The Definitive Guide to Ceramic Processing: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for ceramic processing

Navigating the global market for ceramic processing can be a daunting task for international B2B buyers, especially when sourcing advanced ceramics that meet specific performance standards. The challenge lies not only in identifying reliable suppliers but also in understanding the diverse types of ceramics, their applications, and the associated costs. This comprehensive guide delves into the intricate world of ceramic processing, offering insights into various manufacturing methods, including dry pressing, slip casting, and injection molding.

We explore the wide-ranging applications of ceramics, from traditional pottery to high-tech solutions in aerospace and electronics. This guide also emphasizes the importance of thorough supplier vetting to ensure quality and reliability in your sourcing decisions. By equipping buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Brazil—with actionable insights, we empower them to make informed purchasing decisions.

Whether you are looking to enhance your product line or seeking innovative ceramic solutions, this guide serves as a valuable resource to navigate the complexities of the ceramic market. With the right knowledge, you can confidently engage with suppliers and secure materials that meet your operational needs, ultimately driving your business forward in a competitive landscape.

Understanding ceramic processing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Injection Molding | Uses molten ceramic materials injected into molds. | Electronics, aerospace, medical devices | Pros: High precision, complex shapes. Cons: Initial tooling costs can be high. |

| Slip Casting | Liquid clay poured into plaster molds for shaping. | Tableware, sanitary ware, intricate designs | Pros: Excellent detail, uniform thickness. Cons: Longer cycle times, limited to specific shapes. |

| Dry Pressing | Granular materials compressed into molds. | Industrial applications, automotive parts | Pros: High density, efficient for large volumes. Cons: Potential for density variation and cracks. |

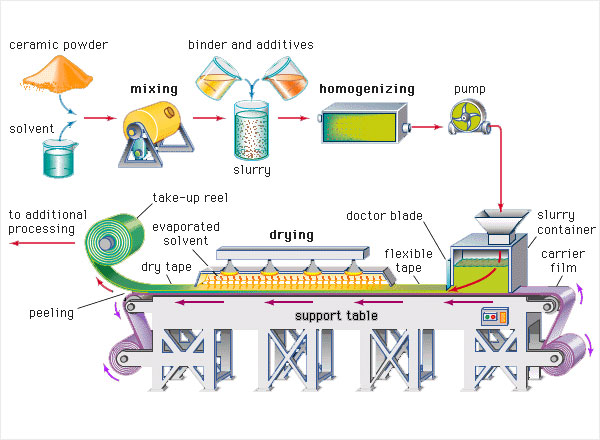

| Tape Casting | Slurry cast onto a flat surface to create thin sheets. | Electronics, capacitors, fuel cells | Pros: Produces uniform thin layers. Cons: Limited to thin products, complex drying process. |

| 3D Printing | Layer-by-layer additive manufacturing of ceramic materials. | Prototyping, custom applications | Pros: Flexibility in design, reduced waste. Cons: Slower production rates, material limitations. |

What Are the Characteristics and Suitability of Injection Molding in Ceramic Processing?

Injection molding is characterized by its ability to produce complex shapes with high precision. This method involves heating ceramic materials until they become molten, then injecting them into molds. It is particularly suitable for industries requiring intricate designs, such as electronics and aerospace. When considering injection molding, B2B buyers should evaluate the initial tooling costs against the volume of production, as this method is most cost-effective for large-scale manufacturing.

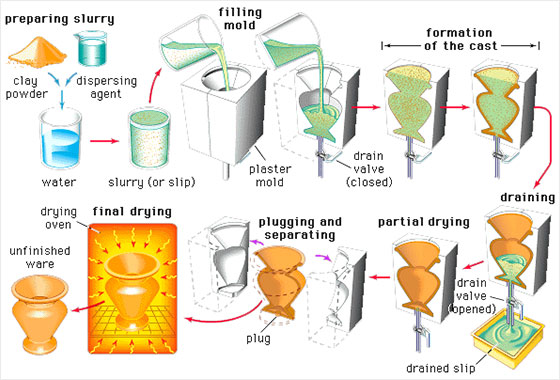

How Does Slip Casting Stand Out in Ceramic Manufacturing?

Slip casting is defined by its use of liquid clay, which is poured into plaster molds. This technique excels in creating detailed and complex shapes, making it ideal for applications like tableware and sanitary ware. B2B buyers should consider the longer cycle times associated with slip casting, as well as its limitations in producing certain geometries. However, the uniform thickness and excellent detail it provides can justify the investment for specific product lines.

What Are the Advantages and Challenges of Dry Pressing?

Dry pressing involves compressing granular ceramic materials into molds, resulting in high-density products. This method is widely used in industrial applications, including automotive parts. Its advantages include efficiency and the ability to produce large volumes, but buyers must be aware of potential issues like density variations and cracking. Ensuring quality control during the pressing process is crucial for maintaining product integrity.

Why Choose Tape Casting for Thin Ceramic Products?

Tape casting is a specialized technique where a ceramic slurry is spread onto a flat surface to create thin layers. This method is primarily used in electronics and fuel cells. The key advantages of tape casting include the production of uniform, thin layers essential for applications requiring precise electrical properties. However, B2B buyers should consider the complexities involved in the drying process and the limitations of this method to thin products only.

How Does 3D Printing Transform Ceramic Processing?

3D printing represents a revolutionary approach to ceramic manufacturing, allowing for the layer-by-layer construction of products. This method provides unparalleled design flexibility and can significantly reduce material waste, making it attractive for prototyping and custom applications. However, B2B buyers should be aware of the slower production rates and the specific material limitations that may affect large-scale manufacturing. Evaluating the trade-offs between design freedom and production efficiency is essential for businesses considering this technology.

Key Industrial Applications of ceramic processing

| Industry/Sector | Specific Application of ceramic processing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Advanced ceramic components for engines | High-temperature resistance, lightweight materials | Certification standards, material properties, supplier reliability |

| Electronics | Ceramic substrates for circuit boards | Enhanced thermal and electrical insulation | Precision manufacturing capabilities, quality control, lead times |

| Medical Devices | Bioceramics for implants | Biocompatibility, durability | Regulatory compliance, material sourcing, long-term supply agreements |

| Automotive | Ceramic brake pads | Improved safety, reduced wear | Performance testing, certification, supplier location |

| Construction Materials | Ceramic tiles and bricks | Aesthetic appeal, durability | Local sourcing, cost efficiency, design flexibility |

How is Ceramic Processing Utilized in Aerospace Applications?

In the aerospace industry, ceramic processing is critical for manufacturing advanced ceramic components used in jet engines and thermal protection systems. These materials are engineered to withstand extreme temperatures while being lightweight, which enhances fuel efficiency. B2B buyers in this sector must ensure that suppliers meet stringent certification standards and can provide detailed specifications on material properties, as performance and safety are paramount.

What Role Does Ceramic Processing Play in Electronics Manufacturing?

Ceramic substrates are essential in electronics for circuit boards, providing excellent thermal and electrical insulation. The precision required in these components means that buyers should prioritize manufacturers with advanced capabilities in ceramic processing, including high-quality control measures and reliable lead times. Meeting the increasing demand for miniaturization in electronics can also necessitate innovative designs, making sourcing from experienced suppliers crucial.

How are Bioceramics Transforming Medical Device Manufacturing?

In the medical field, bioceramics are processed for use in implants due to their biocompatibility and durability. These materials help to reduce the risk of rejection and promote better integration with human tissue. Buyers in this sector must focus on suppliers who comply with regulatory standards and can guarantee consistent quality over time. Long-term partnerships may also be beneficial to ensure a stable supply of these critical materials.

What Benefits Do Ceramic Brake Pads Offer in the Automotive Industry?

