The Definitive Guide to Mechanical Items: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for mechanical items

In today’s interconnected economy, sourcing mechanical items that meet specific operational needs poses a significant challenge for international B2B buyers. Whether you are looking for precision components like screws and bolts or complex systems like mechanical seals and dampers, understanding the vast landscape of available products is crucial. This comprehensive guide serves as an essential resource for navigating the global market for mechanical items, equipping buyers from Africa, South America, the Middle East, and Europe—especially Germany and Saudi Arabia—with the insights necessary to make informed purchasing decisions.

The scope of this guide encompasses a wide range of mechanical items, including standard components, specialized equipment, and their diverse applications across industries. Additionally, it addresses key factors such as supplier vetting processes, cost considerations, and market trends, empowering buyers to identify reliable manufacturers and negotiate favorable terms. By providing actionable insights and practical strategies, this guide not only simplifies the sourcing process but also enhances operational efficiency, ensuring that your business remains competitive in a rapidly evolving market.

As you delve into the sections ahead, you will gain a deeper understanding of how to effectively source and implement mechanical items tailored to your specific needs, ultimately driving growth and innovation within your organization.

Understanding mechanical items Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fasteners | Includes screws, bolts, nuts, and washers; essential for assembly and stability. | Manufacturing, construction, automotive, and electronics. | Pros: Widely available, cost-effective. Cons: Quality varies; requires proper selection for application. |

| Mechanical Seals | Devices that prevent leakage of fluids or gases; includes O-rings and gaskets. | Oil & gas, food processing, pharmaceuticals, and machinery. | Pros: Essential for preventing leaks, customizable. Cons: Installation can be complex; requires precise fitting. |

| Springs | Components that store and release energy; includes compression, tension, and torsion springs. | Automotive, aerospace, and industrial machinery. | Pros: Provides flexibility and shock absorption. Cons: May require regular maintenance; can fatigue over time. |

| Hinges | Mechanisms that allow two parts to pivot relative to each other; includes butt hinges and continuous hinges. | Furniture, doors, and heavy machinery. | Pros: Essential for functionality, available in various materials. Cons: May wear out over time; require proper alignment for optimal performance. |

| Dampers | Devices that absorb and dissipate energy, controlling motion; includes shock absorbers and rotary dampers. | Automotive, industrial machinery, and construction. | Pros: Enhances stability and safety, improves performance. Cons: Can be expensive; requires proper sizing for effectiveness. |

What Are the Key Characteristics of Fasteners for B2B Buyers?

Fasteners are fundamental mechanical components that secure and join various parts together. They come in numerous types, including screws, bolts, nuts, and washers, each designed for specific applications. For B2B buyers, understanding the material and strength specifications is crucial, as these factors affect durability and performance. Fasteners are widely used across industries such as manufacturing, construction, and automotive, making them readily available. However, quality can vary significantly, necessitating careful selection to ensure compatibility with the intended application.

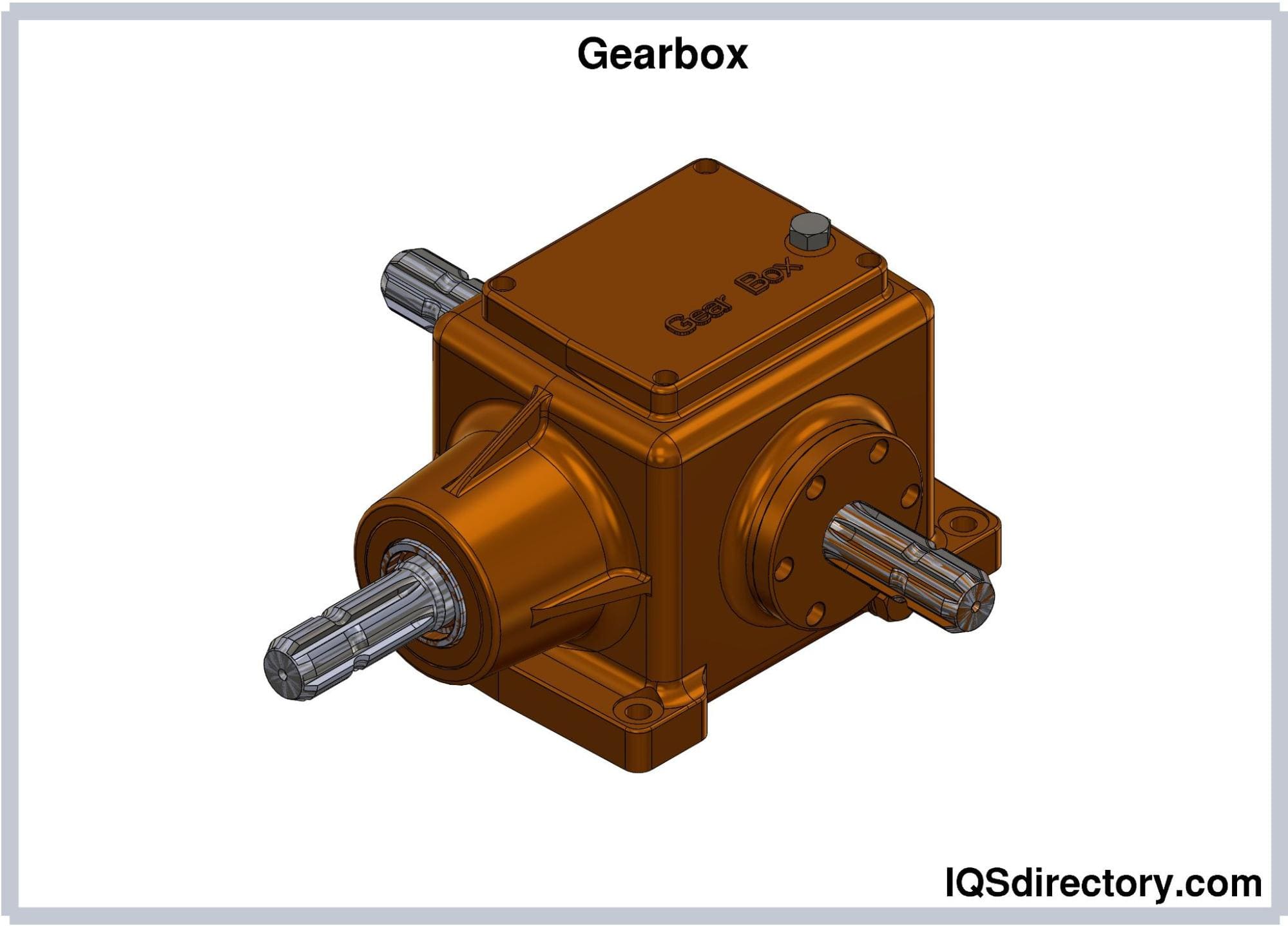

Illustrative image related to mechanical items

How Do Mechanical Seals Function in Industrial Applications?

Mechanical seals play a vital role in preventing the leakage of fluids or gases in machinery and equipment. Comprising components like O-rings and gaskets, they are essential in sectors such as oil and gas, food processing, and pharmaceuticals. The selection of the right material and design is critical, as different applications may expose seals to various pressures and temperatures. While they can be customized for specific needs, installation often requires precision and expertise to ensure optimal functionality and prevent leaks.

Why Are Springs Important in Mechanical Systems?

Springs are versatile mechanical items that store and release energy, providing essential functions in various applications. They come in several forms, including compression, tension, and torsion springs, and are commonly used in automotive, aerospace, and industrial machinery. For B2B buyers, understanding the load capacity and fatigue characteristics of springs is vital for ensuring their suitability in specific applications. While they offer flexibility and shock absorption, regular maintenance is necessary to prevent fatigue and failure over time.

