A B2B Buyer’s Guide to Dolphin Connectors: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for dolphin connectors

In today’s interconnected world, sourcing high-quality dolphin connectors can be a significant challenge for international B2B buyers. With the increasing complexity of electrical and datacom applications, finding reliable suppliers who offer a diverse range of low voltage connectors, adapters, and cable management solutions becomes paramount. This guide is designed to equip businesses across Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—with the insights necessary to make informed purchasing decisions.

Within this comprehensive resource, we delve into the various types of dolphin connectors available, their specific applications across industries, and essential criteria for supplier vetting. Additionally, we provide a detailed overview of cost considerations, helping buyers understand pricing structures and potential cost-saving strategies. By addressing these critical factors, this guide empowers businesses to navigate the complexities of the global market confidently.

Understanding the landscape of dolphin connectors not only aids in enhancing operational efficiency but also ensures compliance with industry standards. As you explore the sections of this guide, you will gain actionable insights that pave the way for strategic sourcing and partnership decisions, ultimately driving your business success in a competitive marketplace.

Understanding dolphin connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Super B “Beanie” Connectors | Compact design, easy crimping, and color-coded | Electrical installations, datacom | Pros: User-friendly, reliable connection. Cons: Limited to low-voltage applications. |

| Compression Connectors | Secure, watertight seal, high durability | Outdoor and industrial uses | Pros: Excellent moisture resistance. Cons: More expensive than standard connectors. |

| Cat 5e/Cat 6 Connectors | Supports high-speed data transmission, versatile | Networking, telecommunications | Pros: High performance, widely compatible. Cons: Requires careful installation for optimal performance. |

| Inline Couplers | Allows extension of existing cables without splicing | Data centers, commercial wiring | Pros: Easy to use, saves time. Cons: May introduce slight signal loss. |

| Keystone Jacks | Modular design, customizable with various ports | Office setups, home networks | Pros: Flexible configurations, easy upgrades. Cons: Requires additional wall plates and hardware. |

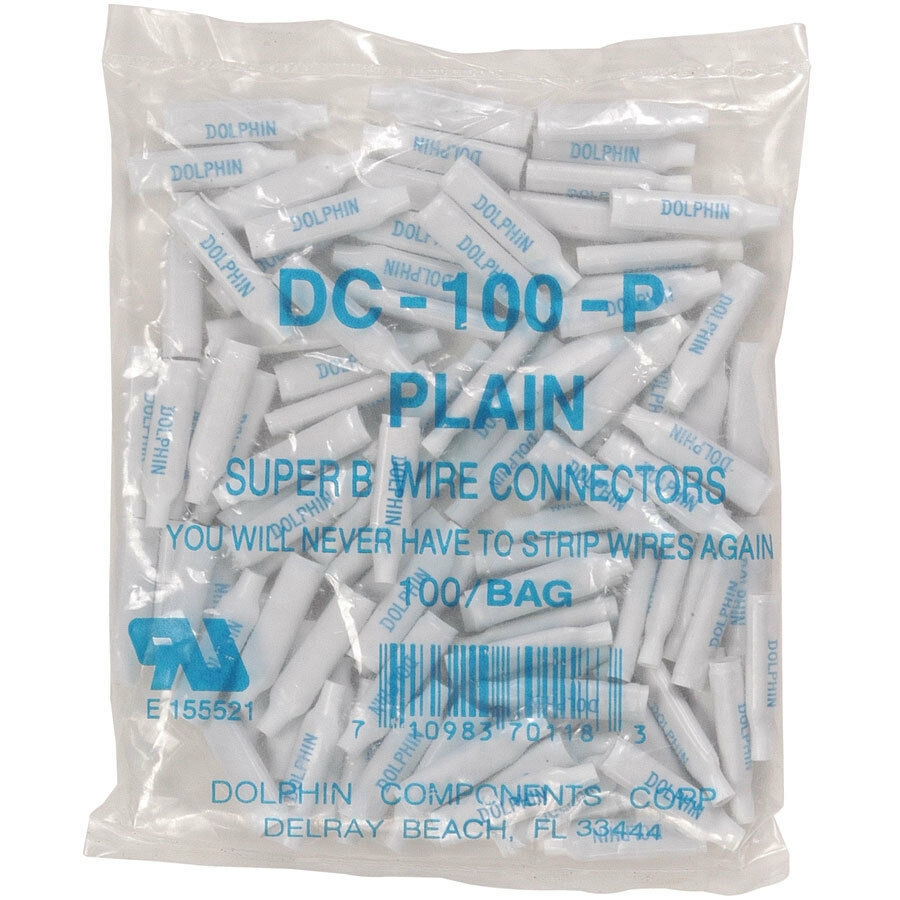

What Are Super B “Beanie” Connectors and Their Applications?

Super B “Beanie” connectors are designed for ease of use in low-voltage applications. Their compact form factor and color-coded design facilitate quick and reliable connections, making them particularly suitable for electrical installations in the datacom and security industries. When purchasing, consider their user-friendliness and reliability, but be aware that they are limited to low-voltage uses, which may not be suitable for all projects.

