A Deep Dive into 4.00 16 Solution

Introduction: Navigating the Global Market for 4.00 16

In today’s competitive landscape, sourcing high-quality 4.00 16 tires presents a unique challenge for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The diverse applications of these tires—from agricultural machinery to motorcycles—demand a comprehensive understanding of the product specifications, supplier reliability, and pricing structures. This guide aims to navigate the complexities of the global market for 4.00 16 tires, providing invaluable insights into various types of tires available, their specific applications, and the nuances of supplier vetting.

Throughout this guide, we will explore the critical factors influencing purchasing decisions, including performance characteristics, durability, and cost-effectiveness. Additionally, we will highlight how to evaluate suppliers to ensure compliance with international standards and quality assurance. By providing a detailed analysis of the market landscape, this guide empowers B2B buyers to make informed choices that align with their operational needs and budget constraints.

Whether you are looking to equip agricultural equipment, enhance your motorcycle inventory, or meet specific industrial demands, understanding the dynamics of the 4.00 16 tire market is essential for optimizing your procurement strategy. Equip yourself with the knowledge needed to navigate this segment effectively and establish lasting partnerships with trusted suppliers.

Understanding 4.00 16 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Agricultural Tire | Designed for traction, often with a tread pattern for soil | Tractors, agricultural implements | Pros: Superior grip, durability. Cons: Higher cost compared to standard tires. |

| Motorcycle Tube | Inner tube designed for various motorcycle sizes | Motorcycles, scooters | Pros: Lightweight, easy to install. Cons: Requires periodic maintenance to avoid leaks. |

| Implement Tire | Built for agricultural machinery with a robust design | Trailers, field equipment | Pros: Enhanced durability, excellent load capacity. Cons: Limited to specific machinery. |

| Multi-Purpose Tire | Versatile design suitable for different vehicles | Lawn and garden equipment, utility vehicles | Pros: Flexibility in applications. Cons: May lack specialized performance. |

| Flat-Free Tire | Solid design that prevents air loss | Wheelbarrows, hand trucks | Pros: No maintenance required, puncture-proof. Cons: Heavier and less cushioned ride. |

What Are the Key Characteristics of Agricultural Tires?

Agricultural tires, such as the 4.00-16 variant, are specifically engineered to provide exceptional traction in various soil conditions. They typically feature deep treads that enhance grip and self-cleaning properties, making them ideal for tractors and other farming machinery. When purchasing these tires, B2B buyers should consider the load capacity and compatibility with their specific equipment. Investing in high-quality agricultural tires can lead to improved operational efficiency and reduced downtime.

How Do Motorcycle Tubes Differ from Other Tire Types?

Motorcycle tubes in the 4.00-16 size are essential for maintaining tire pressure and ensuring optimal performance for motorcycles and scooters. These tubes are crafted from durable materials that meet or exceed OEM standards, providing reliability and safety on the road. B2B buyers should focus on the compatibility with their motorcycle models and the quality of the tube to avoid frequent replacements. Choosing high-quality tubes can significantly enhance the riding experience and reduce the risk of tire failure.

What Should Buyers Know About Implement Tires?

Implement tires, such as those in the 4.00-16 size, are designed for heavy-duty applications in agricultural and industrial settings. Their robust construction allows them to handle significant loads, making them suitable for trailers and field equipment. Buyers should assess the tire’s ply rating and tread design to ensure they meet their operational needs. Investing in quality implement tires can lead to increased productivity and longevity, making them a smart choice for B2B buyers in agriculture.

Why Choose Multi-Purpose Tires for Various Applications?

Multi-purpose tires in the 4.00-16 size offer versatility, making them suitable for a range of vehicles, including lawn and garden equipment. These tires typically feature a balanced tread design that provides decent performance across different terrains. B2B buyers should consider the specific applications they need the tires for, as multi-purpose options may not excel in specialized conditions. However, their adaptability can be a cost-effective solution for businesses with diverse equipment needs.

What Are the Benefits of Flat-Free Tires?

Flat-free tires, such as the 4.00-16 variant, are designed to eliminate the risk of punctures and air loss, making them ideal for wheelbarrows and hand trucks. These solid tires require no maintenance, providing peace of mind for B2B buyers who need reliable performance in demanding environments. While they are heavier and may offer a stiffer ride compared to pneumatic tires, their durability and low upkeep make them an attractive option for businesses looking to reduce operational costs associated with tire management.

Key Industrial Applications of 4.00 16

| Industry/Sector | Specific Application of 4.00 16 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Front tires for tractors and agricultural machinery | Enhanced traction and stability in field operations | Sourcing from reputable manufacturers with quality certifications; consider local availability for quick replacements. |

| Construction | Tires for construction equipment and trailers | Improved durability and load-bearing capacity | Ensure compliance with regional standards; prioritize suppliers with a proven track record in industrial applications. |

| Transportation | Motorcycle tires for urban and off-road vehicles | Optimized performance and safety in diverse terrains | Look for suppliers offering competitive pricing and reliable shipping options; consider tire longevity and maintenance services. |

| Material Handling | Tires for forklifts and telehandlers | Increased efficiency in material transport | Evaluate tire specifications for load capacity; prioritize suppliers that provide after-sales support and service. |

| Recreational Vehicles | Tires for vintage motorcycles and scooters | Authenticity and performance for classic models | Focus on sourcing from specialized manufacturers; assess compatibility with various models and availability of inner tubes. |

How is ‘4.00 16’ Used in Agriculture and What Benefits Does It Provide?

