Choosing Your Belt Material: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for belt material

In the dynamic landscape of global manufacturing, sourcing high-quality belt materials poses a significant challenge for B2B buyers across various industries. Whether you are looking for reinforced rubber for power transmission or durable polyurethane for conveyor systems, understanding the nuances of different belt materials is crucial to maintaining operational efficiency. This comprehensive guide delves into the diverse types of belt materials available, their specific applications, and practical insights into supplier vetting and cost considerations.

By exploring the intricacies of belt materials, this guide equips international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Vietnam—with the knowledge needed to make informed purchasing decisions. From the resilience of nylon fibers to the versatility of PVC, we will outline how each material can enhance your operational capabilities while addressing your unique business requirements.

Moreover, we will highlight best practices for evaluating suppliers, ensuring quality compliance, and optimizing logistics to streamline your sourcing process. With actionable insights and expert recommendations, this guide empowers you to navigate the complexities of the global belt material market, enabling you to secure the best solutions for your production needs.

Understanding belt material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reinforced Rubber | High tensile strength, shock absorption, water-resistant | Automotive, manufacturing, agriculture | Pros: Durable, versatile, excellent resistance. Cons: Can be heavier and more expensive. |

| Polyurethane | Resistant to moisture and wear, durable structure | Packaging, material handling, food processing | Pros: Long-lasting, adaptable to various conditions. Cons: Limited heat resistance compared to rubber. |

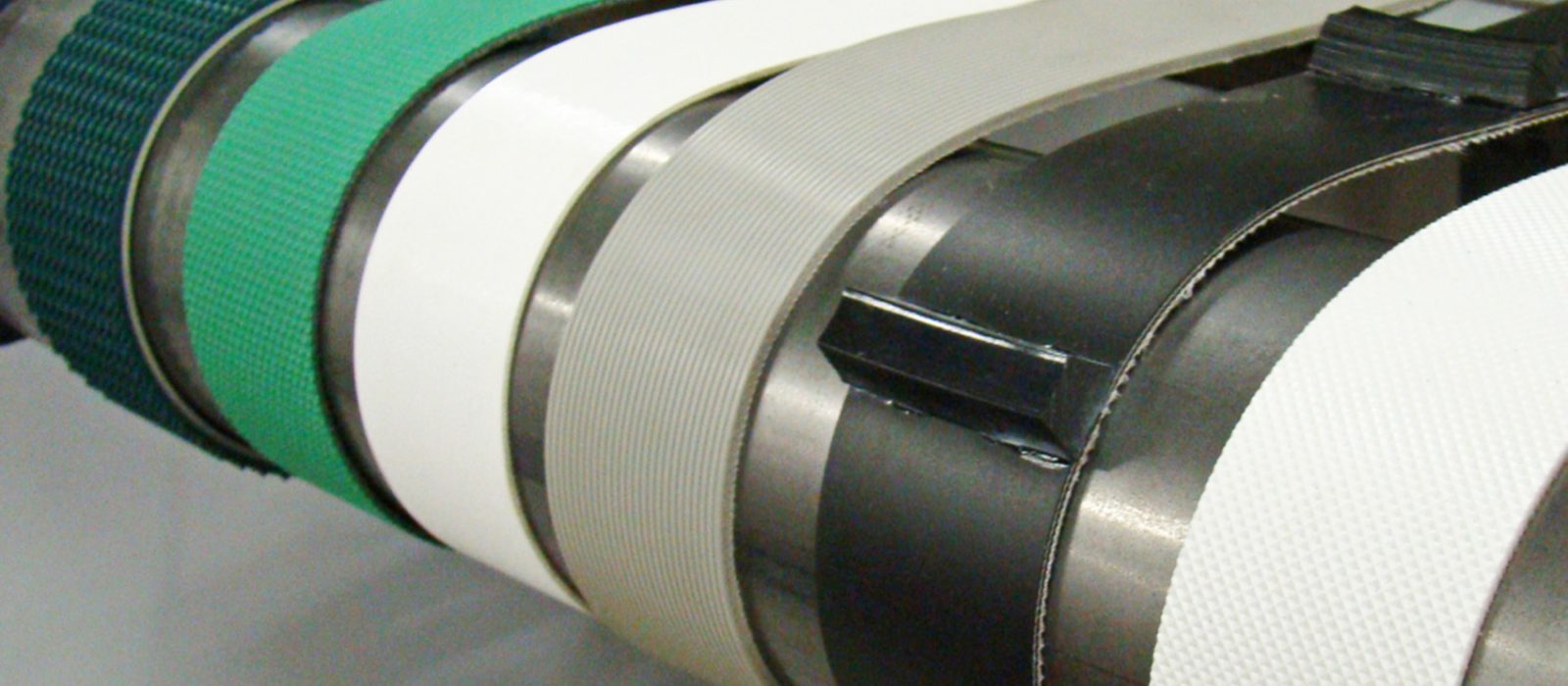

| Polyvinyl Chloride (PVC) | Lightweight, high temperature and speed adaptability | Conveyor systems, packaging, textiles | Pros: Easy to handle and store, cost-effective. Cons: Less durable under extreme conditions. |

| Nylon Fibers | Water-resistant, often reinforced with other materials | Printing, packaging, textiles | Pros: Lightweight, easy to clean. Cons: Can wear down faster in high-friction applications. |

| Leather | Natural material, aesthetically pleasing, durable | Fashion, accessories, specialty applications | Pros: High-quality appearance, strong. Cons: Higher maintenance and cost. |

What are the Characteristics and Suitability of Reinforced Rubber Belts?

Reinforced rubber belts are a staple in various industrial applications due to their exceptional tensile strength and shock absorption capabilities. The addition of materials like fiberglass or polyester enhances their durability, making them suitable for demanding environments such as automotive manufacturing and agriculture. Buyers should consider the specific load requirements and environmental factors, as these belts offer excellent resistance to wear, heat, and chemicals, albeit at a potentially higher cost and weight.

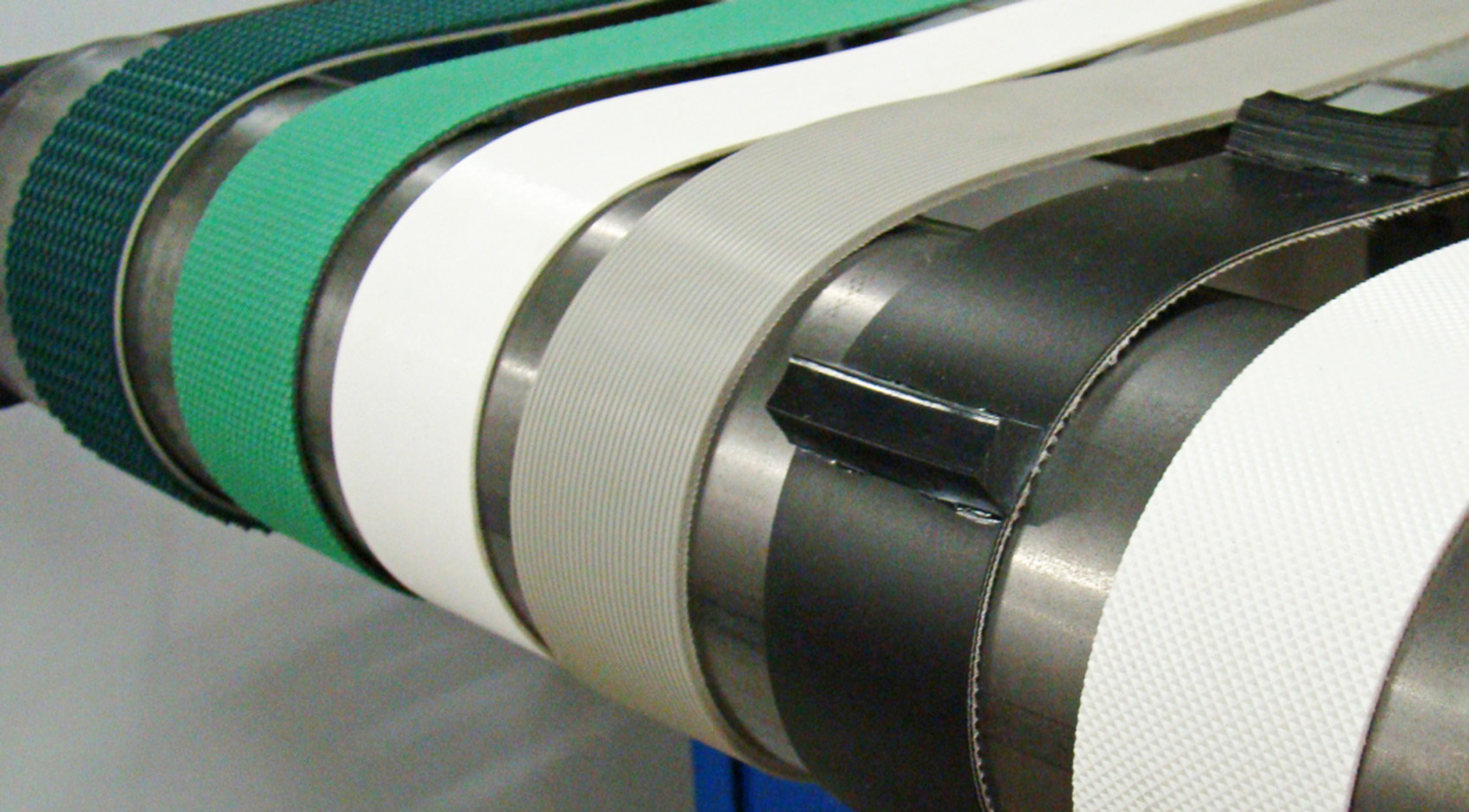

Illustrative image related to belt material

How Do Polyurethane Belts Stand Out in Industrial Applications?

