Gass Spring: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for gass spring

Navigating the complexities of sourcing gas springs can pose significant challenges for international B2B buyers, especially when seeking the right solutions for diverse applications. From selecting the appropriate type and understanding the various specifications to ensuring compatibility with existing systems, the process can be daunting. This guide aims to demystify the global market for gas springs, offering insights into the different types available, their applications across industries, and practical tips for supplier vetting and cost considerations.

In the ever-evolving landscape of manufacturing and product design, understanding the nuances of gas springs—also known as gas struts or dampers—is crucial for optimizing performance and enhancing product functionality. This guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Brazil) to make informed purchasing decisions. By providing a comprehensive overview of gas spring specifications, applications, and supplier reliability, we equip businesses with the knowledge necessary to streamline their procurement processes and achieve operational excellence.

Whether you are looking to replace an existing gas spring or need assistance in configuring a new one, this guide serves as a valuable resource, facilitating smoother transactions and better alignment with your operational needs. By leveraging the insights provided, buyers can effectively navigate the global market landscape, ensuring they acquire the most suitable gas springs for their unique applications.

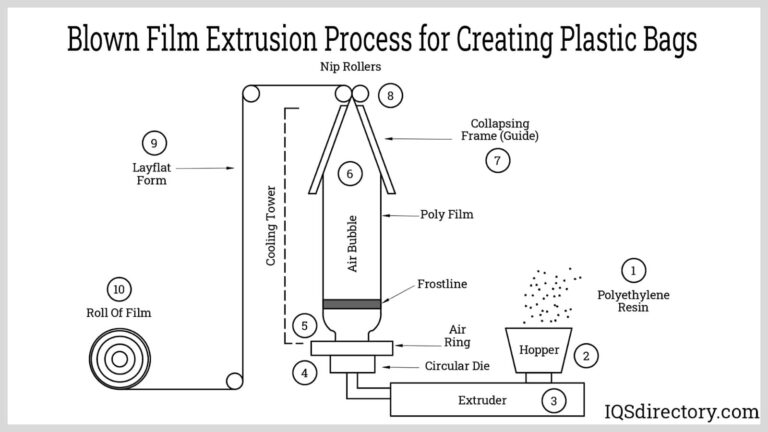

Understanding gass spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gas Spring | Varies in diameter and stroke length; adjustable force via nitrogen | Automotive, furniture, and machinery | Pros: Versatile, easy to install. Cons: Limited customization for specific applications. |

| Damping Gas Spring | Integrated damping for controlled motion; suitable for heavy loads | Industrial machinery, medical devices | Pros: Enhanced control, reduces wear. Cons: Typically higher cost. |

| Lockable Gas Spring | Offers locking mechanism at various positions | Aerospace, automotive, and cabinetry | Pros: Secure positioning, versatile use. Cons: More complex installation. |

| Compact Gas Spring | Smaller dimensions; designed for tight spaces | Electronics, automotive interiors | Pros: Space-saving, lightweight. Cons: Limited load capacity. |

| Heavy-Duty Gas Spring | Designed for high load capacities and durability | Construction equipment, heavy machinery | Pros: Robust performance, ideal for demanding applications. Cons: Bulkier, may require specialized mounts. |

What Are the Characteristics of Standard Gas Springs?

Standard gas springs are the most commonly used type, featuring a range of diameters and stroke lengths. They can be adjusted to provide varying levels of force through the nitrogen gas inside. These springs are widely applicable across industries, particularly in automotive manufacturing, furniture design, and general machinery. When purchasing, consider the specific weight and motion requirements of your application, as well as the ease of installation and compatibility with existing systems.

How Do Damping Gas Springs Enhance Performance?

Damping gas springs are specifically designed with integrated damping mechanisms, allowing for controlled motion and gradual extension or retraction. This feature is essential for applications involving heavy loads, such as industrial machinery or medical devices. Buyers should evaluate the damping characteristics to ensure they meet operational requirements, as well as the spring’s ability to withstand environmental factors, which can impact performance.

What Advantages Do Lockable Gas Springs Offer?

Lockable gas springs provide a unique feature that allows them to lock at various positions, offering secure stability for applications in aerospace, automotive, and cabinetry. This versatility makes them ideal for scenarios where precise positioning is critical. When considering a purchase, assess the complexity of installation and whether the locking mechanism aligns with operational needs, as it may require additional components.

Why Choose Compact Gas Springs for Space-Constrained Applications?

Compact gas springs are designed for applications with limited space, such as in electronics or automotive interiors. Their smaller dimensions make them lightweight and easy to fit into tight areas. However, they typically have a lower load capacity, so buyers should carefully consider their specific application requirements, ensuring that the spring’s strength meets the demands of the intended use.

Illustrative image related to gass spring

What Makes Heavy-Duty Gas Springs Suitable for Tough Environments?

Heavy-duty gas springs are built to handle high load capacities and are ideal for use in construction equipment and heavy machinery. Their robust design ensures durability under demanding conditions, making them a reliable choice for industries that require strength and resilience. When purchasing, it’s essential to evaluate the mounting options and the overall size of the spring, as these factors can influence installation and functionality in heavy-duty applications.

Key Industrial Applications of gass spring

| Industry/Sector | Specific Application of gass spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Lift gates and hoods | Enhances user experience with smooth operation | Ensure compatibility with vehicle models and weight specifications. |

| Furniture | Adjustable tables and chairs | Provides ergonomic solutions and space-saving designs | Look for customizable options to match design aesthetics and load requirements. |

| Aerospace | Cabin doors and hatches | Improves safety and ease of access | Focus on high-strength materials and compliance with aviation standards. |

| Medical Equipment | Hospital beds and examination tables | Facilitates patient comfort and operational efficiency | Prioritize reliability and ease of maintenance in high-use environments. |

| Industrial Machinery | Access panels and covers | Increases operational efficiency and safety | Verify load capacity and environmental resistance for industrial settings. |

How Are Gas Springs Used in the Automotive Industry?

In the automotive sector, gas springs are commonly employed in lift gates and hoods, providing controlled movements that enhance user experience. They enable smooth opening and closing, reducing the risk of injury and improving accessibility. For international buyers, it is crucial to consider compatibility with specific vehicle models and the required extension force to support the weight of the components effectively. A focus on durability and performance under varying environmental conditions is also essential for ensuring long-term reliability.

What Role Do Gas Springs Play in Furniture Design?

Gas springs are integral to the functionality of adjustable tables and chairs in the furniture industry. They allow for effortless height adjustments, promoting ergonomic comfort and efficient use of space. Buyers should seek customizable options that align with their design aesthetics and load requirements. Additionally, sourcing from suppliers who can provide detailed specifications and support for installation can greatly enhance the purchasing experience.

Why Are Gas Springs Critical in Aerospace Applications?

In aerospace, gas springs are utilized in cabin doors and hatches, where they enhance safety and ease of access for both crew and passengers. Their design must meet strict aviation standards, necessitating a focus on high-strength materials that can withstand extreme conditions. International buyers should prioritize suppliers who can provide certifications and demonstrate compliance with industry regulations to ensure the reliability and safety of their applications.

