Choosing Your 4Bt Cummins For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 4bt cummins for sale

In the dynamic landscape of global trade, sourcing reliable 4BT Cummins for sale can be a daunting task for international B2B buyers. The challenge lies not only in identifying quality suppliers but also in understanding the diverse applications and specifications of these versatile diesel engines. As a result, making informed purchasing decisions becomes critical, especially for businesses operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Germany.

This comprehensive guide aims to equip B2B buyers with the essential knowledge needed to navigate the complexities of the 4BT Cummins market. Within these pages, you will discover detailed insights into the various types of 4BT engines available, their industrial and off-road applications, and the nuances of supplier vetting. Additionally, we will delve into cost considerations, warranty options, and maintenance practices that can influence your purchasing strategy.

Empowering informed decisions is our primary goal. By understanding the specifications and applications of the 4BT Cummins engines, international buyers can confidently engage with suppliers, ensuring they secure the best value for their investments. This guide is your roadmap to successfully navigating the global market for 4BT Cummins, helping you achieve operational efficiency and reliability in your projects.

Understanding 4bt cummins for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 4B | Naturally aspirated, lower horsepower (76 hp) | Light-duty industrial applications, small machinery | Pros: Lower cost, simple design. Cons: Limited power output for demanding tasks. |

| 4BT | Turbocharged, moderate horsepower (105 hp) | Step vans, generators, light construction equipment | Pros: Good balance of power and efficiency. Cons: May require additional components for optimal performance. |

| 4BTA | Turbocharged and aftercooled, higher horsepower (130 hp) | Heavy-duty applications, forklifts, and marine engines | Pros: Enhanced performance, better fuel efficiency. Cons: Higher initial investment. |

| Extended Long Block | Nearly complete assembly with new parts, run-tested | Engine replacements in industrial and automotive sectors | Pros: Comprehensive rebuild, minimal downtime. Cons: May not include all ancillary components. |

| Long Block | Core engine parts, requires reuse of some existing components | Cost-effective solution for existing engine replacements | Pros: More affordable than full engines. Cons: Limited to existing parts compatibility. |

What Are the Characteristics of the 4B Engine Type?

The 4B engine is characterized by its naturally aspirated design, producing around 76 horsepower. It is ideal for light-duty industrial applications, such as small machinery and equipment where lower power requirements are sufficient. Buyers should consider the 4B for projects with budget constraints, but it may not be suitable for tasks requiring higher power outputs.

How Does the 4BT Differ in Performance and Application?

The 4BT engine features a turbocharger, elevating its power output to approximately 105 horsepower. This engine is widely used in step vans and generators, making it a versatile option for various light construction equipment. B2B buyers will appreciate the balance of power and efficiency it offers, though they may need to invest in additional components to maximize performance in specific applications.

What Advantages Does the 4BTA Offer for Heavy-Duty Use?

The 4BTA engine enhances the performance of the 4BT by adding an aftercooler, which increases its horsepower to around 130. This engine is particularly suitable for heavy-duty applications such as forklifts and marine engines, where reliability and power are paramount. While the 4BTA may come with a higher upfront cost, its superior efficiency and performance can lead to long-term savings for businesses.