Polyurethane belts are known for their robust structure and resistance to moisture and wear. They are particularly effective in applications requiring durability, such as packaging and material handling. Their adaptability to different environmental conditions makes them a reliable choice for food processing industries. When purchasing, buyers should evaluate the specific wear conditions and temperature ranges, as polyurethane belts provide longevity but may not withstand extreme heat as well as rubber.

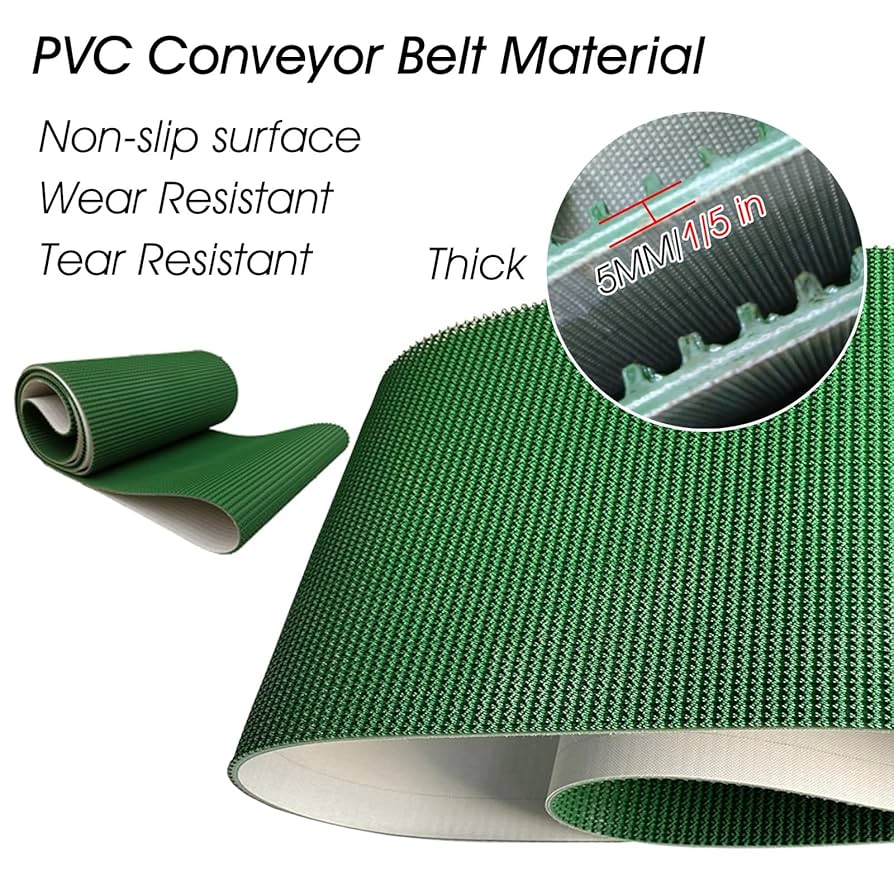

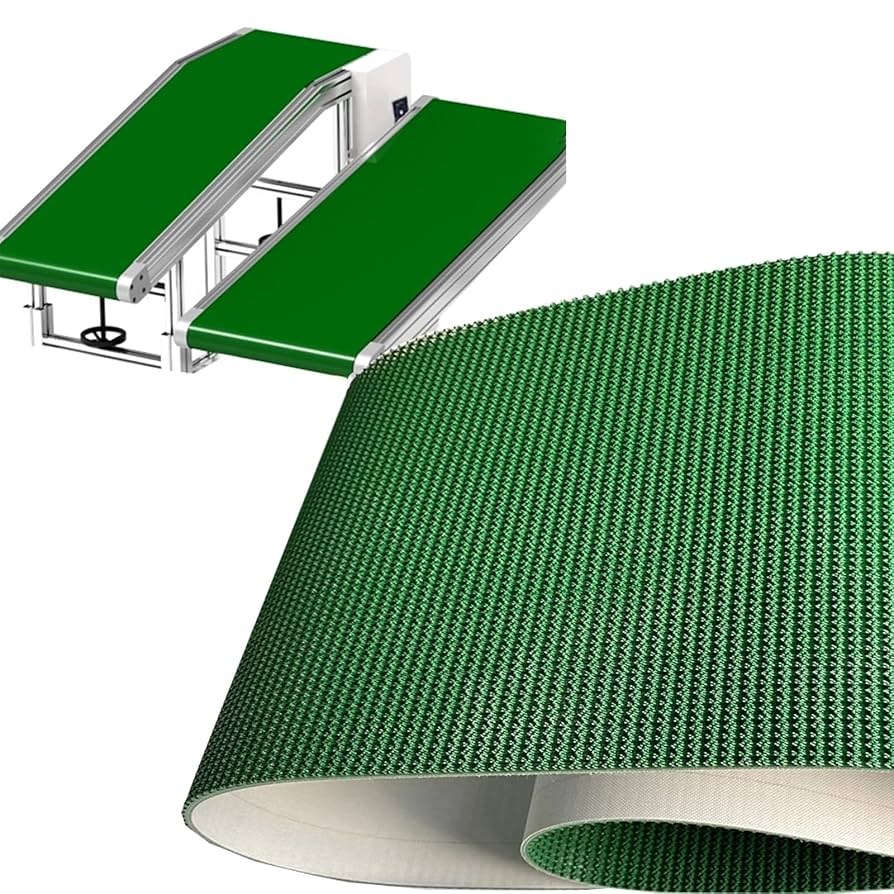

What Makes Polyvinyl Chloride (PVC) Belts a Popular Choice?

PVC belts are lightweight and designed to withstand high temperatures and speeds, making them ideal for conveyor systems and textile applications. Their easy handling and storage properties are significant advantages for businesses looking to optimize logistics. However, buyers must weigh the cost-effectiveness against the potential for reduced durability under extreme conditions, which may limit their applicability in high-stress environments.

