Everything You Need to Know About Vibratory Feeder Sourcing in 2025

Introduction: Navigating the Global Market for vibratory feeder

In the dynamic landscape of global manufacturing, sourcing effective vibratory feeders can be a significant challenge for B2B buyers. These essential components play a critical role in automating processes across various industries, from automotive to food processing. However, navigating the myriad options available—each with unique specifications and applications—can be daunting. This guide aims to demystify the complexities associated with selecting vibratory feeders, providing insights into different types, their applications, and key considerations for supplier vetting.

Our comprehensive guide offers an in-depth exploration of vibratory feeders, including their operational principles, customization options, and cost factors. We delve into the specific needs of international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Vietnam. By equipping you with actionable insights and strategic recommendations, this guide empowers you to make informed purchasing decisions that align with your operational goals.

Whether you are looking to enhance efficiency in your production line or seeking reliable automation solutions, understanding the intricacies of vibratory feeders is crucial. With this resource, you will gain the knowledge necessary to select the right equipment that meets your unique requirements, ensuring a smooth and successful procurement process.

Understanding vibratory feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bowl Feeders | Circular design for consistent orientation | Automotive, electronics, food processing | Pros: Efficient, customizable; Cons: Limited to smaller parts. |

| Linear Feeders | Straight-line design for continuous feeding | Packaging, assembly lines | Pros: High-speed operation; Cons: Requires more space. |

| Wok Feeders | Shallow bowl design with a wide opening | Food processing, pharmaceutical | Pros: Ideal for bulk feeding; Cons: May not suit small parts. |

| Centrifugal Feeders | Uses centrifugal force to move parts | High-speed applications, packaging | Pros: Fast and efficient; Cons: Higher initial cost. |

| Custom Feeders | Tailored designs for specific applications | Various industries (automotive, medical) | Pros: Optimized for unique needs; Cons: Longer lead times. |

What Are the Characteristics of Bowl Feeders and Their Applications?

Bowl feeders are one of the most common types of vibratory feeders, characterized by their circular design that promotes consistent orientation of parts. They are particularly effective in applications where parts need to be fed in a specific direction, such as in automotive or electronics assembly lines. Buyers should consider the size and shape of the parts being handled, as bowl feeders are typically suited for smaller components. Customization options are available, allowing for tailored solutions that enhance operational efficiency.

How Do Linear Feeders Differ in Functionality and Use?

Linear feeders feature a straight-line design, making them ideal for continuous feeding applications. They are well-suited for industries such as packaging and assembly, where speed and efficiency are paramount. Buyers must evaluate the space available for installation, as linear feeders generally require more room compared to bowl feeders. Additionally, the linear feed mechanism allows for high-speed operations, which can significantly enhance throughput in production lines.

Why Choose Wok Feeders for Bulk Feeding Needs?

Wok feeders are designed with a shallow bowl and a wide opening, making them perfect for bulk feeding applications, particularly in the food processing and pharmaceutical industries. Their design allows for easy handling of larger quantities of materials. However, they may not be suitable for smaller parts due to the risk of misalignment. B2B buyers should assess the nature of the materials being handled and ensure that the feeder’s design aligns with their production requirements.

