Everything You Need to Know About 2017 Jeep Renegade Latitude 4X4 Fender Liner…

Introduction: Navigating the Global Market for 2017 jeep renegade latitude 4×4 fender liner

In the competitive landscape of the automotive parts market, sourcing high-quality fender liners for the 2017 Jeep Renegade Latitude 4×4 poses significant challenges for international B2B buyers. The need for durable and reliable fender liners is critical, as these components protect vital areas of the vehicle from debris, moisture, and corrosion, ultimately extending the vehicle’s lifespan. However, navigating the complexities of supplier selection, pricing variations, and quality assurance can be daunting, particularly for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe.

This comprehensive guide addresses these challenges by providing a thorough overview of the various types of fender liners available for the 2017 Jeep Renegade Latitude 4×4, along with their specific applications. Buyers will gain insights into the critical factors influencing their purchasing decisions, including material durability, fitment compatibility, and cost considerations. Additionally, the guide emphasizes the importance of supplier vetting, equipping buyers with the knowledge to discern between OEM and aftermarket options, ensuring they make informed choices.

By leveraging the information presented in this guide, international B2B buyers can navigate the global market with confidence, securing high-quality fender liners that meet their operational needs while optimizing their procurement strategies. Whether you are based in Brazil or Saudi Arabia, this resource empowers you to enhance your supply chain efficiency and ultimately drive business success.

Understanding 2017 jeep renegade latitude 4×4 fender liner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Fender Liners | Manufactured by original equipment manufacturers (OEM) | Dealerships, Auto Repair Shops | Pros: Guaranteed fit and quality; Cons: Higher cost. |

| Aftermarket Fender Liners | Produced by third-party manufacturers, often with variations | Independent Auto Parts Retailers | Pros: Typically lower cost; Cons: Quality may vary. |

| Polypropylene Fender Liners | Made from durable, lightweight plastic | Off-road Vehicle Customization Shops | Pros: Resistant to corrosion; Cons: May not match OEM aesthetics. |

| Foam-Injected Fender Liners | Combines foam for insulation and sound dampening | Specialty Vehicle Upfitters | Pros: Enhanced noise reduction; Cons: More expensive. |

| Custom Fit Fender Liners | Designed for specific modifications or enhancements | Customization Shops, Enthusiast Groups | Pros: Tailored for unique applications; Cons: Longer lead time. |

What Are the Characteristics of OEM Fender Liners for the 2017 Jeep Renegade Latitude 4×4?

OEM fender liners are crafted by the original manufacturers of the Jeep Renegade, ensuring a perfect fit and adherence to quality standards. These parts are ideal for dealerships and auto repair shops that prioritize reliability and customer satisfaction. While they offer the assurance of quality and compatibility, the higher price point may deter some budget-conscious buyers.

How Do Aftermarket Fender Liners Compare for B2B Buyers?

Aftermarket fender liners are produced by third-party manufacturers and can vary significantly in quality and design. They are popular among independent auto parts retailers due to their affordability. However, B2B buyers must carefully assess the brand reputation and product reviews to avoid purchasing subpar parts that may not fit properly.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

Why Choose Polypropylene Fender Liners for Off-Road Applications?

Polypropylene fender liners are lightweight yet durable, making them suitable for off-road applications. Their resistance to corrosion and impact makes them an appealing choice for customization shops focused on enhancing vehicle performance. While they provide excellent functionality, they may not always match the aesthetic qualities of OEM parts, which could be a consideration for some buyers.

What Benefits Do Foam-Injected Fender Liners Offer?

Foam-injected fender liners provide additional insulation and sound dampening, making them a preferred choice for specialty vehicle upfitters. These liners can enhance the overall driving experience by reducing noise and vibration. However, their higher price point may be a consideration for cost-sensitive businesses looking for budget-friendly options.

How Do Custom Fit Fender Liners Cater to Unique B2B Needs?

Custom fit fender liners are designed for specific modifications, catering to businesses that focus on personalization and unique vehicle enhancements. They are particularly useful for customization shops and enthusiast groups seeking to provide tailored solutions. While these liners offer distinct advantages in terms of fit and functionality, buyers should be prepared for longer lead times due to the customization process.

Key Industrial Applications of 2017 jeep renegade latitude 4×4 fender liner

| Industry/Sector | Specific Application of 2017 Jeep Renegade Latitude 4×4 Fender Liner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement of damaged fender liners during vehicle servicing | Enhances vehicle longevity and safety for clients | Ensure compatibility with various Jeep Renegade models |

| Off-Road Vehicle Retailers | Upgrades for off-road enthusiasts looking for enhanced protection | Attracts a niche market interested in off-road customization | Stock a variety of fender liners for different models |

| Fleet Management Companies | Maintenance of company-owned Jeep Renegades to reduce operational costs | Reduces repair frequency and improves vehicle reliability | Consider bulk purchasing options for cost savings |

| Exporters and Distributors | Supply of fender liners to international markets | Expands product offerings for automotive parts | Understand regional compliance and import regulations |

| Automotive Parts Suppliers | Stocking fender liners for retail and online sales | Increases inventory diversity and customer satisfaction | Focus on high-quality materials and competitive pricing |

How Do Automotive Repair Shops Use the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

Automotive repair shops frequently replace damaged fender liners to maintain the structural integrity and aesthetic appeal of vehicles. The 2017 Jeep Renegade Latitude 4×4 fender liner acts as a protective barrier against debris, moisture, and corrosion. For international B2B buyers, understanding the specific fitment for various Renegade models is crucial. Ensuring the availability of OEM or high-quality aftermarket options can lead to increased customer satisfaction and repeat business.