Ceramic brake pads, produced through advanced ceramic processing techniques, provide significant advantages in the automotive sector, including improved safety and reduced wear on braking systems. B2B buyers should consider suppliers who conduct rigorous performance testing and can provide certification for their products. Additionally, sourcing from local suppliers may reduce shipping costs and lead times, enhancing overall supply chain efficiency.

How Do Ceramic Tiles and Bricks Enhance Construction Projects?

In construction, ceramic processing is utilized to create aesthetically appealing and durable tiles and bricks. These materials not only enhance the visual appeal of buildings but also offer long-lasting solutions that withstand environmental stressors. Buyers should consider local sourcing options to minimize costs and ensure timely delivery, while also evaluating the design flexibility offered by manufacturers to meet specific project requirements.

3 Common User Pain Points for ‘ceramic processing’ & Their Solutions

Scenario 1: Navigating Raw Material Quality Issues in Ceramic Processing

The Problem: One of the primary challenges faced by B2B buyers in the ceramic processing industry is ensuring the quality and consistency of raw materials. In regions like Africa and South America, sourcing high-quality clay and other ceramic materials can be problematic due to varying local supplier standards. Impurities or inconsistent particle sizes can lead to defects in the final products, resulting in increased waste and production costs. This inconsistency is particularly concerning for industries that require high precision, such as aerospace or electronics, where even minor defects can lead to significant operational issues.

The Solution: To overcome this problem, buyers should establish a robust supplier evaluation process. This includes conducting regular quality audits and requiring suppliers to provide detailed material specifications and certifications. Utilizing advanced techniques like particle size analysis and impurity testing can help ensure that the materials meet the necessary standards. Additionally, forming partnerships with reputable suppliers who specialize in advanced ceramics can help secure consistent material quality. Implementing a strict incoming quality control process, where samples are tested before they enter production, will further minimize risks associated with raw material quality.

Illustrative image related to ceramic processing

Scenario 2: Addressing Inefficiencies in Ceramic Manufacturing Processes

The Problem: Inefficiencies in the ceramic manufacturing process can lead to longer lead times and higher operational costs, particularly for businesses scaling their production. Common issues include bottlenecks during forming and firing stages, which can be exacerbated by outdated equipment or inadequate workforce training. For companies in competitive markets, such inefficiencies can impact profitability and customer satisfaction, particularly if they struggle to meet delivery deadlines.

The Solution: To address these inefficiencies, B2B buyers should consider investing in modern ceramic processing technologies. Upgrading to automated systems for tasks such as mixing, forming, and glazing can drastically improve throughput. For example, switching from manual slip casting to automated injection molding can reduce cycle times and enhance product consistency. Additionally, providing comprehensive training for the workforce on the latest equipment and techniques is crucial for maximizing operational efficiency. Implementing lean manufacturing principles can also help identify and eliminate wasteful practices, ensuring a smoother production flow.

Scenario 3: Overcoming Challenges in Product Customization for Diverse Markets

The Problem: As B2B buyers expand their market reach, particularly in diverse regions like the Middle East and Europe, they often face challenges in customizing ceramic products to meet varying local demands. This need for customization can lead to increased complexity in production processes, as well as difficulties in managing inventory for different product lines. Companies may find themselves overwhelmed by the need to balance standardization with the flexibility required to cater to different customer preferences.

The Solution: To effectively manage product customization, businesses should adopt a modular production approach. This involves designing a core range of products that can be easily modified with different glazes, shapes, or sizes to meet specific customer requirements. Investing in flexible manufacturing systems that allow for quick reconfiguration can help streamline the production of customized items. Furthermore, establishing a clear communication channel with customers to gather feedback on their needs will ensure that product offerings align closely with market demands. Utilizing digital tools for inventory management can also enhance visibility, allowing companies to adjust stock levels based on the specific preferences of different regions.

Strategic Material Selection Guide for ceramic processing

What Are the Key Properties of Common Materials Used in Ceramic Processing?

Ceramic processing involves various materials, each with distinct properties that influence their performance in specific applications. Here, we analyze four common materials: alumina, silicon carbide, zirconia, and boron nitride.

Alumina: A Versatile Choice for Many Applications

Alumina, or aluminum oxide, is one of the most widely used materials in ceramic processing due to its excellent mechanical properties and thermal stability. It can withstand high temperatures (up to 1,600°C) and exhibits good corrosion resistance, making it suitable for applications in harsh environments, such as aerospace and automotive industries.

Pros: Alumina is relatively cost-effective and can be produced in various forms, from dense ceramics to porous structures. Its high hardness and wear resistance make it ideal for cutting tools and wear-resistant components.

Cons: While alumina has many advantages, it can be brittle, leading to potential failure under impact. Additionally, the manufacturing process can be complex, requiring precise control over sintering conditions.

Impact on Application: Alumina is compatible with a wide range of media, including acids and alkalis, which enhances its versatility in chemical processing applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and compliance with international standards (e.g., ASTM, ISO). The cost-effectiveness of alumina makes it a popular choice in developing markets.

Silicon Carbide: High Performance in Extreme Conditions

Silicon carbide (SiC) is renowned for its exceptional hardness and thermal conductivity, making it suitable for high-performance applications such as semiconductor manufacturing and high-temperature environments.

Pros: SiC can withstand temperatures exceeding 1,600°C and has excellent chemical resistance, particularly against oxidation. Its mechanical strength and thermal shock resistance make it ideal for demanding applications.

Cons: The primary drawback of silicon carbide is its high cost compared to other ceramic materials. Additionally, the complexity of the manufacturing process can limit production scalability.

Impact on Application: SiC’s compatibility with various media, including corrosive chemicals, makes it invaluable in industries like aerospace and automotive where durability is critical.

Considerations for International Buyers: Buyers should be aware of the stringent quality standards associated with SiC products, especially in Europe and the Middle East, where compliance with regulations can affect market entry.

Zirconia: Strength and Toughness for Specialized Applications

Zirconia (ZrO2) is known for its high fracture toughness and resistance to wear, making it ideal for applications in dental ceramics and thermal barrier coatings.

Pros: Zirconia exhibits excellent mechanical properties and can operate at high temperatures without degrading. Its aesthetic appeal also makes it suitable for dental applications, where appearance is crucial.

Cons: Zirconia can be more expensive than alumina and may require specialized processing techniques, such as sintering in a controlled atmosphere, to achieve optimal properties.

Impact on Application: Zirconia’s ability to withstand thermal cycling makes it suitable for applications in environments with fluctuating temperatures, such as gas turbines.

Considerations for International Buyers: Buyers should consider the availability of specialized processing equipment and compliance with dental and medical standards, particularly in Europe and the Middle East.