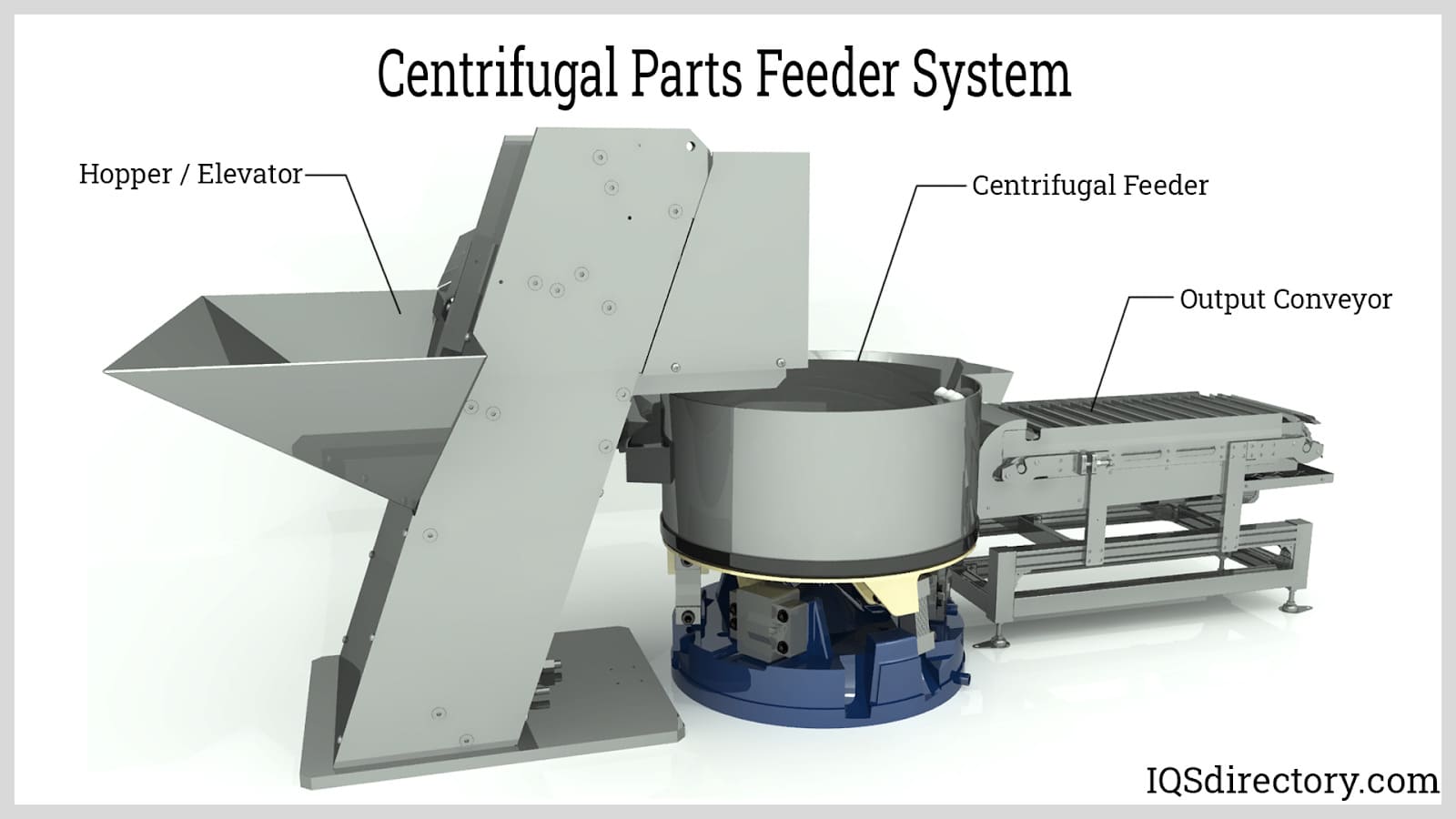

What Are the Benefits of Using Centrifugal Feeders?

Centrifugal feeders utilize centrifugal force to propel parts along a circular track, making them highly efficient for high-speed applications such as packaging and sorting. These feeders are capable of handling a wide range of part sizes and shapes. However, they typically come with a higher initial investment, which may be a consideration for budget-conscious buyers. Evaluating the long-term efficiency and speed benefits against upfront costs is crucial for making an informed purchasing decision.

When Should Custom Feeders Be Considered for Specific Applications?

Custom feeders are designed to meet the unique needs of specific applications across various industries, including automotive and medical. These tailored solutions can optimize part handling and feeding processes, enhancing overall productivity. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom designs. Understanding the specific requirements of the application will help businesses determine if a custom feeder is the right investment for their operations.

Key Industrial Applications of vibratory feeder

| Industry/Sector | Specific Application of vibratory feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Parts feeding for assembly lines | Increases efficiency and reduces labor costs | Customization for part size and orientation, reliability |

| Food Processing | Handling and sorting of packaged food products | Ensures sanitary conditions and maintains product integrity | Compliance with food safety standards, ease of cleaning |

| Pharmaceutical & Medical | Accurate feeding of pills and medical devices | Enhances precision in production and minimizes waste | Pharmaceutical-grade materials, ease of integration with automation |

| Electronics | Feeding components for assembly of electronic devices | Improves speed of production and reduces manual handling | Compatibility with various component sizes, reliability |

| Packaging | Automated feeding for packaging lines | Boosts throughput and optimizes labor resources | Flexibility in feeder design, adaptability to different products |

How Are Vibratory Feeders Used in the Automotive Industry?

In the automotive sector, vibratory feeders are integral to assembly lines where they efficiently supply parts such as nuts, bolts, and clips. These feeders enhance productivity by ensuring a steady flow of components, minimizing downtime associated with manual feeding. For international buyers, sourcing considerations include the ability to customize feeders for specific part sizes and orientations, ensuring compatibility with existing assembly systems.

What Role Do Vibratory Feeders Play in Food Processing?

Vibratory feeders are crucial in food processing for handling and sorting packaged products. They maintain sanitary conditions while ensuring that products are fed at the right speed and orientation for further processing or packaging. Buyers from regions like Africa and South America should prioritize suppliers who comply with stringent food safety standards and provide equipment that is easy to clean, thus minimizing contamination risks.

Illustrative image related to vibratory feeder

How Do Vibratory Feeders Benefit the Pharmaceutical Industry?

In the pharmaceutical and medical industries, vibratory feeders are used for the precise feeding of pills and medical devices during production. This application is vital for enhancing production accuracy and reducing waste, which is crucial for maintaining compliance with regulatory standards. Buyers in this sector need to consider suppliers that offer pharmaceutical-grade materials and equipment that can easily integrate into existing automated systems.

Why Are Vibratory Feeders Important for Electronics Assembly?

For the electronics industry, vibratory feeders facilitate the assembly of components like resistors, capacitors, and connectors. By automating the feeding process, these feeders significantly speed up production and reduce the risk of errors associated with manual handling. Buyers should focus on sourcing feeders that can accommodate various component sizes and ensure high reliability, particularly in high-volume production environments.

How Do Vibratory Feeders Enhance Packaging Processes?

In packaging, vibratory feeders automate the feeding of products into packaging lines, which boosts throughput and optimizes labor resources. This efficiency is particularly beneficial for businesses looking to scale operations. When sourcing, companies should seek flexible feeder designs that can adapt to different product types and sizes, ensuring seamless integration into existing packaging systems.

3 Common User Pain Points for ‘vibratory feeder’ & Their Solutions

Scenario 1: Inefficient Part Orientation Leading to Production Delays

The Problem: In a high-volume manufacturing environment, a B2B buyer faces the challenge of parts not being properly oriented by the vibratory feeder. This misalignment can lead to significant delays in the assembly line, as operators spend valuable time manually correcting the orientation of parts before they can proceed with production. Such inefficiencies not only slow down the manufacturing process but also increase labor costs and reduce overall productivity.

The Solution: To address this issue, buyers should consider investing in custom vibratory feeder bowls that are specifically designed for the type of parts being processed. By engaging with manufacturers who offer tailored solutions, buyers can ensure that the feeder bowl is optimized for the part’s shape and size, enhancing its ability to orient the components correctly. Additionally, implementing a feedback mechanism that monitors the feeder’s performance can help identify and rectify orientation issues in real-time. This proactive approach ensures smoother operations, minimizes downtime, and ultimately enhances the efficiency of the production line.

