A Deep Dive into 3 Phase Transformer Wiring Schematic Solution

Introduction: Navigating the Global Market for 3 phase transformer wiring schematic

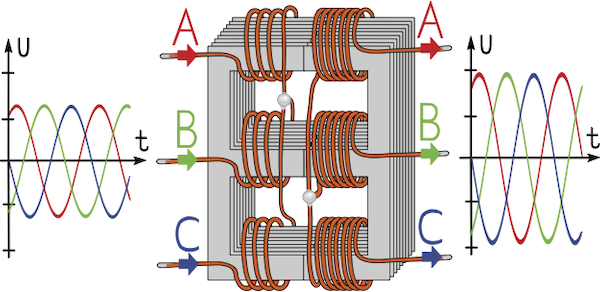

In the dynamic landscape of global energy solutions, sourcing a reliable 3-phase transformer wiring schematic presents a significant challenge for international B2B buyers. The complexity of transformer connections, including Delta and Wye configurations, demands a nuanced understanding to ensure optimal performance and reliability in diverse applications. This comprehensive guide delves into various types of 3-phase transformers, their specific applications across industries, and essential considerations for supplier vetting.

As businesses in Africa, South America, the Middle East, and Europe—particularly in regions like Saudi Arabia and Nigeria—navigate the intricacies of electrical infrastructure, understanding the technical specifications and operational requirements of these transformers becomes critical. This guide empowers buyers to make informed purchasing decisions by providing insights into cost factors, quality standards, and the importance of sourcing from reputable suppliers.

With a focus on practical applications and technical clarity, this resource serves as an essential tool for organizations aiming to enhance their electrical systems while ensuring compliance with regional standards. By leveraging the knowledge contained within this guide, B2B buyers can confidently approach the complexities of 3-phase transformer wiring, ultimately driving efficiency and reliability in their operations.

Understanding 3 phase transformer wiring schematic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Delta-Delta | Closed loop connection; good for balanced loads | Industrial motors, low voltage power applications | Pros: Simple design, robust; Cons: Vulnerable to unbalanced loads. |

| Wye-Wye | Neutral point connection; good for single-phase loads | Commercial buildings, data centers | Pros: Balanced load distribution; Cons: Prone to harmonic issues. |

| Delta-Wye | Phase shift introduced; stable neutral point | Transformer substations, large industrial setups | Pros: Versatile for mixed loads; Cons: Phase shift complicates integration. |

| Wye-Delta | Inverts phase; suitable for high voltage to low voltage | Power distribution networks | Pros: Good for grounding; Cons: Can lead to voltage imbalances. |

| Open Delta | Uses only two transformers; reduced capacity | Temporary power solutions, backup systems | Pros: Cost-effective; Cons: Limited capacity, less efficient. |

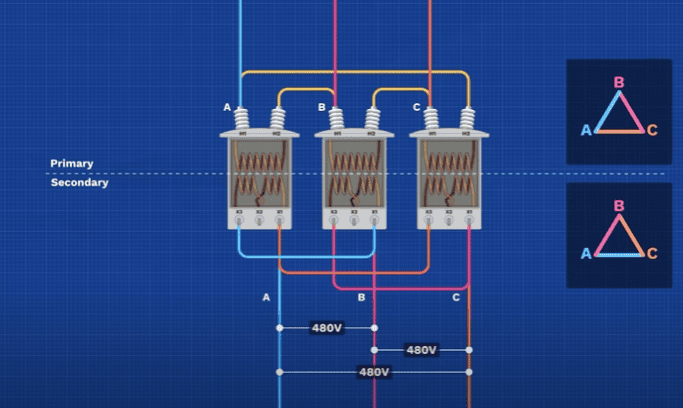

What Are the Characteristics of Delta-Delta Transformers?

Delta-Delta transformers feature a closed-loop connection, ideal for applications requiring balanced three-phase loads, such as industrial motors. They are known for their robustness and simplicity. However, they can struggle with unbalanced loads, which may lead to increased circulating currents and potential overheating. B2B buyers should consider the load characteristics and potential for imbalance when selecting this configuration.

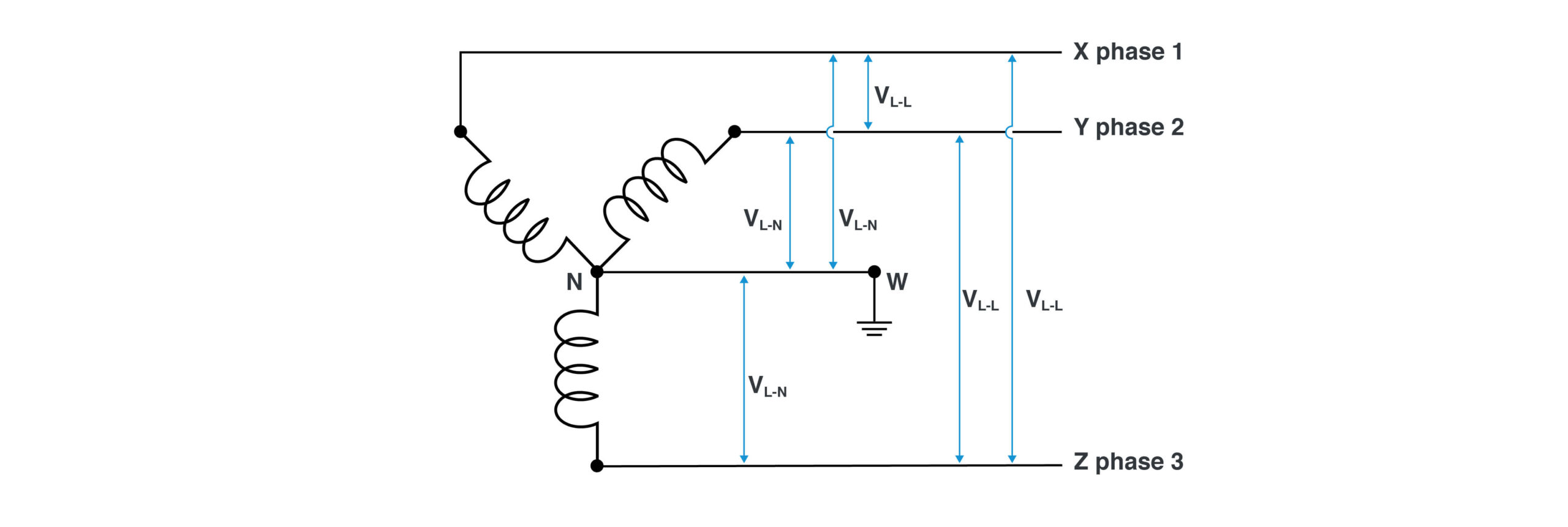

How Do Wye-Wye Transformers Function?