What Role Do Off-Road Vehicle Retailers Play in Fender Liner Upgrades?

Off-road vehicle retailers often promote the 2017 Jeep Renegade Latitude 4×4 fender liner as an essential upgrade for off-road enthusiasts. These fender liners offer enhanced protection against harsh terrains, making them a popular choice among adventurers. Retailers need to stock various fender liners to cater to the diverse preferences of their clientele. Highlighting the durability and performance benefits can help attract customers looking to customize their vehicles for rugged use.

How Do Fleet Management Companies Benefit from Fender Liner Maintenance?

Fleet management companies that operate Jeep Renegades can significantly benefit from regular fender liner maintenance. By replacing worn or damaged liners, companies can reduce the likelihood of costly repairs and extend the lifespan of their vehicles. For international buyers, it is important to consider suppliers who can provide bulk purchasing options, ensuring a consistent supply of parts while minimizing operational costs.

Why Should Exporters and Distributors Focus on the 2017 Jeep Renegade Fender Liner?

Exporters and distributors can leverage the demand for the 2017 Jeep Renegade Latitude 4×4 fender liner in international markets. By offering this product, they can diversify their automotive parts portfolio and cater to a growing customer base. Understanding regional compliance and import regulations is essential for successful transactions, ensuring that the products meet local standards and customer expectations.

How Can Automotive Parts Suppliers Enhance Their Offerings with Fender Liners?

Automotive parts suppliers can enhance their inventory by including the 2017 Jeep Renegade Latitude 4×4 fender liner, which is in demand for both retail and online sales. By providing high-quality options, suppliers can improve customer satisfaction and loyalty. Additionally, focusing on competitive pricing and diverse stock can help suppliers stand out in the marketplace, appealing to both individual consumers and businesses looking for reliable automotive components.

3 Common User Pain Points for ‘2017 jeep renegade latitude 4×4 fender liner’ & Their Solutions

Scenario 1: Sourcing High-Quality Fender Liners for the 2017 Jeep Renegade Latitude 4×4

The Problem: One common challenge faced by B2B buyers, particularly in regions like Africa and South America, is the sourcing of high-quality fender liners that meet both performance and durability standards. Many suppliers offer generic parts that may not fit properly or could deteriorate quickly due to harsh driving conditions. This can lead to increased maintenance costs and potential vehicle damage, causing frustration and financial strain for businesses relying on these vehicles for operations.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

The Solution: To effectively source high-quality fender liners, buyers should prioritize OEM (Original Equipment Manufacturer) parts or reputable aftermarket options known for their durability and precise fit. Begin by verifying the part number—OEM fender liners for the 2017 Jeep Renegade Latitude 4×4 typically have numbers like 68254966AA. Utilize established suppliers who provide detailed specifications and customer reviews. In regions where logistics can be challenging, consider suppliers that offer robust shipping options and return policies to mitigate risks. Additionally, leverage local partnerships with auto parts distributors who can provide insights on the best products suited for specific environments, ensuring you invest in fender liners that stand the test of time.

Scenario 2: Navigating Installation Challenges for Fender Liners

The Problem: Another prevalent issue is the complexity of installing fender liners, which can lead to improper fitting if not handled correctly. B2B buyers often face difficulties during installation due to a lack of comprehensive guides or specialized tools. This can result in extended downtime for vehicles and additional labor costs, which is especially burdensome for businesses that rely on their fleet for transportation and logistics.

The Solution: To overcome installation challenges, companies should invest in detailed installation guides or instructional videos provided by manufacturers or trusted automotive websites. Additionally, ensure that your team is equipped with the necessary tools for the installation process. Consider training sessions for staff on proper installation techniques, which can enhance efficiency and reduce errors. For buyers unfamiliar with installation processes, partnering with local mechanics or auto body shops for professional installation can be a worthwhile investment, ensuring that the fender liners are fitted correctly and securely.

Scenario 3: Addressing Long-Term Maintenance and Durability Concerns

The Problem: B2B buyers often express concerns about the long-term durability and maintenance of fender liners, particularly in regions with varied climates and road conditions. Inferior-quality fender liners may lead to rust, wear, and tear, necessitating frequent replacements. This not only disrupts business operations but also increases overall costs, making it critical for buyers to select products that can withstand their specific environmental conditions.

The Solution: To address durability concerns, it is crucial to select fender liners made from high-quality materials that offer resistance to corrosion and impact. Buyers should look for fender liners with features like UV protection and those designed to handle extreme temperatures. Engaging with suppliers who provide warranties can also offer peace of mind regarding the longevity of the parts. Additionally, implementing a regular maintenance schedule can help identify wear and tear early on, allowing businesses to replace parts proactively before they fail. Educating your maintenance team on signs of wear specific to fender liners can also improve the overall lifespan of these components, ensuring your fleet remains operational without unnecessary disruptions.

