The Definitive Guide to Vskf Wheels: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for vskf wheels

In the ever-evolving automotive industry, sourcing high-quality vskf wheels presents a unique challenge for international B2B buyers. With a diverse range of options available, businesses must navigate complex specifications, varying price points, and supplier reliability to make informed purchasing decisions. This comprehensive guide aims to empower buyers from Africa, South America, the Middle East, and Europe—including regions like Saudi Arabia and Vietnam—by providing essential insights into the vskf wheels market.

Throughout this guide, we will delve into various types of vskf wheels, their applications across different vehicle categories, and the critical factors to consider when vetting suppliers. We will also discuss cost considerations, highlighting the balance between quality and affordability. By understanding the nuances of wheel construction, customization options, and market trends, buyers can better assess their needs and make choices that align with their business objectives.

Armed with this information, B2B buyers will be equipped to navigate the global market with confidence, ensuring they procure the right vskf wheels that meet their operational requirements. Whether you’re seeking to enhance vehicle performance, aesthetics, or durability, this guide is designed to facilitate a seamless purchasing experience and foster successful international partnerships.

Understanding vskf wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Piece Full Reverse | Customizable width and offset; elegant five-spoke design | High-performance vehicles, luxury cars | Pros: High customization, aesthetic appeal; Cons: Higher cost, longer lead times. |

| 3-Piece Reverse Step | Features a stepped rim design; available in larger diameters | Motorsport, drifting, and tuning shops | Pros: Enhanced grip and stability; Cons: May require specialized fittings. |

| Standard PCD Range | Common bolt patterns (e.g., 5×114.3); adaptable to various vehicles | General aftermarket applications | Pros: Versatility across many models; Cons: Limited to standard configurations. |

| Optional Finishes | Variety of finishes, including anodized and painted options | Custom automotive builds | Pros: Personalization for branding; Cons: Additional costs for custom finishes. |

| Lightweight Variants | Constructed for reduced weight while maintaining strength | Racing and performance applications | Pros: Improved speed and fuel efficiency; Cons: Potentially less durable under stress. |

What Are the Characteristics of 3-Piece Full Reverse VSKF Wheels?

The 3-Piece Full Reverse VSKF wheels are designed for high customization, allowing businesses to specify width, offset, and bolt patterns. Their elegant five-spoke design enhances the aesthetic appeal of luxury vehicles while providing a robust performance. They are particularly suitable for high-performance vehicles and luxury cars, making them a popular choice among automotive tuners and retailers. However, the higher cost and extended lead times may be a consideration for budget-conscious buyers.

Illustrative image related to vskf wheels

How Do 3-Piece Reverse Step Wheels Differ?

The 3-Piece Reverse Step wheels feature a stepped rim design, making them ideal for motorsport and drifting applications. This design provides enhanced grip and stability, crucial for high-speed maneuvers. They are typically available in larger diameters, catering to the needs of performance-oriented clients. While they offer significant performance advantages, buyers should be aware that these wheels may require specialized fittings, which could add complexity to the purchasing process.

What Benefits Does the Standard PCD Range Offer?

With a common bolt pattern range, such as 5×114.3, the Standard PCD VSKF wheels offer versatility that appeals to a broad market. They are suitable for general aftermarket applications, making them a go-to choice for many automotive businesses. The key advantages include the ability to fit a variety of vehicle models, but buyers should note that this option is limited to standard configurations, which may not meet the needs of niche markets.

Why Consider Optional Finishes for Customization?

Optional finishes for VSKF wheels, including anodized and various painted options, allow businesses to personalize their offerings. This feature is particularly appealing for custom automotive builds, where branding and aesthetics are paramount. While the added customization can enhance marketability and customer satisfaction, buyers should consider the additional costs associated with custom finishes, which may impact overall profitability.

Illustrative image related to vskf wheels

How Do Lightweight Variants Enhance Performance?

Lightweight VSKF wheels are designed for reduced weight without sacrificing strength, making them ideal for racing and performance applications. These wheels can improve speed and fuel efficiency, providing a competitive edge in performance-driven markets. However, potential buyers should weigh the benefits against the possibility of reduced durability under extreme conditions, as these wheels may not perform as well in everyday driving scenarios.

Key Industrial Applications of vskf wheels

| Industry/Sector | Specific Application of vskf wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom vehicles and motorsport applications | Enhanced performance and aesthetic appeal | Ensure compliance with international quality standards and certifications. |

| Luxury Vehicle Customization | High-end vehicle modifications and restorations | Unique design options and superior craftsmanship | Verify customization capabilities and lead times for bespoke projects. |

| Drift Racing | Specialized wheels for competitive drift racing cars | Improved handling and weight distribution | Confirm availability of specific sizes and offsets for optimal performance. |

| Heavy-Duty Transport | Wheels for heavy-duty trucks and transport vehicles | Increased durability and load-bearing capacity | Assess compatibility with existing vehicle specifications and regulations. |

| Agricultural Equipment | Wheels for specialized agricultural machinery | Enhanced traction and stability on uneven terrain | Evaluate resistance to environmental factors and availability of custom sizes. |

How Are vskf Wheels Used in Automotive Manufacturing?