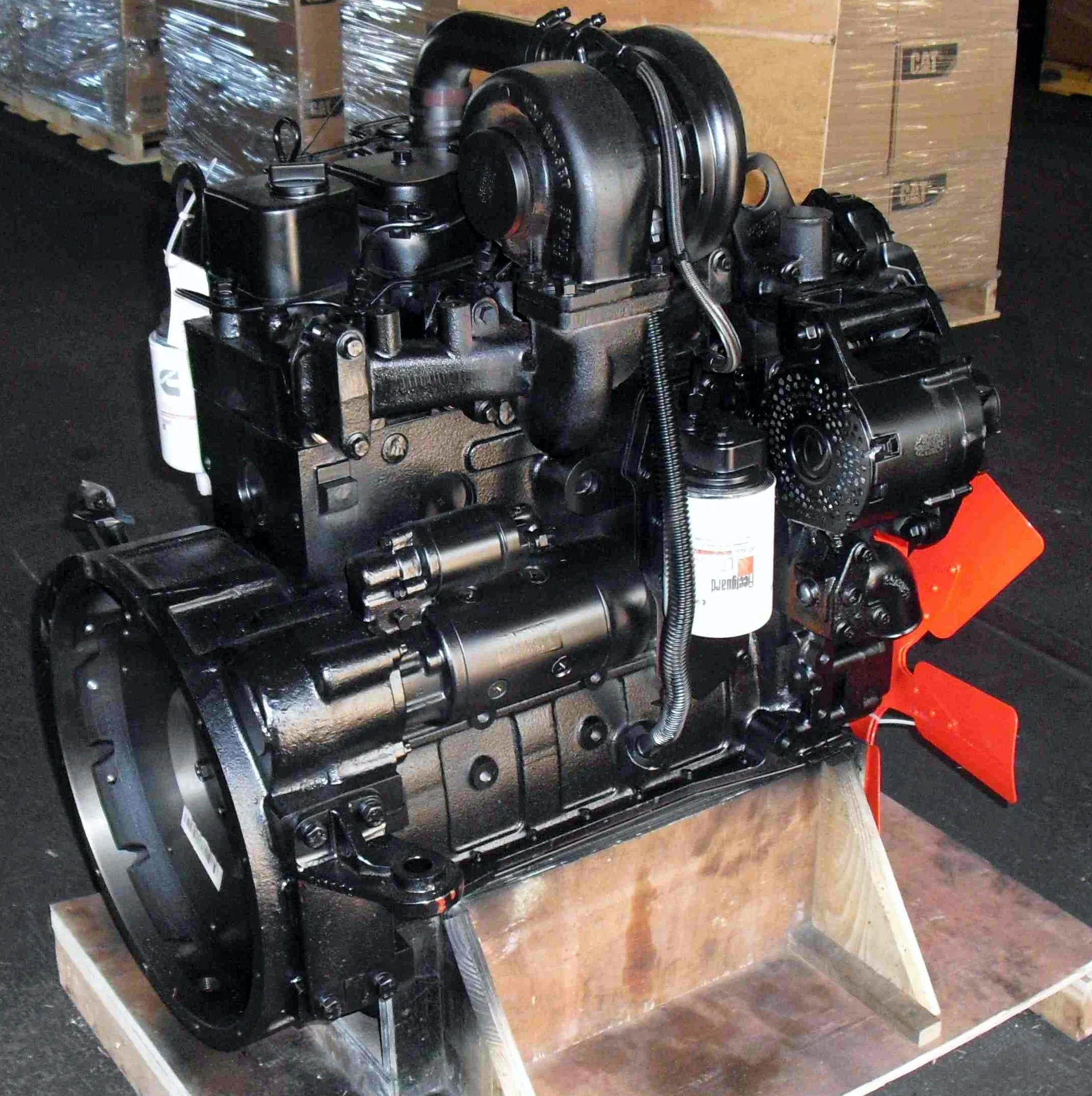

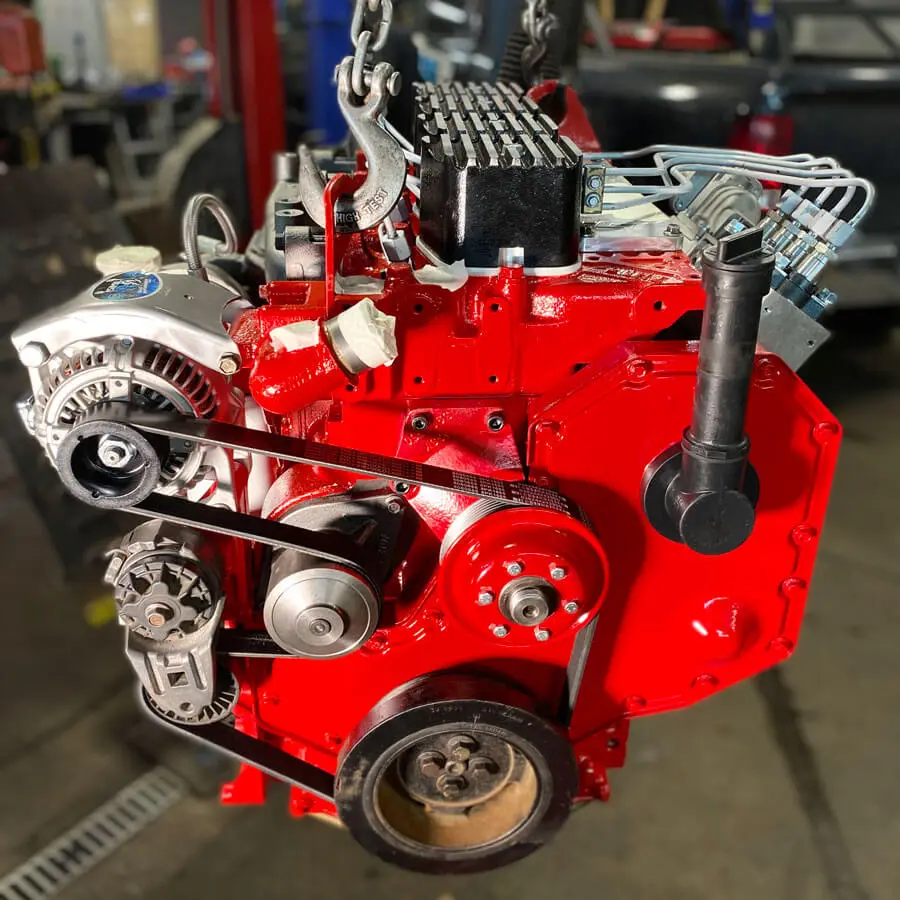

Illustrative image related to 4bt cummins for sale

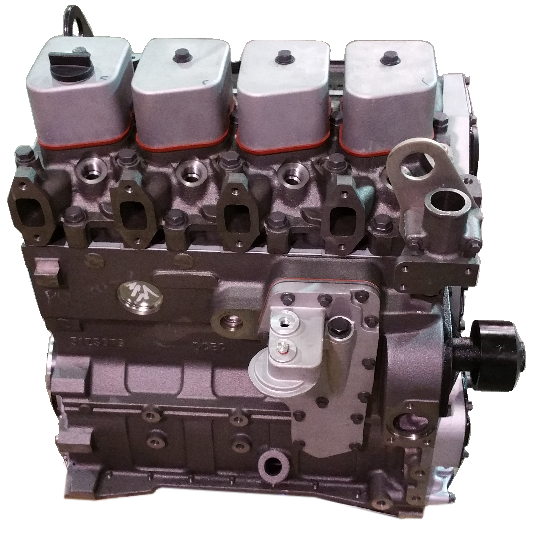

Why Choose Extended Long Block Engines for Replacement Needs?

Extended Long Block engines come nearly fully assembled, incorporating new parts and being run-tested before shipment. This makes them an excellent choice for businesses looking to minimize downtime during engine replacements in both industrial and automotive sectors. While they provide a comprehensive rebuild, buyers should note that not all ancillary components are included, which could necessitate additional purchases.

What Makes Long Block Engines a Cost-Effective Solution?

Long Block engines consist of essential internal components, allowing buyers to reuse existing parts from their current engine. This makes them a cost-effective option for replacing worn engines without the expense of a complete overhaul. Businesses should consider this option for budget-sensitive projects, but they must ensure compatibility with existing components to avoid additional costs.

Key Industrial Applications of 4bt cummins for sale

| Industry/Sector | Specific Application of 4bt cummins for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Skid Steers and Loaders | High torque and durability for heavy lifting and earthmoving tasks. | Ensure compatibility with existing equipment and local regulations. |

| Transportation | Step Vans and Delivery Trucks | Fuel efficiency and reliability for urban logistics. | Evaluate engine power ratings and emissions compliance. |

| Agriculture | Agricultural Equipment (e.g., Pumps, Generators) | Versatile power solutions for irrigation and machinery. | Consider engine size and adaptability to various equipment. |