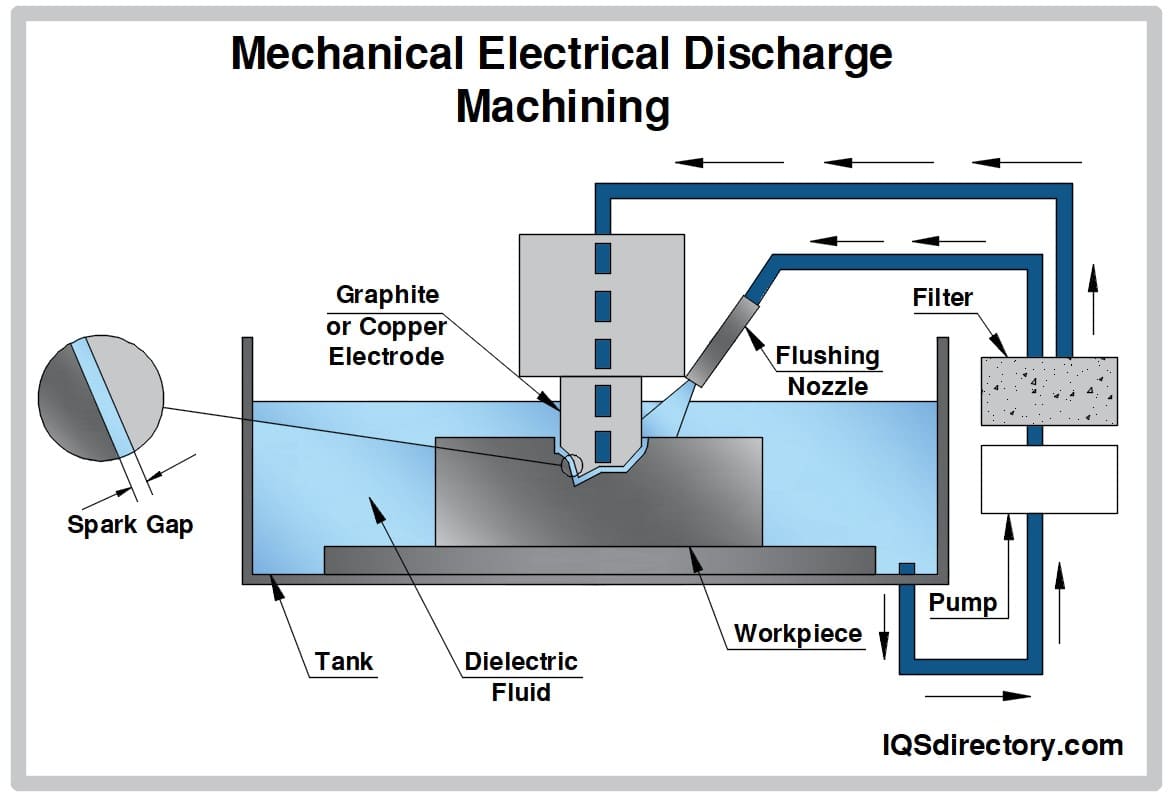

Illustrative image related to ceramic processing

Boron Nitride: A Unique Material for Specialized Applications

Boron nitride (BN) is a versatile material known for its high thermal conductivity and electrical insulation properties. It is often used in applications requiring high thermal stability and low friction.

Pros: BN can operate at temperatures up to 2,000°C and offers excellent chemical resistance, making it suitable for high-performance applications in electronics and aerospace.

Cons: The primary limitation of boron nitride is its cost, which can be significantly higher than that of traditional ceramic materials. Additionally, its brittleness can pose challenges in certain applications.

Illustrative image related to ceramic processing

Impact on Application: BN’s compatibility with various media, including molten metals and corrosive chemicals, enhances its utility in specialized industrial applications.

Considerations for International Buyers: Buyers should assess the cost-benefit ratio of using boron nitride in their applications and ensure compliance with international standards, especially in high-tech industries.

Summary Table of Material Selection for Ceramic Processing

| Material | Typical Use Case for ceramic processing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | Cutting tools, wear-resistant components | Cost-effective and versatile | Brittle; complex manufacturing | Medium |

| Silicon Carbide | Semiconductor manufacturing, aerospace | High thermal stability and strength | High cost; limited scalability | High |

| Zirconia | Dental ceramics, thermal barrier coatings | Excellent toughness and aesthetics | Expensive; requires specialized processing | High |

| Boron Nitride | Electronics, aerospace applications | High thermal conductivity | High cost; brittleness | High |

This guide provides B2B buyers with essential insights into material selection for ceramic processing, enabling informed decisions that align with their operational needs and market conditions.