What Should B2B Buyers Consider When Choosing Hinges?

Hinges are crucial mechanical components that allow for the pivoting of two parts, commonly found in doors, furniture, and heavy machinery. They come in various designs, such as butt hinges and continuous hinges, and are available in multiple materials to suit different environments. B2B buyers should consider the load capacity and installation requirements when selecting hinges. While they provide essential functionality, proper alignment is necessary for optimal performance, and they may wear out over time, necessitating replacements.

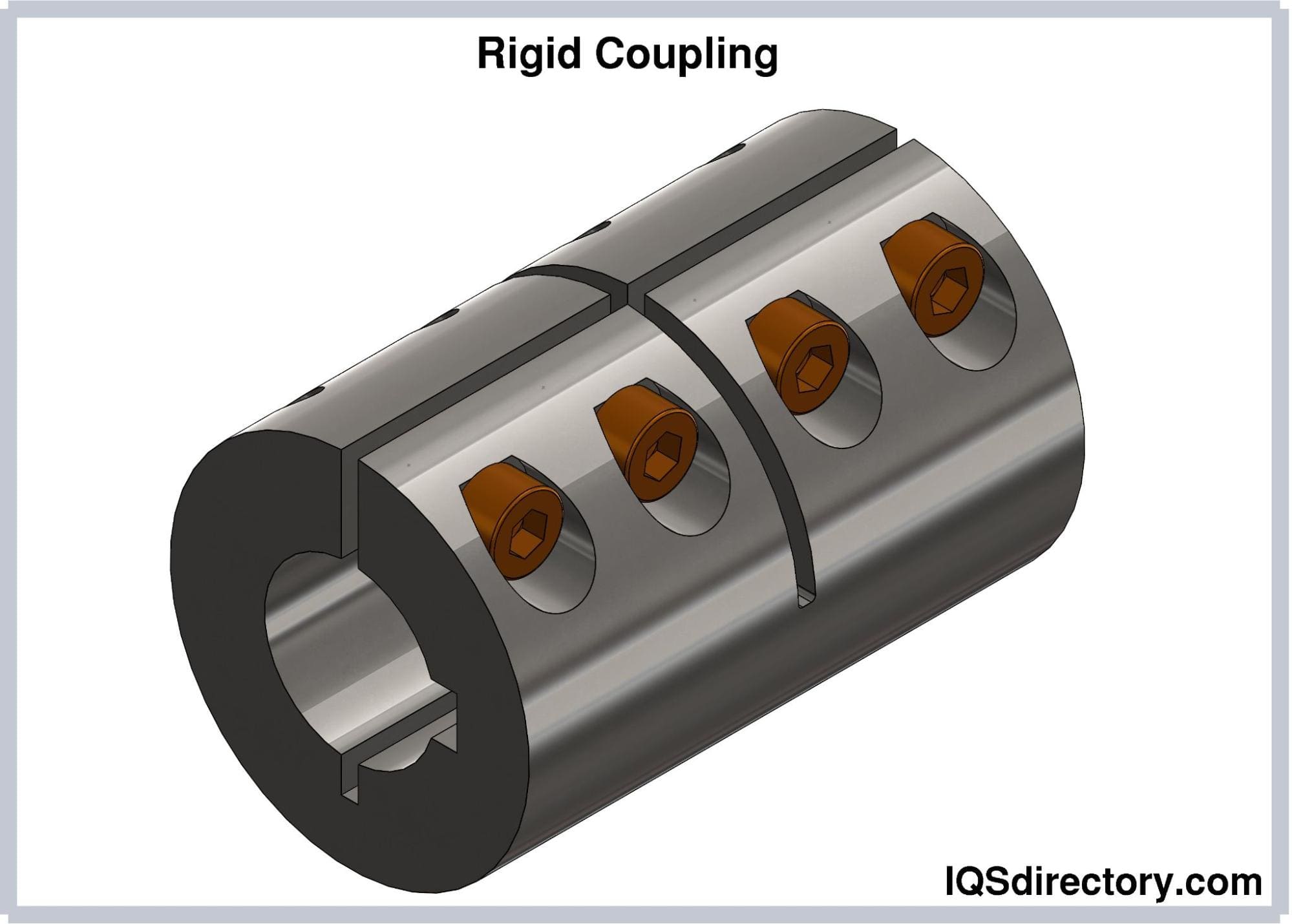

Illustrative image related to mechanical items

How Do Dampers Enhance Performance in Machinery?

Dampers are mechanical devices designed to absorb and dissipate energy, controlling motion and enhancing the stability of various systems. Commonly used in automotive and industrial applications, they include shock absorbers and rotary dampers. For B2B buyers, selecting the right damper involves understanding the application’s specific requirements, including load conditions and motion characteristics. While dampers significantly improve performance and safety, they can be costly and must be appropriately sized to ensure their effectiveness.

Key Industrial Applications of mechanical items

| Industry/Sector | Specific Application of Mechanical Items | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision Fasteners (Screws, Bolts) | Enhanced assembly reliability and strength | Quality certifications, material specifications, and local availability |

| Automotive | Mechanical Seals and Gaskets | Improved durability and reduced leakage | Temperature resistance, compatibility with fluids, and certification standards |

| Construction | Modular Structure Profiles | Faster assembly and reduced labor costs | Load-bearing capacity, corrosion resistance, and customization options |

| HVAC Systems | Dampers and Anti-Vibration Mounts | Increased energy efficiency and noise reduction | Size specifications, material durability, and compliance with local regulations |

| Electronics | Cable Glands and Connectors | Enhanced safety and reliability of connections | IP ratings for dust and water resistance, material compatibility, and ease of installation |

How Are Mechanical Items Used in the Manufacturing Sector?

In the manufacturing sector, precision fasteners such as screws and bolts play a crucial role in ensuring the structural integrity of assembled products. These mechanical items provide enhanced assembly reliability and strength, addressing common issues like loosening under stress. International B2B buyers must consider quality certifications and material specifications to ensure compatibility with their specific applications, especially in regions like Africa and South America, where local sourcing may be limited.

What Role Do Mechanical Seals Play in the Automotive Industry?

Mechanical seals and gaskets are vital in the automotive industry, where they are used to prevent fluid leakage and maintain optimal performance in engines and transmissions. These components significantly improve durability, which translates to lower maintenance costs and increased vehicle reliability. Buyers in this sector should prioritize temperature resistance and compatibility with various automotive fluids, alongside adherence to certification standards to meet regional regulations, particularly in Europe and the Middle East.

How Are Modular Structure Profiles Beneficial in Construction?

Modular structure profiles are increasingly utilized in the construction industry for their ability to streamline assembly processes. They allow for faster construction times and reduced labor costs by enabling pre-fabrication and easy transportation. Buyers should assess load-bearing capacity and corrosion resistance to ensure that these profiles meet their project requirements, particularly in regions with varying climates, such as the Middle East and Africa.

Why Are Dampers Important in HVAC Systems?

Dampers and anti-vibration mounts are essential components in HVAC systems, contributing to energy efficiency and noise reduction. By regulating airflow and minimizing vibrations, these mechanical items enhance system performance and occupant comfort. For international buyers, it is crucial to consider size specifications and material durability to ensure compliance with local regulations, especially in Europe, where energy efficiency standards are stringent.

Illustrative image related to mechanical items

How Do Cable Glands and Connectors Enhance Electronics Safety?

