The Definitive Guide to Wire Edm Wire: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for wire edm wire

In the competitive landscape of global manufacturing, sourcing high-quality wire EDM wire poses a significant challenge for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. As demand for precision machining increases, understanding the nuances of wire EDM wire—from the types available to their specific applications—becomes paramount. This comprehensive guide delves into the various wire options, including brass, molybdenum, and coated varieties, while highlighting their unique properties and suitability for different machining needs.

Additionally, this guide addresses crucial factors in supplier vetting, ensuring that international buyers can confidently select partners who meet stringent quality standards and offer competitive pricing. With insights into cost considerations, sourcing strategies, and market trends, B2B buyers will be empowered to make informed purchasing decisions that optimize their operations and enhance productivity. Whether you are in Brazil navigating local suppliers or in Vietnam seeking innovative wire solutions, this guide serves as a valuable resource, equipping you with the knowledge needed to thrive in the evolving landscape of wire EDM technology.

By understanding the complexities of wire EDM wire and leveraging this information, international buyers can enhance their procurement strategies and ensure their manufacturing processes remain efficient and cost-effective.

Understanding wire edm wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brass EDM Wire | Alloy of copper and zinc; good conductivity and melting point | General machining, tool steels, and metals | Pros: Economical, versatile; Cons: Limited speed on harder materials. |

| Coated EDM Wire | Thin layer of zinc on brass or copper; enhanced cutting speed | Fast roughing and finishing of steels | Pros: Higher efficiency, better surface finish; Cons: Higher cost than standard brass. |

| Molybdenum Wire | High tensile strength; excellent heat and corrosion resistance | Precision machining and high-temperature applications | Pros: Durable, reliable in extreme conditions; Cons: More expensive, less common. |

| Diffusion-Annealed Wire | High zinc content; diffused coating for better performance | Specialized applications requiring high speed | Pros: Improved cutting speed, better surface integrity; Cons: Complex manufacturing process can affect availability. |

| Copper Wire | High electrical conductivity; limited cutting speed | Older EDM machines and specific applications | Pros: Cost-effective for older machines; Cons: Poor performance in modern applications. |

What Are the Key Characteristics of Brass EDM Wire?

Brass EDM wire is a widely used option in the industry due to its favorable balance of conductivity and melting point. Typically an alloy of copper and zinc, brass wires offer tensile strengths ranging from 54,000 to 173,000 psi, making them suitable for general machining, especially with tool steels. Buyers should consider their machining needs, as while brass wires are economical and versatile, they may struggle with speed when cutting harder materials.

How Do Coated EDM Wires Enhance Performance?

Coated EDM wires feature a thin layer of zinc, which significantly enhances cutting speed and reduces wire breakage. These wires are ideal for fast roughing and finishing applications, particularly in steels. The improved surface finish and integrity make them a preferred choice for many manufacturers. However, the increased performance comes at a higher cost compared to standard brass options, which buyers should factor into their purchasing decisions.

Why Choose Molybdenum Wire for High-Temperature Applications?

Molybdenum wire is known for its high tensile strength and excellent resistance to heat and corrosion, making it suitable for precision machining and applications that experience extreme temperatures. While it offers durability and reliability in challenging environments, the higher price point and lower availability compared to more common wire types may be a consideration for budget-conscious buyers.

What Advantages Do Diffusion-Annealed Wires Offer?

Diffusion-annealed wires utilize a unique manufacturing process that allows for a higher zinc content, enhancing their performance during electrical discharge machining. With tensile strengths between 62,000 and 128,000 psi, these wires are particularly effective for specialized applications requiring fast cutting speeds. While they provide superior performance, the complexity of their production can lead to availability issues, which is an essential consideration for B2B buyers looking to maintain consistent supply chains.

When Is Copper Wire Still a Viable Option?

Although copper wire was the original choice for EDM applications due to its high conductivity, it has become less common in modern contexts. It remains useful in older EDM machines that specify its use. For buyers operating such equipment, copper wire can be a cost-effective solution. However, for those with newer machinery, its limitations in speed and efficiency make it less desirable compared to more advanced wire types.

Key Industrial Applications of wire edm wire

| Industry/Sector | Specific Application of wire edm wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision machining of turbine components | Enhances performance and reliability of engines | Focus on high-tensile strength wires for durability and efficiency. |

| Automotive | Production of complex molds for injection molding | Reduces production time and improves part accuracy | Ensure compatibility with high-speed cutting machines. |

| Medical Devices | Fabrication of intricate surgical instruments | Guarantees precision and safety in medical applications | Select wires that provide superior surface finish and corrosion resistance. |

| Electronics | Manufacturing of fine wire connectors and components | Supports miniaturization and efficiency of devices | Look for wires with high conductivity and low vaporization temperature. |

| Tool and Die Making | Creation of molds and dies for metal forming | Increases tool life and reduces maintenance costs | Source wires that offer excellent wear resistance and stability. |

How is Wire EDM Wire Used in Aerospace Applications?

In the aerospace sector, wire EDM wire is essential for the precision machining of turbine components, which require high tolerances to ensure safety and performance. The use of high-tensile strength wires helps to achieve better edge straightness and reduces wire breakage during the machining process. International buyers, particularly from regions like Europe and the Middle East, should prioritize sourcing wires that can withstand extreme temperatures and provide consistent performance, as these factors directly impact the reliability of aerospace components.

What Role Does Wire EDM Wire Play in Automotive Manufacturing?

In automotive manufacturing, wire EDM wire is critical for producing complex molds used in injection molding processes. This application allows for the creation of intricate shapes and features in parts, significantly reducing production time while enhancing accuracy. Buyers from South America and Africa should consider wires that offer a balance of cost-effectiveness and performance, ensuring that they meet the specific demands of high-speed cutting machines used in modern automotive production lines.

Why is Wire EDM Wire Important in Medical Device Fabrication?

The medical device industry relies heavily on wire EDM wire for the fabrication of intricate surgical instruments that demand high precision and reliability. The ability to create complex geometries with superior surface finishes is crucial for ensuring safety in medical applications. Buyers in this sector, especially from developing markets, should seek wires that offer excellent corrosion resistance and are compliant with medical standards to maintain the integrity of surgical instruments.

How is Wire EDM Wire Utilized in Electronics Manufacturing?