Wye-Wye transformers connect each winding to a neutral point, making them suitable for both three-phase and single-phase loads. This configuration is commonly used in commercial buildings and data centers where balanced load distribution is essential. While they effectively manage harmonics, they can introduce power quality issues if not properly specified. Buyers should evaluate the potential for harmonic interference in their specific applications.

What Makes Delta-Wye Transformers Popular?

Delta-Wye transformers are among the most commonly utilized configurations, providing a stable neutral point and accommodating both three-phase and single-phase loads. This versatility is particularly beneficial in transformer substations and large industrial setups. However, the introduction of a 30° phase shift complicates integration with other transformer types. Buyers should assess their network’s compatibility and grounding requirements when considering this option.

Why Choose Wye-Delta Transformers?

Wye-Delta transformers invert the phase, making them suitable for stepping down high voltage to low voltage in power distribution networks. They are advantageous for grounding and can help mitigate voltage imbalances. However, the phase inversion can lead to complications in load balancing, which buyers must consider when selecting this type. Proper analysis of load characteristics is critical for effective deployment.

What Are the Benefits and Drawbacks of Open Delta Transformers?

Open Delta transformers utilize only two of three transformers, making them a cost-effective solution for temporary power needs or backup systems. While they provide flexibility and lower costs, their capacity is limited, and efficiency can be reduced compared to full delta configurations. Businesses should weigh the need for temporary solutions against the potential drawbacks of reduced capacity and efficiency.

Key Industrial Applications of 3 phase transformer wiring schematic

| Industry/Sector | Specific Application of 3 phase transformer wiring schematic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for heavy machinery and production lines | Ensures reliable power for continuous operations, reducing downtime and maintenance costs. | Voltage ratings, transformer type (Delta or Wye), and compliance with local standards. |

| Renewable Energy | Integration of solar and wind energy systems | Facilitates efficient energy conversion and distribution, optimizing renewable energy utilization. | Compatibility with grid systems, phase shifting capabilities, and environmental durability. |

| Mining | Power distribution in remote mining operations | Provides stable and robust power supply to heavy-duty equipment, enhancing productivity. | Robustness for harsh environments, local service support, and adaptability to varying loads. |

| Construction | Temporary power solutions for construction sites | Offers flexibility and reliability in powering tools and equipment, essential for project timelines. | Portability, ease of installation, and compliance with safety regulations. |

| Utilities | Substation and grid connectivity | Enhances grid reliability and capacity, crucial for urban and industrial growth. | Transformer ratings, phase configurations, and integration with existing infrastructure. |

How is 3 Phase Transformer Wiring Schematic Used in Manufacturing?

In manufacturing settings, 3 phase transformer wiring schematics are vital for supplying power to heavy machinery and production lines. These transformers ensure a stable and continuous power supply, which is essential for maintaining production efficiency and minimizing downtime. Businesses must consider the voltage ratings and the type of transformer, such as Delta or Wye configurations, as well as compliance with local electrical standards to ensure optimal performance and safety.

What Role Does 3 Phase Transformer Wiring Play in Renewable Energy?

In renewable energy sectors, particularly solar and wind, 3 phase transformer wiring schematics are utilized to integrate energy systems into the existing power grid. This application is crucial for converting and distributing the generated energy efficiently, enabling businesses to maximize their renewable energy utilization. When sourcing transformers for these applications, compatibility with grid systems and the ability to handle phase shifting are critical, along with environmental durability to withstand outdoor conditions.

How is 3 Phase Transformer Wiring Important in Mining Operations?

Mining operations often take place in remote locations where reliable power is crucial for running heavy-duty equipment. 3 phase transformer wiring schematics provide a robust power distribution solution that enhances productivity and operational efficiency. Buyers in this sector should prioritize transformers that are rugged and designed for harsh environments, with local service support available to address any maintenance needs promptly.

Why Use 3 Phase Transformer Wiring for Construction Sites?

Temporary power solutions in construction sites benefit significantly from 3 phase transformer wiring schematics. They provide the necessary power to tools and equipment, ensuring that projects stay on schedule. Flexibility and reliability are key, so businesses should look for portable transformer solutions that are easy to install and comply with safety regulations to protect workers and equipment.

How Do Utilities Benefit from 3 Phase Transformer Wiring Schematics?

Utilities utilize 3 phase transformer wiring schematics for substation and grid connectivity, enhancing the reliability and capacity of power distribution systems. This is particularly important for urban and industrial areas experiencing growth. When sourcing transformers for utility applications, it is essential to consider transformer ratings, phase configurations, and how well they can integrate with existing infrastructure to ensure seamless operation and service continuity.

3 Common User Pain Points for ‘3 phase transformer wiring schematic’ & Their Solutions

Scenario 1: Misunderstanding Transformer Configurations and Their Implications

The Problem: Many B2B buyers struggle with understanding the various transformer configurations—Delta and Wye—and how they impact system performance and load distribution. This can lead to incorrect specifications, resulting in inefficient energy use, increased operational costs, and potential equipment damage. For instance, a buyer may choose a Delta-Wye configuration without fully understanding its 30° phase shift, resulting in compatibility issues with existing equipment or unexpected harmonics that can disrupt sensitive operations.