How Do Gas Springs Improve Medical Equipment?

Gas springs are vital in medical equipment such as hospital beds and examination tables, where they facilitate easy adjustment for patient comfort and operational efficiency. These components must be reliable and maintainable, as they are often subject to frequent use. Buyers in the medical sector should prioritize sourcing gas springs that offer durability and ease of maintenance, ensuring that they can withstand the rigors of a healthcare environment.

Illustrative image related to gass spring

What Benefits Do Gas Springs Offer in Industrial Machinery?

In industrial settings, gas springs are used for access panels and covers, contributing to operational efficiency and enhanced safety. They provide controlled movements that prevent accidents and facilitate easy access to machinery for maintenance. When sourcing gas springs for industrial applications, it is essential to verify the load capacity and environmental resistance, ensuring that they can perform reliably under demanding conditions.

3 Common User Pain Points for ‘gass spring’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Gas Spring Specifications

The Problem: B2B buyers often struggle to identify the correct specifications for gas springs suited to their specific applications. With a variety of types, sizes, and force ratings available, it can be overwhelming to navigate through the options. For instance, a manufacturer in Brazil may need a gas spring for a heavy machinery cover but is unsure about the required extension force and stroke length. This uncertainty can lead to incorrect orders, resulting in delays and additional costs.

The Solution: To overcome this challenge, buyers should utilize online configurators and calculators provided by reputable suppliers. These tools allow users to input specific parameters such as weight, dimensions, and required functionality. For example, Gasspringsshop.com offers a user-friendly calculator that assists in determining the appropriate gas spring by generating a list of suitable products based on the entered specifications. Buyers should also engage with customer service for expert advice on product selection. By leveraging these resources, B2B buyers can ensure they select gas springs that precisely meet their needs, minimizing the risk of ordering errors.

Scenario 2: Challenges in Replacing Existing Gas Springs

The Problem: Replacing existing gas springs can be a daunting task for businesses, especially if the original components are no longer in production or if there is insufficient documentation. An automotive parts manufacturer in Saudi Arabia might find it difficult to source a replacement for a specific gas spring used in a vehicle model that is now obsolete. This situation can disrupt production schedules and lead to increased downtime, which directly impacts profitability.

Illustrative image related to gass spring

The Solution: To effectively address replacement challenges, B2B buyers should first document the specifications of existing gas springs, including dimensions, force ratings, and any identifiable model numbers. When a direct replacement is not available, utilizing a configurator tool to create a custom gas spring can be invaluable. Suppliers like Gasspringsshop.com provide a “Replace” feature that allows users to search by type or article number, which can help in identifying alternatives. Additionally, businesses should maintain a close relationship with their suppliers, who can offer insights into suitable substitutes or even custom solutions tailored to their requirements. This proactive approach not only streamlines the replacement process but also ensures continuity in operations.

Scenario 3: Installation Issues Leading to Performance Problems

The Problem: After sourcing the correct gas springs, buyers often face installation challenges that can lead to performance issues. For example, a furniture manufacturer in Europe may install gas springs incorrectly, leading to improper function of adjustable tables or chairs. Such issues can not only frustrate end-users but also result in increased warranty claims and customer dissatisfaction.

The Solution: To mitigate installation problems, it is crucial for B2B buyers to invest in detailed installation guides and training for their staff. Suppliers typically provide installation manuals and even online resources like video tutorials that can guide users through the process. Additionally, utilizing suppliers that offer a configurator can help ensure that all necessary mounting parts are selected alongside the gas springs, promoting compatibility and ease of installation. For complex installations, consider consulting with the supplier’s technical support team. They can provide tailored advice and troubleshooting tips to ensure the gas springs are installed correctly, thus enhancing their performance and extending their lifespan. By prioritizing proper installation practices, companies can significantly reduce the likelihood of operational disruptions and improve customer satisfaction.

Strategic Material Selection Guide for gass spring

What Are the Key Materials Used in Gas Springs?

When selecting materials for gas springs, it is essential to consider their properties, advantages, and limitations. The most common materials used in the manufacturing of gas springs include steel, stainless steel, aluminum, and composite materials. Each material offers unique characteristics that cater to different applications and environmental conditions.

How Does Steel Perform as a Material for Gas Springs?

Steel is the most widely used material for gas springs due to its excellent mechanical properties. It typically has a high tensile strength, making it suitable for applications requiring significant load-bearing capabilities. Steel gas springs can operate effectively at a wide range of temperatures and pressures, withstanding harsh conditions.

Pros: Steel gas springs are durable and cost-effective, making them a popular choice for various industrial applications. They are relatively easy to manufacture, allowing for mass production.

Cons: However, steel is susceptible to corrosion, which can compromise the integrity of the gas spring in humid or corrosive environments. Additionally, steel’s weight can be a disadvantage in applications where weight reduction is critical.

Illustrative image related to gass spring

Impact on Application: Steel gas springs are suitable for applications involving heavy machinery and automotive components. However, buyers in regions with high humidity or corrosive environments, such as coastal areas in Africa or South America, should consider protective coatings or alternative materials.

What Advantages Does Stainless Steel Offer for Gas Springs?

Stainless steel is often preferred for applications requiring enhanced corrosion resistance. This material provides similar mechanical properties to standard steel but with added resistance to oxidation and rust.

Pros: Stainless steel gas springs can withstand exposure to moisture, chemicals, and extreme temperatures, making them ideal for outdoor applications or environments with corrosive substances. They also maintain aesthetic appeal due to their shiny finish.

Illustrative image related to gass spring

Cons: The primary drawback of stainless steel is its higher cost compared to standard steel. Additionally, manufacturing processes can be more complex, which may lead to longer lead times.

Impact on Application: Stainless steel gas springs are particularly beneficial in the food processing, pharmaceutical, and marine industries, where hygiene and corrosion resistance are critical. Buyers in the Middle East and Europe, where stringent compliance standards exist, may find stainless steel gas springs more suitable.

How Does Aluminum Compare for Gas Spring Applications?

Aluminum gas springs are increasingly popular due to their lightweight properties. They offer a good strength-to-weight ratio, making them ideal for applications where reducing weight is essential.

Pros: Aluminum is corrosion-resistant and can be anodized for additional protection. Its lightweight nature allows for easier handling and installation.

Cons: However, aluminum gas springs may not provide the same load-bearing capacity as steel or stainless steel. They are also generally more expensive than standard steel options.

Impact on Application: Aluminum gas springs are commonly used in automotive applications, furniture, and aerospace industries. Buyers in regions like Europe, where lightweight materials are favored for fuel efficiency, may prefer aluminum options.

What Role Do Composite Materials Play in Gas Springs?

Composite materials are becoming more prevalent in gas spring applications due to their unique properties, including high strength and low weight. These materials can be engineered to meet specific performance criteria.

Pros: Composites offer excellent resistance to corrosion and can be tailored for specific applications, providing flexibility in design and function.

