The Definitive Guide to 1100 Aluminium Alloy: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 1100 aluminium alloy

In the dynamic landscape of global manufacturing, sourcing the right materials can be a daunting challenge for international B2B buyers, particularly when it comes to the versatile 1100 aluminium alloy. This alloy, known for its excellent workability and high thermal conductivity, is increasingly favored across various industries—from food processing to electrical applications. However, navigating the complexities of quality standards, supplier reliability, and cost-efficiency requires a comprehensive understanding of the market.

This guide aims to equip decision-makers with valuable insights into the diverse types and applications of 1100 aluminium alloy, alongside practical advice on supplier vetting and cost considerations. We delve into the alloy’s unique properties, such as its resistance to corrosion and ease of fabrication, which make it a preferred choice for many manufacturing processes. Additionally, we will explore the regional nuances that affect procurement strategies in Africa, South America, the Middle East, and Europe, including key markets like Vietnam and Germany.

By providing a detailed framework for evaluating potential suppliers and understanding market trends, this guide empowers B2B buyers to make informed purchasing decisions. Whether you’re seeking materials for heat exchangers, cooking utensils, or decorative elements, our insights will help streamline your sourcing process and enhance your operational efficiency.

Understanding 1100 aluminium alloy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1100-O | Fully annealed, soft and ductile. Excellent formability. | Cooking utensils, decorative parts | Pros: High workability; Cons: Low strength. |

| 1100-H14 | Strain-hardened, moderate strength with good ductility. | Heat exchangers, food handling equipment | Pros: Good balance of strength and formability; Cons: Limited to moderate strength applications. |

| 1100-H18 | Higher strength variant, less ductile than H14. | Electrical conductors, rivets | Pros: Suitable for applications requiring more strength; Cons: Reduced formability compared to softer tempers. |

| 1100-H12 | Intermediate strength, retains good formability. | Decorative applications, fin stock | Pros: Good for intricate designs; Cons: Not heat-treatable. |

| 1100-F | As-fabricated, soft, no further processing. | Foil products, packaging | Pros: Excellent surface finish; Cons: Lower tensile strength. |

What Are the Key Characteristics of 1100-O Aluminium Alloy?

The 1100-O variant is recognized for its fully annealed state, making it one of the softest forms of aluminum alloy. Its exceptional workability allows for intricate forming processes, making it ideal for applications such as cooking utensils and decorative parts. Buyers should consider that while it offers high formability, its low strength limits its use in high-stress applications.

How Does 1100-H14 Differ from Other Variants?

1100-H14 is strain-hardened, providing a moderate strength level while maintaining good ductility. This balance makes it suitable for applications like heat exchangers and food handling equipment, where both strength and formability are essential. B2B buyers should note that while it offers a good compromise, it may not be suitable for high-strength requirements compared to other aluminum alloys.