Strategic Material Selection Guide for 2017 jeep renegade latitude 4×4 fender liner

What Materials Are Commonly Used for the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

When selecting materials for the fender liner of the 2017 Jeep Renegade Latitude 4×4, several options are prevalent in the automotive industry. Each material offers distinct properties and performance characteristics that can significantly affect the durability, cost, and suitability for various applications. Here, we analyze four common materials used for this component: plastic, fiberglass, metal, and rubber.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

How Does Plastic Perform as a Material for Fender Liners?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is widely used for fender liners due to its excellent resistance to corrosion, moisture, and chemicals. These materials can withstand a temperature range of -40°F to 200°F (-40°C to 93°C), making them suitable for various climates.

Pros: Plastic is lightweight, cost-effective, and easy to mold, which simplifies manufacturing processes. It also provides good impact resistance, essential for off-road conditions.

Cons: While durable, plastic can become brittle over time, especially when exposed to UV light. Additionally, it may not offer the same level of structural integrity as metal options.

Impact on Application: Plastic fender liners are compatible with a variety of media, including mud, water, and road salts, making them suitable for diverse driving conditions.

International Considerations: Buyers in regions like Africa and South America should ensure that the plastic used meets local environmental regulations, as some plastics may not be recyclable. Compliance with ASTM standards is also critical for quality assurance.

What Are the Benefits of Using Fiberglass for Fender Liners?

Fiberglass is another viable option for fender liners, known for its high strength-to-weight ratio and excellent resistance to corrosion and chemicals. Fiberglass can withstand high temperatures, typically rated up to 300°F (149°C).

Pros: The material is highly durable and can be molded into complex shapes, allowing for a custom fit. It is also resistant to fading and degradation over time.

Cons: Fiberglass can be more expensive than plastic and may require specialized manufacturing processes, increasing costs. Additionally, it is less impact-resistant compared to other materials.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

Impact on Application: Fiberglass fender liners are suitable for environments where exposure to chemicals and extreme weather conditions is common.

International Considerations: In Europe, compliance with EU regulations regarding fiberglass manufacturing and disposal is essential. Understanding local standards like DIN can help buyers ensure product quality.

Why Choose Metal for Fender Liners?

Metal, particularly aluminum or galvanized steel, is often used for its strength and durability. These materials can handle high pressure and temperature variations, making them ideal for rugged applications.

Pros: Metal fender liners provide superior structural integrity and can withstand significant impacts. They also offer excellent corrosion resistance when treated properly.

Cons: Metal is heavier than plastic or fiberglass, which can affect vehicle performance. Additionally, the manufacturing process can be more complex and costly.

Impact on Application: Metal fender liners are particularly effective in environments where heavy debris or off-road conditions are prevalent.

International Considerations: Buyers in the Middle East should consider the effects of high temperatures and humidity on metal components. Compliance with JIS standards is crucial for ensuring quality and durability.

What Role Does Rubber Play in Fender Liners?

Rubber is sometimes used in conjunction with other materials for its flexibility and excellent impact absorption properties. It is particularly useful in areas where vibration dampening is necessary.

Pros: Rubber is highly resistant to wear and tear, providing a good seal against water and dirt intrusion. It also offers excellent flexibility, which can help in adapting to vehicle movements.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

Cons: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. It may also be less effective in terms of structural support compared to other materials.

Impact on Application: Rubber fender liners are ideal for environments where flexibility and vibration dampening are critical.

International Considerations: Buyers should ensure that the rubber used complies with local regulations regarding chemical composition, particularly in regions with stringent environmental laws.

Summary of Material Selection for Fender Liners

| Material | Typical Use Case for 2017 Jeep Renegade Latitude 4×4 Fender Liner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Standard fender liner for general use | Lightweight and cost-effective | Can become brittle over time | Low |

| Fiberglass | Custom-fit applications in harsh conditions | High durability and corrosion resistance | More expensive, complex to manufacture | Medium |

| Metal | Heavy-duty applications in off-road conditions | Superior structural integrity | Heavier, more complex manufacturing | High |

| Rubber | Areas requiring flexibility and vibration dampening | Excellent wear resistance | Degrades over time | Medium |

This analysis provides B2B buyers with actionable insights into material selection for the 2017 Jeep Renegade Latitude 4×4 fender liner, enabling informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for 2017 jeep renegade latitude 4×4 fender liner

What Are the Key Manufacturing Processes for the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

The manufacturing of the 2017 Jeep Renegade Latitude 4×4 fender liner involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Understanding these processes is essential for B2B buyers seeking reliable suppliers.

How Is Material Prepared for Fender Liners?

The first step in the manufacturing process is material preparation. The fender liner is typically made from high-density polyethylene (HDPE) or similar plastic materials known for their durability and resistance to environmental factors. These materials are selected based on their ability to withstand impacts and harsh weather conditions.

