Top 5 Plastic C Channel Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plastic c channel

In today’s competitive landscape, international B2B buyers face the daunting challenge of sourcing high-quality plastic C channels that meet specific project requirements while remaining cost-effective. As industries expand globally, understanding the diverse applications and specifications of plastic C channels becomes essential for ensuring optimal functionality and compliance. This guide serves as a comprehensive resource, covering various types of plastic C channels, their applications across different sectors, and the intricacies of supplier vetting.

By delving into the nuances of material selection, dimensions, and customization options, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—to make informed purchasing decisions. Each section is designed to provide actionable insights that facilitate seamless procurement processes, ensuring that businesses can enhance their product offerings while adhering to budget constraints.

Moreover, the guide addresses critical factors such as cost analysis, lead times, and quality assurance, equipping buyers with the knowledge to navigate the complexities of the global market. With the right information at hand, businesses can confidently select suppliers who not only meet their specifications but also align with their long-term strategic goals.

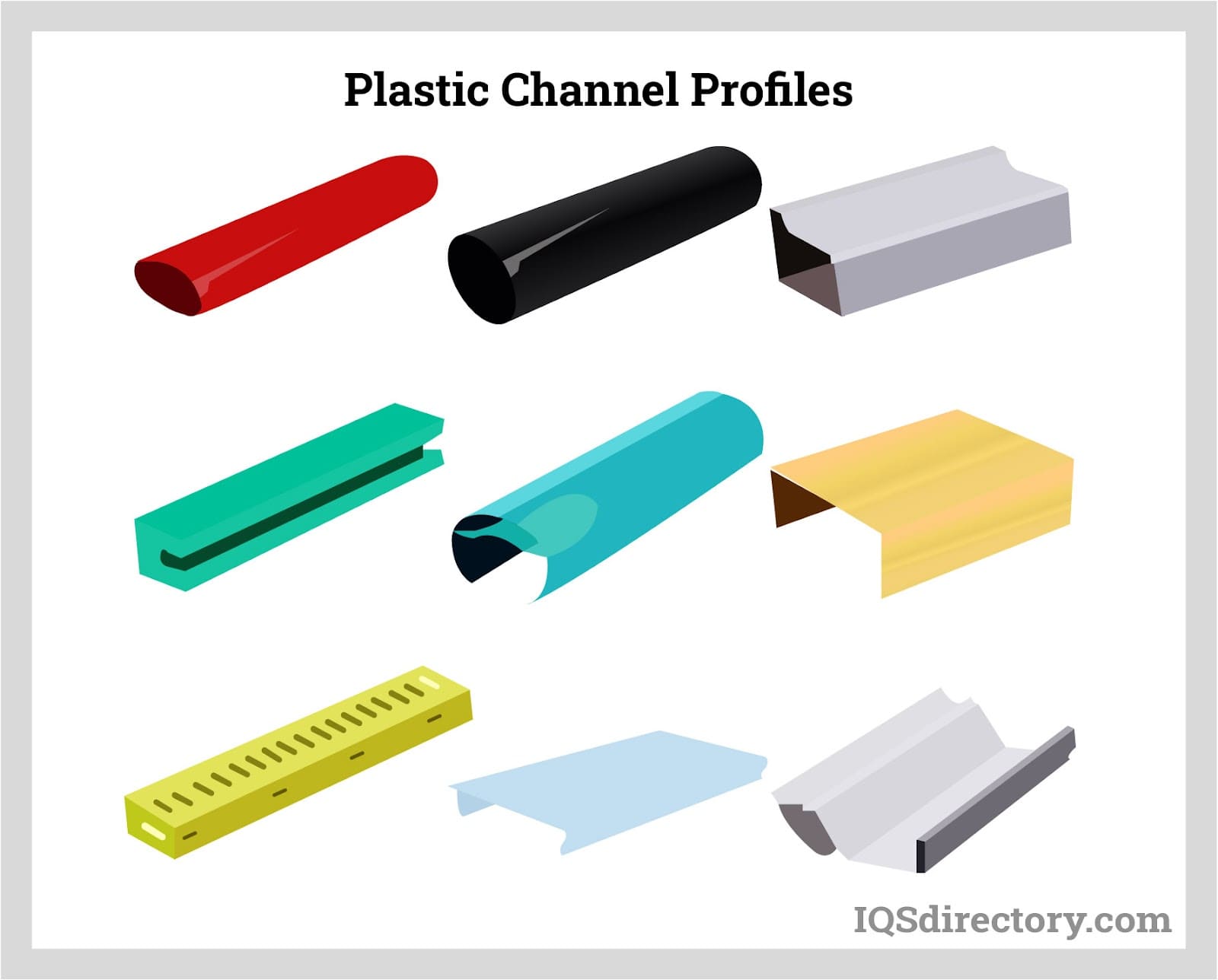

Understanding plastic c channel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid PVC C-Channel | Corrosion-resistant, durable, and versatile | Retail displays, signage, window trim | Pros: Long-lasting, low maintenance. Cons: Limited flexibility in extreme temperatures. |

| Impact Modified Acrylic C-Channel | High impact resistance and clarity | Display cases, POS systems, signage | Pros: Excellent visibility, strong impact resistance. Cons: Higher cost compared to other materials. |

| LDPE C-Channel | Lightweight, flexible, and cost-effective | Packaging, protective edges, signage | Pros: Economical, easy to handle. Cons: Less durable than rigid alternatives. |

| Polycarbonate C-Channel | High strength and UV resistance | Outdoor signage, industrial applications | Pros: Superior durability and weather resistance. Cons: More expensive, can be heavy. |

| ABS C-Channel | Good impact resistance and aesthetic finishes | Decorative trim, industrial applications | Pros: Attractive finish, good strength. Cons: Can warp under extreme heat. |

What are the Characteristics and Suitability of Rigid PVC C-Channels?