In the agriculture sector, the 4.00 16 tire is predominantly used as a front tire for tractors and various agricultural machinery. These tires are designed to provide superior traction on uneven and muddy terrain, enhancing the efficiency of field operations. The unique tread patterns help with self-cleaning, preventing mud accumulation, which can hinder performance. International buyers, particularly from regions like Africa and South America, should prioritize sourcing from manufacturers that offer robust quality certifications to ensure durability against harsh agricultural conditions.

What Role Does ‘4.00 16’ Play in Construction Applications?

In construction, the 4.00 16 tires are integral to the operation of various equipment, including trailers and compact machinery. These tires are engineered for heavy loads and rough terrains, providing the necessary durability and grip essential for construction sites. They help minimize downtime due to tire failures. Buyers in Europe, particularly Germany, should consider sourcing from established suppliers who adhere to stringent safety and quality standards, ensuring compliance with local regulations.

How Do ‘4.00 16’ Tires Enhance Transportation Efficiency?

The 4.00 16 tire is widely used in motorcycles, catering to both urban commuting and off-road adventures. These tires are designed for optimal performance, balancing durability and safety across different terrains. The value lies in their ability to enhance ride comfort while maintaining excellent grip, which is crucial for urban transportation in regions like the Middle East. Buyers should focus on suppliers that not only offer competitive pricing but also provide reliable shipping options to ensure timely delivery.

Why are ‘4.00 16’ Tires Important for Material Handling Equipment?

In material handling, the 4.00 16 tires are utilized on forklifts and telehandlers, where they support the movement of heavy loads across warehouses and construction sites. The tires are engineered for high load-bearing capacity, contributing to improved efficiency and safety during operations. International buyers should evaluate tire specifications carefully, ensuring they meet the specific load requirements of their equipment. Sourcing from suppliers that offer comprehensive after-sales support can further enhance operational reliability.

How Does ‘4.00 16’ Serve the Recreational Vehicle Market?

For recreational vehicles, particularly vintage motorcycles and scooters, the 4.00 16 tire is vital for maintaining authenticity and performance. These tires cater to enthusiasts looking for quality replacements that match the original specifications of classic models. The benefit lies in their ability to provide a smooth ride while ensuring safety. Buyers should focus on sourcing from specialized manufacturers who can guarantee compatibility with various models and offer access to necessary components like inner tubes for maintenance.

3 Common User Pain Points for ‘4.00 16’ & Their Solutions

Scenario 1: Sourcing Quality Tires for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality 4.00-16 tires that meet specific performance needs across various applications, such as agricultural, industrial, and motorcycle uses. In regions like Africa and South America, where supply chains may be less robust, this challenge is compounded by inconsistent quality and the risk of purchasing subpar products that do not deliver the promised performance. Buyers frequently encounter tires that wear out quickly or fail to provide adequate traction, leading to increased downtime and operational inefficiencies.

The Solution: To effectively source quality 4.00-16 tires, buyers should prioritize suppliers that offer a comprehensive range of products with clear specifications and performance ratings. Research manufacturers known for their reliability, such as BKT or IRC, and verify their reputation through customer reviews and industry certifications. When evaluating options, consider factors like ply rating, tread design, and suitability for intended applications (e.g., traction for agricultural implements vs. durability for motorcycles). Engaging directly with suppliers to discuss specific requirements can also yield tailored solutions, ensuring that the selected tires are fit for purpose. Additionally, establishing long-term relationships with trusted suppliers can lead to better pricing, availability, and support.

Scenario 2: Managing Inventory Levels and Costs

The Problem: Another common pain point for B2B buyers is managing inventory levels of 4.00-16 tires while keeping costs in check. Fluctuating demand and unforeseen supply chain disruptions can lead to either overstocking, which ties up capital, or understocking, which risks operational delays. Buyers, especially in regions where tires may have longer lead times, face pressure to maintain an optimal inventory balance without incurring excess costs.

The Solution: Implementing a robust inventory management system can significantly alleviate this issue. Buyers should adopt a just-in-time (JIT) inventory strategy, which allows them to order tires based on real-time demand forecasts, minimizing both excess stock and shortages. Utilizing inventory management software that integrates with sales data can provide insights into usage patterns and help predict future needs. Collaborating with suppliers to establish flexible ordering agreements can also enhance responsiveness to demand fluctuations. Moreover, considering bulk purchasing discounts or consignment stock options may reduce costs while ensuring a steady supply of 4.00-16 tires.

Scenario 3: Addressing Compatibility and Installation Challenges

The Problem: Buyers frequently encounter compatibility issues when sourcing 4.00-16 tires, particularly when it comes to fitting them onto existing equipment or ensuring they work with specific rim types. This challenge is especially prevalent in regions with diverse agricultural machinery and vehicle types, where incorrect specifications can lead to costly installation errors or even equipment damage.