Illustrative image related to vibratory feeder

Scenario 2: Increased Maintenance Costs Due to Wear and Tear

The Problem: Vibratory feeders are subject to wear and tear over time, especially in environments where they handle abrasive or heavy materials. A B2B buyer may find themselves facing escalating maintenance costs and frequent breakdowns, leading to unexpected downtime. This not only disrupts the production schedule but also affects the bottom line, as repairs and replacements can be costly and time-consuming.

The Solution: To mitigate maintenance issues, buyers should prioritize selecting vibratory feeders made from high-quality, durable materials that can withstand the rigors of their specific application. Conducting thorough research on suppliers and opting for feeders that come with warranties or guarantees can also provide peace of mind. Moreover, establishing a regular maintenance schedule that includes inspections and timely servicing can prolong the lifespan of the equipment. Engaging with suppliers who offer comprehensive service packages can further ensure that any issues are promptly addressed, minimizing the risk of costly downtimes.

Scenario 3: Difficulty in Integrating Vibratory Feeders with Existing Systems

The Problem: Many B2B buyers encounter challenges when trying to integrate new vibratory feeders into their existing manufacturing systems. Incompatibilities can arise due to differences in operational specifications, leading to inefficiencies and potential disruptions. This scenario is especially common in industries where automation plays a significant role, and seamless integration is crucial for maintaining workflow continuity.

The Solution: To facilitate smooth integration, buyers should conduct a thorough assessment of their current systems before selecting a vibratory feeder. Engaging with suppliers who offer comprehensive consultation services can help ensure that the new feeder is compatible with existing machinery. Buyers should also inquire about modular designs and flexible configurations that can easily adapt to their production line. Utilizing advanced technologies, such as smart sensors that provide real-time data on performance, can further enhance integration efforts. By taking a strategic approach to integration, buyers can optimize their workflow and minimize disruptions, ensuring a more efficient manufacturing process.

Strategic Material Selection Guide for vibratory feeder

What are the Key Materials Used in Vibratory Feeders?

Vibratory feeders are essential components in various industrial applications, requiring careful consideration of the materials used in their construction. The choice of material can significantly influence performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in vibratory feeders, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

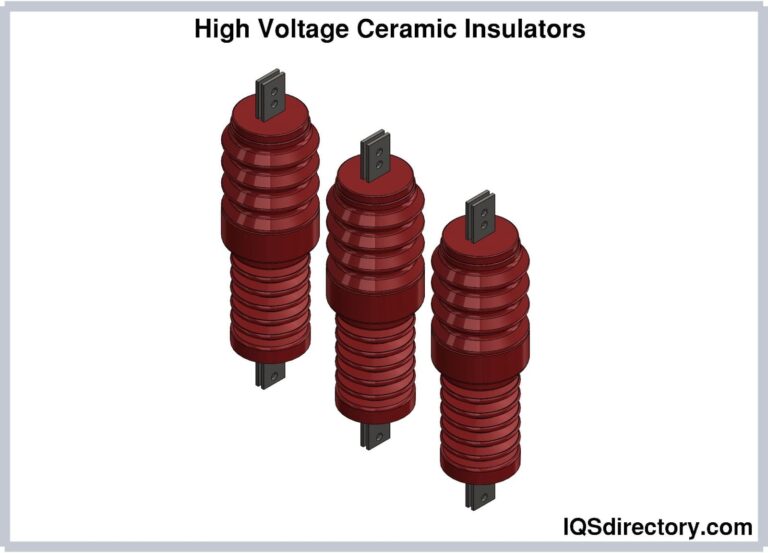

Illustrative image related to vibratory feeder

How Does Stainless Steel Perform in Vibratory Feeders?

Stainless steel is a popular choice for vibratory feeders due to its excellent corrosion resistance and durability. Key properties include a high-temperature rating (up to 1,500°F or 815°C) and the ability to withstand various chemicals, making it suitable for food processing and pharmaceutical applications.

Pros: Stainless steel is highly durable, easy to clean, and complies with sanitary standards, which is crucial for food and medical industries.

Cons: The primary drawback is its cost, as stainless steel is more expensive than other materials. Additionally, manufacturing complexity can increase due to the need for specialized tools.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances. This makes it ideal for applications in regions with stringent health and safety regulations, such as Europe and North America.

Considerations for International Buyers: Buyers must ensure compliance with standards like ASTM A240 for stainless steel in food applications. In regions like Africa and South America, verifying local regulations regarding material safety is essential.

Why Choose Plastic for Vibratory Feeders?

Plastic is another common material, especially in applications where weight and cost are critical factors. Key properties of plastic include a lower temperature rating (typically up to 200°F or 93°C) and good chemical resistance.

Pros: Plastic feeders are lightweight, cost-effective, and can be manufactured in various colors and designs. They are particularly suited for non-corrosive environments.

Cons: The main limitation is reduced durability compared to metals, which may lead to wear and tear over time. Additionally, plastics may not be suitable for high-temperature applications.

Impact on Application: Plastic is ideal for handling lightweight parts and is often used in the packaging and assembly industries.

Illustrative image related to vibratory feeder

Considerations for International Buyers: Buyers should be aware of compliance with standards like FDA regulations for food-grade plastics, particularly in the food processing sector.

What Role Does Aluminum Play in Vibratory Feeders?

Aluminum is valued for its lightweight nature and strength, making it a viable option for vibratory feeders. Key properties include a moderate temperature rating (up to 1,000°F or 538°C) and good corrosion resistance.

Pros: Aluminum is relatively inexpensive and easy to machine, allowing for customized designs. It also offers a good strength-to-weight ratio.

Cons: While corrosion-resistant, aluminum is not as robust as stainless steel and may require protective coatings for certain applications.

Illustrative image related to vibratory feeder

Impact on Application: Aluminum is suitable for a variety of applications, including automotive and electronics, where weight savings are crucial.

Considerations for International Buyers: Buyers should check for compliance with relevant standards, such as ASTM B221 for aluminum alloys, especially in industries with strict material specifications.

How Does Carbon Steel Compare in Vibratory Feeders?

