Temperature Sensor Circuit Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for temperature sensor circuit

In today’s rapidly evolving industrial landscape, sourcing a reliable temperature sensor circuit can pose significant challenges for international B2B buyers. With diverse applications ranging from manufacturing and food safety to HVAC systems, the demand for accurate and durable temperature sensors is paramount. This guide serves as a comprehensive resource, equipping buyers with essential insights into various types of temperature sensor circuits, their specific applications, and how to effectively vet suppliers to ensure quality and reliability.

Navigating the complexities of the global market, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Vietnam—requires a strategic approach. This guide not only outlines key considerations regarding cost, but also delves into the technological advancements shaping the industry. By understanding the intricacies of temperature sensor circuits, buyers can make informed purchasing decisions that enhance operational efficiency and product quality.

Whether you are looking to optimize your supply chain or seeking to understand the latest innovations in temperature sensing technology, this guide empowers you to navigate the global market with confidence. It provides actionable insights and practical recommendations tailored to meet the unique needs of your business in an increasingly competitive environment.

Understanding temperature sensor circuit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermocouples | Wide temperature range, fast response time | Industrial machinery, HVAC systems | Pros: Cost-effective, rugged; Cons: Requires calibration, less precise than other types. |

| RTDs (Resistance Temperature Detectors) | High accuracy, stability, and repeatability | Food processing, pharmaceuticals | Pros: Highly accurate and stable; Cons: More expensive, slower response time than thermocouples. |

| Thermistors | Highly sensitive, small size | Medical devices, consumer electronics | Pros: Excellent sensitivity; Cons: Limited temperature range, non-linear response. |

| PTC Sensors (Positive Temperature Coefficient) | Self-regulating, temperature-dependent resistance | Overcurrent protection, temperature monitoring | Pros: Simple design, self-resetting; Cons: Limited range, slower response compared to thermocouples. |

| Infrared Sensors | Non-contact measurement, quick response | HVAC, automotive, and safety systems | Pros: No physical contact required; Cons: Can be affected by environmental conditions, typically more costly. |

What Are the Key Characteristics of Thermocouples and Their Suitability for B2B Buyers?

Thermocouples are favored for their broad temperature range and rapid response times, making them ideal for applications in industrial machinery and HVAC systems. They operate on the principle of voltage generation due to temperature differences between two junctions. B2B buyers should consider their cost-effectiveness and ruggedness, especially in harsh environments. However, thermocouples may require periodic calibration and may not provide the same level of precision as other sensor types.

How Do RTDs Compare in Terms of Accuracy and Stability?

Resistance Temperature Detectors (RTDs) are known for their high accuracy and stability, making them suitable for critical applications such as food processing and pharmaceuticals. They function by measuring the change in electrical resistance of a metal with temperature. Buyers should prioritize RTDs when precision is paramount, despite their higher cost and slower response times compared to thermocouples. Their long-term stability makes them a worthwhile investment for industries requiring consistent temperature monitoring.

What Advantages Do Thermistors Offer for Sensitive Applications?

Thermistors are characterized by their exceptional sensitivity and small size, making them ideal for medical devices and consumer electronics. They exhibit a significant change in resistance with small temperature variations, allowing for precise measurements. However, B2B buyers should note their limited temperature range and non-linear response, which may necessitate additional calibration. Their affordability and compactness make them attractive for applications where space is a constraint.

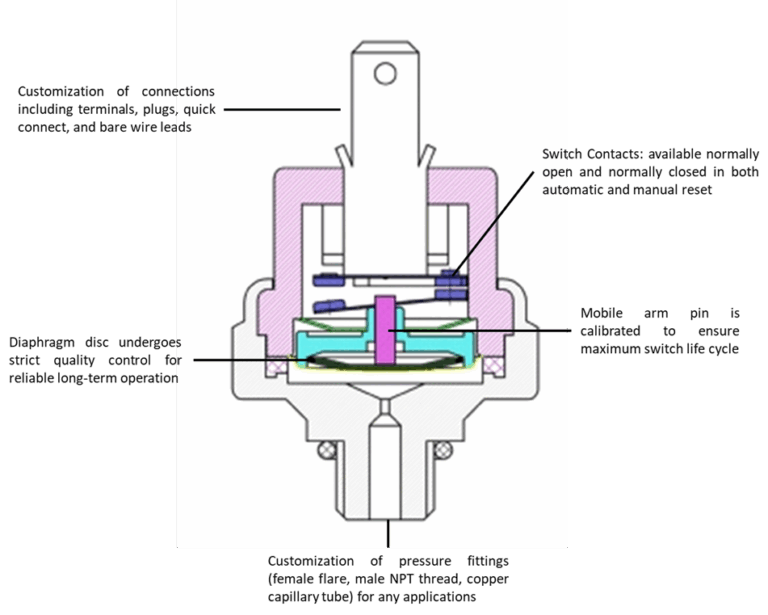

What Are the Unique Features of PTC Sensors for B2B Applications?

Positive Temperature Coefficient (PTC) sensors are unique in their self-regulating nature, which allows them to automatically limit current flow as temperature increases. They are primarily used in overcurrent protection and temperature monitoring applications. Buyers appreciate their simplicity and self-resetting capabilities, although the limited temperature range and slower response times compared to thermocouples can be drawbacks. PTC sensors are particularly beneficial in applications where safety is a priority.

How Do Infrared Sensors Enhance Measurement Capabilities in Various Industries?

Infrared sensors provide non-contact temperature measurement, which is especially useful in HVAC, automotive, and safety systems. They can deliver quick readings without physical contact, reducing the risk of contamination or damage. However, B2B buyers should consider that infrared sensors can be influenced by environmental factors and typically come at a higher price point. Their ability to measure temperature from a distance makes them invaluable in applications where traditional sensors may not be suitable.

Key Industrial Applications of temperature sensor circuit

| Industry/Sector | Specific Application of temperature sensor circuit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Monitoring temperature during food processing | Ensures food safety and compliance with regulations | Accuracy, durability, and compliance with food safety standards |

| HVAC and Building Automation | Temperature control in smart HVAC systems | Enhances energy efficiency and occupant comfort | Compatibility with existing systems and energy certifications |

| Manufacturing | Temperature monitoring in industrial processes | Reduces downtime and enhances product quality | Robustness under industrial conditions and response time |

| Automotive | Engine temperature monitoring and control | Improves vehicle performance and reliability | High-temperature resistance and integration with automotive systems |

| Healthcare | Patient temperature monitoring in medical devices | Enhances patient care and compliance with health standards | Precision, reliability, and regulatory certifications |

How is Temperature Sensor Circuit Used in the Food and Beverage Industry?

In the food and beverage sector, temperature sensor circuits are critical for monitoring temperature during food processing and storage. They help ensure that food is kept at safe temperatures to prevent spoilage and contamination, thus complying with health regulations. Buyers in this industry must prioritize sensors that offer high accuracy and durability, as well as those that meet stringent food safety standards. This ensures not only compliance but also enhances the brand’s reputation for quality.

What Role Does Temperature Sensor Circuit Play in HVAC and Building Automation?

Temperature sensor circuits are integral to smart HVAC systems, where they facilitate precise temperature control. This application enhances energy efficiency and improves occupant comfort by adjusting heating and cooling based on real-time data. International buyers, particularly in regions with varying climates, should consider sensors that are compatible with existing systems and come with energy certifications to maximize efficiency and cost savings.