In the automotive manufacturing sector, vskf wheels are primarily utilized for custom vehicles and motorsport applications. These wheels offer enhanced performance characteristics, allowing vehicles to achieve better handling and responsiveness on the road or track. For manufacturers in regions like Europe and the Middle East, where motorsport culture is prevalent, the aesthetic appeal of vskf wheels also plays a crucial role in attracting customers. Buyers must ensure that the wheels meet international quality standards and are compatible with their specific vehicle models.

What Role Do vskf Wheels Play in Luxury Vehicle Customization?

In the luxury vehicle customization sector, vskf wheels are highly sought after for their unique design options and superior craftsmanship. These wheels can be tailored to fit high-end vehicles, providing a bespoke touch that elevates the overall look and feel of the car. For B2B buyers, particularly in affluent markets such as Saudi Arabia and South America, the ability to customize wheel specifications, including color and size, is essential. Buyers should verify the manufacturer’s capability for customization and the lead times required for bespoke orders.

How Are vskf Wheels Essential for Drift Racing?

Drift racing teams rely on vskf wheels for their specialized design that enhances vehicle handling and weight distribution. The unique specifications of these wheels allow for optimal performance during competitive events, making them a critical component for racers. Buyers in the drift racing industry must confirm the availability of specific sizes and offsets to ensure compatibility with their vehicles. This attention to detail can significantly affect performance outcomes during races.

In What Ways Do vskf Wheels Benefit Heavy-Duty Transport?

In the heavy-duty transport sector, vskf wheels are used for trucks and transport vehicles, offering increased durability and load-bearing capacity. These wheels are designed to withstand the rigors of heavy loads while maintaining performance and safety standards. B2B buyers should assess the compatibility of vskf wheels with existing vehicle specifications and ensure compliance with local regulations. This is especially important in regions with varying transport standards, such as Africa and South America.

Illustrative image related to vskf wheels

How Do vskf Wheels Enhance Agricultural Equipment Performance?

vskf wheels are also applied in agricultural equipment, where they provide enhanced traction and stability on uneven terrain. The ability to customize wheel sizes is particularly beneficial for agricultural machinery, which often operates in challenging environments. Buyers in this sector should evaluate the wheels’ resistance to environmental factors, such as mud and moisture, to ensure longevity and reliability. Access to custom sizes can also be a deciding factor for international buyers looking to optimize their machinery performance.

3 Common User Pain Points for ‘vskf wheels’ & Their Solutions

Scenario 1: Sizing Confusion When Ordering VSKF Wheels

The Problem: One of the most common issues faced by B2B buyers is confusion around the sizing specifications of VSKF wheels. Given the variety of sizes, widths, and offsets available, buyers often struggle to determine the right fit for their vehicles. This confusion can lead to ordering the wrong products, resulting in delays, increased costs, and frustration. For businesses in regions with varying vehicle specifications, such as Africa or South America, this challenge is particularly pronounced, as local models may differ significantly from those in Europe or the Middle East.

The Solution: To avoid sizing mistakes, it is crucial for buyers to utilize comprehensive sizing charts provided by manufacturers. Begin by consulting the manufacturer’s specifications, paying close attention to the bolt pattern (PCD), offset, and width. When placing an order, ensure to provide detailed vehicle information, including make, model, and year. Additionally, consider leveraging the expertise of suppliers who can assist in verifying fitment based on specific vehicle requirements. Establishing a standard operating procedure (SOP) for checking and confirming sizes before placing orders can significantly reduce the incidence of errors.

Scenario 2: Uncertainty About Customization Options

The Problem: Many B2B buyers seeking VSKF wheels are often unaware of the extensive customization options available. This lack of knowledge can lead to missed opportunities for branding or performance enhancements, ultimately impacting their competitive edge in the market. Buyers might also feel overwhelmed by the variety of finishes, colors, and styles, making it difficult to make informed decisions that align with their business needs or customer preferences.

Illustrative image related to vskf wheels

The Solution: To navigate customization effectively, buyers should start by engaging directly with suppliers or manufacturers who can provide detailed information about available options. Create a checklist that outlines desired specifications, such as color finishes, lip styles, and bolt finishes. Additionally, consider requesting samples or visual aids that can help visualize the final product. Attending trade shows or industry exhibitions can also provide valuable insights into the latest trends and customization possibilities. By proactively exploring these options, businesses can tailor their purchases to better meet market demands.

Scenario 3: Challenges in Supply Chain and Delivery Timelines

The Problem: Supply chain disruptions can pose significant challenges for businesses looking to procure VSKF wheels. Factors such as fluctuating demand, manufacturing delays, and shipping issues can lead to unexpected wait times, impacting project timelines and customer satisfaction. For international buyers, especially in regions with less stable logistics infrastructure, these challenges can be exacerbated.