In the electronics industry, wire EDM wire is used for the manufacturing of fine wire connectors and components that require high precision. The miniaturization trend in electronics necessitates the use of wires with high conductivity and low vaporization temperatures, which enhance cutting efficiency and reduce contamination in the spark gap. International buyers, particularly from Asia and Europe, need to focus on sourcing wires that can deliver the fine tolerances and rapid production speeds required for modern electronic devices.

What is the Application of Wire EDM Wire in Tool and Die Making?

Wire EDM wire is extensively used in tool and die making, particularly for creating molds and dies for metal forming processes. The precision and durability offered by wire EDM wire increase the tool life and reduce maintenance costs, making it an invaluable resource in this sector. Buyers from regions like Africa and South America should prioritize sourcing wires that demonstrate excellent wear resistance and stability, ensuring the longevity and reliability of their tooling equipment.

3 Common User Pain Points for ‘wire edm wire’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality Leading to Increased Scrap Rates

The Problem: B2B buyers often struggle with inconsistent cutting quality when using wire EDM, resulting in high scrap rates and wasted materials. This inconsistency can stem from several factors, including the choice of wire type, machine settings, and environmental conditions. For instance, using a low-quality wire may lead to poor edge quality and an increased number of wire breakages, which not only disrupts production schedules but also affects overall project profitability. Buyers may find themselves caught in a cycle of trial and error, leading to frustration and increased costs.

The Solution: To combat these issues, buyers should invest in high-quality wire EDM products specifically tailored for their machining needs. Opt for premium brass or coated EDM wires that offer higher tensile strength and better conductivity. When selecting wire, consider the specific application—such as whether you are machining hard materials like tool steel or softer alloys. Additionally, ensure that machine settings are properly calibrated for the chosen wire type to maximize efficiency and minimize the risk of breakage. Regularly consult with suppliers for technical support and updates on the latest advancements in wire technology to ensure optimal performance.

Scenario 2: Difficulty in Sourcing the Right EDM Wire for Specialized Applications

The Problem: Many international B2B buyers face challenges in sourcing the right EDM wire for specialized applications, particularly in regions with limited access to advanced technology and materials. For example, when machining complex geometries or working with advanced materials like carbide or PCD (polycrystalline diamond), the need for specific wire types becomes critical. Buyers may find themselves overwhelmed by the variety of options available, leading to incorrect purchases that hinder production efficiency and quality.

The Solution: To effectively source the right EDM wire, buyers should conduct thorough market research to identify reputable suppliers who offer a range of wire types designed for specialized applications. Engage in discussions with technical representatives from these suppliers to understand the properties and advantages of different wire options. Additionally, consider establishing partnerships with local distributors who can provide timely access to the required materials. This proactive approach not only simplifies the sourcing process but also ensures that buyers can meet their specific machining requirements with confidence.

Scenario 3: High Costs of Wire EDM Operations Due to Inefficient Practices

The Problem: Cost management is a significant concern for B2B buyers using wire EDM technology, especially when inefficient practices lead to inflated operational costs. Common inefficiencies include using the wrong wire type for the job, improper machine settings, or inadequate maintenance of the wire EDM machines. These issues can result in excessive wear on the wire, higher energy consumption, and increased downtime—all contributing to a negative impact on the bottom line.

The Solution: To reduce operational costs, it is crucial for buyers to implement a systematic approach to wire EDM operations. Start by evaluating current wire usage and identifying any areas of inefficiency. Training staff on the importance of selecting the correct wire type and maintaining optimal machine settings can significantly enhance performance. Moreover, consider investing in wire EDM machines equipped with advanced monitoring systems that can provide real-time data on wire performance and cutting efficiency. This data-driven approach allows for informed decision-making and continuous improvement, ultimately leading to reduced costs and enhanced productivity in wire EDM operations.

Strategic Material Selection Guide for wire edm wire

What Are the Key Properties of Common EDM Wire Materials?

When selecting wire EDM wire, understanding the properties of the materials is crucial for optimizing performance and ensuring compatibility with specific applications. Here, we analyze four common materials used in wire EDM: brass, molybdenum, copper, and coated wires.