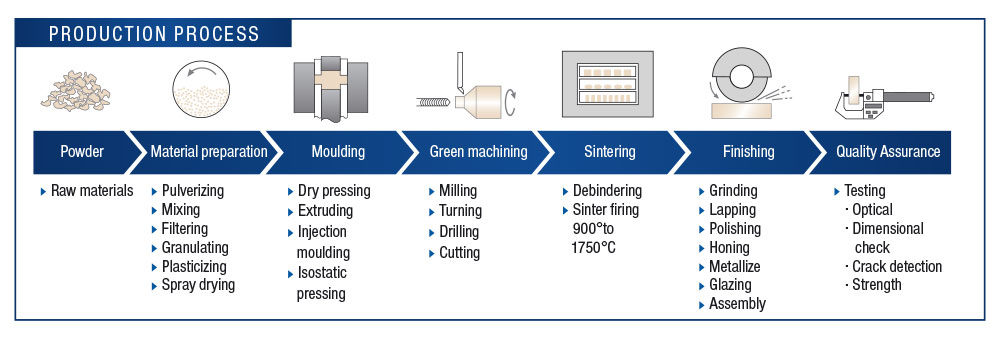

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic processing

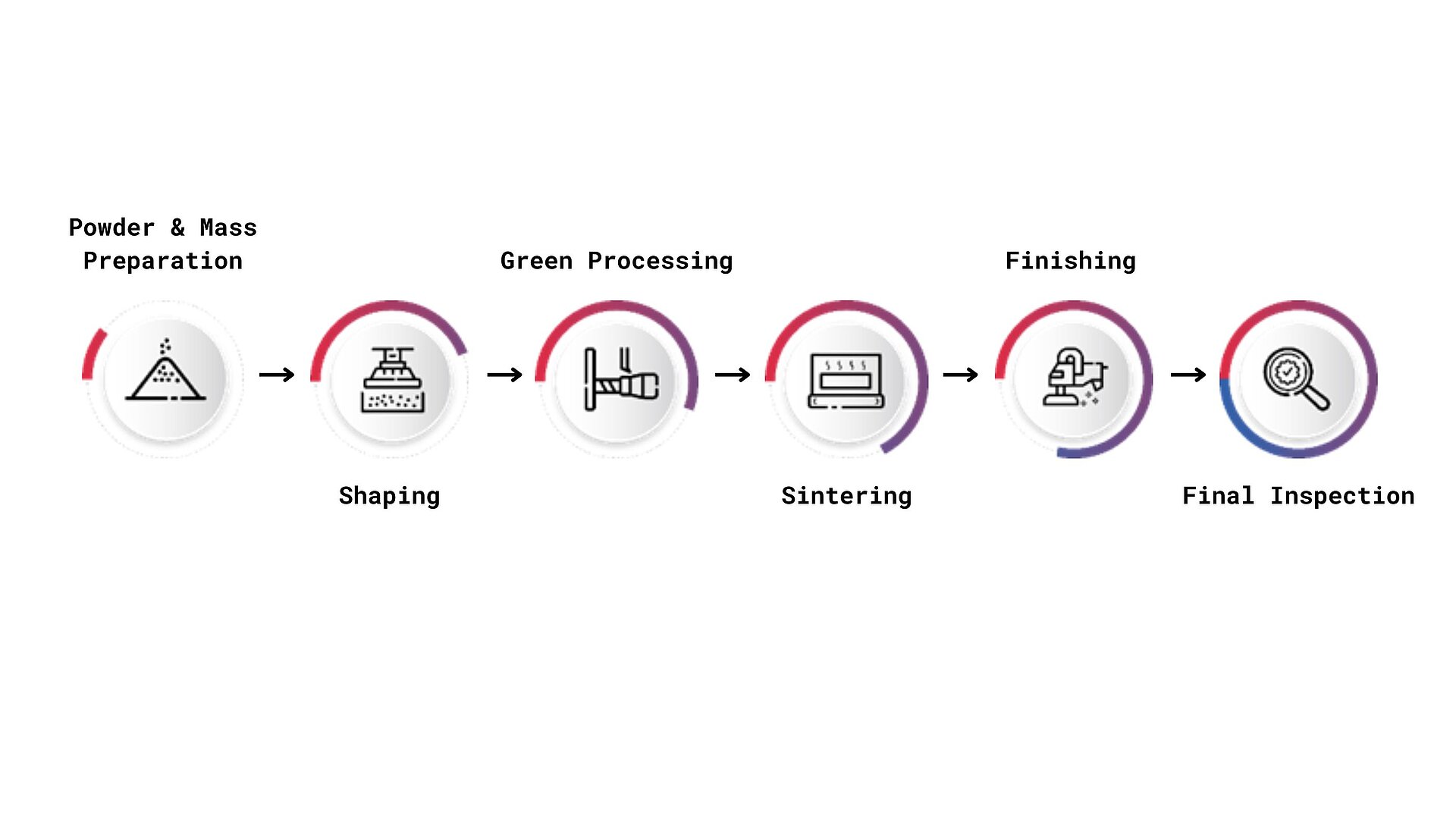

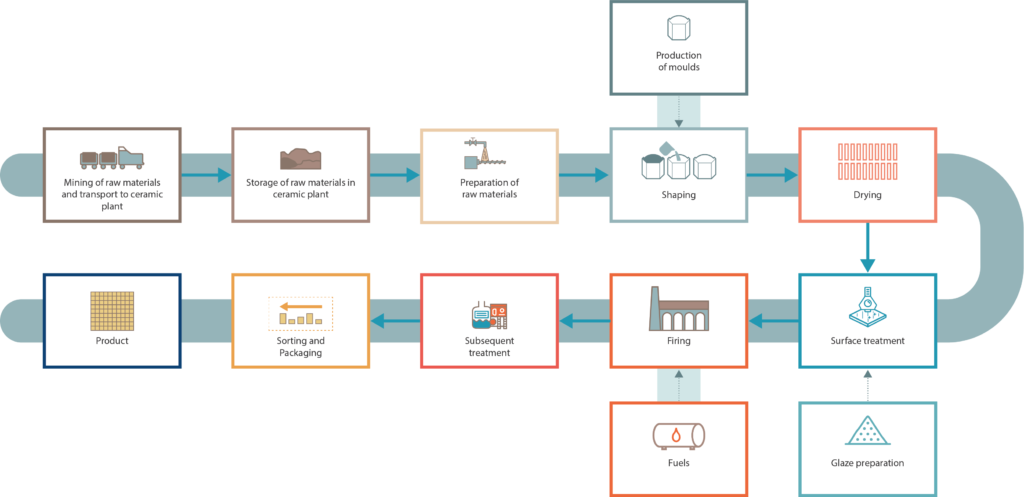

What Are the Main Stages of the Ceramic Manufacturing Process?

Ceramic processing is a complex and multi-faceted operation that involves several critical stages. Understanding these stages can help B2B buyers identify the capabilities of potential suppliers and ensure they meet specific production requirements.

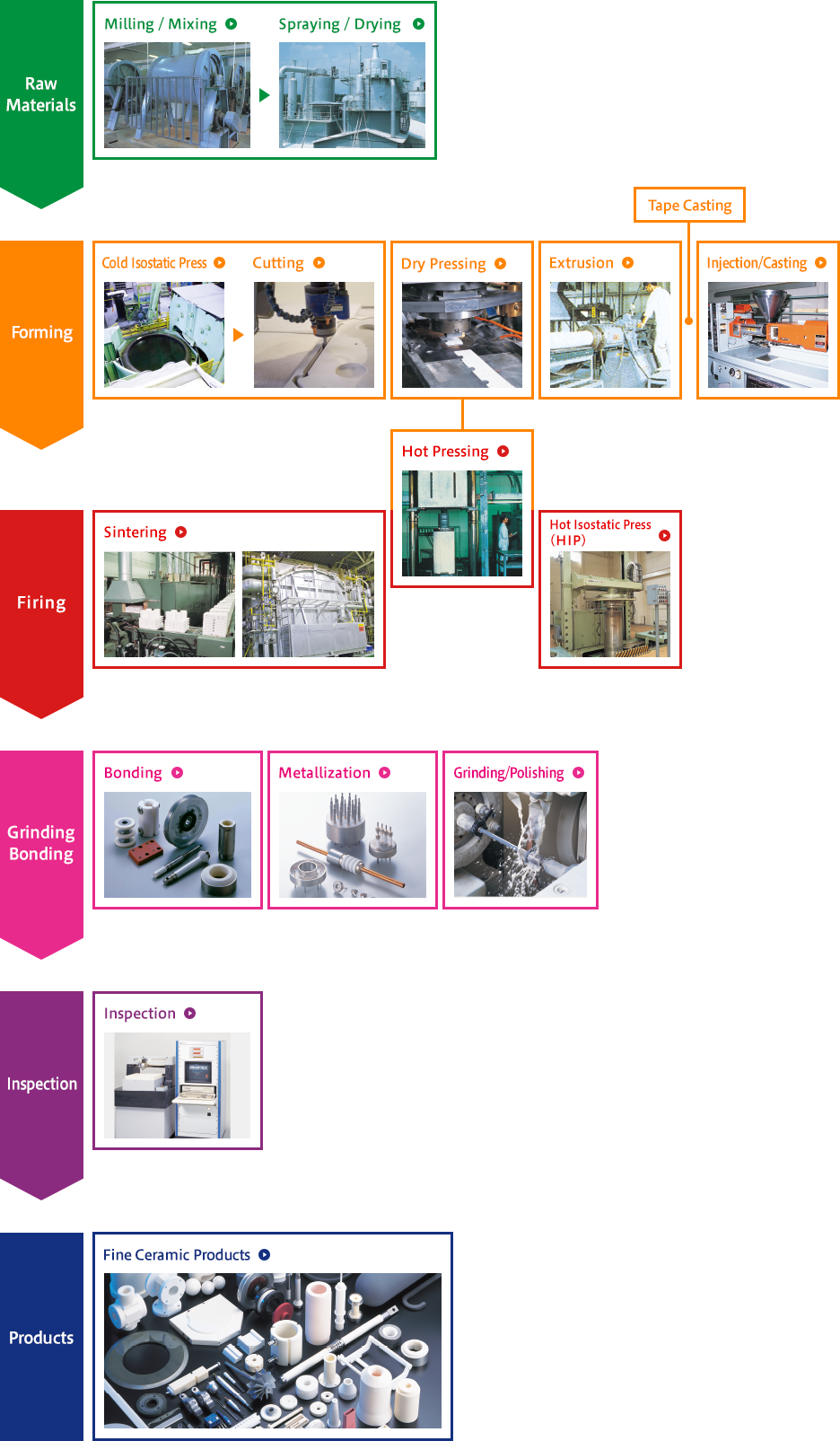

How Is Material Prepared in Ceramic Processing?

The first step in ceramic manufacturing is material preparation. This includes sourcing high-quality raw materials such as clay, silica, and various additives. The materials undergo milling to achieve a uniform particle size, which is crucial for consistency in the final product. Impurities are removed to ensure the integrity of the ceramic materials. B2B buyers should inquire about the sourcing and quality control measures suppliers employ at this stage, as it can significantly affect the properties of the final product.

What Techniques Are Used for Forming Ceramics?

Once the materials are prepared, the forming process begins. Various techniques are employed depending on the desired product characteristics:

-

Injection Molding: This method involves heating the ceramic materials until they become pliable, then injecting them into molds. It is particularly effective for producing complex shapes with high precision and can be automated for mass production.

-

Slip Casting: A liquid clay mixture is poured into plaster molds, allowing for intricate shapes that might be difficult to achieve with other methods. This technique is ideal for items such as porcelain dinnerware.

-

Dry Pressing: This involves compressing granulated ceramic powders into molds under high pressure. The result is a dense and strong product, although it may have limitations in terms of shape complexity.

Understanding these techniques will help B2B buyers evaluate whether a supplier can meet specific design and functional requirements.