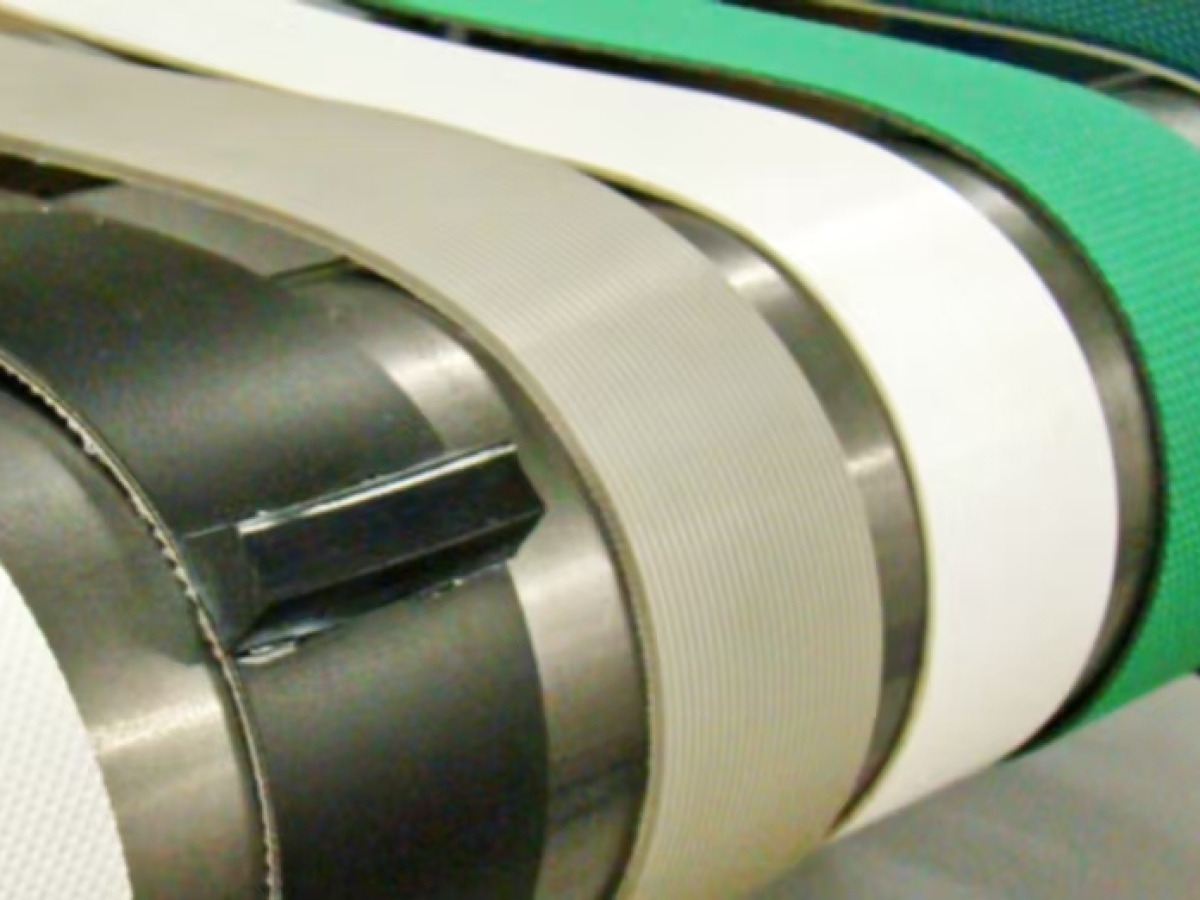

Why Are Nylon Fibers Commonly Used in Specific Industries?

Nylon fiber belts are frequently used in the printing and packaging sectors due to their sleek, water-resistant surfaces that are easy to clean. These belts can be reinforced for added strength, making them suitable for moderate load applications. Buyers should consider the friction levels in their operations, as nylon may wear down more quickly in high-friction settings, impacting long-term costs and performance.

Illustrative image related to belt material

What Are the Benefits and Drawbacks of Leather Belts in B2B Applications?

Leather belts are prized for their durability and aesthetic appeal, making them popular in fashion and specialty applications. They offer a strong and natural alternative to synthetic materials, providing unique branding opportunities. However, leather requires more maintenance and can be more expensive than other belt materials. B2B buyers should assess the intended use and maintenance capabilities when considering leather belts, as they may not be suitable for all industrial environments.

Key Industrial Applications of belt material

| Industry/Sector | Specific Application of belt material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power transmission in machinery | Improved efficiency and reduced downtime | Material compatibility, tensile strength, and heat resistance |

| Food Processing | Conveyor belts for food handling | Enhanced hygiene and compliance with safety standards | FDA-approved materials, ease of cleaning, and durability |

| Packaging | Timing belts in automated packaging systems | Precision in operations and increased productivity | Accuracy of dimensions, resistance to wear, and flexibility |

| Agriculture | Belts for agricultural machinery | Enhanced operational reliability and reduced maintenance | Weather resistance, strength under load, and adaptability |

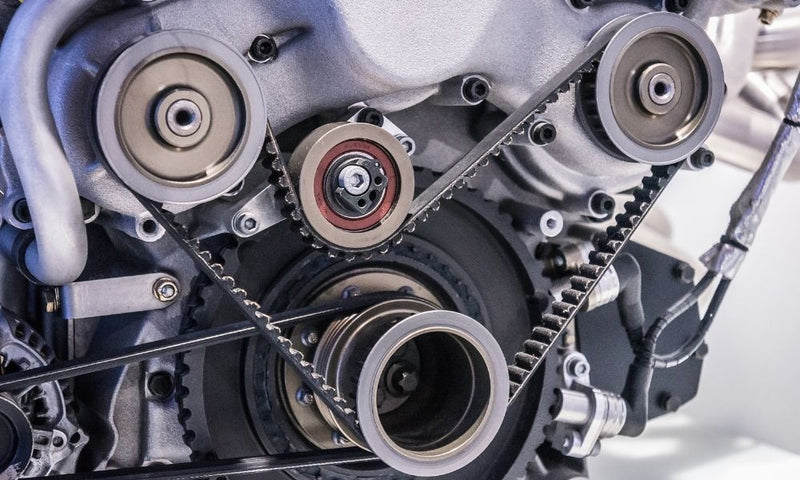

| Automotive | Drive belts in vehicles | Improved performance and fuel efficiency | Compatibility with engine specifications and durability |

How Is Belt Material Used in Manufacturing Applications?

In manufacturing, belt materials are crucial for power transmission in machinery. They connect motors to drive shafts, enabling efficient operation across various equipment. The use of reinforced rubber belts, for instance, enhances shock absorption and resilience against wear, which is vital for minimizing downtime. Buyers in this sector should prioritize sourcing belts that offer high tensile strength and heat resistance to meet the demands of continuous operation, especially in regions with fluctuating temperatures.

What Are the Key Benefits of Using Belt Material in Food Processing?

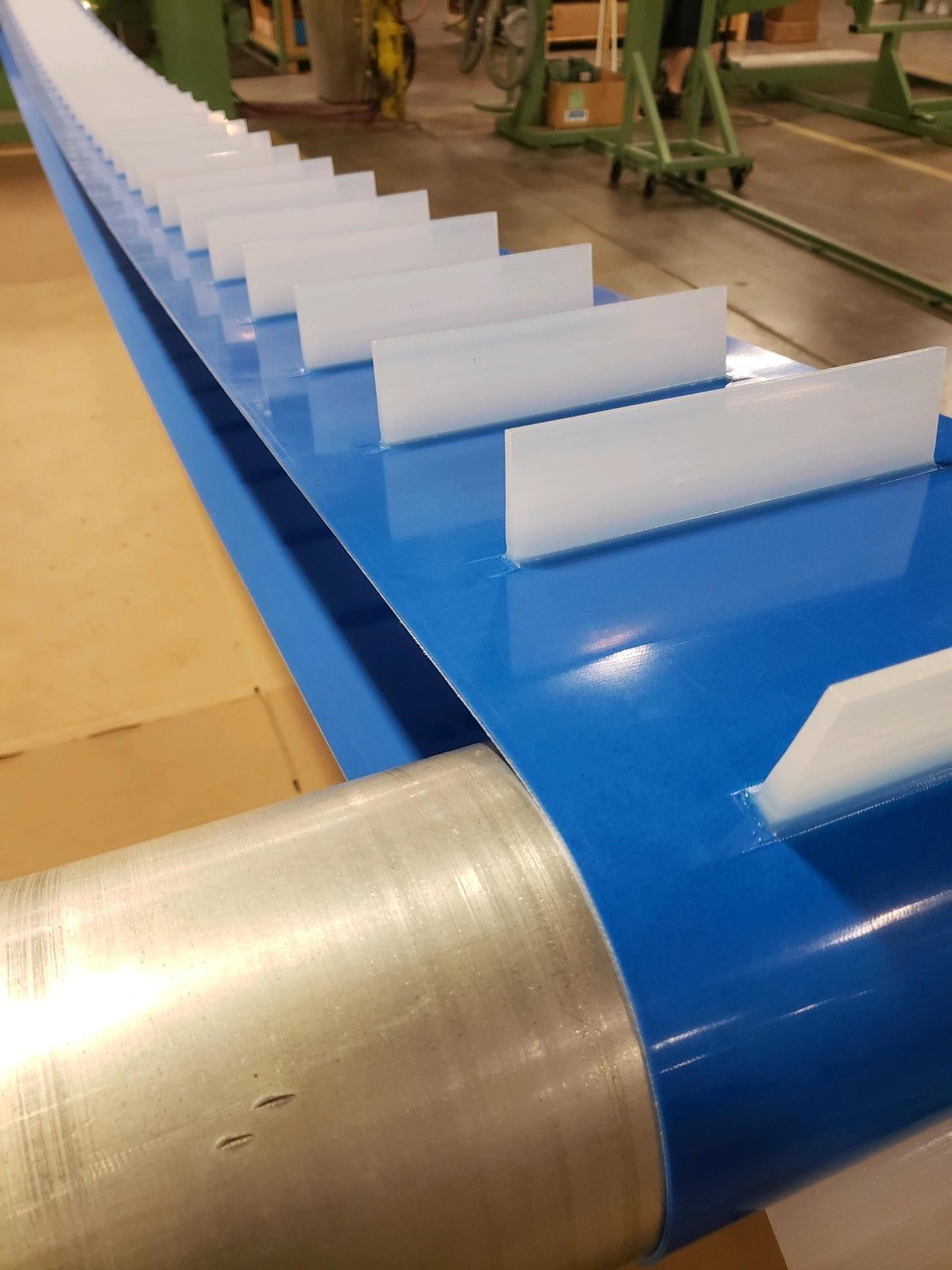

Belt materials are integral to conveyor systems in food processing. They ensure safe and efficient handling of food products while maintaining hygiene standards. Materials such as polyurethane and PVC are preferred for their resistance to moisture and ease of cleaning, which are essential for compliance with health regulations. International buyers should focus on sourcing FDA-approved materials that can withstand high temperatures and are easy to sanitize, particularly in markets like Africa and South America where food safety is paramount.