The Solution: To overcome this challenge, buyers should invest time in training and educational resources about transformer configurations and their operational implications. When sourcing transformers, request detailed specifications that include diagrams of the proposed connections. Collaborate with engineers or consultants who specialize in electrical systems to conduct a thorough analysis of the load requirements and existing infrastructure. Additionally, consider a phased approach to implementation, where smaller pilot projects are executed to evaluate the performance of the chosen configuration before full-scale deployment. This way, potential issues can be identified and rectified early on, ensuring that the selected transformer configuration aligns with operational needs and avoids costly mistakes.

Scenario 2: Difficulty in Sourcing Quality Components for Wiring Schematics

The Problem: Sourcing high-quality components for 3-phase transformer wiring can be a significant pain point, particularly for businesses operating in regions with limited supplier options. Buyers often encounter challenges such as inconsistent quality, delayed shipments, and lack of technical support for installation. This can lead to project delays, increased costs, and potential safety hazards due to subpar components that do not meet industry standards.

The Solution: To mitigate these sourcing challenges, B2B buyers should develop strong relationships with multiple reputable suppliers that specialize in electrical components, particularly those with a proven track record in international markets. It is crucial to conduct thorough supplier evaluations, including on-site visits if feasible, to assess their manufacturing processes and quality control measures. Buyers should also request certifications and compliance documentation for all components to ensure they meet relevant industry standards. Furthermore, consider leveraging technology by using online platforms that aggregate supplier ratings and reviews, allowing buyers to make informed decisions quickly. Establishing contingency plans, such as identifying alternative suppliers and maintaining a stock of critical components, can also help prevent project disruptions.

Scenario 3: Navigating Regulatory Compliance and Standards

The Problem: Navigating the myriad of regulatory compliance requirements for electrical installations, including those related to 3-phase transformer wiring schematics, can be daunting for B2B buyers. This is especially true in regions like Africa and the Middle East, where regulations can vary widely and are often subject to change. Non-compliance can lead to hefty fines, project delays, and reputational damage, making it a pressing concern for companies operating in these markets.

The Solution: To address regulatory compliance issues, B2B buyers should prioritize staying informed about local and international standards relevant to their industry. Engaging with local electrical engineering associations or regulatory bodies can provide insights into current regulations and upcoming changes. Additionally, buyers should consult with legal experts who specialize in compliance to ensure all aspects of their transformer wiring schematics adhere to applicable laws. Establishing a compliance checklist that includes all necessary permits, inspections, and certifications can streamline the process. Incorporating compliance as a core aspect of project planning and execution will not only minimize risks but also enhance the credibility and reliability of the business in the eyes of clients and stakeholders.

Strategic Material Selection Guide for 3 phase transformer wiring schematic

What Are the Key Materials for 3-Phase Transformer Wiring Schematics?

When selecting materials for 3-phase transformer wiring schematics, several factors must be considered, including electrical conductivity, thermal stability, and mechanical strength. The following analysis focuses on four common materials used in this context: copper, aluminum, steel, and insulated conductors.

How Does Copper Perform in 3-Phase Transformer Wiring?

Copper is the most widely used material for electrical wiring in transformers due to its excellent conductivity and thermal properties. It has a high melting point (approximately 1,984°F or 1,085°C) and can withstand considerable thermal stress. Copper also exhibits good resistance to corrosion, which is essential in humid or chemically aggressive environments.

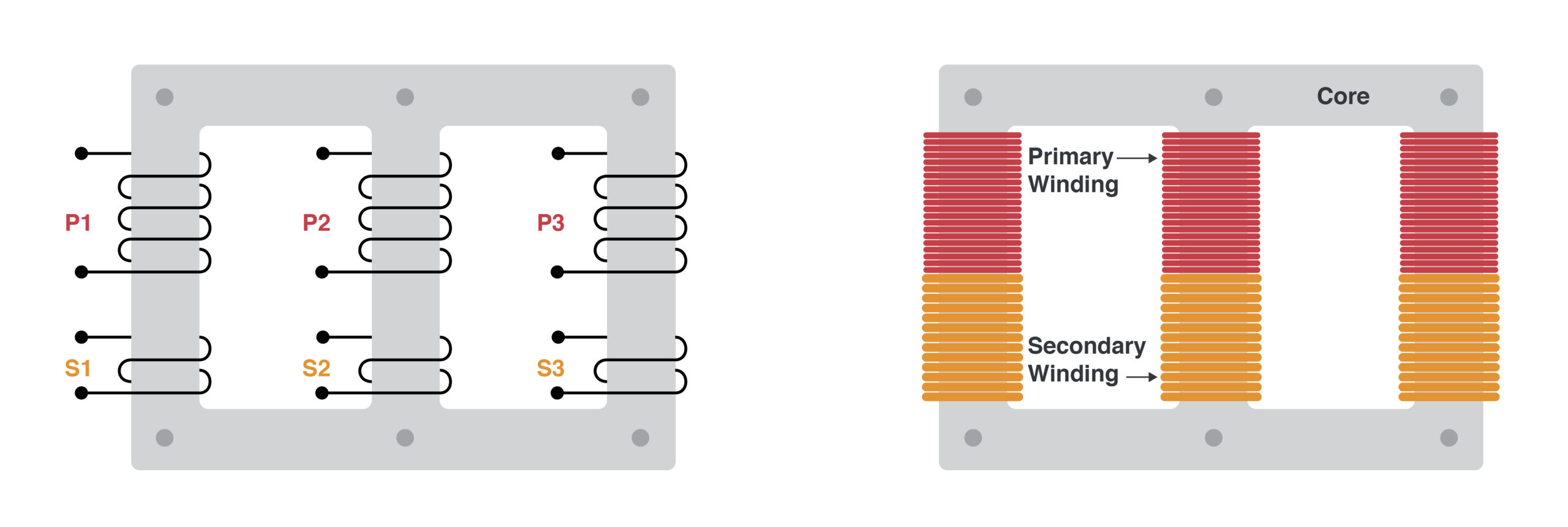

Illustrative image related to 3 phase transformer wiring schematic

Pros: Copper’s high conductivity allows for efficient energy transfer, reducing energy losses. It is also durable and can handle high temperatures, making it suitable for demanding applications.