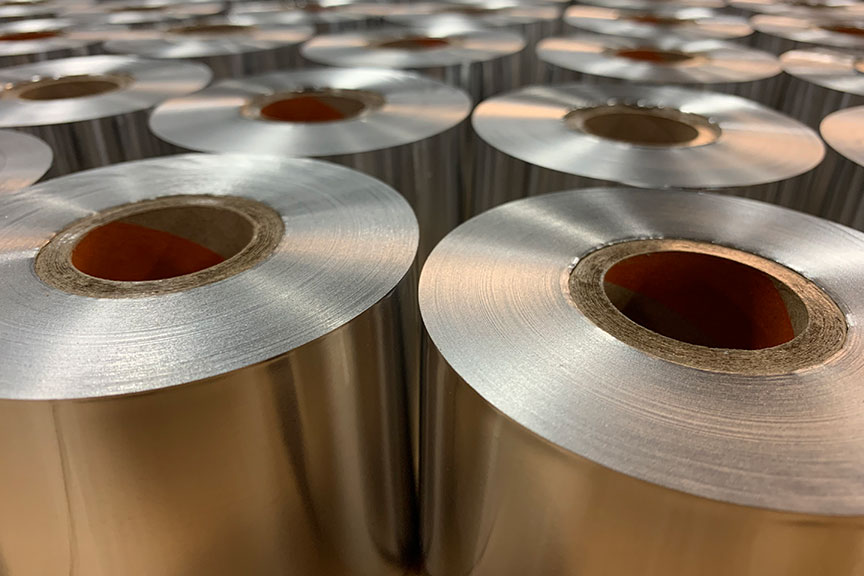

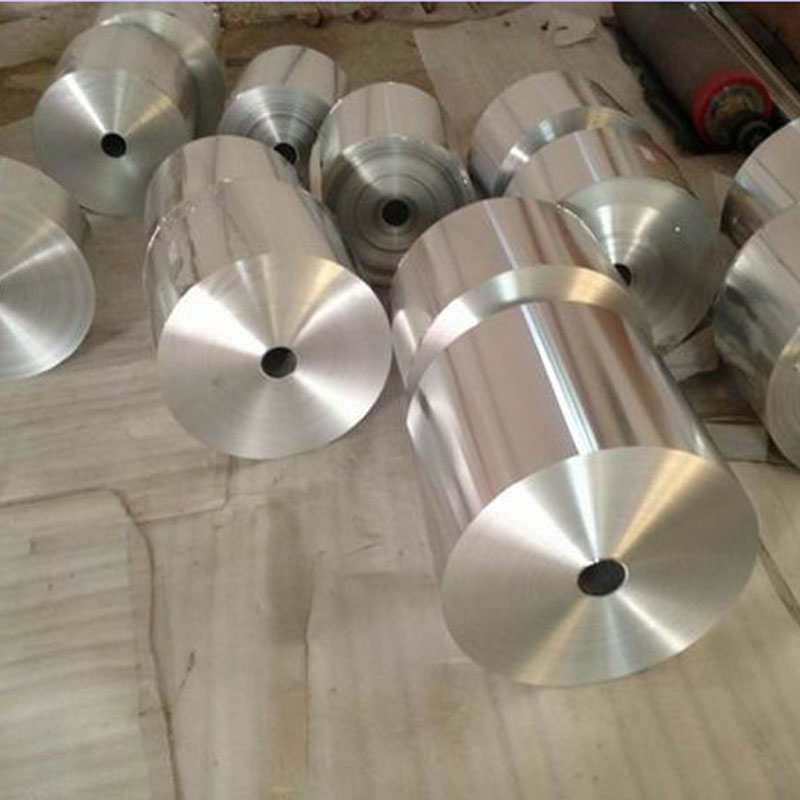

Illustrative image related to 1100 aluminium alloy

Why Choose 1100-H18 for Electrical Applications?

The 1100-H18 variant is characterized by its higher strength compared to other 1100 types, making it a preferred choice for applications like electrical conductors and rivets. However, this increased strength comes at the cost of ductility, which may limit its use in intricate forming. Buyers should weigh the need for strength against the potential loss of formability when selecting this variant.

What Are the Advantages of 1100-H12 Aluminium Alloy?

1100-H12 offers an intermediate strength level while retaining good formability, making it suitable for decorative applications and fin stock. This alloy is particularly beneficial for designs requiring a balance between strength and aesthetic appeal. For B2B buyers, it’s crucial to remember that while it provides versatility, it is not heat-treatable, which may limit its applications in certain industries.

When Should You Consider 1100-F Aluminium Alloy?

The 1100-F variant is typically found in its as-fabricated state, which is soft and ideal for applications like foil products and packaging. Its excellent surface finish makes it highly desirable for decorative and consumer products. However, buyers should be aware that this alloy has lower tensile strength, making it less suitable for structural applications.

Key Industrial Applications of 1100 aluminium alloy

| Industry/Sector | Specific Application of 1100 Aluminium Alloy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Manufacturing of cooking utensils and food handling equipment | High corrosion resistance and safety for food contact | Compliance with food safety standards and certifications |

| Electrical and Electronics | Electrical conductors and heat sinks | Excellent thermal and electrical conductivity | Quality assurance in conductivity and thermal performance |

| HVAC (Heating, Ventilation, Air Conditioning) | Heat exchangers and fins | Efficient heat transfer leading to energy savings | Material thickness and surface finish to optimize performance |

| Automotive | Decorative trim and components | Lightweight with good formability enhances aesthetics | Availability in various tempers and finishes |

| Aerospace | Rivets and structural components | Lightweight yet durable, aiding fuel efficiency | Compliance with aerospace standards and specifications |

How is 1100 Aluminium Alloy Utilized in the Food and Beverage Industry?

In the food and beverage sector, 1100 aluminium alloy is frequently utilized for manufacturing cooking utensils and food handling equipment. Its high corrosion resistance ensures that it remains safe for food contact, addressing hygiene concerns while maintaining durability. For international buyers, compliance with food safety standards and certifications is crucial, necessitating a thorough understanding of local regulations in regions like Europe and South America.

What Role Does 1100 Aluminium Alloy Play in Electrical and Electronics Applications?

The electrical and electronics industry leverages 1100 aluminium alloy primarily for electrical conductors and heat sinks. This alloy’s superior thermal and electrical conductivity makes it an ideal choice for efficient power transmission and heat dissipation. Buyers should prioritize quality assurance processes that guarantee the alloy meets specific conductivity and thermal performance requirements, particularly in competitive markets such as Germany and Vietnam.

Illustrative image related to 1100 aluminium alloy

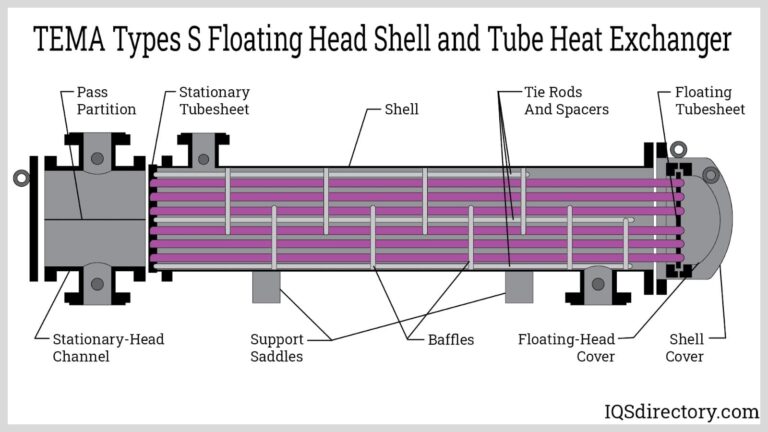

How is 1100 Aluminium Alloy Beneficial in HVAC Systems?

In HVAC applications, 1100 aluminium alloy is commonly used in heat exchangers and fins, where efficient heat transfer is paramount. The alloy’s lightweight nature contributes to energy savings by enhancing overall system efficiency. When sourcing this alloy, businesses must consider material thickness and surface finish to optimize performance, ensuring they meet the technical specifications necessary for high-efficiency systems in diverse climates, including the Middle East.