Cons: The primary limitation of composite materials is their higher cost and potential manufacturing complexity. Additionally, they may not be suitable for all load-bearing applications.

Impact on Application: Composite gas springs are ideal for high-performance applications in aerospace and automotive industries. International buyers should be aware of the specific standards and certifications required for composite materials in their regions.

Illustrative image related to gass spring

Summary Table of Material Selection for Gas Springs

| Material | Typical Use Case for gass spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive components | High durability and cost-effectiveness | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Automotive, furniture, aerospace | Lightweight and corrosion-resistant | Lower load-bearing capacity | Medium |

| Composite | Aerospace, high-performance automotive | Tailored properties for specific needs | Higher cost and manufacturing complexity | High |

This material selection guide serves as a valuable resource for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, helping them make informed decisions based on application requirements and environmental considerations.

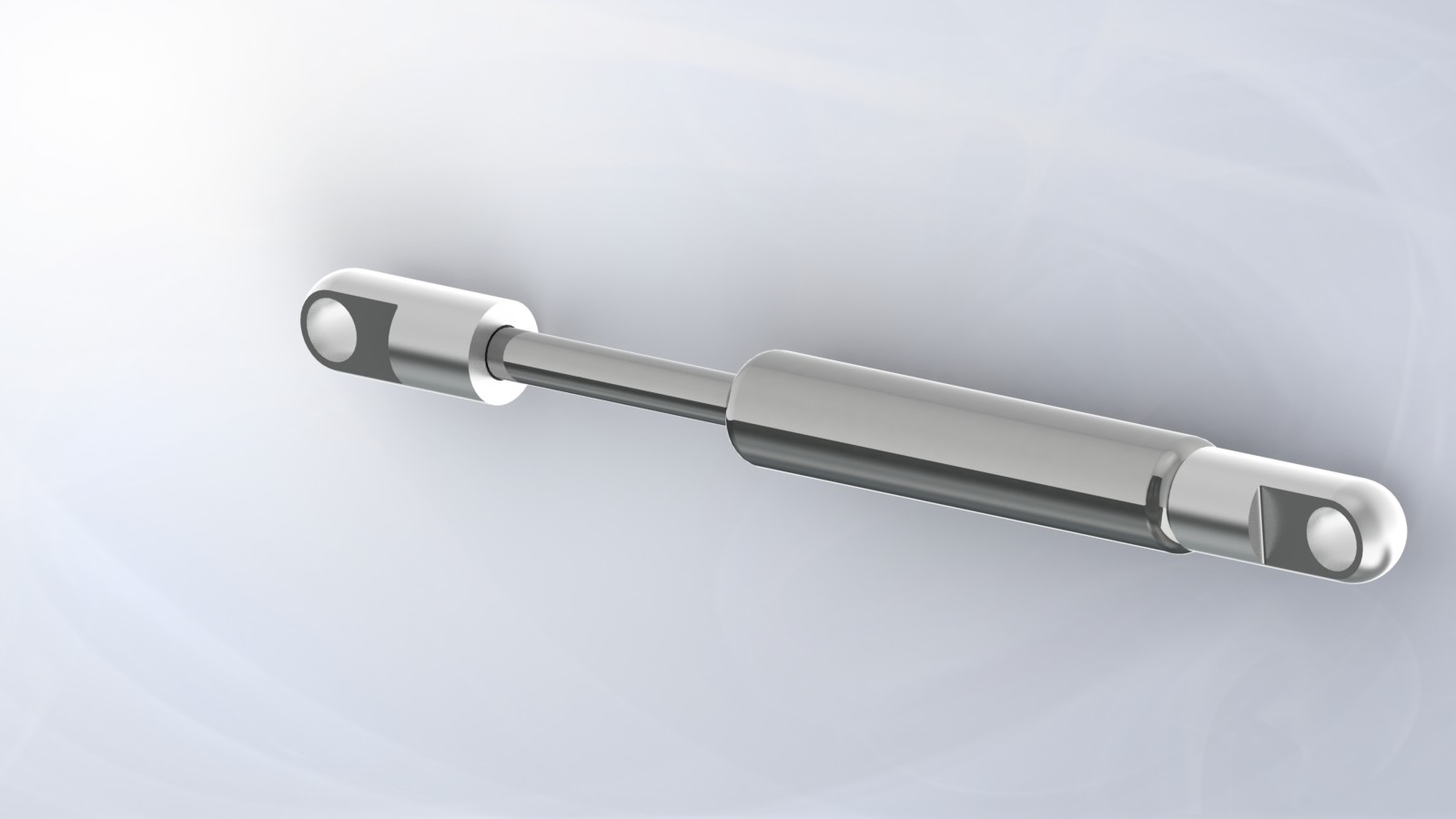

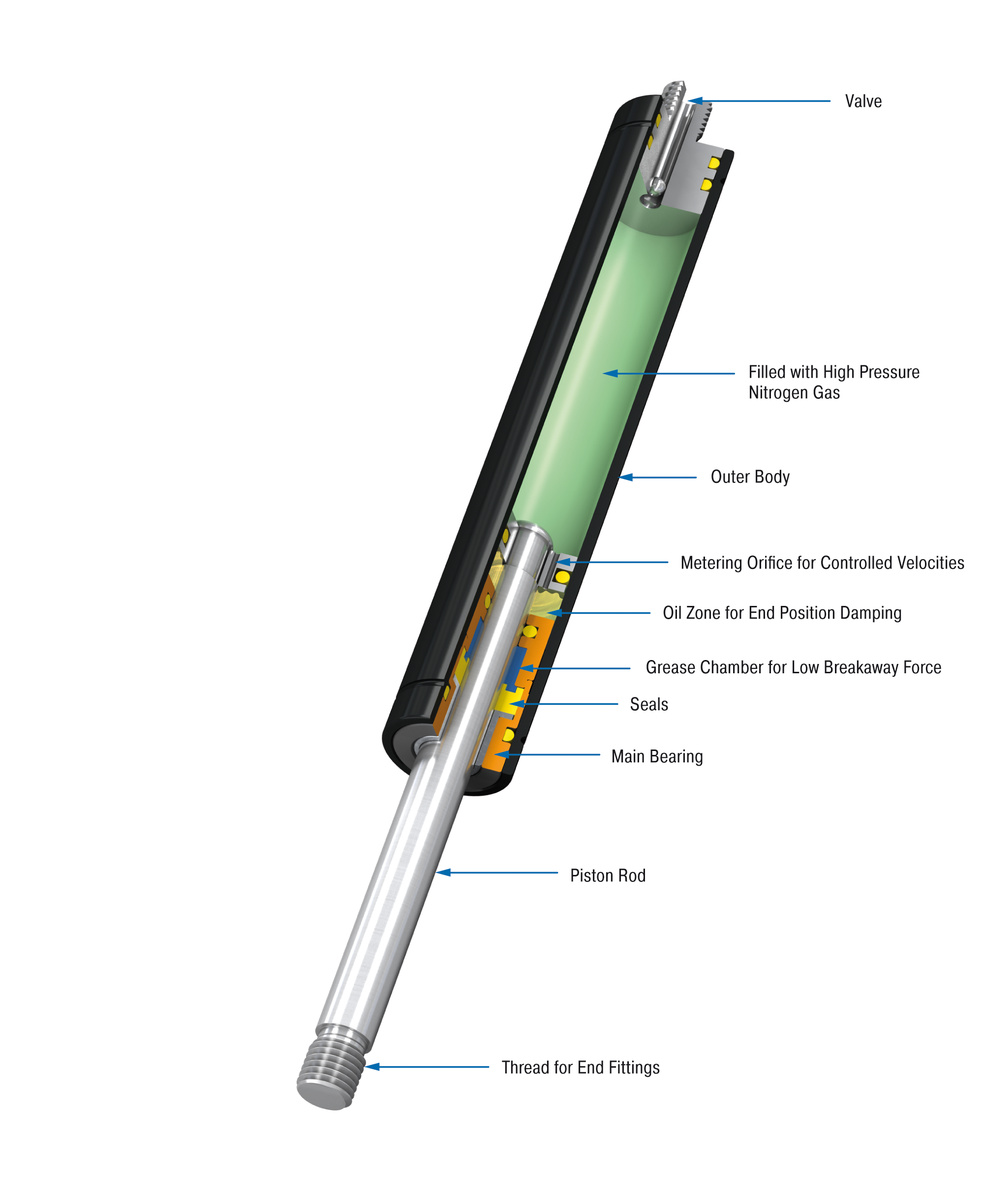

In-depth Look: Manufacturing Processes and Quality Assurance for gass spring

What Are the Main Stages of Manufacturing Gas Springs?

The manufacturing process of gas springs involves several critical stages, each designed to ensure the production of high-quality, reliable components that meet specific application requirements. Understanding these stages is essential for B2B buyers looking for dependable suppliers.