Cons: The primary drawback of copper is its cost, which is significantly higher than aluminum. Additionally, copper is heavier, which can complicate installation and increase shipping costs.

Impact on Application: Copper’s excellent conductivity makes it ideal for high-performance transformers, particularly in regions with stringent energy efficiency regulations.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B3 for copper conductors. In regions like Africa and South America, where cost is a significant factor, the higher price of copper may be a deterrent.

What Role Does Aluminum Play in Transformer Wiring?

Aluminum is often considered a cost-effective alternative to copper. While it has lower electrical conductivity (about 61% that of copper), its lightweight nature and lower cost make it an attractive option for many applications. Aluminum also has a decent resistance to corrosion, especially when treated.

Pros: The primary advantage of aluminum is its lower cost and lighter weight, making it easier to handle and install. It is also suitable for large-scale applications where weight is a critical factor.

Illustrative image related to 3 phase transformer wiring schematic

Cons: The lower conductivity means that larger cross-sectional areas are required to achieve the same electrical performance as copper. This can lead to increased material costs and complexity in manufacturing.

Impact on Application: Aluminum is suitable for medium-voltage applications and can be effectively used in regions with less stringent performance requirements.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B800 for aluminum conductors. In regions like the Middle East, where high temperatures are common, aluminum’s thermal performance must be evaluated carefully.

How Does Steel Contribute to Transformer Wiring Schematics?

Steel is primarily used in the structural components of transformers, such as casings and support structures. It offers excellent mechanical strength and durability, making it suitable for heavy-duty applications.

Pros: Steel’s strength makes it ideal for supporting heavy transformer components. It also has good resistance to mechanical wear and can be treated to improve corrosion resistance.

Cons: Steel is not an electrical conductor, so it cannot be used for the wiring itself. Additionally, its weight can complicate transportation and installation.

Impact on Application: Steel is essential for ensuring the mechanical integrity of transformers, particularly in industrial settings where environmental conditions can be harsh.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in Europe and Africa should also consider local regulations regarding material sourcing and environmental impact.

What Are Insulated Conductors and Their Benefits?

Insulated conductors are essential for ensuring safety and preventing short circuits in transformer wiring. Common insulation materials include PVC, XLPE, and rubber, each offering different thermal and electrical properties.

Pros: Insulated conductors provide excellent safety by preventing electrical leakage. They can also withstand high temperatures and are resistant to moisture and chemicals.

Cons: The cost of insulated conductors can be higher than that of bare conductors, and the manufacturing process can be more complex.

Impact on Application: Insulated conductors are crucial in environments where exposure to moisture or chemicals is a concern, making them ideal for various geographical regions.

Considerations for International Buyers: Buyers should ensure compliance with international insulation standards, such as IEC 60228. In regions like Saudi Arabia, where extreme temperatures are common, selecting the right insulation material is critical.

Summary Table of Material Selection for 3-Phase Transformer Wiring Schematics

| Material | Typical Use Case for 3 phase transformer wiring schematic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance transformers | Excellent conductivity and thermal stability | High cost and weight | High |

| Aluminum | Medium-voltage transformers | Cost-effective and lightweight | Lower conductivity requiring larger sizes | Medium |

| Steel | Structural components of transformers | Mechanical strength and durability | Non-conductive and heavy | Medium |

| Insulated Conductors | Safety in transformer wiring | Prevents electrical leakage and moisture damage | Higher cost and manufacturing complexity | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 phase transformer wiring schematic

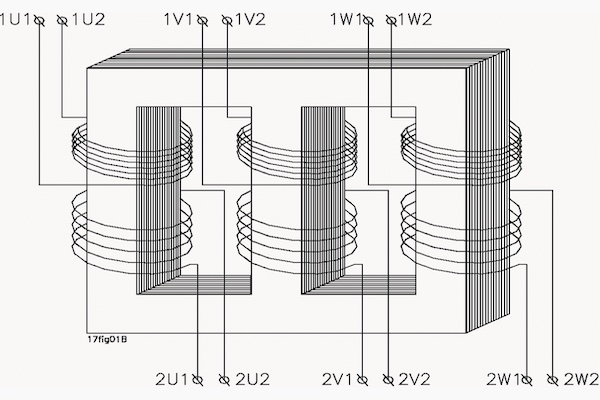

What Are the Main Stages in the Manufacturing Process of 3 Phase Transformers?

The manufacturing of three-phase transformers involves several critical stages, each designed to ensure that the final product meets stringent operational and safety standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step involves sourcing high-quality raw materials, such as silicon steel for the core and copper or aluminum for the windings. Suppliers should provide material certifications to ensure compliance with international standards. Material preparation also includes cutting and shaping the core and winding wire to specified dimensions, which is crucial for achieving optimal efficiency and performance in the transformer. -

Forming

During the forming stage, the prepared materials are shaped into their final form. This includes the lamination of the core to minimize energy losses and the winding of the copper or aluminum wire around the core. Advanced techniques like automatic winding machines can enhance precision and consistency, significantly reducing the risk of human error. -

Assembly

The assembly process integrates all components, including the core, windings, insulation materials, and enclosures. Proper alignment and securing of windings are critical to maintain the integrity of the transformer. Additionally, the assembly should follow specific wiring schematics, such as Delta or Wye configurations, to ensure correct electrical functionality. -

Finishing

The finishing stage involves applying protective coatings to prevent corrosion and enhance durability. This may include varnishing the windings and painting the exterior. Quality checks during this phase are vital, as they help ensure that the transformers can withstand various environmental conditions, particularly in regions with extreme climates, such as Africa and the Middle East.