How Do Temperature Sensors Impact Manufacturing Processes?

In manufacturing, temperature sensor circuits are used for monitoring temperatures in various industrial processes, such as material processing and equipment operation. By providing real-time temperature data, these sensors help reduce downtime and improve product quality, which is essential for maintaining competitive advantage. Buyers need to focus on sensors that are robust enough to withstand harsh industrial environments and have a quick response time to ensure effective process control.

Why are Temperature Sensors Essential in Automotive Applications?

Temperature sensor circuits are crucial in automotive applications for monitoring engine temperatures and ensuring optimal performance. They help prevent overheating, which can lead to engine failure, thereby enhancing vehicle reliability. Buyers in the automotive sector should seek sensors that can withstand high temperatures and integrate seamlessly with existing automotive systems, ensuring they meet the rigorous demands of automotive performance and safety standards.

What is the Importance of Temperature Sensors in Healthcare?

In healthcare, temperature sensor circuits are vital for patient monitoring, especially in critical care settings. They provide accurate and continuous temperature readings, which are essential for patient care and compliance with health standards. Buyers in this sector must prioritize precision and reliability, as well as seek sensors with necessary regulatory certifications to ensure they meet healthcare regulations and enhance patient safety.

3 Common User Pain Points for ‘temperature sensor circuit’ & Their Solutions

Scenario 1: Inaccurate Temperature Readings Leading to Product Failures

The Problem: B2B buyers often face challenges with temperature sensor circuits that provide inaccurate readings due to poor calibration or environmental interference. This can lead to significant problems in production processes, especially in industries such as pharmaceuticals or food and beverage, where precise temperature control is critical. A failure to maintain the correct temperature can result in product spoilage, compliance issues, and costly recalls, damaging a company’s reputation and bottom line.

The Solution: To mitigate this risk, it’s essential to implement a rigorous calibration and testing process for temperature sensor circuits. Buyers should work with suppliers who offer calibration services and ensure that the sensors are calibrated to the specific conditions of their operating environment. Additionally, integrating advanced diagnostic tools that allow for real-time monitoring of sensor performance can help identify deviations promptly. This proactive approach not only enhances accuracy but also builds trust in the data collected, enabling better decision-making in operational processes.

Scenario 2: Complex Integration with Existing Systems

The Problem: Many companies struggle with integrating new temperature sensor circuits into their existing automation or monitoring systems. This can result from compatibility issues, lack of standardization, or insufficient technical support from suppliers. As a result, businesses may experience delays in deployment, increased costs due to additional modifications, or even operational downtime, all of which can impact productivity and profitability.

The Solution: To ensure seamless integration, it is crucial for buyers to conduct a thorough assessment of their current systems and identify specific requirements for new sensor circuits. Engaging with suppliers who provide comprehensive technical documentation, including wiring diagrams and compatibility matrices, can greatly assist in this process. Moreover, opting for temperature sensors that support standardized communication protocols, such as Modbus or CAN bus, can facilitate easier integration. Buyers should also consider working with suppliers that offer on-site technical support during installation to address any integration challenges in real-time.

