Hand Labelling Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for hand labelling

In the ever-evolving landscape of global commerce, sourcing effective hand labelling solutions poses a significant challenge for B2B buyers. The need for precision, compliance, and brand consistency has never been more critical, particularly in regions such as Africa, South America, the Middle East, and Europe, including prominent markets like Germany and Nigeria. Hand labelling remains a vital process, offering unique advantages over traditional in-line systems, especially for businesses dealing with small batches, rework scenarios, or products with complex shapes.

This comprehensive guide delves into the multifaceted world of hand labelling, covering various types of labelling systems, their applications across different industries, and essential factors for supplier vetting. Additionally, we will explore cost considerations and the latest innovations that enhance efficiency and accuracy in labelling processes. By equipping international B2B buyers with actionable insights and a clear understanding of the available options, this guide empowers informed purchasing decisions. Whether you are a manufacturer, distributor, or retailer, navigating the global market for hand labelling can lead to improved operational efficiency and ultimately, increased profitability.

Understanding the nuances of hand labelling not only helps mitigate risks associated with mislabelling but also ensures compliance with local regulations—key components for sustaining a competitive edge in today’s market.

Understanding hand labelling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Handheld Labelers | Operated manually, lightweight, and portable. | Retail pricing, inventory management | Pros: Low cost, easy to use. Cons: Slower labeling speed. |

| Electric Handheld Labelers | Battery-operated, faster label application, often with scanning. | Food safety, product compliance | Pros: High-speed labeling, reduces manual effort. Cons: Higher initial investment. |

| Specialized Hand Labelers | Designed for specific industries (e.g., fruit, pharmaceuticals). | Agriculture, pharmaceuticals, logistics | Pros: Tailored for specific products, ensures precision. Cons: Limited versatility for other uses. |

| Multi-line Labeling Systems | Capable of printing multiple lines of text, often programmable. | Retail, manufacturing, warehousing | Pros: Versatile for complex labeling needs. Cons: More complex operation may require training. |

| Labeling Guns | Simple, handheld devices that apply pre-printed labels. | Retail price tagging, warehouse labeling | Pros: Cost-effective and quick for simple tasks. Cons: Limited customization options. |

What Are the Characteristics of Manual Handheld Labelers?

Manual handheld labelers are lightweight and portable, making them ideal for businesses needing a straightforward labeling solution. These devices require human operation, which allows for greater control over the labeling process. They are particularly suitable for small businesses or those dealing with low-volume labeling tasks, such as retail price tagging or inventory management. When considering purchasing, buyers should evaluate the labeling speed and ease of use, as these factors can significantly impact operational efficiency.

How Do Electric Handheld Labelers Enhance Efficiency?

Electric handheld labelers offer battery-powered operation, enabling faster label application compared to manual devices. They are often equipped with features such as label scanning, which streamlines the labeling process and reduces manual effort. These labelers are particularly beneficial in industries like food safety and product compliance, where speed and accuracy are crucial. Buyers should consider the initial investment and battery life when selecting an electric labeler, as these factors can influence the long-term value.

Why Choose Specialized Hand Labelers for Your Industry?

Specialized hand labelers are designed with specific applications in mind, such as labeling fruits or pharmaceuticals. These devices often feature unique mechanisms that accommodate irregular shapes or sensitive products, ensuring accuracy and compliance with industry regulations. Businesses in agriculture or pharmaceuticals should consider these labelers to enhance productivity and maintain quality standards. However, buyers should be aware that while specialized labelers excel in their niche, they may lack versatility for other labeling needs.

What Advantages Do Multi-line Labeling Systems Provide?

Multi-line labeling systems are capable of printing various text formats, making them suitable for complex labeling requirements in retail and manufacturing environments. These systems often come with programmable features, allowing businesses to customize labels for different products quickly. While they offer versatility, buyers should factor in the complexity of operation and potential training needs for staff. Understanding the balance between functionality and user-friendliness is essential when considering these systems.

When Are Labeling Guns the Right Choice?

Labeling guns are straightforward devices that apply pre-printed labels quickly and efficiently. They are particularly useful in retail environments for price tagging and in warehouses for labeling inventory. The simplicity of these devices makes them cost-effective for businesses that do not require extensive customization. However, buyers should note that labeling guns may not be suitable for complex labeling tasks that demand variable information or detailed graphics.

Key Industrial Applications of hand labelling

| Industry/Sector | Specific Application of Hand Labelling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Labeling of packaged goods and fresh produce | Ensures compliance with food safety standards; enhances product traceability | Durability of labels, compliance with local regulations, ease of use in various environments |

| Retail | Price tagging and promotional labeling | Facilitates quick inventory turnover; improves customer experience | Versatility of labeling options, battery life, and ease of integration with existing systems |

| Pharmaceuticals | Lot coding and expiration date marking | Enhances product safety; minimizes liability risks | Compliance with industry regulations, accuracy of printing, and reliability of equipment |

| Manufacturing | Labeling of parts and components in assembly lines | Streamlines production processes; reduces errors in assembly | Compatibility with different surfaces, speed of application, and ease of label changeover |

| Logistics and Shipping | Shipping labels for packages and pallets | Improves tracking and reduces misdelivery; enhances operational efficiency | Label durability for transport conditions, printer compatibility, and ease of use by staff |

How is Hand Labelling Used in the Food and Beverage Industry?

In the food and beverage sector, hand labelling is crucial for ensuring that packaged goods and fresh produce comply with stringent food safety standards. Handheld labelers allow businesses to quickly apply labels that include essential information such as ingredients, nutritional facts, and expiration dates. This flexibility is particularly beneficial for smaller producers or those with seasonal products, as they can easily adapt their labeling to meet varying demands. International buyers should consider the durability of labels and compliance with local regulations when sourcing labelling solutions.

What Role Does Hand Labelling Play in Retail?