Rigid PVC C-Channels are renowned for their durability and resistance to corrosion, making them ideal for various applications such as retail displays and window trims. Their robust nature allows them to withstand harsh environments without compromising performance. For B2B buyers, the long lifespan and low maintenance requirements are significant advantages. However, it is essential to consider that rigid PVC may become brittle in extreme temperatures, which could affect its functionality in specific applications.

How Do Impact Modified Acrylic C-Channels Stand Out?

Impact Modified Acrylic C-Channels are designed for high visibility and superior impact resistance, making them perfect for display cases and point-of-sale systems. Their clarity allows for effective branding and product showcasing, which is crucial in retail environments. While they offer excellent protection against impacts, the higher price point may be a consideration for budget-conscious buyers. Buyers should also evaluate the specific application to ensure that the benefits justify the investment.

What Advantages Does LDPE C-Channel Offer?

LDPE C-Channels are lightweight and flexible, making them an economical choice for applications such as packaging and signage. Their cost-effectiveness is appealing to businesses looking to minimize expenses while maintaining functionality. However, buyers should be aware that while LDPE is easy to handle and install, it may not provide the same level of durability as more rigid materials. This trade-off is essential to consider based on the intended use and environmental conditions.

Why Choose Polycarbonate C-Channels for Outdoor Use?

Polycarbonate C-Channels are recognized for their high strength and UV resistance, making them suitable for outdoor signage and industrial applications. Their ability to withstand extreme weather conditions ensures longevity and reliability. However, the higher cost and weight of polycarbonate can be a deterrent for some buyers. Companies should assess their specific requirements and budget constraints when considering this option.

What Makes ABS C-Channels a Good Decorative Option?

ABS C-Channels are known for their aesthetic appeal and good impact resistance, making them suitable for decorative trim and industrial applications. They provide a polished look that can enhance the overall presentation of products. However, buyers must consider the potential for warping under extreme heat, which could affect performance in certain environments. Evaluating the application and environmental factors is crucial for making an informed purchasing decision.

Key Industrial Applications of plastic c channel

| Industry/Sector | Specific Application of Plastic C Channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Sign Holders and Display Fixtures | Enhances product visibility and organization in stores | Customization options for size, color, and material type |

| Construction | Window and Door Trim | Provides durable, corrosion-resistant finishing elements | Compliance with local building codes and regulations |

| Manufacturing | Protective Guards and Guides | Increases safety and efficiency in production environments | Material strength and resilience based on specific applications |

| Visual Merchandising | Graphic Holders and POS Displays | Improves customer engagement through effective signage | Availability of UV-resistant materials for outdoor displays |

| Logistics and Shipping | Packaging and Label Holders | Streamlines inventory management and tracking processes | Options for custom lengths and material for durability |

How Are Plastic C Channels Used in Retail Displays?

In the retail sector, plastic C channels are commonly utilized for sign holders and display fixtures. Their open-faced design allows for easy insertion of promotional materials, which enhances product visibility and organization. By using C channels, retailers can reduce the costs associated with adhesive labels while maintaining a professional appearance. For international buyers, it’s vital to consider customization options, such as size and color, to align with branding strategies and local market preferences.

What Role Do Plastic C Channels Play in Construction?

In the construction industry, plastic C channels serve as trim around windows and doors, providing a durable and corrosion-resistant finish. This application not only enhances the aesthetic appeal of buildings but also protects structural elements from environmental damage. Buyers from regions with varying climates should prioritize sourcing channels that meet local building codes and regulations, ensuring compliance and longevity of the installation.

How Are Plastic C Channels Essential in Manufacturing?

Manufacturers leverage plastic C channels as protective guards and guides in their production processes. These channels help in organizing equipment and safeguarding workers from potential hazards, thereby increasing safety and efficiency. When sourcing for manufacturing applications, businesses should focus on the material strength and resilience of the C channels to ensure they can withstand the rigors of industrial environments, particularly in high-demand sectors.