The Solution: To mitigate supply chain risks, B2B buyers should establish strong relationships with multiple suppliers to ensure a backup source in case of delays. It is advisable to engage in open communication with suppliers about lead times and potential bottlenecks. Implementing a proactive inventory management system can also help in anticipating demand and ensuring that stock levels are maintained. Additionally, buyers should consider placing bulk orders or scheduling regular shipments to minimize the impact of delays. Leveraging technology, such as supply chain management software, can provide real-time tracking and alerts for better decision-making. This strategic approach not only reduces risks but also enhances overall operational efficiency.

Illustrative image related to vskf wheels

Strategic Material Selection Guide for vskf wheels

When selecting materials for VS-KF wheels, it is essential to consider the properties, advantages, disadvantages, and specific application impacts of each material. This analysis will help B2B buyers make informed decisions based on their operational needs and regional standards.

What Are the Key Properties of Aluminum Alloy for VS-KF Wheels?

Aluminum alloys are commonly used for VS-KF wheels due to their lightweight nature and excellent strength-to-weight ratio. They typically have a temperature rating up to 150°C and are resistant to corrosion, making them suitable for various environments. The lower density of aluminum helps improve vehicle performance by reducing unsprung weight, thereby enhancing handling and fuel efficiency.

Pros include high durability, good machinability, and cost-effectiveness compared to other metals. Cons involve potential fatigue failure under extreme conditions and susceptibility to scratches and dents. For international buyers, aluminum alloys must comply with standards such as ASTM B221 or JIS H4000, which ensure quality and performance.

How Does Steel Compare as a Material for VS-KF Wheels?

Steel, particularly high-carbon steel, is another option for VS-KF wheels, known for its exceptional strength and impact resistance. Steel wheels can typically withstand higher temperatures and pressures, making them suitable for heavy-duty applications. However, they are heavier than aluminum, which can negatively impact vehicle performance.

The key advantages of steel include its affordability and superior toughness, making it ideal for rugged terrains. On the downside, steel is prone to rust if not properly coated, which can lead to corrosion issues over time. Buyers in regions with high humidity or saline environments, such as coastal areas in Africa or South America, should consider additional protective coatings.

Illustrative image related to vskf wheels

What Role Does Magnesium Play in the Manufacturing of VS-KF Wheels?

Magnesium is a lightweight metal that offers excellent strength and stiffness, making it an attractive option for performance-oriented applications. With a temperature rating similar to aluminum, magnesium wheels can handle significant stress while maintaining a lightweight profile. They also exhibit good vibration-damping properties, which can enhance ride comfort.

The advantages of magnesium include its lightweight nature and the ability to create complex shapes, which can improve aesthetics. However, the disadvantages are significant, including higher costs and lower corrosion resistance compared to aluminum. For international buyers, it’s crucial to ensure compliance with standards such as ASTM B90, especially in regions where magnesium alloys are less common.

What Are the Benefits of Composite Materials in VS-KF Wheel Design?

Composite materials, such as carbon fiber reinforced polymers, are increasingly being explored for VS-KF wheels. These materials offer exceptional strength-to-weight ratios and can withstand high temperatures and pressures. Composites are also resistant to corrosion and can be tailored for specific performance characteristics.

The key advantage of composites is their lightweight nature, which significantly enhances vehicle performance and fuel efficiency. However, they are often more expensive and may require complex manufacturing processes, making them less accessible for budget-conscious buyers. For international buyers, understanding local regulations regarding composite materials is essential, as standards can vary widely between regions.

Summary Table of Material Selection for VS-KF Wheels

| Material | Typical Use Case for vskf wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Performance vehicles | Lightweight and corrosion-resistant | Susceptible to fatigue failure | Medium |

| Steel | Heavy-duty applications | Affordable and tough | Prone to rust without coatings | Low |

| Magnesium | High-performance racing | Excellent strength-to-weight ratio | Higher cost and lower corrosion resistance | High |

| Composite | Luxury and performance vehicles | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

This strategic material selection guide provides essential insights for B2B buyers, enabling them to choose the most suitable materials for VS-KF wheels based on their specific needs and regional considerations.

Illustrative image related to vskf wheels

In-depth Look: Manufacturing Processes and Quality Assurance for vskf wheels

What Are the Key Stages in the Manufacturing Process for VSKF Wheels?

The production of VSKF wheels involves several critical stages, each designed to ensure the highest quality and performance standards. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The manufacturing process begins with the selection of high-quality materials, typically aluminum alloys known for their strength and lightweight properties. The alloys are procured from reputable suppliers who adhere to international standards. Once received, the materials undergo rigorous testing for composition and integrity to ensure they meet specifications.

After quality checks, the materials are cut into appropriate sizes using advanced CNC machines, which provide precision and reduce waste. This step is crucial, as any imperfections at this stage can compromise the structural integrity of the finished wheel.

2. How Are VSKF Wheels Formed?

The next phase involves the forming of the wheel components. VSKF wheels utilize a three-piece construction method, which includes the rim, the inner barrel, and the face. This process involves several techniques:

- Casting: The aluminum alloy is melted and poured into molds to create the wheel components. This method allows for intricate designs and shapes.

- Forging: Some manufacturers may use forging techniques for specific components to enhance strength and performance.

- Machining: Post-casting, the components are machined to achieve precise dimensions and surface finishes. This includes processes like milling and drilling to create bolt holes and attach points.