In retail, hand labelling is widely used for price tagging and promotional labeling. Handheld labelers enable staff to quickly update pricing and apply promotional labels, enhancing the shopping experience for customers and facilitating faster inventory turnover. This adaptability is particularly valuable during sales events or product launches. For B2B buyers in retail, sourcing options should include versatile labeling configurations and robust battery life to ensure uninterrupted operation during peak hours.

How is Hand Labelling Essential in Pharmaceuticals?

The pharmaceutical industry relies heavily on hand labelling for lot coding and expiration date marking. This practice is vital for maintaining product safety and minimizing liability risks associated with mislabeling. Handheld labelers provide precise and clear labeling, which is essential in ensuring that products are traceable and compliant with health regulations. Buyers in this sector must prioritize equipment that meets stringent industry regulations and offers high accuracy in printing.

How Does Hand Labelling Improve Manufacturing Processes?

In manufacturing, hand labelling is utilized for labeling parts and components on assembly lines. This practice streamlines production processes by ensuring that each part is correctly identified, reducing the likelihood of errors during assembly. Handheld labelers are particularly effective in environments where flexibility is required, such as when dealing with multiple products or part variations. Buyers should focus on sourcing labelers that can handle different surfaces and provide fast application speeds.

Why is Hand Labelling Important in Logistics and Shipping?

In logistics and shipping, hand labelling is critical for applying shipping labels to packages and pallets. This process significantly improves tracking, reduces the risk of misdelivery, and enhances overall operational efficiency. Handheld labelers allow for quick and accurate labeling, which is essential in fast-paced logistics environments. When sourcing labelling solutions for this sector, businesses should consider the durability of labels to withstand various transport conditions and the ease of use for staff handling shipments.

3 Common User Pain Points for ‘hand labelling’ & Their Solutions

Scenario 1: Difficulty with Label Accuracy During High-Volume Production

The Problem: In a bustling production environment, accuracy in labeling is paramount. However, many B2B buyers encounter significant challenges when using handheld labelers in high-volume scenarios. Misalignment of labels can lead to costly errors, such as mislabeling products or providing incorrect information, which can tarnish a brand’s reputation and lead to compliance issues. The potential for human error increases with speed, making it critical to find solutions that enhance accuracy without sacrificing efficiency.

The Solution: To combat this issue, B2B buyers should consider investing in handheld labelers equipped with advanced alignment features and user-friendly designs. Look for models that include guides or templates to help ensure that labels are applied consistently. Additionally, implementing a training program for employees can dramatically improve labeling accuracy. Regular practice with the equipment can help staff become adept at using the tools effectively, reducing the likelihood of misalignment. For high-volume needs, opting for labelers that can print and apply labels at higher speeds—while still maintaining precision—can also mitigate these challenges.

Illustrative image related to hand labelling

Scenario 2: Challenges with Labeling Irregularly Shaped Products

The Problem: Many businesses produce goods with irregular shapes or delicate surfaces, making labeling a cumbersome task. For instance, fruits, artisanal products, or items with unique contours often require special handling to ensure the labels adhere properly without damaging the product. B2B buyers often find that traditional labeling solutions are ill-suited for these types of products, leading to wasted materials and increased labor costs as workers struggle to apply labels effectively.

The Solution: To address this pain point, B2B buyers should consider sourcing handheld labelers specifically designed for irregularly shaped items. These devices typically feature adaptable applicators that can conform to various surfaces and shapes. For instance, labelers with adjustable pressure settings can help apply labels without damaging delicate items. Additionally, investing in labelers with ergonomic designs will improve usability for workers, making the labeling process less labor-intensive. It’s also beneficial to conduct product trials with different label types to identify those that adhere best to unique surfaces, ensuring optimal performance without compromising product integrity.

Scenario 3: Inefficiencies in Label Changeover for Small Batches

The Problem: In industries where products are frequently changed or small batches are produced, the need for quick label changeovers can pose a significant challenge. B2B buyers often face delays due to the time-consuming setup processes associated with traditional labeling systems. This inefficiency can lead to increased operational downtime and reduced productivity, particularly in markets that require agility to meet customer demands.

The Solution: To streamline the labeling process for small batches, B2B buyers should prioritize handheld labelers that offer quick changeover capabilities. Models that allow for easy label roll replacement or those equipped with user-friendly interfaces can significantly reduce setup times. Additionally, choosing labelers that support multiple label formats will enhance versatility, allowing businesses to swiftly switch between products without extensive downtime. Implementing a well-organized labeling station, where all necessary tools and labels are readily accessible, can further expedite the changeover process. Regular maintenance and training sessions will ensure that the team is well-equipped to handle rapid transitions, ultimately boosting overall productivity.

Strategic Material Selection Guide for hand labelling

What Are the Key Materials Used in Hand Labelling?

When selecting materials for hand labelling, it’s crucial to understand the properties, advantages, and limitations of different options. This knowledge helps international B2B buyers make informed decisions that align with their specific operational needs and compliance requirements.

