Everything You Need to Know About Conveyor Belt Components Sourcing in 2025

Introduction: Navigating the Global Market for conveyor belt components

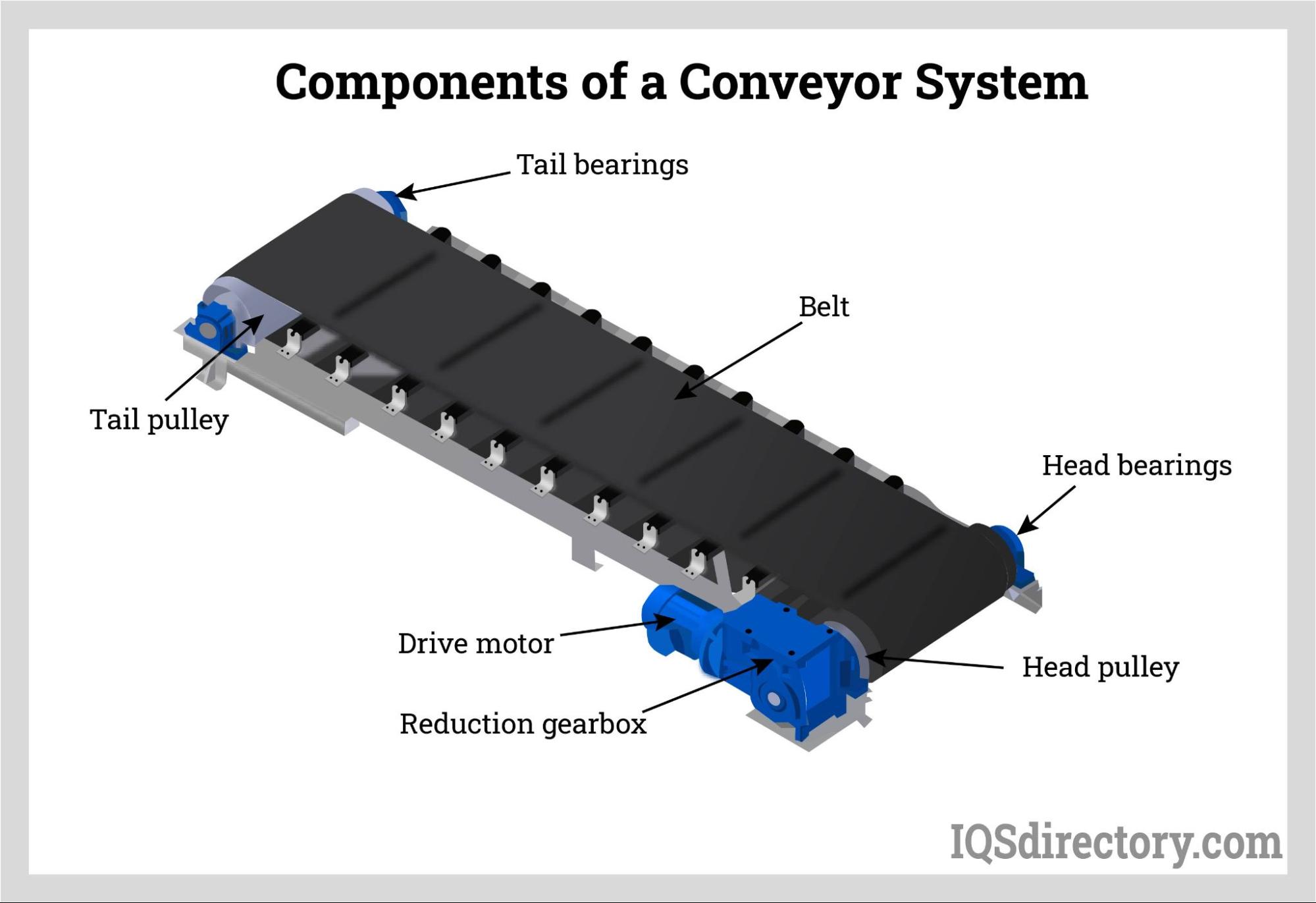

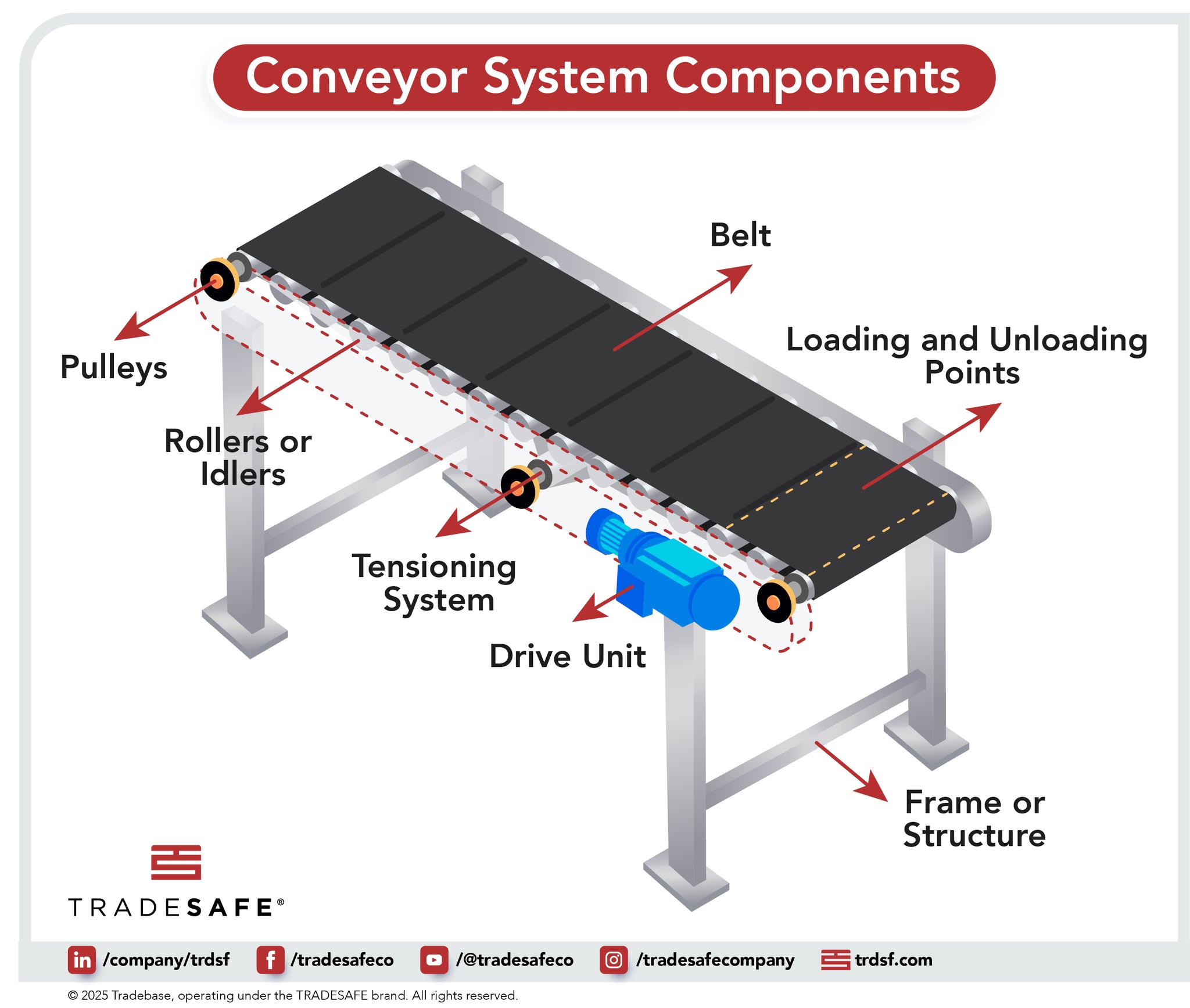

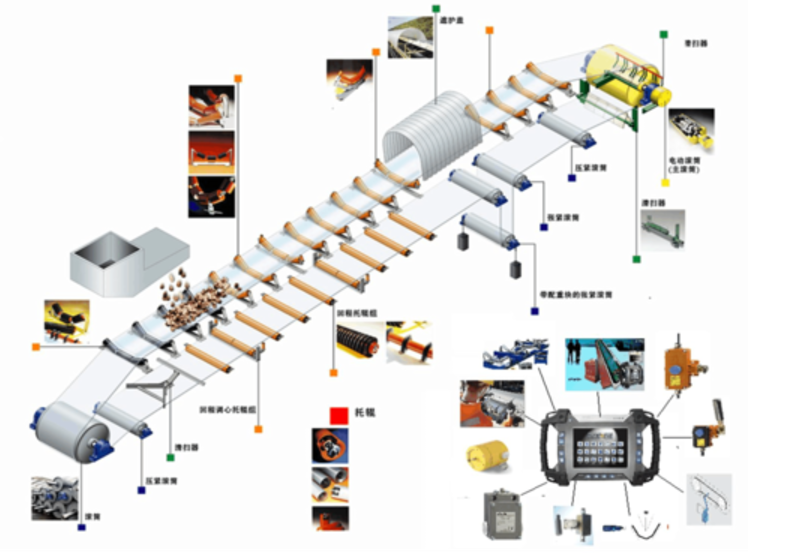

Navigating the complexities of sourcing conveyor belt components can be a daunting task for international B2B buyers, especially in rapidly evolving markets across Africa, South America, the Middle East, and Europe. With diverse applications ranging from manufacturing to agriculture, the challenge lies in identifying high-quality components that meet specific operational demands while ensuring cost-effectiveness. This guide serves as an essential resource, providing a comprehensive overview of various conveyor belt components, including belts, rollers, pulleys, and bearings, as well as their respective functionalities.

In addition to detailing the types of conveyor components available, this guide will delve into supplier vetting processes, helping you to discern reputable manufacturers and distributors. We will also explore cost considerations and maintenance practices that can enhance the longevity and efficiency of your conveyor systems. By equipping you with the knowledge to make informed purchasing decisions, this guide empowers B2B buyers to optimize their operations, reduce downtime, and ultimately improve their bottom line.

Whether you are in Brazil, Nigeria, or any other market, understanding the intricacies of conveyor belt components is crucial for establishing a robust supply chain and maintaining a competitive edge in your industry. Let’s embark on this journey to simplify your sourcing strategy and unlock the full potential of your conveyor systems.