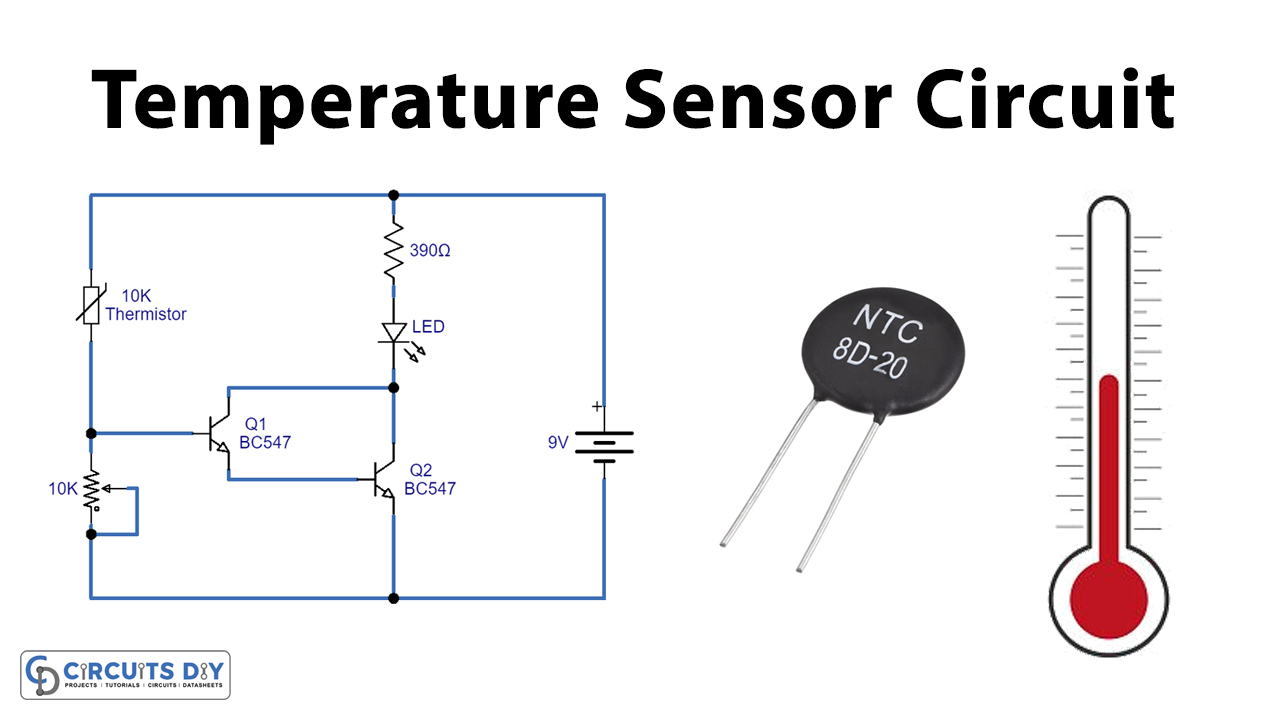

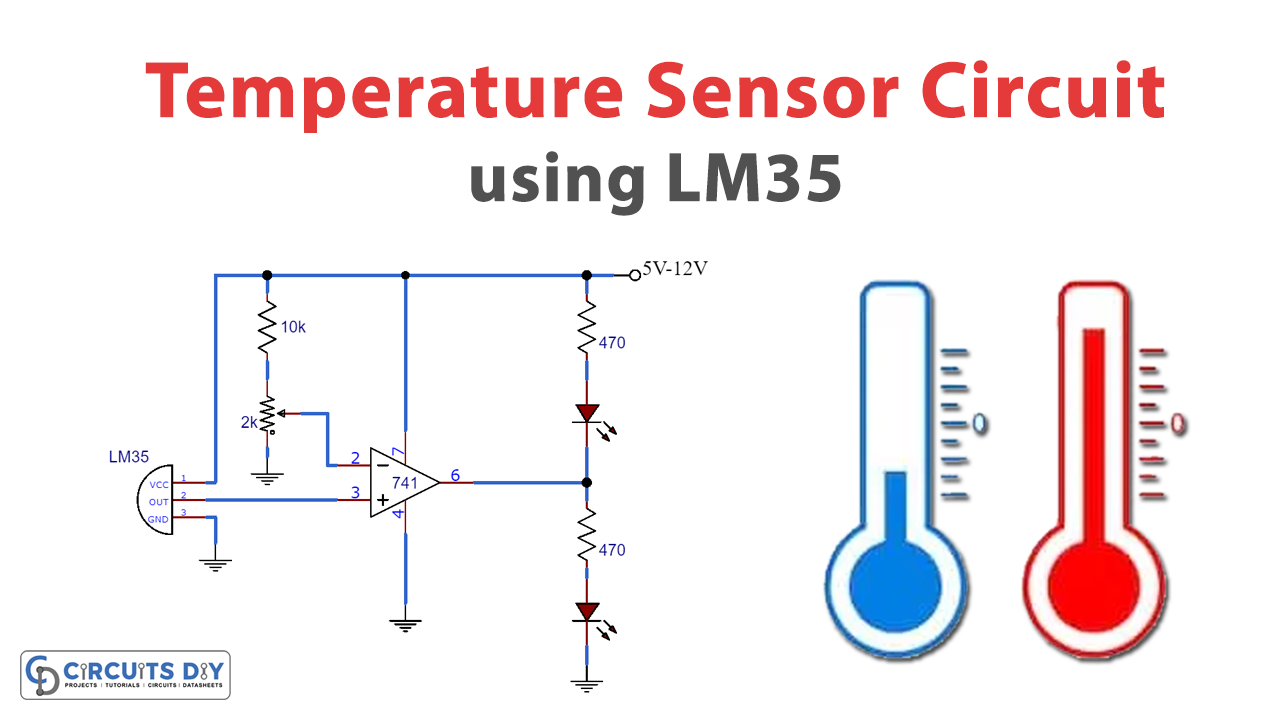

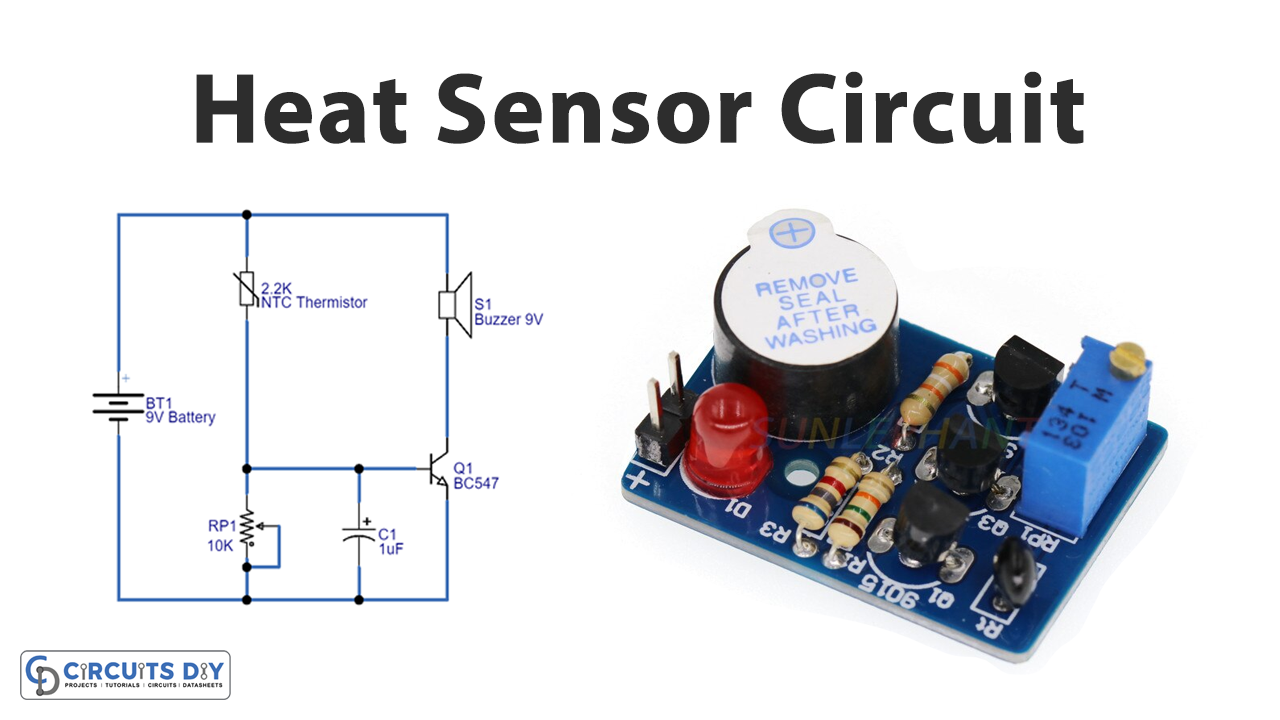

Illustrative image related to temperature sensor circuit

Scenario 3: High Costs Due to Frequent Sensor Failures

The Problem: Frequent failures of temperature sensor circuits can lead to excessive replacement costs and maintenance efforts, impacting overall operational efficiency. This issue is particularly prevalent in environments with extreme temperature fluctuations or corrosive conditions. Buyers may find themselves repeatedly investing in sensors that do not withstand the harsh realities of their applications, which can severely strain budgets and disrupt operations.

The Solution: To combat this issue, businesses should invest in high-quality, robust temperature sensor circuits specifically designed for their operational conditions. Conducting a thorough market analysis to identify manufacturers that specialize in durable sensors for extreme environments is key. Buyers should request samples and conduct rigorous field tests before committing to a large order. Additionally, implementing a predictive maintenance program can help identify potential failures before they occur, allowing for timely replacements and minimizing unexpected costs. This approach not only saves money but also enhances the longevity and reliability of temperature sensing solutions, ensuring smoother operations.

Strategic Material Selection Guide for temperature sensor circuit

What Are the Key Materials Used in Temperature Sensor Circuits?

When selecting materials for temperature sensor circuits, it is crucial to consider their properties and how they align with the specific requirements of the application. Here, we analyze four common materials used in temperature sensor circuits: thermoplastic polymers, metals, ceramics, and composite materials. Each material presents distinct advantages and challenges that can influence performance, durability, and cost.

How Do Thermoplastic Polymers Perform in Temperature Sensor Circuits?

Thermoplastic polymers, such as polyimide and polycarbonate, are often utilized in temperature sensor circuits due to their excellent electrical insulation properties and thermal stability. These materials can typically withstand temperatures ranging from -60°C to 200°C, making them suitable for a variety of applications.

Pros:

– Lightweight and flexible, allowing for easy integration into compact designs.

– Good resistance to chemicals and moisture, enhancing durability in harsh environments.

– Lower manufacturing costs compared to metals and ceramics.

Cons:

– Limited temperature and pressure ratings compared to metals, which may restrict their use in high-temperature applications.

– Potential for thermal degradation over prolonged exposure to extreme temperatures.

Impact on Application:

Thermoplastic polymers are compatible with various media, including oils and mild solvents, but may not perform well in high-pressure environments.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and ISO. In regions like Africa and South America, sourcing locally may also reduce costs.

What Role Do Metals Play in Temperature Sensor Circuits?

Metals, particularly copper and stainless steel, are widely used in temperature sensor circuits due to their excellent thermal conductivity and durability. These materials can operate effectively in high-temperature environments, often exceeding 300°C.