Why is 1100 Aluminium Alloy Preferred in the Automotive Industry?

The automotive sector utilizes 1100 aluminium alloy for decorative trim and various components, capitalizing on its lightweight and excellent formability. This alloy enhances the aesthetic appeal of vehicles while contributing to fuel efficiency through weight reduction. For international buyers, the availability of different tempers and finishes is a key consideration, as these can significantly impact both performance and visual appeal in competitive automotive markets.

How is 1100 Aluminium Alloy Used in Aerospace Applications?

In the aerospace industry, 1100 aluminium alloy is favored for manufacturing rivets and structural components due to its lightweight yet durable characteristics. These properties help improve fuel efficiency, a critical factor in aerospace design. Buyers in this sector must ensure that their sourcing aligns with rigorous aerospace standards and specifications, which can vary significantly across regions, especially in Europe and the Middle East.

3 Common User Pain Points for ‘1100 aluminium alloy’ & Their Solutions

Scenario 1: Challenges with Material Availability and Lead Times

The Problem: B2B buyers often face challenges when sourcing 1100 aluminium alloy due to fluctuating market demands and lead times. This can lead to project delays, increased costs, and ultimately, dissatisfied customers. For instance, a manufacturer in Africa may need aluminum sheets for a production run but finds that suppliers are either out of stock or have long lead times, forcing them to consider alternatives that may not meet their specifications.

Illustrative image related to 1100 aluminium alloy

The Solution: To mitigate these challenges, buyers should establish strong relationships with multiple suppliers to create a reliable supply chain. It’s crucial to conduct a thorough market analysis to identify suppliers that offer consistent stock levels and shorter lead times. Additionally, investing in bulk purchasing agreements can help secure better pricing and availability. Utilizing local suppliers can also reduce transportation time and costs. Maintaining open communication with suppliers regarding anticipated demand can further enhance supply chain efficiency.

Scenario 2: Difficulty in Selecting the Right Alloy Temper

The Problem: Selecting the appropriate temper for 1100 aluminium alloy can be confusing for buyers, especially when different applications require specific mechanical properties. For instance, a buyer in South America might struggle to decide between the softer O temper and the more rigid H14 temper for their heat exchanger production, leading to potential performance issues and increased scrap rates.

The Solution: To address this, buyers should invest time in understanding the specific mechanical properties associated with each temper. Engaging with technical experts from suppliers can provide valuable insights tailored to the intended application. Additionally, conducting small-scale trials using different tempers can help buyers observe performance differences firsthand. Documenting these findings will create a reference that guides future purchasing decisions, ensuring the selected temper aligns with the project requirements.

Scenario 3: Inadequate Knowledge of Welding Techniques for 1100 Aluminium Alloy

The Problem: Many B2B buyers are unaware of the best practices for welding 1100 aluminium alloy, which can lead to poor quality welds and structural failures. For example, a manufacturer in Europe may attempt to weld 1100 alloy components without understanding the unique characteristics of the material, resulting in weak joints that compromise the integrity of their final products.

Illustrative image related to 1100 aluminium alloy

The Solution: To overcome this pain point, buyers should prioritize education on proper welding techniques specific to 1100 aluminium alloy. This includes understanding the importance of pre-weld cleaning, appropriate filler materials, and the recommended welding parameters. Collaborating with welding specialists or attending training sessions can significantly improve the quality of welds. Additionally, utilizing resources such as welding procedure specifications (WPS) tailored for 1100 aluminium can ensure that the welding process is both effective and efficient. Investing in quality control measures to inspect weld integrity will further enhance product reliability, ultimately leading to greater customer satisfaction.

Strategic Material Selection Guide for 1100 aluminium alloy

What Are the Key Properties of 1100 Aluminium Alloy?

Aluminium alloy 1100 is primarily characterized by its high purity, with a minimum aluminum content of 99%. This alloy exhibits excellent thermal and electrical conductivity, making it suitable for applications requiring efficient heat transfer. It is also known for its outstanding corrosion resistance, particularly in chemical and marine environments. The mechanical properties vary with tempering, with the ultimate tensile strength ranging from 13 ksi in the annealed state to 24 ksi in the H18 temper. However, it is important to note that 1100 alloy is not heat treatable, which limits its use in high-strength applications.

What Are the Advantages and Disadvantages of 1100 Aluminium Alloy?

Pros:

– Durability and Corrosion Resistance: 1100 alloy is highly resistant to corrosion, making it ideal for outdoor applications and environments with high humidity or chemical exposure.

– Excellent Workability: It can be easily formed through processes like bending, spinning, and drawing, which is advantageous for manufacturers needing intricate shapes.

– Cost-Effectiveness: The low cost of raw materials and ease of processing contribute to its affordability, making it a popular choice for various applications.

Cons:

– Low Strength: While it is durable, the alloy’s low tensile strength compared to other aluminium alloys limits its use in structural applications.

– Heat Treatment Limitations: The inability to strengthen through heat treatment can be a disadvantage for applications requiring high strength under load.

How Does 1100 Aluminium Alloy Impact Specific Applications?

The impact of 1100 aluminium alloy on applications is significant due to its properties. For instance, in the food and beverage industry, its corrosion resistance and non-toxic nature make it suitable for food handling equipment. In electrical applications, its excellent conductivity is beneficial for wire and cable manufacturing. However, its low strength restricts its use in applications where high mechanical stress is expected, such as in structural components or high-pressure environments.