In the electronics sector, cable glands and connectors are critical for ensuring safe and reliable electrical connections. They protect cables from environmental factors, enhancing the overall safety of electrical installations. Buyers should focus on IP ratings for dust and water resistance, as well as material compatibility, to ensure that these components meet the specific requirements of their applications. This is particularly important in regions like South America and Africa, where environmental conditions may pose additional challenges.

3 Common User Pain Points for ‘mechanical items’ & Their Solutions

Scenario 1: Sourcing Quality Mechanical Components for Diverse Applications

The Problem:

B2B buyers often struggle with sourcing high-quality mechanical components that meet specific application requirements. This challenge is exacerbated in regions like Africa and South America, where access to diverse suppliers may be limited. Buyers face the risk of acquiring subpar products that can lead to equipment failures, increased downtime, and ultimately, financial losses. Furthermore, the variability in quality standards across different manufacturers can make it difficult for buyers to ensure reliability and performance in their mechanical systems.

The Solution:

To overcome this sourcing dilemma, B2B buyers should establish a robust vendor evaluation process. Begin by creating a checklist of essential criteria, including ISO certifications, material specifications, and past performance data. Engaging in a rigorous Request for Quotation (RFQ) process can help gather detailed information from multiple suppliers. Additionally, consider leveraging online platforms that specialize in mechanical components, as these often provide access to a broader range of suppliers, including those with proven track records in international markets. Building relationships with suppliers who offer guarantees or warranties can also provide peace of mind and assurance of quality.

Scenario 2: Managing Supply Chain Disruptions in Mechanical Parts Procurement

The Problem:

Supply chain disruptions are a common challenge faced by B2B buyers of mechanical items, particularly in the current global environment. Events such as geopolitical tensions, pandemics, or natural disasters can lead to delays in product availability, impacting production schedules and project timelines. This unpredictability can result in lost contracts, dissatisfied customers, and a tarnished reputation in the marketplace.

The Solution:

To mitigate the effects of supply chain disruptions, B2B buyers should implement a dual-sourcing strategy. By establishing relationships with multiple suppliers across different regions, companies can reduce their dependency on a single source and create a buffer against localized disruptions. Additionally, maintaining a safety stock of critical components can provide a temporary cushion during supply shortages. Investing in supply chain visibility tools and analytics can also enable buyers to track inventory levels and anticipate shortages, allowing for proactive ordering and planning.

Illustrative image related to mechanical items

Scenario 3: Ensuring Compatibility and Integration of Mechanical Components

The Problem:

Another common pain point for B2B buyers is ensuring that newly sourced mechanical components are compatible with existing systems. The integration of different mechanical parts can be complex, especially when dealing with outdated machinery or equipment from various manufacturers. Compatibility issues can lead to operational inefficiencies, increased maintenance costs, and additional labor for retrofitting or modifying existing systems.

The Solution:

To address compatibility concerns, B2B buyers should invest time in thorough research and specification documentation. Before making a purchase, it is crucial to review technical specifications, compatibility matrices, and installation guidelines provided by manufacturers. Engaging with engineering consultants or using simulation software can help visualize how new components will interact with existing systems. Additionally, consider participating in forums or industry groups where buyers can share experiences and recommendations on compatible products. Finally, establishing a clear line of communication with suppliers about specific integration needs can facilitate a smoother transition and minimize the risk of costly errors.

Strategic Material Selection Guide for mechanical items

What Are the Key Properties of Common Materials Used in Mechanical Items?

When selecting materials for mechanical items, understanding their properties is crucial for ensuring optimal performance under various conditions. Here, we analyze four common materials: steel, aluminum, plastic, and brass, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

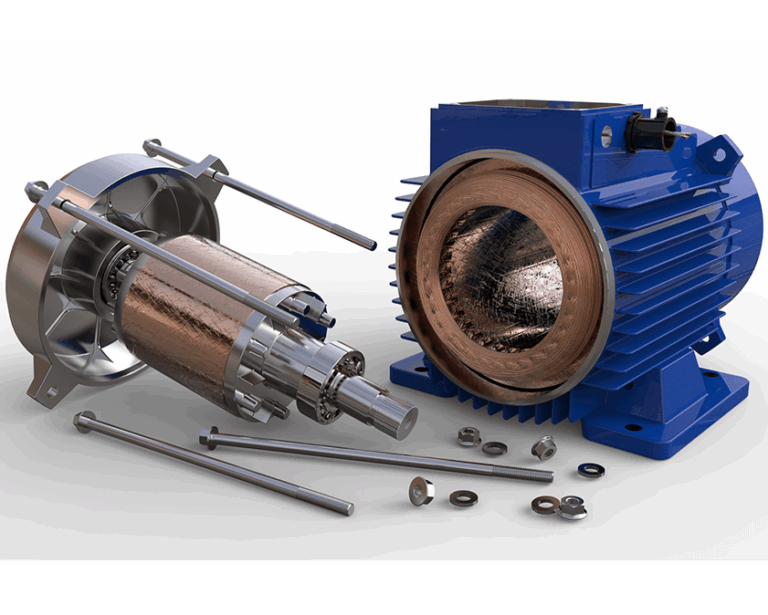

How Does Steel Perform in Mechanical Applications?

Steel is renowned for its strength and versatility, making it a popular choice for mechanical components. Key properties include high tensile strength, excellent fatigue resistance, and the ability to withstand high temperatures and pressures. Steel’s corrosion resistance can be enhanced through galvanization or the use of stainless steel grades.

Pros and Cons: Steel offers exceptional durability and is cost-effective for mass production. However, it can be heavy, which may not be suitable for lightweight applications. Additionally, the manufacturing complexity increases with the need for specialized machining or treatment processes.

Illustrative image related to mechanical items

Impact on Application: Steel is compatible with a wide range of media, including oils, gases, and water. Its robustness makes it suitable for heavy-duty applications like automotive and industrial machinery.

Considerations for International Buyers: Buyers from regions like Germany and Saudi Arabia should ensure compliance with local standards such as DIN and ASTM. The availability of steel grades may vary, impacting sourcing decisions.

What Are the Benefits of Using Aluminum in Mechanical Items?

Aluminum is celebrated for its lightweight and corrosion-resistant properties. It has a lower density than steel, making it ideal for applications where weight reduction is critical. Aluminum also exhibits good thermal and electrical conductivity.

Pros and Cons: The primary advantage of aluminum is its weight, which enhances fuel efficiency in transportation applications. However, it is generally less strong than steel and can be more expensive, particularly in high-strength alloys. The manufacturing processes for aluminum can also be more complex due to its malleability.

Impact on Application: Aluminum is suitable for applications involving exposure to moisture or corrosive environments, such as marine and aerospace industries. Its compatibility with various media, including chemicals, makes it a versatile choice.

Considerations for International Buyers: Buyers should be aware of compliance with standards like JIS for aluminum products, particularly in Japan and other Asian markets. Additionally, sourcing aluminum may be affected by regional supply chains.

How Do Plastics Compare in Mechanical Applications?

Plastics, particularly engineering plastics like nylon and polycarbonate, are increasingly used in mechanical applications due to their lightweight and versatile properties. They offer good chemical resistance and can be engineered to meet specific performance criteria.

Pros and Cons: The key advantage of plastics is their low weight and resistance to corrosion and chemicals, making them suitable for a variety of environments. However, they generally have lower strength and temperature resistance compared to metals, which can limit their use in high-stress applications.

Impact on Application: Plastics are ideal for applications where electrical insulation is required or where weight savings are essential. Their compatibility with various media, including solvents and oils, expands their applicability.

Considerations for International Buyers: Buyers should consider compliance with environmental regulations, such as REACH in Europe, when sourcing plastics. Understanding local preferences for specific plastic grades can also influence purchasing decisions.