Pros:

– Superior thermal conductivity allows for rapid response times in temperature sensing.

– High durability and resistance to mechanical stress, making them suitable for demanding applications.

– Metals like stainless steel offer excellent corrosion resistance.

Cons:

– Higher manufacturing costs and complexity compared to polymers.

– Heavier than other materials, which may be a disadvantage in lightweight applications.

Illustrative image related to temperature sensor circuit

Impact on Application:

Metals are particularly effective in applications involving gases and liquids, as they can withstand high pressures and corrosive environments.

Considerations for International Buyers:

Compliance with standards such as ASTM and DIN is essential, especially in Europe and the Middle East, where regulatory requirements are stringent.

How Do Ceramics Enhance Temperature Sensor Circuit Performance?

Ceramics, such as alumina and zirconia, are known for their high-temperature stability and resistance to thermal shock. They can operate effectively at temperatures above 1000°C, making them ideal for extreme environments.

Pros:

– Exceptional thermal stability and electrical insulation properties.

– High resistance to chemical corrosion, suitable for harsh environments.

– Long lifespan due to their durability.

Cons:

– Brittle nature can lead to failure under mechanical stress.

– Higher manufacturing costs and complexity compared to metals and polymers.

Impact on Application:

Ceramics are particularly well-suited for applications involving aggressive chemicals and extreme temperatures, such as in aerospace and industrial settings.

Considerations for International Buyers:

Buyers should be aware of the specific ceramic grades that comply with international standards, particularly in Europe and the Middle East, where specific certifications may be required.

What Are the Advantages of Composite Materials in Temperature Sensor Circuits?

Composite materials, often a blend of polymers and metals, provide a unique combination of properties. They are engineered to enhance performance in specific applications, offering tailored solutions for temperature sensors.

Pros:

– Customizable properties, allowing for optimization based on specific application needs.

– Lightweight and strong, which can improve overall system performance.

– Enhanced thermal and electrical insulation.

Cons:

– Manufacturing complexity can lead to higher costs.

– May require specialized processing techniques that can complicate production.

Impact on Application:

Composites can be designed to be compatible with a wide range of media, making them versatile for various applications.

Considerations for International Buyers:

Buyers should consider the availability of composite materials in their region and ensure compliance with relevant standards, particularly in emerging markets like Africa and South America.

Summary Table of Material Selection for Temperature Sensor Circuits

| Material | Typical Use Case for temperature sensor circuit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polymers | Consumer electronics, automotive sensors | Lightweight and flexible | Limited temperature range | Low |

| Metals | Industrial applications, HVAC systems | Superior thermal conductivity | Higher cost and weight | Med |

| Ceramics | Aerospace, high-temperature environments | Exceptional thermal stability | Brittle nature | High |

| Composite Materials | Specialized applications, automotive sensors | Customizable properties | Manufacturing complexity | Med |

This detailed analysis provides international B2B buyers with insights into material selection for temperature sensor circuits, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for temperature sensor circuit

What Are the Main Stages of Manufacturing Temperature Sensor Circuits?

The manufacturing of temperature sensor circuits involves several critical stages, ensuring that the final product meets the stringent requirements of reliability and accuracy expected in various applications. Here’s a breakdown of the main stages:

-

Material Preparation: This initial phase includes sourcing high-quality raw materials such as semiconductor substrates, resistors, and conductive materials. It is essential that suppliers provide documentation certifying the quality and traceability of these materials, adhering to international standards such as ISO 9001. This ensures that the inputs into the manufacturing process are of the highest quality, which is crucial for the sensor’s performance.

-

Forming: In this stage, the prepared materials undergo various processes such as photolithography, etching, and doping to create the sensor’s core components. Techniques like Thin Film and Thick Film technology are commonly employed, depending on the desired specifications. These methods allow for the precise shaping and manipulation of materials, creating the necessary structures for effective temperature sensing.

-

Assembly: After forming, the components are assembled into a complete circuit. This includes mounting the sensors onto printed circuit boards (PCBs) using techniques like surface mount technology (SMT) or through-hole technology. Automated assembly lines are often used for efficiency and accuracy, reducing the risk of human error.

-

Finishing: The final stage involves encapsulation and protective coating of the sensor circuits to enhance durability and resistance to environmental factors. This may include applying conformal coatings or potting compounds to protect against moisture, dust, and chemicals. The finishing process is vital for extending the lifespan of the sensors in various operating conditions.

How Is Quality Assurance Implemented in Temperature Sensor Circuit Manufacturing?

Quality assurance (QA) is integral to the manufacturing of temperature sensor circuits, ensuring that each product meets rigorous performance and safety standards. The following are key aspects of the QA process:

-

What International Standards Should B2B Buyers Be Aware Of?

Compliance with international standards such as ISO 9001 is essential for manufacturers. This standard focuses on quality management systems, emphasizing continual improvement and customer satisfaction. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector may also be relevant, depending on the application of the temperature sensors. -

What Are the Key Quality Control Checkpoints?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before they enter production. Suppliers must provide certificates of conformity and material safety data sheets (MSDS).

– In-Process Quality Control (IPQC): During manufacturing, real-time monitoring and testing ensure that processes adhere to established parameters. This includes checking for defects at various stages of assembly.

– Final Quality Control (FQC): The finished products undergo rigorous testing to confirm they meet all specifications. Common tests include thermal cycling, response time, and accuracy under various conditions. -

What Testing Methods Are Commonly Used?

Manufacturers utilize a range of testing methods to validate the performance of temperature sensor circuits. These include:

– Functional Testing: Ensures that the sensor operates correctly under specified conditions.

– Environmental Testing: Assesses performance under extreme temperatures, humidity, and other environmental factors.

– Calibration: Each sensor may need calibration to ensure accuracy, often using reference thermometers or calibration baths.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing from international markets. Here are some strategies:

-

Conducting Audits: Buyers should perform regular audits of their suppliers’ manufacturing facilities. This includes reviewing processes, quality control measures, and compliance with international standards. On-site visits provide insight into the operational practices and commitment to quality.

-

Requesting Quality Assurance Reports: Suppliers should provide comprehensive quality assurance documentation, including inspection reports, testing results, and certificates of compliance. Buyers should analyze these documents to ensure they align with their quality expectations.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct pre-shipment inspections, ensuring that products meet specified standards before leaving the manufacturer.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

Illustrative image related to temperature sensor circuit

-

Cultural and Regulatory Differences: Buyers must navigate diverse regulatory environments and cultural attitudes towards quality. Understanding local regulations and compliance requirements can help in selecting suppliers who meet both international and regional standards.

-

Supply Chain Transparency: In regions with less stringent regulatory oversight, ensuring supply chain transparency is critical. Buyers should establish clear communication with suppliers and leverage technology to track materials and processes.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can facilitate better quality control. Regular communication and collaboration on quality improvement initiatives can lead to enhanced product reliability and performance.

Conclusion

The manufacturing processes and quality assurance for temperature sensor circuits are complex yet vital for ensuring product reliability and safety. By understanding the key stages of manufacturing, the importance of quality control, and the means to verify supplier practices, B2B buyers can make informed decisions that align with their operational needs and quality standards. This comprehensive approach not only enhances the procurement process but also contributes to the overall success of their applications across diverse industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘temperature sensor circuit’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure temperature sensor circuits. Whether you’re in the industrial, agricultural, or HVAC sectors, understanding the nuances of sourcing these components is essential for ensuring quality, reliability, and cost-effectiveness. This guide will help streamline your procurement process, enabling you to make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first critical step in sourcing temperature sensor circuits. Define the parameters such as temperature range, accuracy, response time, and environmental conditions where the sensor will operate. Knowing these specifics ensures you select a product that meets your operational needs and avoids costly mistakes down the line.