How Do Compression Connectors Stand Out in B2B Settings?

Compression connectors are characterized by their ability to provide a secure, watertight seal, which is essential for outdoor and industrial applications. Their high durability makes them ideal for environments exposed to moisture and extreme conditions. Buyers should weigh the advantages of moisture resistance against the higher costs compared to standard connectors, especially for large-scale projects requiring extensive wiring.

Why Choose Cat 5e/Cat 6 Connectors for Networking?

Cat 5e and Cat 6 connectors are vital for high-speed data transmission, making them a preferred choice for networking and telecommunications. Their versatility allows for integration into various systems, ensuring compatibility with existing infrastructure. When considering these connectors, the performance benefits must be balanced against the need for careful installation to achieve optimal results, particularly in high-demand environments.

What Are the Benefits of Using Inline Couplers?

Inline couplers are designed to extend existing cable runs without the need for splicing, making them ideal for data centers and commercial wiring setups. Their ease of use can significantly reduce installation time, which is a crucial factor for project managers. However, buyers should note that while they save time, inline couplers may introduce slight signal loss, which could impact performance in critical applications.

How Do Keystone Jacks Enhance Networking Flexibility?

Keystone jacks offer a modular design that allows for customizable configurations, making them suitable for office setups and home networks. Their flexibility enables easy upgrades and adjustments as networking needs evolve. Buyers should consider the additional hardware requirements, such as wall plates, which may add to the overall installation cost, but the benefits of a tailored setup often outweigh these considerations.

Key Industrial Applications of dolphin connectors

| Industry/Sector | Specific Application of dolphin connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Datacom & Telecommunications | Connecting network cables in data centers and telecom facilities | Ensures reliable data transmission and minimizes downtime | Quality assurance, compatibility with existing systems |

| Electrical Distribution | Wiring for commercial and industrial electrical systems | Enhances safety and efficiency in power distribution systems | Compliance with local standards, durability in harsh environments |

| Security Systems | Integration with alarm systems and surveillance cameras | Provides secure and stable connections critical for safety | Environmental resistance, ease of installation |

| Automotive | Wiring harnesses in vehicles and transportation systems | Reduces risk of electrical failures and improves vehicle reliability | Temperature tolerance, flexibility for different designs |

| Renewable Energy | Connection of solar panels and wind turbines to inverters | Supports sustainable energy solutions and reduces energy loss | Certification for renewable applications, weather resistance |

How Are Dolphin Connectors Used in Datacom and Telecommunications?

In the datacom and telecommunications sectors, dolphin connectors are vital for establishing robust connections between network cables within data centers and telecom facilities. These connectors facilitate high-speed data transmission, which is crucial for maintaining the operational integrity of network infrastructures. For international buyers, particularly in regions like Africa and South America, sourcing connectors that meet global quality standards is essential to avoid issues related to compatibility and reliability, which can lead to costly downtime.

What Role Do Dolphin Connectors Play in Electrical Distribution?

In electrical distribution, dolphin connectors are employed to wire commercial and industrial systems, ensuring safe and efficient power delivery. These connectors are designed to handle high voltage and current loads, minimizing the risk of electrical failures. Buyers from Europe and the Middle East should prioritize sourcing connectors that comply with local electrical standards, as this not only enhances safety but also guarantees long-term durability in diverse environmental conditions.

How Are Dolphin Connectors Integrated into Security Systems?

Dolphin connectors are integral to the installation of security systems, including alarm systems and surveillance cameras. These connectors ensure stable and secure connections, which are critical for the effective functioning of safety systems. For businesses in regions with high security demands, such as parts of Africa and the Middle East, sourcing connectors that are resistant to environmental factors and easy to install can significantly enhance the reliability of their security infrastructure.

In What Ways Are Dolphin Connectors Utilized in the Automotive Sector?

In the automotive industry, dolphin connectors are used in wiring harnesses to connect various electrical components within vehicles. Their reliability reduces the risk of electrical failures, which is essential for maintaining vehicle safety and performance. International buyers, especially in Europe and Asia, should consider connectors that offer temperature tolerance and flexibility, as automotive designs often require custom solutions to fit specific vehicle models.

How Do Dolphin Connectors Support Renewable Energy Applications?

Dolphin connectors are crucial in renewable energy applications, such as connecting solar panels and wind turbines to inverters. They help minimize energy loss and enhance the efficiency of renewable energy systems. Buyers in South America and Africa, where renewable energy projects are on the rise, should seek connectors that are certified for use in renewable applications and capable of withstanding various weather conditions to ensure long-term performance and reliability.

3 Common User Pain Points for ‘dolphin connectors’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Existing Systems

The Problem: A common challenge faced by B2B buyers, particularly in sectors like datacom and electrical installations, is ensuring that dolphin connectors are compatible with their existing systems. Buyers may encounter outdated or non-standard equipment that requires specific connector types. This can lead to installation delays, increased costs, and even project failure if the wrong connectors are used. In regions with diverse electrical standards, such as Europe or Africa, this issue becomes even more pronounced as buyers navigate varying specifications and regulations.