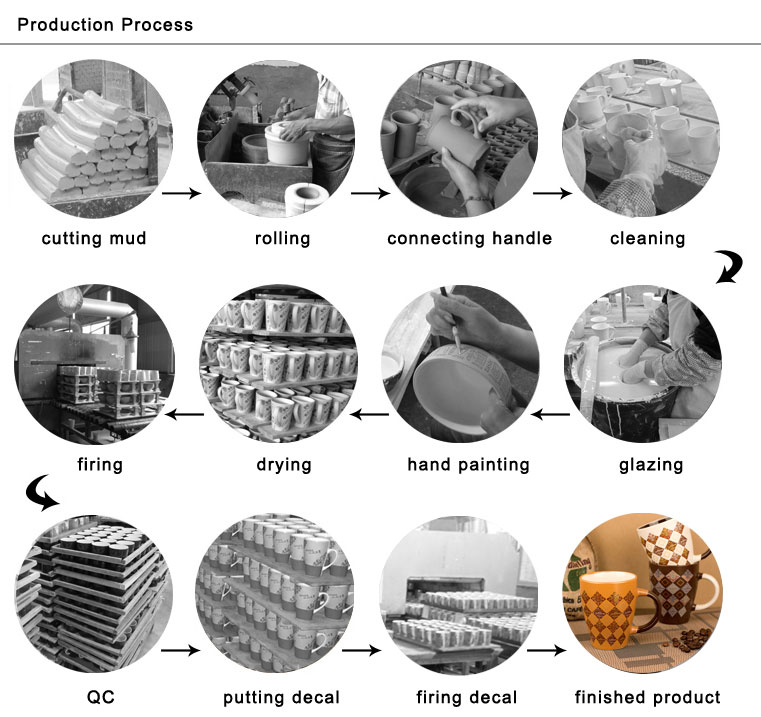

How Is the Finishing Process Conducted in Ceramic Manufacturing?

After forming, the ceramics undergo a finishing process that often includes glazing and firing.

-

Glazing: This step involves applying a liquid glaze to the ceramic surface, which can enhance aesthetics and provide a protective layer. Various glazing techniques exist, including spray glazing and dipping, which can affect the final appearance and durability.

-

Firing: The glazed ceramics are then subjected to high temperatures in a sintering oven. This process solidifies the material, giving it strength and durability. The firing temperature and duration are critical factors that influence the final properties of the ceramic.

B2B buyers should verify the types of finishing techniques used by suppliers to ensure that the final products meet quality standards and client expectations.

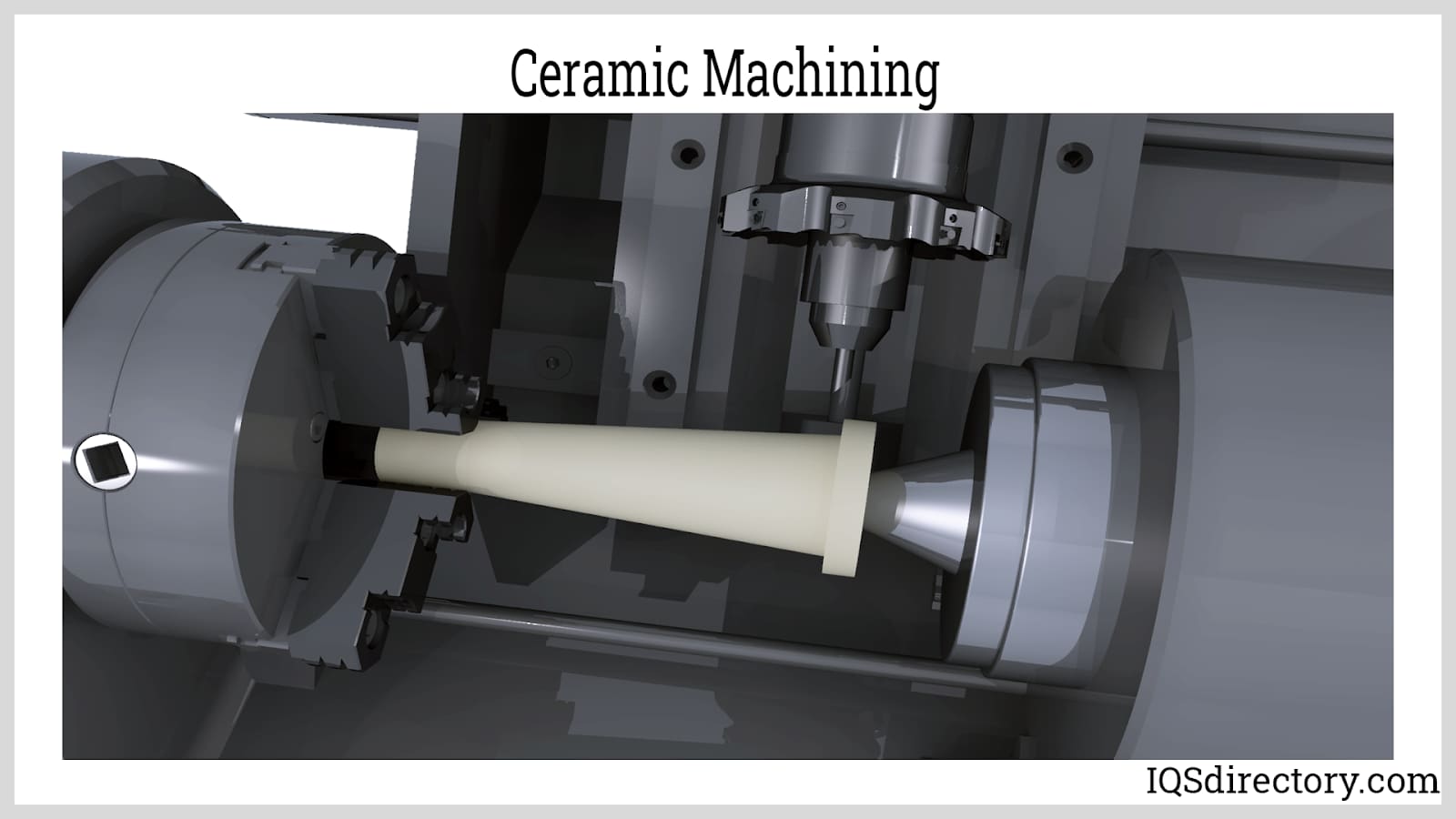

Illustrative image related to ceramic processing

What Quality Assurance Measures Are Critical in Ceramic Processing?

Quality assurance (QA) is essential in ceramic manufacturing to ensure that the products meet international standards and customer expectations.

Which International Standards Should Be Considered?

International standards such as ISO 9001 provide a framework for quality management systems that can enhance operational efficiency and customer satisfaction. Suppliers should be able to demonstrate compliance with these standards. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for ceramics used in the oil and gas sector may also be relevant.

What Are the Key Quality Control Checkpoints in Ceramic Manufacturing?

Quality control checkpoints are vital at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should confirm that suppliers have rigorous testing procedures in place for incoming materials.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is essential to identify any deviations from specified parameters. This may include checking the consistency of the mixture, monitoring forming techniques, and assessing the firing process.

-

Final Quality Control (FQC): After production, finished products undergo thorough inspections to ensure they meet quality specifications. Common testing methods include dimensional checks, mechanical property assessments, and surface quality evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of potential suppliers is crucial to mitigate risks associated with product quality.

What Should B2B Buyers Look for During Audits?

Conducting supplier audits can provide valuable insights into the quality control processes in place. Buyers should assess the supplier’s adherence to international standards, the effectiveness of their quality management system, and the training provided to their workforce regarding quality assurance.

How Important Are Quality Control Reports and Third-Party Inspections?

Suppliers should be able to provide detailed quality control reports that outline testing results and compliance with relevant standards. Third-party inspections can also add an additional layer of assurance, offering unbiased evaluations of the manufacturing processes and end products. B2B buyers should request documentation from these inspections to verify the credibility of their suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regulatory Differences Impact Quality Assurance?