Understanding conveyor belt components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conveyor Belts | Multi-layered materials with a core; various designs (e.g., cleated, modular) | Manufacturing, packaging, agriculture | Pros: Durable, customizable; Cons: Requires maintenance and potential for wear over time. |

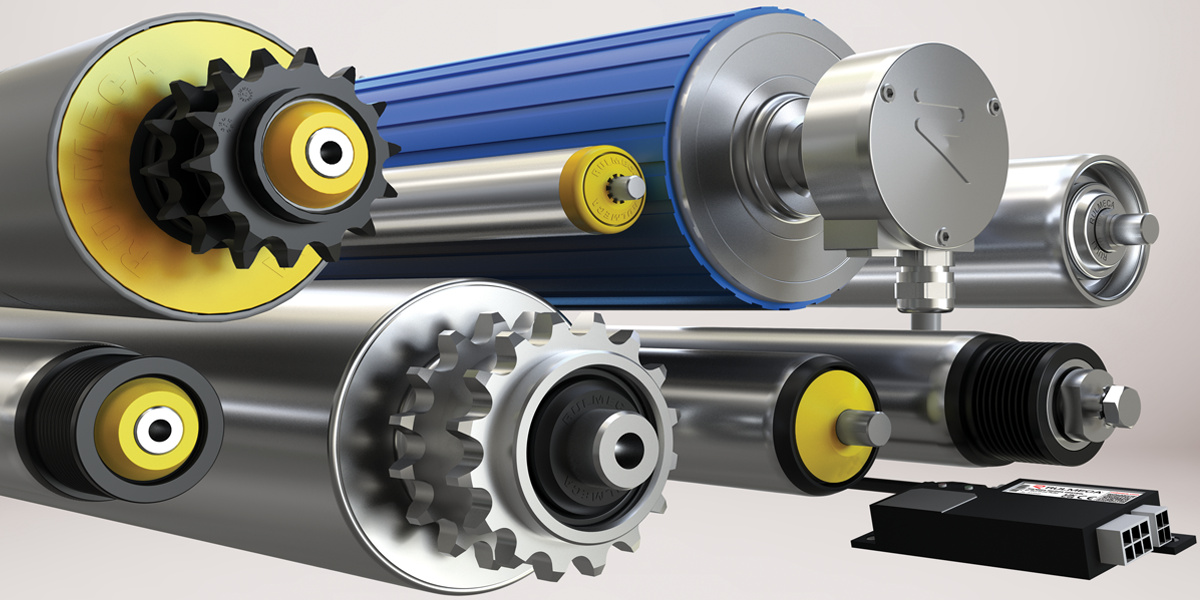

| Rollers | Cylindrical components that facilitate movement; can be motorized or gravity-fed | Warehousing, distribution centers | Pros: Low friction, versatile; Cons: Can be prone to wear and require regular inspection. |

| Pulleys | Essential for directing and tensioning belts; various types (head, tail, take-up) | Material handling, food processing | Pros: Enhances efficiency; Cons: Installation can be complex, may require precise alignment. |

| Bearings | Reduce friction and support moving parts; available in various materials | Mining, automotive, general industry | Pros: Extend equipment life; Cons: Quality varies; improper selection can lead to failures. |

| Motors | Provide power to the conveyor system; available in AC/DC, various sizes | Bulk material handling, assembly lines | Pros: Energy-efficient, low maintenance; Cons: Initial cost can be high depending on specifications. |

What Are the Key Characteristics of Conveyor Belts?

Conveyor belts are foundational components in many material handling systems, featuring multi-layered constructions that provide durability and flexibility. They come in various designs, including cleated belts for inclined applications and modular plastic belts for easy repair and customization. When purchasing conveyor belts, B2B buyers should consider the specific materials they will be transporting and the environmental conditions, as factors like temperature, moisture, and chemical exposure can significantly influence performance.

How Do Rollers Enhance Conveyor Efficiency?