The Solution: To mitigate compatibility issues, it’s essential to conduct thorough research prior to procurement. Buyers should start by documenting their current systems and identifying the specific connector types in use. When sourcing dolphin connectors, utilize detailed product catalogs and specification sheets to verify compatibility. Engaging with manufacturers or distributors for technical support can also provide clarity on the best connector options for unique setups. Additionally, consider investing in adaptable connectors that can accommodate various standards, ensuring long-term flexibility and reducing the risk of future compatibility issues.

Scenario 2: The Challenge of Managing Bulk Purchases

The Problem: For companies operating on large-scale projects, managing bulk purchases of dolphin connectors can present significant challenges. Fluctuations in demand, storage issues, and the risk of over- or under-ordering can complicate inventory management. In regions with limited supply chain reliability, such as parts of South America and the Middle East, these issues can lead to project delays and unexpected costs.

The Solution: To effectively manage bulk purchases, businesses should implement a robust inventory management system. This system should track connector usage and project timelines to better predict future needs. Establishing relationships with multiple suppliers can also provide backup options in case of supply chain disruptions. Additionally, consider negotiating flexible purchasing agreements that allow for smaller, more frequent orders instead of one large purchase. This strategy reduces the risk of excess inventory while ensuring that necessary connectors are available when needed. Regular reviews of inventory levels and usage patterns will also help in adjusting orders based on actual project demands.

Scenario 3: Navigating Quality Control and Reliability Issues

The Problem: Quality control is a significant concern for B2B buyers of dolphin connectors, especially in regions where counterfeit products may infiltrate the supply chain. Buyers risk using subpar connectors that can lead to system failures, safety hazards, and increased maintenance costs. In industries like security and electrical installations, where reliability is paramount, the consequences of poor-quality connectors can be severe.

The Solution: To navigate quality control challenges, buyers should prioritize sourcing connectors from reputable manufacturers with a proven track record. Request certifications and quality assurance documents that validate the performance and safety standards of the connectors. Conducting periodic audits of suppliers can also ensure that they maintain high-quality standards. Additionally, implementing a quality inspection process upon receipt of connectors can help catch any defects before installation. Providing training for installation teams on the importance of using high-quality components can further enhance overall reliability and safety in the long run.

Strategic Material Selection Guide for dolphin connectors

When selecting materials for dolphin connectors, it is essential to consider their properties, advantages, and limitations. The choice of material directly impacts the performance, durability, and suitability of the connectors for specific applications. Here, we analyze four common materials used in dolphin connectors: copper, aluminum, plastic, and stainless steel.

What are the Key Properties of Copper in Dolphin Connectors?

Copper is a widely used material for electrical connectors due to its excellent electrical conductivity and thermal properties. With a high melting point of approximately 1,984°F (1,085°C), copper can withstand significant temperatures without degrading. Additionally, it offers good corrosion resistance when properly treated, making it suitable for various environments.

Pros and Cons of Copper Connectors

The primary advantage of copper is its superior conductivity, which leads to minimal energy loss during transmission. However, copper connectors can be more expensive than alternatives, and they may require additional coatings to enhance corrosion resistance, increasing manufacturing complexity.

Impact on Application

Copper connectors are ideal for high-performance electrical applications, particularly in environments with fluctuating temperatures. They are compatible with a wide range of media, including electrical currents and signals.

Considerations for International Buyers

For buyers in regions like Europe and the Middle East, compliance with standards such as ASTM and DIN is crucial. Copper connectors are often preferred in high-tech industries, necessitating a focus on quality certifications.

How Does Aluminum Compare as a Material for Dolphin Connectors?

Aluminum is another popular choice, known for its lightweight and cost-effective properties. With a melting point of about 1,221°F (660.3°C), aluminum can handle moderate temperatures but is less robust than copper at extreme levels. It has good corrosion resistance, particularly when anodized.

Pros and Cons of Aluminum Connectors

The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, its lower conductivity compared to copper may lead to higher energy losses in some applications. Additionally, aluminum connectors can be more prone to mechanical wear over time.

Impact on Application

Aluminum connectors are suitable for applications where weight is a critical factor, such as in aerospace or automotive industries. They are also effective in outdoor environments due to their corrosion resistance.

Considerations for International Buyers

Buyers should ensure that aluminum connectors meet local standards like JIS in Japan or EN in Europe. The preference for aluminum in certain sectors may vary based on regional practices.

What Role Does Plastic Play in Dolphin Connectors?

Plastic, particularly thermoplastics, is often used for insulation and housing in dolphin connectors. It offers excellent electrical insulation properties and is resistant to moisture and chemicals. The temperature tolerance varies by type, but many plastics can withstand temperatures up to 200°F (93°C).

Illustrative image related to dolphin connectors

Pros and Cons of Plastic Connectors

The primary advantage of plastic is its cost-effectiveness and versatility in design. However, plastics may not be suitable for high-temperature applications and can degrade over time when exposed to UV light or extreme conditions.

Impact on Application

Plastic connectors are commonly used in low-voltage applications and environments where electrical insulation is paramount. They are compatible with various media, including water and chemicals.