Illustrative image related to 1100 aluminium alloy

What Should International B2B Buyers Consider When Selecting 1100 Aluminium Alloy?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several considerations are crucial. Compliance with local and international standards (e.g., ASTM, DIN, JIS) is essential to ensure product quality and safety. Buyers should also be aware of regional preferences for specific temper grades based on application needs. Additionally, understanding the supply chain dynamics in their region can help in sourcing the alloy effectively, considering factors like lead times and shipping costs.

Summary Table of 1100 Aluminium Alloy Properties

| Material | Typical Use Case for 1100 aluminium alloy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 1100 Aluminium Alloy | Food handling equipment | Excellent corrosion resistance | Low tensile strength | Low |

| 1100 Aluminium Foil | Packaging and insulation | High thermal conductivity | Limited mechanical strength | Medium |

| 1100 Aluminium Sheet | Decorative parts and dials | Excellent workability | Not suitable for high-stress applications | Low |

| 1100 Aluminium Wire | Electrical conductors | Good electrical conductivity | Not heat-treatable | Medium |

This analysis provides a comprehensive overview of the strategic material selection considerations for 1100 aluminium alloy, catering to the needs of B2B buyers across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 1100 aluminium alloy

What Are the Main Stages in the Manufacturing Process of 1100 Aluminium Alloy?

Manufacturing 1100 aluminium alloy involves several critical stages that ensure the final product meets the required specifications for various applications. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing process begins with the careful selection of raw materials, primarily 99% pure aluminium. The aluminium is often sourced in ingot form and needs to be melted and cast into semi-finished products such as sheets, plates, or extrusions. This stage may involve alloying elements to fine-tune the characteristics of the aluminium, although for 1100, the focus remains on maintaining high purity.

Forming Techniques

Once the material is prepared, forming processes such as rolling, stamping, or extrusion come into play. Due to its excellent workability, 1100 aluminium alloy is particularly suited for intricate forming operations. Techniques like deep drawing or spinning are often employed, capitalizing on the alloy’s ability to maintain integrity while being manipulated into complex shapes. For instance, the rolling process produces thin sheets that are commonly used in food handling equipment and decorative applications.

Assembly Methods

In some applications, multiple parts made from 1100 aluminium may need to be assembled. Techniques such as welding, riveting, or mechanical fastening are typical. The alloy’s good weldability, especially in the O (annealed) and H (hardened) tempers, allows for strong joints that are essential in structural applications. Careful attention must be paid to the assembly process to ensure that the integrity and performance characteristics of the alloy are preserved.

Finishing Processes

The final stage involves various finishing techniques to enhance the surface properties of the alloy. These may include anodizing, which not only improves corrosion resistance but also allows for aesthetic color finishes. Other processes like polishing or coating may be applied, depending on the end-use requirements. The finishing stage is vital for ensuring the product meets the visual and functional expectations of the market.

How Is Quality Assurance Ensured in the Manufacturing of 1100 Aluminium Alloy?

Quality assurance (QA) is a critical component in the manufacturing process of 1100 aluminium alloy. Ensuring product quality involves adhering to international standards and implementing systematic quality control measures.

International and Industry-Specific Standards

Manufacturers of 1100 aluminium alloy typically follow international standards such as ISO 9001, which outlines the requirements for a quality management system. In addition, industry-specific standards may apply, such as those from the American Society for Testing and Materials (ASTM) or the European Committee for Standardization (CEN). Compliance with these standards ensures that the products are manufactured consistently and meet the necessary specifications for safety and performance.

Illustrative image related to 1100 aluminium alloy

Quality Control Checkpoints

To maintain high-quality production, several quality control checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections and tests are conducted to monitor the production process. This may include checking dimensions, surface finishes, and mechanical properties.

-

Final Quality Control (FQC): Upon completion of the manufacturing process, final inspections and testing are performed to verify that the finished product meets all specifications and quality standards.

Common Testing Methods for 1100 Aluminium Alloy

Testing methods employed to ensure the quality of 1100 aluminium alloy include:

-

Mechanical Testing: Evaluating tensile strength, yield strength, and elongation through standardized tests to ensure the material meets performance criteria.

-

Chemical Composition Analysis: Utilizing methods like Optical Emission Spectrometry (OES) to verify the chemical composition and ensure it aligns with specifications.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or eddy current testing may be used to detect internal defects without damaging the material.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and compliance with local regulations.

Supplier Audits and Reports

One effective way to verify a supplier’s quality control processes is through site audits. Buyers can request access to the manufacturer’s facility to observe their production processes and quality assurance measures firsthand. Additionally, suppliers should provide quality control reports that detail inspection results, testing methodologies, and compliance with relevant standards.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These independent organizations can conduct thorough inspections and testing, ensuring that the products meet the required specifications before shipment. This is particularly important for buyers who may face language barriers or unfamiliar regulatory landscapes.

What Are the Quality Control and Certification Nuances for International Buyers?

When dealing with suppliers in different regions, international buyers must navigate various quality control and certification nuances. Understanding the specific requirements of each market is essential.

Regulatory Compliance

Different countries have unique regulations governing the use of materials in specific applications. For example, products intended for food handling in Europe must comply with stringent food safety standards. Buyers should ensure that suppliers provide the necessary certifications, such as CE marking for European markets, to demonstrate compliance.

Documentation and Traceability

Buyers should also emphasize the importance of documentation and traceability in the supply chain. This includes material certificates, test reports, and compliance documents that confirm the quality and safety of the products. Effective traceability helps mitigate risks associated with product recalls or non-compliance issues.