Illustrative image related to mechanical items

What Role Does Brass Play in Mechanical Components?

Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. It has good thermal and electrical conductivity, making it suitable for electrical and plumbing applications.

Pros and Cons: The main advantage of brass is its durability and resistance to tarnishing, which makes it ideal for aesthetic applications. However, brass can be more expensive than other materials, and its strength is lower than steel.

Impact on Application: Brass is highly compatible with water and various gases, making it a preferred choice for fittings and valves. Its properties allow for reliable performance in plumbing and electrical applications.

Considerations for International Buyers: Compliance with standards like ASTM for brass components is essential for international buyers. Additionally, understanding local market preferences for brass alloys can impact sourcing strategies.

Summary Table of Material Selection for Mechanical Items

| Material | Typical Use Case for mechanical items | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, industrial machinery | High strength and durability | Heavy and complex to manufacture | Medium |

| Aluminum | Aerospace components, lightweight structures | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic | Electrical insulators, lightweight parts | Low weight and chemical resistance | Lower strength and temperature limits | Low |

| Brass | Plumbing fittings, electrical connectors | Excellent machinability and aesthetics | Higher cost and lower strength | Medium |

This guide provides actionable insights for B2B buyers, ensuring informed decisions in material selection for mechanical items across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for mechanical items

What Are the Main Stages of Manufacturing Mechanical Items?

The manufacturing process for mechanical items is a multi-stage operation that emphasizes precision, efficiency, and quality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process involves selecting the appropriate raw materials, such as metals, plastics, or composites, based on the desired properties and application of the mechanical item. Suppliers often conduct thorough assessments of material quality, including chemical composition and mechanical properties, to ensure they meet industry standards.

Once the materials are chosen, they undergo various preparation processes, such as cutting, grinding, or heat treatment, to achieve the required specifications. This stage is crucial because the quality of raw materials directly impacts the durability and performance of the final product.

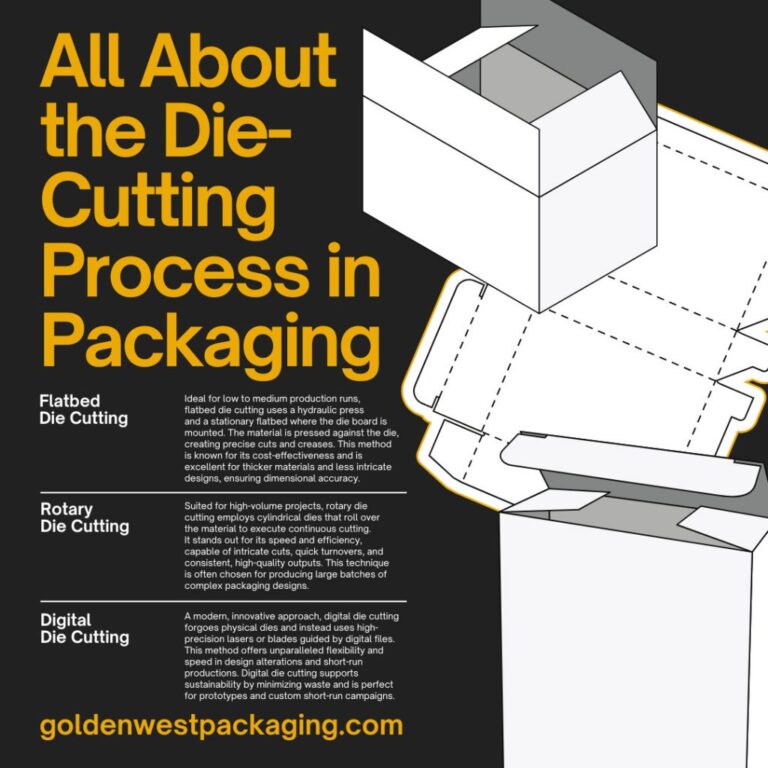

Forming: What Techniques Are Used to Shape Mechanical Components?

The forming stage encompasses various techniques to shape the prepared materials into the desired forms. Common methods include:

- Casting: Pouring molten material into a mold to create complex shapes.

- Machining: Removing material using tools such as lathes, mills, or grinders to achieve precise dimensions.

- Stamping and Forging: Using dies to shape materials under pressure, which enhances their strength and integrity.

Each technique has its advantages and is chosen based on factors such as cost, production volume, and material properties. For instance, machining is ideal for precision parts, while casting is more suitable for larger components.

Assembly: How Are Mechanical Items Assembled for Optimal Performance?

After the individual components are formed, they are assembled into the final mechanical item. This process may involve welding, fastening, or bonding parts together. The assembly stage is critical, as it influences the overall functionality and reliability of the product.

Quality assurance during assembly includes verifying that components fit together correctly and function as intended. B2B buyers should inquire about the assembly techniques used by suppliers, as well as any automated processes that may enhance consistency and reduce human error.

Finishing: What Are the Final Touches Applied to Mechanical Products?

Finishing processes are employed to enhance the appearance and performance of mechanical items. These processes may include:

- Surface Treatments: Such as anodizing, plating, or painting to improve corrosion resistance and aesthetics.

- Heat Treatment: To enhance material properties like hardness and ductility.

- Quality Inspection: Conducted post-finishing to ensure the product meets the required specifications and standards.

The finishing stage is vital for ensuring that the mechanical item performs reliably over time, especially in harsh environments.

Illustrative image related to mechanical items

What Quality Assurance Measures Are Essential for Mechanical Items?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that mechanical items meet defined standards and specifications. B2B buyers should be familiar with the relevant international standards and industry-specific certifications that impact their purchasing decisions.

Which International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems (QMS) that help organizations consistently meet customer and regulatory requirements. Other relevant certifications include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Certification: Relevant for mechanical items in the oil and gas industry, ensuring adherence to quality and safety standards.

Understanding these certifications can help buyers assess the credibility of potential suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure each stage meets quality standards. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials before production begins.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing stages to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify it meets specifications.

Implementing these checkpoints helps reduce the risk of defects and ensures that only high-quality products reach the customer.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Key methods include:

- Audits: Conducting on-site inspections to assess the supplier’s QMS and production processes.

- Reviewing Quality Reports: Requesting documentation of past QC inspections and compliance with relevant standards.

- Third-Party Inspections: Engaging independent organizations to evaluate the supplier’s manufacturing processes and product quality.

These measures can provide insights into the supplier’s commitment to quality and reliability, which is particularly important for international buyers navigating different regulatory environments.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is critical. Each region may have unique regulatory requirements, certifications, and industry practices that can impact procurement.

- Regional Standards: Familiarize yourself with local regulations that may differ from international standards. For instance, the EU has stringent requirements for product safety and environmental impact.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and expectations regarding quality.

- Logistics and Supply Chain: Be aware of how international logistics can affect product quality, such as potential delays in delivery that may compromise material integrity.

By being informed about these factors, B2B buyers can make more strategic purchasing decisions that align with their quality assurance objectives.

Illustrative image related to mechanical items

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial for B2B Buyers?

For B2B buyers, a comprehensive understanding of manufacturing processes and quality assurance measures is essential to ensure they source reliable and high-quality mechanical items. By focusing on the key stages of manufacturing, relevant international standards, and effective QC practices, buyers can mitigate risks and enhance their supply chain efficiency. This knowledge not only fosters better supplier relationships but also ultimately contributes to the success of their own operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mechanical items’

Introduction

Sourcing mechanical items can be a complex process, especially for international B2B buyers navigating diverse markets. This checklist aims to streamline your procurement efforts, ensuring you acquire high-quality mechanical components that meet your specific requirements. By following these steps, you will enhance your purchasing strategy, mitigate risks, and foster successful supplier relationships.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your technical requirements. This includes dimensions, materials, tolerances, and specific performance characteristics. A well-defined specification minimizes misunderstandings and ensures that the components meet your operational needs.