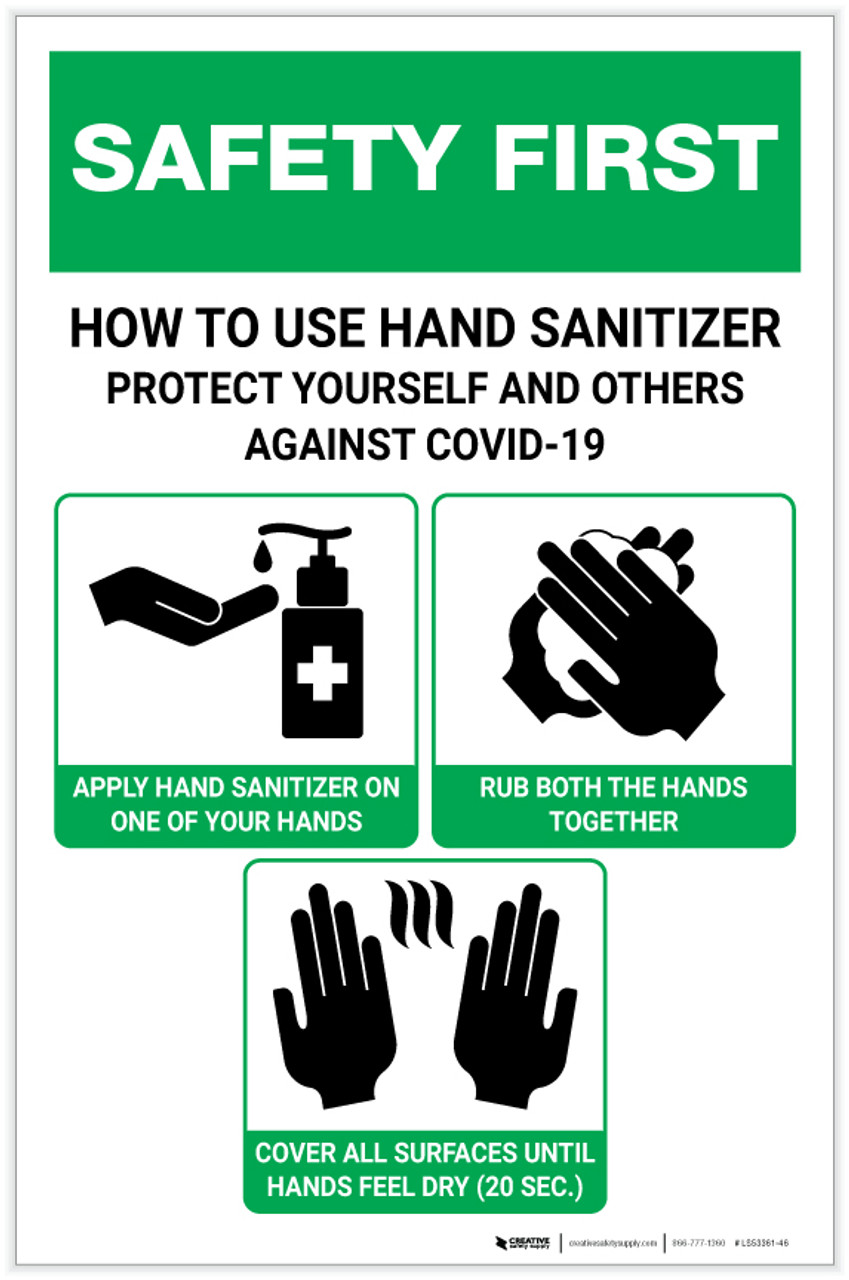

Illustrative image related to hand labelling

How Does Polypropylene Perform in Hand Labelling Applications?

Polypropylene (PP) is a widely used material in the production of labels due to its excellent chemical resistance and durability. It can withstand a temperature range of -20°C to 80°C, making it suitable for various environments. Additionally, PP is resistant to moisture, oils, and many solvents, which is beneficial in industries like food and chemicals.

Pros: Polypropylene labels are lightweight, cost-effective, and offer good print quality. They are also flexible, allowing for easy application on curved surfaces.

Cons: While PP is durable, it may not perform well under extreme temperatures or prolonged exposure to UV light, leading to potential fading.

Impact on Application: PP labels are ideal for products stored in cooler environments or those exposed to moisture, but they may not be suitable for outdoor applications without additional UV protection.

Considerations for International Buyers: Buyers from regions such as Africa and South America should consider local climate conditions, as extreme heat may affect label performance. Compliance with local standards, such as ASTM for material safety, is also essential.

Illustrative image related to hand labelling

What Role Does Vinyl Play in Hand Labelling?

Vinyl is another popular material for labels, especially in applications requiring flexibility and weather resistance. It can endure temperatures from -40°C to 90°C and is inherently resistant to water, making it suitable for outdoor use.

Pros: Vinyl labels are highly durable, resistant to tearing, and maintain their appearance over time, even in harsh conditions. They also offer excellent adhesion properties.

Cons: The production of vinyl can be more expensive than other materials, and its environmental impact is a concern due to its non-biodegradable nature.

Illustrative image related to hand labelling

Impact on Application: Vinyl is perfect for outdoor labelling on products exposed to the elements, such as garden supplies and outdoor equipment.

Considerations for International Buyers: Buyers in Europe may face stricter regulations regarding the environmental impact of materials. Compliance with European Union standards for materials may influence purchasing decisions.

How Does Paper Compare in Hand Labelling?

Paper is a traditional choice for labels, particularly in retail and logistics. It is available in various finishes and weights, making it versatile for different applications.

Pros: Paper labels are cost-effective and easy to print on, making them suitable for short runs or promotional labels.

Cons: Paper is less durable than synthetic materials, particularly in wet or humid environments, where it can easily deteriorate.

Illustrative image related to hand labelling

Impact on Application: Paper labels are ideal for indoor applications, such as product packaging and retail displays, but should be avoided in environments where moisture is prevalent.

Considerations for International Buyers: Buyers should consider local recycling regulations, as paper is often preferred in regions with strong sustainability initiatives, such as Germany.

What About Polyester for Hand Labelling?

Polyester (PET) is a robust material that offers excellent resistance to tearing and moisture. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various applications.

Pros: Polyester labels are highly durable and resistant to chemicals and UV light, ensuring longevity in demanding environments.

Cons: The cost of polyester labels is generally higher than that of paper or polypropylene, which may not be feasible for all businesses.

Impact on Application: Polyester is ideal for industrial applications, such as chemical labeling and outdoor products, where durability and resistance to harsh conditions are critical.