Carbon steel is often used in vibratory feeders due to its strength and cost-effectiveness. Key properties include a high tensile strength and a lower corrosion resistance compared to stainless steel.

Pros: Carbon steel is durable and offers a lower initial cost, making it attractive for budget-conscious projects.

Cons: The primary disadvantage is its susceptibility to rust and corrosion, which can limit its application in wet or corrosive environments.

Impact on Application: Carbon steel is best suited for applications where exposure to harsh environments is minimal, such as in manufacturing settings.

Considerations for International Buyers: Buyers must consider protective coatings or treatments to enhance corrosion resistance, particularly in humid regions like parts of Africa and South America.

Summary Table of Material Selection for Vibratory Feeders

| Material | Typical Use Case for vibratory feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Plastic | Packaging, assembly | Lightweight, cost-effective | Reduced durability, lower temperature rating | Low |

| Aluminum | Automotive, electronics | Good strength-to-weight ratio | Requires protective coatings | Medium |

| Carbon Steel | General manufacturing | Cost-effective, durable | Susceptible to rust and corrosion | Low |

This guide provides a detailed overview of the materials used in vibratory feeders, helping international B2B buyers make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vibratory feeder

What Are the Key Stages in the Manufacturing Process of Vibratory Feeders?

The manufacturing process of vibratory feeders is essential for ensuring high performance and reliability in various applications across industries such as automotive, food processing, and pharmaceuticals. Understanding the main stages of manufacturing provides B2B buyers with insights into the quality and efficiency of the products they are considering.

Illustrative image related to vibratory feeder

Material Preparation

The first stage in manufacturing vibratory feeders involves selecting and preparing the appropriate materials. Common materials used include stainless steel, aluminum, and specialized plastics, chosen for their durability and resistance to corrosion. The material is then cut to size using precision cutting techniques, which may include laser cutting or CNC machining, ensuring accuracy that is critical for subsequent processes.

Forming Techniques

Once the materials are prepared, they undergo forming processes. This stage may involve bending, stamping, or molding, depending on the design requirements of the vibratory feeder. For instance, bowl feeders often require intricate shapes that are achieved through specialized tooling. The forming techniques must adhere to precise specifications to maintain the feeder’s functionality, such as the angle and depth of the bowl, which directly influence the feeder’s performance.

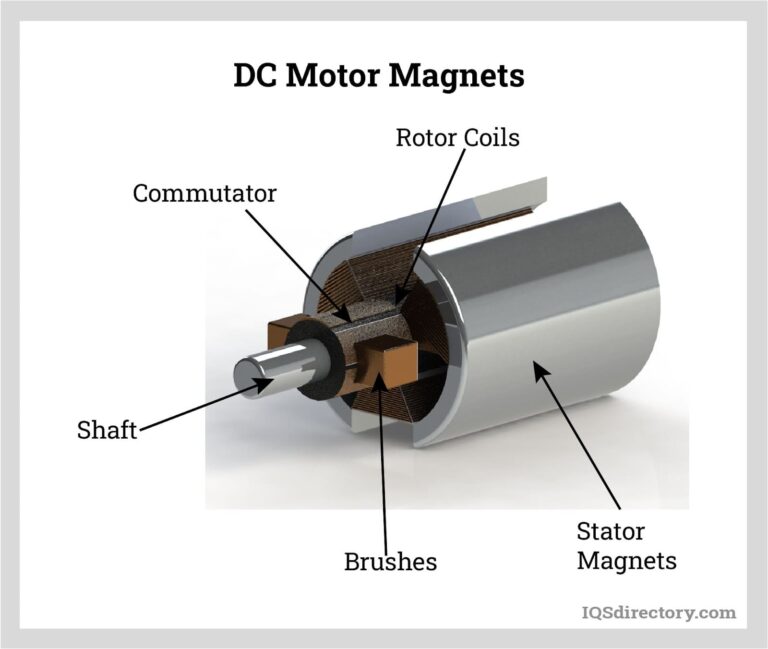

Assembly of Components

After forming, the assembly stage brings together various components, including the bowl, drive unit, and control systems. Each component is meticulously fitted to ensure that the vibratory feeder operates smoothly. This stage often incorporates automated assembly systems, which enhance efficiency and reduce the risk of human error. During assembly, careful attention is paid to alignment and torque specifications, ensuring that all parts function harmoniously.

Illustrative image related to vibratory feeder

Finishing Touches

The final manufacturing stage involves finishing processes that enhance the feeder’s durability and aesthetic appeal. This may include surface treatments such as anodizing or powder coating, which provide additional protection against wear and corrosion. Quality checks are performed at this stage to verify that the finishing meets both aesthetic and functional standards.

How is Quality Assurance Implemented in Vibratory Feeder Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for vibratory feeders, ensuring that the final product meets international standards and customer expectations. A robust QA process not only guarantees product quality but also builds trust with B2B buyers.

What International Standards Guide Quality Assurance?

Vibratory feeder manufacturers often adhere to internationally recognized quality management standards such as ISO 9001. This standard emphasizes a systematic approach to managing quality, focusing on process improvements and customer satisfaction. Additionally, for specific industries, compliance with standards such as CE marking (for products sold in the European Economic Area) and API specifications (for petroleum and natural gas industries) is crucial.

What are the Key Quality Control Checkpoints?

Quality control (QC) in vibratory feeder manufacturing is typically segmented into several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Suppliers must provide certifications and test reports to verify material quality.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure that production processes comply with established standards. This may involve regular inspections and functional testing of components.

-

Final Quality Control (FQC): Once assembly is complete, a thorough inspection is performed on the finished product. This includes functional testing to ensure that the feeder operates as intended under various conditions.

What Testing Methods Are Commonly Used for Vibratory Feeders?

To ensure that vibratory feeders meet quality standards, manufacturers employ several testing methods throughout the production process:

-

Vibration Testing: This assesses the operational efficiency and stability of the feeder. It simulates the actual working conditions to identify any potential issues.