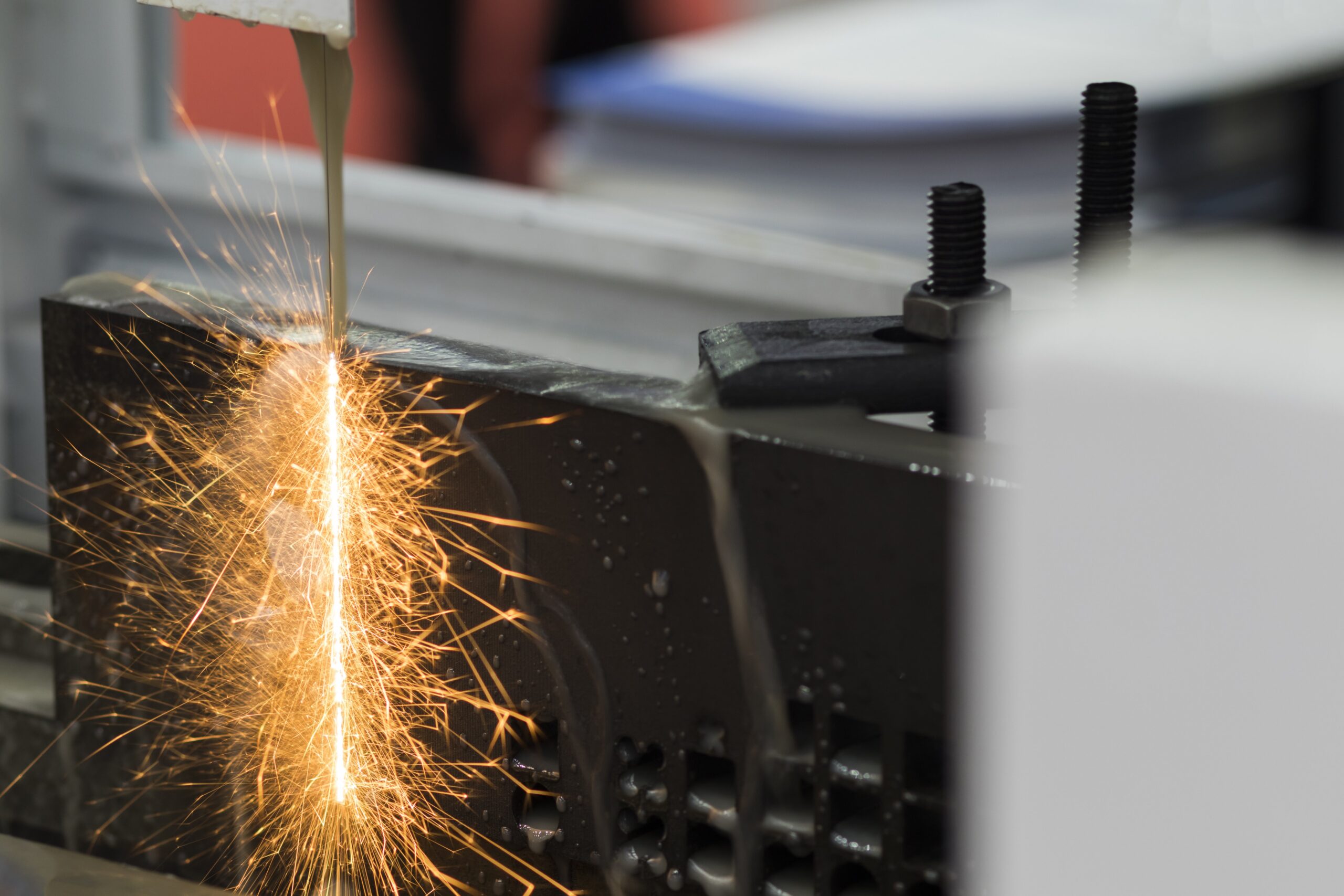

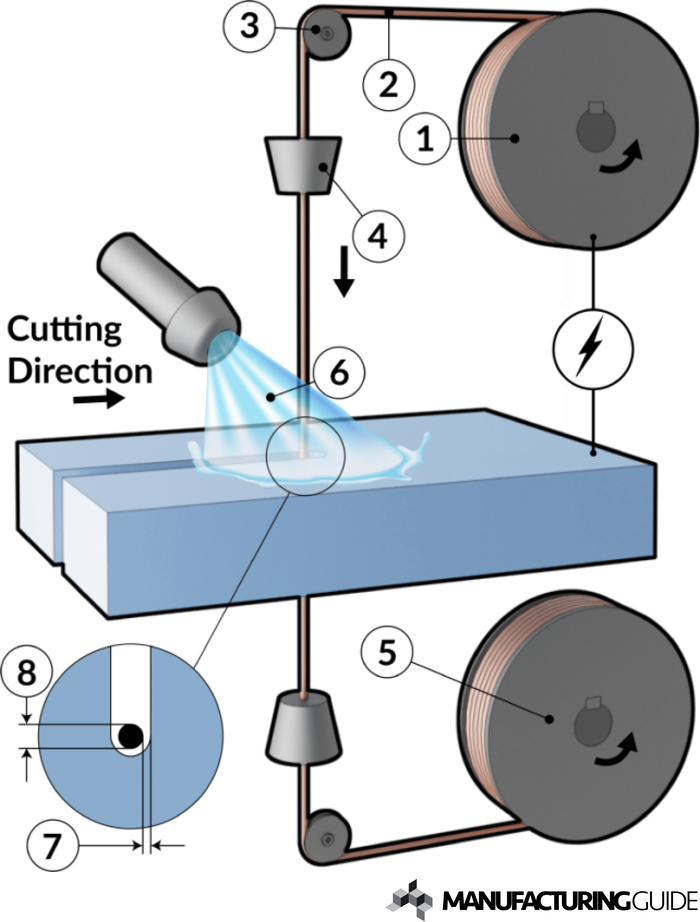

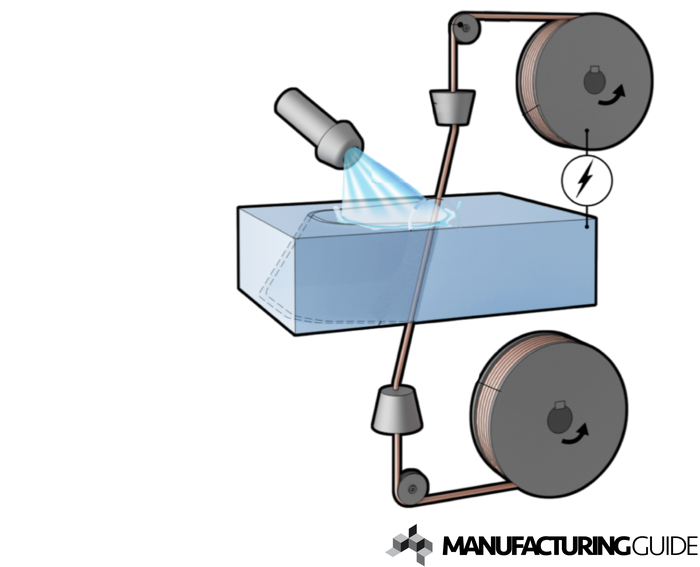

Illustrative image related to wire edm wire

Brass EDM Wire: A Versatile Choice

Brass wire is the most widely used material in wire EDM due to its balanced properties. It typically has a tensile strength ranging from 54,000 to 173,000 psi, depending on its alloy composition. Brass exhibits good corrosion resistance and a relatively low vaporization temperature, which enhances its flushing capabilities during machining.

Pros: Brass is economical and offers good cutting speeds, making it suitable for a variety of metals. Its ductility allows for reliable threading and tapering in EDM applications.

Cons: While brass wire is versatile, it can be prone to oxidation, which may affect its performance. Additionally, its tensile strength may not be sufficient for high-stress applications.

Impact on Application: Brass wire is particularly effective for cutting tool steels and other metals, but may not be ideal for high-precision applications requiring minimal wear.

Illustrative image related to wire edm wire

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, particularly in regions like Europe and South America. Buyers should ensure that the brass wire meets these standards to avoid quality issues.

Molybdenum Wire: High-Performance Alternative

Molybdenum wire is known for its high tensile strength and excellent corrosion resistance, making it suitable for demanding applications. It can withstand high temperatures and is often used in high-precision machining tasks.

Pros: Molybdenum wire offers superior durability and can maintain its properties under extreme conditions, making it ideal for high-stress applications.

Cons: The cost of molybdenum wire is generally higher than that of brass, and its manufacturing process can be more complex, resulting in longer lead times.

Impact on Application: Molybdenum wire is particularly effective for cutting hard materials and is often used in aerospace and automotive applications.

Considerations for International Buyers: Buyers should be aware of specific regulations regarding the use of molybdenum in their regions, especially in the Middle East and Europe, where compliance with environmental standards may be stricter.