During this stage, raw materials are sourced from certified suppliers who adhere to international standards. The materials undergo rigorous testing to ensure they meet specifications for strength, flexibility, and thermal resistance. This quality assurance right from the beginning helps prevent issues in later stages of production.

What Techniques Are Used in Forming Fender Liners?

Once the materials are prepared, the forming process begins. This stage often involves techniques such as injection molding or thermoforming, which are commonly used in automotive part production.

-

Injection Molding: This method involves melting plastic granules and injecting the molten material into a mold that shapes the fender liner. The advantage of this technique is its ability to produce complex geometries with high precision, allowing for a perfect fit on the vehicle.

-

Thermoforming: This technique involves heating a plastic sheet until it becomes pliable and then draping it over a mold. While less precise than injection molding, thermoforming can be advantageous for larger or less complex parts.

Both methods are designed to ensure that the fender liners are lightweight yet strong enough to provide necessary protection to the vehicle’s components.

How Are Fender Liners Assembled and Finished?

After forming, the assembly process takes place. This may involve attaching additional components, such as fasteners or clips, that secure the fender liner to the vehicle. This stage often incorporates automated systems to enhance efficiency and reduce labor costs.

Finishing touches, such as surface treatments or coatings, may also be applied. These treatments can enhance the part’s resistance to UV rays, abrasions, and chemical exposure, further extending the lifespan of the fender liner.

The final product undergoes visual inspections to ensure there are no defects in the surface or shape, ensuring that it meets the aesthetic and functional standards expected by consumers.

What Quality Assurance Measures Are in Place for Fender Liners?

Quality assurance (QA) is a critical component of the manufacturing process. It ensures that each fender liner produced adheres to industry standards and customer expectations.

Which International Standards Apply to Fender Liner Production?

International standards, such as ISO 9001, play a significant role in the quality assurance framework for fender liner manufacturers. ISO 9001 outlines the requirements for a quality management system (QMS) that organizations must follow to ensure consistent quality in their products and services.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

In addition to ISO standards, industry-specific certifications may also apply, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. For suppliers targeting markets in regions like Africa or the Middle East, compliance with local regulations and standards (such as GSO in the Gulf region) may also be necessary.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): During production, regular checks are performed to monitor the manufacturing process and identify any deviations from quality standards.

-

Final Quality Control (FQC): After production, the finished fender liners undergo thorough inspections, which may include dimensional checks, visual inspections, and functional tests to ensure they meet performance standards.

Common testing methods include tensile strength tests, impact resistance tests, and environmental simulations to assess how the fender liner performs under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must be proactive in verifying the quality control practices of their suppliers to ensure product reliability. Here are several approaches:

What Audit Processes Should Buyers Consider?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers should consider:

-

Supplier Audits: Schedule regular audits of the supplier’s manufacturing facility to review their quality management systems, production processes, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party organizations to conduct independent inspections can provide an unbiased view of a supplier’s quality practices.

How Can Buyers Leverage Quality Reports?

Requesting quality reports from suppliers can also help buyers assess reliability. These reports should detail the results of quality checks performed at each stage of the manufacturing process. Look for documentation of any issues encountered and how they were resolved, as this indicates a supplier’s commitment to continuous improvement.

What Are the QC Considerations for International B2B Buyers?

For international buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, there are additional QC considerations.

-

Cultural and Regulatory Differences: Understanding the local regulations and cultural expectations regarding product quality is crucial. Buyers should familiarize themselves with the specific standards that apply in their region.

-

Logistics and Supply Chain Risks: International buyers must also consider the potential for delays or damage during shipping. Ensuring that suppliers have robust packaging and shipping practices can help mitigate these risks.

By focusing on thorough manufacturing processes and stringent quality assurance practices, B2B buyers can ensure they are sourcing high-quality fender liners for the 2017 Jeep Renegade Latitude 4×4, ultimately leading to better customer satisfaction and reduced warranty claims.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2017 jeep renegade latitude 4×4 fender liner’

In this guide, international B2B buyers will find a comprehensive checklist to effectively source the fender liner for the 2017 Jeep Renegade Latitude 4×4. This practical approach will ensure that you make informed decisions, securing quality parts while navigating the complexities of global procurement.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the specifications required for the fender liner. This includes material type, dimensions, and compatibility with the 2017 Jeep Renegade Latitude 4×4. Understanding these technical details helps in narrowing down suitable suppliers and ensures that the parts meet your operational needs.

Step 2: Research Potential Suppliers

Engage in thorough market research to identify potential suppliers who specialize in automotive parts, particularly for Jeep vehicles. Utilize platforms such as Alibaba, global trade directories, and industry-specific websites. Pay attention to supplier reviews and ratings, which can provide insights into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications, such as ISO 9001 or specific automotive industry certifications. These credentials are critical as they indicate adherence to quality management standards. Request documentation to verify their compliance and assess their commitment to quality assurance.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the fender liners. This step is vital to assess the quality, fit, and finish of the product before placing a bulk order. Evaluate the samples against your specifications and consider factors like durability, weight, and ease of installation.

Step 5: Negotiate Pricing and Terms

After evaluating samples, initiate negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and explore volume discounts. It’s essential to establish favorable terms to enhance your overall procurement strategy and ensure a profitable partnership.