-

Load Testing: This method evaluates the feeder’s performance under maximum load conditions, ensuring it can handle the required capacities.

-

Electrical Testing: For feeders with electronic components, electrical testing ensures that all systems function correctly and safely.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several proactive steps to verify the quality assurance processes of suppliers:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing and quality control processes. This can be done through on-site visits or third-party audits.

-

Request Documentation: Buyers should request quality assurance documentation, including test reports, certifications, and compliance statements for relevant standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating suppliers:

-

Cultural Differences: Understanding cultural variations in business practices can enhance communication and expectations regarding quality standards.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that impact product standards and certifications. Buyers should be well-versed in these regulations to ensure compliance.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can affect the quality of products upon delivery. Buyers should discuss shipping methods and handling procedures with suppliers to mitigate risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for vibratory feeders empowers B2B buyers to make informed decisions. By focusing on the key stages of manufacturing, relevant quality standards, and verification methods, buyers can ensure they are selecting reliable and high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibratory feeder’

In the fast-paced world of manufacturing and automation, sourcing the right vibratory feeder is crucial for optimizing efficiency and productivity. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring that you select a system that meets your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Consider factors such as the type of materials you will be handling, the required feeding rate, and the desired orientation of parts. This clarity helps streamline supplier discussions and ensures that you receive appropriate solutions tailored to your unique requirements.

- Material Type: Identify if you need food-grade, pharmaceutical-grade, or standard industrial feeders.

- Capacity Needs: Determine the volume of parts to be processed to avoid under or over-specifying your feeder.

Step 2: Research Available Technologies

Understanding the various vibratory feeder technologies can significantly influence your decision-making. Familiarize yourself with different feeder types, such as bowl feeders, linear feeders, and custom systems. Each technology serves distinct applications, so knowing which is best suited for your needs will guide your supplier selection.

- Bowl Feeders: Ideal for small to medium-sized parts that require orientation.

- Linear Feeders: Best for moving larger parts or bulk materials efficiently.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps ensure that the supplier has a proven track record and the technical expertise to meet your needs.

- Supplier Reputation: Look for reviews and testimonials from other businesses.

- Industry Experience: Prioritize suppliers who have experience in your specific industry sector.

Step 4: Verify Supplier Certifications

Confirming that suppliers hold relevant certifications is vital for ensuring compliance with industry standards. Certifications can reflect a supplier’s commitment to quality, safety, and environmental practices. This verification minimizes risks associated with equipment failure or non-compliance in regulated industries.

- Quality Standards: Check for ISO certifications or other relevant quality management systems.

- Safety Compliance: Ensure that the supplier adheres to safety regulations applicable in your region.

Step 5: Request Quotes and Proposals

Once you have shortlisted potential suppliers, request detailed quotes and proposals. This will give you insight into pricing structures, delivery timelines, and warranty options. Analyzing these details helps you make informed comparisons and select the best offer that aligns with your budget and operational needs.

- Cost Analysis: Look for transparency in pricing, including potential hidden costs.

- Warranty Terms: Understand the warranty period and what it covers to safeguard your investment.

Step 6: Conduct Site Visits or Virtual Tours

If possible, arrange site visits or virtual tours of the supplier’s facility. Observing their operations firsthand can provide valuable insights into their manufacturing processes, quality control measures, and overall capabilities. This step can further solidify your confidence in the supplier’s ability to meet your requirements.

- Production Capabilities: Assess their equipment and technology to ensure they can deliver what you need.

- Quality Control Practices: Inquire about their quality assurance processes to ensure consistency in product performance.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier, it’s time to finalize contracts and terms. Ensure that all agreed-upon specifications, delivery schedules, and payment terms are clearly documented. This step is crucial for protecting your interests and ensuring accountability throughout the procurement process.

Illustrative image related to vibratory feeder

- Detailed Agreements: Include provisions for service support and maintenance after purchase.

- Clear Terms: Ensure that both parties understand the terms to avoid any future disputes.

By following this checklist, you will be well-equipped to source a vibratory feeder that meets your operational needs while fostering a successful partnership with your chosen supplier.

Comprehensive Cost and Pricing Analysis for vibratory feeder Sourcing

What Are the Key Cost Components Involved in Sourcing Vibratory Feeders?

When sourcing vibratory feeders, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials used significantly affects the cost. Common materials include stainless steel for food-grade applications and aluminum for lighter applications. Higher-quality materials often lead to higher prices but may improve durability and performance.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor, particularly in regions with a robust manufacturing workforce, may command higher wages, impacting overall pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Manufacturers with advanced technologies or in regions with high operational costs may pass these expenses onto buyers.

-

Tooling: Custom tooling for specialized vibratory feeders can be a significant upfront cost. The complexity of the design and the materials used in tooling can influence this cost.

-

Quality Control (QC): Implementing stringent QC measures ensures reliability and compliance with industry standards, especially in sectors like pharmaceuticals and food processing. This can add to the overall cost but is essential for long-term operational efficiency.

-

Logistics: Transportation and handling costs can vary greatly depending on the geographic location of the supplier and buyer. International shipping can introduce additional costs, including tariffs and insurance.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. Understanding the average margins in the industry can help buyers gauge fair pricing.

What Influences Pricing for Vibratory Feeders?

Several factors can influence the pricing of vibratory feeders, including:

-

Volume/MOQ: Bulk purchases often result in lower unit prices. Manufacturers may offer discounts for larger orders, so negotiating for a minimum order quantity (MOQ) can lead to significant savings.

-

Specifications and Customization: Custom-designed feeders tailored to specific applications can significantly increase costs. Buyers should evaluate the necessity of customization versus off-the-shelf solutions.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, FDA) can elevate costs. Buyers in regulated industries must weigh the importance of certification against potential cost savings from lower-quality options.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can influence pricing. Suppliers with established track records may command premium prices but often provide superior service and support.