Building Strong Supplier Relationships

Finally, fostering strong relationships with suppliers can lead to better transparency in quality control practices. Regular communication and collaboration on quality improvement initiatives can help ensure that both parties are aligned on quality expectations.

By understanding the manufacturing processes and quality assurance measures associated with 1100 aluminium alloy, B2B buyers can make informed decisions that enhance their supply chain reliability and product integrity.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1100 aluminium alloy’

This guide provides a comprehensive checklist for B2B buyers looking to procure 1100 aluminium alloy. The goal is to ensure that you make informed decisions that meet your specific needs while navigating the complexities of international sourcing.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the 1100 aluminium alloy. This includes specifications related to thickness, temper (e.g., O, H14, H18), and form (sheets, rods, or custom shapes). Defining these parameters early on will streamline communications with suppliers and help avoid costly misunderstandings later.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of 1100 aluminium alloy. Look for manufacturers with a strong track record in your region or industry. Key aspects to investigate include:

– Certifications: Ensure suppliers have relevant ISO certifications to guarantee quality management.

– Industry Experience: Prioritize suppliers who specialize in aluminium alloys and have experience with clients in your sector.

Step 3: Evaluate Supplier Certifications

Once you have a shortlist of suppliers, verify their certifications and compliance with international standards. This step is crucial to ensuring that the materials you receive meet quality and safety standards. Look for:

– ISO 9001 Certification: Indicates a commitment to quality management.

– Material Safety Data Sheets (MSDS): Essential for understanding the properties and handling of the alloy.

Step 4: Request Samples

Before placing a large order, request samples of the 1100 aluminium alloy. Testing samples allows you to assess the material’s properties, such as formability, weldability, and corrosion resistance. Make sure to evaluate:

– Physical Properties: Check for compliance with the specifications you defined.

– Processing Characteristics: Test how well the material performs under your intended manufacturing processes.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms. Understanding the cost implications upfront will help you manage your budget effectively. Consider:

– Volume Discounts: Inquire if bulk purchasing can lead to cost savings.

– Payment Flexibility: Assess payment options that may include letters of credit or partial payments upon delivery.

Step 6: Assess Delivery Capabilities

Timely delivery is essential in B2B transactions, especially for materials like 1100 aluminium alloy that may be time-sensitive for production. Evaluate suppliers on their:

– Lead Times: Confirm how long it typically takes for orders to be processed and shipped.

– Shipping Options: Ensure they can accommodate your preferred shipping methods, whether by sea or air.

Illustrative image related to 1100 aluminium alloy

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Open lines of communication can facilitate problem-solving and ensure that any issues are addressed promptly. Key points to cover include:

– Regular Updates: Agree on how often you will receive updates regarding your order status.

– Point of Contact: Designate a specific contact person for both parties to streamline communication.

By following this checklist, you can confidently navigate the sourcing process for 1100 aluminium alloy, ensuring that you select a supplier who meets your technical, logistical, and financial needs.

Comprehensive Cost and Pricing Analysis for 1100 aluminium alloy Sourcing

What Are the Key Cost Components in Sourcing 1100 Aluminium Alloy?

Understanding the cost structure for sourcing 1100 aluminium alloy is crucial for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The main components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary material in 1100 aluminium alloy is high-purity aluminium (99% or greater). Fluctuations in global aluminium prices can significantly impact sourcing costs. Buyers should monitor market trends and consider long-term contracts to stabilize pricing.

-

Labor: Labor costs can vary widely based on the region and the complexity of the manufacturing process. Skilled labor is essential for tasks such as welding and forming, especially since 1100 alloy has excellent workability but requires expertise to avoid defects.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can lower overhead, which is particularly beneficial for buyers looking to negotiate better prices.

-

Tooling: Initial tooling costs can be substantial, particularly for custom orders. However, these costs can be amortized over larger production runs. Buyers should assess their projected volume to determine the most cost-effective tooling solutions.

-

Quality Control (QC): Ensuring that the alloy meets specific standards requires investment in quality control measures. Certifications such as ISO can enhance product value but may also increase costs.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, mode of transport, and Incoterms will influence overall logistics expenses. Understanding these can help buyers optimize their supply chain.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary based on market competition and supplier relationship dynamics. Establishing long-term relationships can lead to better pricing.

How Do Price Influencers Impact the Cost of 1100 Aluminium Alloy?

Several factors can influence the pricing of 1100 aluminium alloy, which are essential for buyers to consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect unit prices. Larger orders often attract discounts, making it essential for buyers to forecast their needs accurately.

-

Specifications/Customization: Custom specifications, such as specific temper or thickness, can raise costs. Buyers should balance their requirements against budget constraints.

-

Quality/Certifications: Higher quality and certification levels can lead to increased pricing. Buyers should assess the necessity of such certifications based on their application needs.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: The chosen Incoterm can dramatically alter the total cost of ownership. Buyers must clearly understand shipping responsibilities to avoid unexpected costs.

What Buyer Tips Can Help Optimize Costs for 1100 Aluminium Alloy Sourcing?

For B2B buyers, especially those from diverse international markets, there are several strategies to consider for optimizing costs:

-

Negotiation: Engage in negotiations with suppliers. Understanding the cost breakdown can empower buyers to negotiate more effectively, particularly on volume discounts or long-term contracts.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. This includes considering logistics, potential wastage, and the cost of delays.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Buyers should also consider tariffs and trade regulations that may affect final costs.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Trust can enhance collaboration, resulting in mutual benefits.