Illustrative image related to belt material

How Does Belt Material Improve Packaging Efficiency?

In the packaging industry, timing belts are employed in automated systems to ensure precise movement and synchronization of machinery. The durability and wear resistance of these belts contribute to increased productivity and reduced operational costs. Buyers should consider sourcing belts that offer flexibility and high accuracy in dimensions, as these factors are critical for seamless integration into existing systems. This is especially important for businesses in Europe looking to enhance their packaging lines.

Why Is Belt Material Important in Agriculture?

Agricultural machinery relies heavily on belt materials for optimal performance. Belts are used in various equipment, from tractors to harvesters, to transmit power efficiently. The strength and weather resistance of these belts are vital for ensuring reliability and reducing maintenance needs in challenging environments. Buyers in this sector should prioritize sourcing belts that can withstand heavy loads and varying weather conditions, particularly in regions like the Middle East where agricultural practices face unique challenges.

How Do Automotive Applications Benefit from Belt Material?

In the automotive sector, drive belts play a crucial role in connecting various engine components, affecting overall vehicle performance and fuel efficiency. The use of high-quality materials ensures durability and longevity, reducing the frequency of replacements. Buyers should focus on sourcing belts that are compatible with specific engine specifications, as this compatibility directly impacts vehicle performance. This consideration is particularly relevant for international buyers in markets such as Nigeria and Vietnam, where vehicle maintenance practices are evolving.

3 Common User Pain Points for ‘belt material’ & Their Solutions

Scenario 1: Inconsistent Performance Across Varied Applications

The Problem: B2B buyers often face challenges when sourcing belt materials that can perform consistently across different industrial applications. For instance, a manufacturing company may require belts for both high-speed conveyor systems and slower, heavier applications. Using a single type of belt material might lead to premature wear, increased downtime, and unexpected maintenance costs, as the material may not withstand the varying loads and speeds effectively. Buyers need to ensure that the selected belts can handle the specific demands of each application without sacrificing performance.

Illustrative image related to belt material

The Solution: To address this issue, it’s essential to conduct a thorough assessment of the operational environment before selecting belt materials. Begin by categorizing your applications based on speed, load, and environmental factors (e.g., temperature, moisture). For high-speed operations, consider using reinforced rubber or polyurethane belts that offer enhanced tensile strength and durability. Conversely, for heavier applications, opt for materials like PVC that can bear significant loads without deformation. Additionally, consulting with manufacturers or suppliers who can provide tailored recommendations based on your unique requirements can ensure that you procure the right materials. Regular performance reviews and supplier communication can also help in adjusting specifications as needed.

Scenario 2: Limited Knowledge of Material Properties

The Problem: Many B2B buyers lack in-depth knowledge about the specific properties and advantages of different belt materials. This lack of understanding can lead to poor purchasing decisions that negatively impact production efficiency. For instance, a buyer might select a nylon belt for an application requiring high chemical resistance, only to find that it deteriorates quickly in the presence of certain substances, resulting in costly downtimes and replacements.

The Solution: To mitigate this pain point, it is crucial to invest time in training and education regarding belt materials and their properties. Buyers should familiarize themselves with the strengths and weaknesses of common materials like urethane, rubber, and PVC. Consider organizing workshops or webinars with industry experts who can share insights on material performance in various conditions. Additionally, create a detailed specification sheet that outlines the chemical, thermal, and mechanical properties of the belt materials you are considering. This resource will aid in making informed choices and ensure that the selected materials align with operational needs.

Illustrative image related to belt material

Scenario 3: Difficulty in Sourcing Reliable Suppliers

The Problem: A significant challenge faced by B2B buyers is the difficulty in finding reliable suppliers for high-quality belt materials. In regions with less established supply chains, such as parts of Africa and South America, buyers may encounter inconsistent product quality, delayed shipments, or lack of responsive customer service. These issues can severely disrupt operations and lead to lost revenue and productivity.

The Solution: To improve supplier reliability, it’s advisable to develop a strategic sourcing plan. Start by researching potential suppliers who have a proven track record in your industry. Look for those who offer comprehensive product lines, consistent quality, and robust after-sales support. Establishing long-term relationships with a select few suppliers can enhance communication and ensure a better understanding of your needs. Additionally, consider utilizing global platforms to connect with reputable manufacturers and suppliers who can offer competitive pricing and quality assurance. Finally, implementing a supplier evaluation system can help track performance and identify any potential issues early, allowing for proactive solutions and maintaining operational continuity.

Strategic Material Selection Guide for belt material

What Are the Key Properties of Common Belt Materials?

When selecting belt materials for industrial applications, understanding the properties of each material is crucial for optimizing performance. Here, we analyze four common belt materials: Reinforced Rubber, Urethane, Polyvinyl Chloride (PVC), and Nylon Fibers, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Reinforced Rubber Enhance Belt Performance?

Reinforced rubber is a long-standing choice for industrial belts due to its excellent shock absorption, elasticity, and water resistance. The reinforcement with materials like fiberglass or polyester significantly enhances its tensile strength, heat resistance, and chemical resistance, making it suitable for demanding environments.

Pros: This material is highly durable and can withstand various industrial conditions, including high temperatures and abrasion. Its flexibility allows it to perform well in applications requiring frequent bending.

Cons: The manufacturing complexity can lead to higher costs, especially when specialized reinforcement is involved. Additionally, rubber belts may degrade under certain chemical exposures, necessitating careful selection based on the specific application.

Impact on Application: Reinforced rubber belts are ideal for power transmission systems in automotive and manufacturing sectors, where they handle high loads and dynamic movements.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Familiarity with standards such as ASTM or DIN can assist in selecting appropriate products.

What Advantages Do Urethane Belts Offer?

Urethane belts are known for their resistance to moisture, wear, and tear, making them a reliable choice for various industrial applications. Their robust structure allows them to handle strenuous demands without significant degradation.

Pros: Urethane belts are versatile, offering excellent performance in both high-load and delicate applications. They are also resistant to cuts and abrasions, extending their lifespan.

Cons: While they are durable, urethane belts can be more expensive than other materials. Additionally, they may not perform well in extremely high-temperature environments.

Impact on Application: Urethane belts are commonly used in food processing and packaging industries due to their hygienic properties and ability to handle diverse media.

Illustrative image related to belt material

Considerations for International Buyers: Buyers should verify that urethane belts meet food safety standards applicable in their regions. Understanding local certifications can help in making informed purchasing decisions.

How Does Polyvinyl Chloride (PVC) Compare?

Polyvinyl Chloride (PVC) is a lightweight synthetic polymer that offers good adaptability to various conditions, including high temperatures and weights. Its structural design makes it suitable for numerous applications.

Pros: The lightweight nature of PVC makes it easy to handle, transport, and store. It also provides good chemical resistance, which is beneficial in many industrial environments.

Cons: PVC may not be as durable as rubber or urethane in high-stress applications. Its performance can diminish under extreme temperature variations.

Impact on Application: PVC belts are often used in conveyor systems for light to moderate loads, particularly in packaging and material handling sectors.

Illustrative image related to belt material

Considerations for International Buyers: Compliance with local environmental regulations regarding PVC usage is essential, especially in Europe, where restrictions may apply. Buyers should also consider the availability of PVC products in their regions.