Copper Wire: The Traditional Choice

Copper wire was the first material used in EDM, valued for its excellent conductivity. However, its lower tensile strength and cutting speed limit its modern applications.

Pros: Copper wire is readily available and provides high electrical conductivity, which can be beneficial in specific applications.

Cons: Its low tensile strength (34,000-60,000 psi) and slower cutting speeds make it less suitable for high-performance requirements.

Impact on Application: Copper is still used in older EDM machines but is generally not recommended for modern applications requiring efficiency and precision.

Considerations for International Buyers: Buyers should verify if their equipment is compatible with copper wire, particularly in regions like Africa and South America, where older machines may still be in use.

Illustrative image related to wire edm wire

Coated EDM Wire: Enhanced Performance

Coated wires, typically brass or copper with a thin layer of zinc, offer improved cutting speeds and reduced breakage. The coating enhances the wire’s surface integrity and flushing capabilities.

Pros: Coated wires provide better surface finishes and are less likely to break, making them suitable for both roughing and finishing operations.

Cons: The manufacturing process for coated wires can be more complex, leading to higher costs. Additionally, the performance may vary based on the coating method used.

Impact on Application: Coated wires are particularly effective for cutting steels and carbides, offering versatility across various machining tasks.

Considerations for International Buyers: Buyers should ensure that coated wires comply with local standards and preferences, especially in regions with stringent quality control measures.

Summary Table of EDM Wire Materials

| Material | Typical Use Case for wire edm wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General-purpose machining | Economical and versatile | Prone to oxidation | Low |

| Molybdenum | High-precision applications | High tensile strength and durability | Higher cost and complex manufacturing | High |

| Copper | Older EDM machines | Excellent conductivity | Low tensile strength and cutting speed | Med |

| Coated Wire | Fast roughing and finishing | Improved surface finish and reduced breakage | Higher manufacturing complexity | Med |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various wire EDM materials, ensuring informed decision-making tailored to their specific needs and regional compliance requirements.

Illustrative image related to wire edm wire

In-depth Look: Manufacturing Processes and Quality Assurance for wire edm wire

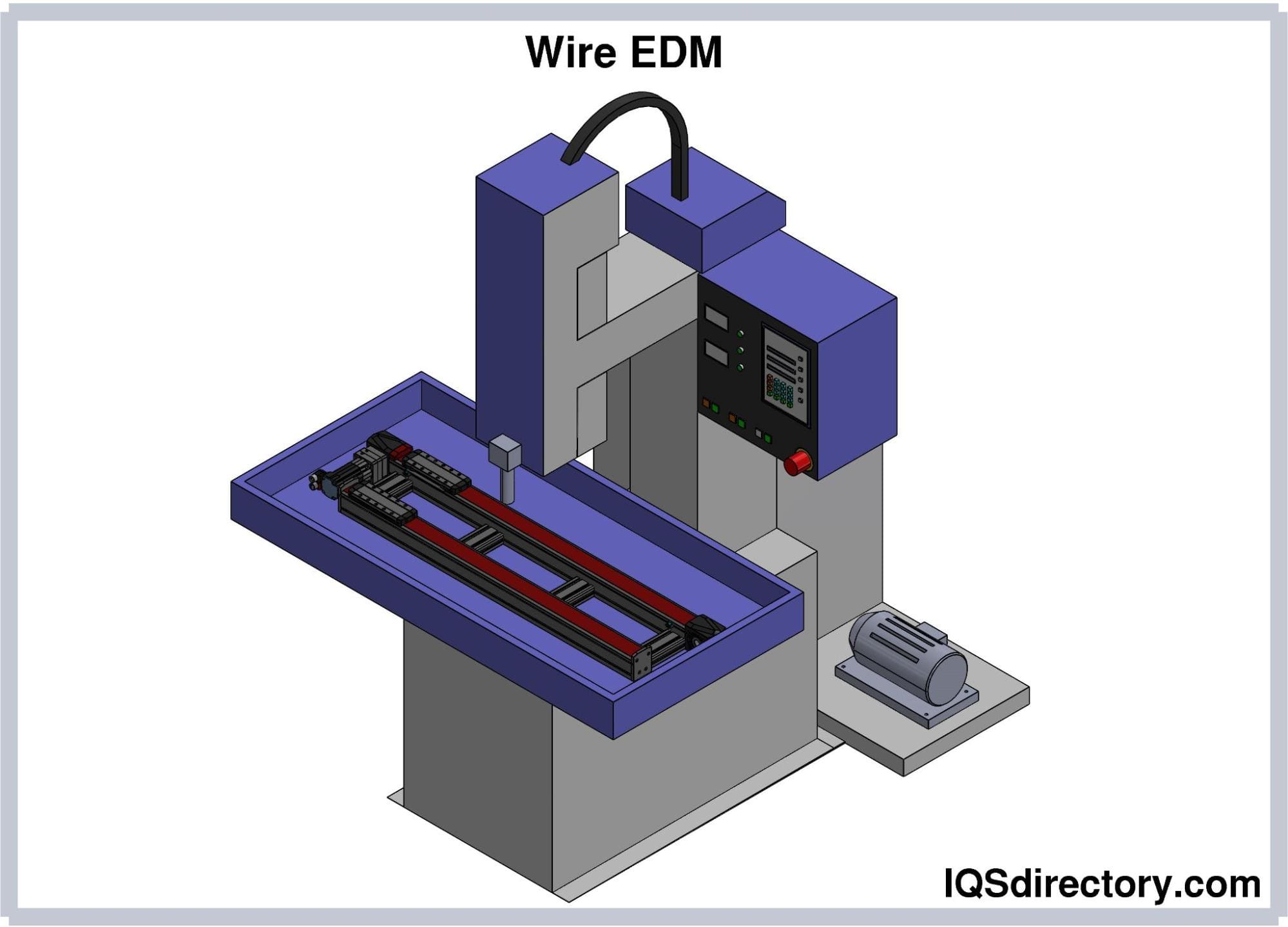

What Are the Main Stages of Manufacturing Wire EDM Wire?

The manufacturing of wire EDM wire involves several critical stages, each designed to ensure that the final product meets the stringent requirements of electrical discharge machining. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality raw materials, typically brass, copper, or specialized alloys like molybdenum. These materials must be carefully chosen for their electrical conductivity, tensile strength, and melting point. Suppliers often source raw materials from reputable manufacturers to guarantee quality. Pre-treatment processes, including cleaning and chemical treatment, are also essential to remove impurities that could affect the wire’s performance.