How Does Quality Assurance Fit into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process of three-phase transformers, ensuring that products meet or exceed industry standards and customer expectations. A robust QA program encompasses various international and industry-specific standards, checkpoints, and testing methods.

Illustrative image related to 3 phase transformer wiring schematic

-

What International Standards Should Buyers Be Aware Of?

Buyers should look for compliance with international standards such as ISO 9001, which establishes criteria for a quality management system. Other relevant certifications include CE marking for European markets and API standards for transformers used in oil and gas applications. These certifications indicate that the manufacturer adheres to quality management practices and regulatory requirements. -

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process. These include:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to identify defects early.

– Final Quality Control (FQC): Comprehensive testing and inspection of the finished product to confirm it meets performance and safety standards. -

What Common Testing Methods Are Used?

Common testing methods for three-phase transformers include:

– Electrical testing: This includes measuring insulation resistance, power factor testing, and short circuit testing to ensure operational safety.

– Thermal testing: Evaluating the transformer’s heat dissipation capabilities under load conditions.

– Load testing: Assessing the performance of the transformer under actual operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

-

Conducting Audits

Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards. Buyers should assess the effectiveness of the supplier’s quality management system and their compliance with ISO and other relevant standards. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports that document testing results and compliance with international standards. These reports should include information on testing methods, results, and any corrective actions taken in case of non-conformance. -

Engaging Third-party Inspectors

Utilizing third-party inspection services can add an additional layer of assurance. Independent inspectors can evaluate the manufacturing process and product quality, providing unbiased assessments that can help buyers make informed decisions.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control and certification:

-

Understanding Regional Standards

Different regions may have specific regulatory requirements and standards. For instance, CE marking is essential for products sold in Europe, while other regions may require compliance with local electrical safety standards. -

Cultural Considerations

Cultural differences may affect communication and expectations regarding quality and delivery timelines. Establishing clear communication channels and understanding the local business practices can facilitate smoother transactions. -

Supply Chain Transparency

International buyers should prioritize suppliers who demonstrate transparency in their supply chain. This includes clear documentation of sourcing, manufacturing processes, and quality checks, which can help mitigate risks associated with international procurement.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make more informed decisions when selecting suppliers for three-phase transformers, ensuring they receive high-quality products that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 phase transformer wiring schematic’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure a 3-phase transformer wiring schematic. Understanding the essential steps in sourcing these critical components can streamline your procurement process, ensuring that you select the right specifications and suppliers to meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your 3-phase transformer. This includes voltage ratings, current capacity, and specific connection types (Delta, Wye, or a combination). Defining these specifications upfront is crucial as they dictate the transformer’s performance and compatibility with your existing systems.

- Voltage and Current Ratings: Ensure they match your operational demands.

- Connection Type: Choose between Delta, Wye, or other configurations based on your load requirements.

Step 2: Research Compliance Standards

Investigate the compliance and regulatory standards applicable in your region or industry. Compliance ensures safety, efficiency, and reliability, which are critical for operational continuity.

- Local Regulations: Look for local safety and environmental regulations that may apply.

- International Standards: Ensure adherence to international standards such as IEC or ANSI for quality assurance.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. A reliable supplier can significantly impact the quality and performance of your transformer.

- Supplier Experience: Look for suppliers with a proven track record in transformer manufacturing.

- Customer Feedback: Seek testimonials or reviews from previous clients to gauge reliability.

Step 4: Request Detailed Quotations

After identifying potential suppliers, request detailed quotations that include pricing, lead times, and warranty terms. This transparency allows for effective comparison and negotiation.

- Cost Breakdown: Ensure quotations include all costs, such as shipping and installation.

- Warranty and Support: Understand the terms of the warranty and what post-purchase support is available.

Step 5: Assess After-Sales Support

Evaluate the after-sales support offered by the supplier. Reliable support can minimize downtime and maintenance costs in the long run.

- Technical Assistance: Ensure that technical support is readily available for installation and troubleshooting.

- Spare Parts Availability: Confirm that spare parts are accessible for future repairs or upgrades.

Step 6: Conduct a Final Review

Before making a purchase decision, conduct a final review of all gathered information. Ensure that the selected supplier meets all your criteria and that the chosen transformer aligns with your operational needs.

Illustrative image related to 3 phase transformer wiring schematic

- Compare Specifications: Cross-check the technical specifications against your initial requirements.

- Review Compliance and Support: Confirm that compliance standards and after-sales support meet your expectations.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and confirmed all details, finalize the purchase agreement. Ensure that all terms, including delivery schedules and payment conditions, are clearly outlined to avoid future disputes.

- Contract Clarity: Ensure the contract specifies all agreed terms and conditions.

- Payment Terms: Understand the payment structure and any deposit requirements.

By following this checklist, B2B buyers can make informed decisions when sourcing 3-phase transformer wiring schematics, ultimately leading to successful procurement and operational efficiency.

Comprehensive Cost and Pricing Analysis for 3 phase transformer wiring schematic Sourcing

What Are the Key Cost Components of 3 Phase Transformer Wiring Schematics?

When sourcing a 3 phase transformer wiring schematic, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materials: The quality of materials, such as copper or aluminum for windings, insulation materials, and core laminations, significantly influences the overall cost. High-grade materials ensure better efficiency and longevity but may come at a premium.

-

Labor: Skilled labor is necessary for design, assembly, and quality control. Labor costs can vary widely based on geographic location and the skill level required. In regions such as Africa and South America, labor may be less expensive, but the availability of skilled workers can impact timelines.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses. Efficient manufacturing processes can reduce overhead and, consequently, the final pricing.

-

Tooling: Specific tooling and machinery are required for the production of transformers, which adds to the initial capital expenditure. Custom tooling for unique specifications can further increase costs.