Considerations for International Buyers

International buyers should consider the specific plastic grades used, ensuring compliance with standards such as RoHS and REACH in Europe, which govern the use of hazardous substances.

Why Choose Stainless Steel for Dolphin Connectors?

Stainless steel is favored for its strength and corrosion resistance, making it suitable for harsh environments. With a melting point of around 2,500°F (1,370°C), it can withstand extreme temperatures and pressures, making it ideal for heavy-duty applications.

Pros and Cons of Stainless Steel Connectors

The key advantage of stainless steel is its durability and resistance to corrosion, which ensures a long lifespan in challenging environments. However, the higher cost and weight compared to other materials may limit its use in certain applications.

Illustrative image related to dolphin connectors

Impact on Application

Stainless steel connectors are often used in industrial applications, particularly in chemical processing or marine environments where corrosion is a significant concern.

Considerations for International Buyers

Buyers should verify that stainless steel connectors meet relevant international standards, such as ASTM A240 for stainless steel sheets and plates. The preference for stainless steel may vary based on industry needs and regional practices.

Summary Table of Material Selection for Dolphin Connectors

| Material | Typical Use Case for dolphin connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance electrical applications | Superior conductivity | Higher cost and potential corrosion issues | High |

| Aluminum | Aerospace and automotive applications | Lightweight and cost-effective | Lower conductivity and mechanical wear | Medium |

| Plastic | Low-voltage and insulation applications | Cost-effective and versatile | Limited temperature tolerance | Low |

| Stainless Steel | Industrial and marine environments | Exceptional strength and corrosion resistance | Higher cost and weight | High |

This guide provides a comprehensive overview of material selection for dolphin connectors, aiding international B2B buyers in making informed decisions based on performance, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dolphin connectors

What Are the Main Stages of Manufacturing Dolphin Connectors?

The manufacturing of dolphin connectors involves several critical stages that ensure the final product meets the required specifications for durability and performance. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. Dolphin connectors typically use high-quality metals such as copper or aluminum for conductivity, as well as various plastics for insulation. These materials are sourced from reliable suppliers who adhere to international quality standards.

Once the materials are selected, they undergo preprocessing, which may include cutting, stripping, and cleaning to remove any contaminants. This stage is crucial because the quality of raw materials directly affects the performance and reliability of the connectors.

What Techniques Are Used in the Forming Process of Dolphin Connectors?

After material preparation, the forming process begins. This may involve various techniques such as stamping, extrusion, or injection molding, depending on the specific type of connector being produced.

- Stamping is often used for metal parts, where sheets of metal are cut and shaped into specific forms using dies.

- Extrusion can be employed to create long, uniform shapes from thermoplastics, while

- Injection molding is utilized for producing complex plastic parts, allowing for intricate designs that enhance functionality and aesthetics.

These techniques require precision machinery and skilled operators to ensure that the components meet tight tolerances.

How Is the Assembly of Dolphin Connectors Conducted?

Once the individual components are formed, they are assembled into final products. This stage may involve manual assembly or automated processes, depending on the volume and complexity of the connectors.

During assembly, connectors are fitted together, ensuring that each part aligns correctly for optimal performance. Quality control checks may occur at this stage to catch any defects before the product moves on to the finishing stage.

What Finishing Processes Are Commonly Applied to Dolphin Connectors?

The finishing stage involves applying protective coatings or treatments to enhance the connectors’ durability and resistance to environmental factors. Common processes include:

- Plating: Often used for metal components to improve corrosion resistance.

- Painting or Coating: Providing insulation or additional protection against wear and tear.

- Testing and Inspection: Conducted to ensure that the connectors meet all specified criteria before packaging and shipment.

This stage is critical, especially for connectors intended for harsh environments, such as those used in outdoor applications or industrial settings.

What Quality Assurance Measures Are In Place for Dolphin Connectors?

Quality assurance (QA) is vital in the manufacturing process of dolphin connectors to ensure that they meet international and industry-specific standards.

Which International Standards Are Relevant for Dolphin Connectors?

Dolphin connectors often comply with several international standards, including ISO 9001, which outlines quality management system requirements. This standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, certifications such as CE (Conformité Européenne) indicate compliance with European health, safety, and environmental protection standards. For specific applications, connectors might also adhere to API (American Petroleum Institute) standards, particularly in the oil and gas industry.

Illustrative image related to dolphin connectors

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early.

- Final Quality Control (FQC): Conducting comprehensive tests on finished products to ensure they meet all specifications.

These checkpoints help maintain high-quality standards and reduce the likelihood of defects reaching the end customer.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

B2B buyers can take several steps to verify the quality control measures of their suppliers:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality management processes in place.

- Request Quality Assurance Reports: Suppliers should be able to provide documentation demonstrating compliance with relevant standards and results from internal quality checks.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased evaluation of the supplier’s quality practices.

These steps are particularly important for international buyers who may face challenges related to product quality and compliance with local regulations.

What Testing Methods Are Commonly Used for Dolphin Connectors?