- Consider the application: Understand how the mechanical items will be used in your processes.

- Consult with your engineering team: Collaborate with engineers or technicians to validate your specifications.

Step 2: Research Potential Suppliers

Identifying suitable suppliers is a critical step in the sourcing process. Conduct thorough research to compile a list of potential vendors, focusing on their reputation, product range, and market presence.

- Use online directories: Platforms like DirectIndustry can help you find reliable manufacturers of mechanical components.

- Check industry reviews: Look for testimonials or case studies that reflect the supplier’s reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is vital for ensuring quality and compliance. Check if suppliers hold relevant industry certifications, such as ISO 9001, which indicate adherence to quality management standards.

- Request documentation: Ask for copies of certifications and quality assurance processes.

- Assess industry compliance: Ensure the supplier meets local and international regulations relevant to your market.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the mechanical items you intend to purchase. Evaluating these samples allows you to assess the quality and compatibility with your specifications.

- Conduct thorough testing: Check for durability, functionality, and any specific requirements outlined in your specifications.

- Involve your technical team: Have engineers or technicians assess the samples for compliance with operational standards.

Step 5: Negotiate Terms and Conditions

Once you have chosen a supplier, negotiate clear terms and conditions before finalizing the purchase. This includes pricing, delivery timelines, payment terms, and warranty agreements.

- Be transparent: Communicate your expectations regarding timelines and quality standards.

- Consider long-term relationships: Discuss potential for future orders or partnerships to foster a mutually beneficial relationship.

Step 6: Establish a Communication Protocol

Effective communication is crucial throughout the sourcing process. Establish a clear communication protocol with your chosen supplier to facilitate smooth interactions and prompt issue resolution.

- Define points of contact: Identify key contacts on both sides for streamlined communication.

- Set regular updates: Schedule periodic check-ins to monitor progress and address any concerns.

Step 7: Implement a Quality Control Process

After procurement, implement a robust quality control process to monitor the performance of the mechanical items within your operations. Regular audits and feedback loops will help maintain product quality and supplier accountability.

- Document performance metrics: Track how the components perform over time and gather data for future sourcing decisions.

- Provide feedback to suppliers: Share insights regarding product performance to help suppliers improve their offerings.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing mechanical items, ensuring they make informed decisions that enhance operational efficiency and product quality.

Illustrative image related to mechanical items

Comprehensive Cost and Pricing Analysis for mechanical items Sourcing

What Are the Key Cost Components in Mechanical Item Sourcing?

Understanding the cost structure is critical for international B2B buyers sourcing mechanical items. The primary cost components include:

-

Materials: The choice of raw materials significantly affects the cost. For instance, high-grade steel or specialized plastics will command higher prices compared to standard materials. Regularly analyzing market trends can help buyers identify cost-effective materials without compromising quality.

-

Labor: Labor costs vary by region and can influence the overall pricing of mechanical items. Countries with higher labor costs may produce items at a premium, while regions with lower labor costs might offer more competitive pricing. Assessing the labor market in your sourcing region can reveal potential savings.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as factory utilities and administrative expenses. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: The investment in tooling is essential, especially for customized items. Tooling costs can be amortized over larger production runs, making it crucial to negotiate minimum order quantities (MOQs) that align with tooling investments.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to costs. Establishing clear quality standards and certifications can help buyers understand the implications on pricing.

-

Logistics: Shipping and handling costs vary significantly depending on the mode of transport, distance, and the complexity of the supply chain. Understanding Incoterms can help buyers manage logistics costs more effectively.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the competitive landscape can provide leverage during negotiations.

How Do Price Influencers Impact the Sourcing of Mechanical Items?

Several factors can influence the pricing of mechanical items, particularly for international buyers:

-

Volume/MOQ: Suppliers often offer better pricing for bulk orders. Establishing a clear understanding of your requirements and negotiating favorable MOQs can lead to significant cost savings.

-

Specifications and Customization: Custom designs or unique specifications can increase costs due to the additional tooling and labor required. Buyers should evaluate the necessity of customization against the potential cost increase.

-

Materials and Quality Certifications: The choice of materials and quality certifications can significantly impact pricing. Items that require specific certifications, such as ISO or CE, may be priced higher due to the additional compliance costs.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge more for their products but often provide better quality assurance and service. Assessing supplier reliability can help buyers make informed decisions.

-

Incoterms: Understanding Incoterms is vital for managing logistics costs and responsibilities. Different terms can alter the overall cost structure significantly, affecting landed costs.

What Are Effective Tips for Buyers to Optimize Costs?

To maximize cost-efficiency in sourcing mechanical items, consider the following strategies:

-

Negotiate Effectively: Always negotiate prices and terms. Suppliers expect negotiation, and there may be room for discounts, especially for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including maintenance, operational efficiency, and potential downtimes. This holistic view can guide better purchasing decisions.

-

Research Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from Europe might come with higher standards and costs compared to South America or Africa, but the quality assurance could justify the price difference.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and priority service. Regular communication and feedback can enhance collaboration.

-

Stay Informed: Keep abreast of market trends and fluctuations in material costs. This knowledge can empower buyers to make timely purchasing decisions, potentially capitalizing on lower prices.

Final Thoughts

While the pricing of mechanical items can be influenced by various factors, a thorough understanding of the cost components and effective negotiation strategies can significantly benefit international B2B buyers. Always remember that prices can fluctuate based on market conditions, and it’s wise to seek indicative pricing before making significant commitments.

Alternatives Analysis: Comparing mechanical items With Other Solutions

Exploring Alternatives to Mechanical Items in Industrial Applications

In the realm of industrial solutions, mechanical items have long been a staple for various applications. However, as technology evolves, alternative solutions are emerging that can provide similar or enhanced functionalities. Understanding these alternatives allows B2B buyers to make informed decisions that align with their operational needs and budget constraints. Below, we compare mechanical items with two viable alternatives: Pneumatic Systems and Electromechanical Solutions.

Illustrative image related to mechanical items

| Comparison Aspect | Mechanical Items | Pneumatic Systems | Electromechanical Solutions |

|---|---|---|---|

| Performance | Reliable, consistent under load | High speed, good for repetitive tasks | High precision, adaptable to various tasks |

| Cost | Moderate initial investment | Lower initial cost, but higher operating costs | Higher upfront cost, but low maintenance |

| Ease of Implementation | Straightforward installation | Requires specialized training for installation | Can be complex, often needs integration with software |

| Maintenance | Generally low, but wear over time | Moderate, dependent on air quality | Low, with minimal moving parts |

| Best Use Case | General assembly, fasteners | High-speed automation processes | Robotics, precision applications |

Understanding Pneumatic Systems: Benefits and Drawbacks

Pneumatic systems utilize compressed air to perform work, making them an attractive alternative to mechanical items in certain contexts. They excel in applications requiring high-speed operation and repetitive tasks, such as in conveyor systems or assembly lines. The initial setup cost for pneumatic systems is generally lower than that of mechanical systems, making them appealing for businesses with budget constraints.

However, the operational costs can be higher due to energy consumption and the need for air quality maintenance. Moreover, pneumatic systems may require specialized training for effective installation and operation, which could pose challenges for companies lacking technical expertise.