1. Material Preparation

The first stage in the manufacturing of gas springs involves selecting and preparing the raw materials. Typically, gas springs are produced from high-strength steel or stainless steel to withstand the internal pressures and environmental conditions they may encounter. The chosen materials undergo processes such as cutting and surface treatment to ensure they meet the necessary specifications for durability and performance.

2. Forming Techniques

Forming techniques play a crucial role in shaping the components of gas springs. This stage includes processes like cold drawing for the piston rod and tube, which enhances the material’s strength while achieving precise dimensions. Advanced technologies such as CNC machining may also be employed to ensure accuracy in component dimensions.

3. Assembly Process

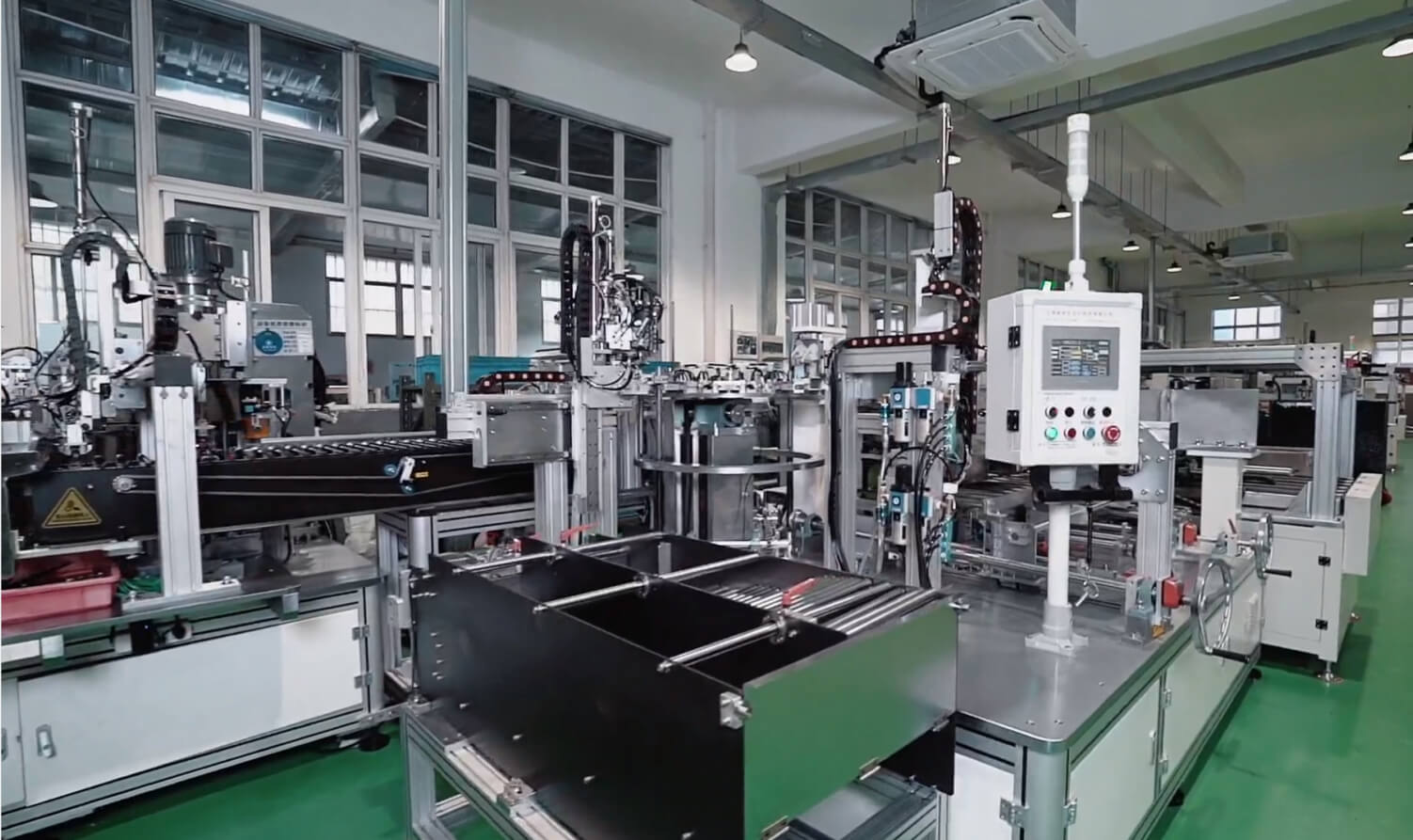

The assembly of gas springs involves integrating various components, including the pressure tube, piston rod, and sealing systems. A critical aspect of this stage is the installation of the valve, which controls the gas pressure within the spring. The assembly process often utilizes automated systems for consistent quality, allowing for the handling of high volumes while reducing human error.

Illustrative image related to gass spring

4. Finishing Touches

Finishing processes include surface treatments such as painting or plating to enhance corrosion resistance and aesthetic appeal. This stage may also involve rigorous testing of the assembled gas springs to ensure they meet the desired performance criteria before they are packaged for shipping.

How Is Quality Assurance Implemented in Gas Spring Manufacturing?