Testing is an integral part of the quality assurance process. Common testing methods for dolphin connectors include:

Illustrative image related to dolphin connectors

- Electrical Testing: Ensuring that connectors meet conductivity and resistance specifications.

- Mechanical Testing: Assessing the durability and mechanical strength of connectors under various conditions.

- Environmental Testing: Evaluating performance under extreme temperature, humidity, and exposure to corrosive elements.

These tests help verify that the connectors will perform reliably in their intended applications, providing peace of mind for B2B buyers.

How Do Quality Control Nuances Affect International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. This can include:

- Understanding Local Regulations: Different countries may have specific requirements for electrical components that must be met.

- Logistics and Supply Chain Considerations: Ensuring that quality standards are maintained throughout the supply chain, especially when materials are sourced from multiple regions.

- Cultural Differences in Quality Expectations: Recognizing that perceptions of quality may vary by region, affecting how products are designed and manufactured.

By being aware of these factors, international buyers can make more informed decisions and ensure that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dolphin connectors’

Introduction

Sourcing dolphin connectors requires a strategic approach to ensure you acquire high-quality products that meet your specific needs. This guide provides a step-by-step checklist tailored for B2B buyers, enabling you to navigate the procurement process effectively. By following these steps, you can make informed decisions, mitigate risks, and establish strong supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s vital to clearly outline the technical specifications of the dolphin connectors you require. Consider factors such as voltage ratings, compatibility with existing systems, and environmental conditions.

- Voltage Ratings: Ensure the connectors can handle the required electrical load.

- Compatibility: Confirm that the connectors work seamlessly with your current infrastructure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of dolphin connectors. Look for manufacturers and distributors with a solid reputation in the electrical components industry.

- Industry Experience: Prioritize suppliers with extensive experience in providing connectors for your specific application, such as datacom or security systems.

- Customer Reviews: Investigate customer feedback to gauge reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers possess relevant certifications. Certifications ensure that the products meet industry standards and regulations.

- ISO Certification: Look for suppliers with ISO 9001 certification, which indicates adherence to quality management principles.

- Product Compliance: Ensure that the connectors comply with local and international electrical safety standards.

Step 4: Request Samples for Testing

Once you have narrowed down your supplier options, request samples of the dolphin connectors you plan to purchase. Testing samples allows you to evaluate the quality and compatibility of the products before placing a bulk order.

Illustrative image related to dolphin connectors

- Quality Assessment: Check for consistency in manufacturing and verify that the connectors meet your specifications.

- Functional Testing: Assess the connectors’ performance in real-world applications to ensure they function as intended.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your chosen suppliers to secure favorable pricing and terms. Effective negotiation can lead to cost savings and better service agreements.

- Bulk Discounts: Inquire about discounts for large orders, which can significantly reduce overall costs.

- Payment Terms: Discuss payment options that align with your budget and cash flow needs.

Step 6: Establish a Communication Plan

Develop a clear communication plan with your supplier to ensure smooth collaboration throughout the procurement process. Effective communication helps to address any issues that may arise promptly.

- Regular Updates: Set expectations for regular updates on order status and delivery schedules.

- Point of Contact: Designate a specific contact person on both sides to streamline communication.

Step 7: Monitor Delivery and Quality Control

Upon receiving your order, conduct a thorough inspection to ensure that the dolphin connectors meet the agreed-upon specifications. Implementing quality control measures helps prevent future issues.

- Quantity Verification: Check that the number of connectors received matches the order.

- Quality Check: Inspect connectors for any defects or inconsistencies before they are put into use.

By following this practical sourcing guide, you can confidently procure dolphin connectors that meet your technical requirements while fostering strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for dolphin connectors Sourcing

What Are the Key Cost Components in Sourcing Dolphin Connectors?

When sourcing dolphin connectors, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality of materials used significantly impacts costs. For instance, high-grade copper for electrical connectors may be more expensive but provides better conductivity and durability.

-

Labor: Labor costs vary based on the region and manufacturing practices. Countries with higher wage standards may yield higher production costs but can ensure better craftsmanship.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized connectors. Buyers should consider these costs when evaluating supplier quotes.

-

Quality Control (QC): Ensuring product reliability through rigorous QC processes can increase costs but is essential for maintaining high standards, especially in critical applications.

-

Logistics: Transportation and shipping costs can fluctuate based on distance, shipping method, and whether products are sourced locally or internationally.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the expected markup in your target market can aid in negotiations.

How Do Price Influencers Affect Dolphin Connector Costs?

Several factors can influence the pricing of dolphin connectors:

-

Volume/MOQ: Bulk orders usually lead to lower per-unit costs. Suppliers often have minimum order quantities (MOQs), and negotiating these can provide cost benefits.

-

Specifications and Customization: Custom specifications can drive up costs due to the need for specialized manufacturing processes. Buyers should assess whether customization is necessary or if standard options suffice.

-

Materials and Quality Certifications: Premium materials and certifications (such as RoHS or ISO) can increase costs but may be essential for compliance in specific markets.