The combination of casting and machining ensures that the wheels not only meet aesthetic demands but also deliver high performance on the road.

3. What Is the Assembly Process for VSKF Wheels?

Once all components are formed, they are assembled in a controlled environment. The assembly process typically includes:

- Joining Components: The inner barrel is connected to the outer rim and face using high-strength bolts. This three-piece design allows for customization in terms of width, offset, and finish.

- Balancing: Each assembled wheel is balanced to eliminate vibrations and ensure smooth performance. This step is critical, especially for high-performance applications.

The assembly process is conducted under strict supervision to maintain consistency and quality.

4. What Finishing Techniques Are Applied to VSKF Wheels?

Finishing is a crucial step in the manufacturing of VSKF wheels, as it not only enhances aesthetics but also protects against environmental factors. Common finishing techniques include:

Illustrative image related to vskf wheels

- Anodizing: This electrochemical process increases corrosion resistance and can be used to achieve various surface finishes, such as polished or matte.

- Painting: Optional painted finishes allow for customization, with a range of colors available to meet client specifications.

- Quality Control on Finishing: The finished wheels undergo visual inspections to check for defects, ensuring that only products meeting the highest standards are shipped.

What Quality Assurance Measures Are Implemented for VSKF Wheels?

Quality assurance is paramount in the manufacturing of VSKF wheels, ensuring that every product meets international safety and performance standards. Here’s how it’s typically structured.

1. What International Standards Guide the Quality Assurance Process?

Manufacturers of VSKF wheels typically adhere to several international standards, including:

- ISO 9001: This standard focuses on quality management systems and is designed to ensure consistent quality in products and services.

- CE Marking: Compliance with CE marking indicates that the wheels meet EU safety, health, and environmental protection standards.

- API Standards: While primarily for petroleum and natural gas industries, adherence to API standards can apply to aspects of manufacturing that require rigorous quality measures.

These certifications not only enhance the credibility of the product but also facilitate easier market access for international buyers.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for quality and compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor the production process and ensure standards are maintained.

- Final Quality Control (FQC): After assembly and finishing, a thorough inspection is conducted, including dimensional checks and performance testing.

These checkpoints help identify issues early in the process, minimizing waste and ensuring that only high-quality products reach the market.

Illustrative image related to vskf wheels

3. What Testing Methods Are Commonly Employed?

Testing methods for VSKF wheels typically include:

- Visual Inspections: To check for surface defects and ensure aesthetic quality.

- Dimensional Testing: Using gauges and calipers to confirm that the wheels meet specified dimensions.

- Load Testing: Assessing the wheel’s ability to withstand stress and pressure under various conditions.

Such tests are crucial for verifying that the wheels can perform reliably in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

1. Requesting Documentation and Reports

Buyers should request detailed documentation regarding the supplier’s quality management system, including:

Illustrative image related to vskf wheels

- Certificates of compliance with international standards (ISO, CE, etc.).

- Recent quality audit reports that outline the findings and corrective actions taken.

2. Conducting Supplier Audits

Conducting on-site audits can provide valuable insights into a supplier’s manufacturing capabilities and quality control processes. This includes reviewing:

- Production facilities and equipment.

- Quality assurance procedures and records.

- Employee training and competence levels.

3. Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent audits and tests to verify that the products meet specified standards before shipment.

Conclusion: What Should B2B Buyers Consider When Sourcing VSKF Wheels?

When sourcing VSKF wheels, B2B buyers must prioritize suppliers who demonstrate robust manufacturing processes and stringent quality assurance measures. By understanding the manufacturing stages and the associated quality control practices, buyers can make informed decisions, ensuring that the wheels they procure meet their performance and safety requirements. This diligence is especially critical in diverse markets across Africa, South America, the Middle East, and Europe, where quality and compliance standards may vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vskf wheels’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring Work VS-KF wheels. By following these actionable steps, you can ensure that your purchasing decisions are informed, strategic, and aligned with your business needs.

Illustrative image related to vskf wheels

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for your VS-KF wheels. This includes aspects like wheel size (e.g., 18″, 19″, 20″, or 21″), width, offset, and bolt pattern (PCD). Having precise specifications helps in avoiding compatibility issues with vehicles and ensures that the wheels meet performance expectations.

- Common Sizing Options: Familiarize yourself with the standard sizes and widths available, such as 5×114.3 or 5×120.65.

- Consider Customizations: Determine if custom colors or finishes are necessary for your branding or aesthetic requirements.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers of VS-KF wheels. Seek suppliers with a solid track record in the automotive industry, especially those with experience in international shipping to your region.

- Check Reviews and Testimonials: Look for customer feedback on platforms like Trustpilot or industry-specific forums.

- Verify Years in Business: A supplier with a longer history is often more reliable and experienced in handling international orders.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet your shortlisted suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and product quality.

- Ask for Product Samples: If possible, request samples of the wheels to evaluate quality and craftsmanship firsthand.

- Review Certifications: Ensure the supplier holds necessary certifications that comply with international automotive standards.