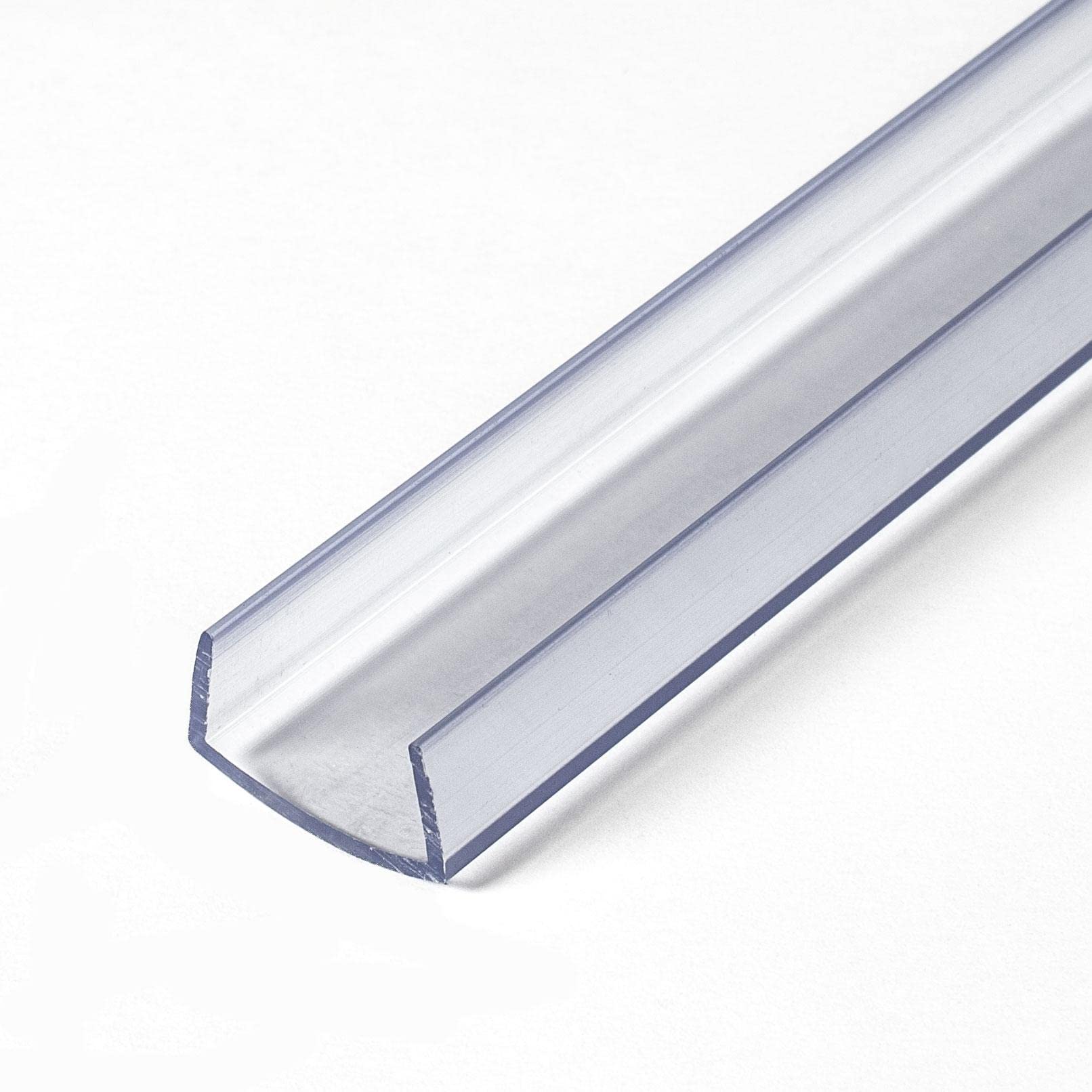

Illustrative image related to plastic c channel

Why Are Plastic C Channels Important for Visual Merchandising?

In visual merchandising, plastic C channels are used to hold graphics and point-of-sale (POS) displays. They facilitate effective customer engagement by providing clear and organized signage. For businesses targeting international markets, it’s essential to consider the availability of UV-resistant materials, especially for outdoor displays, to ensure that the signage remains vibrant and effective over time.

How Do Plastic C Channels Enhance Logistics and Shipping Operations?

Plastic C channels also find applications in logistics and shipping as packaging and label holders. They streamline inventory management and tracking processes by securely holding labels and tags in place. For companies involved in global trade, sourcing options that provide custom lengths and durable materials are crucial for ensuring that packaging withstands the challenges of international shipping.

3 Common User Pain Points for ‘plastic c channel’ & Their Solutions

Scenario 1: Sizing Issues Leading to Product Incompatibility

The Problem: A common challenge faced by B2B buyers is the complexity of selecting the correct size and specifications for plastic C channels. Many manufacturers offer a range of sizes and wall thicknesses, and buyers often find themselves overwhelmed by the options. This can lead to ordering channels that do not fit their intended applications, resulting in wasted resources and increased costs. For instance, a retailer may require a specific channel to hold signage, but if they select the wrong size, it can lead to poor display visibility and customer confusion.

The Solution: To mitigate sizing issues, it’s crucial for buyers to engage in thorough planning before placing orders. Start by defining the specific application and the requirements for the plastic C channel, including dimensions, load-bearing capacity, and material properties. Utilize tools such as CAD (Computer-Aided Design) software to visualize how the channel will fit into the existing setup. Additionally, when sourcing, work with suppliers that offer custom extrusion services. This allows you to specify exact dimensions and wall thicknesses tailored to your needs. Always request samples before finalizing large orders to ensure compatibility and performance.

Scenario 2: Material Selection Challenges Affecting Durability

The Problem: B2B buyers often struggle with selecting the right material for their plastic C channels, which can significantly affect the product’s durability and performance. For instance, in environments with high humidity or exposure to chemicals, using a standard PVC channel may lead to degradation and failure over time. This challenge is particularly pronounced in industries like retail or manufacturing, where the integrity of display and structural components is critical.

The Solution: To address material selection challenges, buyers should conduct a detailed analysis of the environment in which the C channels will be used. This includes considering factors such as temperature variations, exposure to UV light, and potential chemical interactions. Consult with suppliers who offer a variety of materials, such as HDPE for its chemical resistance or polycarbonate for its strength and UV stability. It may also be beneficial to request technical data sheets that provide information on material performance under specific conditions. Engaging in discussions with manufacturers about your specific use case can lead to tailored recommendations that enhance the longevity and reliability of your plastic C channels.