Different regions may have varying regulations and standards governing ceramic products. Buyers should be aware of these differences and ensure that their suppliers comply with both local and international regulations. This is particularly important for products that may be exported or used in regulated industries.

What Role Does Communication Play in Ensuring Quality?

Establishing clear communication with suppliers about quality expectations is critical. B2B buyers should engage in discussions about quality control measures, testing protocols, and compliance standards to ensure alignment. Regular updates and feedback loops can help maintain product quality throughout the manufacturing process.

In summary, understanding the manufacturing processes and quality assurance measures in ceramic processing is vital for B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and robust quality control mechanisms, buyers can make informed decisions and establish strong partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic processing’

Introduction

Navigating the procurement process for ceramic processing can be complex, particularly for international B2B buyers. This guide provides a clear, step-by-step checklist to help you effectively source ceramic processing equipment and materials. Each step is designed to ensure you make informed decisions that align with your operational needs and business goals.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for ceramic processing. This includes specifying the types of ceramics you intend to produce, such as traditional ceramics or advanced technical ceramics.

– Considerations: Think about the size, shape, and volume of products you need, as well as any specific performance characteristics, such as thermal resistance or electrical insulation.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in ceramic processing equipment and materials. Utilize industry directories, trade shows, and online platforms to compile a list of potential partners.

– What to Look For: Evaluate suppliers based on their industry experience, product offerings, and geographical reach, especially focusing on suppliers familiar with your regional market, such as those in Africa, South America, the Middle East, or Europe.

Illustrative image related to ceramic processing

Step 3: Evaluate Supplier Certifications

Verify the certifications of potential suppliers to ensure they meet international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems.

– Importance: This step reduces the risk of receiving subpar materials or equipment that could compromise your production quality or compliance with local regulations.

Step 4: Request Product Samples

Always request samples of materials or equipment before making a bulk purchase. This allows you to assess the quality and suitability of the products for your specific applications.

– Evaluation Criteria: Check for consistency, durability, and adherence to your technical specifications. If possible, conduct tests to evaluate performance under your operational conditions.

Step 5: Assess Manufacturing Capabilities

Understand the manufacturing capabilities of your potential suppliers. This includes their production capacity, technology used, and lead times for orders.

– Why It Matters: Ensuring that a supplier can meet your demand within your required timeframe is crucial for maintaining your production schedule and avoiding delays.

Step 6: Negotiate Pricing and Terms

Once you have selected a preferred supplier, enter into negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget and expectations.

– Key Aspects: Discuss bulk order discounts, warranty terms, and after-sales support to ensure you receive the best value for your investment.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your supplier. This should outline how you will exchange information about orders, quality checks, and potential issues that may arise.

– Importance: Effective communication is vital for addressing concerns promptly and ensuring a smooth operational relationship moving forward. Regular check-ins can help maintain alignment and foster a strong partnership.

By following this checklist, B2B buyers can streamline their sourcing process for ceramic processing, ensuring they select the right partners and materials for their production needs.

Comprehensive Cost and Pricing Analysis for ceramic processing Sourcing

What Are the Key Cost Components in Ceramic Processing Sourcing?

When evaluating the cost structure of ceramic processing, several components come into play. Understanding these can help B2B buyers make informed decisions.

Illustrative image related to ceramic processing

-

Raw Materials: The cost of raw materials is often the largest expense in ceramic processing. Traditional ceramics rely on clay minerals, while advanced ceramics may incorporate specialized compounds like tungsten carbide or silicon carbide. Prices can vary significantly based on material quality, sourcing location, and market demand.

-

Labor: Labor costs encompass wages for skilled technicians, engineers, and factory workers involved in the ceramic manufacturing process. Regions with lower labor costs may offer competitive pricing, but it’s crucial to consider skill levels and training, as they impact product quality and production efficiency.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and indirect labor. Overhead costs can vary widely depending on the operational scale and location of the manufacturing facility.

-

Tooling and Equipment: Investment in specialized machinery—such as milling machines, sintering ovens, and casting machines—can be significant. Buyers should assess whether the supplier has up-to-date equipment, as older machines may lead to inefficiencies and increased production costs.

-

Quality Control (QC): Ensuring product quality incurs costs associated with inspection, testing, and compliance with industry standards. Buyers should prioritize suppliers who invest in robust QC processes, as this can prevent costly reworks and product failures.

-

Logistics: Transporting raw materials and finished products adds another layer of costs. Factors such as distance, shipping methods, and Incoterms influence logistics expenses. International buyers should also factor in customs duties and tariffs.

-

Profit Margin: Finally, suppliers will add a profit margin to cover their business risks and ensure sustainability. This margin can vary based on market competition, supplier reputation, and the complexity of the ceramics being produced.

How Do Price Influencers Affect Ceramic Processing Costs?

Several key factors influence pricing in ceramic processing, which buyers should consider when sourcing.

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to reduced unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specialized specifications can drive up costs. Clearly communicating requirements can help manage expectations and avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and products with industry certifications typically command higher prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the agreed Incoterms is critical, as they define responsibilities for shipping, insurance, and tariffs. This knowledge can help buyers anticipate total costs more accurately.

What Tips Can Buyers Use for Negotiating and Achieving Cost Efficiency?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to substantial savings.

-

Engage in Open Dialogue: Establishing a strong relationship with suppliers can facilitate better negotiation outcomes. Transparency about needs and budget can lead to mutually beneficial agreements.

-

Consider Total Cost of Ownership (TCO): Beyond initial purchase prices, buyers should evaluate the TCO, which includes maintenance, operational costs, and potential rework expenses. This broader perspective can lead to smarter purchasing decisions.

-

Research Market Trends: Staying informed about market fluctuations, material costs, and industry standards can empower buyers during negotiations. Leverage this knowledge to advocate for fair pricing.

-

Explore Local Sourcing: In some cases, sourcing materials locally can reduce logistics costs and lead times. Buyers should evaluate local suppliers as a viable alternative to international ones.

-

Be Aware of Pricing Nuances: International buyers may face unique challenges such as currency fluctuations and differing taxation policies. Understanding these nuances can help buyers navigate pricing discussions more effectively.

Disclaimer

The prices and cost structures mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to ceramic processing

Alternatives Analysis: Comparing ceramic processing With Other Solutions

Understanding Alternatives to Ceramic Processing for Industrial Applications

In the realm of manufacturing, ceramic processing is a well-established method for producing durable and high-performance materials. However, there are alternative solutions that may cater to specific needs or applications. This section provides a comparative analysis of ceramic processing against two viable alternatives: metal injection molding (MIM) and polymer-based additive manufacturing (3D printing). Understanding these alternatives can help international B2B buyers make informed decisions tailored to their operational requirements.

| Comparison Aspect | Ceramic Processing | Metal Injection Molding (MIM) | Polymer-Based Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High strength, excellent wear resistance | High precision, good mechanical properties | Versatile designs, suitable for complex geometries |

| Cost | Moderate initial investment; lower operational costs | High tooling costs, but lower per-unit cost at scale | Lower initial costs; variable costs based on material and complexity |

| Ease of Implementation | Requires specialized equipment and processes | High setup complexity; requires skilled labor | User-friendly; minimal training required for operation |

| Maintenance | Moderate; equipment needs regular checks | High; molds require regular maintenance | Low; mainly software and printer upkeep |

| Best Use Case | Aerospace, electronics, medical devices | Automotive parts, industrial components | Prototyping, small batch production, custom parts |

Analyzing Metal Injection Molding (MIM)

Metal injection molding (MIM) is an alternative that combines the advantages of plastic injection molding with the performance of metal materials. MIM is particularly effective for producing complex shapes and intricate parts with high precision. The process involves mixing metal powders with a binder, injecting the mixture into molds, and then removing the binder through a debinding process before sintering.