- Consider compatibility: Ensure that the sensor circuit is compatible with existing systems and technologies in use.

- Understand your application: Different applications may require different types of sensors (e.g., thermocouples vs. RTDs).

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is essential for obtaining high-quality temperature sensor circuits. Research potential suppliers by checking their market reputation, years of experience, and customer reviews. Reliable suppliers not only deliver quality products but also provide support and after-sales service.

- Check industry certifications: Look for suppliers who hold relevant certifications such as ISO 9001 or specific industry standards.

- Evaluate their product range: A supplier with a diverse product portfolio may offer better solutions tailored to your needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps ensure that the supplier can meet your quality and delivery expectations.

- Assess their manufacturing capabilities: Understanding their production processes can give insights into the quality of the products they offer.

- Inquire about lead times: A reliable supplier should provide clear timelines for production and delivery.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the temperature sensor circuits. Testing samples in real-world conditions helps you evaluate their performance and compatibility with your systems.

- Conduct thorough testing: Check for accuracy, response time, and durability under expected operating conditions.

- Compare results: Use the sample results to compare different suppliers and make an informed decision.

Step 5: Negotiate Terms and Pricing

Once you are satisfied with the samples, it’s time to negotiate pricing and terms. Ensure you understand the total cost of ownership, including shipping, taxes, and potential duties, which can significantly impact your budget.

Illustrative image related to temperature sensor circuit

- Discuss payment terms: Establish clear payment terms, whether it be upfront, net 30, or other arrangements that suit your cash flow.

- Explore bulk discounts: If you plan to order in large quantities, inquire about volume discounts to maximize savings.

Step 6: Verify Supplier Certifications

Before finalizing your order, verify that your chosen supplier holds all necessary certifications and complies with industry regulations. This step is crucial for ensuring that the products meet safety and quality standards, which can be particularly important in regulated industries.

- Request documentation: Ask for copies of certifications and compliance documents.

- Check for ongoing quality assurance: Ensure the supplier has procedures in place for continuous quality monitoring.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your supplier. Clear communication helps address any issues promptly and fosters a better working relationship.

- Define points of contact: Establish primary contacts for technical support and order inquiries.

- Schedule regular check-ins: Regular updates can help ensure that both parties are aligned on expectations and timelines.

By following this checklist, B2B buyers can navigate the procurement process for temperature sensor circuits with confidence, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for temperature sensor circuit Sourcing

When sourcing temperature sensor circuits, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the key components that contribute to the overall cost, influential pricing factors, and actionable tips for buyers aiming to optimize their procurement processes.

What Are the Key Cost Components in Temperature Sensor Circuit Sourcing?

-

Materials: The primary cost driver in temperature sensor circuits is the raw materials used. This includes semiconductors, resistors, and other electronic components. The quality and sourcing of these materials can significantly influence the price. For example, high-grade materials often yield better performance but come at a premium.

-

Labor: Labor costs vary significantly based on geographical location. In regions with lower wage standards, labor costs can be minimized, impacting the overall pricing. However, the skill level of labor is also a critical factor, as more experienced technicians may command higher wages but can also lead to better quality products.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, facility costs, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, thereby lowering the price for buyers.

-

Tooling: The initial investment in tooling for production can be substantial, especially for custom designs. Buyers should consider whether the tooling costs can be amortized over a sufficient volume to justify the investment.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring product reliability and performance. However, enhanced QC measures can increase costs. Buyers should assess the balance between quality assurance and cost-effectiveness.

-

Logistics: Transportation, warehousing, and distribution costs must be factored into the total cost. The choice of shipping methods and routes can lead to significant variations in logistics costs, especially for international shipments.

-

Margin: Suppliers typically include a margin in their pricing to account for profit. This margin can vary widely depending on the supplier’s market positioning, reputation, and the perceived value of their products.

How Do Price Influencers Affect Temperature Sensor Circuit Pricing?

-

Volume/MOQ: Bulk purchases often lead to lower unit prices. Suppliers are more willing to negotiate favorable terms for larger orders, which can significantly reduce the cost per unit.

-

Specifications and Customization: Custom specifications can lead to increased costs due to unique tooling and material requirements. Buyers should weigh the necessity of customization against potential price increases.

-

Materials: Fluctuations in the price of raw materials can directly affect the final price. Buyers should stay informed about market trends and negotiate contracts that account for potential price volatility.

-

Quality and Certifications: Products that meet higher quality standards or possess certifications (e.g., ISO, CE) may come at a premium. Buyers should assess the importance of these certifications relative to their application needs.

-

Supplier Factors: The supplier’s reputation, reliability, and market position can influence pricing. Established suppliers may command higher prices due to perceived quality and service guarantees.

-

Incoterms: The chosen Incoterms can significantly impact the overall cost. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, affecting the total landed cost.

What Are Some Effective Buyer Tips for Cost-Efficient Sourcing?

-

Negotiate: Leverage volume discounts and long-term contracts to negotiate better pricing. Building strong relationships with suppliers can also lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, logistics, and potential failures. TCO analysis can reveal hidden costs that affect overall profitability.

-

Understand Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that can impact pricing.

-

Request Multiple Quotations: Engaging multiple suppliers can provide insights into competitive pricing and help identify the best value for quality and service.

-

Stay Informed: Keep abreast of market trends and technological advancements in temperature sensor circuits. This knowledge can empower buyers to make informed decisions and negotiate effectively.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on specific supplier offerings, market conditions, and negotiations. Always conduct thorough research and due diligence before finalizing procurement decisions.

Illustrative image related to temperature sensor circuit

Alternatives Analysis: Comparing temperature sensor circuit With Other Solutions

Understanding Alternatives to Temperature Sensor Circuits

In the realm of temperature measurement, businesses often seek the most effective solutions to meet their specific needs. While temperature sensor circuits are widely used due to their reliability and precision, various alternatives can also provide effective temperature monitoring. This section compares the traditional temperature sensor circuit with two alternative technologies: infrared thermometers and thermocouples.

Comparison Table

| Comparison Aspect | Temperature Sensor Circuit | Infrared Thermometer | Thermocouple |

|---|---|---|---|

| Performance | High accuracy; good for controlled environments | Quick readings; less accurate for distant objects | Wide temperature range; suitable for extreme conditions |

| Cost | Moderate initial investment; low operational costs | Generally lower cost; may require frequent calibration | Low initial cost; requires additional equipment for readings |

| Ease of Implementation | Requires a circuit design; moderate complexity | Very easy to use; minimal setup | Requires proper installation; more complex than sensors |

| Maintenance | Low maintenance; periodic calibration needed | Low maintenance; regular checks recommended | Moderate maintenance; needs recalibration and replacement |

| Best Use Case | Industrial processes; HVAC systems | Non-contact temperature measurement; medical applications | Heavy industries; high-temperature environments |

Analyzing Infrared Thermometers: What Are Their Advantages and Disadvantages?