Step 4: Analyze Pricing Structures

Pricing can vary significantly between suppliers, so it’s important to analyze pricing structures carefully. Look beyond the base price and consider additional costs like shipping, taxes, and potential tariffs when importing to your region.

- Compare Quotes: Obtain quotes from multiple suppliers to find the best overall value.

- Consider Bulk Discounts: Inquire about pricing for bulk orders, as many suppliers offer discounts for larger purchases.

Step 5: Confirm Shipping and Delivery Terms

Discuss shipping and delivery terms in detail with your chosen supplier. Understanding these terms is crucial to avoid unexpected delays or additional costs.

- Check Shipping Methods: Ensure the supplier offers reliable shipping options that suit your timeline.

- Clarify Delivery Times: Confirm estimated delivery times and any potential delays due to customs or local regulations.

Step 6: Establish Payment Terms

Clarify payment terms and conditions before finalizing your order. Understanding the payment process helps in managing your budget and cash flow effectively.

- Negotiate Payment Options: Discuss options like letters of credit, wire transfers, or escrow services for added security.

- Understand Refund Policies: Familiarize yourself with the supplier’s refund or return policies in case of defects or discrepancies.

Step 7: Finalize the Order and Maintain Communication

Once you’ve selected a supplier, finalize the order and maintain open lines of communication throughout the process. Regular updates can help you stay informed about the status of your order and address any issues promptly.

- Document Everything: Keep a record of all communications, contracts, and transaction details for future reference.

- Follow Up: Regularly check in with the supplier to ensure the order is on track and to resolve any potential concerns.

By adhering to this checklist, you can navigate the sourcing process for VS-KF wheels effectively, ensuring that your purchase aligns with your business requirements and expectations.

Comprehensive Cost and Pricing Analysis for vskf wheels Sourcing

What Are the Key Cost Components Involved in Sourcing VS-KF Wheels?

Understanding the cost structure for sourcing VS-KF wheels is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as aluminum alloys, which are essential for producing high-quality wheels, significantly impacts overall pricing. Premium materials can enhance performance and durability but also increase costs.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may provide a competitive advantage, but quality should never be compromised. Skilled labor is essential for precise manufacturing and quality control.

-

Manufacturing Overhead: This includes costs related to facility operation, utilities, and indirect labor. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: Initial setup costs for molds and dies can be substantial, especially for customized designs. These costs are amortized over the production volume, making them a critical factor for buyers to consider, particularly when negotiating minimum order quantities (MOQs).

-

Quality Control (QC): Investing in robust QC processes ensures the wheels meet safety and performance standards. This may involve additional costs but is necessary to avoid costly returns and reputational damage.

-

Logistics: Transportation and warehousing costs can vary significantly based on the shipping method and distance. International buyers should account for tariffs, customs duties, and local transportation when calculating total costs.

-

Margin: Suppliers typically add a profit margin on top of their costs. Understanding the typical markup in the market can aid buyers in negotiating better deals.

How Do Price Influencers Affect Sourcing Decisions for VS-KF Wheels?

Several factors can influence the pricing of VS-KF wheels, impacting sourcing decisions:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable pricing by committing to higher volumes.

-

Specifications/Customization: Customizing specifications such as size, finish, and bolt pattern can lead to increased costs. Buyers must weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials or certifications (e.g., ISO standards) may come at a premium but can enhance product reliability and performance. Buyers should assess whether these factors justify the additional costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, but this can mitigate risks associated with quality and delivery.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms can help buyers make more informed decisions about total costs.

What Are the Best Practices for Negotiating VS-KF Wheel Prices as an International Buyer?

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing VS-KF wheels:

-

Conduct Market Research: Understanding the market landscape and average pricing can empower buyers during negotiations. Utilize industry reports and competitor pricing to inform your strategy.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery timelines, and bulk pricing. Suppliers may be willing to offer discounts for upfront payments or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with sourcing VS-KF wheels, including shipping, import duties, and potential warranty claims. A lower upfront price may not always equate to better value.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers helps identify competitive pricing and can strengthen your negotiating position.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, which can impact pricing. Locking in prices at the time of order can mitigate risks associated with currency volatility.

Conclusion

While indicative prices for VS-KF wheels can range significantly based on specifications and supplier factors, understanding the comprehensive cost structure and price influencers can empower international B2B buyers to make informed sourcing decisions. By leveraging best practices in negotiation and cost analysis, businesses can enhance their procurement strategies while ensuring product quality and compliance.

Illustrative image related to vskf wheels

Alternatives Analysis: Comparing vskf wheels With Other Solutions

Understanding Alternatives in Wheel Solutions

In the competitive landscape of automotive wheels, it’s essential for B2B buyers to explore various options to determine the best fit for their specific requirements. While VS-KF wheels are recognized for their quality and customization, several alternative solutions offer comparable benefits that may align better with certain business needs. This analysis will evaluate VS-KF wheels against two viable alternatives: Forged Wheels and Cast Aluminum Wheels.

| Comparison Aspect | Vskf Wheels | Forged Wheels | Cast Aluminum Wheels |

|---|---|---|---|

| Performance | High strength and lightweight | Superior strength-to-weight ratio | Good performance for general use |

| Cost | Premium pricing ($864 – $882 each) | Higher cost due to manufacturing | More affordable ($200 – $600 each) |

| Ease of Implementation | Custom made, longer lead time | Quick turnaround for standard sizes | Readily available off-the-shelf |

| Maintenance | Low, durable finish | Low, but requires careful handling | Moderate, prone to cosmetic damage |

| Best Use Case | High-performance vehicles, customization | Racing and high-performance vehicles | Everyday vehicles, budget-conscious buyers |

What Are the Pros and Cons of Forged Wheels?

