shipping laws. Additionally, factor in potential delays due to customs clearance, and choose a reliable shipping method that balances cost and delivery speed. -

8. Are there specific certifications I need to look for when sourcing DC to DC converters for international markets?

Yes, certifications such as CE, UL, and RoHS are critical for compliance with international safety and environmental standards. Depending on your market, other certifications may also be necessary, such as ATEX for explosive atmospheres or IECEx for hazardous locations. Ensure that your supplier provides documentation for these certifications to facilitate smooth market entry and customer acceptance.

Top 8 Dc To Dc Regulated Power Supply Manufacturers & Suppliers List

1. Acopian – Modular Regulated Power Supply

Domain: acopian.com

Registered: 1996 (29 years)

Introduction: Modular Regulated Power Supply: High Voltage DC to DC; Output ranges: 0-1,000 volts to 0-30,000 volts; DC inputs from 21.6 to 32.0 Vdc; Continuous adjustable outputs; 20-turn controls for precise setability; Designed to withstand severe arching and short circuits; Rugged construction with quality components; Shipped within 6 days; Five Year Warranty (internal encapsulated multiplier module – One Y…

2. Phoenix Contact – MINI-PS-12-24DC/5-15DC/2

Domain: phoenixcontact.com

Registered: 1996 (29 years)

Introduction: DC/DC converters from Phoenix Contact provide a regulated DC voltage, helping to avoid disturbances in applications by regenerating voltages. They can alter voltage levels or create independent supply systems through electrical isolation. Key products include: 1. MINI-PS-12-24DC/5-15DC/2 – Input: 12-24 V DC, Output: 5-15 V DC/2 A. 2. MINI-PS-12-24DC/24DC/1 – Input: 12-24 V DC, Output: 24 V DC/1 A….

3. Reddit – Voltage Regulator vs. DC-DC Converter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Difference between Voltage Regulator and DC-DC converter: A DC-DC converter can output a voltage higher than the input voltage or provide isolation, typically using a switching regulator. A voltage regulator is usually a linear device used to output a lower voltage than the input. Not every DC-DC converter is a regulator, but every regulator is a DC-DC converter. Regulators are used when a steady …

4. Recom – High Efficiency DC/DC Converter

Domain: recom-power.com

Registered: 2006 (19 years)

Introduction: Compact regulated DC/DC converter with high efficiency, wide input voltage range, and various output voltage options. Designed for industrial applications, it features short circuit protection, overvoltage protection, and thermal shutdown. Suitable for use in harsh environments with a robust design and compact size.

5. PULS – DC/DC Converters

Domain: products.pulspower.com

Registered: 2000 (25 years)

Introduction: Efficient and reliable PULS DC/DC converters provide regulated DC voltages of 12 V, 24 V, or 48 V. They are designed to enhance system reliability and increase endurance during voltage fluctuations. The compact design allows for installation in standard decentralized on-machine cabinets, saving space on the DIN-rail.

Key Product Details:

– DC Output Range: 5 V, 12 V, 24 V, 36 V, 48 V

– Power Inp…

6. Newark – DC/DC Converters

Domain: newark.com

Registered: 1994 (31 years)

Introduction: DC / DC Converters: 16,178 Products Found. SIP and DIP Board-mounting packages, encapsulated DC-DC converters suitable for providing point-of-load supplies for distributed power systems across PCBs. High galvanic noise-reduction isolation with choices of input and output voltages; single or multiple outputs. 1W or 3W output power. Wide temperature performance -40°C to +85°C at 1W option. Categorie…

7. ACDC Power Shack – Adjustable DC Power Supply

Domain: acdcpowershack.com

Registered: 2017 (8 years)

Introduction: Adjustable DC Power Supply

– DC Output: 0~15VDC, 2~24VDC, 0~30VDC/0-10 Amps, 0~60VDC/0-5 Amps

– Availability: In stock (7), Out of stock (0)

– Price Range: $12.00 – $85.00

– Input Voltage: 90~120VAC, 117VAC, 120VAC, 115VAC @60Hz

– Output Current: 2A, 4A, 7A, 0~10A, 0~5A

– Part Numbers: 5486, PS-10T, APS-415, APS-415Y, APS-724K, SPS-3010C, R-SPS605

– Reviews: Ratings range from 4.07 to 5.0 out of 5…

8. Digi-Key – DC-DC Converters

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, Digi-Key – DC-DC Converters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for dc to dc regulated power supply

In today’s competitive landscape, strategic sourcing of DC to DC regulated power supplies is paramount for businesses aiming to enhance operational efficiency and reliability. Buyers should prioritize suppliers that offer customizable solutions, robust warranties, and rapid shipping options. The ability to source power supplies with advanced features such as programmable outputs, power factor correction, and redundancy can significantly impact system performance and longevity.

For companies in regions like Africa, South America, the Middle East, and Europe, understanding local market demands and regulatory requirements is crucial. Engaging with reputable manufacturers who can provide tailored solutions will facilitate smoother integration into existing systems, ensuring compliance and optimized performance.

As we look ahead, the demand for high-efficiency DC to DC converters is set to grow, driven by advancements in technology and the increasing need for sustainable energy solutions. International buyers are encouraged to forge strong partnerships with suppliers who not only understand their specific needs but also anticipate market trends. By investing in strategic sourcing today, businesses can position themselves for success in an evolving marketplace, enhancing their competitive edge and fostering innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.