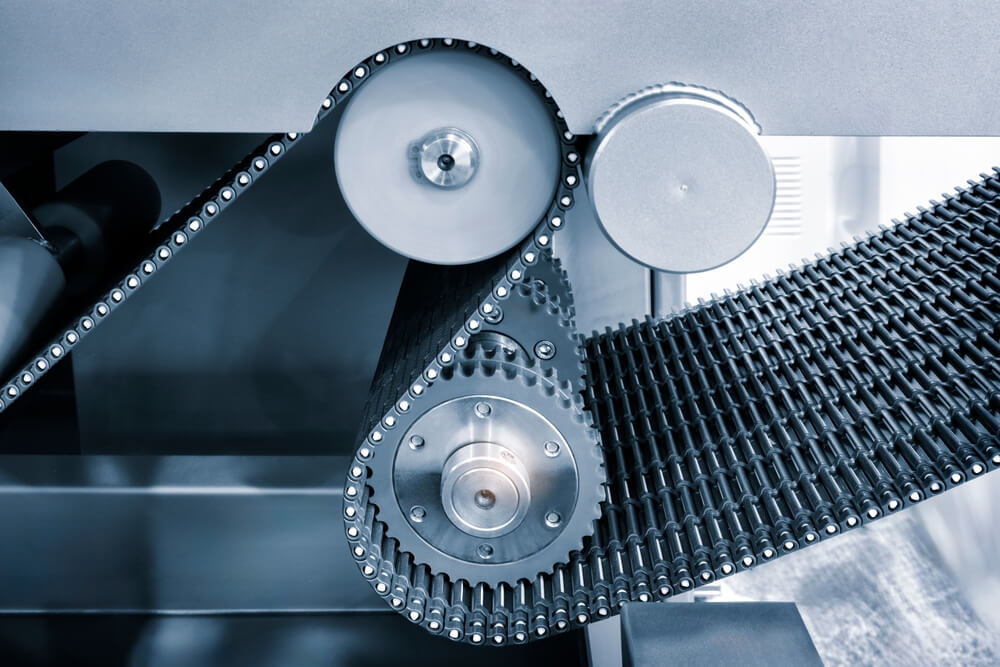

Rollers are cylindrical components that facilitate the smooth movement of products along conveyor systems. They can be designed for gravity-fed systems or motorized applications, providing versatility in various settings. B2B buyers should focus on the roller material and type, as plastic rollers may be suited for lightweight items, while steel rollers are ideal for heavy-duty applications. Regular inspection and maintenance are crucial to ensure rollers remain effective and do not impede product flow.

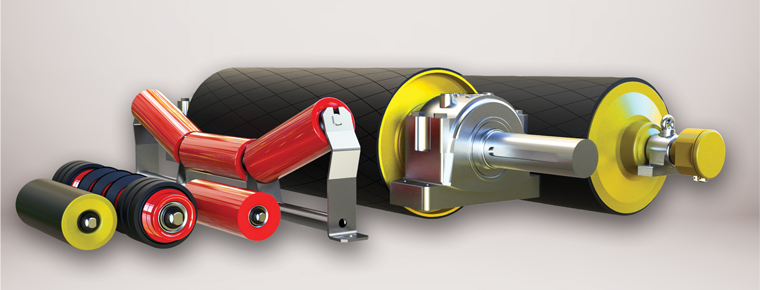

What Role Do Pulleys Play in Conveyor Systems?

Pulleys are vital for directing the movement of conveyor belts and maintaining proper tension. Different types of pulleys, such as head, tail, and take-up pulleys, serve specific functions in a conveyor system. B2B buyers should consider the layout of their systems and the required belt tension when selecting pulleys, as improper alignment can lead to increased wear and operational inefficiencies. Additionally, the choice of materials can affect durability and resistance to environmental factors.

Why Are Bearings Critical in Conveyor Operations?

Bearings are essential for minimizing friction and enabling smooth operation of conveyor systems. They support various moving components, including rollers and pulleys, and are available in different materials to suit specific applications. When purchasing bearings, B2B buyers must consider load ratings and compatibility with existing equipment to prevent premature failures. Regular maintenance and monitoring of bearing conditions can significantly enhance the lifespan of the entire conveyor system.

How Do Motors Drive Conveyor Systems?

Motors are the power source for conveyor systems, available in various types, including AC and DC, tailored to specific operational needs. They can be selected based on power requirements, speed, and torque output, making them adaptable for diverse applications. B2B buyers should evaluate the energy efficiency and maintenance requirements of motors, as well as their compatibility with existing control systems. Investing in high-quality motors can lead to reduced operational costs and improved system reliability.

Key Industrial Applications of conveyor belt components

| Industry/Sector | Specific Application of conveyor belt components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated packaging and sorting systems | Enhanced efficiency and reduced labor costs | Compliance with food safety standards, material durability, and ease of cleaning |

| Mining and Minerals | Bulk material handling and transportation | Increased throughput and minimized operational downtime | Heavy-duty components, resistance to harsh environments, and low maintenance needs |

| Automotive Manufacturing | Assembly line conveyor systems | Streamlined production processes and improved quality control | Customization options for specific assembly tasks and compatibility with existing systems |

| Pharmaceuticals | Automated drug packaging and distribution | Improved accuracy and compliance with regulations | Material certifications, precision in component sizing, and reliability under high-speed operations |

| Agriculture | Grain handling and processing systems | Increased productivity and reduced spoilage | Resistance to moisture and chemicals, ease of maintenance, and adaptability to varying loads |

How Are Conveyor Belt Components Applied in the Food and Beverage Industry?

In the food and beverage sector, conveyor belt components are integral to automated packaging and sorting systems. These systems facilitate the efficient movement of products from one stage of processing to another, significantly enhancing operational efficiency and reducing labor costs. Buyers in this sector must prioritize components that comply with stringent food safety standards, ensuring that materials are durable, easy to clean, and resistant to contamination. Additionally, the ability to withstand frequent washdowns is crucial to maintaining hygiene.

What Role Do Conveyor Belt Components Play in Mining and Minerals?

Conveyor systems in the mining and minerals industry are essential for bulk material handling and transportation. Conveyor belt components ensure increased throughput and minimize operational downtime by providing reliable movement of heavy materials. Buyers should consider sourcing heavy-duty components that can resist harsh environmental conditions, such as dust and moisture. Furthermore, low maintenance needs are critical for sustaining productivity in remote mining locations, where downtime can be costly.

How Are Conveyor Systems Used in Automotive Manufacturing?

In automotive manufacturing, conveyor belt components are pivotal for assembly line systems. They streamline production processes by facilitating the smooth flow of parts and ensuring quality control at various stages of assembly. Buyers should look for customization options that cater to specific assembly tasks, as well as compatibility with existing systems to avoid costly retrofitting. The ability to adapt to various vehicle sizes and types is also a key consideration for international buyers.

What Benefits Do Conveyor Belt Components Provide in Pharmaceuticals?

The pharmaceutical industry utilizes conveyor belt components for automated drug packaging and distribution. These systems improve accuracy and compliance with strict regulatory requirements, which are critical in this highly regulated sector. Buyers must focus on sourcing materials that have the necessary certifications and ensure precision in component sizing to maintain the integrity of drug products. Reliability under high-speed operations is also essential to meet increasing demand without sacrificing quality.

How Are Conveyor Belt Components Enhancing Agricultural Productivity?

In agriculture, conveyor belt components are utilized in grain handling and processing systems. These components increase productivity by facilitating the efficient transport of grains and minimizing spoilage during processing. For international buyers, sourcing components that are resistant to moisture and chemicals is vital, as these conditions are prevalent in agricultural environments. Additionally, ease of maintenance and the ability to handle varying loads are important factors that influence purchasing decisions in this sector.