-

Supplier Factors: Supplier reliability, reputation, and proximity to your location can impact pricing. Local suppliers may offer lower shipping costs, while reputable suppliers may justify higher prices with quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers regarding shipping costs and risks. This can significantly affect the total landed cost of goods.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Dolphin Connectors?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Leverage your purchasing power by negotiating prices, payment terms, and shipping costs. Building a long-term relationship with suppliers may yield further discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the overall costs associated with sourcing, including shipping, handling, and potential warranty claims. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Understand Pricing Nuances for International Trade: Currency fluctuations, tariffs, and import duties can affect pricing significantly. Buyers should stay informed about trade regulations in their respective regions to avoid unexpected costs.

-

Research Market Prices: Conducting market research can provide insights into typical pricing structures. Understanding competitor pricing can empower buyers during negotiations.

-

Consider Alternate Suppliers: Diversifying your supplier base can lead to better pricing and terms. It also mitigates risks associated with relying on a single supplier.

Disclaimer Regarding Indicative Prices

Prices for dolphin connectors can vary widely based on the aforementioned factors. The information provided here serves as a guideline and may not reflect current market prices or specific supplier quotes. Always conduct thorough research and consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing dolphin connectors With Other Solutions

Understanding Alternatives to Dolphin Connectors in Electrical Solutions

In the rapidly evolving landscape of electrical components, businesses often seek alternatives to established products like Dolphin connectors. With various options available, understanding the comparative advantages and drawbacks of each can empower B2B buyers to make informed decisions that align with their specific operational needs.

| Comparison Aspect | Dolphin Connectors | Alternative 1: Push-in Wire Connectors | Alternative 2: Soldered Connections |

|---|---|---|---|

| Performance | High reliability and low resistance. Suitable for low voltage applications. | Good performance for quick connections; can handle moderate loads. | Excellent conductivity; ideal for high power applications. |

| Cost | Competitive pricing, especially in bulk. | Generally lower cost per connection. | Higher initial costs due to materials and labor. |

| Ease of Implementation | Simple installation with minimal tools required. | Very easy to use; no tools necessary for most designs. | Requires soldering skills and tools, making it less accessible for some users. |

| Maintenance | Low maintenance; durable and long-lasting. | Generally low maintenance, but can degrade over time if not properly installed. | Requires periodic checks; potential for joint failure if not executed correctly. |

| Best Use Case | Ideal for datacom and low voltage projects. | Great for quick home and low-voltage applications. | Best for high-performance electronics and permanent installations. |

In-Depth Analysis of Alternatives

What Are Push-in Wire Connectors and Their Benefits?

Push-in wire connectors are a popular alternative due to their ease of use. They allow for quick connections without the need for tools, making them highly efficient for small-scale projects or in environments where speed is critical. However, while they are cost-effective and simple to implement, they may not provide the same level of reliability as Dolphin connectors in high-stress or high-voltage situations.

How Do Soldered Connections Compare?

Soldered connections offer exceptional conductivity and are often considered the gold standard for high-power applications. They create a permanent bond that can withstand significant stress and environmental factors. The downside is that they require skilled labor to execute properly, leading to higher costs and potential for human error. This method is best suited for applications where durability and performance are paramount.

Conclusion: How to Choose the Right Connector Solution for Your Needs

When selecting the right connector solution, B2B buyers should evaluate their specific requirements, including performance needs, budget constraints, and installation capabilities. Dolphin connectors provide a reliable and cost-effective solution for low voltage applications, while alternatives like push-in connectors excel in speed and ease of use, and soldered connections are unmatched in performance but come with higher costs and complexity. By carefully considering these factors, businesses can choose the connector that best meets their operational demands and enhances their project outcomes.

Essential Technical Properties and Trade Terminology for dolphin connectors

What Are the Key Technical Properties of Dolphin Connectors?

When sourcing dolphin connectors, understanding their technical properties is crucial for ensuring compatibility and reliability in various applications. Here are several essential specifications that B2B buyers should consider:

1. Material Grade

Dolphin connectors are typically made from materials like PVC, nylon, or thermoplastic elastomers. The choice of material affects the connector’s durability, flexibility, and resistance to environmental factors such as moisture and UV exposure. For instance, connectors made from high-grade nylon are often preferred for outdoor applications due to their superior weather resistance. Selecting the appropriate material is vital for ensuring long-term performance and reducing maintenance costs.

2. Current Rating

The current rating indicates the maximum amount of electrical current the connector can safely handle. This specification is expressed in amperes (A) and is critical for preventing overheating and potential failure. For B2B buyers, understanding the current rating is essential for ensuring that the connector can meet the demands of the specific application, whether in industrial, commercial, or residential settings.

3. Voltage Rating

Similar to current ratings, voltage ratings are crucial for the safety and functionality of dolphin connectors. Voltage ratings specify the maximum voltage the connector can handle without risk of breakdown or arcing. In applications where higher voltages are present, selecting connectors with appropriate voltage ratings is essential to ensure operational safety and compliance with industry standards.

4. Temperature Range

The operating temperature range defines the conditions under which the connector can function effectively without degradation. This specification is critical for applications in extreme environments, such as outdoor installations or industrial settings where temperature fluctuations are common. Understanding the temperature range helps buyers select connectors that will maintain performance and reliability over time.