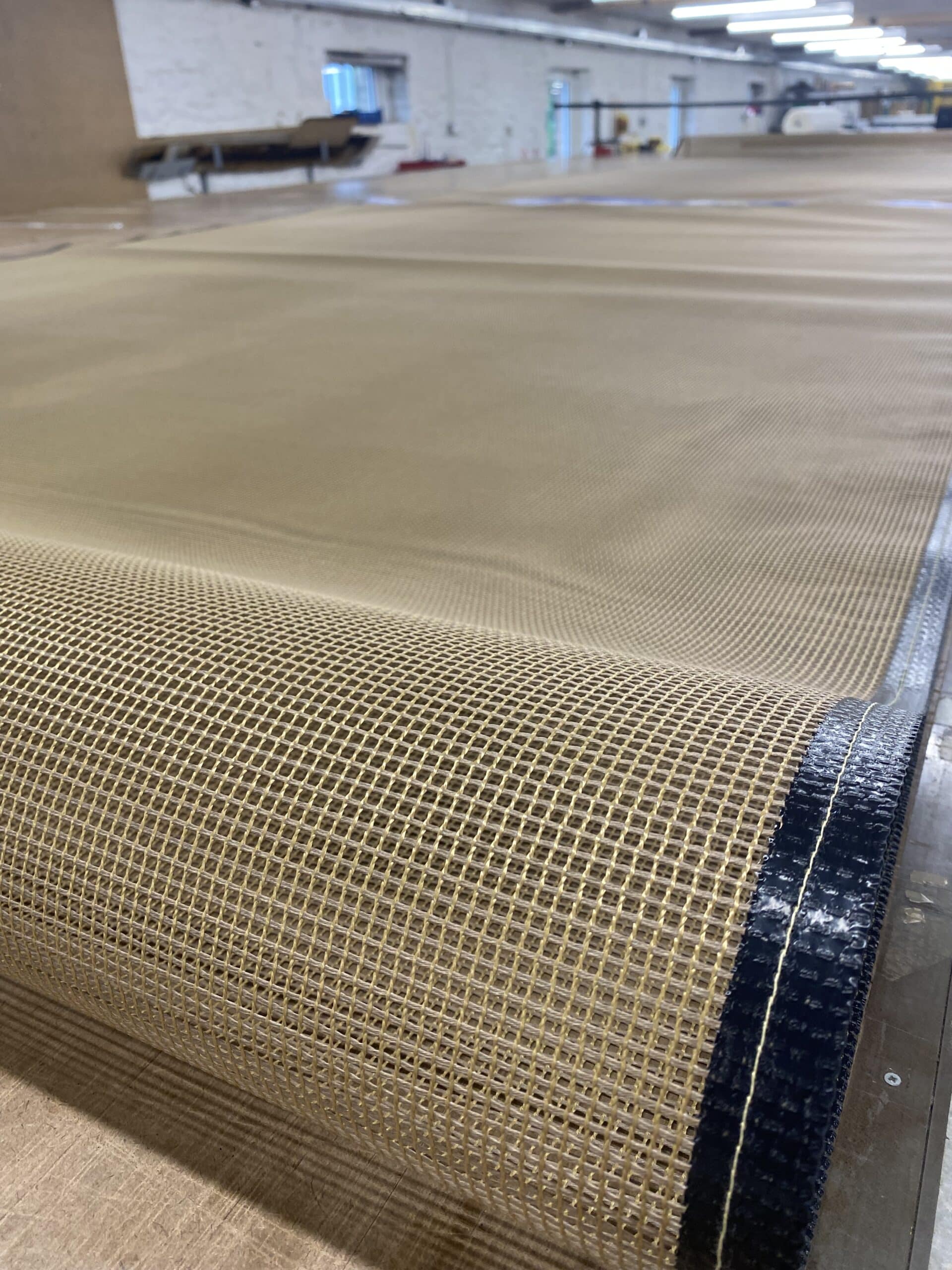

What Role Do Nylon Fibers Play in Belt Manufacturing?

Nylon fibers are frequently reinforced to enhance their performance characteristics. They are particularly favored in the printing and packaging industries for their water-resistant properties and ease of cleaning.

Pros: Nylon belts are durable and provide a sleek surface, making them ideal for applications requiring cleanliness and aesthetic appeal. Their flexibility allows for smooth operation in various systems.

Illustrative image related to belt material

Cons: The cost of nylon can be higher than that of simpler materials, and its performance can be affected by exposure to certain chemicals.

Impact on Application: Nylon belts excel in environments where cleanliness and resistance to moisture are critical, such as food packaging and textile manufacturing.

Considerations for International Buyers: Buyers should ensure that nylon products meet local standards for safety and performance. Familiarity with international standards can facilitate smoother transactions.

Summary Table of Belt Materials

| Material | Typical Use Case for belt material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Reinforced Rubber | Power transmission in automotive systems | High durability and shock absorption | Higher manufacturing complexity and cost | Medium |

| Urethane | Food processing and packaging | Excellent wear resistance and versatility | Higher cost and limited high-temperature performance | High |

| Polyvinyl Chloride (PVC) | Conveyor systems for light loads | Lightweight and easy to handle | Limited durability under high stress | Low |

| Nylon Fibers | Printing and packaging applications | Sleek, water-resistant surfaces | Higher cost and chemical sensitivity | Medium |

This guide provides actionable insights for B2B buyers, helping them make informed decisions about belt material selection based on their specific industry needs and regional considerations.

Illustrative image related to belt material

In-depth Look: Manufacturing Processes and Quality Assurance for belt material

What Are the Key Stages in the Manufacturing Process of Belt Material?

The manufacturing process of belt material is complex and involves several critical stages that ensure durability, performance, and quality. Understanding these stages is essential for B2B buyers looking to procure high-quality belt materials for various industrial applications.

Material Preparation: What Goes Into the Production of Belt Materials?

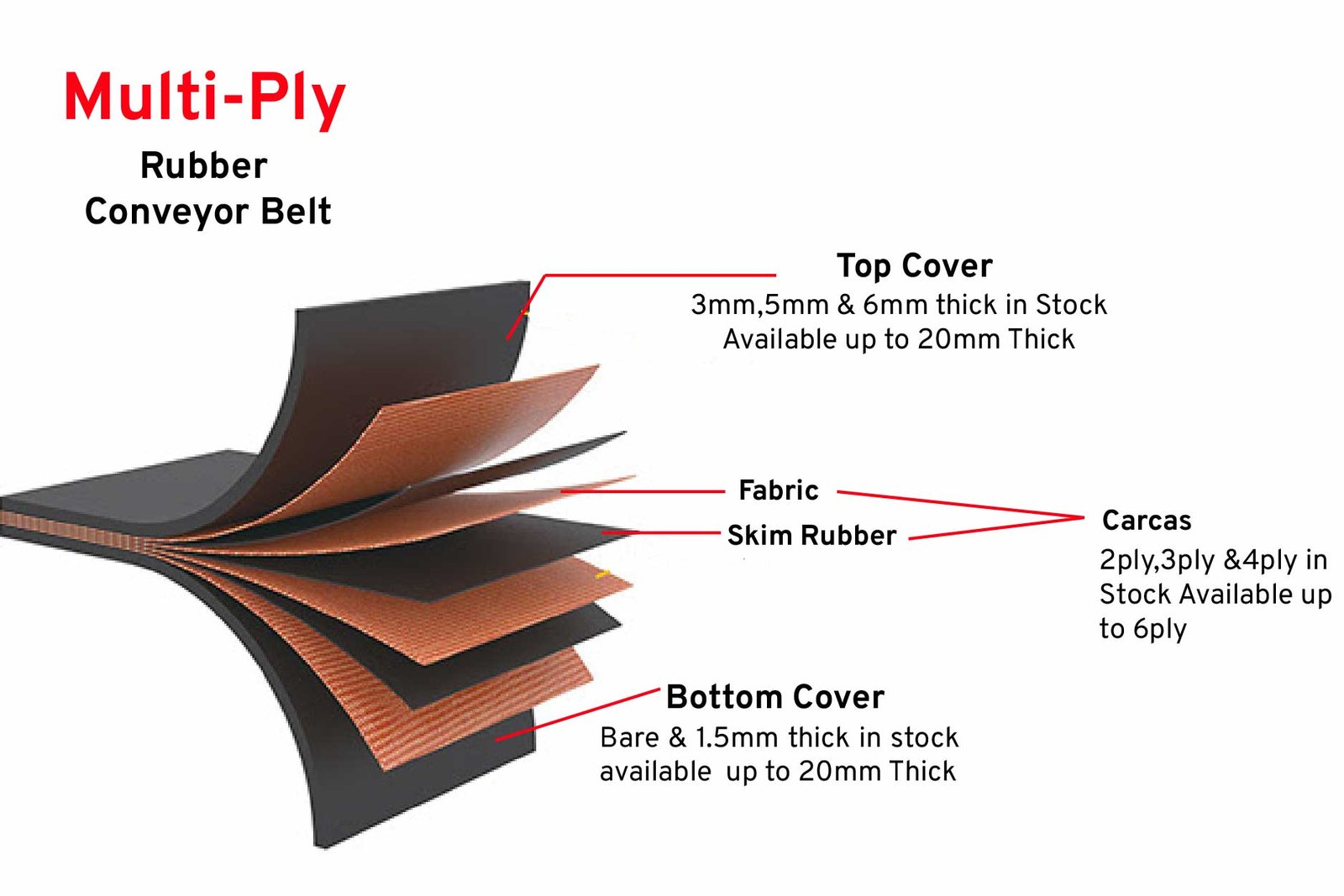

The first stage in manufacturing belt materials involves the careful selection and preparation of raw materials. Common materials include reinforced rubber, polyurethane, PVC, and nylon fibers. Each material is sourced based on specific performance requirements.