-

Quality Control (QC): Ensuring that transformers meet international standards and certifications (like ISO or IEC) is essential, particularly for buyers in Europe and the Middle East. Rigorous QC processes incur additional costs but are necessary to ensure reliability and performance.

-

Logistics: Shipping costs, including freight, insurance, and handling, can vary significantly, particularly for international shipments. Factors such as distance and chosen Incoterms (like FOB or CIF) will affect these costs.

-

Margin: Supplier margins vary based on market competition, brand reputation, and the uniqueness of the product. Established suppliers with a strong track record may charge higher margins due to perceived reliability.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence pricing in the procurement of 3 phase transformer wiring schematics:

-

Volume/MOQ: Larger orders often lead to discounts due to economies of scale. Buyers should consider their long-term needs to negotiate better pricing on bulk purchases.

-

Specifications and Customization: Customized solutions can increase costs due to additional design and manufacturing requirements. It’s crucial for buyers to balance their specific needs with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications can lead to increased upfront costs but may offer savings in maintenance and operational efficiency over time.

-

Supplier Factors: Supplier reliability, reputation, and geographical location influence pricing. Suppliers with extensive experience in international markets may provide better insights into local regulations and certifications.

-

Incoterms: Understanding Incoterms is essential to accurately assess total costs, including shipping responsibilities and risks. This knowledge aids in negotiating favorable terms with suppliers.

What Tips Can Help Buyers Navigate Pricing Nuances?

For international B2B buyers, particularly in regions like Africa, South America, and the Middle East, effective negotiation and cost management strategies are vital:

-

Negotiate with Confidence: Leverage volume discounts and long-term partnerships to negotiate better pricing. Be prepared to discuss your total purchasing power and future needs.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the initial purchase price but also the long-term costs associated with maintenance, efficiency, and potential downtime. This holistic view can justify higher upfront costs for superior products.

-

Understand Regional Variances: Pricing can be affected by local economic conditions, tariffs, and import duties. Buyers should conduct thorough market research to understand these dynamics.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide leverage in negotiations and a clearer picture of fair market pricing.

Disclaimer on Indicative Prices

Prices for 3 phase transformer wiring schematics can fluctuate based on market conditions, material availability, and supplier capabilities. It’s advisable to obtain current quotes and consider all influencing factors when making purchasing decisions.

Alternatives Analysis: Comparing 3 phase transformer wiring schematic With Other Solutions

Understanding Alternative Solutions to 3 Phase Transformer Wiring Schematics

When considering the electrical infrastructure for industrial applications, the choice of transformer wiring schematics can significantly influence performance, cost, and reliability. While the 3 phase transformer wiring schematic is a popular choice, several alternatives exist that may better suit specific operational needs. This section compares the 3 phase transformer wiring schematic with two viable alternatives: using multiple single-phase transformers and employing autotransformers.

Comparison Table

| Comparison Aspect | 3 Phase Transformer Wiring Schematic | Multiple Single-Phase Transformers | Autotransformer |

|---|---|---|---|

| Performance | High efficiency with balanced loads | Versatile; performance varies based on configuration | High efficiency, but limited to specific applications |

| Cost | Generally higher upfront investment | Lower initial cost; additional units may be required | Lower cost for certain applications |

| Ease of Implementation | Requires skilled installation | Easier to configure; requires careful polarity management | Simple to implement but limited flexibility |

| Maintenance | Moderate; complex systems can be harder to maintain | Easier maintenance; individual units can be replaced | Low maintenance but limited to specific uses |

| Best Use Case | Large industrial applications needing consistent power | Small to medium-sized applications with diverse loads | Applications requiring voltage regulation over a wide range |

In-Depth Analysis of Alternatives

Multiple Single-Phase Transformers

Using multiple single-phase transformers can provide flexibility and reliability. Each transformer can be individually monitored and maintained, allowing for quick replacements in case of failure. This approach is particularly beneficial in critical applications where downtime needs to be minimized. However, it does require careful attention to ensure proper wiring and polarity. The performance can vary significantly based on how the transformers are configured, and it may not achieve the same efficiency levels as a dedicated 3 phase transformer system.

Autotransformer

Autotransformers are a cost-effective alternative for applications requiring voltage adjustment. They utilize a single winding for both primary and secondary circuits, resulting in a more compact and lighter design compared to traditional transformers. While they are efficient and generally lower in cost, autotransformers have limitations in terms of isolation between circuits. This may pose risks in applications where electrical isolation is critical. Additionally, they are best suited for specific voltage regulation needs rather than general-purpose power distribution.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right transformer wiring schematic or alternative solution hinges on your specific application requirements, budget constraints, and operational priorities. If your business demands high efficiency and reliable power for industrial applications, the 3 phase transformer wiring schematic may be the best fit. However, for scenarios where flexibility, ease of maintenance, or cost-effectiveness is prioritized, exploring options like multiple single-phase transformers or autotransformers can yield substantial benefits. By assessing these factors carefully, B2B buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for 3 phase transformer wiring schematic

What Are the Key Technical Properties of a 3-Phase Transformer Wiring Schematic?

Understanding the technical properties of a 3-phase transformer wiring schematic is crucial for B2B buyers, especially when making procurement decisions. Here are some essential specifications to consider:

-

Voltage Rating

This specification indicates the maximum voltage the transformer can handle. It’s crucial for ensuring compatibility with existing electrical systems. Buyers must ensure that the voltage rating meets or exceeds the operational requirements of their facilities to prevent damage or inefficiency. -

Power Rating (kVA)

The power rating defines the maximum load the transformer can support. This is vital for determining whether a transformer can meet the specific energy demands of equipment and operations. Selecting a transformer with an appropriate kVA rating helps avoid overloading, which can lead to failures or increased operational costs. -

Impedance

Impedance affects the voltage drop and short-circuit current in the transformer. A lower impedance generally indicates better performance, especially in systems with fluctuating loads. Understanding impedance helps businesses anticipate operational efficiency and safety during short-circuit conditions. -

Temperature Rise

This specification indicates how much the temperature of the transformer will increase during operation. It is essential for assessing the transformer’s longevity and reliability. A transformer with a low temperature rise can operate more efficiently, reducing maintenance costs and downtime. -

Material Grade

The materials used in the transformer windings and core significantly impact its efficiency and durability. High-grade materials can enhance performance and lifespan, making them more attractive for long-term investments. Buyers should consider the material specifications to ensure they meet industry standards. -

Phase Shift

Phase shift indicates the phase difference between the primary and secondary windings, particularly important in Delta-Wye transformers. Understanding phase shift is crucial when integrating transformers into existing systems, as it affects the overall power quality and system stability.