3 Common User Pain Points for ‘conveyor belt components’ & Their Solutions

Scenario 1: Ensuring Durability in Harsh Environments

The Problem: Many B2B buyers operating in industries such as agriculture, mining, or food processing face significant challenges with conveyor belt components that are exposed to harsh environments. For instance, conveyor systems may be subjected to corrosive substances, extreme temperatures, and high humidity, which can accelerate wear and tear on components like bearings and belts. This not only leads to frequent breakdowns but also increases maintenance costs and downtime, affecting overall productivity.

The Solution: To combat these challenges, it is crucial to select conveyor belt components specifically designed for durability in harsh conditions. Buyers should consider using sealed bearings that are resistant to water and chemicals, ensuring they can withstand exposure without significant degradation. Additionally, investing in high-quality belts made from specialized materials, such as modular plastic or rubber with enhanced resistance to abrasions and chemicals, will prolong their lifespan. It’s also advisable to implement a regular maintenance schedule that includes inspections and timely replacements of worn components. This proactive approach minimizes the likelihood of unexpected failures and optimizes operational efficiency.

Scenario 2: Managing Conveyor System Downtime

The Problem: Frequent downtimes in conveyor systems due to component failures can severely disrupt operations and lead to lost revenue. B2B buyers often experience this pain point when critical components like motors, pulleys, or rollers fail unexpectedly. Such incidents can cause a ripple effect, delaying production schedules and diminishing customer satisfaction.

The Solution: To effectively manage and reduce downtime, it is essential to adopt a predictive maintenance strategy that leverages technology. This involves utilizing sensors and monitoring systems to track the performance of conveyor components in real-time. By analyzing data on vibrations, temperature, and wear, businesses can predict when a component is likely to fail and schedule maintenance accordingly. Furthermore, ensuring that spare parts are readily available can drastically reduce the time needed for repairs. Engaging with reliable suppliers who provide high-quality components and quick delivery options is also crucial. This combination of monitoring and preparedness will enhance the reliability of conveyor systems and improve overall productivity.

Scenario 3: Navigating the Complexity of Component Sourcing

The Problem: B2B buyers often struggle with sourcing the right conveyor belt components due to the vast array of options available in the market. This complexity can lead to purchasing mismatched or substandard components that do not fit their specific application needs. For example, choosing the wrong type of belt or roller can result in inefficiencies, increased wear, and potential safety hazards.

The Solution: To navigate this complexity, buyers should start by conducting a thorough assessment of their specific operational requirements, including load capacity, environmental conditions, and the types of materials being transported. Engaging with experienced suppliers who specialize in conveyor systems can provide valuable insights into the most suitable components for their needs. It is beneficial to request samples or prototypes to test compatibility before making bulk purchases. Additionally, utilizing comprehensive product catalogs that include detailed specifications and application guidelines can aid in informed decision-making. Establishing strong relationships with suppliers for ongoing support and technical assistance will further ensure that the right components are sourced, leading to optimized performance and safety in conveyor operations.

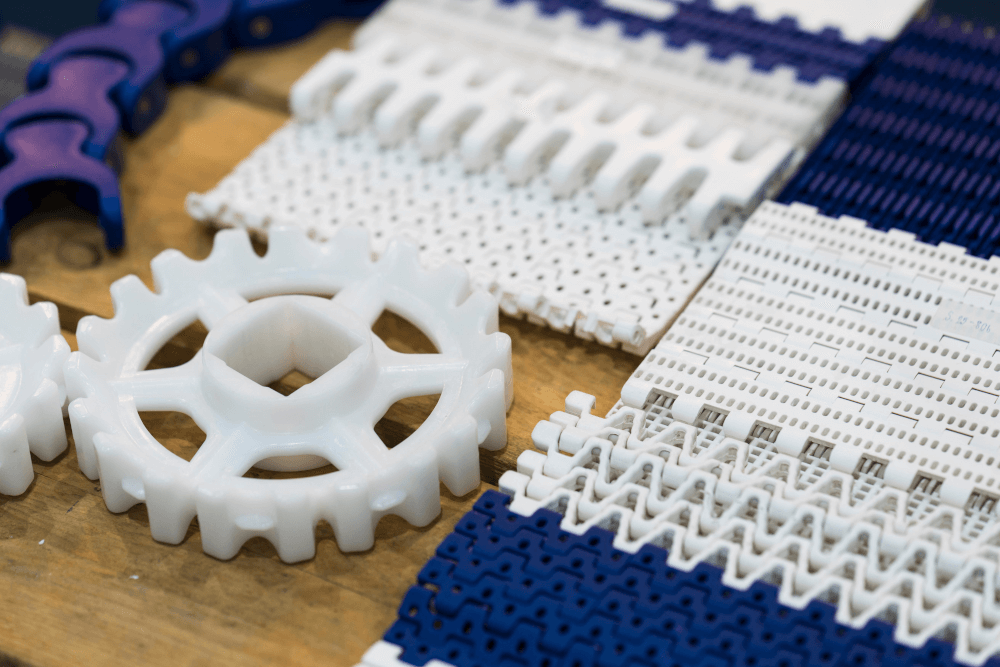

Illustrative image related to conveyor belt components

Strategic Material Selection Guide for conveyor belt components

What Are the Key Properties of Common Materials for Conveyor Belt Components?

When selecting materials for conveyor belt components, several factors must be considered to ensure optimal performance and longevity. Here, we analyze four common materials used in conveyor systems: rubber, plastic, stainless steel, and thermoplastics. Each material has unique properties that impact its suitability for various applications.

Rubber: The Versatile Workhorse

Rubber is one of the most widely used materials for conveyor belts due to its excellent flexibility and durability. It typically withstands a temperature range of -30°C to 80°C, making it suitable for various environments. Rubber also offers good abrasion resistance and can handle moderate levels of chemical exposure.

Pros: Rubber is highly durable and cost-effective, making it suitable for a wide range of applications, from agriculture to manufacturing. Its ease of repair through splicing and vulcanization is another significant advantage.

Cons: However, rubber can degrade in extreme temperatures or harsh chemical environments, limiting its applicability in some sectors. Additionally, its weight can increase operational costs in terms of energy consumption.

International Considerations: Buyers from regions like Africa and South America should ensure that the rubber meets local compliance standards, such as ASTM D2000 for rubber materials, to avoid issues with quality and performance.

Plastic: Lightweight and Flexible

Plastic materials, particularly modular plastic belts, are gaining popularity due to their lightweight nature and flexibility. They can operate effectively in temperatures ranging from -20°C to 60°C and are resistant to moisture and many chemicals, making them ideal for food processing and packaging applications.

Pros: The primary advantage of plastic is its low weight, which reduces energy consumption and makes installation easier. Additionally, plastic belts can be easily cleaned and sanitized, meeting stringent hygiene standards.

Cons: On the downside, plastic can be less durable than rubber and may require more frequent replacements in high-wear applications. Its initial cost can also be higher than traditional rubber belts.

Illustrative image related to conveyor belt components

International Considerations: Compliance with food safety standards, such as FDA regulations or EU directives, is crucial for buyers in the food and beverage industry, particularly in Europe and the Middle East.