5. Tolerances

Tolerances refer to the allowable deviation from specified dimensions in manufacturing. Tight tolerances are essential for ensuring a snug fit and reliable electrical connections. Inconsistent tolerances can lead to connection failures, which can be costly for businesses. Buyers should prioritize connectors with well-defined tolerances to ensure compatibility with their systems.

What Are Common Trade Terms Related to Dolphin Connectors?

Understanding industry jargon can enhance communication and negotiation processes for B2B buyers. Here are some common terms that are frequently encountered when dealing with dolphin connectors:

Illustrative image related to dolphin connectors

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dolphin connectors, sourcing from an OEM can ensure high-quality components that meet specific standards. Buyers should be aware of whether they are purchasing directly from an OEM or through a distributor, as this can affect pricing and availability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage their inventory and budget effectively. Suppliers may set MOQ to offset production costs, and being aware of these requirements helps buyers plan their orders accordingly.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. This process is vital for securing competitive pricing and ensuring that all specifications are met. B2B buyers should prepare detailed RFQs to facilitate clear communication with suppliers regarding their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in international transactions, as it helps prevent misunderstandings and ensures compliance with legal obligations.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is crucial for effective supply chain management, especially for businesses that rely on timely delivery of components. Buyers should inquire about lead times when placing orders to ensure they align with project timelines.

Illustrative image related to dolphin connectors

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions when sourcing dolphin connectors, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the dolphin connectors Sector

What Are the Key Market Dynamics and Trends Influencing Dolphin Connectors?

The global market for dolphin connectors is shaped by several key drivers, including technological advancements, increasing demand for low-voltage electrical supplies, and a shift towards more versatile connectivity solutions. As industries such as telecommunications, security, and data communication continue to expand, the need for reliable and efficient connectors has surged. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are increasingly looking for products that not only meet quality standards but also offer scalability to accommodate future technological advancements.

Emerging trends in sourcing highlight the importance of digital transformation, with many companies adopting e-commerce platforms and digital procurement tools to streamline their purchasing processes. Buyers are prioritizing suppliers that can provide comprehensive catalogs online, coupled with robust product support, including instructional videos and detailed specifications. Additionally, there is a growing trend toward customization, allowing businesses to tailor connector solutions to their specific needs, which is particularly relevant in fast-evolving sectors like smart home technology and industrial automation.

Illustrative image related to dolphin connectors

How Are Sustainability and Ethical Sourcing Shaping the Dolphin Connectors Market?

Sustainability has become a cornerstone of B2B purchasing decisions, with companies increasingly focused on the environmental impact of their supply chains. In the dolphin connectors sector, this translates to sourcing practices that emphasize the use of eco-friendly materials and processes. Ethical sourcing not only enhances brand reputation but also mitigates risks associated with environmental regulations and consumer backlash.

Buyers are now seeking suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances. The incorporation of recyclable materials in the manufacturing of dolphin connectors can significantly reduce the overall environmental footprint. Furthermore, transparency in the supply chain is becoming essential; companies that can provide insight into their sourcing practices and material origins are likely to gain a competitive edge in the market.

What Is the Historical Context of Dolphin Connectors in B2B?

The evolution of dolphin connectors can be traced back to the increasing complexity of electrical systems in both residential and commercial settings. Initially focused on basic connectivity needs, the sector has expanded to incorporate advanced solutions that cater to the burgeoning demand for data transmission and low-voltage applications. Over the past several decades, innovations in design and materials have enabled manufacturers to produce connectors that are not only more reliable but also more efficient in terms of energy consumption.

Illustrative image related to dolphin connectors

As businesses worldwide adapt to rapid technological changes, the dolphin connectors sector has positioned itself to meet the needs of modern industries. This historical context highlights the importance of ongoing innovation and adaptation in maintaining competitiveness and relevance in a dynamic market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of dolphin connectors

-

How do I solve compatibility issues with dolphin connectors?

To address compatibility issues with dolphin connectors, first ensure that the connectors you select are suitable for your specific application, considering factors such as voltage, current rating, and wire gauge. Review the specifications provided by the manufacturer, and consult with your technical team to confirm compatibility with existing systems. If necessary, consider using adapters or custom solutions to bridge any gaps. Engaging with suppliers who offer technical support can also assist in resolving any compatibility concerns efficiently. -

What is the best type of dolphin connector for low voltage applications?

For low voltage applications, the Super B “Beanie” wire connectors are highly recommended. These connectors are designed for ease of use and reliability, making them ideal for datacom, electrical, and security industries. Their robust design ensures secure connections, reducing the risk of failure. Always assess the specific requirements of your project, including wire size and environmental conditions, to determine the most suitable connector type. -

What are the minimum order quantities (MOQs) for dolphin connectors?

Minimum order quantities (MOQs) for dolphin connectors can vary significantly depending on the supplier and the specific product line. Typically, MOQs may range from 100 to 1,000 units. It is advisable to inquire directly with suppliers for their specific MOQs. Additionally, some suppliers may offer flexibility for larger orders or provide options for sample orders, allowing you to evaluate product quality before committing to larger quantities. -

How can I vet suppliers of dolphin connectors effectively?