Considerations for International Buyers: Buyers should be aware of compliance with international standards, such as JIS in Japan, which may dictate the use of specific materials in certain industries.

Summary Table of Materials for Hand Labelling

| Material | Typical Use Case for Hand Labelling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Food and chemical labels | Excellent chemical resistance | Limited UV resistance | Low |

| Vinyl | Outdoor labels | Highly durable and weather-resistant | Higher production cost | Medium |

| Paper | Retail and logistics | Cost-effective and easy to print | Not suitable for wet environments | Low |

| Polyester | Industrial and chemical labeling | Excellent durability and UV resistance | Higher cost compared to other materials | High |

Understanding these materials and their properties will help international B2B buyers select the most appropriate options for their hand labelling needs, ensuring compliance and efficiency in their operations.

In-depth Look: Manufacturing Processes and Quality Assurance for hand labelling

What are the Key Stages in the Manufacturing Process of Hand Labelling Devices?

The manufacturing process of hand labelling devices is a critical aspect that ensures the final product meets quality standards and customer expectations. This process typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The first stage involves sourcing high-quality materials, which often includes durable plastics and metals for the device body and components. Manufacturers must carefully select materials that can withstand the rigors of use, especially in varying environmental conditions typical of regions like Africa and South America. Quality control begins at this stage, with incoming quality checks (IQC) to ensure that materials meet specified standards. -

Forming

The forming stage includes techniques such as injection molding for plastic components and stamping for metal parts. Advanced machinery is utilized to create precise components that fit together seamlessly. This stage is crucial for achieving the ergonomic design that enhances usability for operators. Manufacturers often employ Computer Numerical Control (CNC) machines for accuracy in this phase, ensuring that each part adheres to strict dimensional tolerances. -

Assembly

The assembly process combines all the formed parts into a cohesive unit. This stage often employs a mix of automated and manual assembly techniques. For high-volume production, automated assembly lines are common, while low-volume or specialized products may require more manual intervention. Quality checks are integrated throughout the assembly process (In-Process Quality Control, or IPQC) to identify and rectify any issues immediately. -

Finishing

The final stage involves applying finishes, such as painting or coating, to enhance durability and aesthetics. This stage may also include the installation of labels or branding elements, which are essential for marketing and compliance. Post-finishing inspections are vital to ensure that the product meets both functional and visual standards.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of hand labelling devices, especially for international B2B buyers. Understanding the relevant standards and practices can help buyers ensure they are sourcing reliable products.

Illustrative image related to hand labelling

-

International Standards

ISO 9001 is a widely recognized quality management standard that many manufacturers adhere to. Compliance with this standard indicates that a company has a systematic approach to managing its processes and ensuring consistent quality. Buyers should request certifications or audit reports from suppliers to confirm adherence to ISO 9001. -

Industry-Specific Certifications

Depending on the application, additional certifications may be relevant. For instance, CE marking is essential for products sold within the European Economic Area, indicating compliance with safety and environmental requirements. Similarly, the American Petroleum Institute (API) certification may be necessary for products used in oil and gas applications.

What are the Common Quality Control Checkpoints in Hand Labelling Manufacturing?

Quality control checkpoints are integral to ensuring the reliability and performance of hand labelling devices. B2B buyers should be aware of these checkpoints to assess supplier capabilities effectively.

-

Incoming Quality Control (IQC)

This initial checkpoint examines the raw materials before they are used in manufacturing. It involves testing samples for compliance with specifications and ensuring that they are free from defects. -

In-Process Quality Control (IPQC)

During production, IPQC involves monitoring the manufacturing process at various stages. This includes checking the dimensional accuracy of parts, ensuring assembly processes are followed correctly, and identifying any potential issues early. -

Final Quality Control (FQC)

After assembly, FQC checks the completed products against quality standards. This may include functional tests, performance assessments, and visual inspections. Any products that do not meet standards are typically reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that they are partnering with reliable manufacturers, B2B buyers should employ several verification strategies:

-

Supplier Audits

Conducting supplier audits can provide invaluable insights into a manufacturer’s quality control processes. This includes evaluating their facilities, equipment, and practices against industry standards. -

Requesting Quality Reports

Buyers should ask for comprehensive quality reports that outline the supplier’s quality assurance practices, including results from IQC, IPQC, and FQC. These documents can help assess the manufacturer’s commitment to quality. -

Third-Party Inspections

Engaging third-party inspection services can offer an objective assessment of the supplier’s quality control measures. These inspections can occur at various stages, from material sourcing to final product evaluation.

What Quality Control Nuances Should International Buyers Be Aware Of?

International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must navigate several nuances in quality control:

-

Cultural and Regulatory Differences

Different regions may have varying quality expectations and regulatory requirements. Understanding these differences can help buyers communicate effectively with suppliers and ensure compliance with local regulations. -

Language Barriers

Language differences can lead to misunderstandings regarding quality specifications. Buyers should ensure clear communication channels are established and may consider using translators or bilingual staff. -

Logistics and Supply Chain Challenges

International shipping can introduce risks such as damage during transit. Buyers should discuss packaging and handling practices with suppliers to mitigate these risks and ensure that products arrive in optimal condition.

In conclusion, understanding the manufacturing processes and quality assurance practices for hand labelling devices is essential for B2B buyers. By being informed about the stages of production, relevant standards, and quality control checkpoints, buyers can make educated decisions and select suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hand labelling’

The following guide is designed to assist international B2B buyers in effectively sourcing hand labelling solutions. It outlines essential steps to ensure that the products you procure align with your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical requirements for your hand labelling needs. This includes understanding the types of labels you will use, the volume of labels needed, and the specific applications (e.g., pricing, compliance, or promotional purposes). Defining these parameters will help you communicate effectively with suppliers and ensure you select a machine that meets your operational demands.