Forged wheels are manufactured through a process that involves shaping solid metal under high pressure. This results in wheels that are not only lighter but also stronger than their cast counterparts. The primary advantage of forged wheels is their superior strength-to-weight ratio, making them ideal for high-performance racing applications. However, this advantage comes at a higher price point, often exceeding $1,000 per wheel. Additionally, while they can be customized, standard sizes are typically available for quicker delivery.

How Do Cast Aluminum Wheels Compare?

Cast aluminum wheels are a popular choice for many automotive applications due to their affordability and availability. They are produced by pouring molten aluminum into a mold, making them less expensive to manufacture than forged wheels. This option works well for everyday vehicles, where performance demands are moderate. However, they may not offer the same level of performance or customization as VS-KF wheels or forged alternatives. Moreover, cast wheels can be more prone to cosmetic damage, which may require more frequent maintenance.

Choosing the Right Wheel Solution for Your Business

Selecting the right wheel solution involves understanding the specific needs of your operation, including performance requirements, budget constraints, and the desired aesthetic. For businesses focused on high-performance applications, VS-KF wheels or forged wheels may be the best choice despite the higher cost. Conversely, if budget is a primary concern and the application is less demanding, cast aluminum wheels may suffice. Ultimately, evaluating these alternatives against your operational objectives will lead to a more informed purchasing decision, ensuring you invest in the right wheel solution for your fleet or products.

Essential Technical Properties and Trade Terminology for vskf wheels

What Are the Key Technical Properties of VSKF Wheels?

Understanding the technical properties of VSKF wheels is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications:

-

Material Grade

VSKF wheels are commonly constructed from high-quality aluminum alloys, known for their strength-to-weight ratio. The material grade affects the wheel’s durability, performance, and overall weight, which can significantly impact fuel efficiency and vehicle handling. Selecting the right material grade ensures that buyers receive a product that meets their performance and safety standards. -

Width and Diameter Specifications

The width and diameter of VSKF wheels vary across models, typically ranging from 18 inches to 21 inches in diameter and widths from 7.0 inches to 15.5 inches. These measurements are crucial for compatibility with specific vehicle models and affect performance characteristics such as traction, stability, and aesthetics. Buyers should carefully consider their vehicle’s specifications when selecting wheel sizes. -

Offset and Backspacing

Offset refers to the distance between the wheel’s mounting surface and its centerline, while backspacing is the distance from the mounting surface to the rear edge of the wheel. These specifications influence how the wheel sits within the wheel arch, affecting handling and steering response. A proper offset ensures that the wheels align correctly with the vehicle’s suspension geometry, leading to optimal performance. -

Bolt Pattern (PCD)

The Pitch Circle Diameter (PCD) indicates the arrangement of the wheel’s bolt holes. VSKF wheels typically have standard PCDs, such as 5×114.3. This specification is vital for ensuring compatibility with the vehicle’s hub, as incorrect bolt patterns can lead to improper fitment and safety issues. Buyers should verify the PCD before placing an order to avoid costly returns. -

Finish Options

VSKF wheels come in various standard and optional finishes, including anodized and painted surfaces. The finish not only enhances aesthetics but also contributes to corrosion resistance and longevity. Selecting the right finish is essential for buyers looking to maintain the appearance and performance of their wheels in diverse environments, especially in regions with harsh climates.

What Trade Terminology Is Commonly Used in VSKF Wheel Transactions?

Familiarity with industry jargon is crucial for B2B buyers to navigate the procurement process effectively. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of a vehicle’s components. When discussing VSKF wheels, buyers may seek OEM specifications to ensure compatibility with their vehicles. Understanding OEM standards helps buyers select wheels that meet or exceed the performance of factory-installed options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product a supplier is willing to sell. For VSKF wheels, knowing the MOQ is essential for buyers, especially when negotiating bulk purchases. This term can significantly impact inventory management and cost-effectiveness for businesses operating in various markets. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to obtain pricing for specific products or services. B2B buyers should utilize RFQs when sourcing VSKF wheels to ensure they receive competitive pricing and terms. This process helps in making informed decisions based on comprehensive market comparisons. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk transfer, and delivery obligations when importing VSKF wheels from different regions. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For VSKF wheels, understanding lead times is vital for inventory planning and ensuring timely availability for customers. Buyers should always inquire about lead times, especially when dealing with custom specifications or large orders. -

Customization Options

This term encompasses the various ways buyers can tailor VSKF wheels to meet specific requirements, such as size, finish, and bolt pattern. Knowing the customization options available can help buyers create a unique product that aligns with their branding and performance needs.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to navigate the VSKF wheel market effectively, ensuring they make informed purchasing decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the vskf wheels Sector

What Are the Key Market Dynamics and Trends Influencing the VSKF Wheels Sector?