The Solution: To mitigate compatibility issues, B2B buyers should conduct thorough assessments of their existing equipment and the specifications of the tires they intend to purchase. This includes checking rim widths, valve stem types, and load ratings to ensure a proper fit. It is advisable to consult with tire specialists or manufacturers to clarify any uncertainties regarding compatibility before making a purchase. Additionally, investing in training for installation personnel can help avoid common pitfalls associated with tire fitting, ensuring that the tires are installed correctly and perform optimally. Establishing a clear communication channel with suppliers for technical assistance can further enhance the buyer’s confidence in their purchases, ensuring that they select the right tires for their specific machinery and applications.

Strategic Material Selection Guide for 4.00 16

What Are the Key Materials for 4.00 16 Tires and Their Properties?

When selecting materials for 4.00 16 tires, it is essential to consider the unique properties and performance characteristics of each material. The most common materials include rubber compounds, synthetic polymers, steel belts, and inner tubes. Each material has distinct advantages and disadvantages that can impact the tire’s performance, durability, and cost-effectiveness.

How Do Rubber Compounds Affect Tire Performance?

Rubber compounds are the primary material used in tire manufacturing. They provide flexibility, traction, and durability. Key properties include excellent temperature resistance, withstanding a range of -40°C to 70°C, and good wear resistance.

Pros: Rubber compounds are relatively inexpensive and can be formulated to enhance specific performance aspects, such as grip or durability. They are also lightweight, which can improve fuel efficiency.

Cons: However, rubber can degrade over time due to UV exposure and ozone, leading to cracking and reduced lifespan. Additionally, the performance can vary significantly based on the formulation, which may complicate sourcing for international buyers.

What Role Do Synthetic Polymers Play in Tire Manufacturing?

Synthetic polymers, such as styrene-butadiene rubber (SBR) and ethylene-propylene-diene monomer (EPDM), are increasingly used in tire manufacturing due to their superior performance characteristics. They typically offer higher resistance to wear and aging compared to natural rubber.

Pros: Synthetic polymers can enhance the tire’s performance in extreme conditions, providing better traction and stability. They are also less susceptible to environmental degradation.

Cons: The manufacturing process for synthetic materials can be more complex and costly than natural rubber. This complexity may lead to higher prices, which could be a consideration for budget-conscious buyers in developing regions.

How Do Steel Belts Enhance Tire Durability?

Steel belts are often incorporated into tires to improve structural integrity and puncture resistance. They provide additional strength and help maintain the tire’s shape under load.

Pros: The use of steel belts significantly enhances durability and performance, especially for heavy-duty applications. They can also improve handling and stability, making them suitable for agricultural and industrial vehicles.

Cons: The primary drawback is the added weight, which can negatively impact fuel efficiency. Additionally, steel belts can increase production costs, making them less appealing for budget-sensitive markets.

What Are the Considerations for Inner Tubes in 4.00 16 Tires?

Inner tubes are essential for maintaining air pressure within tires, particularly for those designed for agricultural and industrial applications. They are typically made from rubber or synthetic materials.

Pros: Inner tubes are relatively inexpensive and easy to replace. They provide a reliable seal against air loss, which is critical for maintaining tire performance.

Cons: However, inner tubes can be susceptible to punctures, leading to potential downtime. Additionally, the need for inner tubes can complicate tire maintenance and replacement, which may be a concern for buyers in remote areas.

Summary Table of Material Selection for 4.00 16 Tires

| Material | Typical Use Case for 4.00 16 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber Compounds | General tire applications | Cost-effective and flexible | Degrades over time due to environmental factors | Low |

| Synthetic Polymers | High-performance tire applications | Superior wear resistance and durability | Higher manufacturing complexity and cost | Medium |

| Steel Belts | Heavy-duty and agricultural tires | Enhanced durability and stability | Increased weight and production costs | High |

| Inner Tubes | Agricultural and industrial applications | Inexpensive and easy to replace | Susceptible to punctures and maintenance issues | Low |

This strategic guide provides a comprehensive overview of the materials used in 4.00 16 tires, helping international B2B buyers make informed decisions based on performance, cost, and application suitability. Understanding these factors is crucial for sourcing the right products to meet specific operational needs in various global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 4.00 16

What Are the Main Stages of the Manufacturing Process for 4.00 16 Tires?

The manufacturing process for 4.00 16 tires involves several critical stages, each designed to ensure the final product meets the required quality and performance standards.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, including rubber compounds, fabric, steel belts, and other additives. Suppliers often use specialized compounds to enhance durability and performance under various environmental conditions. The materials are then weighed and mixed according to precise formulations to achieve the desired properties.

-

Forming: In this stage, the prepared materials are shaped into tire components. This involves creating the tire’s inner liner, body plies, and tread. Techniques such as extrusion and calendaring are commonly used. Extrusion involves forcing the rubber through a die to create a continuous shape, while calendaring combines layers of rubber and fabric into a single sheet. These components are then cut to size for assembly.