-

Incoterms: The agreed-upon Incoterms can affect pricing structures. For instance, buyers opting for FOB (Free on Board) may face lower initial costs but should anticipate additional freight charges.

How Can Buyers Negotiate for Better Pricing on Vibratory Feeders?

To optimize costs, buyers can adopt several strategies:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A higher upfront cost may be justifiable if the equipment offers lower operational costs and longer lifespan.

-

Leverage Volume Discounts: If planning to purchase multiple units over time, negotiate for volume discounts upfront. Establishing a long-term relationship with suppliers can also lead to better pricing.

-

Request Detailed Quotes: Ask suppliers for breakdowns of their pricing. Understanding the components can provide leverage during negotiations, especially if you can identify areas where costs can be trimmed.

-

Be Aware of Pricing Nuances in International Markets: Factors like currency fluctuations, local market conditions, and tariffs can impact pricing. Buyers from Africa, South America, and the Middle East should factor these elements into their budgets.

What Should Buyers Keep in Mind Regarding Indicative Pricing?

It is essential to recognize that prices for vibratory feeders can vary widely based on the factors outlined above. Indicative prices often serve as a starting point for negotiations rather than final figures. Buyers should conduct thorough market research and solicit multiple quotes to gain a comprehensive understanding of the pricing landscape before making a commitment.

Alternatives Analysis: Comparing vibratory feeder With Other Solutions

When evaluating feeding systems for automation processes, it’s essential to consider various alternatives to vibratory feeders. Each solution presents unique advantages and drawbacks, catering to different operational needs and contexts. This analysis will compare vibratory feeders with two prominent alternatives: centrifugal feeders and belt conveyors.

Illustrative image related to vibratory feeder

| Comparison Aspect | Vibratory Feeder | Centrifugal Feeder | Belt Conveyor |

|---|---|---|---|

| Performance | High precision and consistent flow | Fast, suitable for bulk feeding | Moderate speed, good for continuous flow |

| Cost | Moderate initial investment | Higher upfront cost, but efficient long-term | Low to moderate, depending on length and complexity |

| Ease of Implementation | Requires setup and calibration | More complex installation and tuning | Generally straightforward installation |

| Maintenance | Regular maintenance needed; lower wear | Less frequent, but can be complex repairs | Low maintenance, easy access |

| Best Use Case | Small to medium parts, precise orientation | Bulk parts, high-speed applications | Continuous transportation of materials |

What Are the Key Advantages and Disadvantages of Centrifugal Feeders Compared to Vibratory Feeders?

Centrifugal feeders utilize rotational motion to propel parts through a series of tracks, allowing for rapid feeding of bulk items. Their primary advantage is speed; they can handle large volumes quickly, making them ideal for high-throughput applications. However, they may struggle with the precision required for smaller parts, and the complexity of their installation and tuning can lead to longer setup times. Additionally, their higher initial investment may not be justified for all operations.

How Do Belt Conveyors Compare with Vibratory Feeders in Material Handling?

Belt conveyors are a versatile solution for transporting materials over varying distances and elevations. They are generally more cost-effective, especially in simple applications, and offer low maintenance due to fewer moving parts. However, they lack the precision orientation capabilities that vibratory feeders provide, making them less suitable for applications requiring careful part placement. Furthermore, their speed is moderate, which may not meet the demands of high-speed production lines.

How Can B2B Buyers Decide Which Feeding Solution Best Fits Their Needs?

When selecting the right feeding solution, B2B buyers should assess their specific operational requirements, including part size, speed, and precision needs. Vibratory feeders are ideal for applications requiring accuracy and control, particularly for smaller or intricately shaped components. Conversely, if the goal is to handle large volumes of bulk materials quickly, centrifugal feeders may be the better choice. For continuous movement of materials over longer distances with minimal precision requirements, belt conveyors can be the most cost-effective solution. Ultimately, understanding the nuances of each option will enable buyers to make informed decisions tailored to their unique manufacturing processes.

Essential Technical Properties and Trade Terminology for vibratory feeder

What Are the Essential Technical Properties of Vibratory Feeders?

Understanding the critical specifications of vibratory feeders is essential for B2B buyers looking to optimize their production processes. Here are some key technical properties to consider:

Illustrative image related to vibratory feeder

1. Material Grade

The material grade of a vibratory feeder significantly impacts its durability and suitability for various applications. Common materials include stainless steel for food and pharmaceutical applications, and aluminum for lighter parts. Selecting the right material ensures compliance with industry regulations and enhances the longevity of the equipment.

2. Tolerances

Tolerances refer to the allowable variation in dimensions and performance of the feeder components. Precise tolerances are crucial in applications requiring high accuracy, such as automotive or electronic component assembly. Tight tolerances can reduce waste and improve the efficiency of the production line, making it a critical factor for B2B buyers.

3. Feed Rate

The feed rate indicates how many parts can be processed within a specific time frame. This property is vital for determining the efficiency of your production line. A higher feed rate often correlates with increased productivity, but it must be balanced with the need for accuracy and part orientation.

4. Vibration Frequency

The vibration frequency affects how parts move through the feeder system. Different parts may require different frequencies for optimal handling. Understanding this property helps buyers select feeders that align with their specific operational needs, ensuring smooth and efficient part handling.

5. Bowl Diameter

The diameter of the feeder bowl impacts its capacity and the size of the parts it can accommodate. A larger bowl can handle more parts, which can be beneficial for high-volume operations. Buyers should consider their production scale and part sizes when assessing bowl dimensions.

6. Drive System Type

The drive system (electromagnetic vs. pneumatic) influences the feeder’s performance and maintenance requirements. Electromagnetic systems are often more efficient and require less maintenance, while pneumatic systems may offer greater flexibility for certain applications. Understanding the differences can guide buyers in making informed decisions based on their operational priorities.

What Are Common Trade Terms Related to Vibratory Feeders?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are several key terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of vibratory feeders, knowing whether a feeder is an OEM product can help assess its quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses that may not require large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is a critical step in the procurement process, allowing buyers to compare options and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with their orders.