Infrared thermometers are excellent for measuring temperature from a distance, making them particularly useful in scenarios where contact with the object is not feasible. They provide quick results, which is advantageous in dynamic environments like medical facilities or industrial settings. However, their accuracy can diminish when measuring temperatures of shiny or reflective surfaces, which may not be ideal for all applications. Additionally, while the initial investment may be lower, they often require frequent calibration to maintain accuracy, which can add to operational costs over time.

Exploring Thermocouples: What Makes Them a Viable Alternative?

Thermocouples are known for their ability to operate over a broad temperature range, making them suitable for extreme environments, such as those found in heavy industries or scientific research. They are relatively inexpensive and can be deployed in various applications. However, thermocouples necessitate more complex installation and calibration procedures compared to temperature sensor circuits. Additionally, they typically require auxiliary equipment to convert voltage readings into temperature, which can complicate the setup. Regular maintenance and recalibration are also essential to ensure reliable performance.

Conclusion: How Can B2B Buyers Choose the Right Temperature Measurement Solution?

When selecting the appropriate temperature measurement solution, B2B buyers must consider several factors, including performance requirements, budget constraints, ease of implementation, and maintenance needs. Temperature sensor circuits offer high accuracy and are well-suited for controlled environments, making them ideal for industrial applications. In contrast, infrared thermometers are preferable for quick, non-contact measurements, while thermocouples provide versatility in extreme conditions. Ultimately, the best choice will depend on the specific operational context and requirements of the business, ensuring optimal performance and cost-effectiveness.

Essential Technical Properties and Trade Terminology for temperature sensor circuit

What Are the Key Technical Properties of Temperature Sensor Circuits?

Understanding the essential technical specifications of temperature sensor circuits is crucial for B2B buyers. These properties not only determine performance but also impact long-term reliability and cost-effectiveness.

1. Material Grade

The material used in temperature sensors, such as thermocouples or resistive temperature devices (RTDs), significantly affects their durability and performance. Common materials include platinum for RTDs and nickel for thermocouples. The choice of material can influence the sensor’s resistance to corrosion, thermal conductivity, and overall lifespan. For buyers, selecting sensors made from high-quality materials ensures better reliability in harsh environments, reducing the need for frequent replacements.

2. Tolerance

Tolerance refers to the allowable deviation from a specified measurement. In temperature sensors, a lower tolerance means higher accuracy in temperature readings. Common tolerances range from ±0.1°C to ±2.0°C, depending on the application. For B2B buyers, understanding tolerance levels is essential for ensuring that the temperature measurement meets industry standards, particularly in sectors like pharmaceuticals or food processing, where precision is critical.

3. Temperature Range

This specification indicates the minimum and maximum temperatures that a sensor can accurately measure. Typical ranges can vary from -200°C to +850°C. Buyers must consider the operating environment when selecting sensors, as exceeding the specified range can lead to sensor failure or inaccurate readings. A suitable temperature range not only ensures operational efficiency but also enhances safety in applications involving extreme conditions.

Illustrative image related to temperature sensor circuit

4. Response Time

Response time measures how quickly a sensor can detect a change in temperature. It is typically expressed in seconds or milliseconds. A fast response time is vital for applications requiring real-time monitoring, such as in HVAC systems or industrial processes. Buyers should prioritize sensors with optimal response times to ensure timely data acquisition, which can lead to improved process control and efficiency.

5. Power Supply Requirements

Temperature sensors can operate on various power supply levels, from low-voltage batteries to higher voltage AC supplies. Understanding the power requirements is crucial for integration into existing systems. For B2B buyers, ensuring compatibility with current infrastructure can lead to lower installation costs and easier maintenance.

What Are Common Trade Terms Related to Temperature Sensor Circuits?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms associated with temperature sensor circuits:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of temperature sensors, OEMs often provide custom sensors tailored to specific applications. Understanding the OEM landscape helps buyers identify potential suppliers who can meet their unique needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it affects purchasing decisions and inventory management. Knowing the MOQ allows buyers to plan their procurement effectively, ensuring they meet demand without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. In the context of temperature sensors, submitting an RFQ can help buyers obtain competitive pricing and understand delivery timelines. It is a key step in the procurement process that enables informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers in different regions, understanding Incoterms is crucial for budgeting and logistical planning when sourcing temperature sensors from international suppliers.

5. Calibration

Calibration refers to the process of configuring a sensor to provide accurate readings. Regular calibration is essential for maintaining sensor accuracy over time. For buyers, ensuring that sensors are calibrated according to industry standards can prevent costly errors and improve overall process reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting temperature sensor circuits, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the temperature sensor circuit Sector

What Are the Current Market Dynamics and Sourcing Trends in the Temperature Sensor Circuit Sector?

The temperature sensor circuit sector is witnessing significant growth fueled by advancements in technology and increasing demand across various industries, including automotive, healthcare, and industrial automation. Key global drivers include the rising need for precision in temperature measurement and control, particularly in critical applications like climate monitoring and manufacturing processes. Additionally, the proliferation of Internet of Things (IoT) devices is enhancing the integration of temperature sensors in smart systems, facilitating real-time data collection and analysis.

Emerging B2B tech trends such as the adoption of wireless communication technologies and the development of miniaturized sensors are reshaping the landscape. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial. Companies are increasingly favoring suppliers who can provide not only high-quality sensors but also robust integration capabilities that can seamlessly connect with existing systems. The market is also seeing a shift towards more adaptable, scalable solutions to accommodate diverse operational needs.

Furthermore, the demand for customized solutions is on the rise, as businesses seek sensors that meet specific regulatory and operational requirements. As global supply chains become more interconnected, B2B buyers must navigate fluctuating costs, technological advancements, and evolving customer expectations, making it essential to establish strong relationships with reliable suppliers.

How Is Sustainability and Ethical Sourcing Impacting the Temperature Sensor Circuit Sector?

Sustainability has become a pivotal concern in the temperature sensor circuit sector, reflecting broader trends in environmental responsibility. The environmental impact of manufacturing processes, including waste generation and resource depletion, has prompted companies to prioritize sustainable practices. For B2B buyers, this means sourcing from suppliers who demonstrate a commitment to reducing their carbon footprint and employing eco-friendly materials.

Ethical sourcing is also gaining traction, with businesses increasingly recognizing the importance of transparent supply chains. Buyers are looking for suppliers that adhere to ethical labor practices and have certifications that validate their environmental and social responsibility. Green certifications, such as ISO 14001 for environmental management and RoHS compliance for hazardous substances, are becoming essential criteria in supplier selection.

Moreover, the use of sustainable materials in the production of temperature sensors—such as recyclable plastics and non-toxic substances—can enhance product appeal and compliance with regulatory standards. As more companies adopt sustainable practices, B2B buyers can leverage this trend to not only fulfill their corporate social responsibility goals but also to improve their market positioning.

What Is the Historical Context of Temperature Sensor Circuits in B2B Transactions?