Quality assurance is paramount in gas spring manufacturing, ensuring that each product meets international standards and customer specifications. B2B buyers must be aware of the various quality control measures in place.

What Are the Relevant International Standards for Gas Springs?

Manufacturers of gas springs typically adhere to several international standards to maintain quality and safety. The ISO 9001 certification is a key standard that outlines requirements for a quality management system, ensuring consistent product quality. Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards and API standards for products used in the oil and gas sector, are also crucial.

What Are the Key Quality Control Checkpoints?

Quality control in gas spring manufacturing involves several checkpoints throughout the production process:

Illustrative image related to gass spring

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring is performed during the manufacturing process to detect and rectify any deviations from quality standards.

- Final Quality Control (FQC): Finished products undergo comprehensive testing to verify that they meet performance specifications before shipment.

What Common Testing Methods Are Used for Gas Springs?

Testing methods play a vital role in ensuring the performance and safety of gas springs. Common testing procedures include:

- Pressure Testing: This method assesses the gas spring’s ability to withstand internal pressure, ensuring it does not leak or fail under operational conditions.

- Cycle Testing: Gas springs are cycled through their full range of motion to evaluate their durability and performance over time.

- Functional Testing: This involves verifying that the gas spring operates correctly under specified load conditions, checking extension and retraction speeds.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is critical in ensuring the reliability of gas springs. Here are several strategies to consider:

1. Conduct Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. These audits should focus on compliance with international standards and the effectiveness of their quality management systems.

Illustrative image related to gass spring

2. Request Quality Control Reports

Buyers should request quality control reports that detail the testing results of the gas springs. These reports should include data on pressure tests, cycle tests, and other relevant metrics that reflect the product’s reliability.

3. Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can validate that the gas springs meet required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that the gas springs comply with local regulations, which may involve additional certifications.

- Supply Chain Transparency: Establishing a transparent supply chain is crucial for verifying the quality of materials used in gas spring production. Buyers should inquire about the origin of materials and the manufacturing processes employed.

- Cultural and Language Considerations: Effective communication with suppliers in different regions is essential. Buyers may need to consider language barriers and cultural differences that could impact negotiations and quality expectations.

Conclusion

Understanding the manufacturing processes and quality assurance measures for gas springs is vital for B2B buyers. By being informed about the key stages of production, quality control standards, testing methods, and verification strategies, buyers can make informed decisions when selecting suppliers. This knowledge not only helps in securing high-quality products but also fosters long-term partnerships built on trust and reliability in the competitive global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gass spring’

Introduction

Sourcing gas springs, also known as gas struts, is a critical component for various applications, from automotive to furniture. This step-by-step checklist is designed to guide international B2B buyers through the procurement process, ensuring that you select the right product and supplier to meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications of the gas springs you require is essential. Consider factors such as length, diameter, extension force, and material (e.g., steel or stainless steel). This will help you communicate effectively with suppliers and ensure that the products meet the exact requirements of your application.

- Extension Force: Determine the weight that the gas spring needs to support.

- Stroke Length: Identify how far the spring must extend or compress.

- Environmental Conditions: Consider whether the springs will be used indoors or outdoors, as this affects material choice.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in gas springs. Look for companies with a strong track record, positive customer reviews, and certifications that indicate quality standards.

- Supplier Experience: Assess how long the supplier has been in the industry and their expertise in gas springs.

- Customer Testimonials: Check reviews and case studies from previous buyers to gauge satisfaction.

Step 3: Evaluate Product Range and Customization Options

Examine the product range offered by potential suppliers. A diverse selection indicates that they can cater to various applications and that they may offer customization options for unique requirements.

- Standard vs. Custom Products: Determine whether you need standard gas springs or if your application requires customized solutions.

- Configurator Tools: Look for suppliers that provide online configurators to easily select the right specifications.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the gas springs you are considering. Testing samples in real-world conditions can help validate their performance and suitability for your application.

- Performance Evaluation: Assess the functionality, durability, and ease of installation of the samples.

- Compatibility Check: Ensure that the gas springs work well with your existing systems or products.

Step 5: Verify Supplier Certifications

It is crucial to ensure that your supplier adheres to international quality standards. Certifications like ISO 9001 can provide assurance of their manufacturing processes and quality control.

- Quality Assurance: Confirm that the supplier’s products meet industry-specific standards.

- Compliance with Regulations: Ensure that the gas springs comply with safety regulations relevant to your region.

Step 6: Discuss Pricing and Terms of Service

Engage in discussions regarding pricing, lead times, and terms of service. Understanding the total cost, including shipping and potential customs duties, is vital for budgeting.

Illustrative image related to gass spring

- Bulk Purchase Discounts: Inquire about discounts for large orders or long-term contracts.

- Payment Terms: Clarify payment methods and conditions to avoid misunderstandings later.

Step 7: Finalize Your Order and Establish Communication

Once you have selected a supplier, finalize your order and ensure that you establish clear lines of communication for any future inquiries or issues.

- Order Confirmation: Double-check all specifications and quantities before placing your order.

- Ongoing Support: Discuss how the supplier will provide support post-purchase, including warranty information and customer service availability.

By following this checklist, B2B buyers can streamline their sourcing process for gas springs, ensuring that they make informed decisions that align with their operational needs and goals.

Comprehensive Cost and Pricing Analysis for gass spring Sourcing

What Are the Key Cost Components in Gass Spring Sourcing?

When sourcing gas springs, understanding the underlying cost structure is essential for B2B buyers. The main cost components include:

-

Materials: Gas springs are typically made from steel or stainless steel, with varying costs based on the grade and quality. The material choice significantly influences the durability and performance of the product.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembling, and testing gas springs. Skilled labor may demand higher wages but can lead to better quality control.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Tooling costs refer to the expenses associated with the machinery and tools required for production. Custom tooling can lead to higher initial costs but may result in lower per-unit costs for larger production runs.

-

Quality Control (QC): Ensuring that gas springs meet specified standards involves costs associated with testing and inspection. High-quality certifications can enhance product reliability but may increase upfront expenses.

-

Logistics: Transportation costs for shipping raw materials to the manufacturing facility and delivering finished products to buyers are significant. Factors such as distance, mode of transport, and volume impact these costs.

-

Margin: Suppliers typically apply a markup to cover their costs and profit. Understanding the margin can help buyers negotiate better pricing.

What Influences Pricing for Gas Springs?

Several factors influence the pricing of gas springs in the B2B market:

-

Volume/MOQ: Pricing often improves with larger orders due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs.

-

Specifications/Customization: Customized gas springs tailored to specific applications may incur higher costs. Buyers should weigh the need for customization against potential price increases.

-

Materials: The choice between standard and premium materials can affect pricing. High-quality materials may result in higher initial costs but can lead to lower maintenance and replacement expenses.

-

Quality and Certifications: Products with international quality certifications (ISO, etc.) may command higher prices. However, these certifications often correlate with better performance and reliability.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographic location can impact pricing. Established suppliers may offer better service and reliability at a premium.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly influence final costs. Buyers should clarify responsibilities for shipping, insurance, and tariffs to avoid unexpected expenses.