Scenario 3: Inefficiencies in Ordering and Supply Chain Disruptions

The Problem: Timely delivery of plastic C channels is vital for maintaining production schedules and project timelines. However, many B2B buyers experience delays due to inefficient ordering processes or supply chain disruptions, especially when sourcing from international suppliers. Such delays can lead to project bottlenecks, increased costs, and even the potential loss of client contracts.

The Solution: To combat ordering inefficiencies, buyers should establish strong relationships with reliable suppliers who understand the importance of timely delivery. When placing orders, use streamlined communication channels and clarify lead times upfront. Consider implementing a just-in-time (JIT) inventory system that allows for smaller, more frequent orders, reducing the risk of stockouts. Additionally, diversifying your supplier base can provide a safety net against regional disruptions. Utilize tools such as automated ordering systems or inventory management software to track stock levels and reorder points effectively, ensuring that you can respond swiftly to changes in demand without overstocking.

Strategic Material Selection Guide for plastic c channel

What Are the Key Properties of Common Materials Used for Plastic C Channels?

When selecting materials for plastic C channels, it is essential to consider the properties that influence product performance. Here, we analyze four common materials: Rigid PVC, Polycarbonate, ABS, and HDPE, focusing on their suitability for various applications in the international B2B market.

Rigid PVC: A Versatile Choice for Many Applications

Rigid PVC (Polyvinyl Chloride) is widely used in plastic C channels due to its excellent corrosion resistance and durability. It can withstand a temperature range of -15°C to 60°C, making it suitable for various environments.

Pros: Rigid PVC is cost-effective, easy to manufacture, and provides good impact resistance. It is also lightweight, which can reduce shipping costs.

Cons: However, it has limited UV resistance, which may lead to degradation in outdoor applications unless treated with additives.

Impact on Application: Rigid PVC is compatible with a range of media, including water and many chemicals, making it ideal for retail displays and signage.

Considerations for International Buyers: Compliance with ASTM and DIN standards is crucial, especially in regions like Europe where regulations are stringent. Buyers in Africa and South America may also look for local suppliers to reduce lead times.

Polycarbonate: High Strength and Impact Resistance

Polycarbonate is known for its exceptional strength and impact resistance, making it suitable for applications requiring durability. It can handle temperatures from -40°C to 120°C, providing versatility in extreme conditions.

Pros: Its high transparency and UV resistance make it an excellent choice for outdoor signage and protective barriers.

Cons: The manufacturing process can be more complex and costly compared to other materials, which may affect pricing.

Impact on Application: Polycarbonate is ideal for applications exposed to high impact or where visibility is critical, such as in safety equipment and display cases.

Considerations for International Buyers: Polycarbonate products should meet international safety standards, especially in the Middle East and Europe, where product certifications are often required.

ABS: Cost-Effective with Good Mechanical Properties

Acrylonitrile Butadiene Styrene (ABS) is another popular choice for plastic C channels, known for its good mechanical properties and ease of fabrication. It operates effectively within a temperature range of -20°C to 80°C.

Pros: ABS is lightweight, offers good impact resistance, and is relatively inexpensive, making it an attractive option for budget-conscious buyers.

Cons: Its chemical resistance is not as robust as PVC or polycarbonate, limiting its use in certain applications.

Impact on Application: ABS is suitable for indoor applications such as decorative trim and displays but may not be ideal for harsh environments.

Considerations for International Buyers: Buyers should ensure that ABS products comply with local regulations, particularly in Europe, where environmental standards can be stringent.

HDPE: Durable and Environmentally Friendly

High-Density Polyethylene (HDPE) is known for its excellent chemical resistance and durability. It can withstand temperatures from -40°C to 60°C, making it suitable for various applications.

Pros: HDPE is resistant to many chemicals and is recyclable, appealing to environmentally conscious buyers.

Cons: It can be more challenging to bond and fabricate compared to PVC and ABS, which may complicate manufacturing processes.

Impact on Application: HDPE is ideal for outdoor applications and environments exposed to moisture, such as marine settings.

Considerations for International Buyers: Compliance with international recycling standards is essential, especially in Europe where sustainability is a priority.

Summary Table of Material Selection for Plastic C Channels

| Material | Typical Use Case for Plastic C Channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid PVC | Retail displays, signage | Cost-effective and durable | Limited UV resistance | Low |

| Polycarbonate | Outdoor signage, protective barriers | High strength and UV resistance | Higher manufacturing cost | High |

| ABS | Decorative trim, indoor displays | Lightweight and inexpensive | Limited chemical resistance | Low |

| HDPE | Outdoor applications, marine settings | Excellent chemical resistance | Difficult to bond and fabricate | Medium |

This strategic material selection guide provides insights into the various materials available for plastic C channels, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic c channel

What Are the Key Stages in the Manufacturing Process of Plastic C Channels?

The manufacturing of plastic C channels involves several critical stages, each designed to ensure that the final product meets specific quality standards and performance criteria. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate thermoplastic materials, such as rigid PVC, HDPE, or polystyrene, based on the application requirements. Materials are sourced from reputable suppliers, ensuring they meet international quality standards. The materials are then compounded to achieve the desired properties, such as color and UV resistance, which is crucial for applications in outdoor signage or retail displays.

-

Forming: The forming process typically employs extrusion, where the prepared thermoplastic is heated and forced through a die to create the C channel shape. This method allows for continuous production and the ability to create complex profiles. Advanced techniques like co-extrusion can also be used to produce multi-layered channels, enhancing durability and aesthetic appeal.

-

Assembly: While plastic C channels are often produced as single extruded pieces, additional components may be assembled for specific applications. This can involve integrating label holders or graphic inserts. The assembly process must ensure that all components fit securely and function as intended, particularly in retail environments where visual merchandising is key.