Stainless Steel: Strength and Corrosion Resistance

Stainless steel is often used in conveyor components like rollers and frames due to its exceptional strength and corrosion resistance. It can withstand extreme temperatures and is highly durable, making it suitable for heavy-duty applications.

Pros: The key advantage of stainless steel is its longevity and resistance to rust and corrosion, which is vital in industries like mining and food processing. Its structural integrity allows for high load capacities.

Cons: However, stainless steel is more expensive than other materials and can be challenging to manufacture and install, requiring specialized skills and tools.

International Considerations: Buyers should look for compliance with standards such as ASTM A240 for stainless steel to ensure quality and durability, particularly in regions with stringent safety regulations.

Illustrative image related to conveyor belt components

Thermoplastics: Innovative and Customizable

Thermoplastics are increasingly used for conveyor components due to their customizable properties. They can operate in a wide temperature range and are resistant to chemicals, making them suitable for various applications, including pharmaceuticals and food processing.

Pros: Thermoplastics are lightweight and can be molded into complex shapes, offering design flexibility. They are also recyclable, making them an environmentally friendly choice.

Cons: The main limitation is that thermoplastics may not be as durable as rubber or stainless steel in high-wear applications, leading to potential replacements.

International Considerations: Buyers should verify that thermoplastics meet international standards like ISO 9001 for quality management systems, especially in regions with strict regulatory environments.

Summary Table of Material Selection for Conveyor Belt Components

| Material | Typical Use Case for conveyor belt components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General material handling | Highly durable and cost-effective | Degrades in extreme conditions | Low |

| Plastic | Food processing and packaging | Lightweight and easy to clean | Less durable than rubber | Med |

| Stainless Steel | Heavy-duty applications | Exceptional strength and corrosion resistance | High cost and manufacturing complexity | High |

| Thermoplastics | Pharmaceuticals and food processing | Customizable and recyclable | May lack durability in high-wear applications | Med |

This strategic material selection guide serves as a valuable resource for B2B buyers, helping them make informed decisions based on their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor belt components

What Are the Main Stages in the Manufacturing Process of Conveyor Belt Components?

The manufacturing process for conveyor belt components is typically divided into several key stages: material preparation, forming, assembly, and finishing. Each of these stages is critical to ensure that the components meet the necessary performance and quality standards.

Material Preparation

The first step in manufacturing conveyor belt components involves sourcing high-quality raw materials. Common materials include various types of rubber, plastics, and metals, each selected based on the specific application and environmental conditions. For example, rubber compounds may be specially formulated to resist abrasion, chemicals, or temperature extremes. Once sourced, these materials undergo rigorous testing to ensure they meet predefined specifications.

After testing, the materials are cut or shaped into manageable sizes suitable for further processing. This often includes pre-treating materials, such as applying adhesives or coatings that enhance performance and durability.

How Are Conveyor Belt Components Formed?

The forming stage utilizes various techniques to shape the prepared materials into specific components. For conveyor belts, techniques such as extrusion, molding, and weaving are common.

-

Extrusion: This method is often used for rubber belts, where the material is heated and forced through a die to create long, continuous sheets. This allows for precise control over thickness and width.

-

Molding: For components like pulleys and brackets, injection molding is frequently employed. This process involves injecting molten plastic or rubber into a mold to create complex shapes with high accuracy.

-

Weaving: In the case of fabric-reinforced belts, the weaving process combines different fibers to form a robust carcass that can withstand significant loads. This is particularly important in heavy-duty applications.

What Happens During the Assembly of Conveyor Belt Components?

Once the individual components are formed, they are assembled into the final product. This process may involve various techniques, including:

-

Joining: Components such as belts and rollers are joined using mechanical fasteners or adhesives. Care is taken to ensure that the alignment is precise to prevent operational issues.

-

Integration: During assembly, various parts like motors, bearings, and sensors are integrated into the system. This requires attention to detail, as any misalignment can lead to increased wear or failure.

-

Testing: Before final assembly is complete, each component is often tested for functionality. This may include running the conveyor system at various speeds to ensure all components work seamlessly together.

What Finishing Techniques Are Used for Conveyor Belt Components?

The finishing stage of the manufacturing process focuses on enhancing the durability and aesthetic appeal of the components. Techniques include:

-

Coating: Protective coatings are applied to prevent corrosion, particularly for metal components. This is essential for systems operating in harsh environments, such as food processing or chemical handling.

-

Surface Treatment: Processes like polishing or sandblasting can be used to enhance the surface finish of components, reducing friction and wear.

-

Quality Inspection: Final quality checks are conducted to ensure that all components meet the required specifications and standards.

How Is Quality Assurance Implemented in Conveyor Belt Component Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that all components meet international and industry-specific standards. For conveyor belt components, adherence to standards such as ISO 9001 is common, signifying a commitment to quality management systems.

What International Standards Are Relevant for Conveyor Belt Components?

ISO 9001 provides a framework for consistent quality assurance processes across manufacturing. In addition, industry-specific certifications, such as CE marking for compliance with European health and safety regulations, play a significant role in assuring buyers of the product’s safety and reliability.

Illustrative image related to conveyor belt components

For specialized applications, certifications from organizations like the American Petroleum Institute (API) may also be relevant, particularly for components used in oil and gas industries.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor and ensure quality. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet the required specifications before they enter the production process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections and tests are conducted to monitor the quality of work in progress. This includes assessing dimensions, materials, and assembly accuracy.

-

Final Quality Control (FQC): Once the conveyor belt components are fully assembled, a final inspection is performed. This may include operational testing and performance evaluations to verify that the components function as intended.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done either by the buyer’s team or through third-party inspection services.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports, including test results and compliance certifications. Buyers should review these documents to assess the supplier’s commitment to quality.

-

Third-Party Inspection: Engaging third-party inspectors for independent assessments can add an extra layer of assurance. These professionals can evaluate the manufacturing processes and verify compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of various nuances related to quality control. Different regions may have varying standards and certifications, which can impact product quality. For example:

-

Cultural Differences: Understanding the supplier’s cultural context can influence communication and expectations regarding quality. Establishing clear guidelines and mutual understanding is vital.

-

Regulatory Compliance: Buyers must ensure that their suppliers comply with both local and international regulations, as non-compliance can lead to significant operational risks.

-

Supply Chain Transparency: Maintaining transparency in the supply chain can help buyers track quality assurance efforts. This includes knowing the origin of materials and the manufacturing processes involved.

By focusing on these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing conveyor belt components, ensuring they receive reliable products that meet their specific operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor belt components’

Introduction

Sourcing conveyor belt components requires careful consideration to ensure operational efficiency and reliability in your material handling systems. This checklist aims to guide B2B buyers through the essential steps to procure high-quality components that meet their specific needs. By following these steps, you can mitigate risks, enhance system performance, and achieve cost savings.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. This includes the type of materials you will be transporting, the load capacity, and the environmental conditions (e.g., temperature, moisture, or chemical exposure).

– Consider material types: Different materials like rubber, plastic, or metal will have varying durability and cost implications.

– Evaluate operational requirements: Understand the speed and frequency of operation to select appropriate motor and drive systems.

Step 2: Research and Identify Potential Suppliers

Start by compiling a list of reputable suppliers specializing in conveyor belt components. Utilize industry directories, trade shows, and online platforms to identify potential partners.