How Can Buyers Negotiate Better Prices for Gas Springs?

B2B buyers can implement several strategies to enhance cost efficiency in gas spring sourcing:

-

Leverage Volume Discounts: Consolidate orders to reach higher volumes that may qualify for discounts. This approach can significantly lower unit costs.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term costs associated with maintenance, durability, and replacement. A higher upfront cost may be justified if the product lasts longer or requires less maintenance.

-

Understand Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and other factors that can affect overall costs. Engaging with local suppliers or distributors can sometimes mitigate these challenges.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products.

Disclaimer on Indicative Prices

It is important to note that prices for gas springs can vary significantly based on the factors discussed. Buyers should obtain quotes from multiple suppliers and conduct thorough market research to ensure they are getting the best value for their investment.

Illustrative image related to gass spring

Alternatives Analysis: Comparing gass spring With Other Solutions

Understanding Alternatives to Gas Springs

In the realm of industrial applications, gas springs are commonly utilized for various functions, such as lifting, lowering, and supporting mechanisms. However, there are alternative solutions available that may better suit specific needs or applications. This section examines gas springs in comparison to two viable alternatives: mechanical springs and hydraulic actuators. Each solution has its own strengths and weaknesses, making it essential for B2B buyers to understand these differences to make informed purchasing decisions.

Comparison Table

| Comparison Aspect | Gass Spring | Mechanical Spring | Hydraulic Actuator |

|---|---|---|---|

| Performance | High precision and control | Moderate control, variable force | High force and speed |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Simple installation | Requires precise fitting | Complex installation and setup |

| Maintenance | Low, generally long-lasting | Moderate, may require adjustment | Moderate, needs regular checks |

| Best Use Case | Light to medium load applications | General purpose, cost-sensitive | Heavy loads, precise movements |

Detailed Breakdown of Alternatives

Mechanical Springs

Mechanical springs, such as coil or leaf springs, are widely used across industries due to their simplicity and cost-effectiveness. They store energy and release it when needed, making them suitable for applications where variable force is acceptable. The primary advantage of mechanical springs is their low cost and ease of availability. However, they have limitations in terms of precision and the ability to control the extension speed, which may lead to abrupt movements. Mechanical springs are best used in applications where cost is a primary concern, and the control of motion is less critical.

Hydraulic Actuators

Hydraulic actuators utilize fluid pressure to generate movement, providing powerful and precise control over heavy loads. They are ideal for applications requiring high force and speed, such as construction machinery and industrial equipment. The main advantage of hydraulic actuators is their ability to deliver significant force in a compact size. However, they tend to have a higher upfront cost and can be more complex to install and maintain due to the need for hydraulic fluid and regular maintenance checks. Additionally, they may require specialized knowledge for setup and repairs, which can lead to increased operational costs over time.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution between gas springs, mechanical springs, and hydraulic actuators depends on the specific requirements of your application. B2B buyers should consider factors such as the load requirements, precision needs, budget constraints, and maintenance capabilities. Gas springs offer a balance of performance and ease of use, making them suitable for a wide range of applications. In contrast, mechanical springs are a cost-effective option for general use, while hydraulic actuators excel in high-force scenarios but come with higher costs and complexity. By thoroughly evaluating these aspects, buyers can make informed decisions that align with their operational needs and financial constraints.

Essential Technical Properties and Trade Terminology for gass spring

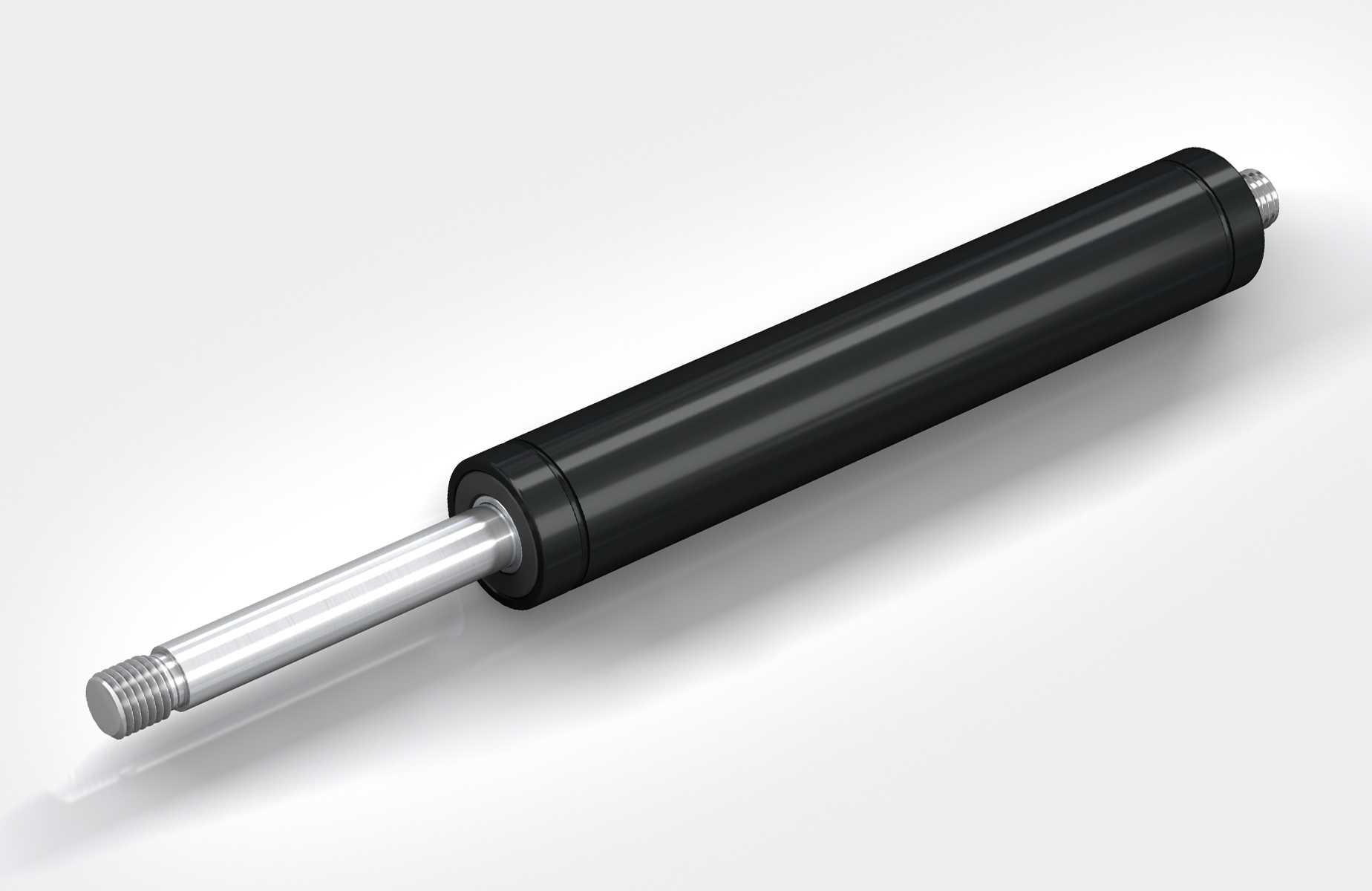

What Are the Key Technical Properties of Gas Springs?