Step 2: Identify Your Budget Constraints

Establishing a budget is crucial for any procurement process. Determine how much you are willing to invest in hand labelling equipment, considering both initial costs and ongoing maintenance expenses. This step helps narrow down your options and ensures that you are looking at solutions that are financially feasible for your business.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of hand labelling machines. Look for companies with a solid track record in your industry and region. Key considerations include:

– Supplier Certifications: Verify any relevant industry certifications that ensure quality and compliance.

– Customer Reviews: Examine testimonials and case studies from other businesses similar to yours to gauge supplier reliability.

Step 4: Evaluate Product Features and Versatility

When comparing different models, assess their features and versatility. Look for machines that can handle various label sizes, materials, and applications. Consider whether the labeler can adapt to unique product shapes and surfaces, which is particularly important for industries dealing with fragile or irregular items. Features like battery life and speed of application should also be evaluated to match your operational pace.

Step 5: Request Product Demonstrations

Before making a final decision, request demonstrations or trials of the equipment. This hands-on experience will allow you to assess the usability, efficiency, and performance of the labelling machines. It’s an opportunity to ensure that the machine meets your needs and that your team feels comfortable operating it.

Step 6: Inquire About After-Sales Support and Maintenance

After-sales support can significantly affect the longevity and performance of your hand labelling equipment. Inquire about the supplier’s maintenance services, availability of spare parts, and warranty policies. Strong support can reduce downtime and ensure that your labelling process remains efficient.

Illustrative image related to hand labelling

Step 7: Negotiate Terms and Place Your Order

Once you have selected a supplier and product, negotiate the terms of the purchase, including pricing, delivery timelines, and payment conditions. Ensure that all agreements are documented clearly to avoid misunderstandings. Placing your order with a reputable supplier who meets all your criteria will facilitate a smoother procurement process and enhance your operational capabilities.

By following these steps, you can make informed decisions that will enhance your hand labelling operations and ultimately contribute to your business’s success.

Comprehensive Cost and Pricing Analysis for hand labelling Sourcing

What Are the Key Cost Components in Hand Labelling Sourcing?

When evaluating the cost structure of hand labelling sourcing, several key components come into play.

-

Materials: The primary materials include label stock, ink, and the handheld labelling machines themselves. The cost can vary significantly based on the quality and type of materials used. For example, eco-friendly labels or those with special adhesives may come at a premium.

-

Labor: Labor costs encompass both the workforce required to operate the labelling machines and the personnel involved in quality control and maintenance. In regions like Africa and South America, labor costs may be lower, affecting overall pricing. However, skilled labor may be necessary for precise operations, which can increase expenses.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment depreciation. Manufacturing overhead can be a significant factor in the total cost, especially for suppliers operating in high-cost regions.

-

Tooling: Depending on the complexity of the labels and the machines used, tooling costs can vary. Custom tooling for unique label shapes or sizes may be necessary, adding to initial setup costs.

-

Quality Control (QC): Investing in quality control processes ensures that labels meet the required standards. This includes inspections, testing, and compliance with industry regulations, which can add to the cost structure.

-

Logistics: Shipping and handling costs can greatly influence the final price. Factors such as distance, shipping method, and local tariffs or taxes are crucial in determining logistics costs.

-

Margin: Supplier margins can differ based on market positioning, brand reputation, and competitive landscape. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Impact Hand Labelling Costs?

Several factors influence pricing in the hand labelling market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically lead to lower per-unit costs. Understanding the MOQ policies of suppliers can help buyers negotiate better terms.

-

Specifications and Customization: Customized labels or specific machine features can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or eco-labels) often come at a premium. Buyers should assess whether these certifications are essential for their market.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer competitive rates to gain market share.

-

Incoterms: Understanding shipping terms can significantly impact total costs. Incoterms dictate responsibilities and risks in the shipping process, influencing the overall expense.

What Are the Best Buyer Tips for Negotiating Hand Labelling Costs?

To secure the best deals in hand labelling sourcing, buyers can consider the following strategies:

-

Effective Negotiation: Open communication with suppliers can lead to better pricing. Discussing long-term partnerships or bulk orders can incentivize suppliers to offer discounts.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, not just the upfront price. Consider maintenance, operational efficiency, and potential downtime when assessing costs.

-

Understand Pricing Nuances for International Transactions: Different regions may have varying pricing structures. For instance, buyers in Europe may face higher shipping costs compared to local suppliers in Africa or South America. Understanding these nuances can help in making informed purchasing decisions.

-

Research and Benchmark: Conduct market research to compare prices from multiple suppliers. Benchmarking against industry standards can provide insights into fair pricing.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to preferential pricing and terms. Suppliers are often more willing to negotiate with loyal customers.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and other influencing factors. It is advisable for buyers to conduct thorough research and obtain quotes from multiple suppliers to determine the most accurate pricing for their specific needs.

Alternatives Analysis: Comparing hand labelling With Other Solutions

Exploring Viable Alternatives to Hand Labelling Solutions

In the realm of product labelling, businesses often face the challenge of selecting the most effective solution for their specific operational needs. While hand labelling remains a popular choice due to its flexibility and precision, alternative methods have emerged that offer different advantages and disadvantages. This section compares hand labelling with two notable alternatives: automated label applicators and digital printing solutions.

Illustrative image related to hand labelling

| Comparison Aspect | Hand Labelling | Automated Label Applicators | Digital Printing Solutions |

|---|---|---|---|

| Performance | High precision for small batches | High speed for large volumes | Customizable labels in real-time |

| Cost | Low initial investment | Higher upfront costs, but saves in labor | Variable costs based on volume and technology |

| Ease of Implementation | Simple setup and operation | Requires training and installation | Needs software setup and integration |

| Maintenance | Minimal maintenance required | Moderate; requires regular checks | High; ongoing software and printer maintenance |

| Best Use Case | Small to medium runs, rework tasks | High-volume production lines | Custom labels, variable data needs |

What Are the Pros and Cons of Automated Label Applicators?