– Look for industry experience: Suppliers with a proven track record in your specific sector will better understand your unique needs.

– Check geographical relevance: Consider suppliers with logistics capabilities in your region to reduce shipping costs and lead times.

Step 3: Evaluate Supplier Certifications and Compliance

It’s crucial to verify that potential suppliers meet industry standards and regulatory compliance. Look for certifications such as ISO 9001 for quality management and other relevant safety and environmental certifications.

– Request documentation: Ask for copies of certifications and compliance documents to ensure they adhere to international standards.

– Investigate their supply chain: Understanding their sourcing and manufacturing processes can reveal their commitment to quality.

Step 4: Assess Product Quality and Reliability

Request samples or detailed specifications of the components you are considering. Quality assurance is vital to prevent downtime and costly repairs in your conveyor systems.

– Examine materials and construction: Ensure the components are made from durable materials suited for your operational conditions.

– Inquire about warranties: Strong warranties can indicate the manufacturer’s confidence in their products.

Step 5: Analyze Pricing and Terms of Sale

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. This step is crucial for budgeting and ensuring you receive competitive pricing.

– Consider total cost of ownership: Beyond initial costs, factor in maintenance, energy efficiency, and lifespan of the components.

– Negotiate terms: Don’t hesitate to negotiate payment terms or bulk purchase discounts to enhance your overall savings.

Step 6: Check References and Customer Feedback

Before finalizing a supplier, request references from their previous clients. This will provide insights into their reliability and customer service.

– Seek feedback on performance: Ask about the longevity and performance of the components supplied.

– Evaluate their responsiveness: Understanding how suppliers handle issues can be critical for ongoing support.

Step 7: Finalize and Place Your Order

After thorough evaluation, choose your supplier and finalize the order details. Ensure that all specifications, delivery timelines, and payment terms are clearly documented.

– Confirm logistics: Discuss shipping methods and timelines to avoid delays in your operations.

– Establish a communication plan: Maintain an open line of communication with your supplier to address any issues that may arise during the procurement process.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing conveyor belt components, ensuring they make informed decisions that support their operational needs.

Comprehensive Cost and Pricing Analysis for conveyor belt components Sourcing

What Are the Key Cost Components in Sourcing Conveyor Belt Components?

When analyzing the cost structure for conveyor belt components, several key elements come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of materials significantly influences costs. Common materials include rubber, fabric, plastic, and metal. High-performance materials, such as those resistant to chemicals or extreme temperatures, generally come at a premium.

Illustrative image related to conveyor belt components

Labor: Labor costs can vary based on the region and the complexity of the manufacturing processes. Regions with lower labor costs may offer competitive pricing, but buyers should consider the potential trade-offs in quality and reliability.

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Understanding the manufacturer’s overhead can provide insights into their pricing strategy and help buyers assess value.

Tooling: Tooling costs can be significant, especially for custom components. Buyers should inquire about these costs upfront, particularly if they require specific designs or modifications.

Quality Control: Investing in quality assurance processes adds to the cost but is essential for ensuring reliable performance. Manufacturers with robust QC protocols may charge higher prices, but this can lead to lower total costs over time due to reduced downtime and maintenance.

Illustrative image related to conveyor belt components

Logistics: Shipping and handling costs can vary widely based on distance, shipment size, and chosen Incoterms. Buyers should evaluate logistics not just in terms of cost but also delivery timelines and reliability.

Margin: Lastly, the profit margin that suppliers include in their pricing can depend on market demand, competition, and brand reputation. Understanding the competitive landscape can help buyers negotiate better prices.

How Do Price Influencers Affect Conveyor Belt Component Costs?

Several factors can influence the pricing of conveyor belt components significantly:

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can lead to significant discounts. Suppliers often have tiered pricing structures, incentivizing larger orders. Buyers should assess their needs carefully to determine the most cost-effective order size.

Specifications and Customization: Custom parts tailored to specific applications may incur higher costs due to additional design and manufacturing processes. Buyers should weigh the need for customization against off-the-shelf options.

Material Quality and Certifications: Higher-quality materials and compliance with industry standards (e.g., ISO, FDA certifications) can increase costs but offer assurance of performance and longevity. For industries like food and beverage, investing in certified components is often non-negotiable.

Supplier Factors: The reputation and reliability of suppliers can greatly affect pricing. Established suppliers may charge more for their reputation and reliability, while newer entrants may offer lower prices to gain market share. Conducting thorough supplier evaluations can uncover the best options.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Buyers should negotiate terms that minimize their risk and maximize cost efficiency.

Illustrative image related to conveyor belt components

What Tips Can Help B2B Buyers Optimize Costs in Conveyor Belt Component Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies for cost optimization:

Negotiation: Establishing long-term relationships with suppliers can lead to better pricing. Regular communication and negotiation can help uncover hidden costs and secure discounts.

Total Cost of Ownership (TCO): When evaluating suppliers, consider the TCO rather than just the upfront price. This includes installation, maintenance, and potential downtime costs. A lower-priced component may lead to higher long-term costs if it requires frequent replacement or repair.

Pricing Nuances for International Buyers: Currency fluctuations, import tariffs, and local regulations can all impact the final cost. Buyers should factor these elements into their budgeting and sourcing strategies.

Illustrative image related to conveyor belt components

Market Research: Conduct thorough market research to understand local supplier dynamics and pricing trends. This knowledge can empower buyers during negotiations and sourcing decisions.

In conclusion, navigating the cost and pricing landscape of conveyor belt components requires a comprehensive understanding of the various cost components and price influencers. By implementing strategic sourcing practices, international buyers can optimize their procurement processes and achieve better financial outcomes.

Alternatives Analysis: Comparing conveyor belt components With Other Solutions

Introduction: Exploring Alternatives to Conveyor Belt Components

In the realm of material handling, conveyor belt components are a well-established solution for transporting goods efficiently. However, as industries evolve, so do the technologies available for similar applications. This section explores viable alternatives to conveyor belt components, allowing international B2B buyers to make informed decisions based on performance, cost, implementation ease, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Conveyor Belt Components | Automated Guided Vehicles (AGVs) | Overhead Conveyor Systems |

|---|---|---|---|

| Performance | High efficiency in transporting bulk materials over fixed paths. | Flexible routing and dynamic loading, ideal for changing layouts. | Efficient for transporting items in tight spaces, especially in manufacturing. |

| Cost | Moderate initial investment; ongoing maintenance costs. | Higher upfront costs; potential for long-term savings through labor reduction. | Varies widely based on complexity; often cost-effective for high-volume operations. |

| Ease of Implementation | Relatively straightforward installation; requires adequate space. | Requires planning for routing and navigation; may need integration with existing systems. | Installation can be complex due to structural requirements and system design. |

| Maintenance | Routine checks needed for wear and tear; splicing and vulcanization can be simple. | Low maintenance but requires software updates and occasional hardware checks. | Regular inspections necessary; can involve significant downtime for repairs. |

| Best Use Case | Ideal for heavy, bulk materials in fixed locations (e.g., warehouses, manufacturing). | Best suited for environments with dynamic workflows (e.g., assembly lines, distribution centers). | Excellent for assembly lines and environments where vertical space is at a premium. |

Detailed Breakdown of Alternatives

Automated Guided Vehicles (AGVs)

AGVs represent a modern approach to material handling, utilizing autonomous vehicles to transport goods throughout a facility. One of the key advantages of AGVs is their flexibility; they can navigate around obstacles and adjust their routes based on real-time needs. However, the initial investment can be substantial due to the technology and infrastructure required. AGVs are best for operations that require adaptability and have variable workflows, making them suitable for dynamic environments like assembly lines.