-

Assembly: The formed components are assembled in a specific sequence. The inner liner is placed first, followed by the body plies and tread. This assembly process can be performed manually or using automated systems. Proper alignment and bonding of layers are crucial to ensure tire integrity and performance.

-

Finishing: After assembly, the tires undergo a curing process, which involves heating them in a mold. This step is essential for vulcanization, where the rubber undergoes a chemical reaction that enhances its strength and elasticity. The finished tires are then inspected for defects, measured for dimensions, and prepared for packaging and shipping.

How Is Quality Assurance Implemented in Tire Manufacturing?

Quality assurance is a fundamental component of tire manufacturing, ensuring that products meet international and industry-specific standards.

-

International Standards: Many manufacturers adhere to ISO 9001, which sets the criteria for a quality management system. Compliance with this standard demonstrates a commitment to consistent quality and continuous improvement. Additionally, certifications like CE (European Conformity) and API (American Petroleum Institute) may apply, depending on the tire’s intended use.

-

Quality Control Checkpoints: Quality control is integrated throughout the manufacturing process with several key checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor critical parameters, such as temperature and pressure during curing.

– Final Quality Control (FQC): After curing, each tire undergoes a thorough inspection for visual defects, dimensional accuracy, and performance characteristics. -

Common Testing Methods: Various testing methods are employed to evaluate tire performance and safety. These include:

– Dynamic Testing: Assessing the tire’s performance under real-world conditions, including traction, handling, and durability.

– Static Testing: Measuring properties like hardness, tensile strength, and wear resistance in a controlled environment.

– Environmental Testing: Simulating conditions such as temperature fluctuations and humidity to ensure the tire’s longevity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their certifications, inspection reports, and compliance with international standards.

-

Quality Reports: Requesting quality reports from suppliers can help assess their performance metrics. These reports should include data on defect rates, testing results, and corrective actions taken in response to issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s operations. These inspectors can evaluate the manufacturing process, conduct product tests, and verify compliance with specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international B2B buyers. Different regions may have varying regulations and expectations regarding tire quality.

-

Regional Standards: Buyers should be aware of the specific standards applicable in their regions. For instance, European markets may require CE marking, while Middle Eastern countries might have different certification requirements. Familiarity with these standards can help buyers make informed purchasing decisions.

-

Cultural Considerations: Cultural differences may influence manufacturing practices and quality perceptions. Building strong relationships with suppliers can enhance communication and understanding regarding quality expectations.

-

Logistics and Supply Chain: Factors such as shipping and handling can impact tire quality. Buyers should consider suppliers’ capabilities to manage logistics effectively, ensuring that products are delivered without damage and within the agreed timelines.

Conclusion

The manufacturing processes and quality assurance measures for 4.00 16 tires are intricate and multifaceted. By understanding these processes, international B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs. Engaging with suppliers who prioritize quality control and adhere to international standards will not only enhance product reliability but also foster long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4.00 16’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure the 4.00-16 tire. Understanding the specific requirements and ensuring a smooth procurement process is essential for maintaining operational efficiency and cost-effectiveness. This guide outlines critical steps that will help you make informed purchasing decisions, ensuring that you select the right products and suppliers for your needs.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications of the 4.00-16 tire you require. This includes identifying whether you need agricultural, industrial, or motorcycle tires, as each type has unique attributes suited for different applications. Documenting specifications such as load capacity, tread pattern, and ply rating will help you communicate your needs effectively to suppliers.

Step 2: Conduct Market Research

Invest time in researching the market for 4.00-16 tires. Analyze competitor offerings, pricing structures, and common features that are valued in your industry. Understanding market trends will equip you with the knowledge to negotiate better prices and make informed choices when selecting suppliers.

Step 3: Identify Reliable Suppliers

Create a list of potential suppliers who specialize in 4.00-16 tires. Look for vendors with a strong reputation and experience in your specific market sector. Pay attention to factors such as:

– Customer reviews: Seek testimonials from other businesses to gauge reliability.

– Industry certifications: Ensure suppliers meet necessary quality and safety standards.

Step 4: Evaluate Supplier Certifications

Prioritize suppliers with relevant certifications and quality assurance processes. Certifications such as ISO 9001 can indicate a commitment to quality management practices. Additionally, inquire about the supplier’s production processes and whether they adhere to international standards, especially if sourcing from regions with varying quality controls.

Step 5: Request Samples and Product Data

Once you have shortlisted suppliers, request samples of the 4.00-16 tires you are considering. Evaluating physical samples allows you to assess quality, durability, and suitability for your operations. Additionally, ask for product data sheets that provide technical details, warranty information, and compliance with industry regulations.

Step 6: Assess Pricing and Payment Terms

Obtain quotes from multiple suppliers and compare pricing structures. Consider not just the initial purchase price but also shipping costs and potential tariffs, especially when sourcing internationally. Negotiate payment terms that work for your cash flow, and inquire about discounts for bulk purchases or long-term contracts.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure all terms are clearly outlined in a purchase agreement. This should include delivery timelines, payment schedules, and return policies. Establishing clear communication channels with the supplier will help address any issues that arise during the procurement process, ensuring a smooth transaction.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing 4.00-16 tires, ensuring that they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for 4.00 16 Sourcing

What Are the Key Cost Components in Sourcing 4.00 16 Tires?