Pros: MIM offers high production rates and is cost-effective for large volumes. It also allows for the creation of parts with excellent mechanical properties and surface finishes.

Cons: However, the initial costs for tooling and setup can be significant, and the process requires skilled labor. Additionally, the materials used may have limitations in terms of temperature resistance compared to advanced ceramics.

Evaluating Polymer-Based Additive Manufacturing (3D Printing)

Polymer-based additive manufacturing, commonly known as 3D printing, has gained popularity for its versatility and ease of use. This method allows manufacturers to create complex geometries and customized parts without the need for extensive tooling. It can accommodate a wide range of polymers, providing flexibility in material selection.

Illustrative image related to ceramic processing

Pros: The initial investment is typically lower than ceramic processing or MIM, and the ability to rapidly prototype designs is a significant advantage. Furthermore, 3D printing can reduce waste, as materials are added layer by layer.

Cons: Despite its advantages, the mechanical properties of polymer parts are generally inferior to those of ceramics or metals. Additionally, production speed can be slower for larger quantities, making it less suitable for high-volume applications.

Making the Right Choice for Your Business Needs

Choosing the appropriate processing method depends heavily on the specific requirements of your application. For industries requiring high durability and thermal resistance, ceramic processing may be the best choice. Conversely, if precision and intricate designs are paramount, metal injection molding could be more advantageous. For rapid prototyping and customization, polymer-based additive manufacturing presents a compelling option.

By evaluating the strengths and weaknesses of each alternative, B2B buyers can align their manufacturing processes with their operational goals, ensuring they select the most efficient and effective solution for their needs.

Essential Technical Properties and Trade Terminology for ceramic processing

What Are the Key Technical Properties in Ceramic Processing?

Understanding the technical properties of ceramics is essential for B2B buyers in industries ranging from construction to electronics. Here are some critical specifications that play a vital role in ensuring product quality and performance:

1. Material Grade

Material grade refers to the specific classification of ceramic materials based on their composition and mechanical properties. High-grade ceramics, such as alumina or zirconia, offer superior strength, wear resistance, and thermal stability. For B2B buyers, selecting the right material grade can impact the durability and functionality of the end product, making it crucial for applications that require high performance.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension. In ceramic processing, tight tolerances are often required for precision components, particularly in industries such as aerospace and medical devices. Understanding tolerance specifications is essential for B2B buyers to ensure that components fit perfectly and operate as intended, minimizing the risk of defects and costly rework.

3. Density

Density is a measure of mass per unit volume and is critical in assessing the strength and durability of ceramic materials. Higher density typically correlates with better mechanical properties, making it an important factor for applications in high-stress environments. For buyers, knowing the density of the ceramics can inform choices about material suitability for specific applications.

Illustrative image related to ceramic processing

4. Hardness

Hardness indicates a material’s resistance to deformation or scratching. In ceramic processing, hardness is often assessed using scales such as Mohs or Vickers. Hard ceramics are essential in applications requiring wear resistance, such as cutting tools and grinding media. B2B buyers should prioritize hardness specifications to ensure longevity and performance in demanding environments.

5. Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat. In ceramics, this property is vital for applications in electronics and aerospace, where temperature control is critical. Understanding thermal conductivity helps B2B buyers select materials that can effectively manage heat transfer, reducing the risk of overheating and failure in end products.

What Common Trade Terms Should B2B Buyers Know in Ceramic Processing?

Familiarity with industry terminology is crucial for effective communication and negotiation in ceramic processing. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. In the ceramics industry, OEMs often create specialized ceramic components for various applications. B2B buyers should consider OEM partnerships to access high-quality, tailored products that meet specific industry requirements.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure that they meet supplier requirements while managing inventory effectively. It can influence purchasing decisions and impact overall cost management.

Illustrative image related to ceramic processing

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products or services. In the ceramic processing sector, an RFQ helps streamline the procurement process by providing clear specifications, quantities, and delivery timelines. B2B buyers should prepare detailed RFQs to receive accurate and competitive quotes.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. They clarify who is responsible for shipping costs, insurance, and risk during transportation. B2B buyers should familiarize themselves with Incoterms to avoid misunderstandings and ensure smooth transactions across borders.

5. Sintering

Sintering is a key process in ceramic manufacturing where powdered materials are heated to a temperature below their melting point to form a solid mass. This process is crucial for enhancing the mechanical properties of ceramics. Understanding sintering can help B2B buyers appreciate the production techniques that influence the quality and performance of ceramic products.

Conclusion

By grasping the essential technical properties and trade terminology associated with ceramic processing, B2B buyers can make informed decisions that enhance product quality and operational efficiency. Knowledge in these areas not only fosters better supplier relationships but also contributes to the overall success of their projects and applications.

Navigating Market Dynamics and Sourcing Trends in the ceramic processing Sector

What Are the Current Market Trends Influencing the Ceramic Processing Sector?

The ceramic processing sector is experiencing robust growth driven by several global factors. A notable trend is the increasing demand for advanced ceramics in industries such as aerospace, electronics, and medical applications, which require high-performance materials that offer superior durability and thermal resistance. In regions like Africa and South America, the construction boom is propelling the demand for traditional ceramics such as tiles and bricks, while the Middle East sees a growing interest in innovative ceramic solutions for oil and gas extraction technologies.

Illustrative image related to ceramic processing

Emerging technologies, such as additive manufacturing and digitalization, are transforming traditional manufacturing processes. For B2B buyers, this means the opportunity to source more precise and customized ceramic components, leading to enhanced product performance and cost savings. Additionally, the trend towards automation in production is reducing lead times and increasing efficiency, making it essential for international buyers to seek suppliers who can adapt to these technological advancements.

Furthermore, the ceramic processing market is becoming increasingly competitive, with suppliers from Europe and Asia capitalizing on their established manufacturing capabilities. Buyers from regions like Nigeria and Brazil must navigate this landscape carefully, assessing not only price but also the technological capabilities and reliability of suppliers to ensure they meet their specific project requirements.

How Are Sustainability and Ethical Sourcing Shaping the Ceramic Processing Industry?

Sustainability has emerged as a critical concern in the ceramic processing sector, influencing sourcing decisions for international B2B buyers. The environmental impact of ceramic production, including energy consumption and waste generation, has prompted manufacturers to seek greener practices. Buyers are increasingly prioritizing suppliers who implement eco-friendly manufacturing processes, such as using renewable energy sources and minimizing water usage.

Ethical sourcing is equally important, as buyers demand transparency in their supply chains. This includes ensuring that raw materials are sourced responsibly, without contributing to environmental degradation or social injustices. Certifications such as ISO 14001 for environmental management and LEED for sustainable building materials are becoming essential criteria for suppliers. Buyers should look for partners who can demonstrate compliance with these standards, as this not only enhances their own brand reputation but also aligns with the growing consumer demand for sustainable products.

Moreover, the adoption of ‘green’ materials, such as recycled ceramics and non-toxic glazes, is on the rise. This shift not only addresses environmental concerns but also opens new market opportunities for innovative ceramic products that appeal to eco-conscious consumers.

What Historical Developments Have Influenced Modern Ceramic Processing?

The evolution of ceramic processing dates back thousands of years, beginning with primitive pottery crafted from natural clay. Over time, advancements in technology have significantly transformed the industry. The introduction of high-temperature sintering and advanced forming techniques, such as injection molding and slip casting, have allowed for the production of complex shapes and high-performance ceramics.

In the last century, the demand for specialized ceramics in sectors like electronics and aerospace catalyzed the development of advanced materials, including alumina and silicon carbide. These materials are now pivotal in applications ranging from semiconductors to body armor. The shift from artisanal to industrial production has not only increased efficiency but also introduced stringent quality controls, making today’s ceramic products more reliable and versatile than ever before.