Forming

Once the raw materials are prepared, they undergo a forming process where they are drawn into wire. This stage involves several passes through a series of dies to achieve the desired diameter and ensure uniformity. Advanced techniques like cold drawing are often employed to enhance the wire’s tensile strength and reduce surface defects. The wire is continuously monitored for consistency in diameter and surface quality during this stage.

Assembly

In some cases, particularly for coated wires, an assembly stage is necessary. Here, the wire may receive additional coatings, such as a zinc layer, to improve its performance characteristics. Techniques such as electro-galvanization are utilized to apply a precise and uniform coating. This stage is crucial for enhancing the wire’s cutting efficiency and longevity during machining.

Finishing

The final stage is finishing, which includes processes like annealing, where the wire is heated and then cooled to relieve internal stresses and improve ductility. Surface treatments may also be applied to enhance the wire’s corrosion resistance and electrical properties. After finishing, the wire is cut to specified lengths and packaged for shipment. Quality checks are essential at this stage to ensure that the wire meets all performance specifications.

How Is Quality Assurance Integrated Into the Manufacturing of Wire EDM Wire?

Quality assurance (QA) is a cornerstone of the manufacturing process for wire EDM wire, ensuring that the product adheres to both international standards and customer specifications. Companies typically follow a structured QA process that encompasses several checkpoints.

International Standards and Industry-Specific Certifications

Manufacturers often comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, particularly for wire used in specialized applications. These certifications help buyers ensure that the products meet regulatory and safety requirements in their respective markets.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects early. Incoming Quality Control (IQC) checks raw materials for compliance with specifications before they enter production. In-Process Quality Control (IPQC) involves real-time monitoring during the forming and assembly stages, ensuring that any deviations are addressed immediately. Finally, Final Quality Control (FQC) assesses the finished product for adherence to standards before shipment.

What Common Testing Methods Are Used for Wire EDM Wire Quality Assurance?

Various testing methods are employed to verify the quality of wire EDM wire, ensuring it meets operational performance and safety standards. These methods include:

- Tensile Testing: This determines the wire’s tensile strength and elongation, providing insights into its performance under stress.

- Conductivity Testing: Measuring the wire’s electrical conductivity is essential, as higher conductivity correlates with better machining efficiency.

- Surface Quality Inspection: Visual inspections and surface roughness measurements help identify defects that could affect machining performance.

- Dimensional Checks: Automated systems are often used to ensure that the wire’s diameter and length conform to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits provides an in-depth view of a supplier’s manufacturing and QC processes. This step allows buyers to assess compliance with international standards and industry practices.

- Requesting Quality Reports: Buyers should ask suppliers for comprehensive quality reports, including results from tensile and conductivity tests, as well as compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide unbiased assessments of product quality. This step is especially valuable for buyers who may not have the resources for on-site evaluations.

What Are the Quality Control Nuances for International Buyers?

B2B buyers must navigate specific nuances related to quality control when sourcing wire EDM wire internationally. Understanding these nuances can help mitigate risks and ensure quality:

- Cultural Differences: Different regions may have varying standards and practices regarding quality assurance. Buyers should familiarize themselves with local regulations and manufacturing norms.

- Shipping and Handling: Quality can be compromised during shipping. Buyers should discuss packaging and handling procedures with suppliers to ensure that products arrive in optimal condition.

- Customs Regulations: Ensure that the products meet the importing country’s regulations to avoid delays and additional costs. Compliance with local standards can also impact the acceptance of the goods upon arrival.

By understanding the manufacturing processes and quality assurance protocols associated with wire EDM wire, B2B buyers can make informed purchasing decisions that align with their operational needs and standards.

Illustrative image related to wire edm wire

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire edm wire’

In the competitive landscape of wire EDM wire procurement, making informed decisions is crucial for optimizing machining efficiency and ensuring product quality. This guide provides a structured approach to sourcing wire EDM wire, tailored for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the wire EDM wire meets your machining needs. Consider parameters such as wire diameter, tensile strength, conductivity, and melting temperature. Each of these factors will affect the wire’s performance in your specific applications, such as fine cutting or rough machining.

Step 2: Research Material Types and Properties

Understand the various types of wire EDM wire available and their specific properties. For instance, brass wire is commonly used due to its balance of cost and performance, while molybdenum wire is preferred for high-temperature applications. Familiarize yourself with tensile strength and conductivity, as these factors can significantly influence cutting efficiency and wire longevity.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet industry standards. Request detailed company profiles, technical data sheets, and references from other clients in similar industries. Look for suppliers that have certifications, such as ISO, to validate their quality management systems.

Step 4: Request Samples for Testing

Once you’ve narrowed down your supplier options, request samples of the wire EDM wire for testing. This step allows you to assess the wire’s performance in your specific machining conditions and verify its compatibility with your equipment. Testing can help identify any potential issues before bulk purchasing, saving time and resources.

Illustrative image related to wire edm wire

Step 5: Compare Pricing and Value

Evaluate the pricing structures offered by different suppliers, but don’t make decisions based solely on cost. Consider the overall value, including the quality of the wire, supplier reliability, and the level of customer support provided. A lower price might not be advantageous if it compromises quality or service.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms and conditions, including delivery timelines, payment options, and return policies. Clear agreements can prevent misunderstandings and ensure that both parties have aligned expectations regarding the transaction. Pay attention to warranty provisions, as these can provide added security for your investment.

Step 7: Establish a Long-Term Relationship

Once you’ve made a successful purchase, consider establishing a long-term relationship with the supplier. Frequent communication and feedback can enhance collaboration and lead to better pricing, customized solutions, and priority service in the future. A strong partnership can significantly benefit your operations as your needs evolve.

By following this checklist, B2B buyers can streamline the procurement process for wire EDM wire, ensuring that they select the right products from reliable suppliers while maximizing efficiency and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for wire edm wire Sourcing

What Are the Key Cost Components in Wire EDM Wire Sourcing?

When evaluating the cost structure of wire EDM wire sourcing, it’s essential to consider several key components. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of wire—brass, molybdenum, or coated variants—significantly influences material costs. For instance, brass wires generally range from $3.50 per lb for clearance pricing to over $400 for specialized coatings that improve efficiency.

-

Labor: Skilled labor is required for wire production and quality assurance. Labor costs can vary widely based on the region, with higher wages in developed markets impacting overall pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and facility expenses. Companies with efficient operations can offer more competitive pricing.