Automated label applicators are designed for high-volume production environments, making them suitable for businesses that require rapid and consistent labelling. Their primary advantage is speed; they can apply labels to thousands of products per hour, which significantly reduces labor costs in large-scale operations. However, the initial investment and installation costs can be substantial, and they may require specialized training for operators. Additionally, they may not be as flexible as hand labelling for smaller batches or custom applications, making them less ideal for businesses that frequently switch between products.

How Do Digital Printing Solutions Compare?

Digital printing solutions offer a different approach, allowing companies to print labels on demand with variable data, such as barcodes or batch numbers. This technology is particularly beneficial for businesses that require customization and quick turnaround times. While digital printing enables high levels of personalization, the cost can vary greatly depending on the volume produced, and ongoing maintenance of both the software and printer can be high. Furthermore, the setup may be more complex than hand labelling, requiring integration with inventory management systems.

Conclusion: Choosing the Right Labelling Solution for Your Business

When selecting a labelling solution, B2B buyers must carefully evaluate their specific operational needs, including production volume, budget constraints, and the types of products being labelled. Hand labelling remains an excellent option for smaller batches or situations where precision is paramount. In contrast, automated label applicators excel in high-volume environments, while digital printing solutions shine in scenarios requiring customization and flexibility. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their business objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for hand labelling

What Are the Essential Technical Properties of Hand Labelling Machines?

When evaluating hand labelling machines, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties that B2B buyers should consider:

1. Material Grade

The material grade of a hand labelling machine impacts its durability and performance. Common materials include high-grade plastics and metals like stainless steel. A robust construction not only extends the lifespan of the machine but also ensures consistent performance in various environments, from retail to manufacturing. This is particularly important for businesses in regions with diverse climatic conditions, such as Africa and the Middle East, where equipment may face harsher operational demands.

2. Labeling Speed

Labeling speed is typically measured in labels per minute (LPM) or labels per second (LPS). A faster labeller can significantly enhance productivity, especially for businesses dealing with high volumes of products. For instance, some handheld devices can apply up to 18,000 labels per hour. This capability allows companies to meet tight deadlines and adapt to fluctuating demand without compromising quality.

3. Battery Life

For cordless hand labellers, battery life is a critical specification. Machines that can operate for extended periods—often up to two days on a single charge—are particularly advantageous for businesses that require mobility and flexibility in their labeling processes. A dependable battery ensures that labeling tasks can be completed efficiently, reducing downtime and increasing operational efficiency.

4. Label Width Compatibility

Hand labellers vary in the width of labels they can accommodate, typically ranging from 25 mm to 45 mm. Understanding the width compatibility is essential for businesses to ensure that the labels they intend to use are suitable for the machine. This specification directly affects the versatility of the labeller in different applications, from retail pricing to industrial batch coding.

5. Error Detection Mechanisms

Many modern hand labellers incorporate advanced error detection systems that allow for immediate corrections during the labeling process. This feature is vital for maintaining product integrity, especially in sectors where compliance with labeling regulations is mandatory. Immediate error detection minimizes wastage and improves overall efficiency, making it a critical aspect for businesses focusing on quality control.

What Are Common Trade Terminology and Concepts in Hand Labelling?

Understanding industry-specific terminology is essential for effective communication and negotiation in the hand labelling market. Here are several key terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hand labelling, buyers may deal with OEMs for customized machines or specific components that fit their unique operational needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, as it can affect overall procurement strategies. Suppliers often set MOQs based on production costs, and understanding this can help buyers negotiate better terms.

Illustrative image related to hand labelling

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products or services. Crafting a comprehensive RFQ can lead to competitive pricing and better understanding of supplier capabilities, making it an essential step in the purchasing process for hand labelling equipment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border purchases, as they clarify who is responsible for shipping, insurance, and tariffs, thereby minimizing potential disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the hand labelling sector, understanding lead times is essential for effective project planning and inventory management. Longer lead times can affect production schedules, making it important for buyers to factor this into their procurement strategies.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their operational efficiency and product compliance in the hand labelling domain.

Illustrative image related to hand labelling

Navigating Market Dynamics and Sourcing Trends in the hand labelling Sector

What are the Current Market Dynamics and Key Trends in the Hand Labelling Sector?

The hand labelling sector is experiencing significant transformation driven by global market dynamics and emerging technologies. As businesses increasingly prioritize flexibility and adaptability, the demand for hand labellers is surging, particularly in regions like Africa, South America, the Middle East, and Europe. This shift is partly due to the growing need for cost-effective solutions that cater to small batch production and re-work tasks. Hand labelling machines allow for quick label changes without the lengthy setup associated with larger in-line systems, making them ideal for companies that frequently alter their product lines or engage in trial runs.

Moreover, advancements in handheld technology are enhancing productivity and precision. Modern hand labellers can process thousands of labels per hour, thereby increasing operational efficiency. The integration of smart features, such as label size scanning and error detection, further positions hand labellers as essential tools for ensuring compliance and brand integrity. International B2B buyers are also seeking equipment that can accommodate a diverse range of products, from irregularly shaped items to delicate goods, underscoring the importance of versatility in sourcing decisions.

In addition, the rise of e-commerce and the corresponding demand for efficient packaging solutions are influencing sourcing trends. Businesses are looking for suppliers who can provide reliable and quick turnaround times, which is critical for maintaining competitive advantage in fast-paced markets. As companies continue to navigate these dynamics, understanding the unique challenges and opportunities presented by the hand labelling sector will be crucial for making informed procurement decisions.

How Does Sustainability and Ethical Sourcing Impact the Hand Labelling Sector?