As international B2B buyers navigate the ceramic processing landscape, understanding this historical context can provide valuable insights into the capabilities and innovations available in the market today.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic processing

-

How do I choose the right supplier for ceramic processing?

Choosing the right supplier involves thorough research and vetting. Start by evaluating their experience in ceramic processing and their production capabilities. Request samples of their products to assess quality and consistency. It’s also essential to check customer reviews and testimonials. Ensure the supplier complies with international quality standards, such as ISO certifications. Communication is key; a responsive supplier who understands your needs can significantly enhance your purchasing experience. -

What are the common methods for ceramic processing?

Common methods for ceramic processing include dry pressing, slip casting, and injection molding. Dry pressing is favored for its efficiency and ability to produce high-density products. Slip casting is ideal for complex shapes and high precision. Injection molding is widely used for mass production of intricate designs. Each method has its advantages and is chosen based on the product specifications and production volume requirements. -

What factors should I consider when negotiating payment terms with ceramic suppliers?

When negotiating payment terms, consider factors such as order size, supplier reputation, and your credit history. Common payment terms include upfront deposits, net 30, or net 60 days. Ensure terms are mutually beneficial to maintain a healthy business relationship. Additionally, inquire about payment methods accepted (e.g., bank transfers, letters of credit) and any discounts for early payments or bulk orders. -

What is the minimum order quantity (MOQ) for ceramic products?

Minimum order quantities for ceramic products can vary significantly among suppliers, typically ranging from 100 to several thousand units. Factors influencing MOQ include the complexity of the product, production methods, and material costs. If your needs are below the MOQ, discuss customization options or see if the supplier can accommodate smaller orders, possibly at a higher price per unit. -

How can I ensure quality assurance in ceramic products?

To ensure quality assurance, request detailed information about the supplier’s quality control processes. Look for certifications like ISO 9001, which indicate adherence to quality management standards. Consider implementing third-party inspections at various production stages or upon delivery. Establish clear specifications and testing protocols to ensure the final products meet your requirements and industry standards. -

What are the logistics considerations for importing ceramic products?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling ceramics, as they can provide guidance on best practices for packaging and shipping. Be aware of import duties and taxes that may apply. Additionally, ensure that the supplier provides proper documentation to facilitate smooth customs clearance. -

How do I address issues with defective ceramic products?

In case of defective products, promptly communicate with your supplier. Document the issues with photos and detailed descriptions to support your claim. Review the supplier’s return and warranty policy before purchasing, as this will dictate how returns are handled. A reputable supplier will often offer replacements or refunds for defective items. Establishing a clear communication channel can help resolve disputes efficiently. -

What advanced ceramic materials should I consider for specialized applications?

For specialized applications, consider advanced ceramic materials like silicon carbide, alumina, and zirconia. Silicon carbide is known for its excellent wear resistance and thermal stability, making it ideal for aerospace and automotive sectors. Alumina is widely used for electronic components due to its electrical insulation properties. Zirconia offers high toughness and is suitable for biomedical applications. Assess your specific application needs to select the most suitable material.

Top 7 Ceramic Processing Manufacturers & Suppliers List

1. Sentro Tech – Industrial Furnaces & Heating Elements

Domain: sentrotech.com

Registered: 2000 (25 years)

Introduction: Industrial Furnaces & Ovens: Muffle & Box Furnaces (1200°C to 1800°C), Vacuum Furnaces, Sintering Furnaces, Tube Furnaces (Horizontal, Vertical, Rotary), Custom Industrial Furnaces, Custom Muffle Furnaces, Custom Vacuum Furnaces, Custom Tube Furnaces. Furnace Heating Elements: MoSi2 Heating Elements, Custom Heating Elements, Heating Element Holders, Braided Contact Straps, Terminal Clamps. Ceramic…

2. Ceramic Processing – 1st Edition

Domain: link.springer.com

Registered: 1997 (28 years)

Introduction: {‘title’: ‘Ceramic Processing’, ‘edition’: ‘1st’, ‘publish_date’: ’31 July 1995′, ‘softcover_price’: ‘USD 169.99’, ‘hardcover_price’: ‘USD 169.99’, ‘softcover_ISBN’: ‘978-94-010-4236-9’, ‘hardcover_ISBN’: ‘978-0-412-59830-2’, ‘eBook_ISBN’: ‘978-94-011-0531-6’, ‘number_of_pages’: ‘217’, ‘editors’: [‘R. A. Terpstra’, ‘P. P. A. C. Pex’, ‘A. H. Vries’], ‘publisher’: ‘Springer Dordrecht’, ‘access_info’…

3. ScienceDirect – Ceramics Processing

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Ceramics processing involves systematic alterations to enhance the chemical and physical properties of ceramic components for improved performance and reliability. Key processes include forming shapes from powders mixed with water and organic binders, followed by densification through sintering at temperatures of 950 to 1300 °C. Specific methods for preparing hydroxyapatite (HA) ceramics include a…

4. Slideshare – Ceramics Processing Essentials

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: This document discusses the processing of traditional and new ceramics, highlighting key steps such as preparation of raw materials, shaping, drying/dewatering, and firing/sintering. Traditional ceramics utilize naturally occurring minerals that are powdered and shaped through methods like slip casting or plastic forming, followed by drying and firing. New ceramics employ synthetic powders and adv…

5. Cleveland Vibrator – Industrial Vibratory Solutions

Domain: solutionsinmotion.clevelandvibrator.com

Registered: 2000 (25 years)

Introduction: Industrial Vibrators, Fine Mesh Vibratory Sifting Equipment, HKC Single Drive Sifter Series, EMS Electromechanical Screener, Vibratory Screener, CF-A Air Powered Feeders, EMF Electromechanical Feeder, Vibratory Jogger Tables, FA Flat Deck Vibratory Tables.

6. Routledge – Ceramic Processing

Domain: routledge.com

Registered: 1994 (31 years)

Introduction: {“title”: “Ceramic Processing – 2nd Edition”, “author”: “Mohamed N. Rahaman”, “publisher”: “Routledge”, “publication_year”: 2017, “pages”: 554, “illustrations”: 441, “ISBN”: “9781498716413”, “description”: “Ceramic Processing, Second Edition provides a comprehensive treatment of the principles and practical methods used in producing ceramics with controlled microstructure. It covers the main steps…

7. KDM Fab – Advanced Ceramic Processing

Domain: kdmfab.com

Registered: 2022 (3 years)

Introduction: The text discusses the advanced ceramic processing, highlighting seven key steps: 1. Raw material collection and storage – emphasizes the importance of high-quality, high-purity raw materials (purity above 99.9%) and proper storage to prevent contamination. 2. Crushing and milling – involves grinding raw materials to remove impurities and achieve fine particle sizes beneficial for manufacturing. T…

Strategic Sourcing Conclusion and Outlook for ceramic processing

In the evolving landscape of ceramic processing, strategic sourcing emerges as a critical component for international B2B buyers seeking to enhance their operational efficiency and product quality. By understanding the diverse manufacturing methods—from traditional techniques to advanced processes like dry pressing and slip casting—businesses can tailor their procurement strategies to align with specific market demands. This not only minimizes costs but also ensures access to high-quality materials essential for producing advanced ceramics used across various industries, including aerospace, electronics, and medical applications.

Investing in strategic sourcing enables companies to forge strong partnerships with suppliers, fostering innovation and adaptability in a competitive market. As global supply chains continue to face disruptions, establishing reliable sources for ceramic raw materials and manufacturing capabilities becomes paramount.

Looking forward, B2B buyers in Africa, South America, the Middle East, and Europe should proactively explore partnerships that emphasize sustainability and technological advancements in ceramic processing. By doing so, they position themselves to capitalize on emerging opportunities while contributing to a more resilient and efficient manufacturing ecosystem. Take the next step—engage with suppliers who can meet your specific needs and drive your business forward in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.