Step 6: Confirm Shipping and Logistics

Discuss shipping options with your supplier to ensure timely delivery. Depending on your location, consider logistics partners that can provide efficient shipping solutions. Pay attention to shipping costs, delivery times, and customs regulations in your country to avoid unexpected delays.

Step 7: Establish a Quality Assurance Process

Before finalizing your order, implement a quality assurance process to monitor the products upon arrival. This includes inspecting the fender liners for any defects or discrepancies from the agreed specifications. Establish a clear protocol for addressing any issues with the supplier to ensure a smooth resolution.

By following these steps, B2B buyers can effectively navigate the sourcing process for the 2017 Jeep Renegade Latitude 4×4 fender liner, ensuring they procure high-quality parts that meet their needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 2017 jeep renegade latitude 4×4 fender liner Sourcing

What Are the Key Cost Components in Sourcing a 2017 Jeep Renegade Latitude 4×4 Fender Liner?

When analyzing the cost structure for the 2017 Jeep Renegade Latitude 4×4 fender liner, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary materials used in fender liner production typically include high-quality plastics or composite materials that offer durability and resistance to environmental factors. Prices for these materials can vary based on market conditions and supplier sourcing.

-

Labor: Labor costs can significantly impact the overall pricing structure. This encompasses wages for skilled workers involved in the manufacturing process, which may vary depending on the region and labor market conditions.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, contributing to a more competitive pricing strategy.

-

Tooling: The initial investment in tooling can be substantial, especially for custom or high-volume production runs. Tooling costs are often amortized over the production volume, affecting the unit price.

-

Quality Control: Ensuring product quality through rigorous QC processes is essential, especially for parts subjected to wear and tear. The costs associated with QC can be factored into the overall pricing.

-

Logistics: Transportation and shipping costs can vary significantly depending on the destination and chosen Incoterms. This is particularly relevant for international buyers who may face additional customs duties and tariffs.

-

Margin: Suppliers typically apply a markup to cover their operational costs and profit, which can be influenced by competition and market demand.

How Do Price Influencers Impact the Sourcing of Fender Liners?

Several factors influence the final price of a fender liner, especially for international B2B buyers.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

-

Volume/MOQ: Minimum Order Quantities (MOQs) can lead to better pricing for larger orders. Suppliers may offer tiered pricing structures, encouraging bulk purchases which can reduce per-unit costs.

-

Specifications/Customization: Custom specifications may increase costs due to additional design and manufacturing complexities. Buyers should evaluate if standard options meet their needs to avoid unnecessary expenses.

-

Materials: The choice of materials can significantly affect pricing. High-performance materials may come at a premium, but they can also offer better longevity and performance, thus influencing the Total Cost of Ownership (TCO).

-

Quality/Certifications: Parts that meet specific quality certifications may command higher prices. However, investing in certified parts can reduce long-term costs associated with replacements and repairs.

-

Supplier Factors: The reputation and reliability of the supplier play a vital role. Established suppliers may offer better support and guarantees, justifying higher prices.

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms can impact overall costs, including who bears the risk and cost of shipping and customs duties.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Fender Liners?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate: Don’t hesitate to negotiate pricing and terms. Suppliers may have flexibility in pricing, especially for larger orders or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also factors like durability, warranty, and maintenance costs. Investing in higher-quality parts can lead to savings in the long run.

-

Understand Pricing Nuances: Be aware of regional pricing differences and how local economic conditions can affect costs. For instance, import tariffs in Brazil or logistical challenges in Saudi Arabia might influence final pricing.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better service, pricing, and priority during high-demand periods.

-

Research Market Trends: Staying informed about market trends and material costs can help you time your purchases effectively and negotiate better deals.

In summary, a comprehensive understanding of the cost components, price influencers, and strategic buying practices can significantly enhance the sourcing process for the 2017 Jeep Renegade Latitude 4×4 fender liner, ensuring that B2B buyers make informed and cost-effective decisions.

Alternatives Analysis: Comparing 2017 jeep renegade latitude 4×4 fender liner With Other Solutions

Exploring Alternatives to the 2017 Jeep Renegade Latitude 4X4 Fender Liner

When considering fender liners for the 2017 Jeep Renegade Latitude 4X4, it’s essential to evaluate various alternatives available in the market. Different products and materials can offer unique benefits and drawbacks, which can influence purchasing decisions for B2B buyers, especially those operating in diverse geographical markets such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | 2017 Jeep Renegade Latitude 4X4 Fender Liner | Alternative 1: Aftermarket Plastic Fender Liner | Alternative 2: Rubber Fender Liner |

|---|---|---|---|

| Performance | High durability and fit tailored to vehicle | Good fit, may vary by manufacturer | Excellent flexibility and resistance |

| Cost | $184.99 – OEM quality | $50 – $150, depending on brand | $70 – $120, more economical option |

| Ease of Implementation | Moderate, requires basic tools | Easy, often comes with installation instructions | Moderate, may need specific tools |

| Maintenance | Low, typically long-lasting | Varies, some may need periodic checks | Low, resistant to wear and tear |

| Best Use Case | Ideal for OEM replacement in urban settings | Suitable for budget-conscious consumers | Best for off-road and rugged terrains |

Detailed Breakdown of Alternatives

Alternative 1: Aftermarket Plastic Fender Liner

Aftermarket plastic fender liners are widely available and can be a cost-effective solution for those looking to replace the original fender liner. These liners often mimic the fit and design of OEM parts but may vary in quality depending on the manufacturer. The primary advantage is their lower price point, making them attractive for budget-conscious buyers. However, the variability in manufacturing quality can lead to inconsistent performance and durability.