In conclusion, navigating the complexities of sourcing 1100 aluminium alloy requires a thorough understanding of cost components, price influencers, and strategic buying practices. By leveraging these insights, buyers can optimize their sourcing strategies and achieve cost-effective solutions tailored to their specific needs.

Alternatives Analysis: Comparing 1100 aluminium alloy With Other Solutions

Understanding Alternatives for 1100 Aluminium Alloy in B2B Applications

When considering materials for various applications, B2B buyers often explore alternatives to traditional options like 1100 aluminium alloy. This alloy, known for its excellent formability and corrosion resistance, may not always be the best fit depending on the specific requirements of a project. Evaluating alternative materials can lead to cost savings, improved performance, or enhanced suitability for specialized applications.

Comparison of 1100 Aluminium Alloy with Alternatives

| Comparison Aspect | 1100 Aluminium Alloy | Alternative 1: 3003 Aluminium Alloy | Alternative 2: Stainless Steel 304 |

|---|---|---|---|

| Performance | Good thermal conductivity; low strength (max 24 ksi) | Better strength and formability (max 22 ksi) | High strength and corrosion resistance; can withstand extreme environments |

| Cost | Generally lower cost due to high purity | Moderate cost, slightly higher than 1100 | Higher cost due to alloying elements and processing |

| Ease of Implementation | Excellent workability; easy to form and weld | Good workability; requires more force for forming | Moderate; tougher to work with and weld due to hardness |

| Maintenance | Low maintenance; excellent corrosion resistance | Low maintenance; good corrosion resistance | Low to moderate; resistant to rust but may require treatment in harsh environments |

| Best Use Case | Applications needing excellent conductivity and low strength | Suitable for food and chemical processing; good for structural applications | Ideal for high-stress environments and where corrosion resistance is critical |

Detailed Breakdown of Alternatives

3003 Aluminium Alloy

3003 aluminium alloy offers enhanced strength compared to 1100 while maintaining excellent formability and corrosion resistance. With a tensile strength of up to 22 ksi, it is suitable for applications such as food processing equipment and chemical storage tanks. However, it is slightly more expensive than 1100 and requires more force for forming, which may complicate certain fabrication processes.

Illustrative image related to 1100 aluminium alloy

Stainless Steel 304

Stainless Steel 304 is renowned for its high strength and excellent corrosion resistance, making it a go-to choice for harsh environments. Its tensile strength can significantly exceed that of both aluminium alloys, making it ideal for structural applications. However, it comes with a higher cost and can be more challenging to work with due to its toughness. Additionally, welding stainless steel requires specialized techniques, which could lead to increased labor costs.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right material depends on the specific requirements of your application, including performance, cost, and ease of processing. For projects prioritizing conductivity and low weight, 1100 aluminium alloy remains a solid choice. However, if strength and durability are paramount, exploring alternatives like 3003 aluminium or Stainless Steel 304 may yield better long-term value. B2B buyers should assess their unique operational needs, budget constraints, and environmental conditions to make an informed decision that aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for 1100 aluminium alloy

What Are the Key Technical Properties of 1100 Aluminium Alloy?

When considering 1100 aluminium alloy for various applications, understanding its critical specifications is essential for informed decision-making in B2B transactions. Here are some of the most important properties:

-

Material Grade

The 1100 aluminium alloy falls under the 1XXX series, which indicates that it is composed of at least 99% pure aluminium. This high purity level contributes to excellent corrosion resistance and electrical conductivity, making it suitable for applications like electrical conductors and heat exchangers. -

Temper Designations

The temper of an alloy refers to its thermal treatment and mechanical work, which significantly affects its mechanical properties. Common tempers for 1100 include O (annealed), H14, and H18. Each designation indicates different levels of strength and ductility. For example, 1100-H14 offers a balance of good strength and formability, which is crucial for applications requiring intricate shaping. -

Tensile and Yield Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled. For 1100 aluminium alloy, the tensile strength varies based on the temper, with 1100-O having a tensile strength of approximately 13 ksi, while 1100-H18 can reach up to 24 ksi. Understanding these values helps B2B buyers select the right alloy for their strength requirements. -

Corrosion Resistance

1100 aluminium alloy exhibits excellent resistance to corrosion, making it ideal for outdoor applications or environments that are prone to moisture. This characteristic is particularly valuable in industries such as construction and food processing, where material longevity is critical. -

Electrical Conductivity

With one of the highest electrical conductivities among aluminium alloys, 1100 is often used in electrical applications. This property is vital for manufacturers in the electrical and electronics sectors, as it ensures efficient performance and energy transfer. -

Formability and Workability

The alloy’s soft nature allows for excellent workability, making it suitable for processes such as bending, spinning, and deep drawing. This flexibility is essential for manufacturers looking to create complex shapes without compromising material integrity.

What Trade Terminology Should B2B Buyers Know About 1100 Aluminium Alloy?

Navigating the world of aluminium alloys involves understanding specific trade terminology that can impact procurement and supply chain processes. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for B2B buyers who need to source aluminium components for their own products. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers to manage inventory costs and ensure they are purchasing enough material to meet their production needs without overcommitting. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to bid on specific products or services. This is particularly useful in B2B transactions involving 1100 aluminium alloy, as it allows for comparison of prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps mitigate risks related to international transactions involving 1100 aluminium alloy. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to plan their production schedules effectively, especially when sourcing materials like 1100 aluminium alloy from international suppliers. -

Certification Standards

These are industry standards that materials must meet to ensure quality and safety. For aluminium alloys, certifications may include ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). Knowing these standards can help buyers ensure they are procuring high-quality materials that meet regulatory requirements.