For rubber belts, the preparation may involve mixing natural rubber with additives to enhance properties such as tensile strength and heat resistance. Polyurethane materials are often processed to achieve the desired elasticity and durability. This preparation stage is crucial, as the quality of raw materials directly impacts the final product’s performance.

How Are Belt Materials Formed into Their Final Shape?

Once the materials are prepared, they undergo various forming techniques to create the belt shape. Common methods include extrusion, molding, and weaving.

-

Extrusion: Primarily used for rubber and polyurethane belts, this method forces material through a die to achieve a specific cross-sectional shape. The extruded belts are then cut to the desired length.

-

Molding: This technique is often employed for PVC belts, where heated material is poured into molds to form specific shapes or profiles.

-

Weaving: For nylon belts, weaving techniques are used to create a fabric-like structure that offers flexibility and strength.

The forming stage is critical for ensuring the belts meet precise dimensions and performance specifications.

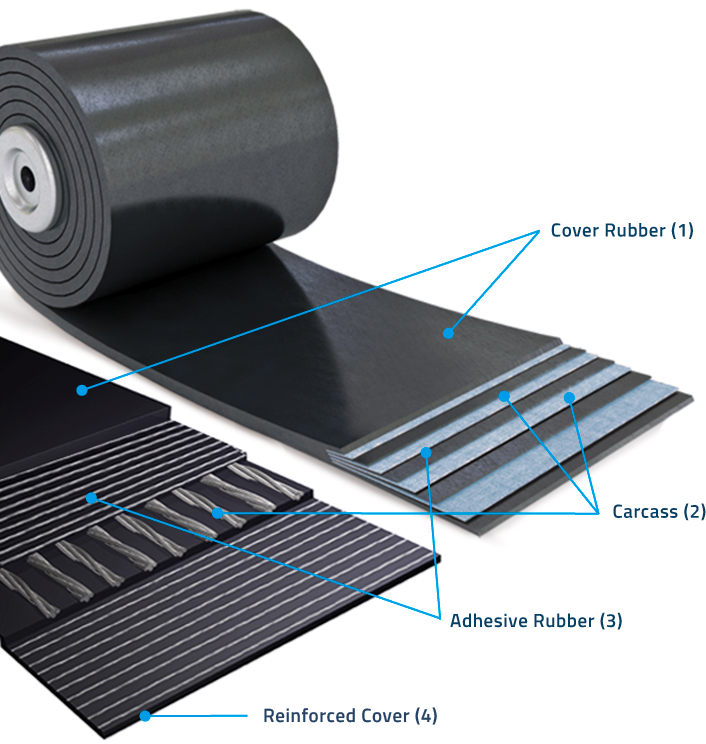

What Happens During the Assembly Stage of Belt Manufacturing?

The assembly stage involves combining various components of the belt. For instance, in reinforced rubber belts, layers of rubber may be combined with reinforcing materials such as fiberglass or polyester. In some cases, additional elements like metal or plastic fittings are integrated to enhance the belt’s functionality.

Illustrative image related to belt material

This stage requires meticulous attention to detail to ensure that all components are securely attached, which directly affects the belt’s performance and longevity.

How Is the Finishing Process Conducted for Belt Materials?

The finishing stage is where the belts undergo final adjustments and enhancements. This can include trimming edges, applying coatings, or adding finishes that improve resistance to wear and tear. For example, belts may be treated with anti-static coatings or UV protectants, depending on their intended application.

Additionally, this stage often involves surface testing to ensure the belts meet industry-specific standards before they are packaged and shipped.

What Quality Assurance Practices Are Essential for Belt Materials?

Quality assurance is a critical aspect of belt manufacturing, ensuring that the final products meet both international standards and specific industry requirements. Buyers should be aware of the quality control processes that manufacturers implement throughout production.

Which International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are pivotal in ensuring quality management systems are in place. ISO 9001 certification indicates that a manufacturer adheres to a set of quality management principles, including strong customer focus, the involvement of top management, and a process-based approach.

Illustrative image related to belt material

Additionally, industry-specific certifications such as CE (for European markets) and API (for the oil and gas sector) can provide assurance regarding safety and environmental considerations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to monitor and ensure product quality. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to monitor processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After production, the finished belts undergo rigorous testing and inspection to ensure they meet performance specifications and quality standards.

How Can B2B Buyers Verify a Supplier’s Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are effective strategies:

-

Supplier Audits: Conducting regular audits allows buyers to evaluate the manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports, including testing results and compliance certificates, can provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes, ensuring that they meet required standards before shipment.

What Are the Nuances in Quality Control for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various challenges related to quality control.

Illustrative image related to belt material

-

Regulatory Compliance: Different countries have varying regulations regarding product standards, so understanding local compliance requirements is crucial.

-

Cultural Differences: Business practices and communication styles can differ significantly between regions, impacting how quality control measures are perceived and implemented.

-

Logistical Considerations: International shipping can introduce risks such as damage during transport, necessitating robust quality assurance practices to ensure products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices associated with belt materials, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt material’

In the competitive landscape of industrial operations, sourcing the right belt materials is crucial for ensuring efficiency and longevity in machinery. This guide provides a structured checklist to assist B2B buyers in making informed decisions when procuring belt materials.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating your sourcing process. Determine the type of belt material required based on the application, such as power transmission or conveyor systems. Consider factors like load capacity, environmental conditions, and specific performance characteristics (e.g., heat resistance, chemical compatibility) that align with your operational needs.

Step 2: Research Material Options

Understanding the various belt materials available is critical for making an informed choice. Common options include reinforced rubber, polyurethane, PVC, and nylon. Each material has unique properties:

– Reinforced Rubber: Known for shock absorption and durability.

– Polyurethane: Offers resistance to moisture and wear, ideal for demanding environments.

– PVC: Lightweight and adaptable to various conditions, suitable for high-speed applications.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is a crucial step to ensure reliability and quality. Request company profiles, product certifications, and references from other buyers in similar industries. Look for suppliers who have experience in your specific market region (e.g., Africa, South America, Europe), as they will understand local challenges and regulatory requirements.

Step 4: Assess Quality Standards and Certifications

Quality assurance is paramount when sourcing belt materials. Verify if the suppliers adhere to international quality standards, such as ISO certifications. This not only ensures that the materials meet safety and performance benchmarks but also provides peace of mind regarding the supplier’s commitment to quality.

Step 5: Request Samples and Test Performance

Before finalizing your order, always request material samples for evaluation. Testing samples in your specific application can help identify any potential issues related to fit, performance, and durability. This step is crucial to avoid costly mistakes and ensure that the material meets your operational demands.

Illustrative image related to belt material

Step 6: Consider Cost and Total Cost of Ownership

While price is a significant factor, it’s important to evaluate the total cost of ownership. This includes not only the initial purchase price but also factors like maintenance, replacement frequency, and operational efficiency. Cheaper materials may lead to higher long-term costs due to increased wear and tear or inefficiency.

Step 7: Establish Clear Communication and Terms

Effective communication with your supplier can prevent misunderstandings and ensure smooth transactions. Discuss lead times, payment terms, and return policies upfront. Establishing clear agreements regarding delivery schedules and expectations can help mitigate risks associated with supply chain disruptions.

By following this checklist, B2B buyers can streamline their sourcing process and make informed decisions that enhance their operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for belt material Sourcing

What Are the Key Cost Components in Belt Material Sourcing?

When considering the sourcing of belt materials, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly affects pricing. Common materials such as reinforced rubber, polyurethane, and PVC each have different cost implications based on their properties and availability. For instance, reinforced rubber is often more expensive due to its enhanced durability and performance characteristics.

-

Labor: Labor costs include wages for skilled workers involved in the manufacturing process. The complexity of the production methods, such as cutting and shaping the belts, can influence these costs.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and facility costs. High overhead can occur in regions with stringent labor laws or high energy costs.

-

Tooling: The initial investment in tooling can be significant, especially for customized belts. This includes molds and dies that need to be created for specific designs.

-

Quality Control (QC): Ensuring that belts meet industry standards involves QC testing, which can add to the overall cost. Certifications for quality assurance may also influence pricing.

-

Logistics: Shipping and handling costs vary based on the origin and destination of the materials. Import duties, taxes, and transportation fees can all impact the final cost.

-

Margin: Suppliers typically include a profit margin that can range from 10% to 30%, depending on market conditions and competition.