The global market for VSKF wheels is currently characterized by several pivotal trends that international B2B buyers should be aware of. First, the increasing demand for high-performance and aesthetically pleasing wheels is driving manufacturers to innovate continuously. The VSKF wheels, known for their bespoke designs and technical specifications, are particularly appealing in markets such as Africa, South America, the Middle East, and Europe, where customization and quality are paramount.

Emerging technologies in manufacturing, such as advanced casting techniques and 3D printing, are reshaping sourcing strategies. These technologies not only enhance production efficiency but also allow for greater customization, which is essential for meeting diverse market needs. Moreover, the rise of e-commerce platforms is streamlining the procurement process, enabling buyers to access a wider range of products and suppliers globally.

Importantly, shifts in consumer preferences towards performance vehicles and luxury automobiles are influencing purchasing decisions. For B2B buyers, understanding local market demands and aligning sourcing strategies with these trends can create significant competitive advantages. Additionally, geopolitical factors and trade agreements play a critical role in pricing and availability, particularly for buyers in regions like the Middle East and South America, where import tariffs may affect the overall cost.

How Is Sustainability and Ethical Sourcing Shaping the VSKF Wheels Market?

Sustainability is becoming a non-negotiable aspect of sourcing strategies in the VSKF wheels sector. As environmental concerns grow globally, buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of recycled materials and eco-friendly manufacturing processes that minimize waste and carbon footprints.

Illustrative image related to vskf wheels

Moreover, ethical sourcing has gained traction, with buyers seeking suppliers who maintain transparent supply chains and fair labor practices. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential criteria for evaluation. Buyers should conduct thorough due diligence to ensure that their suppliers are compliant with these standards, as it not only mitigates reputational risk but also aligns with consumer expectations for responsible business practices.

Incorporating sustainability into the sourcing strategy not only helps in regulatory compliance but also enhances brand value. For B2B buyers looking to differentiate themselves in competitive markets, promoting a commitment to sustainability can be a compelling selling point.

What Is the Historical Context Behind the Evolution of VSKF Wheels?

The VSKF wheels have a rich heritage rooted in high-performance automotive culture. Originally designed for motorsport applications, these wheels have evolved into a symbol of both performance and luxury. Their three-piece construction allows for extensive customization, making them a favorite among car enthusiasts and professionals alike.

Illustrative image related to vskf wheels

As the automotive industry transitioned towards more personalized vehicles, VSKF wheels adapted to meet the changing demands of consumers. Today, they are crafted using advanced technologies that enhance durability and aesthetic appeal, reflecting the trends of modern automotive design. Understanding this evolution is vital for B2B buyers, as it highlights the importance of quality and customization in their purchasing decisions, ensuring they align with contemporary market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of vskf wheels

-

How do I determine the right specifications for vskf wheels for my vehicles?

To select the appropriate vskf wheels, first identify the specifications required for your vehicles, including the bolt pattern, width, offset, and diameter. The standard PCD (Pitch Circle Diameter) for vskf wheels generally includes options like 5×114.3, but customization is available. Consult the sizing charts provided by manufacturers to match your vehicle’s requirements. Additionally, consider the load capacity and intended use of the wheels, whether for performance, aesthetics, or heavy-duty applications, to ensure optimal functionality. -

What is the best way to customize vskf wheels to fit my brand’s needs?

Customization of vskf wheels can be achieved through various options such as selecting specific sizes, finishes, and bolt patterns. Work Wheels offers multiple color finishes, including anodized and painted options, allowing you to align the product with your brand identity. When placing an order, specify your desired features under special instructions. Collaborating closely with suppliers during the design phase can help ensure the wheels meet your exact specifications, enhancing your product’s appeal in the market. -

What are the minimum order quantities (MOQ) for vskf wheels?

Minimum order quantities for vskf wheels can vary significantly depending on the supplier and the specific model. Generally, manufacturers may require a MOQ ranging from 4 to 10 wheels per order, especially for custom designs. It’s advisable to inquire directly with suppliers to understand their specific requirements and explore options for bulk purchasing or discounts, which can be beneficial for larger B2B transactions. Be sure to assess your inventory needs before placing an order to avoid excess stock. -

What payment terms should I expect when ordering vskf wheels internationally?

Payment terms for international orders of vskf wheels typically vary by supplier but often include options such as wire transfers, letters of credit, or PayPal. Many suppliers may require a deposit upfront, particularly for custom orders, with the balance due upon shipment or delivery. It’s crucial to clarify the payment terms in advance, including any fees related to currency exchange or international transactions. Establishing a clear agreement with the supplier can help facilitate smoother transactions and reduce the risk of misunderstandings. -

How can I ensure the quality of vskf wheels before making a purchase?