Overhead Conveyor Systems

Overhead conveyor systems are designed to transport items above the ground, freeing up valuable floor space. They are particularly effective in manufacturing and warehousing settings where items need to be moved across workstations without obstructing pedestrian traffic. While overhead systems can be cost-effective for high-volume operations, their installation can be complex and may require significant structural support. They excel in environments where space is constrained, and efficiency is paramount.

Conclusion: How to Choose the Right Solution for Your Needs

When considering alternatives to conveyor belt components, B2B buyers should evaluate their specific operational requirements, including the nature of the materials being handled, the layout of their facility, and their budget constraints. While conveyor belts offer robustness and reliability, alternatives like AGVs and overhead conveyor systems provide unique advantages that may better suit certain applications. Ultimately, understanding the strengths and limitations of each option will empower buyers to make decisions that enhance productivity and efficiency in their operations.

Essential Technical Properties and Trade Terminology for conveyor belt components

What Are the Key Technical Properties of Conveyor Belt Components?

Understanding the technical properties of conveyor belt components is essential for B2B buyers to ensure optimal performance and longevity of their systems. Here are some critical specifications to consider:

1. Material Grade

The material grade of conveyor belts significantly affects their durability and suitability for specific applications. Common materials include rubber, PVC, and modular plastics. High-grade materials can withstand harsh environments, chemicals, and high temperatures, making them ideal for industries like food processing or mining. Selecting the right material grade minimizes maintenance costs and downtime.

2. Tolerance

Tolerance refers to the permissible limit of variation in a dimension. In conveyor systems, tight tolerances are crucial for components like pulleys and rollers to ensure proper alignment and smooth operation. Poor tolerances can lead to increased wear, misalignment, and failure of the conveyor system. Understanding tolerance levels helps in selecting components that will fit seamlessly, enhancing operational efficiency.

3. Load Capacity

Load capacity indicates the maximum weight a conveyor belt can transport without compromising performance. This specification is vital for B2B buyers to determine whether a conveyor system can handle their specific material handling needs. Exceeding load capacity can lead to premature wear and system failure, resulting in costly downtimes.

4. Belt Speed

Belt speed is the rate at which the conveyor moves materials from one point to another. It is measured in meters per minute (m/min) and varies based on the application. Understanding the required belt speed is essential for optimizing throughput and ensuring that the conveyor meets production demands without overloading or underperforming.

5. Pulley Diameter

The diameter of pulleys affects the tension and tracking of the conveyor belt. Larger pulleys can reduce wear on the belt and improve its lifespan, while smaller pulleys can increase belt tension, which might be necessary for certain applications. Selecting the appropriate pulley diameter is crucial for maintaining effective belt operation and reducing maintenance costs.

What Are Common Trade Terms in the Conveyor Belt Industry?

Familiarity with industry jargon is vital for smooth communication and successful transactions in the B2B marketplace. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the conveyor belt industry, OEM components are crucial for ensuring compatibility and performance. Understanding OEM specifications can help buyers select the right components that meet their operational needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ helps businesses plan their purchases effectively, especially when dealing with large-scale conveyor systems.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is an effective way to compare offers and negotiate better deals. Crafting a comprehensive RFQ ensures that suppliers provide accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B transactions, as they define who is responsible for shipping, insurance, and tariffs, thereby minimizing disputes and ensuring smooth logistics.

5. VFD (Variable Frequency Drive)

A VFD is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of its power supply. In conveyor systems, VFDs enhance energy efficiency and operational flexibility. Understanding VFD technology is essential for optimizing performance and reducing energy costs.

Illustrative image related to conveyor belt components

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring that their conveyor systems operate efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the conveyor belt components Sector

What are the Current Market Dynamics and Key Trends in Conveyor Belt Components?

The conveyor belt components market is experiencing significant transformation driven by global industrialization, technological advancements, and increasing demand for automation across various sectors, including manufacturing, logistics, and food processing. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly focused on sourcing high-quality, durable components that can withstand challenging operational conditions. The rise of e-commerce and the need for efficient supply chains are further propelling the demand for advanced conveyor systems.

Emerging trends in the B2B landscape include the integration of IoT (Internet of Things) technologies, which allow for real-time monitoring and predictive maintenance of conveyor systems. This capability enhances operational efficiency and reduces downtime, providing a competitive edge for businesses. Additionally, there is a growing preference for modular conveyor systems that offer flexibility and scalability, allowing businesses to adapt to changing production needs without extensive overhauls.

Moreover, international buyers are increasingly seeking suppliers who can provide comprehensive support, including installation, maintenance, and training services. This trend underscores the importance of building long-term partnerships with reliable manufacturers who understand the unique challenges of various industries.

How is Sustainability and Ethical Sourcing Impacting the Conveyor Belt Components Market?

Sustainability has become a critical consideration for B2B buyers in the conveyor belt components sector. As companies face increasing pressure to reduce their environmental impact, the demand for eco-friendly materials and practices is on the rise. Buyers are now more inclined to choose suppliers that prioritize sustainability in their manufacturing processes, such as using recycled materials or energy-efficient technologies.

Ethical sourcing is equally important. Companies are under scrutiny to ensure that their supply chains adhere to ethical labor practices and environmental regulations. This includes ensuring that raw materials are sourced responsibly and that workers are treated fairly. As a result, many manufacturers are obtaining certifications that demonstrate their commitment to sustainable and ethical practices, such as ISO 14001 for environmental management and Fair Trade certifications.

Incorporating these considerations into sourcing strategies not only mitigates risks associated with compliance and brand reputation but also resonates with increasingly conscientious consumers. Buyers who prioritize sustainability and ethical sourcing are likely to enhance their competitive position in the market.

What is the Brief Evolution of Conveyor Belt Components in the B2B Sector?

The evolution of conveyor belt components can be traced back to the late 18th century when the first rudimentary conveyor systems were designed for material handling. Initially, these systems were simple, relying on gravity and manual labor. However, with the advent of the Industrial Revolution, there was a significant shift towards mechanization.

By the mid-20th century, advancements in materials science led to the development of more robust and efficient conveyor belts, including the introduction of rubber and synthetic materials that enhanced durability and load capacity. The late 20th and early 21st centuries saw the integration of electronics and automation into conveyor systems, allowing for increased efficiency and reduced labor costs.

Today, the conveyor belt components market is characterized by continuous innovation, driven by the need for greater efficiency, sustainability, and adaptability in manufacturing and logistics processes. As businesses seek to optimize their supply chains, understanding this evolution is crucial for making informed sourcing decisions in the current landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor belt components

-

How do I solve conveyor belt misalignment issues?

Conveyor belt misalignment can lead to increased wear, reduced efficiency, and potential safety hazards. To address this issue, first, inspect the conveyor’s pulleys and rollers for wear or damage. Ensure that the belt is properly tensioned and aligned within the frame. Adjust the tracking by using the take-up pulley to bring the belt into alignment. Regular maintenance checks, including monitoring wear patterns on the belt edges, can help prevent misalignment before it becomes a significant problem. -

What is the best material for conveyor belts in harsh environments?