Evaluating Electromechanical Solutions: Pros and Cons

Electromechanical solutions combine electrical and mechanical systems to provide precise control over movement and force. These systems are particularly beneficial in robotics and applications requiring high precision, such as CNC machines. While the initial investment for electromechanical solutions is typically higher than for mechanical items, their low maintenance requirements can lead to cost savings over time.

Illustrative image related to mechanical items

On the downside, the complexity of electromechanical systems can necessitate advanced knowledge for installation and integration, potentially increasing the time to deploy. Additionally, these systems may not be as robust in extreme environmental conditions compared to traditional mechanical items.

Making the Right Choice for Your Business Needs

When choosing between mechanical items and their alternatives, it’s essential for B2B buyers to consider their specific operational requirements. Factors such as the nature of the tasks, budget constraints, and available technical expertise should guide the decision-making process. For example, if your operations involve high-speed repetitive tasks, pneumatic systems may be the best fit. Conversely, for applications requiring precision, investing in electromechanical solutions could yield better long-term benefits.

Ultimately, understanding the strengths and weaknesses of each option will empower businesses to select the most suitable solution that aligns with their goals, ensuring operational efficiency and cost-effectiveness in their processes.

Essential Technical Properties and Trade Terminology for mechanical items

What Are the Key Technical Properties of Mechanical Items in B2B Transactions?

In the realm of mechanical items, understanding the technical properties is crucial for ensuring compatibility, reliability, and performance. Here are some essential specifications that B2B buyers should consider:

-

Material Grade:

The material grade indicates the quality and type of material used in mechanical components, such as steel, aluminum, or plastics. Each material has unique properties that affect strength, corrosion resistance, and weight. For instance, stainless steel is often preferred for its durability and resistance to rust, making it ideal for outdoor applications. Selecting the right material grade ensures that the mechanical item can withstand the operational environment it will be used in. -

Tolerance:

Tolerance refers to the permissible limit of variation in a physical dimension. It is crucial in mechanical design, as it determines how parts fit together. High precision components may require tighter tolerances, which can increase production costs. Understanding tolerance helps B2B buyers ensure that parts will function correctly and reduce the risk of assembly issues or equipment failure. -

Load Capacity:

Load capacity indicates the maximum weight a mechanical component can support without failure. This specification is vital for applications where components bear significant loads, such as in construction or machinery. Knowing the load capacity helps buyers select the right items for their projects, ensuring safety and functionality. -

Operating Temperature Range:

This property defines the temperature limits within which a mechanical item can operate effectively. Components designed for extreme temperatures—both high and low—are essential in industries such as aerospace and automotive. Ensuring that items can withstand the expected temperature range prevents premature wear and failure. -

Surface Finish:

Surface finish describes the texture and smoothness of a component’s surface. It can affect friction, wear resistance, and aesthetic appeal. For example, a polished finish may be necessary for parts that require minimal friction, while a rougher finish may be acceptable for items that do not interact with other surfaces. Understanding surface finish requirements is critical for performance and longevity.

What Are Common Trade Terms Used in Mechanical Items Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer):

An OEM produces parts or equipment that may be marketed by another manufacturer. In B2B procurement, working with OEMs can assure buyers of the quality and compatibility of components, as they are often tailored for specific applications. -

MOQ (Minimum Order Quantity):

MOQ refers to the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and pricing strategies. Buyers should evaluate whether the MOQ aligns with their operational needs and budget constraints. -

RFQ (Request for Quotation):

An RFQ is a formal document used to solicit price quotes from suppliers. It outlines specific requirements, including quantities, specifications, and delivery terms. Utilizing RFQs helps B2B buyers obtain competitive pricing and ensure that they receive the correct products. -

Incoterms:

International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing logistics, costs, and risks associated with shipping mechanical items across borders. -

Lead Time:

Lead time is the amount of time between placing an order and receiving the goods. In the context of mechanical items, lead times can vary based on production schedules and supply chain factors. Knowing the lead time helps buyers plan their operations effectively and avoid delays. -

Certification Standards:

These are regulatory benchmarks that mechanical items must meet to ensure safety and performance. Certifications such as ISO, CE, or ASTM can influence buyer decisions, as they reflect a commitment to quality and compliance. Being aware of relevant certification standards is vital for maintaining product integrity and customer trust.

By understanding these key technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their mechanical components meet operational requirements and industry standards.

Illustrative image related to mechanical items

Navigating Market Dynamics and Sourcing Trends in the mechanical items Sector

What Are the Key Trends Shaping the Global Mechanical Items Market?

The mechanical items sector is witnessing significant transformation driven by various global market dynamics. One of the primary drivers is the increasing demand for automation across industries, particularly in manufacturing and logistics. This trend is leading to a surge in the need for precision-engineered components, such as screws, bolts, and mechanical seals, which are essential for the efficient functioning of automated systems. Additionally, the rise of Industry 4.0 technologies, including IoT and AI, is influencing sourcing strategies, as businesses seek suppliers who can provide smart, connected components that enhance operational efficiency.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing from suppliers who demonstrate agility and responsiveness to market changes. This has resulted in a shift towards just-in-time (JIT) inventory systems, which minimize holding costs and optimize supply chain efficiency. Moreover, the growing trend of digitalization in procurement processes is enabling buyers to leverage platforms for real-time data and analytics, facilitating informed decision-making regarding sourcing and supplier management.

Emerging markets are also seeing heightened interest from global suppliers, as they look to tap into the expanding industrial sectors in these regions. For instance, countries in Africa and South America are investing in infrastructure development, driving the demand for various mechanical items. Buyers should keep an eye on these trends to identify opportunities for collaboration and growth in the mechanical components market.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Mechanical Items Sector?

Sustainability has become a critical consideration for B2B buyers in the mechanical items sector. The environmental impact of manufacturing processes and materials is under increasing scrutiny, compelling companies to adopt sustainable practices. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing carbon footprints, utilizing eco-friendly materials, and implementing waste reduction strategies. This shift is not just about compliance; it is also about enhancing brand reputation and meeting the expectations of environmentally conscious customers.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from human rights violations and exploitative labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainable and ethical practices. By collaborating with suppliers who adhere to these standards, international buyers can mitigate risks and enhance their corporate social responsibility profiles.

Additionally, there is a growing market for ‘green’ materials, such as biodegradable plastics and recycled metals, which can be incorporated into mechanical item production. Buyers should actively seek out suppliers offering these materials, as they not only align with sustainability goals but also cater to a market that increasingly values environmentally friendly products.

What Is the Historical Context of Mechanical Items in B2B Markets?

The evolution of mechanical items has its roots in the industrial revolution, which marked a significant shift from manual labor to machine-based manufacturing. The introduction of standardized mechanical components, such as bolts and screws, revolutionized production processes, allowing for mass production and interchangeability. This historical context is crucial for B2B buyers today, as it highlights the importance of quality and consistency in mechanical components.

Over the decades, advancements in materials science and engineering have further refined the manufacturing of mechanical items. Innovations such as lightweight alloys and advanced polymers have expanded the functionality and application of these components across various industries. Understanding this evolution helps buyers appreciate the complexity and precision involved in modern mechanical items, guiding them in making informed sourcing decisions that align with contemporary market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of mechanical items

-

How do I solve issues with mechanical parts compatibility?

To address compatibility issues with mechanical parts, start by confirming the specifications of each component, including size, material, and design standards. Utilize detailed drawings and technical data sheets from suppliers to ensure alignment with your machinery’s requirements. Conduct a trial assembly if possible, or consult with an engineering expert to verify compatibility. Additionally, establishing clear communication with your supplier about your specific needs can prevent future issues. -

What is the best mechanical component for high-stress applications?