What Are Common Trade Terms Related to 3-Phase Transformer Wiring Schematics?

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for ensuring quality and compatibility when sourcing transformers. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest amount of a product that a supplier is willing to sell. Being aware of MOQ is crucial for budgeting and inventory management, particularly for businesses looking to scale their operations efficiently. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price for specific goods or services. It is an important step in the procurement process, allowing buyers to compare offers and select the most cost-effective option. -

Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for managing logistics, costs, and risks associated with international transactions. -

FCL (Full Container Load)

FCL refers to a shipment in which a single buyer fills an entire container. This term is significant for B2B buyers looking to optimize shipping costs and manage inventory more effectively. -

Lead Time

Lead time is the period between the initiation of an order and its completion. Knowing the lead time helps buyers plan their operations and manage expectations regarding delivery schedules.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing 3-phase transformers, ensuring they meet their operational needs efficiently.

Navigating Market Dynamics and Sourcing Trends in the 3 phase transformer wiring schematic Sector

What Are the Key Market Dynamics and Trends in the 3 Phase Transformer Wiring Schematic Sector?

The global market for three-phase transformer wiring schematics is experiencing significant transformation driven by several key factors. One of the primary drivers is the increasing demand for reliable and efficient power distribution systems, particularly in developing regions like Africa and South America, where infrastructure development is rapidly advancing. The adoption of renewable energy sources, such as solar and wind, is also prompting the need for innovative transformer solutions to manage variable power loads effectively. Furthermore, the shift toward smart grids is revolutionizing how transformers are integrated into electrical networks, enabling better monitoring and control.

Emerging technologies, such as IoT and AI, are influencing sourcing trends as buyers seek advanced solutions that enhance operational efficiency. For instance, predictive maintenance powered by AI can significantly reduce downtime and maintenance costs, making it a priority for B2B buyers. Additionally, the trend towards modular transformer designs is gaining traction, allowing for easier scalability and customization based on specific project needs. International buyers, particularly from the Middle East and Europe, are increasingly looking for suppliers who can provide not only high-quality products but also comprehensive technical support and after-sales services.

How Is Sustainability and Ethical Sourcing Shaping the 3 Phase Transformer Wiring Schematic Market?

Sustainability is becoming a focal point in the sourcing of three-phase transformer wiring schematics, driven by both regulatory requirements and growing consumer awareness. The environmental impact of traditional transformer manufacturing processes has led many companies to adopt greener practices. This includes using eco-friendly materials and minimizing waste during production. Buyers are increasingly favoring suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001, which signifies effective environmental management systems.

Ethical sourcing is equally important, as companies aim to ensure that their supply chains are free from unethical practices. This includes ensuring fair labor practices and responsible sourcing of raw materials. B2B buyers are now more inclined to partner with suppliers who can provide transparency in their supply chain operations, including sourcing of copper and silicon, which are critical for transformer manufacturing. As the market continues to evolve, the integration of green technologies and ethical practices will not only enhance brand reputation but also drive long-term profitability.

What Is the Brief Evolution of 3 Phase Transformer Wiring Schematics?

The evolution of three-phase transformer wiring schematics can be traced back to the late 19th century when the need for efficient power transmission became apparent. Initially, transformers were designed primarily for simplicity and cost-effectiveness, utilizing basic configurations such as Delta and Wye connections. Over time, advancements in electrical engineering and materials science led to the development of more complex transformer designs that improved efficiency and reliability.

The introduction of smart technologies in the 21st century has further transformed the landscape, enabling real-time monitoring and management of transformer performance. This evolution has resulted in the emergence of modular transformers, which allow for greater flexibility in design and installation. Today, three-phase transformer wiring schematics are not only critical components in power distribution but also play a vital role in the integration of renewable energy sources and the advancement of smart grid technologies. As the market continues to grow, the focus will remain on enhancing performance, sustainability, and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 phase transformer wiring schematic

-

How do I solve issues with unbalanced loads in a 3-phase transformer system?

Unbalanced loads in a 3-phase transformer system can lead to overheating and reduced efficiency. To address this, ensure that the transformers are properly rated for the load and that they are connected in a suitable configuration, such as Delta-Wye, which helps distribute single-phase loads evenly across the three phases. Regular monitoring of the load balance is crucial, and employing phase balancing equipment can help mitigate issues. If problems persist, consulting with a transformer specialist for a detailed analysis may be necessary. -

What is the best transformer configuration for mixed loads?

For systems with both three-phase and single-phase loads, the Delta-Wye configuration is often the best choice. This setup allows for a stable neutral point, which is beneficial for grounding and helps distribute single-phase loads evenly among the phases. Additionally, it minimizes the risk of overheating and ensures better voltage regulation. However, the specific needs of your application, such as load types and environmental conditions, should be considered when selecting a configuration. -

What should I consider when sourcing 3-phase transformers internationally?

When sourcing 3-phase transformers internationally, consider the supplier’s certifications, quality assurance processes, and compliance with local regulations. Verify their track record in delivering reliable products and their capability to provide technical support. It’s also essential to assess the compatibility of the transformer with local voltage and frequency standards. Additionally, ensure that the supplier can provide documentation, such as wiring schematics and installation guidelines, to facilitate proper installation and maintenance. -

How can I vet suppliers for 3-phase transformers?