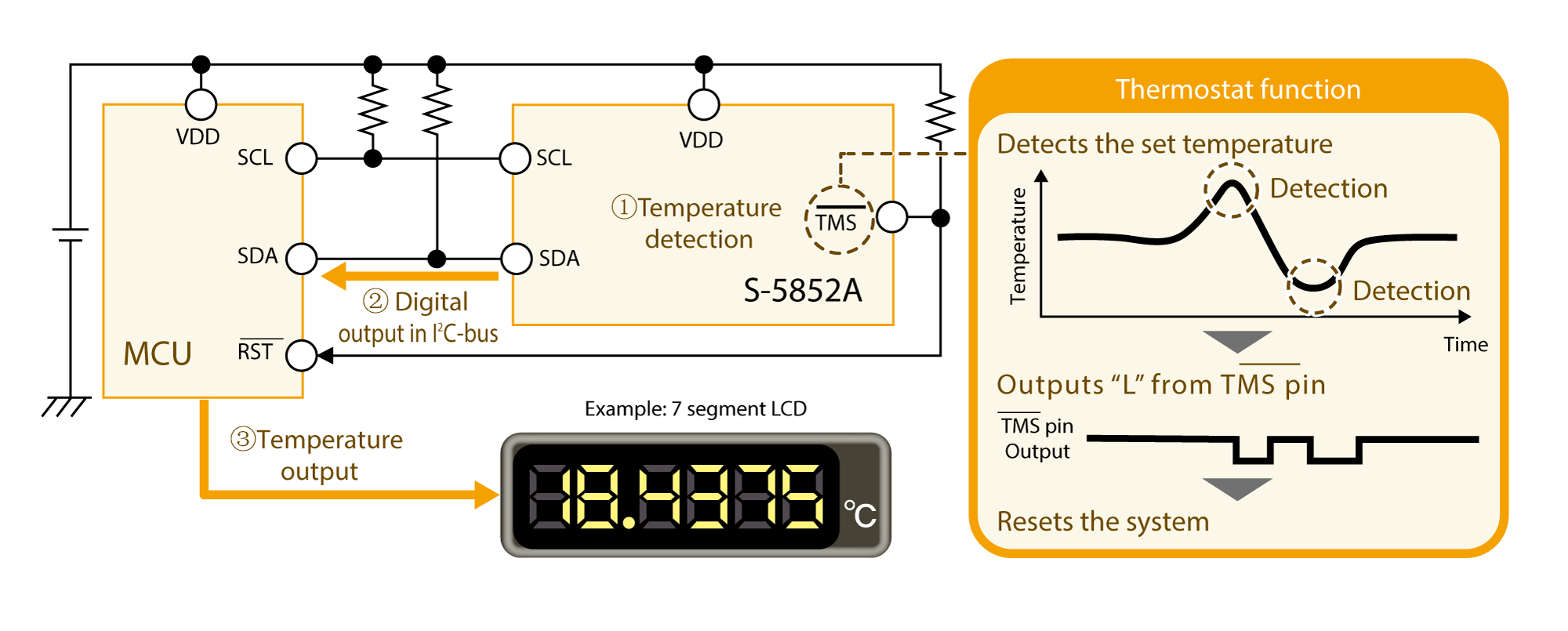

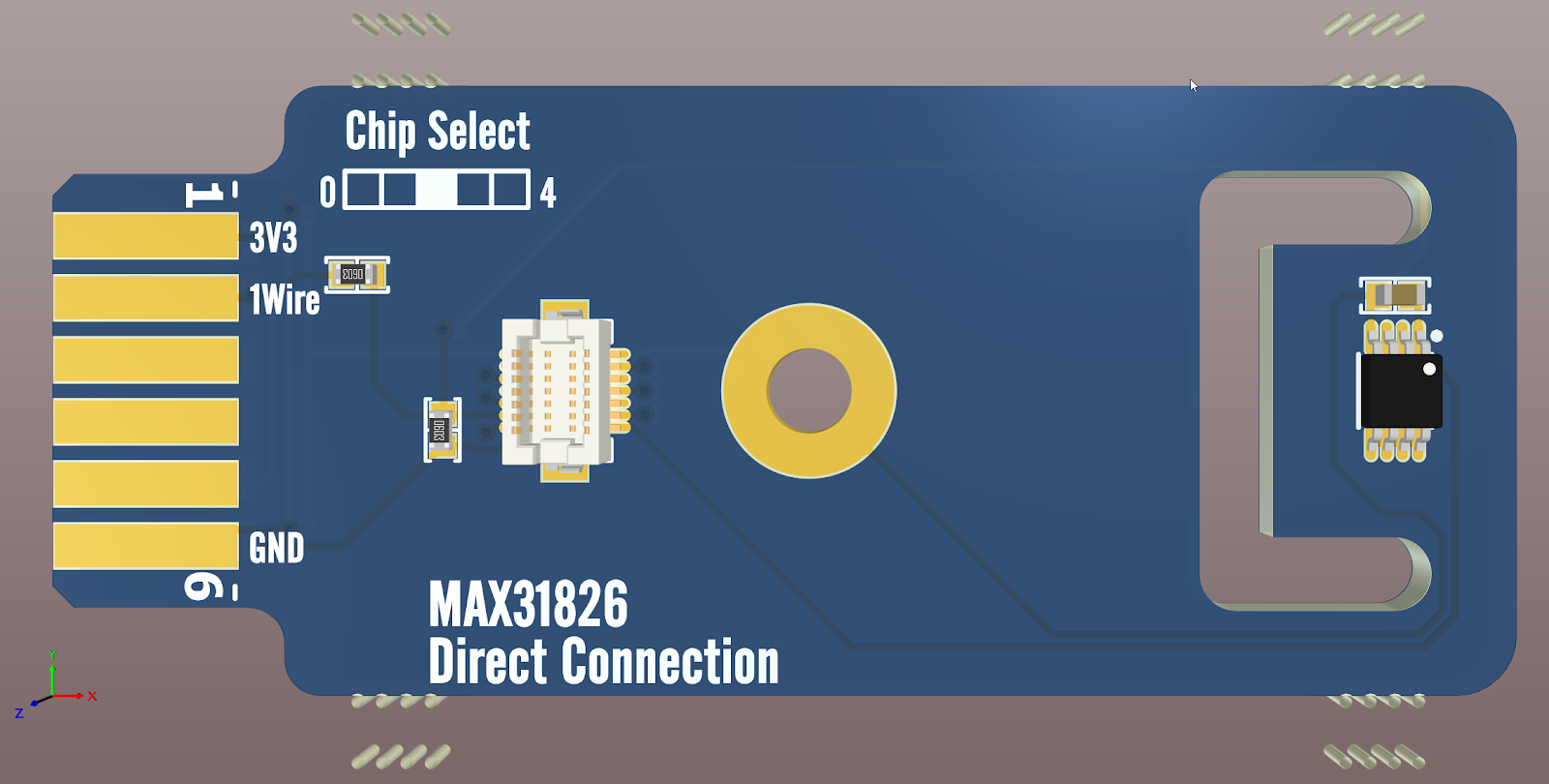

The evolution of temperature sensor circuits dates back several decades, with early sensors primarily focused on basic temperature measurement. Over time, the integration of semiconductor technology revolutionized the sector, allowing for the development of more precise and compact sensors. The introduction of digital temperature sensors in the late 20th century marked a significant milestone, enabling enhanced accuracy and easier integration into electronic systems.

As industries grew more reliant on automation and data analytics, the demand for advanced temperature sensing solutions surged. This shift has led to the development of smart sensors capable of communicating data wirelessly, further expanding their applications across various sectors. Today, temperature sensor circuits are integral to numerous industries, reflecting their critical role in ensuring operational efficiency and safety.