-

Finishing: The finishing stage includes cutting the extruded C channels to specified lengths, as well as any necessary surface treatments. This may involve additional processes such as drilling, notching, or adding protective coatings to enhance durability. Quality checks are crucial in this phase to ensure that the dimensions and surface finishes meet the specifications.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) in the manufacturing of plastic C channels is fundamental to ensuring that products consistently meet or exceed customer expectations. Various international standards and industry-specific certifications guide the QA processes.

-

International Standards: Many manufacturers adhere to ISO 9001:2015 standards, which outline requirements for a quality management system (QMS). This certification ensures that a company has the processes in place to enhance customer satisfaction through effective system management. Compliance with ISO standards is often a requirement for B2B buyers, especially in regions like Europe and the Middle East.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials upon delivery to ensure they meet specified criteria before production begins.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the process and identify any deviations from quality standards. This proactive approach helps catch potential issues early.

– Final Quality Control (FQC): After production, the finished C channels undergo final inspections to verify that they meet all specifications, including dimensional accuracy and surface quality. -

Testing Methods: Common testing methods employed during QC include tensile strength tests, impact resistance tests, and UV exposure tests. These assessments ensure that the plastic C channels will perform as expected in real-world applications. Additionally, suppliers may use advanced equipment for non-destructive testing to evaluate the structural integrity of the products.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential to mitigate risks and ensure product reliability.

-

Supplier Audits: Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. This involves visiting the manufacturing facility to evaluate the QMS, production processes, and compliance with international standards.

-

Quality Reports: Requesting quality assurance reports can provide insight into a supplier’s performance metrics. These reports typically include data on defect rates, inspection results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These organizations can conduct independent assessments of the manufacturing processes and the final products, providing unbiased verification of quality claims.

-

Certifications and Compliance: B2B buyers should look for suppliers that hold relevant certifications, such as ISO 9001 and CE marking, indicating compliance with European safety standards. These certifications serve as a benchmark for quality and reliability.

What Are the Challenges and Considerations for International B2B Buyers?

When sourcing plastic C channels internationally, buyers must consider several factors that may impact quality and delivery.

-

Cultural Differences and Communication: Effective communication is vital in establishing quality expectations. Cultural differences may affect how quality standards are interpreted, so it’s essential to ensure that both parties have a clear understanding of requirements.

-

Regulatory Compliance: Different regions may have varying regulations regarding materials and product safety. Buyers should ensure that suppliers are knowledgeable about and compliant with the specific regulations in their target markets, especially for products intended for use in Europe or North America.

-

Logistics and Supply Chain: The complexity of international logistics can introduce risks related to product quality during transportation. Buyers should work with suppliers who have robust logistics management practices to minimize the risk of damage or loss of quality during shipping.

-

Sustainability Practices: As global awareness of environmental issues increases, buyers may also prioritize suppliers who implement sustainable manufacturing practices. This can include using recycled materials, minimizing waste, and ensuring energy-efficient production processes.

In summary, understanding the manufacturing processes and quality assurance measures for plastic C channels is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic c channel’

In the dynamic world of B2B procurement, sourcing the right materials can significantly impact the success of your projects. This guide provides a practical checklist for international buyers looking to procure plastic C channels, ensuring that you cover all essential aspects before making a purchase.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the plastic C channels you require. This includes dimensions, wall thickness, and the specific type of plastic (e.g., PVC, HDPE, or ABS) that suits your application. Providing precise specifications helps suppliers understand your needs and ensures compatibility with your projects.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in plastic C channels. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay attention to their reputation and experience in the market, as established suppliers are more likely to meet your quality and delivery expectations.

Step 3: Verify Supplier Certifications

It’s essential to ensure that your chosen suppliers hold relevant certifications. Look for ISO certifications or compliance with industry standards, which indicate a commitment to quality and safety. Certifications provide assurance that the supplier follows best practices in manufacturing and quality control.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the plastic C channels. This step allows you to evaluate the material quality, finish, and dimensions to ensure they meet your specifications. Testing samples also provides an opportunity to assess the supplier’s responsiveness and willingness to accommodate your needs.

Step 5: Evaluate Supplier Capabilities

Assess the capabilities of potential suppliers in terms of production capacity, lead times, and customization options. Inquire about their manufacturing processes, including whether they can handle custom extrusions if your project requires specific features. Understanding these aspects helps you gauge if the supplier can meet your demands.

Step 6: Review Pricing and Terms of Sale

Once you have shortlisted suppliers, request detailed quotations that outline pricing, payment terms, and shipping options. Comparing prices helps you find competitive offers, but also consider the total cost of ownership, including shipping and potential tariffs. Clear terms of sale ensure you know what to expect throughout the transaction.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful procurement process. Ensure that the supplier has a responsive customer service team that can assist you with inquiries and issues that may arise. Establishing clear communication channels fosters a strong partnership and can lead to better support throughout your project lifecycle.

By following this checklist, you can streamline your sourcing process for plastic C channels and ensure that you partner with reliable suppliers who meet your technical and business needs.

Comprehensive Cost and Pricing Analysis for plastic c channel Sourcing

What Are the Key Cost Components in Plastic C Channel Sourcing?

When considering sourcing plastic C channels, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of raw materials significantly impacts the cost. Common materials include LDPE, HDPE, PVC, and ABS, each varying in price and properties. For example, rigid PVC is often preferred for its corrosion resistance and durability, but it may come at a higher cost compared to lower-grade plastics.