Alternative 2: Rubber Fender Liner

Rubber fender liners provide excellent flexibility and durability, making them a preferred choice for users who frequently drive in challenging environments. These liners are resistant to wear and provide good protection against debris and moisture. While they tend to be slightly more expensive than some aftermarket options, their longevity and performance in off-road conditions make them a worthwhile investment. However, they may require more precise installation and specific tools, which could complicate the implementation for some buyers.

Conclusion: How to Choose the Right Fender Liner Solution

In selecting the right fender liner for the 2017 Jeep Renegade Latitude 4X4, B2B buyers should consider factors such as budget, intended use, and ease of installation. While the OEM fender liner offers a guarantee of fit and durability, aftermarket options can provide significant savings and flexibility. For those operating in rugged conditions, a rubber fender liner may deliver the best performance. Ultimately, assessing the specific needs of the vehicle and the driving conditions will guide buyers in making the most suitable choice for their operations.

Essential Technical Properties and Trade Terminology for 2017 jeep renegade latitude 4×4 fender liner

What Are the Key Technical Properties of the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

Understanding the technical specifications of the 2017 Jeep Renegade Latitude 4×4 fender liner is crucial for B2B buyers. Here are some essential properties to consider:

-

Material Composition

The fender liner is typically made from high-density polyethylene (HDPE) or similar plastic compounds. This material is chosen for its durability, resistance to impact, and ability to withstand various weather conditions. For B2B buyers, selecting a fender liner made from quality materials can prevent premature wear and reduce the need for frequent replacements, ultimately lowering operational costs. -

OEM vs. Aftermarket Parts

Original Equipment Manufacturer (OEM) parts are made by the vehicle’s manufacturer and are designed to fit perfectly. Aftermarket parts, on the other hand, are produced by third-party manufacturers and can vary in quality. For businesses, sourcing OEM fender liners ensures compatibility and reliability, which is essential for maintaining vehicle performance and warranty compliance. -

Fitment Specifications

Fitment refers to how well the fender liner aligns with the vehicle’s body. For the 2017 Jeep Renegade, the fender liner must accommodate specific dimensions and mounting points. Accurate fitment is critical to avoid installation issues that could lead to water ingress or damage to the vehicle’s electrical systems. B2B buyers should prioritize suppliers who provide detailed fitment information. -

Weight and Dimensions

The weight and dimensions of the fender liner affect shipping costs and installation ease. A lighter liner may reduce fuel consumption during transport, while precise dimensions ensure a straightforward installation process. Understanding these metrics helps businesses calculate total costs and plan logistics effectively. -

Corrosion Resistance

Many fender liners are treated to resist corrosion, especially in regions where vehicles are exposed to road salt or high humidity. For B2B buyers, investing in corrosion-resistant parts can enhance the longevity of the vehicle and reduce maintenance expenses. -

Warranty and Certifications

A warranty provides assurance regarding the product’s quality and durability. Certifications, such as ISO standards, can indicate that the manufacturing processes meet specific quality benchmarks. Buyers should consider these factors as they reflect the manufacturer’s commitment to quality, which can mitigate risks associated with product failures.

What Are Common Trade Terms Related to the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

Familiarity with industry jargon is vital for effective communication and decision-making. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the vehicle’s manufacturer. OEM parts are designed to fit and function perfectly, ensuring compatibility and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for businesses looking to stock parts for resale or fleet maintenance. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers often use RFQs to compare offers from different suppliers, ensuring they receive the best value. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including shipping costs and risk management. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead times is crucial for supply chain management and ensuring that vehicles are maintained or repaired in a timely manner. -

Aftermarket

This term refers to parts and accessories made by manufacturers other than the OEM. While often less expensive, the quality can vary, making it important for buyers to assess the reputation of aftermarket suppliers.

In summary, grasping the technical properties and terminology related to the 2017 Jeep Renegade Latitude 4×4 fender liner is essential for B2B buyers. This knowledge aids in making informed purchasing decisions that can enhance operational efficiency and vehicle longevity.

Navigating Market Dynamics and Sourcing Trends in the 2017 jeep renegade latitude 4×4 fender liner Sector

What Are the Current Market Dynamics and Key Trends for the 2017 Jeep Renegade Latitude 4×4 Fender Liner?

The market for automotive parts, specifically fender liners for the 2017 Jeep Renegade Latitude 4×4, is experiencing notable growth driven by several global factors. The increasing popularity of off-road vehicles in regions such as Africa, South America, the Middle East, and Europe is a significant driver, as consumers seek durable and reliable accessories to enhance their vehicles’ performance and aesthetic appeal. International buyers are increasingly looking for high-quality, OEM (Original Equipment Manufacturer) parts that ensure compatibility and reliability.