How Do Price Influencers Affect Belt Material Costs?

Several factors influence the pricing of belt materials, particularly for international B2B buyers:

-

Volume/MOQ: Bulk orders often lead to reduced unit costs. Suppliers may offer discounts for larger minimum order quantities (MOQs), which can be a strategic advantage for buyers.

-

Specifications and Customization: Customized products tailored to specific applications generally incur higher costs. Buyers should weigh the benefits of tailored solutions against their budgets.

-

Material Quality and Certifications: Higher quality materials that meet specific certifications (such as ISO standards) often come at a premium. Buyers should consider the long-term benefits of investing in quality, which can reduce maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more, but they often provide better service and product consistency.

-

Incoterms: The terms of shipping (Incoterms) significantly influence the total cost. Buyers should clarify responsibilities related to shipping, insurance, and tariffs to avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

Illustrative image related to belt material

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost over the product’s lifecycle, including maintenance and operational costs. This approach can justify higher upfront costs for better-quality materials.

-

Leverage Volume Discounts: If possible, consolidate orders to qualify for volume discounts. This can substantially reduce the per-unit cost.

-

Explore Multiple Suppliers: Diversifying your supplier base can create competitive pricing pressure. It also mitigates risks associated with relying on a single source.

-

Be Transparent About Needs: Clearly communicating your requirements can help suppliers offer better pricing structures or alternatives that fit your budget.

What Pricing Nuances Should International Buyers Consider?

International buyers should remain aware of unique pricing nuances, such as:

-

Currency Fluctuations: Prices may change due to currency exchange rates. Locking in prices early can protect against sudden increases.

-

Local Market Conditions: Understand the local market dynamics in the supplier’s country. Economic conditions, labor costs, and availability of materials can all influence pricing.

-

Regulatory Compliance: Ensure that the materials comply with local regulations in your country, as this can impact costs related to customs and import duties.

Disclaimer on Indicative Prices

The prices for belt materials can vary significantly based on the factors discussed. It’s essential for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing belt material With Other Solutions

Understanding the Importance of Evaluating Alternatives in Belt Material Solutions

In the industrial sector, selecting the right belt material is crucial for optimizing performance and ensuring longevity in applications ranging from power transmission to material handling. However, there are various alternative solutions available that can serve similar purposes. Understanding the comparative advantages and disadvantages of these alternatives can empower B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison Table of Belt Material and Alternatives

| Comparison Aspect | Belt Material | Chain Drives | Direct Drive Systems |

|---|---|---|---|

| Performance | High tensile strength, shock absorption | Strong load-bearing capacity, efficient power transmission | High efficiency, minimal energy loss |

| Cost | Moderate initial investment, longer lifespan | Lower initial cost, higher maintenance costs | Higher initial investment, lower ongoing costs |

| Ease of Implementation | Requires specific alignment and setup | Relatively easy to install with standard tools | Requires specialized installation and setup |

| Maintenance | Low maintenance, durable materials | Moderate maintenance, wear on links | Minimal maintenance, long-lasting components |

| Best Use Case | General industrial applications | Heavy-duty applications with high load | Applications requiring precise control and efficiency |

What Are the Pros and Cons of Chain Drives?

Chain drives consist of a series of links connected in a loop, which transfers power between two rotating shafts.

Pros:

– They excel in heavy-duty applications where high torque is needed, making them suitable for industries such as mining and construction.

– Chain drives are typically less expensive upfront compared to belt systems.

Cons:

– They require more frequent maintenance due to wear on the links and may need regular lubrication.

– Noise and vibration can be issues, making them less suitable for applications requiring quiet operation.

How Do Direct Drive Systems Compare?

Direct drive systems utilize a motor connected directly to a driven component, eliminating the need for belts or chains.

Pros:

– They offer high efficiency with minimal energy loss, making them ideal for applications that require precise control, such as robotics and automated machinery.

– Direct drive systems have fewer moving parts, leading to less wear and tear over time.

Cons:

– The initial investment can be significant, which may deter some businesses, particularly those with limited budgets.

– Installation may require specialized skills, which can complicate the implementation process.

Making the Right Choice: How Can B2B Buyers Decide?

When choosing between belt materials and alternative solutions like chain drives or direct drive systems, B2B buyers should consider their specific operational needs, including load capacity, environment, and budget constraints. Assessing factors such as performance requirements, cost-effectiveness, maintenance demands, and ease of implementation will guide buyers in selecting the most appropriate solution. For instance, industries requiring heavy lifting may benefit from the robustness of chain drives, while those prioritizing efficiency and precision might lean toward direct drive systems. Ultimately, a thorough understanding of both the advantages and limitations of each option will lead to more strategic decision-making.

Illustrative image related to belt material

Essential Technical Properties and Trade Terminology for belt material

What Are the Key Technical Properties of Belt Materials?

When selecting belt materials for industrial applications, understanding their technical properties is crucial for ensuring optimal performance and longevity. Here are some essential specifications:

-

Material Grade

The material grade refers to the quality and type of material used in the belt’s construction, such as reinforced rubber, polyurethane, or PVC. Higher-grade materials typically offer better resistance to wear, heat, and chemicals. For B2B buyers, selecting the appropriate material grade can significantly impact the operational efficiency and maintenance costs of machinery. -

Tensile Strength

This property indicates the maximum amount of tensile (pulling) stress that a belt can withstand before breaking. It is measured in pounds per square inch (PSI) or megapascals (MPa). For industries that require high power transmission, such as manufacturing or logistics, a belt with higher tensile strength is essential to prevent failures and downtime. -

Temperature Resistance

Temperature resistance defines a belt’s ability to function effectively under varying temperature conditions. Different materials can withstand different temperature ranges, which is critical for applications involving heat-generating processes. Choosing a belt with suitable temperature resistance ensures operational stability and extends the lifespan of the belt. -

Abrasion Resistance

This property measures how well a belt can resist wear from friction and contact with abrasive materials. It is vital for applications in environments with high particulate matter or heavy loads. High abrasion resistance translates to reduced maintenance and replacement costs, making it an important consideration for B2B buyers. -

Chemical Resistance

Chemical resistance indicates how well a belt can withstand exposure to various chemicals without degrading. This property is particularly crucial in industries like food processing, pharmaceuticals, and chemical manufacturing, where belts may come into contact with harsh substances. Selecting belts with appropriate chemical resistance can prevent premature failure and ensure compliance with industry regulations. -

Flexibility and Elasticity

Flexibility refers to a material’s ability to bend without breaking, while elasticity describes its capacity to return to its original shape after deformation. For applications that involve curves or variable loads, belts with high flexibility and elasticity can improve performance and reduce the risk of tearing.

What Are Common Trade Terms Related to Belt Materials?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is critical for buyers looking for replacement belts that fit existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It’s important for buyers to know the MOQ to manage inventory effectively and ensure they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. Utilizing RFQs can help businesses compare options and negotiate better terms with multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international transactions to clarify responsibilities regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers involved in cross-border purchases to ensure smooth logistics and compliance. -

Lead Time

Lead time is the duration from placing an order to receiving the product. In the context of belt materials, understanding lead times can help businesses plan their operations and avoid production delays. -

Lifecycle Cost

This term refers to the total cost of ownership of a belt over its entire lifespan, including purchase price, maintenance, and replacement costs. B2B buyers should consider lifecycle costs when evaluating belt materials to make informed financial decisions.

By grasping these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget considerations.

Illustrative image related to belt material

Navigating Market Dynamics and Sourcing Trends in the belt material Sector

What Are the Key Trends Shaping the Belt Material Market for International Buyers?

The belt material sector is currently experiencing significant transformations driven by technological advancements, evolving consumer demands, and global economic shifts. One prominent trend is the increasing adoption of advanced materials such as polyurethane and reinforced rubber, which offer enhanced durability, resistance to wear, and operational efficiency. These materials are particularly appealing to international B2B buyers in regions like Africa and South America, where industrial growth is rapidly expanding.

Moreover, the rise of automation and smart manufacturing technologies is influencing sourcing strategies. Buyers are increasingly seeking suppliers who can provide not only high-quality materials but also integrated solutions that enhance productivity and reduce operational downtime. This trend is especially relevant for industries such as food processing, packaging, and material handling, where reliability and performance are paramount.

Another key dynamic is the emphasis on local sourcing. International buyers are now prioritizing suppliers closer to their operational bases to mitigate supply chain disruptions, reduce lead times, and manage logistics costs effectively. This trend is particularly evident in the Middle East and Europe, where geopolitical factors and economic fluctuations necessitate a more localized approach to sourcing.

Illustrative image related to belt material

How Is Sustainability and Ethical Sourcing Reshaping the Belt Material Industry?