When analyzing the cost structure for sourcing 4.00 16 tires, various components come into play. Materials account for a significant portion of the cost, with rubber quality and additives impacting durability and performance. For instance, high-grade natural rubber may increase material costs but can also enhance the tire’s lifespan and grip, which is crucial for agricultural or industrial applications.

Labor costs also influence pricing, particularly in regions with varying wage standards. Manufacturers in countries with lower labor costs might offer competitive pricing but may compromise on quality control (QC) and manufacturing standards. Manufacturing overhead, which includes utilities, maintenance, and operational expenses, should be factored into the overall price, often constituting around 10-20% of the total cost.

Tooling costs, especially for custom designs or specifications, can further inflate prices. If a buyer requires unique tread patterns or tire dimensions, the initial investment in tooling can be substantial.

How Do Logistics and Margins Affect the Pricing of 4.00 16 Tires?

Logistics play a pivotal role in the pricing of 4.00 16 tires, particularly for international buyers. Shipping costs can vary dramatically based on the origin of the tires and the destination, influenced by factors such as distance, freight method (air vs. sea), and local tariffs. Additionally, costs associated with storage and distribution should be included in the total cost analysis.

Margins set by suppliers can vary based on market demand, competition, and perceived value. Generally, margins for tire manufacturers can range from 15% to 30%. Buyers should be aware that brand reputation and certifications can justify higher margins, particularly for tires designed for specialized applications.

What Influences Pricing for International B2B Buyers of 4.00 16 Tires?

Several factors influence pricing for international B2B buyers of 4.00 16 tires. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often lead to lower unit costs. Suppliers may offer tiered pricing based on order size, encouraging bulk purchases.

Specifications and Customization can also affect pricing. Tires with specialized features, such as enhanced tread designs for specific terrains or weather conditions, typically incur additional costs. Buyers should evaluate the necessity of these features against their intended use.

Material quality and certifications are significant price influencers. Tires that meet international safety standards or possess certifications may command higher prices but offer peace of mind regarding performance and safety.

What Are Effective Buyer Tips for Negotiating Prices and Ensuring Cost Efficiency?

International buyers must consider several strategies when negotiating prices. Understanding Total Cost of Ownership (TCO) is vital; this includes not just the purchase price but also maintenance, potential downtime, and replacement costs over the tire’s lifespan. Buyers should seek to assess the longevity and reliability of the tires in their specific application to understand the true value.

Negotiation tactics should focus on establishing long-term relationships with suppliers. Demonstrating commitment through repeat orders can lead to better pricing agreements.

Pricing nuances vary by region; for example, buyers from Europe may face different import duties compared to those in Africa or South America. Familiarity with local regulations and market conditions can significantly impact negotiations.

What Should Buyers Consider Regarding Incoterms When Sourcing 4.00 16 Tires?

Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterm can help mitigate risks associated with logistics and unforeseen costs.

For instance, opting for DDP (Delivered Duty Paid) may simplify the process for buyers, as it places the responsibility for shipping costs and duties on the seller. Conversely, terms like FOB (Free On Board) may require buyers to manage shipping logistics, which could lead to additional costs if not handled properly.

Conclusion: Pricing Insights for Sourcing 4.00 16 Tires

In summary, sourcing 4.00 16 tires involves a multifaceted analysis of costs, pricing influencers, and strategic negotiation tactics. By understanding the cost components, leveraging volume discounts, and navigating Incoterms effectively, international buyers can enhance their sourcing strategies and achieve cost efficiencies in their procurement processes. Prices are indicative and can vary based on specific supplier agreements and market conditions.

Alternatives Analysis: Comparing 4.00 16 With Other Solutions

Introduction to Alternatives for 4.00 16

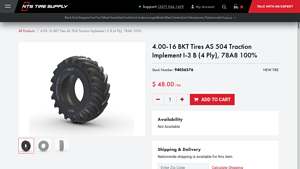

In the competitive landscape of tire solutions, particularly for agricultural and industrial applications, exploring alternatives to the 4.00 16 tire is essential for B2B buyers. The 4.00 16 tire is widely recognized for its versatility, but various alternatives may better suit specific needs based on performance, cost, and application. This analysis compares the 4.00 16 tire with two viable alternatives: the BKT AS 504 Traction Implement Tire and the IRC Motorcycle Tube 4.00/4.60-16.

Comparison Table

| Comparison Aspect | 4.00 16 Tire | BKT AS 504 Traction Implement Tire | IRC Motorcycle Tube 4.00/4.60-16 |

|---|---|---|---|

| Performance | Good traction for general use | Excellent self-cleaning, high grip | OEM quality, reliable performance |

| Cost | $150 – $211 per tire | $100 – $150 per tire | $17.95 per tube |

| Ease of Implementation | Standard fitting | Requires specific rim width | Simple installation |

| Maintenance | Moderate, occasional checks needed | Low, durable design | Low, replace when damaged |

| Best Use Case | General agricultural applications | Soil tillage and material handling | Motorcycles and light vehicles |

Detailed Breakdown of Alternatives

BKT AS 504 Traction Implement Tire

The BKT AS 504 tire excels in agricultural settings, particularly for tasks involving soil tillage and material handling. Its unique tread design ensures superior traction and self-cleaning capabilities, making it ideal for muddy or uneven terrains. While the cost is competitive, especially when considering its performance, buyers need to ensure compatibility with their equipment’s rim width. The durability of this tire can lead to lower long-term maintenance costs, making it a smart investment for intensive agricultural operations.