-

Labor and Manufacturing Overhead: Labor costs depend on the region and the complexity of the extrusion process. Manufacturing overhead, including energy costs and equipment maintenance, also plays a role. Efficient production facilities can minimize these costs, which is why buyers should consider suppliers with advanced manufacturing capabilities.

-

Tooling: Custom tooling can incur significant upfront costs, but many manufacturers offer no-cost tooling options for standard profiles. Understanding tooling costs is essential, especially when customizing dimensions or designs, as these can affect both lead times and pricing.

-

Quality Control: Ensuring that the products meet industry standards and specifications incurs additional costs. Suppliers with ISO certifications often charge a premium, but the investment can lead to higher quality and reliability, which is crucial for maintaining brand integrity.

-

Logistics: Freight and shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Factors such as Incoterms, which define responsibilities for shipping, can also affect the overall cost structure. Buyers should consider local suppliers to reduce logistics costs and lead times.

-

Margins: Profit margins can vary depending on the supplier’s market position and the overall demand for plastic C channels. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Plastic C Channel Costs?

Several factors influence the pricing of plastic C channels:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can lead to significant cost savings. Suppliers often provide tiered pricing based on order volume, so understanding MOQ requirements is essential for optimizing costs.

-

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should assess whether standard options meet their needs before opting for custom solutions, as customization often involves additional tooling and production time.

-

Material Quality and Certifications: Higher-quality materials and products with certifications (like ISO) typically command higher prices. Buyers should weigh the benefits of these features against their budget and application requirements.

-

Supplier Factors: Supplier reputation, reliability, and customer service can influence pricing. Established suppliers may charge more due to their proven track record, but the assurance of quality and service can justify the investment.

-

Incoterms and Payment Terms: The choice of Incoterms can impact total costs, particularly regarding shipping responsibilities. Negotiating favorable payment terms can also enhance cash flow management for buyers.

What Tips Can Help Buyers Optimize Costs in Plastic C Channel Sourcing?

B2B buyers can employ various strategies to enhance cost efficiency:

-

Negotiation: Always negotiate pricing based on volume and long-term relationships. Suppliers may offer discounts for repeat orders or larger quantities, which can significantly reduce costs.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the total cost of ownership, including maintenance, durability, and potential downtime. Investing slightly more upfront in higher-quality materials can save money in the long run.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. Factors such as currency fluctuations, import tariffs, and local regulations can impact pricing and should be factored into the overall cost analysis.

-

Supplier Diversification: Engaging multiple suppliers can foster competition and lead to better pricing. It also mitigates risks associated with supply chain disruptions.

-

Market Research: Stay informed about market trends and pricing fluctuations. This knowledge can empower buyers during negotiations and help them identify the best times to purchase.

By understanding the cost structure, price influencers, and strategic approaches to sourcing plastic C channels, B2B buyers can make informed decisions that align with their budgetary constraints and quality requirements.

Alternatives Analysis: Comparing plastic c channel With Other Solutions

Exploring Viable Alternatives to Plastic C Channels

In the quest for effective solutions for organizational and structural applications, businesses often evaluate multiple product options. Plastic C channels are widely used for their versatility and ease of use, but there are alternative solutions worth considering. This analysis compares plastic C channels with two viable alternatives: Aluminum Channels and Acrylic Channels.

Illustrative image related to plastic c channel

Comparison Table

| Comparison Aspect | Plastic C Channel | Aluminum Channel | Acrylic Channel |

|---|---|---|---|

| Performance | Good structural integrity; corrosion-resistant | High strength-to-weight ratio; durable | Lightweight; good clarity; moderate strength |

| Cost | Generally lower cost | Higher initial investment | Moderate cost |

| Ease of Implementation | Simple to install; lightweight | Requires special tools for cutting and installation | Easy to install, but may require additional support |

| Maintenance | Low maintenance; resistant to moisture | Low maintenance; can corrode if not treated | Requires cleaning to maintain clarity |

| Best Use Case | Retail displays, signage, and protective trim | Structural applications, frameworks, and supports | Display cases and decorative applications |

In-Depth Analysis of Alternatives

1. Aluminum Channels

Aluminum channels are renowned for their durability and strength, making them suitable for structural applications where weight and load-bearing capacity are essential. They are often used in construction and manufacturing settings. The initial cost of aluminum channels is typically higher than plastic C channels, and installation can require specialized tools, which may increase overall project costs. However, their longevity and resistance to wear can justify the investment, particularly in environments where heavy-duty support is necessary.

2. Acrylic Channels

Acrylic channels offer a lightweight alternative that excels in clarity and aesthetics, making them ideal for display cases and signage where visibility is crucial. They are relatively easy to install, though larger installations may require additional structural support to prevent sagging. Acrylic channels are moderately priced, placing them between plastic and aluminum options. Maintenance primarily involves regular cleaning to prevent scratches and maintain clarity, which may be a consideration for businesses focused on presentation and visual appeal.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating whether to use plastic C channels or one of the alternatives, B2B buyers should consider several factors including the specific application requirements, budget constraints, and long-term maintenance considerations. Plastic C channels are often the most cost-effective solution for point-of-purchase displays and lightweight applications, while aluminum channels may be better suited for structural integrity in demanding environments. Acrylic channels shine in aesthetic applications where visibility and presentation are paramount. By carefully assessing these elements, businesses can select the most appropriate channel solution that aligns with their operational goals and budgetary limitations.