For harsh environments, such as those found in mining or chemical processing, rubber and modular plastic belts are often the best choices. Rubber belts offer durability and resistance to abrasion, while modular plastic belts can be customized for specific applications, providing excellent chemical resistance and ease of cleaning. Consider factors like temperature extremes, moisture exposure, and the types of materials being transported when selecting the best belt material for your specific needs. -

How can I evaluate potential suppliers of conveyor belt components?

When evaluating suppliers, consider their reputation, experience, and product quality. Request samples and certifications to assess the materials’ durability and compliance with international standards. Check reviews and testimonials from other clients, particularly those in your industry. It’s also beneficial to inquire about their manufacturing processes and quality assurance practices. A reliable supplier should be transparent about their sourcing, production, and logistics capabilities, ensuring they can meet your specific requirements. -

What are the common minimum order quantities (MOQs) for conveyor belt components?

Minimum order quantities for conveyor belt components can vary significantly between suppliers and product types. Typically, MOQs can range from as low as 50 units for standard components to several hundred for specialized items. Always confirm MOQs with suppliers before placing an order, as some may offer flexibility for first-time buyers or bulk purchases. Understanding the MOQ can help you better manage your inventory and cash flow. -

What payment terms should I expect when purchasing conveyor belt components internationally?

Payment terms for international purchases of conveyor belt components generally include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for larger orders, with the balance due before shipment or upon receipt. It’s crucial to negotiate terms that align with your cash flow needs and ensure that you have a clear understanding of currency exchange rates, potential duties, and taxes. -

How can I ensure quality assurance in my conveyor belt components?

To ensure quality assurance, work with suppliers who have established quality control processes. Request documentation of quality certifications, such as ISO standards, which indicate adherence to international quality norms. Conduct periodic audits of the supplier’s facilities and processes if possible. Additionally, consider implementing a robust inspection process upon receipt of components, including testing for material integrity and compliance with specifications to mitigate risks of defects. -

What logistics considerations should I keep in mind when sourcing conveyor belt components?

When sourcing conveyor belt components internationally, consider factors such as shipping methods, lead times, and customs regulations. Determine whether air freight or sea freight is more cost-effective based on urgency and volume. Ensure that your supplier is familiar with the customs processes in your country to avoid delays. It’s also wise to discuss packaging requirements that protect components during transit, minimizing the risk of damage. -

What customization options are available for conveyor belt components?

Many suppliers offer customization options for conveyor belt components to meet specific operational needs. This can include variations in material, size, and design features such as cleating or surface texture. Discuss your application requirements with potential suppliers to explore available options. Customization may also extend to features like special coatings for corrosion resistance or modifications to fit unique installation spaces, enhancing the overall efficiency of your conveyor system.

Top 7 Conveyor Belt Components Manufacturers & Suppliers List

1. Conveyor Rollers – Key Components

Domain: conveyorrollers.com

Registered: 2002 (23 years)

Introduction: Types of Conveyor Components: 1. Rollers: – Standard Rollers: Made of steel, versatile for medium load capacity, used in packaging and warehousing. – Heavy-Duty Rollers: Made of steel, engineered for high load capacities, ideal for industrial settings like mining and construction. – Coated Rollers: Made of plastic with a rubber layer for extra grip, medium load capacity, used in food and printing …

2. Belt Power – Conveyor Components & Belting

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: Conveyor Components: Segmented Transfer Plates, Roller Chain Sprockets, Belt Scrapers / Brushes, Belt Trackers, Take-Ups, Clean-In-Place, Wear Strips, Guide Rails, Hose Guarding, Bearing Covers, Hoppers. Conveyor Belting: Lightweight Conveyor Belting, Food Conveyor Belting (FDA, USDA, AAA Dairy), General Conveyor Belting, Incline Conveyor Belting, Machine Tapes / Power Transmission, Airport / Dist…

3. Martin Engineering – Conveyor Systems

Domain: foundations.martin-eng.com

Registered: 1995 (30 years)

Introduction: A typical conveyor comprises a continuous rubber belt stretched between terminal pulleys, with the tail end for cargo loading and the head end for cargo discharge. The belt is supported by flat or troughing rollers called idlers, which shape the belt into a U-shape to increase cargo capacity. Return idlers support the lower side of the belt. Conveyor drive motors are usually positioned to rotate t…

4. BBC Arizona – Bearings & Power Transmission Solutions

Domain: bbcarizona.com

Registered: 2006 (19 years)

Introduction: 1. Bearings – Pillow Blocks / Take Ups

2. Belting – Heavy Duty / Light Duty

3. Chain Drives – Roller Chain / Engineered Chain & Sprockets

4. Clippered Fasteners / Alligator Fasteners / Flexco Fasteners

5. Idlers – Balls & Roller

6. Pulleys – Drum / Wing / Lagged / Motorized

7. Reducers – Shaft Mount / Gearmotor / Worm Gear / Screw Conveyor Components

8. Skirt Board Rubber

9. V-Belt Drives – V Belt…

5. Ashland Conveyor – Conveyor Components

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: Conveyor Parts | Replacement Parts | Ashland Conveyor includes a wide selection of components for conveyor systems such as: Gravity Rollers, Tapered Rollers, Roller Conveyor, Skatewheel Conveyor, FlexExtend Skatewheel, Telescoping Conveyor, Ball Transfer Tables, Ball Transfer Insert Assys, Flow Rail, Power Belt, Incline Power Belt, Chain Driven Live Roller, Controls, H-Stands, Tripods, Ceiling Han…

6. McMaster – Conveyor Parts & Hardware

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Parts & Hardware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Dorner Conveyors – In-House Spare Parts & Key Conveyor Solutions

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: In-house Spare Conveyor Parts and Replacements – Dorner Conveyors Products include: 1100 Miniature Conveyors, 2200 Low Profile Conveyors, 2700 Medium Duty Conveyors, 3200 Heavy Duty Conveyors, DCMove Heavy Duty Steel Precision Move, Compact Curve Conveyor, Flexible Chain, FlexMove, FlexMove Helix, FlexMove Stainless Pallet Systems, ERT DualMove Pallet System, AquaGard, AquaPruf, AquaPruf Ultimate,…

Strategic Sourcing Conclusion and Outlook for conveyor belt components

In the dynamic world of conveyor belt components, strategic sourcing emerges as a crucial factor in achieving operational efficiency and cost-effectiveness. By understanding the diverse components—from belts and rollers to bearings and motors—buyers can make informed decisions that enhance the reliability and performance of their conveyor systems. Prioritizing quality suppliers and integrating advanced materials and technologies can significantly reduce downtime and improve productivity, especially in challenging environments.

Moreover, international buyers from regions such as Africa, South America, the Middle East, and Europe should leverage local insights and global best practices to navigate their unique market challenges. Establishing partnerships with manufacturers that prioritize sustainability and innovation will not only meet current demands but also future-proof operations against evolving industry standards.

As you consider your next sourcing strategy, focus on building relationships with suppliers who offer comprehensive solutions tailored to your specific needs. By doing so, you position your business for growth and resilience in an increasingly competitive landscape. Embrace the opportunity to enhance your conveyor systems today—your operational success depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.