Illustrative image related to vibratory feeder

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and can impact production schedules.

6. Aftermarket Support

Aftermarket support includes services provided after the initial sale, such as maintenance, repairs, and spare parts. This is particularly important for B2B buyers who rely on vibratory feeders for continuous production, as reliable support can minimize downtime and enhance operational efficiency.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that they select the right vibratory feeder solutions for their unique needs.

Navigating Market Dynamics and Sourcing Trends in the vibratory feeder Sector

What Are the Current Market Dynamics and Key Trends Influencing the Vibratory Feeder Sector?

The vibratory feeder market is currently experiencing significant growth, driven by advancements in automation and increased demand for efficient material handling solutions across various industries. Key drivers include the rise of manufacturing automation, particularly in automotive, pharmaceutical, and food processing sectors. As businesses seek to enhance productivity and reduce operational costs, the adoption of vibratory feeders is becoming increasingly prevalent.

Emerging technologies such as IoT and AI are shaping the future of vibratory feeders. Smart feeders equipped with sensors and connectivity features allow for real-time monitoring and data analytics, enabling businesses to optimize their operations. Moreover, the trend towards customization is gaining traction, with suppliers offering tailored solutions to meet specific client needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. For instance, the demand for food-grade and pharmaceutical-grade feeders is rising as regulatory standards become more stringent.

International buyers are also focusing on supply chain resilience and flexibility. The recent disruptions caused by global events have highlighted the importance of sourcing from multiple suppliers and regions. Buyers are increasingly evaluating the agility and reliability of suppliers, making it essential for manufacturers to demonstrate their ability to adapt to changing market conditions and customer demands.

How Is Sustainability and Ethical Sourcing Being Addressed in the Vibratory Feeder Sector?

Sustainability is becoming a critical consideration for B2B buyers in the vibratory feeder sector. The environmental impact of manufacturing processes and the materials used in vibratory feeders are under scrutiny. Companies are increasingly seeking suppliers who prioritize eco-friendly practices, such as reducing waste and energy consumption during production.

Ethical sourcing is equally important, particularly as global supply chains become more complex. Buyers are looking for suppliers who can provide transparency regarding their sourcing practices, ensuring that materials are obtained responsibly. Certifications such as ISO 14001 for environmental management and other ‘green’ labels are becoming essential for suppliers aiming to attract environmentally conscious buyers.

Incorporating sustainable materials into vibratory feeder designs—such as recyclable plastics or sustainably sourced metals—can also enhance a company’s marketability. Suppliers who commit to sustainability not only improve their environmental footprint but also build trust and loyalty among B2B customers who prioritize ethical considerations in their purchasing decisions.

Illustrative image related to vibratory feeder

What Is the Historical Context Behind the Development of Vibratory Feeders?

The development of vibratory feeders dates back to the mid-20th century when automation began to reshape manufacturing processes. Initially used in the automotive industry for parts handling, vibratory feeders quickly gained traction across various sectors due to their efficiency and adaptability. Over the decades, advancements in technology have transformed vibratory feeders from simple mechanical devices to sophisticated automated systems integrated with smart technology.

As industries evolved, so did the design and functionality of vibratory feeders. Today, they are essential components in production lines, capable of handling diverse materials with precision and speed. This evolution reflects the broader trend in manufacturing towards automation and efficiency, making vibratory feeders a cornerstone of modern industrial operations.

Frequently Asked Questions (FAQs) for B2B Buyers of vibratory feeder

-

How do I choose the right vibratory feeder for my application?

Choosing the right vibratory feeder involves assessing your specific application requirements, including the type of material being handled, the desired feed rate, and the level of automation needed. Consider factors such as the feeder’s capacity, bowl design (standard, custom, or specialty), and compatibility with your existing production line. Additionally, consult with suppliers about their customization options to ensure the feeder can meet your operational goals effectively. -

What are the key benefits of using vibratory feeders in manufacturing?

Vibratory feeders offer numerous advantages in manufacturing, including increased efficiency, precise part orientation, and reduced labor costs. They are designed to handle various materials, facilitating smooth and consistent feeding. Their adaptability allows integration into diverse production lines, ensuring they can accommodate changes in product types and sizes, which is particularly beneficial for manufacturers looking to scale operations without significant downtime. -

What customization options are available for vibratory feeders?

Customization options for vibratory feeders can include bowl size, shape, material (e.g., stainless steel for food-grade applications), and drive mechanisms. Additionally, features such as adjustable feed rates, orientation styles, and integration with vision systems can be tailored to meet specific operational needs. It is essential to communicate your requirements with potential suppliers early in the procurement process to ensure the final product aligns with your production objectives. -

What is the typical minimum order quantity (MOQ) for vibratory feeders?

Minimum order quantities for vibratory feeders vary by manufacturer and product type. Generally, MOQs can range from one unit for custom solutions to larger quantities for standard models. For international buyers, it’s advisable to discuss your needs with suppliers to negotiate terms that accommodate your budget and project timelines, especially if you are looking to place an initial order to test the product before scaling up. -

What payment terms should I expect when purchasing vibratory feeders internationally?

Payment terms for international purchases of vibratory feeders typically vary by supplier and can include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to clarify these terms upfront and understand any associated fees, currency exchange rates, and potential tariffs that may apply. Establishing a good relationship with your supplier can also facilitate more favorable payment arrangements. -

How can I ensure quality assurance when sourcing vibratory feeders?

To ensure quality assurance when sourcing vibratory feeders, request certifications such as ISO or other relevant industry standards from your supplier. It’s beneficial to ask for samples or conduct factory visits to evaluate manufacturing processes. Additionally, inquire about their testing procedures, warranty policies, and after-sales support to guarantee that the equipment meets your quality expectations and operational requirements. -

What logistics considerations should I keep in mind when importing vibratory feeders?