IRC Motorcycle Tube 4.00/4.60-16

For buyers looking for a lightweight and cost-effective solution, the IRC Motorcycle Tube provides an excellent alternative for lighter vehicles and motorcycles. Priced significantly lower than full tires, this tube maintains OEM quality, ensuring reliable performance. However, it is essential to note that tubes are susceptible to punctures and may require more frequent replacements compared to solid tires. This solution is best suited for businesses with smaller vehicles or those that prioritize budget over heavy-duty performance.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right tire or tube solution, B2B buyers should consider their specific operational requirements and budget constraints. The 4.00 16 tire is a solid choice for general agricultural applications, offering good performance and moderate maintenance. In contrast, the BKT AS 504 tire is tailored for specialized agricultural use, providing enhanced traction at a competitive price point. For lighter vehicles, the IRC motorcycle tube represents an economical option, though it may not offer the same durability as full tires. By carefully evaluating the performance, cost, and maintenance needs of each option, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 4.00 16

What Are the Key Technical Properties of 4.00 16 Tires?

When sourcing 4.00 16 tires, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Tire Size: The designation “4.00 16” indicates a tire that is 4.00 inches wide and designed to fit a 16-inch rim. This is a standard size for various agricultural and industrial applications, making it vital for compatibility with existing equipment.

-

Ply Rating: This specification indicates the tire’s strength and load-carrying capacity. A typical ply rating for a 4.00 16 tire might be 4-ply (B), meaning it can support a load limit of approximately 935 lbs at a maximum pressure of 41 PSI. Understanding ply ratings helps buyers assess durability and suitability for specific applications, especially in heavy-duty environments.

-

Tread Design: The tread design affects traction and performance. For instance, an I-3 tread pattern is designed for agricultural implements, offering excellent self-cleaning properties and grip on various surfaces. Choosing the right tread design can enhance performance and safety in field operations.

-

Material Composition: Tires are typically made from synthetic rubber compounds designed for specific applications. The composition can affect performance characteristics like wear resistance, heat dissipation, and overall longevity. Buyers should inquire about the materials used to ensure they meet their operational needs.

-

Valve Stem Type: Tires such as the 4.00 16 often utilize specific valve stem types, like TR4 for motorcycle tubes. The correct valve stem ensures proper inflation and maintenance, which is essential for optimal tire performance.

Which Trade Terminology Should B2B Buyers Know About 4.00 16 Tires?

Navigating the procurement process for 4.00 16 tires requires familiarity with industry-specific terminology. Here are several key terms that can aid in understanding and communication:

-

OEM (Original Equipment Manufacturer): This term refers to manufacturers that produce parts and equipment that may be marketed by another manufacturer. In the tire industry, OEM tires are those specifically made for certain vehicles or machinery. Knowing whether a tire is OEM can influence purchasing decisions regarding quality and compatibility.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers, as it can affect inventory management and cash flow.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the context of 4.00 16 tires, an RFQ can help buyers compare costs, terms, and delivery options among various suppliers.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk management, and delivery responsibilities when sourcing 4.00 16 tires from global suppliers.

-

LTL (Less Than Truckload): This shipping term refers to freight shipments that do not require a full truckload. Since tires can be bulky and heavy, understanding LTL options can help buyers save on shipping costs and manage logistics more effectively.

-

TT/TL (Tube-Type/Tubeless): This terminology indicates whether a tire requires an inner tube or can function without one. Knowing the type of tire is essential for ensuring compatibility with existing wheel setups and for maintenance considerations.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when procuring 4.00 16 tires, ensuring they select the best options for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 4.00 16 Sector

What Are the Current Market Dynamics and Key Trends in the 4.00-16 Tire Sector?

The global market for 4.00-16 tires is increasingly influenced by several key drivers, including the rise of agricultural mechanization, the growth of the automotive sector, and the expansion of infrastructure projects in emerging markets. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for versatile tires that can be utilized in various applications, ranging from agricultural machinery to motorcycles and utility vehicles.

Emerging technologies are reshaping the sourcing landscape. Digital platforms are facilitating easier access to suppliers, allowing buyers to compare prices and specifications more efficiently. Additionally, the integration of IoT in tire management systems is helping businesses optimize their fleet operations through real-time monitoring, predictive maintenance, and enhanced performance analytics. As companies focus on operational efficiency, the ability to track tire usage and condition becomes critical.

Moreover, the market is increasingly competitive, with numerous manufacturers offering diverse product lines. This intensifies the need for international buyers to evaluate suppliers based not only on price but also on product quality, service reliability, and delivery timelines. It is essential for buyers to stay updated on market trends, such as the growing preference for specialty tires that offer better traction and durability, especially in rugged terrains.