By grasping these essential properties and terminology, B2B buyers can make more informed decisions when sourcing 1100 aluminium alloy, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the 1100 aluminium alloy Sector

What Are the Current Market Dynamics and Key Trends in the 1100 Aluminium Alloy Sector?

The global market for 1100 aluminium alloy is driven by a growing demand across various industries, including automotive, aerospace, and food processing. As industries increasingly seek lightweight materials for enhanced fuel efficiency and reduced emissions, aluminium alloys, particularly those with high thermal and electrical conductivity, are gaining traction. The increasing focus on renewable energy technologies, such as solar panels and wind turbines, further propels demand for 1100 aluminium alloy, which is extensively used in heat exchangers and electrical components.

Emerging B2B technologies are reshaping sourcing strategies in this sector. Digital platforms and e-commerce are streamlining procurement processes, allowing international buyers from Africa, South America, the Middle East, and Europe to access a broader supplier base. The rise of data analytics enables companies to forecast trends more accurately, making it easier to negotiate pricing and manage inventory levels. Additionally, the adoption of blockchain technology is enhancing supply chain transparency, allowing buyers to verify the authenticity and quality of materials sourced.

Market dynamics are also influenced by geopolitical factors and trade regulations. For instance, tariffs and import restrictions can affect pricing and availability, necessitating buyers to develop robust contingency plans. Companies are increasingly looking to diversify their supplier networks to mitigate risks associated with supply chain disruptions.

Illustrative image related to 1100 aluminium alloy

How Are Sustainability and Ethical Sourcing Shaping the 1100 Aluminium Alloy Market?

Sustainability has become a critical concern for B2B buyers, with increasing pressure to minimize environmental impacts. In the 1100 aluminium alloy sector, this translates into a focus on recycling and the use of secondary aluminium, which significantly reduces energy consumption and greenhouse gas emissions compared to primary production. Buyers are encouraged to seek suppliers who prioritize sustainable practices and offer recycled materials, aligning with their corporate social responsibility (CSR) objectives.

Ethical sourcing is equally important, as companies aim to ensure that their supply chains are free from human rights abuses and comply with local labor laws. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are gaining importance among suppliers. These certifications provide assurance that the materials sourced meet high environmental and ethical standards.

Moreover, the concept of “green” materials is becoming a market differentiator. Suppliers who can demonstrate a commitment to sustainability through transparent reporting and eco-friendly practices are likely to gain a competitive edge. Buyers should prioritize suppliers with recognized sustainability certifications and actively engage in discussions about their sourcing practices to ensure alignment with their values.

What Is the Brief Evolution of the 1100 Aluminium Alloy in B2B Context?

The development of 1100 aluminium alloy can be traced back to the early 20th century when the need for lightweight, corrosion-resistant materials became apparent. Initially utilized in the automotive and aerospace industries, its application has expanded due to its excellent formability and thermal conductivity. As manufacturing techniques evolved, so did the processing of aluminium alloys, leading to innovations in welding and fabrication.

Over the decades, the alloy’s versatility has made it a staple in industries requiring high purity and low strength. Its use in food handling equipment and decorative applications underscores its adaptability. The 1100 aluminium alloy has consistently maintained relevance in modern manufacturing, thanks to ongoing advancements in metallurgy and processing technologies. This evolution is particularly significant for international B2B buyers, as it reflects the alloy’s enduring value and adaptability in meeting diverse industrial needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 1100 aluminium alloy

-

How do I determine the right temper for 1100 aluminium alloy for my application?

Choosing the appropriate temper for 1100 aluminium alloy depends on the specific requirements of your application. For instance, the -O temper is fully annealed and offers excellent formability, making it ideal for intricate shapes. The -H14 temper provides increased strength while still allowing for good workability, suitable for parts that require some bending or stamping. Assess your product’s structural needs, processing methods, and environmental factors to select the best temper. -

What are the key properties of 1100 aluminium alloy that make it suitable for my project?

Aluminium alloy 1100 is renowned for its excellent corrosion resistance, high thermal and electrical conductivity, and superior workability. Its softness allows for easy fabrication processes such as bending, stamping, and spinning. Additionally, it is non-heat treatable, which simplifies its processing for various applications, including heat exchangers and food handling equipment. These properties make it an ideal choice for projects prioritizing formability and resistance to chemical attack. -

What are the typical applications of 1100 aluminium alloy in international markets?

In international markets, 1100 aluminium alloy is commonly used in applications such as electrical conductors, heat exchangers, cooking utensils, decorative parts, and rivets. Its excellent corrosion resistance and formability make it a preferred choice for industries like food processing, automotive, and construction. Understanding these applications can help you identify potential markets and customer needs in regions like Africa, South America, the Middle East, and Europe. -

How do I vet suppliers for 1100 aluminium alloy in international trade?

When vetting suppliers for 1100 aluminium alloy, consider several factors such as their certification (ISO, ASTM), production capacity, and quality assurance processes. Request samples to assess material quality and perform due diligence by checking references and customer reviews. Additionally, evaluate their ability to meet your specific requirements regarding customization, lead times, and logistics. Establishing a reliable relationship with a certified supplier can significantly enhance your procurement process. -

What customization options are available for 1100 aluminium alloy products?