Essential Technical Properties and Trade Terminology for plastic c channel

What Are the Key Technical Properties of Plastic C Channels for B2B Buyers?

Understanding the technical properties of plastic C channels is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications:

Illustrative image related to plastic c channel

-

Material Grade

The material grade determines the channel’s durability, flexibility, and resistance to environmental factors. Common materials include Rigid PVC, LDPE, HDPE, and ABS. Each material has unique properties; for instance, Rigid PVC is known for its strength and corrosion resistance, making it suitable for outdoor applications. Selecting the right material is crucial for ensuring the longevity and performance of the application. -

Wall Thickness

Wall thickness affects the strength and load-bearing capacity of the C channel. Options typically range from 0.035 inches to 0.1 inches or more. Thicker walls provide increased stability and are better suited for heavy-duty applications, while thinner walls may be sufficient for lightweight uses. Understanding wall thickness helps buyers match the product to their specific application requirements. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. This is critical in ensuring that the C channel fits seamlessly into existing structures or systems. Tighter tolerances may be necessary for precision applications, while looser tolerances could be acceptable for less demanding environments. Buyers should consider tolerance requirements to avoid installation issues. -

Color and Finish Options

Plastic C channels come in various colors and finishes, which can enhance aesthetic appeal or match branding needs. Custom color options are often available, allowing businesses to choose a look that complements their design. This can be particularly important in retail or visual merchandising applications where presentation plays a key role. -

Customizability

Many manufacturers offer custom extrusion services, allowing buyers to specify dimensions, materials, and other properties tailored to their needs. This flexibility is essential for projects requiring unique specifications or those with specific operational environments. Customizability can significantly affect project timelines and costs, making it a vital consideration for B2B buyers.

What Are Common Trade Terms Related to Plastic C Channels?

Familiarity with industry jargon can streamline communication and negotiation. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who can meet their specific requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request pricing and terms from suppliers. This document typically outlines the specifications and quantities needed, allowing suppliers to provide accurate quotes. Using RFQs can lead to more competitive pricing and better supplier relationships. -

Incoterms (International Commercial Terms)

These are predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks in global transactions, ensuring smoother logistics. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. Understanding lead times is essential for project planning, especially in industries with tight schedules. It can also influence a buyer’s decision when selecting suppliers, as shorter lead times may be more favorable.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing plastic C channels, ensuring they choose the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the plastic c channel Sector

What Are the Key Market Dynamics and Trends in the Plastic C Channel Sector?

The global plastic C channel market is experiencing significant growth, driven by the increasing demand across various industries such as retail, construction, and manufacturing. The versatility of plastic C channels, which can be utilized for applications ranging from point-of-purchase displays to structural components, is a key factor in their rising popularity. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers are increasingly looking for customizable solutions that can meet specific requirements, reflecting a broader trend towards personalization in manufacturing.

Emerging technologies in extrusion processes, such as co-extrusion and multi-material capabilities, are revolutionizing how plastic C channels are produced. These advancements enable manufacturers to offer a wider variety of materials and finishes, catering to the diverse needs of international buyers. For instance, buyers from Germany may prioritize durability and aesthetic appeal, while those in Vietnam might focus on cost-effectiveness and ease of sourcing. Additionally, the rise of e-commerce platforms is making it easier for B2B buyers to compare products, prices, and suppliers globally, enhancing market accessibility and competitiveness.

How Is Sustainability Impacting the Sourcing of Plastic C Channels?

Sustainability has become a crucial consideration in the sourcing of plastic C channels, as businesses are increasingly aware of their environmental footprint. The production of plastic can have significant environmental impacts, leading to a demand for ethical sourcing practices. B2B buyers are now prioritizing suppliers that adopt sustainable manufacturing processes and use recycled or biodegradable materials. This shift is particularly pronounced among international buyers from Europe, where stringent regulations and consumer preferences are pushing for greener alternatives.

Certifications such as ISO 14001 for environmental management systems or materials that carry labels indicating they are sourced from recycled content can significantly influence purchasing decisions. Additionally, the use of ‘green’ materials, such as bio-based plastics or recycled polymers, is becoming a selling point for suppliers. Buyers are encouraged to seek out suppliers that provide transparency in their supply chains, ensuring that ethical practices are upheld throughout the production process. This not only aligns with corporate social responsibility goals but also enhances brand reputation in an increasingly eco-conscious market.

What Is the Historical Evolution of Plastic C Channels in B2B Markets?

The plastic C channel has evolved significantly since its inception, originally developed for simple structural applications. Over the decades, advancements in extrusion technology have allowed for greater versatility in design and function. The introduction of various materials, including PVC, polycarbonate, and polypropylene, has expanded the potential applications of plastic C channels, making them suitable for everything from retail displays to construction components.

In the late 20th century, the rise of consumerism and retail marketing led to an increased demand for visually appealing point-of-purchase displays, further driving innovation in the plastic C channel sector. Today, the focus has shifted towards customization and sustainability, with manufacturers responding to the growing demand for tailored solutions and environmentally friendly materials. This evolution highlights the sector’s adaptability to market needs and sets the stage for future developments in plastic C channel applications.

Overall, understanding these market dynamics, sustainability practices, and the historical context can empower international B2B buyers to make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic c channel

-

How do I ensure the quality of plastic C channels before purchasing?