How Does Sustainability Influence Sourcing in the 4.00-16 Sector?

Sustainability has emerged as a pivotal concern for businesses in the 4.00-16 tire sector. As environmental regulations tighten globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing raw materials responsibly, minimizing waste during production, and ensuring that products are recyclable or made from recycled materials.

Ethical sourcing is not merely a trend; it is becoming a fundamental expectation. Buyers are looking for manufacturers that can provide transparency regarding their supply chains, including certifications that verify sustainable practices. Certifications such as the Global Organic Textile Standard (GOTS) or the Forest Stewardship Council (FSC) can be significant for buyers interested in minimizing their ecological footprint.

Furthermore, innovative materials are being developed to reduce the environmental impact of tires. For instance, manufacturers are exploring bio-based rubbers and eco-friendly chemicals that offer similar performance characteristics while being less harmful to the environment. This shift towards greener alternatives not only appeals to eco-conscious consumers but also aligns with the global push for sustainability, making it a vital consideration for international buyers.

What Is the Historical Context of the 4.00-16 Tire Sector and Its Evolution?

The 4.00-16 tire has a rich history rooted in the agricultural and automotive industries. Initially designed for agricultural machinery, these tires have evolved to meet the diverse needs of various sectors, including motorcycles and utility vehicles. The design has significantly improved over the decades, with advancements in tire technology enhancing durability, performance, and safety.

The rise of mechanized agriculture in the mid-20th century propelled the demand for reliable tire options, leading manufacturers to innovate in tread design and materials. This evolution has been crucial in enabling agricultural productivity, especially in developing regions. As global markets expand, the 4.00-16 tire continues to adapt, reflecting changes in technology, consumer preferences, and environmental considerations, ultimately making it a versatile choice for various applications today.

In conclusion, navigating the complexities of the 4.00-16 tire market requires a keen understanding of current trends, sustainability imperatives, and historical context. For international B2B buyers, staying informed and strategically sourcing from ethical suppliers can lead to significant competitive advantages.

Frequently Asked Questions (FAQs) for B2B Buyers of 4.00 16

-

1. How can I find reliable suppliers for 4.00 16 tires?

Finding reliable suppliers for 4.00 16 tires involves thorough research and vetting. Start by utilizing B2B marketplaces such as Alibaba or Global Sources, where you can review supplier ratings and feedback. Additionally, attend trade shows or industry expos to meet suppliers in person and assess their products. Always request samples and check their certifications, such as ISO or other quality assurance marks, to ensure they meet international standards. -

2. What are the common applications for 4.00 16 tires?

4.00 16 tires are commonly used in agricultural machinery, motorcycles, and various types of trailers. They provide essential traction and stability for implements during soil tillage and handling operations. Understanding the specific requirements for your application—such as load capacity and tread design—can help you choose the right tire type, whether for agricultural, industrial, or recreational use. -

3. What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider factors such as order size, payment methods, and currency fluctuations. Establish clear terms regarding deposits, balance payments, and acceptable payment methods (e.g., wire transfer, letter of credit). For international transactions, be mindful of potential delays in processing and ensure that all terms are documented to avoid misunderstandings. It’s also wise to discuss any available financing options that may ease cash flow. -

4. Are there customization options available for 4.00 16 tires?

Many manufacturers offer customization options for 4.00 16 tires, including tread patterns, rubber compounds, and sidewall markings. Customization can be particularly beneficial for businesses with specific performance requirements or branding needs. When engaging with suppliers, inquire about their capabilities for custom designs and the minimum order quantities (MOQs) required for these services to ensure you meet your operational demands. -

5. What are the typical minimum order quantities (MOQs) for 4.00 16 tires?

Minimum order quantities (MOQs) for 4.00 16 tires can vary significantly based on the supplier and production capabilities. Generally, MOQs may range from 50 to 100 units for standard products. However, custom orders may require higher quantities. Always clarify MOQs upfront to avoid unexpected costs and ensure that your order aligns with your business needs and inventory management strategies. -

6. How can I ensure the quality of 4.00 16 tires?

To ensure the quality of 4.00 16 tires, request detailed specifications and certifications from the supplier. Conduct quality assurance inspections either in-person or through third-party services before shipment. Additionally, establish a return policy in case the tires do not meet your agreed-upon specifications. Consistent communication with your supplier throughout the production process can also help mitigate potential quality issues. -

7. What logistics considerations should I keep in mind for international shipments?

When planning for international shipments of 4.00 16 tires, consider shipping methods, customs regulations, and potential tariffs. Choose between air and sea freight based on urgency and cost-effectiveness. Additionally, work with logistics providers who have experience in handling tires and can navigate the complexities of customs clearance. Ensure all shipping documents are accurate to avoid delays and additional charges during transit. -

8. How can I manage risks associated with international trade for tire purchases?

Managing risks in international trade involves thorough due diligence, including supplier vetting and contract negotiation. Utilize trade insurance to protect against potential losses from defaults or damages during transit. Keep abreast of geopolitical developments and market trends that may impact supply chains. Establish clear communication channels with suppliers to address any issues proactively, ensuring a smoother transaction process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 4.00 16 Manufacturers & Suppliers List