To ensure quality, conduct thorough research on potential suppliers, checking their certifications, reviews, and reputation in the market. Request samples or detailed specifications and quality assurance processes. Many reputable manufacturers provide warranties or guarantees on their products, which can serve as an additional quality assurance measure. Additionally, consider requesting third-party inspections for large orders to verify compliance with international quality standards, ensuring the wheels meet your expectations. -

What logistics considerations should I keep in mind for shipping vskf wheels internationally?

When shipping vskf wheels internationally, consider factors such as shipping methods, customs regulations, and delivery times. Choose a reliable logistics partner experienced in handling automotive parts to ensure timely delivery. Be aware of any import duties and taxes that may apply in your country, as these can significantly affect the overall cost. Discussing logistics details with your supplier can also help streamline the process, ensuring all necessary documentation is in order for smooth customs clearance. -

What are the common challenges faced when sourcing vskf wheels globally?

Common challenges include navigating customs regulations, language barriers, and varying quality standards across countries. Additionally, fluctuations in shipping costs and delays can impact timelines. To mitigate these issues, establish clear communication with suppliers, utilize experienced freight forwarders, and stay informed about regulations in your target market. Building strong relationships with suppliers can also enhance trust and facilitate smoother transactions, reducing potential hurdles in the sourcing process. -

How can I effectively vet suppliers of vskf wheels for my business?

To effectively vet suppliers, start by researching their history, reputation, and customer reviews online. Request references from previous clients and look for certifications that demonstrate adherence to industry standards. Conducting site visits, if feasible, can provide insights into their manufacturing processes. Utilize trade shows or industry events to meet suppliers in person and assess their offerings. Establishing clear communication about your expectations and requirements will also help ensure a good fit for your business needs.

Top 5 Vskf Wheels Manufacturers & Suppliers List

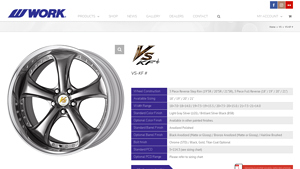

1. Work Wheels – VS-KF

Domain: threepiece.us

Registered: 2014 (11 years)

Introduction: {“brand”: “Work Wheels”, “model”: “VS-KF”, “available_sizes”: [{“size”: “18×14-18”, “offset”: “-10”, “color”: “Light Grey Silver”, “disk_type”: “R Disk”, “price”: “$882.00”}, {“size”: “18×14-10”, “offset”: “-10”, “color”: “Light Grey Silver”, “disk_type”: “L Disk”, “price”: “$882.00”}, {“size”: “18×14+8”, “offset”: “+8”, “color”: “Light Grey Silver”, “disk_type”: “O Disk”, “price”: “$882.00”}, {“s…

2. Work Wheels USA – VS-KF Wheels

Domain: workwheelsusa.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “VS-KF #”, “Wheel Construction”: “3 Piece Reverse Step Rim (19\”SR / 20\”SR / 21\”SR), 3 Piece Full Reverse (18\” / 19\” / 20\” / 21\”)”, “Available Sizing”: “18\” / 19\” / 20\” / 21\””, “Width Range”: “18×7.0~18×14.0 / 19×7.5~19×15.5 / 20×7.5~20×15.0 / 21×7.5~21×14.0”, “Standard Color Finish”: “Light Gray Silver (LGS) / Brilliant Silver Black (BSB)”, “Optional Color Finish”: “Ava…

3. Vs KF Wheels – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Vs KF Wheels include: Rim diameters available: 15, 16, 17, 18, 19, 20 inches; Bolt patterns: 5×114.3, 4×100, 6×139.7; Rim widths: 6.5, 7, 7.5, 8.5, 9, 9.5, 10, 10.5 inches; Quantity options: sets of 2 or 4; Brands: WORK, Mercedes-Benz; Offset options: -27, -12, 0, 31, 32, 38, 42, 45; Country of manufacture: Japan; Wheel materials: Aluminum; Wheel construction: Forged; Condi…

4. Work – Three-Piece Wheel

Domain: systemmotorsports.com

Registered: 2016 (9 years)

Introduction: This company, Work – Three-Piece Wheel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Instagram – Scraping Services Inquiry

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact for scraping Instagram services; inquire about the number of pages to scrape per month.

Strategic Sourcing Conclusion and Outlook for vskf wheels

In conclusion, the strategic sourcing of VS-KF wheels presents a unique opportunity for international B2B buyers to enhance their product offerings while ensuring quality and performance. These wheels, renowned for their three-piece construction and customizable options, cater to a diverse range of vehicles and market preferences. Buyers should prioritize suppliers who provide detailed specifications and customization options, as this ensures alignment with regional market demands and vehicle compatibility.

Moreover, the emphasis on quality materials and advanced manufacturing techniques underscores the importance of sourcing from reputable manufacturers, particularly those who can deliver on both aesthetics and durability. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying ahead of trends and consumer preferences will be crucial for success.

Looking forward, now is the ideal time for B2B buyers to engage with trusted suppliers to secure the latest designs and innovations in VS-KF wheels. By doing so, they can not only meet the growing demand for high-performance wheels but also establish a competitive edge in their respective markets. Reach out today to explore the possibilities of enhancing your product lineup with these exceptional wheels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.