Sustainability and ethical sourcing are increasingly pivotal in the hand labelling sector, reflecting broader environmental concerns and consumer preferences. The production and disposal of labelling materials can have significant environmental impacts, prompting buyers to seek solutions that minimize waste and promote sustainability. For instance, opting for biodegradable or recyclable label materials not only aligns with eco-friendly practices but also enhances brand reputation among environmentally conscious consumers.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are now more inclined to partner with manufacturers that demonstrate a commitment to fair labor practices and responsible sourcing. This trend is particularly relevant in regions like Africa and South America, where ethical sourcing can significantly influence buyer decisions. Certifications such as Fair Trade and ISO standards for environmental management can serve as indicators of a supplier’s commitment to sustainability, making them vital considerations for international buyers.

As the demand for green products continues to rise, suppliers in the hand labelling sector are responding by innovating and diversifying their offerings. This includes developing eco-friendly inks and materials that reduce environmental footprints. By prioritizing sustainability and ethical sourcing, businesses can not only comply with regulatory requirements but also tap into new market segments and foster consumer loyalty.

What is the Brief Evolution and History of Hand Labelling?

The evolution of hand labelling dates back to the early 20th century when manual processes dominated the packaging industry. Initially, hand labelling was a labor-intensive task, often requiring significant time and effort to ensure accuracy and compliance. However, as industries grew and product lines expanded, the need for more efficient labelling solutions became evident.

In the late 20th century, technological advancements led to the development of handheld label printers and applicators, transforming the landscape of hand labelling. These innovations allowed for faster and more accurate label application, catering to both low and high-volume production needs. Today, the hand labelling sector continues to evolve with the integration of smart technology and automated features, further enhancing efficiency and precision. As businesses adapt to changing market dynamics, the hand labelling sector remains a critical component of the global supply chain, providing versatile and responsive solutions for a diverse range of applications.

Frequently Asked Questions (FAQs) for B2B Buyers of hand labelling

-

How do I solve label misalignment issues with my handheld labeler?

Label misalignment can occur due to improper setup or mechanical issues. To resolve this, first ensure that the label roll is correctly aligned in the machine. Check the applicator’s settings for any adjustments needed for label size. Regularly clean the rollers to prevent buildup that can affect alignment. If problems persist, refer to the manufacturer’s manual for troubleshooting steps or consider contacting customer support for technical assistance. -

What is the best handheld labeling solution for small batch production?

For small batch production, a high-speed handheld labeler is often the best choice. These machines are designed for flexibility and can easily handle varying label sizes without extensive setup. Look for models with features like quick label changes and battery operation to enhance mobility. Brands known for durability and ease of use, such as SATO or Berstron, offer reliable options that cater to low-volume applications. -

How can I vet suppliers for handheld labeling equipment?

Vetting suppliers is crucial for ensuring product quality and reliability. Start by checking their reputation through online reviews and industry references. Request product samples to assess quality firsthand. Verify their certifications and compliance with international standards, especially for safety and performance. Engage in direct communication to gauge their responsiveness and willingness to address your concerns, which can indicate their commitment to customer service. -

What customization options are available for handheld labelers?

Many manufacturers offer customization options for handheld labelers to meet specific business needs. Customizations can include label size, printing options (like barcodes or QR codes), and even branding on the label itself. Discuss your requirements with potential suppliers to explore available configurations. Ensure that the customization aligns with your production processes and regulatory compliance for your industry. -

What are the typical minimum order quantities (MOQs) for handheld labeling devices?

MOQs for handheld labeling devices can vary widely depending on the supplier and the specific product. Generally, for bulk purchases, MOQs may range from 10 to 50 units. Some manufacturers might offer lower MOQs for trial orders or smaller businesses. Always clarify MOQs before placing an order, and consider negotiating if you require a smaller quantity to test the product in your operations. -

What payment terms should I expect when purchasing from international suppliers?

Payment terms can differ significantly across suppliers and regions. Common practices include upfront payment, partial payments, or payment upon delivery. Many international suppliers accept various payment methods, including bank transfers, letters of credit, or online payment platforms. It’s crucial to discuss and agree on payment terms before finalizing the purchase to ensure a smooth transaction and avoid potential issues. -

How do I ensure quality assurance (QA) for handheld labeling products?

To ensure quality assurance for handheld labeling products, work with suppliers that have established QA processes. Request documentation of their quality control measures, including testing standards and inspection protocols. It’s also beneficial to conduct periodic audits or reviews of their manufacturing processes. If possible, consider sourcing samples for testing before committing to a larger order to evaluate product performance firsthand. -

What logistics considerations should I keep in mind for importing labeling equipment?

When importing labeling equipment, consider factors such as shipping methods, customs regulations, and delivery timelines. Ensure that your supplier provides accurate documentation for customs clearance to avoid delays. Evaluate shipping costs and choose a logistics provider experienced in handling international shipments. Additionally, factor in potential tariffs or duties applicable to your region, as these can affect overall costs.

Top 8 Hand Labelling Manufacturers & Suppliers List

1. Berstron – Hand Labeler

Domain: berstron.com

Registered: 2003 (22 years)

Introduction: Hand Labeler

– Designed for labeling small batches, re-work batches, and delicate products.

– High-speed labeling capability: applies 5 labels per second, totaling 18,000 labels per hour.

– Features a 7.4V Lithium battery that lasts for two days on a two-hour charge.

– Intelligent label dispensing system that scans label size and feeds the appropriate amount.

– Ideal for products with irregular sh…

2. Brother – PTH110 Label Maker

Domain: brother-usa.com

Registered: 2000 (25 years)

Introduction: Product Name: Brother PTH110; Type: Label Maker; Features: Compact design, easy-to-use, 14 fonts, 97 symbols, 10 frame options, 2-line printing, 1″ printing width; Connectivity: None; Power: 6 AAA batteries; Dimensions: 4.1″ x 6.0″ x 1.7″; Weight: 0.8 lbs; Ideal for: Home, office, and school use.