To ensure the quality of plastic C channels, request samples from potential suppliers. Evaluate the materials used, such as PVC, HDPE, or ABS, as these influence durability and application suitability. Verify certifications like ISO 9001 to ensure compliance with quality standards. Additionally, inquire about their manufacturing processes and any quality assurance measures they have in place. Establishing a clear communication channel with the supplier can also help address any concerns regarding product specifications and performance. -

What are the most common applications for plastic C channels in various industries?

Plastic C channels are versatile and commonly used in retail for signage and label holders, offering an organized display for point-of-purchase materials. In construction, they serve as trim or protective edges around windows and doors due to their corrosion resistance. Other applications include use in visual merchandising, packaging, and as structural components in manufacturing equipment. Understanding the specific application can help you choose the right material and specifications for your needs. -

What customization options are available for plastic C channels?

Most manufacturers offer extensive customization options for plastic C channels, including variations in size, wall thickness, color, and material type. You can specify dimensions to fit particular applications or choose materials that meet environmental or durability standards. It’s advisable to discuss your project requirements with suppliers and request custom prototypes to evaluate fit and functionality before placing a bulk order. -

What are the minimum order quantities (MOQs) for plastic C channels?

Minimum order quantities for plastic C channels can vary significantly among suppliers, often ranging from 100 to 1,000 units, depending on the complexity of the design and production capabilities. Some manufacturers may have lower MOQs for standard sizes or stock items. It’s beneficial to negotiate MOQs based on your project needs, especially if you’re considering a long-term partnership or need custom extrusions. -

How do payment terms work when sourcing plastic C channels internationally?

Payment terms when sourcing plastic C channels internationally typically involve a combination of upfront deposits and final payments upon delivery. Common practices include a 30% deposit with the order, followed by the remaining balance before shipment. Some suppliers may also offer payment via letters of credit or escrow services for larger orders. Always clarify payment terms upfront to avoid misunderstandings and ensure smooth transactions. -

What logistics considerations should I keep in mind when importing plastic C channels?

When importing plastic C channels, consider shipping costs, customs duties, and delivery times. Ensure that the supplier provides accurate shipping dimensions and weight for proper logistics planning. It’s also wise to work with a freight forwarder familiar with international trade regulations to streamline customs clearance. Understanding the potential for delays in transit due to local regulations or shipping routes can help you manage your inventory more effectively. -

How do I vet suppliers for plastic C channels?

Vetting suppliers for plastic C channels involves researching their reputation in the industry, checking references, and reviewing customer feedback. Requesting certifications and quality assurance documentation can also provide insights into their manufacturing practices. Conducting site visits, if possible, allows you to evaluate their production capabilities firsthand. Establishing a trial order can further help assess the supplier’s reliability and product quality before committing to larger orders. -

What are the environmental considerations when sourcing plastic C channels?

When sourcing plastic C channels, consider the environmental impact of the materials used. Many manufacturers now offer eco-friendly options, such as recycled plastics or biodegradable materials. Inquire about the supplier’s sustainability practices, including waste management and energy efficiency in production. Understanding the lifecycle of the materials can help you align your sourcing strategy with environmental standards and corporate social responsibility goals.

Top 5 Plastic C Channel Manufacturers & Suppliers List

1. Preferred Plastics – Custom Plastic Channels

Domain: preferredplastics.com

Registered: 2002 (23 years)

Introduction: Custom plastic channels including U-Channels, H-Channels, J-Channels, C-Channels, L-Channels, and custom shapes. Used in construction and manufacturing equipment industries. Capabilities include profile extrusion, co-extrusion, crosshead, and tube extrusion. Manufacturing facilities totaling 200,000 square feet with 38 advanced extruders. Offers a wide range of thermoplastic materials such as PVC,…

2. Zoro – UHMW Polyethylene C Channel

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Plastic C Channel products available on Zoro.com include various sizes and types, primarily made from UHMW polyethylene and clear materials. Key products include: 1. Zoro Select UHMW Polyethylene C Channel Stock, 120 in L, White – Prices range from $51.29 to $118.99 depending on the specific item. 2. Azar Displays Clear C-Channels in various heights (0.5″ to 4″) and lengths (6 ft), sold in packs o…

3. Grainger – Plastic U-Shaped Channels

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Plastic U-Shaped Channels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Outwater – Plastic Angle Mouldings

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater – Plastic Angle Mouldings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Plastic U Channel – Versatile Options

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Plastic U Channel available in various sizes and colors, including black and clear. Features include easy installation, waterproof, and heat resistant options. Manufacturer warranties range from 6 months to 5 years. Products are primarily made in China and the United States. Condition options include new and used. Price range varies from under $13 to over $25. Shipping options include free interna…

Strategic Sourcing Conclusion and Outlook for plastic c channel

Strategic sourcing in the realm of plastic C-channels offers a multitude of benefits for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By prioritizing quality, customization, and supplier relationships, organizations can significantly enhance their operational efficiency and product offerings. The versatility of plastic C-channels, utilized across various industries from retail displays to construction, underscores their value as essential components in modern manufacturing and merchandising.

Engaging with suppliers who provide tailored solutions and a broad range of materials ensures that businesses can meet specific project requirements while maintaining cost-effectiveness. Emphasizing strategic sourcing allows companies to leverage competitive pricing, superior quality, and innovative materials, which are crucial in today’s fast-paced market.

Looking ahead, the demand for sustainable and customizable plastic solutions is expected to rise, presenting an opportunity for businesses to align with forward-thinking suppliers. As you evaluate your sourcing strategies, consider reaching out to manufacturers who can offer insights and innovative products tailored to your needs. Start building those vital partnerships today to secure a competitive edge in the evolving landscape of plastic C-channels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.