-

Tooling: The setup costs for specialized tooling can be substantial, especially for customized wire EDM solutions. This upfront investment can be spread over larger production runs to reduce per-unit costs.

-

Quality Control: Ensuring the wire meets specified standards incurs additional costs. Certifications and testing can be particularly crucial for international buyers looking for consistent quality.

-

Logistics: Transportation costs depend on the shipping method and distance. International buyers must factor in customs duties, tariffs, and potential delays, which can add to the total cost.

-

Margin: Supplier profit margins vary based on market competition, brand reputation, and service levels. Established suppliers may command higher prices due to perceived quality and reliability.

What Factors Influence Pricing in Wire EDM Wire Procurement?

Several influencers affect wire EDM wire pricing that buyers should be aware of:

-

Volume/MOQ: Bulk purchases often result in lower per-unit costs. Suppliers may offer discounts for minimum order quantities (MOQs), which can be advantageous for larger operations.

-

Specifications and Customization: Custom wire specifications can increase costs due to additional processing and quality checks. Clearly defining requirements upfront can help avoid unexpected expenses.

-

Materials: The choice of wire material directly correlates with price. High-performance options like molybdenum or specially coated wires will typically cost more than standard brass.

-

Quality and Certifications: Higher quality wires with certifications for specific applications will command a premium. Buyers should assess whether the added cost aligns with their operational needs.

-

Supplier Factors: Supplier reliability, lead times, and customer service play critical roles in pricing. Established suppliers may charge more but can offer better support and consistent quality.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears shipping costs and risks, influencing the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Wire EDM Wire Sourcing?

To maximize cost-efficiency in sourcing wire EDM wire, consider the following strategies:

-

Negotiation: Don’t hesitate to negotiate prices, especially for bulk orders or long-term contracts. Building a relationship with suppliers can yield better terms.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the upfront price. This includes maintenance, downtime, and the quality of the final product. A cheaper wire may lead to higher operational costs if it requires more frequent replacement.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import duties, and local regulations that can affect pricing. It’s wise to consult with local experts or partners to navigate these complexities.

-

Supplier Diversity: Engaging multiple suppliers can foster competition and potentially lead to better pricing and service options. However, ensure that all suppliers meet the quality and delivery standards required for your operations.

-

Research and Benchmarking: Regularly benchmark prices and quality across suppliers to ensure competitive sourcing. Utilize industry reports and trade shows to stay informed about market trends and emerging technologies.

Disclaimer

The prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your needs.

Alternatives Analysis: Comparing wire edm wire With Other Solutions

When evaluating manufacturing processes, particularly in the realm of precision machining, it’s crucial to consider various alternatives to wire EDM (Electrical Discharge Machining) wire. Each method has unique attributes that cater to specific requirements, and understanding these differences can guide B2B buyers in making informed decisions.

| Comparison Aspect | Wire EDM Wire | Laser Cutting | Waterjet Cutting |

|---|---|---|---|

| Performance | High precision and intricate cuts; excellent for hard materials. | Excellent speed and versatility; effective for thin materials. | Good for thick materials; offers versatility with various materials. |

| Cost | Moderate initial investment; wire cost can vary based on type. | Higher equipment costs; operational costs depend on material thickness. | High equipment and operational costs; water and abrasive materials add to expenses. |

| Ease of Implementation | Requires specialized EDM machines; operator skill necessary. | More user-friendly; less specialized training required. | Equipment setup can be complex; requires skilled operators. |

| Maintenance | Regular maintenance of EDM machines; wire quality affects performance. | Lower maintenance; laser systems are generally robust. | High maintenance due to wear on nozzles and pumps. |

| Best Use Case | Ideal for complex geometries and hard metals; excellent for tool and die making. | Best for cutting sheet metal and non-metal materials; quick and efficient for prototypes. | Suitable for thick materials and materials sensitive to heat; ideal for food and aerospace industries. |

What Are the Advantages and Disadvantages of Laser Cutting as an Alternative to Wire EDM Wire?

Laser cutting utilizes a focused laser beam to slice through materials. This method is particularly advantageous for its speed and ability to cut a variety of materials, including metals, plastics, and wood. However, it may not achieve the same level of precision as wire EDM, especially when dealing with intricate designs or hard metals. Additionally, while initial setup costs can be high, operational expenses can be lower than EDM in some contexts, particularly for high-volume production.

How Does Waterjet Cutting Compare to Wire EDM Wire in Terms of Performance?

Waterjet cutting employs a high-pressure stream of water, often mixed with abrasive materials, to cut through thick materials. One of its primary advantages is the ability to cut a wide range of materials, including metals, glass, and composites, without introducing heat, thereby avoiding thermal distortion. However, the process is generally slower than wire EDM and may require more maintenance due to wear on the cutting apparatus. Furthermore, the cost of operation can be significant, especially with the need for abrasives and water management.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a machining solution, B2B buyers should carefully evaluate their specific requirements, including material types, desired precision, production volume, and budget constraints. Wire EDM wire excels in applications demanding high precision and the ability to work with hard materials, making it a prime choice for tool and die manufacturing. Conversely, for projects prioritizing speed and material versatility, laser cutting may be more suitable. For those needing to cut thick materials without heat distortion, waterjet cutting presents a strong alternative. Ultimately, the right choice will depend on aligning the technology with the project demands and operational capabilities.

Essential Technical Properties and Trade Terminology for wire edm wire

What Are the Key Technical Properties of Wire EDM Wire?

When sourcing wire EDM wire, understanding its technical properties is essential for ensuring optimal performance in electrical discharge machining processes. Here are some critical specifications:

1. Material Composition

Wire EDM wires are primarily composed of brass, copper, molybdenum, or tungsten. Brass wires are most common due to their favorable balance of conductivity and tensile strength, making them suitable for various applications. Molybdenum and tungsten wires are often chosen for their high-temperature resistance and durability, particularly in demanding environments. Selecting the right material directly impacts machining efficiency and cost-effectiveness.

2. Tensile Strength

Tensile strength refers to the maximum load a wire can withstand without breaking, measured in pounds per square inch (psi). High tensile strength is crucial for maintaining wire integrity during machining, especially in applications requiring precision and minimal wire breakage. Wires with tensile strengths ranging from 54,000 psi to 173,000 psi are available, with higher values offering improved performance for complex geometries and reduced downtime.