When importing vibratory feeders, consider logistics factors such as shipping methods, lead times, and customs clearance processes. It’s important to collaborate with a reliable freight forwarder familiar with international trade regulations in your region. Ensure that you understand the total landed cost, including shipping, insurance, and duties, to avoid unexpected expenses. Proper planning can help streamline the delivery process and minimize disruptions to your operations. -

What industries benefit most from using vibratory feeders?

Vibratory feeders are beneficial across various industries, including automotive, food processing, pharmaceuticals, and electronics. They are particularly effective in applications requiring precise part handling and orientation, such as assembly lines, packaging, and sorting systems. Understanding the specific needs of your industry will help you select the right vibratory feeder solution to enhance productivity and maintain quality in your manufacturing processes.

Top 8 Vibratory Feeder Manufacturers & Suppliers List

1. Hoosier Feeder – Vibratory Feeders

Domain: hoosierfeeder.com

Registered: 2012 (13 years)

Introduction: Vibratory Feeders provide high-quality and efficient parts orienting solutions. They are designed for various applications including counting, feeding, separating, laning, and orienting. The product range includes cosmetic-grade and pharmaceutical-grade vibratory feeders, as well as custom parts handling solutions tailored to specific applications. The company emphasizes its commitment to customer…

2. Eriez – Electromagnetic Vibratory Feeders

Domain: eriez.com

Registered: 1995 (30 years)

Introduction: Vibratory Feeders and Conveyors from Eriez provide effective and efficient conveying, screening, and feeding of materials in various applications. Key product details include: 1. Electromagnetic Vibratory Feeders: Offer precise flow rate control for accurate material handling of bulk products, from granulated sugar to rock products. 2. Mechanical Vibratory Feeders: Utilize eccentric motors to gene…

3. Hoosier Feeder Company – Vibratory Feeders

Domain: hoosierfeedercompany.com

Registered: 2007 (18 years)

Introduction: Vibratory Feeders are high-quality and efficient parts orienting solutions designed for various applications including counting, feeding & separating, laning, and orienting. The company offers custom parts handling solutions tailored to meet specific automation goals. They provide a complete line of food processing solutions, including food-grade feeder bowls and high-speed placement systems for e…

4. Vibratory Feeders Inc. – Key Products

Domain: vibratoryfeeders.com

Registered: 1998 (27 years)

Introduction: Vibratory Feeders Inc. manufactures automation machines, vibratory bowl feeders, and ancillary components such as supply hoppers and linear power tracks. Key products include: 1. Outside-Track Bowls: Specially designed bowls for intricate tooling. 2. Cascade Bowls: Smart and cost-effective bowls for feeding easily oriented parts. 3. Supply Hoppers: Sturdy and hard-wearing bulk parts feeders. 4. Li…

5. Vibratory Feeders – Automated Material Handling Solutions

Domain: vibratory-feeders.com

Registered: 2001 (24 years)

Introduction: Vibratory feeders are automated devices used for efficient material handling and processing across various industries. They utilize vibration to transport and feed materials such as solid components, bulk solids, and delicate items. Key applications include manufacturing, food processing, pharmaceuticals, and mining. Types of vibratory feeders include bowl feeders, tube feeders, grizzly screens, p…

6. AutoDev – Vibratory Feeding Systems

Domain: autodev.com

Registered: 1996 (29 years)

Introduction: Automation Devices, Inc. (ADI) offers a wide range of vibratory feeding systems and components, including:

– Vibratory Parts Feeding Systems

– Feeder Bowls

– Base Units and Feeder Stands/Tables

– Inline Feeders

– Sensing Devices

– Orienting Devices

– Amplitude Controllers

– Hoppers

– Industrial Vibrators

– Noise Reduction Forks

– Rhino Forklift Ball Hitch Attachments

– SWAN-MATIC Bottle Capping Ma…

7. Cleveland Vibrator – Vibratory Feeders

Domain: clevelandvibrator.com

Registered: 2000 (25 years)

Introduction: Cleveland Vibrator Company offers a range of vibratory feeders including: CF-A Air Powered Vibratory Feeder, EMF Electromechanical Vibratory Feeder, RFM Volumetric Vibratory Feeder, CT-A Air Powered Vibratory Tube Feeder, and EMF-T Vibratory Tube Feeder. Key features include:

– CF-A Series: Economical, effective, feed rates up to 50 tons/hour, suitable for hazardous environments.

– EMF Models: Lin…

8. RNA Automation – Vibratory Bowl Feeders

Domain: rnaautomation.com

Registered: 2010 (15 years)

Introduction: RNA Automation offers a range of Vibratory Bowl Feeders, including Conventional, Digital, EcoType™, Multi-lane Linear Systems, Centrifugal Feeders, and VariFeed® Step Feeders. Key features include:

– Suitable for various industries such as Industrial, Pharmaceuticals, and Medicals.

– Constructed from materials like stainless steel, aluminium, and polyamide with various coatings.

– Sizes range fro…

Strategic Sourcing Conclusion and Outlook for vibratory feeder

As businesses increasingly prioritize efficiency and automation, strategic sourcing of vibratory feeders has become essential for optimizing production processes. By leveraging high-quality, customized solutions tailored to specific applications—ranging from automotive to food processing—companies can enhance productivity, reduce downtime, and improve product quality. The ability to count, sort, and orient components with precision not only streamlines operations but also supports compliance with industry standards, particularly in sectors such as pharmaceuticals and food processing.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the long-term benefits of investing in advanced vibratory feeding systems. These systems offer flexibility and scalability, accommodating various production demands while minimizing waste. Collaborating with experienced manufacturers who provide comprehensive service and support can further ensure a successful integration into existing workflows.

Illustrative image related to vibratory feeder

Looking ahead, the vibratory feeder market is poised for growth, driven by technological advancements and a rising demand for automation. Now is the time to explore innovative feeding solutions that can propel your operations forward. Engage with trusted suppliers to discuss your unique requirements and discover how vibratory feeders can transform your manufacturing processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.