To vet suppliers, start by researching their industry reputation and customer reviews. Request references from previous clients and evaluate their responses. Check for certifications such as ISO and compliance with international standards. Conduct site visits if feasible, or request virtual tours to assess their manufacturing capabilities. Additionally, consider their responsiveness and willingness to provide technical support, which is crucial for resolving any issues that may arise during installation or operation. -

What is the minimum order quantity (MOQ) for 3-phase transformers?

Minimum order quantities for 3-phase transformers can vary significantly among suppliers, often ranging from one unit to several dozen. Factors influencing MOQ include the supplier’s production capacity, the complexity of the transformers, and the customization required. When negotiating with suppliers, inquire about flexibility in the MOQ, especially if you are a new buyer or if you have specific project timelines. Some suppliers may offer lower MOQs for trial orders or for established relationships. -

What payment terms should I expect when purchasing transformers?

Payment terms for purchasing 3-phase transformers typically vary by supplier and can include options like upfront payments, net 30/60/90 days, or payment upon delivery. It’s common to negotiate terms based on your relationship with the supplier and the size of the order. Always ensure that the payment terms align with your cash flow needs, and consider utilizing letters of credit or escrow services to protect your investment, especially in international transactions. -

How can I ensure quality assurance for my transformer order?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Inquire about their testing procedures, including factory acceptance tests (FAT) and compliance with international standards. It’s advisable to include quality assurance clauses in your purchase agreement, outlining expectations for product performance and testing. Additionally, consider hiring third-party inspection services to verify quality before shipment, especially for large or critical orders. -

What logistics considerations should I keep in mind for shipping transformers?

Logistics for shipping transformers involve several key considerations, including transport mode (air, sea, land), customs clearance, and handling requirements due to the weight and size of transformers. Ensure that your supplier has experience with international shipping and can provide necessary documentation for customs. It’s also important to discuss insurance options to protect against potential damage during transit. Lastly, factor in lead times and coordinate delivery schedules to align with your project timelines.

Top 6 3 Phase Transformer Wiring Schematic Manufacturers & Suppliers List

1. Electrical Engineering – Three-Phase Transformer Connections

Domain: electrical-engineering-portal.com

Registered: 2010 (15 years)

Introduction: Three-phase transformer connections: Delta–Delta, Wye–Wye, Delta–Wye, Wye–Delta. Delta–Delta transformers are used for primarily three-phase loads with a small single-phase component, suitable for motor loads and lighting. Wye–Wye transformers serve both three-phase and single-phase loads but can have issues with third-harmonic currents. Delta–Wye is the most common connection, allowing balanced p…

2. Electrical4U – Three-Phase Transformer Connections

Domain: electrical4u.com

Registered: 2012 (13 years)

Introduction: Three-phase transformer connections involve connecting primary and secondary windings in star or delta configurations for various electrical applications. Key types of connections include: Delta-Delta (Δ-Δ), Star-Star (Y-Y), Delta-Star (Δ-Y), and Star-Delta (Y-Δ). The star connection creates a neutral point, while the delta connection forms a closed loop. Factors affecting the choice of connection…

3. Bel Fuse – 3-Phase Transformers

Domain: belfuse.com

Registered: 1996 (29 years)

Introduction: 3-Phase Transformers are electrical devices that transform power between circuits at the same frequency, typically changing voltage and current values. They are constructed by winding three single-phase transformers on a single core, making them smaller, more cost-effective, and lighter than three individual single-phase transformers. 3-phase transformers typically have at least 6 windings (3 prim…

4. All About Circuits – Three-Phase Transformers

Domain: allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: Three-phase transformers are designed for power distribution systems, allowing for voltage transformation in various configurations. They consist of three sets of primary and secondary windings connected in either Δ (Delta) or Y (Wye) configurations. Key configurations include Y-Y, Y-Δ, Δ-Y, Δ-Δ, and V (open-Δ). Y connections provide multiple voltage options, while Δ connections offer higher relia…

5. Daelim – Electrical Transformers

Domain: daelimtransformer.com

Registered: 2019 (6 years)

Introduction: 1,000+ Electrical Transformers (7.2–34.5 kV, 25–3000 kVA) — UL Evaluated, Certificate of Compliance Available — In Stock & Ready to Ship from Houston, CA & Florida. Types of transformers include: Pad Mounted Transformer, Three Phase Pad Mounted Transformer, Single Phase Pad Mounted Transformer, Substation Transformer (Skid Mounted Transformer), Power Transformer (66kV, 69 kV, 110 kV, 115 kV, 132 k…

6. Pinterest – Three-Phase Transformer Connections

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: The article provides an overview of three-phase transformer connections, focusing on the four common types (Y-Y, Y-∆, ∆-Y, ∆-∆), their configurations, advantages, disadvantages, and phasor relationships.

Strategic Sourcing Conclusion and Outlook for 3 phase transformer wiring schematic

As the demand for reliable and efficient energy solutions continues to rise across Africa, South America, the Middle East, and Europe, understanding the intricacies of 3-phase transformer wiring schematics becomes imperative for international B2B buyers. The Delta and Wye configurations offer distinct advantages depending on load requirements and operational contexts, highlighting the importance of selecting the right transformer setup to optimize performance and minimize downtime.

Strategic sourcing not only facilitates cost-effective procurement but also ensures access to high-quality transformers that meet specific operational needs. By prioritizing suppliers with proven expertise and a strong track record, businesses can mitigate risks associated with transformer failures and enhance the longevity of their electrical systems.

Looking ahead, it is crucial for decision-makers to stay informed about emerging technologies and best practices in transformer applications. Engaging with reputable suppliers and leveraging their insights will empower organizations to make informed choices that drive efficiency and sustainability. Embrace the opportunity to enhance your energy infrastructure by connecting with trusted partners who can support your strategic sourcing initiatives today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.