3. Diameter and Tolerance

Wire diameter typically ranges from 0.1 mm to 0.3 mm, and precise tolerance is vital for achieving desired cut quality and accuracy. A smaller diameter allows for intricate designs and finer cuts, while larger diameters are better suited for heavy-duty applications. Consistent tolerance ensures that the wire performs uniformly across different batches, which is critical for maintaining production quality.

4. Vaporization Temperature

The vaporization temperature of the wire affects its efficiency during the cutting process. A lower vaporization temperature allows for better flushing and faster cutting speeds, which is essential for maintaining clean spark gaps. This characteristic is particularly important when machining tough materials, as it reduces the risk of wire contamination and enhances the overall machining process.

5. Coating Types

Coated wires, such as those with a zinc or plasma coating, provide enhanced performance characteristics. The coating improves flushing capabilities and increases cutting speeds by preventing the wire from becoming clogged with debris. Understanding the type of coating and its properties can help B2B buyers select the right wire for specific applications, optimizing machining results.

Which Trade Terms Are Essential in the Wire EDM Wire Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the wire EDM wire market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of wire EDM wire, understanding OEM specifications is crucial for ensuring compatibility with specific machines and maintaining quality standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and procurement strategies. Understanding the MOQ can help companies plan their purchasing schedules and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products or services. Submitting an RFQ allows buyers to compare offers, negotiate prices, and ensure they are getting the best deal for their wire EDM wire requirements.

Illustrative image related to wire edm wire

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping costs, insurance, and risk transfer. Familiarity with Incoterms is essential for B2B buyers engaging in cross-border trade to clarify shipping obligations and reduce misunderstandings.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the products. Understanding lead times is crucial for effective production planning and inventory management, especially in industries where time-sensitive projects are common.

By mastering these technical properties and trade terminology, B2B buyers can make informed decisions, enhance their procurement strategies, and ultimately achieve better outcomes in their wire EDM machining processes.

Navigating Market Dynamics and Sourcing Trends in the wire edm wire Sector

What Are the Key Trends Shaping the Global Wire EDM Wire Market?

The wire EDM (Electrical Discharge Machining) wire sector is experiencing significant growth driven by advancements in manufacturing technologies and increasing demand for precision machining across various industries. Key market dynamics include the rising adoption of automation and Industry 4.0 practices, which facilitate more efficient manufacturing processes. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, must stay informed about emerging sourcing trends such as the shift towards high-performance materials like diffusion-annealed and coated wires, which offer better cutting speeds and surface finishes.

Additionally, the trend toward customizability is gaining traction. Manufacturers are increasingly offering tailored solutions to meet specific customer requirements, particularly in sectors like aerospace, automotive, and medical devices. This customization enhances operational efficiency and optimizes the machining process, thus driving demand for specialized wire EDM wires. Moreover, the expansion of e-commerce platforms is revolutionizing how B2B buyers source materials, allowing for more competitive pricing and easier access to a broader range of products.

How Important Is Sustainability and Ethical Sourcing in the Wire EDM Wire Sector?

Sustainability and ethical sourcing have become paramount in the wire EDM wire market, reflecting a broader global movement towards environmental responsibility. The production and disposal of conventional EDM wires can have significant environmental impacts due to the materials used and the energy consumed during manufacturing. As such, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical supply chains not only enhance brand reputation but also attract customers who value corporate responsibility. Certifications such as ISO 14001 for environmental management and adherence to REACH regulations for chemical safety are becoming essential for suppliers. Furthermore, the development of “green” materials—such as wires with reduced toxic content or those produced using renewable energy—offers buyers a way to minimize their environmental footprint while maintaining high performance in machining applications.

What Is the Evolution of Wire EDM Technology and Its Relevance to B2B Buyers?

The evolution of wire EDM technology has significantly influenced the wire EDM wire market. Initially dominated by copper and brass wires, the sector has expanded to include a variety of high-performance wires designed for specific applications. The introduction of coated and diffusion-annealed wires has revolutionized machining capabilities, allowing for faster cutting speeds and better surface finishes.

This evolution is crucial for B2B buyers as it directly impacts their operational efficiency and cost-effectiveness. Understanding the historical context of wire EDM technology enables buyers to make informed decisions about the types of wires that best suit their machining needs. As manufacturers continue to innovate, staying updated on these technological advancements will be essential for international buyers looking to maintain a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of wire edm wire

-

How do I select the right type of wire EDM wire for my application?

Selecting the appropriate wire EDM wire involves considering the material you’re machining, the desired precision, and the machining conditions. For general purposes, brass wire is commonly used due to its balance of cost and performance. If you need higher cutting speeds and better surface finishes, consider zinc-coated or diffusion-annealed wires. Additionally, assess the tensile strength and conductivity; higher values will improve efficiency and reduce wire breakage. Always consult with your wire supplier for recommendations tailored to your specific requirements and machine capabilities. -

What is the best wire EDM wire for high-speed cutting?

For high-speed cutting applications, zinc-coated or diffusion-annealed EDM wires are optimal. These wires have enhanced conductivity and lower vaporization temperatures, allowing for faster metal removal rates and improved flushing efficiency. The zinc coating facilitates quicker cutting speeds while minimizing wire breakage. If working with hard materials or requiring fine details, opt for high-tensile strength wires, which provide better edge straightness and geometric accuracy. Always ensure that the wire is compatible with your specific EDM machine for best results. -

What are the minimum order quantities (MOQ) for wire EDM wire?

Minimum order quantities for wire EDM wire can vary significantly among suppliers and may depend on the specific type of wire, spool size, and material. Typically, MOQs can range from 100 meters to several kilometers, especially for specialty wires. When sourcing internationally, it’s essential to discuss MOQs upfront to ensure they align with your production needs. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders, so be sure to negotiate and clarify these terms before finalizing your order. -

How can I vet suppliers for wire EDM wire in international markets?

To effectively vet suppliers, begin by researching their reputation in the industry. Look for reviews, testimonials, and case studies to gauge customer satisfaction. Verify their certifications and quality control processes, such as ISO standards. It’s also beneficial to request samples of their wire products to assess quality firsthand. Engage in direct communication to evaluate their responsiveness and willingness to address your inquiries. Establishing relationships with local distributors can also provide insights into supplier reliability and service levels in your target market. -

What payment terms should I expect when purchasing wire EDM wire internationally?