Emerging B2B tech trends, such as the integration of e-commerce platforms and advanced supply chain management software, are reshaping the sourcing landscape. Buyers can now access a wider variety of suppliers and products online, facilitating price comparisons and enabling informed purchasing decisions. Additionally, the rise of data analytics allows businesses to forecast demand more accurately, leading to more effective inventory management and reduced overhead costs.

Market dynamics are also influenced by the need for customization and personalization. Buyers are keen on sourcing fender liners that not only fit their vehicles but also align with their brand image or personal preferences. This trend is particularly pronounced in regions where vehicle modifications are popular. As a result, suppliers that offer a diverse range of products, including aftermarket options, are likely to gain a competitive edge.

Illustrative image related to 2017 jeep renegade latitude 4×4 fender liner

How Are Sustainability and Ethical Sourcing Addressing Environmental Concerns in the Automotive Parts Industry?

Sustainability is becoming a critical consideration for B2B buyers in the automotive parts sector. The environmental impact of sourcing materials for products like the fender liner is under scrutiny, with many companies now prioritizing eco-friendly options. Buyers are increasingly seeking suppliers that adhere to sustainable practices, such as using recycled materials or manufacturing processes that minimize waste and carbon emissions.

Ethical sourcing is equally important, especially for international buyers who are concerned about labor practices in their supply chains. Ensuring that suppliers comply with ethical labor standards not only enhances brand reputation but also fosters long-term partnerships based on trust and mutual respect. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential for buyers looking to make responsible sourcing decisions.

In the context of the 2017 Jeep Renegade Latitude 4×4 fender liner, suppliers that can demonstrate their commitment to sustainability and ethical practices will likely attract more business from conscientious buyers. This shift towards ‘green’ certifications and materials is not just a trend but a fundamental change in the way companies operate and engage with their supply chains.

What Is the Brief History and Evolution of Fender Liners in the Automotive Industry?

Fender liners have evolved significantly since their introduction in the automotive industry. Initially designed primarily for aesthetic purposes, they have transformed into essential components that protect various vehicle parts from debris, moisture, and corrosion. The 2017 Jeep Renegade Latitude 4×4 fender liner exemplifies this evolution, incorporating advanced materials and designs that enhance both functionality and durability.

The development of high-quality, impact-resistant plastics has allowed manufacturers to produce fender liners that withstand harsh conditions, particularly in off-road environments. This evolution reflects broader trends in the automotive industry, where the focus on performance and longevity is paramount. As vehicles become more sophisticated, the demand for reliable and innovative parts like fender liners continues to grow, shaping the future of automotive accessories and aftermarket products.

In summary, the market for the 2017 Jeep Renegade Latitude 4×4 fender liner is shaped by evolving buyer preferences, sustainability concerns, and technological advancements, making it essential for suppliers to adapt to these trends to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of 2017 jeep renegade latitude 4×4 fender liner

-

How do I ensure the quality of the 2017 Jeep Renegade Latitude 4×4 fender liner when sourcing from international suppliers?

To ensure quality, request samples or detailed product specifications from potential suppliers. Verify that the fender liners comply with OEM standards and industry regulations. Additionally, consider suppliers with ISO certifications or positive reviews from previous clients. Establishing a quality assurance process, including third-party inspections before shipment, can further mitigate risks associated with international sourcing. -

What is the best material for a durable 2017 Jeep Renegade Latitude 4×4 fender liner?

The best material for a fender liner is typically high-density polyethylene (HDPE) or polypropylene, which offer excellent resistance to impacts, chemicals, and moisture. These materials ensure longevity and protect the vehicle from road debris and corrosion. When sourcing, inquire about the specific material used and any additional protective coatings that enhance durability. -

What customization options are available for fender liners for the 2017 Jeep Renegade Latitude 4×4?

Customization options can include various colors, finishes, and additional features like sound insulation or increased thickness for better protection. Some manufacturers might offer branding opportunities, such as logos or unique designs. When discussing with suppliers, clearly outline your customization requirements and request samples to evaluate the final product. -

What are the typical minimum order quantities (MOQ) for fender liners?

Minimum order quantities can vary significantly between suppliers, typically ranging from 50 to 500 units, depending on the manufacturer’s capacity and your specific needs. It’s crucial to communicate your volume requirements early in negotiations to find a supplier willing to accommodate your needs. Some suppliers may offer lower MOQs for first orders to establish a business relationship. -

How can I vet suppliers for fender liners in international markets?

Vetting suppliers involves a multi-step process: research their business history, check customer reviews, and confirm their certifications. Request references from previous clients and assess their production capabilities through site visits or virtual tours. Utilizing platforms like Alibaba or Global Sources can also provide insights into supplier credibility through ratings and feedback from other buyers. -

What payment terms should I negotiate when sourcing fender liners?