1. Continental – 4.00-16 A TL AS Farmer Tire

Domain: stmtires.com

Registered: 2003 (22 years)

Introduction: {“brand”:”Continental”,”model”:”4.00-16 A TL AS Farmer”,”type”:”Tire”,”size”:”4.00-16″,”application”:”Agricultural”,”features”:”All-season performance, excellent traction, durable construction”}

2. HD Pneumatic Tire Assembly – 4.00 x 16

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, HD Pneumatic Tire Assembly – 4.00 x 16, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Affordable Tractor Sales – 4.00X16 Front Tire

Domain: affordabletractorsalesco.com

Registered: 2002 (23 years)

Introduction: {“name”: “4.00X16 Front Tire”, “sku”: “”, “price”: “$90.00”, “description”: “Front tire for 2-wheel drive”, “shipping”: “Special shipping required”, “return_policy”: “20% restocking charge on all returns, no return on electrical parts. Customer pays all shipping charges on returned parts.”, “stock_status”: “Current Stock: Quantity: Decrease Quantity of undefined Increase Quantity of undefined”, “r…

4. IRC – Standard Motorcycle Tube 4.00/4.60-16

Domain: americanmototire.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “IRC Standard Motorcycle Tube 4.00/4.60-16, 120/90-16 Tr4 Straight Metal Valve Stem – Center”, “Price”: “$15.95”, “SKU”: “T20035”, “Condition”: “New”, “Fits Tire Sizes”: [“4.00-16”, “4.10-16”, “4.25-16”, “4.50-16”, “4.60-16”, “120/90-16”], “Stem Type”: “TR4 Straight Metal Valve Stem – Center”, “Mfg. Part No.”: “T20035”, “Model”: “Standard Tube”, “Quality”: “Highest quality Japanes…

5. Woodward Equipment – 16 x 4.00 Black Wheel and Tire

Domain: woodwardequipment.com

Registered: 1999 (26 years)

Introduction: Wheel and tire, 16″ x 4.00 black

6. BKT Tires – AS 504 Traction Implement

Domain: store.ntstiresupply.com

Registered: 2007 (18 years)

Introduction: {“Stock Number”: “94056576”, “Brand”: “BKT Tires”, “Model/Style”: “AS 504 Traction Implement”, “Tread Style”: “I-3”, “Tire Size”: “4.00-16”, “Rim Width”: “3”, “Preferred Rim RCI Group”: “25 (23.81″ – 25.15″)”, “Casing Technology”: “Casing Application”, “Belt Construction”: “”, “Sidewall Style”: “TT/TL (TT)”, “Tubetype”: “”, “Weight”: “11.0”, “Diameter”: “24.7”, “Width”: “4.3”, “Rolling Circumferen…

7. SimpleTire – 4.00×16 Tires

Domain: simpletire.com

Registered: 2009 (16 years)

Introduction: 4.00×16 Tires | Rims not included with purchase | Free shipping on all tires (excluding oversized tires) | Easy returns within 30 days for unmounted tires | Military discount: 5% off for U.S. military | Customer support available Mon-Fri: 8am-7pm ET, Sat: 9am-5pm ET | Contact via SMS, phone, or email | Special offers and financing options available.

8. BKT – 4.00-16 TF-8181 Tire

Domain: heuver.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “4.00-16 BKT TF-8181”, “load_index”: “69A6/61A8”, “ply_rating”: “4PR”, “type”: “TT”, “pattern_depth”: “11 mm”, “weight”: “5.45 kg”, “recommended_pressure”: “3.4 bar”}

9. eBay – 4.00 16 Tire

Domain: ebay.ca

Registered: 2000 (25 years)

Introduction: 4.00 16 Tire for sale on eBay. Various options available including new and used tires. Prices range from C $20.00 to C $551.76. Shipping costs vary, with some items offering free shipping. Notable products include:

– 4.80/4.00-8″ Wheelbarrow Tire, 16″ Flat-Free Solid Tire and Wheel, priced at C $205.52 with C $58.03 shipping.

– 16″ Flat Free Wheelbarrow Wheels and Tires 4.80/4.00-8 Solid Tire with…

Strategic Sourcing Conclusion and Outlook for 4.00 16

In conclusion, the strategic sourcing of 4.00-16 tires presents significant opportunities for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. By understanding the diverse applications of these tires—from agricultural uses to construction—buyers can make informed decisions that enhance operational efficiency. The value of strategic sourcing lies not only in cost savings but also in ensuring the procurement of high-quality products that meet specific industry standards.

As the demand for reliable and durable tires continues to grow, particularly for agricultural and industrial applications, it is essential for buyers to establish robust relationships with reputable suppliers. Engaging with manufacturers that offer a range of options, such as BKT and IRC, can further ensure the availability of the right products tailored to specific needs.

Looking ahead, B2B buyers are encouraged to stay proactive and explore new sourcing channels and partnerships. By leveraging technology and maintaining flexibility in their supply chains, businesses can navigate market fluctuations effectively. Now is the time to take action—seize the opportunity to secure the best solutions for your tire needs and drive your business forward.