Gas springs, also known as gas struts, are critical components in various applications requiring controlled motion. Understanding their essential specifications can significantly impact performance, safety, and cost-effectiveness. Here are some of the most important technical properties:

-

Extension Force (N)

The extension force is a crucial specification that determines how much weight a gas spring can support when extended. Measured in Newtons (N), this force is essential for applications where gas springs counterbalance loads, such as in hatches, lids, or furniture. B2B buyers must match the extension force of a gas spring with the weight of the object it will support to ensure proper functionality. -

Stroke Length (mm)

The stroke length is the maximum distance the piston rod can extend. This measurement is vital for applications requiring a specific range of motion. Buyers need to consider the stroke length to ensure that the gas spring fits within the design constraints of their equipment or machinery, avoiding operational failures. -

Material Grade

Most gas springs are constructed from steel or stainless steel, influencing their durability and resistance to corrosion. The choice of material grade impacts the lifespan of the gas spring, especially in harsh environments. For B2B buyers, selecting the appropriate material can reduce maintenance costs and enhance the reliability of the application. -

Damping Characteristics

Damping refers to the gas spring’s ability to control the speed of extension and retraction. This characteristic is crucial for applications requiring smooth operation to prevent sudden jolts or impacts. Gas springs can be designed with varying levels of damping, impacting user experience and safety. Buyers should assess the damping requirements based on their specific application needs. -

Operating Temperature Range

Gas springs operate effectively within specific temperature ranges. Understanding this specification is essential for ensuring that the gas spring performs reliably under varying environmental conditions. Buyers must verify that the selected gas spring can withstand the temperatures in their application area to avoid premature failure. -

Pressure Tolerance

The pressure within a gas spring is a critical factor that affects its performance. Manufacturers typically fill gas springs with nitrogen gas at high pressure. Understanding the pressure tolerance helps buyers select the right gas spring for high-stress applications, ensuring safety and functionality.

What Are Common Trade Terms in the Gas Spring Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms used in the gas spring sector:

-

OEM (Original Equipment Manufacturer)

OEMs are companies that produce parts or equipment that may be marketed by another manufacturer. In the gas spring industry, buyers often work with OEMs to ensure compatibility and reliability of parts within their machinery or products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it directly impacts inventory management and cash flow. Understanding MOQ can help buyers negotiate better terms based on their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This process allows B2B buyers to compare offers and make informed decisions. Clear RFQs can lead to better pricing and service terms. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They are crucial for defining the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms helps buyers minimize risk in cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order until delivery. It is a critical factor for B2B buyers in planning their inventory and production schedules. Understanding lead times can help businesses maintain operational efficiency and avoid delays in project timelines. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the gas spring over a specified period. This term is important for B2B buyers as it affects their long-term costs and risk management strategies. A strong warranty can provide peace of mind and protect against unforeseen failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the gass spring Sector

What Are the Current Market Dynamics and Key Trends Influencing the Gass Spring Sector?

The global gass spring market is witnessing significant growth, driven by increasing demand across various industries, including automotive, aerospace, and manufacturing. Key factors influencing this market include the ongoing industrialization in emerging economies, particularly in Africa and South America, where infrastructure development is paramount. Additionally, the adoption of advanced manufacturing technologies is revolutionizing production processes, making them more efficient and cost-effective.

Emerging B2B tech trends are also reshaping sourcing strategies. Digital platforms that facilitate real-time configuration and calculation of gas springs are gaining traction. These tools allow buyers to customize products to their specific needs, enhancing the purchasing experience. Furthermore, the rise of e-commerce in the gass spring sector enables international buyers to access a wider range of products and suppliers, streamlining the sourcing process.

Market dynamics are also influenced by geopolitical factors and trade policies, particularly in regions like the Middle East and Europe. Buyers must remain vigilant regarding tariffs and trade agreements that could impact pricing and availability. Understanding local market regulations and compliance requirements is crucial for international B2B buyers to navigate these complexities effectively.

How Is Sustainability and Ethical Sourcing Reshaping the Gass Spring Market?

Sustainability is becoming a cornerstone of sourcing strategies in the gass spring sector. Buyers are increasingly prioritizing products that are manufactured with minimal environmental impact. The use of eco-friendly materials, such as recycled steel or biodegradable components, is gaining popularity, aligning with global sustainability goals.

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are now expected to ensure that their suppliers adhere to ethical labor practices and environmental regulations. This not only enhances corporate reputation but also mitigates risks associated with supply chain disruptions.

Green certifications are becoming essential in the decision-making process. Certifications such as ISO 14001 or LEED can provide buyers with the assurance that they are sourcing from manufacturers committed to sustainable practices. By prioritizing suppliers with these certifications, businesses can contribute to a circular economy while ensuring product quality and reliability.

What Is the Brief Evolution and History of Gass Springs in the B2B Context?

The evolution of gass springs dates back to the early 20th century, initially designed for automotive applications. Over time, their use expanded into diverse sectors, including aerospace, furniture, and industrial machinery. The introduction of hydraulic damping technology in the 1960s marked a significant advancement, allowing for more controlled movements and enhanced user experience.

As technology progressed, manufacturers began to focus on customization and precision engineering. Today, buyers can configure gas springs to meet specific requirements, thanks to advanced design software and online configurators. This evolution reflects the growing need for tailored solutions in a competitive B2B landscape, making gass springs a vital component in various applications worldwide.

In summary, understanding the current market dynamics, embracing sustainability, and recognizing the historical context of gass springs can empower international B2B buyers to make informed sourcing decisions that align with their strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of gass spring

-

How do I solve issues with gas spring installation?

To address installation challenges with gas springs, ensure you have the correct specifications for your application, including weight, dimensions, and required force. Utilize online configurators or calculators offered by suppliers to determine the appropriate gas spring type and mounting parts. If problems persist, consult the supplier’s customer service for expert guidance. Providing detailed information about your application will help them suggest the best solutions tailored to your needs. -

What is the best gas spring for heavy-duty applications?

For heavy-duty applications, look for gas springs designed with higher extension forces and robust materials, such as stainless steel. Check the supplier’s specifications for maximum load capacities and stroke lengths to ensure they meet your operational requirements. Brands like SUSPA® offer a range of gas springs specifically engineered for demanding environments. Always consult with your supplier to confirm the spring’s compatibility with your application to ensure optimal performance. -

How can I customize gas springs for my specific needs?

Most suppliers offer customization options for gas springs, allowing you to specify dimensions, forces, and materials based on your application. When requesting customization, clearly outline your requirements, including load capacity, stroke length, and environmental conditions. Engage with the supplier’s technical team to discuss the feasibility and any additional costs involved. Customization ensures that the gas springs will function effectively in your specific use case. -

What are the minimum order quantities (MOQs) for gas springs?