For high-stress applications, components made from high-strength materials such as stainless steel or titanium are often the best choice. Look for parts specifically designed for durability, like heavy-duty bearings, shock absorbers, or anti-vibration mounts. It’s essential to consider the operating environment; for example, components exposed to corrosive elements should have appropriate coatings. Partnering with reputable manufacturers who specialize in high-performance parts can also ensure quality and reliability. -

How can I vet suppliers for mechanical components effectively?

Vetting suppliers requires a thorough assessment of their credentials, including certifications (ISO, CE, etc.), production capabilities, and quality control processes. Request references and case studies from previous clients, and consider visiting the manufacturing facility if feasible. Evaluate their responsiveness and willingness to provide detailed information about products and processes. Additionally, using third-party platforms or industry-specific networks can help you find reliable suppliers with positive reputations. -

What should I consider when customizing mechanical components?

When customizing mechanical components, consider factors like material selection, tolerances, and intended application. Clearly define your requirements and work closely with your supplier to develop a prototype that meets your specifications. Ensure that the customization does not compromise the integrity or functionality of the component. It’s also crucial to discuss lead times and costs upfront to avoid unexpected delays or expenses during production. -

What are the typical minimum order quantities (MOQs) for mechanical items?

Minimum order quantities (MOQs) for mechanical items can vary significantly based on the supplier and the complexity of the item. Standard components may have lower MOQs, while custom parts often require larger orders. It’s advisable to communicate your needs directly with suppliers to negotiate MOQs that align with your project requirements. Consider discussing bulk purchasing options or forming a partnership for recurring orders to reduce costs. -

What payment terms should I expect when sourcing internationally?

International payment terms can vary widely, but common methods include letters of credit, advance payments, or net payment terms (e.g., net 30, net 60). It’s essential to negotiate clear terms that protect both parties, including currency considerations and any additional fees (such as bank transfer charges). Ensure you understand the implications of exchange rates and potential tariffs. Establishing a good relationship with your supplier can also facilitate smoother transactions. -

How do I ensure quality assurance (QA) for mechanical components?

To ensure quality assurance for mechanical components, implement a robust QA process that includes supplier audits, incoming inspection, and product testing. Specify quality standards in your purchase agreements and request certifications that verify compliance with industry norms. Regularly communicate with your suppliers about quality expectations and establish a feedback loop to address any issues promptly. Utilizing third-party inspection services can provide additional assurance, especially for critical components. -

What logistics considerations should I keep in mind when sourcing mechanical parts?

When sourcing mechanical parts internationally, logistics considerations are crucial. Evaluate shipping options based on cost, transit time, and reliability. Understand customs regulations and ensure that all necessary documentation (invoices, packing lists, certificates of origin) is prepared to avoid delays. Consider working with logistics providers who specialize in international trade to navigate complexities. Additionally, factor in potential tariffs and duties that could affect your overall cost.

Top 6 Mechanical Items Manufacturers & Suppliers List

1. Pinterest – 3D Printed & CNC Cut Machinery

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 3D Printed and CNC Cut Rotomolding Machine, Linear Servo Motor, Pneumatic Regulator, Automatic Transmission Parts, Fanuc Servo Motor, Luban Lock Educational Intellectual Toys, Mechanical Clock Mechanism, Steam Bending Automaton Mechanism, Gear Transmission Mechanism, Reciprocating Gear Mechanism, Quick Release Mechanism, Scissor Lift Mechanism, Chainless bike with 4-bar linkages.

2. HeirloomGiftsCo – Unique Stress Relief Toy

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: [{‘title’: ‘Unique Gift for Men Who Have Everything – Stress Relief Toy for Men’s Desk, Custom Floating Gyroscope for Desk, Funny Groomsmen Gift Idea’, ‘seller’: ‘HeirloomGiftsCo’, ‘sale_price’: ‘$29.96’, ‘original_price’: ‘$119.84’, ‘discount’: ‘75% off’, ‘shipping’: ‘FREE’}, {‘title’: ‘Wooden Floating House Automaton | Magnetic Levitating Up House with Balloons’, ‘seller’: ‘NickWoodcarvingHouse’…

3. Fandom – Mechanical Components

Domain: create.fandom.com

Registered: 1996 (29 years)

Introduction: Adjustable Chain Gearshift, Build Order, Clockwork Bearing, Clutch, Cogwheel, Contraption, Crushing Wheel, Deployer, Elevator Pulley, Encased Chain Drive, Encased Fan, Gantry Carriage, Gearbox, Gearshift, Linear Chassis, Mechanical Arm, Mechanical Bearing, Mechanical Belt, Mechanical Crafter, Mechanical Drill, Mechanical Mixer, Mechanical Piston, Mechanical Press, Mechanical Saw, Millstone, Piston…

4. Hanswerner – Key Products

Domain: hanswerner.net

Registered: 2023 (2 years)

Introduction: 1. Bicycle: Showcases mechanics behind movement and balance; components include gears and chain. 2. Mechanical Pencil: Features controlled precision for consistent lead advancement; eliminates need for sharpening. 3. Ballpoint Pen: Focuses on smooth ink flow and ergonomic design; transforms simple mistakes into art of precision. 4. Door Lock (Deadbolt): Intricate miniaturized device; components wo…

5. IQS Directory – Mechanical Components

Domain: iqsdirectory.com

Registered: 2004 (21 years)