Payment terms can vary widely depending on the supplier and the relationship established. Common terms include upfront payment, net 30, or net 60 days. For first-time transactions, many suppliers may require partial payment upfront and the remainder upon delivery. It’s advisable to negotiate terms that provide you with sufficient cash flow while ensuring the supplier’s confidence in the transaction. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect both parties during international transactions. -

What quality assurance measures should I look for in wire EDM wire?

When sourcing wire EDM wire, inquire about the supplier’s quality assurance (QA) processes. Look for certifications such as ISO 9001, which indicates adherence to international quality management standards. Request documentation for material properties, including tensile strength, conductivity, and chemical composition. Suppliers should also have a robust testing protocol to ensure consistency and reliability, including periodic inspections and customer feedback loops. Establishing clear quality expectations in your purchase agreement can help mitigate risks associated with substandard products. -

How does logistics impact the sourcing of wire EDM wire internationally?

Logistics plays a crucial role in the timely delivery of wire EDM wire. Factors such as shipping methods, customs clearance, and local regulations can significantly affect lead times and costs. When sourcing internationally, work with suppliers who have experience in your target market to navigate these complexities. It’s important to establish clear timelines and shipping terms upfront. Consider using freight forwarders or logistics partners who specialize in industrial supplies to streamline the process and avoid potential delays. -

Can I customize wire EDM wire for specific applications?

Yes, many suppliers offer customization options for wire EDM wire to meet specific application requirements. Customization can include variations in wire diameter, coating types, and tensile strengths tailored to your machining needs. When seeking customization, provide detailed specifications and performance expectations to the supplier. Keep in mind that custom orders may have longer lead times and higher MOQs. Collaborating closely with the supplier during the design and production phases can ensure that the final product aligns perfectly with your operational needs.

Top 8 Wire Edm Wire Manufacturers & Suppliers List

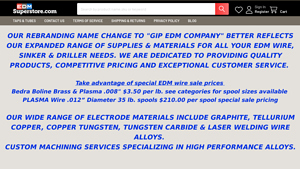

1. EDM Superstore – EDM Wires

Domain: edmsuperstore.com

Registered: 2020 (5 years)

Introduction: EDM Wires available: Brass EDM Wires, Coated EDM Wires, Molybdenum Specialty Wire. Special sale prices: Bedra Boline Brass EDM Wire at $3.50 per lb, Plasma Coated EDM Wire priced between $154.00 – $440.00, Molybdenum Wire at $198.50. Features of Plasma Coated EDM Wire include proprietary coating for improved flushing and higher metal removal rates. Molybdenum Wire is designed for EDM with high ten…

2. McMaster – EDM Wire Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – EDM Wire Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

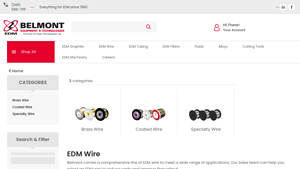

3. Belmont – EDM Wire Solutions

Domain: belmont4edm.com

Registered: 1997 (28 years)

Introduction: Belmont offers a comprehensive line of EDM wire suitable for various applications. Key product details include: 1. Moly EDM Wire available in multiple diameters: 0.002″, 0.003″, 0.004″, 0.005″, 0.006″, 0.008″, and 0.010″. 2. Length options: 2000 meters and 5000 meters. 3. Premium Brass Wire available in 0.008″ diameter, 22 lbs. P-10 spool. 4. Categories include Brass Wire, Coated Wire, Specialty W…

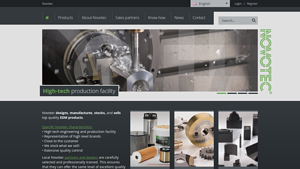

4. Novotec – EDM Wire Selection

Domain: us.novotec-edm.com

Registered: 1998 (27 years)

Introduction: EDM wire selection includes various types and properties: 1. **Wire Properties**: – **Tensile Strength**: Maximum load-bearing capability; high-tensile wires improve edge straightness and reduce breakage. – **Fracture Resistance**: Describes wire toughness; important for dynamic spark gap environments. – **Conductivity**: Higher conductivity allows for more power delivery and increased cutting spe…

5. Reddit – 420 Stainless Precision Part

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 420 Stainless material used for the part, with a tolerance of about .0003″ per side for a precise fit.

6. MSC Direct – Brass Hard Grade EDM Wire

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Brass Hard Grade EDM Wire, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Proterial – Wire EDM Wire

Domain: proterial.com

Registered: 2021 (4 years)

Introduction: Product Name: Wire Electric Discharge Machining (EDM) Wire

Description: Designed for cutting hard metals using the EDM process, featuring superior electric properties for high-speed machining and surface precision.

Manufacturing: Manufactured and quality-controlled in Japan.

Recommended by: Many W-EDM machine manufacturers.

Key Features:

– Stable discharging enabled by carefully selected material…

8. SST Consumables – EDM Brass Wires

Domain: sstconsumables.com

Registered: 2020 (5 years)

Introduction: SST Consumables offers a variety of EDM Brass Wires suitable for standard applications and productivity requirements. Key product details include:

– **Brands Available**: Sumitomo, Proterial, Bedra, PremiumCut, VersaCut, Axiom.

– **Wire Diameter Options**: 0.004″ (0.1mm), 0.006″ (0.15mm), 0.008″ (0.2mm), 0.010″ (0.25mm), 0.012″ (0.3mm), 0.01″ (0.25mm).

– **Tensile Strength**: Ranges from 600 N/mm…

Strategic Sourcing Conclusion and Outlook for wire edm wire

How Can Strategic Sourcing Enhance Your Wire EDM Wire Procurement?

In today’s competitive landscape, the strategic sourcing of wire EDM wire is pivotal for enhancing operational efficiency and reducing costs. By understanding the diverse range of wire options—such as brass, molybdenum, and coated wires—businesses can select materials that align with their specific machining needs and performance requirements. High-tensile and diffusion-annealed wires, for instance, offer improved cutting speeds and reduced breakage, translating to higher productivity and superior surface finishes.

The value of strategic sourcing extends beyond mere cost savings; it fosters stronger supplier relationships, ensuring consistent quality and supply chain reliability. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, investing in a strategic sourcing approach will enable you to navigate fluctuating market dynamics more effectively.

Looking ahead, the wire EDM wire market is poised for innovation, driven by advancements in materials and manufacturing techniques. By prioritizing strategic sourcing, you position your business to capitalize on these developments and maintain a competitive edge. Engage with reliable suppliers today to ensure your operations are equipped with the best resources for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to wire edm wire

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.