3. Sneed Coding Solutions – SNEED-PACK Label Applicators

Domain: sneedcoding.com

Registered: 2017 (8 years)

Introduction: SNEED-PACK Label Applicators are designed to simplify the labeling process. They are part of Sneed Coding Solutions’ range of products, which includes various labeling machines and equipment tailored for industries such as beverage, cannabis, craft beers, food packaging, and plastics & metals. The company offers a performance guarantee and emphasizes customer satisfaction.

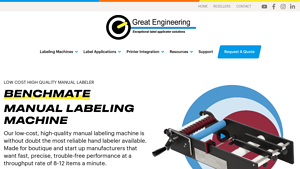

4. Great Engineering – BenchMATE Manual Label Applicator

Domain: greatengineering.com

Registered: 1998 (27 years)

Introduction: BenchMATE Manual Label Applicator

– Type: Manual Labeling Machine

– Throughput Rate: 8-12 items per minute

– Weight: 6kg (13.23lbs)

– Dimensions: Length: 52cm (20.47″), Width: 34cm (13.39″), Height: 12cm (4.72″)

– Material: Anodized 6061 Aluminum, Food grade Stainless steel shafts and bolts

– Compatible Container Shapes: Round (bottles, jars, vials, tubes)

– Compatible Container Size: Minimum diam…

5. Dix Engineering – Hand Labellers

Domain: dixengineering.com

Registered: 2017 (8 years)

Introduction: Hand labellers from Dix Engineering are designed for efficient labeling in various applications. They offer features such as ease of use, durability, and versatility, making them suitable for different environments. The labellers can handle various label sizes and types, ensuring that users can find the right solution for their labeling needs. Additionally, they are built to withstand rigorous use…

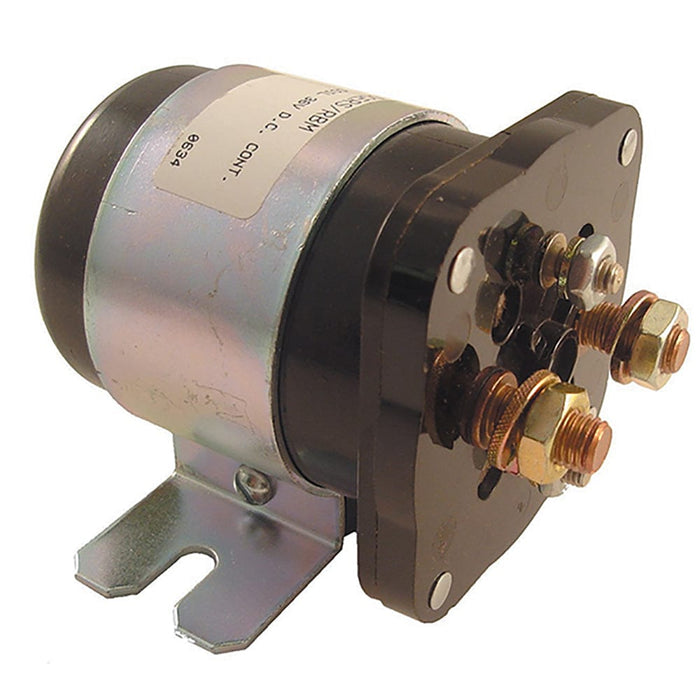

6. PDC Healthcare – Handheld Labeling Devices

Domain: pdchealthcare.com

Registered: 2013 (12 years)

Introduction: Handheld Labeling Devices: Available in single, 2-line, or 3-line options. Key products include: 1. Labeling Gun Two-Line Hand-Held Device, compatible with 15/16″ X 5/8″ labels, priced at $410.96. 2. Meto® Label Gun Model 2026, a two-line device with 10/10 plastic, priced at $411.94. Both products are categorized as hand-held labeling devices made of plastic.

7. TubeWriter – TubeWriter 400

Domain: tubewriter.com

Registered: 2005 (20 years)

Introduction: Product Name: TubeWriter 400

Key Features:

– Direct printing on labware (tubes, vials, etc.)

– Enhanced readability for accurate information

– Increased speed with high-speed automated printing

– Improved efficiency by simplifying the labeling process

– Improved quality with industrial Inkjet technology, resistant to alcohol, formalin, temperature/solvent, and waterproof

– Cost reduction by elimin…

8. Dasco – Hand-held Dispensers

Domain: dasco.com

Registered: 1994 (31 years)

Introduction: Hand-held dispensers for various applications, designed for ease of use and efficiency. Suitable for dispensing labels, tags, and other materials. Features include ergonomic design, adjustable settings for different materials, and compatibility with various label sizes. Ideal for retail, warehouse, and manufacturing environments.

Strategic Sourcing Conclusion and Outlook for hand labelling

In navigating the complexities of hand labelling, strategic sourcing emerges as a pivotal element for international B2B buyers. The versatility of handheld labelling solutions offers significant advantages, particularly for businesses dealing with small batches, rework scenarios, or products with unique shapes. By investing in these adaptable tools, companies can enhance operational efficiency, reduce errors, and ensure compliance with labelling standards.

Moreover, the cost-effectiveness of handheld labellers cannot be overstated. They eliminate the extensive setup times associated with larger machines, allowing businesses to pivot quickly based on demand. This agility is crucial in dynamic markets across Africa, South America, the Middle East, and Europe, where consumer preferences can shift rapidly.

As the market continues to evolve, embracing innovative labelling technologies will be essential for maintaining competitiveness. International buyers should prioritize sourcing solutions that align with their specific operational needs and compliance requirements. By doing so, they can not only streamline their labelling processes but also position themselves for future growth.

Take the next step in optimizing your labelling operations by exploring the latest handheld labelling solutions. Invest in flexibility, precision, and efficiency to elevate your brand and meet your customers’ expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.