Customization options for 1100 aluminium alloy products typically include variations in thickness, temper, and shapes such as sheets, coils, rods, and extrusions. Suppliers often offer tailored dimensions and finishes to meet specific application requirements. Discuss your needs with potential suppliers to explore available options, including cutting, anodizing, or other surface treatments that can enhance performance and aesthetic appeal. -

What are the common minimum order quantities (MOQs) for 1100 aluminium alloy?

Minimum order quantities (MOQs) for 1100 aluminium alloy can vary significantly between suppliers and may depend on the specific product and customization options. Generally, MOQs can range from 100 kg to several tons. It’s essential to communicate your specific needs with suppliers to understand their MOQ policies and negotiate terms that align with your project requirements. -

What payment terms are typically offered in B2B transactions for 1100 aluminium alloy?

Payment terms for B2B transactions involving 1100 aluminium alloy can vary widely depending on the supplier and the nature of the order. Common terms include upfront payment, 30% deposit with the balance upon delivery, or net 30/60 days after invoice. Establishing clear payment terms at the outset can help mitigate risks and ensure a smooth transaction process. Be sure to discuss any potential for bulk discounts or credit terms based on your purchasing history. -

How can I ensure quality assurance (QA) for my 1100 aluminium alloy orders?

To ensure quality assurance (QA) for your 1100 aluminium alloy orders, request detailed documentation from your supplier, including material certifications, test reports, and compliance with industry standards (e.g., ISO, ASTM). Consider specifying inspection protocols or third-party quality checks prior to shipment. Additionally, maintaining open communication with your supplier throughout the production process can help address any concerns promptly and ensure that the final product meets your specifications.

Top 6 1100 Aluminium Alloy Manufacturers & Suppliers List

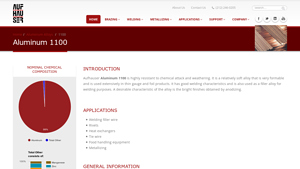

1. Online Metals – Aluminum 1100

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Aluminum 1100 is known for its superior corrosion resistance, formability, conductivity, and high weldability. It is typically used for chemical equipment, food handling equipment, decorative trim, lighting equipment, and heat exchangers. It is nonmagnetic, weldable, and not heat treatable. Common trade names include UNS A91100, ISO Al99.0Cu, AA1100-H14, and Al1100-H14. Specifications include ASTM…

2. Aufhauser – Aluminum 1100

Domain: brazing.com

Registered: 1995 (30 years)

Introduction: This company, Aufhauser – Aluminum 1100, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Azom – Aluminium 1100 Alloy

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Aluminium / Aluminum 1100 Alloy (UNS J91100)

**Chemical Composition:**

– Aluminium / Aluminum (Al): 99.00% (min)

– Copper (Cu): 0.12%

**Physical Properties:**

– Density: 2.71 g/cm³ (0.0979 lb/in³)

**Mechanical Properties:**

– Elastic Modulus: 70-80 GPa (10152-11603 ksi)

– Poisson’s Ratio: 0.33

**Thermal Properties:**

– Thermal Conductivity: 218 W/mK at 25°C (H18)

– Thermal Expansion: 23.6 x 10…

4. MatWeb – Aluminum 1100-O

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘Aluminum 1100-O’, ‘categories’: [‘Metal’, ‘Nonferrous Metal’, ‘Aluminum Alloy’, ‘1000 Series Aluminum’], ‘material_notes’: “This is a common commercial grade sold when ‘aluminum’ is specified. It is used where the intrinsic formability and corrosion resistance of aluminum is needed while high strength is not. Example applications include chemical and food handling, sheet metal, hollowwar…

5. Metal Supermarkets – Aluminum Sheet 1100

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Aluminum Sheet 1100 is a thin, flat-shaped sheet of commercially pure aluminum. It is soft and ductile with excellent workability, ideal for applications involving intricate forming. It has the highest thermal conductivity of any aluminum alloy and its electrical conductivity is second only to the electrical conductor grade. Specifications include:

– Corrosion Resistance: Excellent

– Formability/W…

6. Hydro – 1100 Aluminum Alloy

Domain: hydro.com

Registered: 1991 (34 years)

Introduction: 1100 Aluminum is a commercially pure aluminum alloy with a purity of at least 99.0% aluminum. It is non-heat-treatable, soft, and ductile with excellent workability. This alloy is known for being the most weldable of aluminum alloys and work hardens more slowly than others. It is ideal for applications requiring maximum ductility and relatively low strength, such as chemical and food handling equi…

Strategic Sourcing Conclusion and Outlook for 1100 aluminium alloy

In the evolving landscape of materials sourcing, 1100 aluminium alloy stands out as a versatile and cost-effective choice for international B2B buyers across various industries. Its exceptional formability, high thermal and electrical conductivity, and excellent corrosion resistance make it suitable for applications ranging from food handling equipment to electrical conductors. Understanding the alloy’s mechanical properties and its suitability for specific applications is crucial for making informed purchasing decisions.

Strategic sourcing of 1100 aluminium alloy not only ensures the procurement of high-quality materials but also enhances operational efficiency and product performance. As markets in Africa, South America, the Middle East, and Europe continue to expand, leveraging the strengths of this alloy can lead to significant competitive advantages. Buyers should prioritize relationships with suppliers who can provide reliable specifications and consistent quality to meet their unique needs.

Looking ahead, it is essential for B2B buyers to stay informed about market trends and innovations related to aluminium alloys. By embracing strategic sourcing practices and fostering partnerships with reputable suppliers, businesses can position themselves for growth and success in an increasingly competitive global market. Engage with your suppliers today to explore how 1100 aluminium alloy can elevate your product offerings and operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.