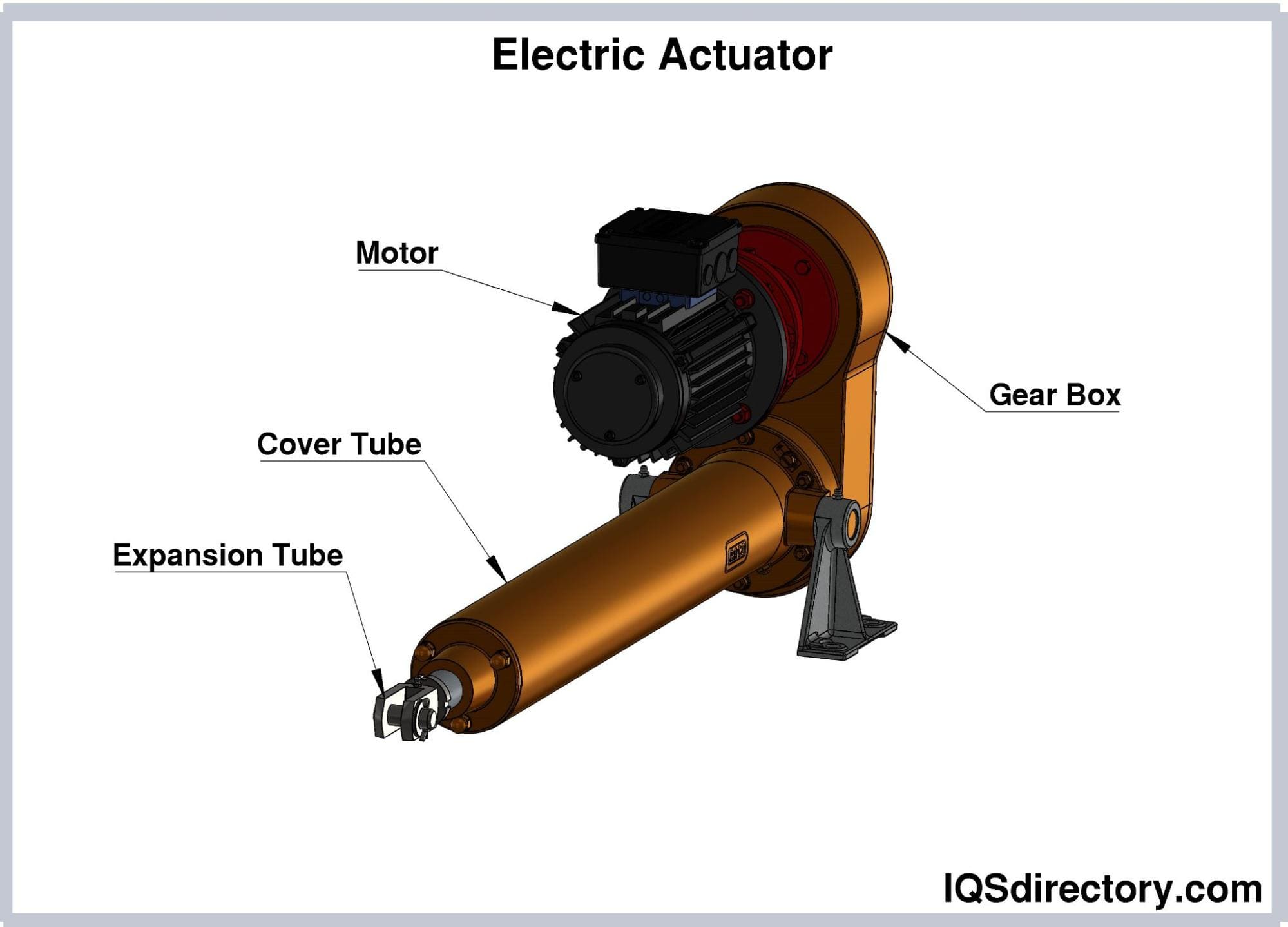

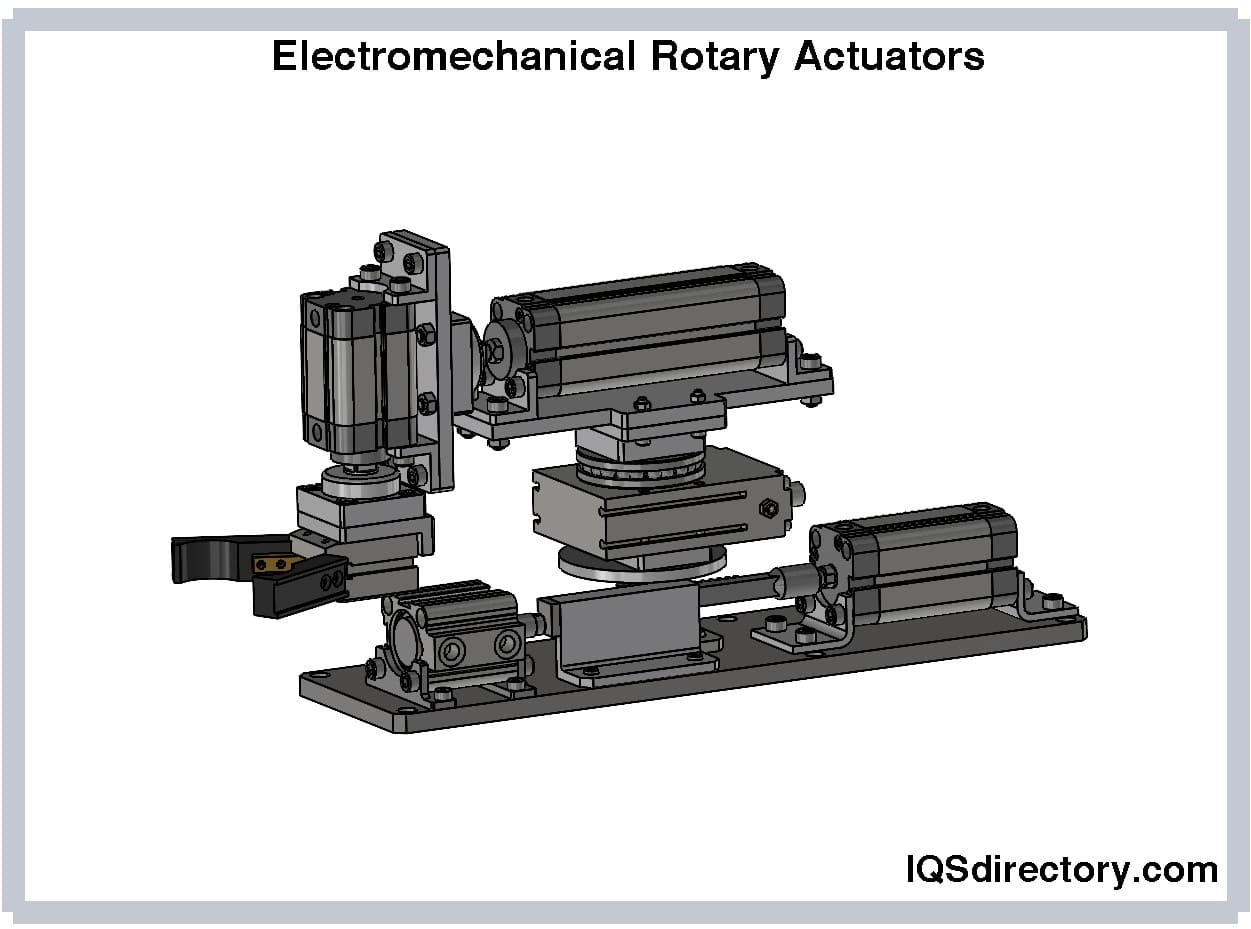

Introduction: Mechanical components are essential building blocks of machines and devices that produce work. Key types include: 1. Actuators – typically made from high-grade aluminum alloys, robust plastics, and sometimes thermo bimetals, with surface treatments for corrosion resistance. 2. Bearings – commonly made from chrome steel, carbon steel, or stainless steel, with specialty applications using ceramic be…

6. General – 14-Piece Quad Saw/Driver Set

Domain: generaltools.com

Registered: 1997 (28 years)

Introduction: General’s Mechanical Tools include pliers, strippers, scrapers, and pin vises of various styles and sizes. Notable products include the #86014 14-piece Quad Saw/Driver set, which combines jab and keyhole saws with power and speed drivers, including eight insert bits and saw blades for drywall, metal/PVC, and wood. Other tools listed include T Handle Reamer (1/8-1/2), various Ratchet Tap Wrenches f…

Strategic Sourcing Conclusion and Outlook for mechanical items

Why is Strategic Sourcing Essential for Mechanical Items?

As the global market for mechanical components continues to evolve, the importance of strategic sourcing cannot be overstated. International buyers, particularly those from Africa, South America, the Middle East, and Europe, can benefit significantly from a well-structured sourcing strategy. By focusing on quality, cost-efficiency, and supplier reliability, businesses can ensure they procure the best mechanical components, such as screws, bolts, and seals, tailored to their operational needs.

How Can International Buyers Navigate the Mechanical Component Market?

Understanding the landscape of mechanical items is crucial. Buyers should leverage technology and digital platforms to streamline their procurement processes, facilitating easier access to diverse suppliers. This approach not only enhances transparency but also fosters competition among suppliers, driving down costs while improving quality.

What Does the Future Hold for Mechanical Item Sourcing?

Looking ahead, the strategic sourcing of mechanical items presents opportunities for innovation and collaboration. As industries increasingly prioritize sustainability, buyers should consider suppliers who demonstrate environmental responsibility in their manufacturing processes. This shift not only aligns with global trends but can also enhance brand reputation.

International buyers are encouraged to embrace these strategic sourcing practices to maximize their purchasing power and stay competitive in an ever-changing market. The future of sourcing mechanical items is bright—take action today to ensure your business is at the forefront of this evolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to mechanical items