Understanding this historical context helps B2B buyers appreciate the advancements in technology and the ongoing evolution of sensor applications, equipping them to make informed sourcing decisions that align with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of temperature sensor circuit

-

How do I select the right temperature sensor circuit for my application?

Choosing the right temperature sensor circuit involves assessing your specific application requirements, including the temperature range, accuracy, response time, and environmental conditions. Consider whether you need a contact or non-contact sensor, as well as the required output signal (analog or digital). Evaluate the compatibility with your existing systems and whether the sensor’s specifications align with your operational needs. Consulting with suppliers about customization options can also help ensure that the sensor fits your unique application. -

What are the most common types of temperature sensor circuits?

The most common types of temperature sensor circuits include thermocouples, thermistors, and resistance temperature detectors (RTDs). Thermocouples are ideal for high-temperature applications due to their wide range and durability. Thermistors provide high sensitivity and are often used in consumer electronics. RTDs are known for their accuracy and stability, making them suitable for industrial applications. The choice of sensor will depend on factors such as the temperature range, required precision, and response time. -

How can I ensure the quality of temperature sensor circuits from suppliers?

To ensure quality, assess suppliers based on their certifications, such as ISO 9001, which indicates a commitment to quality management. Request samples for testing before making bulk purchases to evaluate performance under your specific conditions. Ask about the supplier’s quality assurance processes, including testing methods and traceability of components. Engaging in third-party audits or relying on industry reviews can also provide insights into the supplier’s reliability and product quality. -

What is the minimum order quantity (MOQ) for temperature sensor circuits?

MOQs can vary significantly between suppliers, often depending on the type of sensor and manufacturing processes involved. Some suppliers may offer low MOQs for standard products, while custom-designed sensors might require higher quantities to be economically viable. It’s essential to discuss your needs with potential suppliers to understand their MOQ policies and explore options for smaller orders if necessary. Negotiating terms upfront can lead to more flexible arrangements. -

What payment terms should I expect when sourcing temperature sensor circuits internationally?

Payment terms can vary widely depending on the supplier’s policies and the nature of your agreement. Common terms include advance payment, letter of credit, or payment upon delivery. For first-time orders, suppliers may request partial upfront payment to mitigate risk. It’s advisable to clarify payment terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection. -

How long does shipping typically take for temperature sensor circuits?

Shipping times can vary based on the supplier’s location, shipping method, and customs clearance processes. Generally, express shipping may take 3-7 days, while standard shipping could range from 2-4 weeks. It’s important to discuss shipping options with your supplier, factoring in lead times for production and potential delays at customs. Establishing a clear timeline will help you plan your project more effectively and manage expectations. -

What are the options for customizing temperature sensor circuits?

Customization options can include changes in sensor specifications, such as temperature range, output signal types, and physical form factors. Many suppliers offer tailored solutions to meet specific application needs. It’s beneficial to communicate your requirements clearly and inquire about the design and prototyping process. Keep in mind that customization may affect lead times and pricing, so it’s essential to discuss these factors during the initial conversations. -

How can I verify the reliability of a supplier when sourcing temperature sensor circuits?

To verify supplier reliability, conduct thorough research, including checking customer reviews and references. Request documentation of certifications and quality control processes. Engaging with suppliers through direct communication can provide insights into their responsiveness and professionalism. Additionally, consider visiting their manufacturing facilities if possible or using third-party inspection services to assess their operations and capabilities before committing to a partnership.

Top 6 Temperature Sensor Circuit Manufacturers & Suppliers List

1. Analog – Thermistor-Based Temperature Sensing System

Domain: analog.com

Registered: 1990 (35 years)

Introduction: Thermistor-based temperature sensing system; NTC thermistors measure temperature from –80°C to +150°C; nominal resistances at 25°C range from a few ohms to 10 MΩ; advantages include high sensitivity, fast response time, and simple 2-wire configuration; challenges include signal conditioning, analog-to-digital conversion, linearization, and compensation; comparison with RTDs shows RTDs cover –200°C…

2. Dwyer Omega – IC Temperature Sensors

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: IC Temperature Sensors are two terminal integrated circuit temperature transducers that produce an output current proportional to absolute temperature. They have a small package with low thermal mass and fast response time. Typical temperature range is -55 to 150°C (-58 to 302°F). Outputs can be analog or digital. Voltage Output IC Sensors typically provide 10mV per degree C, with nominal output c…

3. SparkFun – TMP36 Temperature Sensor Project

Domain: learn.sparkfun.com

Registered: 2002 (23 years)

Introduction: Circuit 9: Temperature Sensor

– Purpose: Create a DIY environmental monitor or weather station using the TMP36 temperature sensor.

– Parts Needed:

– 1x Breadboard

– 1x SparkFun RedBoard

– 3x Jumper Wires

– 1x TMP36 Temperature Sensor

– Alternative Parts (if Tinker Kit not available):

– SparkFun RedBoard Qwiic – $21.95

– Breadboard – Self-Adhesive (White) – $6.25

– Temperature Sensor …

4. Reddit – LM35 Temperature Sensor Circuit Issues

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Temperature sensor circuit using LM35; designed to turn on a fan when temperature exceeds 38C; issues with fan not turning off; suspected fried LM35 sensor; circuit connections double-checked; no voltage output from LM35 when measured.

5. Instructables – TMP36 Analog Temperature Sensor

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Temperature Sensor: TMP36

– Type: Analog temperature sensor

– Measurement Technique: Solid-state, voltage change across a diode

– Size: TO-92 package (approximately 0.2″ x 0.2″ x 0.2″) with three leads

– Price: $2.00

– Temperature Range: -40 degrees C to 150 degrees C / -40 degrees F to 302 degrees F

– Output Range: 0.1V (-40 degrees C) to 2.0V (150 degrees C), accuracy decreases after 125 degrees…

6. Circuit Digest – Simple Heat Sensor Circuit

Domain: circuitdigest.com

Registered: 2015 (10 years)

Introduction: Simple Heat Sensor Circuit using Transistor BC547. Components include: Transistor BC547, Diode 1N4148, Variable Resistor (1k ohm). The circuit detects temperature changes by monitoring the PN junction of the transistor, which conducts more as temperature increases. Sensitivity can be adjusted with the variable resistor. The circuit can illuminate an LED or activate a buzzer when the temperature ex…

Strategic Sourcing Conclusion and Outlook for temperature sensor circuit

In conclusion, the strategic sourcing of temperature sensor circuits presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging advanced technologies and supplier partnerships, businesses can enhance product reliability and operational efficiency while meeting diverse market demands. It is essential to prioritize suppliers that not only offer competitive pricing but also demonstrate commitment to quality and innovation.

The value of strategic sourcing extends beyond cost savings; it fosters long-term relationships that drive mutual growth and sustainability. As industries increasingly adopt IoT and automation, the demand for precision temperature sensing will continue to rise, making it imperative for buyers to align with suppliers who can provide not just products, but comprehensive solutions tailored to their unique needs.

Looking ahead, we encourage B2B buyers to actively seek out partnerships with manufacturers and distributors who are at the forefront of technological advancements in temperature sensing. By doing so, you can position your business for success in an evolving marketplace. Engage with potential suppliers today to explore innovative solutions that will elevate your operations and drive competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to temperature sensor circuit

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.