Common payment terms in international trade include a deposit upfront (usually 30%) with the remaining balance due upon shipment or delivery. Consider using secure payment methods like letters of credit or escrow services to protect your investment. Clearly outline payment schedules in your contracts to avoid misunderstandings and ensure a smooth transaction process. -

What logistics considerations should I keep in mind when importing fender liners?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with automotive parts to streamline the process. Ensure that all documentation, such as invoices and packing lists, is accurate to avoid delays at customs. Additionally, factor in potential tariffs or duties that may apply when importing into your specific region. -

How do I handle quality assurance for fender liners sourced internationally?

Implement a quality assurance plan that includes pre-production samples, in-process inspections, and final quality checks before shipment. Establish clear quality standards and communicate them to your supplier to ensure alignment. Consider hiring third-party inspection services that specialize in automotive parts to verify that the fender liners meet your specifications and compliance requirements before they leave the factory.

Top 6 2017 Jeep Renegade Latitude 4X4 Fender Liner Manufacturers & Suppliers List

1. ExtremeTerrain – Jeep Renegade Left Front Fender Liner

Domain: extremeterrain.com

Registered: 2000 (25 years)

Introduction: Jeep Renegade Front Fender Liner; Driver Side (15-18 Jeep Renegade BU, Excluding Trailhawk) – Price: $184.99 – Free Shipping on Orders $149+ – Fits 2015-2018 Jeep Renegade models excluding Trailhawk – Left Front Fender Liner – CA Residents: WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov – 4.7 out of 5 reviews for similar exterior products.

2. Crown Automotive – Jeep Renegade Fender Liners

Domain: throtl.com

Registered: 2009 (16 years)

Introduction: 2017 Jeep Renegade Fender Liners – Crown Automotive Jeep Replacement Left Front Fender Liner for 15-18 BU Renegade w/o Trailhawk Package – 68254966AB; Crown Automotive Jeep Replacement Left Front Fender Liner for 15-18 BU Renegade w/ Trailhawk Package – 68254969AA; Crown Automotive Jeep Replacement Right Front Fender Liner for 15-18 BU Renegade w/o Trailhawk Package – 68254968AA; Crown Automotive …

3. CarParts – Fast Delivery

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: This company, CarParts – Fast Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Jeep – Renegade Fender Liner Left

Domain: paintedautobodyparts.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Jeep Renegade Fender Liner Left (Driver Side)”, “Exclusions”: “EXC TRAILHAWK”, “Material”: “PE/Vacuum Foam”, “OEM Part Number”: “68254966AA-PFM”, “PartsLink Number”: “CH1248183”, “Compatible Years”: [2015, 2016, 2017, 2018], “List Price”: “$270.20”, “Our Price”: “$31.45”, “Your Save”: “$238.75”, “SKU”: “BG005188”, “Availability”: “In stock”}

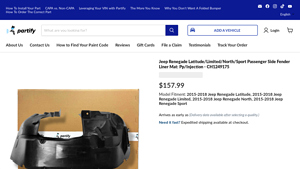

5. Partify USA – Jeep Renegade Fender Liner Mat

Domain: partifyusa.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Jeep Renegade Latitude/Limited/North/Sport Passenger Side Fender Liner Mat”, “part_number”: “CH1249175”, “model_years”: “2015-2018”, “compatible_models”: [“Jeep Renegade Latitude”, “Jeep Renegade Limited”, “Jeep Renegade North”, “Jeep Renegade Sport”], “material”: “PP/Injection”, “price”: “$157.99”, “quality_options”: [{“type”: “Aftermarket”, “price”: “$157.99”, “description”: “B…

6. Jeep – 2017 Renegade Rear Passenger Inner Fender Liner

Domain: ahparts.com

Registered: 2007 (18 years)

Introduction: {“item_name”:”2017 Jeep Renegade Rear Passenger Inner Fender Liner”,”part_number”:”68431659AA”,”condition”:”Used”,”price”:”$25.00″,”warranty”:”1 year warranty”,”availability”:”Recently Sold”,”donor_vehicle”:”2017 Jeep Renegade”,”compatibility”:”Fits 2017 Jeep Renegade Latitude, Limited, Sport, Trailhawk; 2016 Jeep Renegade 75th Anniversary, Dawn Of Justice, Latitude, Limited, Sport, Trailhawk; 201…

Strategic Sourcing Conclusion and Outlook for 2017 jeep renegade latitude 4×4 fender liner

In the evolving landscape of automotive parts, particularly for the 2017 Jeep Renegade Latitude 4×4 fender liner, strategic sourcing remains pivotal for B2B buyers. By focusing on high-quality components, businesses can enhance vehicle performance while ensuring customer satisfaction. The availability of OEM and aftermarket options provides flexibility, enabling buyers to select parts that align with their cost and quality requirements.

As global markets continue to grow, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable automotive parts will only increase. Buyers should prioritize suppliers who demonstrate robust quality assurance and competitive pricing. Engaging in long-term partnerships with trusted manufacturers can significantly streamline procurement processes and reduce lead times.

Looking ahead, now is the opportune moment for international buyers to leverage the growing market dynamics and secure their supply chains. With the right strategies in place, you can ensure a steady flow of quality fender liners that meet both regulatory standards and customer expectations. Take the next step in your sourcing journey today by exploring partnerships that align with your business goals and enhance your competitive edge in the automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.