Sustainability has become a critical consideration for B2B buyers in the belt material sector. The environmental impact of manufacturing processes, particularly those involving synthetic materials, has prompted a shift towards more sustainable practices. Buyers are increasingly interested in sourcing materials that are not only durable but also environmentally friendly, such as biodegradable polyurethane or recycled rubber.

Ethical sourcing is another important aspect, as buyers seek to ensure that their supply chains adhere to fair labor practices and responsible resource management. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming essential criteria for supplier selection. Buyers from regions like Africa and South America, where social and environmental issues are particularly pronounced, are increasingly advocating for transparency and accountability in their supply chains.

Furthermore, the demand for ‘green’ certifications and materials is growing. Products that carry eco-labels or are produced using renewable resources are more attractive to international buyers who are conscious of their corporate social responsibility and the impact of their purchasing decisions on the environment.

What Is the Historical Context of the Belt Material Sector That Matters for B2B Buyers?

The belt material sector has evolved significantly over the past century, transitioning from traditional materials like leather to modern synthetic options such as PVC, polyurethane, and reinforced rubber. Initially, belts were primarily crafted for mechanical applications in agriculture and manufacturing. However, as industrial processes advanced and automation took hold, the demand for more robust, efficient, and versatile materials surged.

The introduction of synthetic materials revolutionized the industry, providing solutions that could withstand higher loads, resist wear and tear, and operate under extreme conditions. This evolution has enabled manufacturers to cater to diverse sectors, including automotive, food processing, and logistics, enhancing their operational efficiencies. Understanding this historical context helps B2B buyers appreciate the innovations available today and make informed sourcing decisions that align with their operational needs and sustainability goals.

In conclusion, navigating the belt material sector requires a keen understanding of market dynamics, a commitment to ethical sourcing practices, and an appreciation for the historical advancements that shape current offerings. By leveraging these insights, international B2B buyers can forge strategic partnerships that drive efficiency and sustainability in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of belt material

-

How do I select the right belt material for my application?

Choosing the appropriate belt material involves understanding the specific requirements of your application. Consider factors such as load capacity, operating environment, temperature ranges, and exposure to chemicals or moisture. For heavy-duty industrial applications, reinforced rubber or urethane belts may be ideal due to their strength and durability. Conversely, for lighter or more delicate tasks, PVC or nylon belts could be more suitable. Conducting a thorough needs assessment will help you identify the best material for optimal performance. -

What is the best material for high-temperature applications?

For high-temperature applications, materials like silicone or heat-resistant urethane are recommended. These materials maintain their integrity and performance even under extreme heat, making them suitable for processes such as food processing or manufacturing environments where heat exposure is common. Additionally, reinforced rubber belts can also be effective, but it’s essential to check the specific temperature ratings provided by manufacturers to ensure compliance with your operational standards. -

What factors should I consider when vetting a belt material supplier?

When vetting a belt material supplier, consider their experience and expertise in the industry, quality certifications, and customer reviews. It’s also beneficial to inquire about their manufacturing processes and whether they have a reliable quality assurance program in place. Additionally, assess their ability to provide customization options, lead times, and responsiveness to inquiries. A supplier that offers comprehensive technical support and after-sales service can also enhance your partnership. -

What are typical minimum order quantities (MOQs) for belt materials?

Minimum order quantities (MOQs) for belt materials can vary significantly depending on the supplier and the type of material. Generally, MOQs can range from as low as 50 meters for standard materials to several hundred meters for specialized or custom belts. It’s advisable to discuss your specific needs with the supplier to understand their MOQ policies and explore options for smaller orders if necessary. -

What payment terms should I expect when sourcing belt materials internationally?

Payment terms for international sourcing of belt materials typically include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that suit your cash flow and risk management strategies. Some suppliers may offer flexible payment plans, while others may require a deposit upfront. Ensure that you clarify these terms before finalizing any agreements to avoid misunderstandings. -

How can I ensure quality assurance for belt materials sourced internationally?

To ensure quality assurance for internationally sourced belt materials, request detailed product specifications and certifications from your supplier. Conducting third-party inspections or audits can also help verify that the materials meet your required standards. Additionally, consider establishing a clear quality control process that includes sampling and testing upon receipt of goods. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistics considerations should I keep in mind when importing belt materials?

When importing belt materials, consider factors such as shipping methods, lead times, and customs regulations in your country. Selecting a reliable freight forwarder familiar with the specifics of your materials can streamline the process. Additionally, ensure that all necessary documentation, including invoices, packing lists, and certificates of origin, are prepared accurately to avoid delays at customs. Planning ahead for potential disruptions can also help mitigate risks associated with international logistics. -

Can I customize belt materials for specific applications?

Yes, many suppliers offer customization options for belt materials to meet specific application needs. Customization may include modifications in size, thickness, material composition, or surface treatment. When discussing customization with suppliers, be clear about your requirements and any performance criteria your belts need to meet. Engaging in a collaborative dialogue can lead to tailored solutions that enhance the efficiency and effectiveness of your operations.

Top 7 Belt Material Manufacturers & Suppliers List

1. Mol Belting – Conveyor Solutions & Accessories

Domain: molbelting.com

Registered: 1998 (27 years)

Introduction: Belt Finder, Conveyor Belting, Motorized Pulleys & Driven Rollers, PTFE Belting, Fabric, & Tapes, Belting Adhesives & Accessories, Additional Conveyor Components, Belting Installation, Custom Solutions.

2. Bowman Hollis – Flat Belt Materials

Domain: bowmanhollis.com

Registered: 2001 (24 years)

Introduction: Flat belt materials are essential components in various industrial applications, providing reliable performance and durability. These materials are designed for use in conveyor systems, power transmission, and other mechanical systems. Key features include a range of sizes, thicknesses, and materials to suit different operational needs. The product category may include options such as rubber, poly…

3. The ECW Corp – Elastic Belt Material

Domain: theecwcorp.com

Registered: 1999 (26 years)

Introduction: Elastic Belt Material: Wide, flat elastic materials used for elastic belts. Features: Stretchy, woven elastics provide comfort and grip, allowing for movement and reducing abdominal pressure. Lightweight with sufficient hold for various textile applications. Applications: Apparel, textiles, sporting goods, home goods, luggage straps, decorative trim, climbing equipment, athletic uniforms. Material…

4. Tyma – Belt Materials Expertise

Domain: tyma.eu

Introduction: Belt Materials: Knowledge of belt materials, their physical and chemical properties, and durability is crucial for selecting suitable belts for machine devices. Modern belts are made from special materials and reinforced fibers. Basic materials in belt manufacturing include woven fabric, compound rubber or polyurethane teeth, reinforced fibers, and rubber. Key types of rubber used are natural rubb…

5. Tandy Leather – Belt Making Essentials

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Belt Making Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Thomas Bates – Durable Fabric Belts

Domain: thomasbates.com

Registered: 2000 (25 years)

Introduction: Fabric belts are designed for durability and comfort, available in various colors and styles. They are suitable for both casual and formal wear, offering a versatile accessory option. The belts are made from high-quality materials, ensuring longevity and resistance to wear and tear. Adjustable sizes are available to fit different waist sizes, providing a customizable fit for users.

7. IQS Directory – Flat Belts

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Flat belts are essential components in power transmission, crafted from materials such as rubber, synthetic composites, or leather. They feature a flat cross-sectional form with a trapezoidal contour, reducing slippage and increasing efficiency. Key types include: 1. Rubber Belts – Known for elasticity, abrasive resistance, and superior grip, suitable for high-speed and heavy-duty applications. 2….

Strategic Sourcing Conclusion and Outlook for belt material

What Are the Key Insights for Strategic Sourcing of Belt Materials?

In conclusion, effective strategic sourcing of belt materials is crucial for optimizing operational efficiency and ensuring the longevity of industrial systems. Key takeaways include understanding the diverse properties of materials such as reinforced rubber, polyurethane, PVC, and nylon, each tailored for specific applications. By prioritizing factors such as durability, resistance to wear, and adaptability to environmental conditions, buyers can make informed decisions that align with their operational needs.

Moreover, the importance of establishing strong supplier relationships cannot be overstated. Engaging with reputable manufacturers and distributors not only enhances the reliability of your supply chain but also opens doors to innovative solutions that can further streamline your operations.

How Can International Buyers Prepare for Future Trends in Belt Materials?

Looking ahead, international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, should remain proactive in exploring advancements in belt material technology. As industries evolve, so do the demands for higher performance and sustainability. Embracing these changes will position your business for success in a competitive market.

We encourage you to assess your current sourcing strategies and consider integrating more advanced materials and suppliers into your procurement processes. By doing so, you will not only enhance operational efficiency but also drive long-term value for your organization.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.