Minimum order quantities for gas springs can vary significantly among suppliers. Generally, MOQs may range from a single unit for specialized suppliers to larger batches for bulk buyers. It’s advisable to inquire directly with potential suppliers regarding their MOQs, especially if you’re sourcing for large projects or ongoing needs. Some suppliers may offer flexibility in MOQs for first-time buyers or strategic partnerships. -

What payment terms should I expect when purchasing gas springs internationally?

Payment terms for international purchases of gas springs typically include options such as advance payment, letters of credit, or net payment terms (e.g., net 30 days). Factors influencing payment terms may include your relationship with the supplier, order size, and country of origin. Always clarify payment terms during negotiations to avoid misunderstandings. It’s also prudent to review any additional fees related to currency conversion or international transactions. -

How do I vet suppliers for gas springs?

To effectively vet suppliers, research their reputation by checking reviews and ratings on industry platforms. Evaluate their experience in manufacturing gas springs and request case studies or references from previous clients. Additionally, inquire about their quality assurance processes and certifications (e.g., ISO standards). Establishing clear communication and understanding their lead times and customer service responsiveness can also help gauge their reliability. -

What quality assurance measures should I look for in gas springs?

Quality assurance in gas springs should include rigorous testing for performance, durability, and safety. Look for suppliers that adhere to industry standards and possess certifications such as ISO 9001. Inquire about their testing procedures, including pressure testing, fatigue testing, and environmental resistance evaluations. A supplier that provides detailed documentation on their QA processes can offer greater assurance of product reliability. -

What logistics considerations should I keep in mind when ordering gas springs?

When ordering gas springs, consider factors such as shipping methods, lead times, and customs regulations specific to your country. Ensure that the supplier can provide reliable shipping options that align with your project timelines. Additionally, inquire about packaging to prevent damage during transit. Understanding the import duties and taxes applicable in your region can also help you manage overall costs effectively.

Top 8 Gass Spring Manufacturers & Suppliers List

1. McMaster – Gas Springs Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Gas Springs Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ace Controls – Industrial Gas Springs GS-8 to GS-70

Domain: acecontrols.com

Registered: 1997 (28 years)

Introduction: Product Name: GS-8 to GS-70 – Industrial Gas Springs – Push Type

Extension Force: 2 lbs to 2,923 lbs (10 to 13,000 N)

Stroke Length: 0.79 in to 39.37 in

Piston Rod Diameter: Ø 0.12 in to Ø 1.18 in

Progression: Approx. 13 % to 76 % (depending on size and stroke)

Lifetime: Approx. 32,808 ft

Operating Temperature Range: -4 °F to 176 °F

Material: Outer body – Coated steel; Piston rod – Steel or stainl…

3. Industrial Gas Springs, Inc. – Gas Spring Solutions

Domain: industrialgassprings.com

Registered: 2000 (25 years)

Introduction: Industrial Gas Springs, Inc. manufactures and supplies a variety of gas spring solutions, including Compression Gas Springs, Adjustable Locking Gas Springs, Stainless Steel Gas Springs, Dampers, Tension Gas Springs, and Custom Designed Springs. The company is accredited with AS9100C and ISO 9001, ensuring high-quality standards. Their products are used across multiple industries such as Aerospace,…

4. Guden – Gas Springs

Domain: guden.com

Registered: 1995 (30 years)

Introduction: Guden offers a wide selection of gas springs for industrial equipment, known for their reliability and durability in motion control applications. Key features include:

– Types: Standard, Mini, Friction Stop, Locking, Adjustable, Stainless Steel gas springs.

– Materials: Available in steel with black nitride rods and 316L stainless steel.

– Sizes: Mini (4mm x 12mm), Compact (6mm x 15mm), Standar…

5. Stabilus – LIFT-O-MAT Gas Springs

Domain: stabilus.com

Registered: 1996 (29 years)

Introduction: Stabilus LIFT-O-MAT gas springs provide controlled lifting and lowering of loads, offering force assistance for optimal counterbalancing. Key features include:

– Hydropneumatic adjusting element with a pressure tube, piston rod, and end fitting.

– Customized filling pressure for application-specific force.

– Advantages over mechanical springs: defined speed profile, outstanding damping capacities….

6. Bansbach – Gas Springs

Domain: bansbach.com

Registered: 1997 (28 years)

Introduction: Gas Springs: Over 100 years experience, customized productions, made in Germany. Force range: 7-12,000 N. Stroke length: 10-1,000 mm. Diameter options: 3/8-30/70 mm. Variants include standard gas springs, lockable gas springs (0-2,600 N, 10-800 mm stroke, 8/19-14/40 mm diameter), and gas traction springs (30-4,000 N, 10-600 mm stroke, 6/19-14/40 mm diameter). Applications in medical, furniture, me…

7. Industrial Springs – M-Struts Gas Spring

Domain: industrial-springs.com

Registered: 2005 (20 years)

Introduction: Product Name: M-Struts – Mechanical “Gas Spring”\nMaterial: Black painted steel\nPiston Rod Diameter (Ø1): 6.00 mm or 8.00 mm\nTube Diameter (Ø2): 15.00 mm or 18.00 mm\nStroke (L1): Ranges from 51.00 mm to 305.00 mm (+/- 2 mm)\nUnloaded Length Between Thread (L2): Ranges from 156.00 mm to 918.00 mm (+/- 3 mm)\nMaximum Load (Fn): Ranges from 27.00 N to 120.00 N\nThread (G): 6.00 M\nWorking Temperat…

8. Pascal Engineering – Gas Springs

Domain: pascalenginc.com

Registered: 1999 (26 years)

Introduction: Gas springs are a powerful, durable, and space-saving alternative to coil springs, used to apply force and absorb motion or impact. They are essential components in stamping and molding tools. Key models include: Model DSD, which holds blanks and supports piercing and flanging operations in stamping, and Model DNA, which pushes ejector plates in injection molding. Pascal’s gas springs are availabl…

Strategic Sourcing Conclusion and Outlook for gass spring

How Can Strategic Sourcing Enhance Your Gas Spring Procurement?

In the competitive landscape of gas spring sourcing, strategic procurement is paramount. By leveraging advanced configurators and calculators, buyers can quickly identify the ideal gas spring specifications for their unique applications, ensuring optimal performance and cost-efficiency. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the ability to adapt sourcing strategies to local demands and regulatory standards becomes crucial.

The emphasis on quality and reliability cannot be overstated. Selecting reputable suppliers who offer robust support services, including installation guidance and product customization, not only enhances operational efficiency but also mitigates risks associated with poor product performance. Furthermore, as industries increasingly prioritize sustainability, sourcing gas springs made from eco-friendly materials can align with corporate responsibility goals.

As we look to the future, the demand for gas springs is poised for growth, driven by innovations in manufacturing and design. International B2B buyers are encouraged to engage proactively with suppliers, explore new technologies, and invest in partnerships that will drive mutual success. Embrace strategic sourcing today to secure a competitive edge in your operations tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to gass spring

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.