To vet suppliers of dolphin connectors, consider their industry experience, customer reviews, and product certifications. Request samples to assess product quality and ensure they meet your specifications. Verify their manufacturing capabilities and quality assurance processes, such as ISO certifications. Engaging in direct communication can also help gauge their responsiveness and reliability. Finally, check for any references or case studies that demonstrate their experience in serving similar markets or industries. -

What payment terms are commonly offered by suppliers of dolphin connectors?

Payment terms can vary among suppliers, but common options include net 30, net 60, or upfront payments. Many international suppliers may also accept letters of credit or escrow services for larger orders, which can provide added security for both parties. It’s essential to clarify payment terms during negotiations and ensure they align with your cash flow needs. Additionally, inquire about any discounts for early payment or bulk orders, which could enhance your overall cost efficiency. -

What quality assurance measures should I look for when sourcing dolphin connectors?

When sourcing dolphin connectors, look for suppliers that implement rigorous quality assurance (QA) measures. This includes adherence to international standards, such as ISO 9001, and thorough testing protocols for their products. Request documentation on quality control processes, including batch testing and certifications for safety and performance. A reliable supplier should be transparent about their QA practices and willing to provide reports or certificates upon request. -

How do logistics and shipping impact the procurement of dolphin connectors?

Logistics and shipping play a crucial role in the timely procurement of dolphin connectors. Factors such as shipping methods, lead times, and customs regulations can affect delivery schedules and costs. It is important to discuss shipping options with your supplier to find the most efficient and cost-effective solution. Consider potential delays related to international shipping, and ensure that your supplier has a robust logistics plan in place to manage these challenges effectively. -

Can dolphin connectors be customized for specific projects?

Yes, many suppliers offer customization options for dolphin connectors to meet specific project requirements. Customizations can include variations in size, color, or materials, as well as modifications to connector design for unique applications. When pursuing customization, provide detailed specifications and requirements to your supplier. Be prepared for potential lead times associated with custom orders, and ensure that the supplier has the necessary capabilities to deliver the desired modifications.

Top 3 Dolphin Connectors Manufacturers & Suppliers List

1. Dolphin – Super B Beanie Wire Connectors

Domain: snapav.com

Registered: 2006 (19 years)

Introduction: Dolphin Components Super B “Beanie” Wire Connectors, available at Snap One. This product is subject to a Unilateral Pricing Policy and qualifies for a Double Money Back Guarantee. It is not stocked at local pickup locations and ships directly from the vendor, typically within 5–7 business days. This item is reserved for Control4 Authorized partners only.

2. Dolphin – Weatherproof Super B Connector

Domain: industrialcommerciallighting.com

Registered: 2024 (1 years)

Introduction: Weatherproof Dolphin Super B Connector with Sealant – 100 Pieces

Part Number: DC-x-S

Manufacturer Part Number: x

Price: Starting at $9.95 per Pack

In Stock: Yes

Free Shipping: On orders $300 and up within the contiguous U.S.

IP Rating: IP65 (Weatherproof)

Wire Gauge Compatibility: 16 AWG, 18 AWG, 20 AWG, 22 AWG, 24 AWG

Certifications: UL Listed

Finish: Blue

Return Policy: 45-Day Return & 90-Day Ex…

3. Reddit – Dolphin Connectors

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dolphin connectors (also known as B-connectors or beenies) are commonly used for access control terminations. They are easy to use, secure, and can fit into small spaces. Users appreciate that they allow for testing without needing to contact the actual wire conductors. There is a debate on whether to strip wires before using these connectors; some users argue that they should not be stripped as i…

Strategic Sourcing Conclusion and Outlook for dolphin connectors

What Are the Key Takeaways for Sourcing Dolphin Connectors?

In summary, dolphin connectors represent a vital component in various industries, including datacom, electrical, and security sectors. With a legacy of over 50 years, Dolphin Components has established itself as a reliable supplier of high-quality low voltage electrical products. Strategic sourcing of these connectors not only enhances operational efficiency but also ensures compatibility and reliability in your projects. Buyers must evaluate suppliers based on their product range, quality assurance processes, and customer support capabilities.

How Can International B2B Buyers Leverage Strategic Sourcing for Future Growth?

As international B2B buyers from Africa, South America, the Middle East, and Europe (including Germany and Vietnam) look to optimize their supply chains, understanding the nuances of strategic sourcing becomes imperative. Engaging with established manufacturers like Dolphin Components can lead to cost-effective solutions and improved product availability.

What’s Next for Your Sourcing Strategy?

Looking ahead, the demand for high-performance connectors will continue to grow as industries evolve and technology advances. Now is the time to strengthen your partnerships and explore innovative sourcing strategies that align with your business objectives. Take the initiative to contact suppliers, request samples, and assess how dolphin connectors can enhance your projects today. Investing in quality now will pave the way for sustainable success in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to dolphin connectors

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.