| Marine | Small Boats and Bilge Pumps | Robust performance in harsh marine environments. | Assess weight and space constraints for installation. |

| Off-Road Vehicles | Jeep and 4×4 Conversions | Exceptional low-end torque for challenging terrains. | Verify the engine’s adaptability for vehicle modifications. |

How is the Cummins 4BT Used in the Construction Sector?

In the construction industry, the Cummins 4BT engine is commonly utilized in skid steers and loaders. These machines benefit from the engine’s high torque and durability, enabling efficient heavy lifting and earthmoving tasks. International buyers, particularly from regions like Africa and South America, should assess compatibility with existing machinery and ensure compliance with local emissions regulations to maximize operational efficiency and sustainability.

What are the Benefits of Using Cummins 4BT in Transportation?

For the transportation sector, particularly in urban logistics, the Cummins 4BT engine is a popular choice for step vans and delivery trucks. Its fuel efficiency and reliability are critical for businesses looking to optimize operational costs while ensuring timely deliveries. Buyers should evaluate the engine’s power ratings and emissions compliance to meet local regulations, especially in Europe and the Middle East, where environmental standards are stringent.

How Does the Cummins 4BT Enhance Agricultural Operations?

In agriculture, the Cummins 4BT engine powers various equipment, including pumps and generators. Its versatility allows for effective irrigation and operation of agricultural machinery, which is essential for maximizing productivity. Buyers in developing regions should consider the engine size and adaptability to ensure it meets the specific requirements of their farming equipment, facilitating seamless integration into their operations.

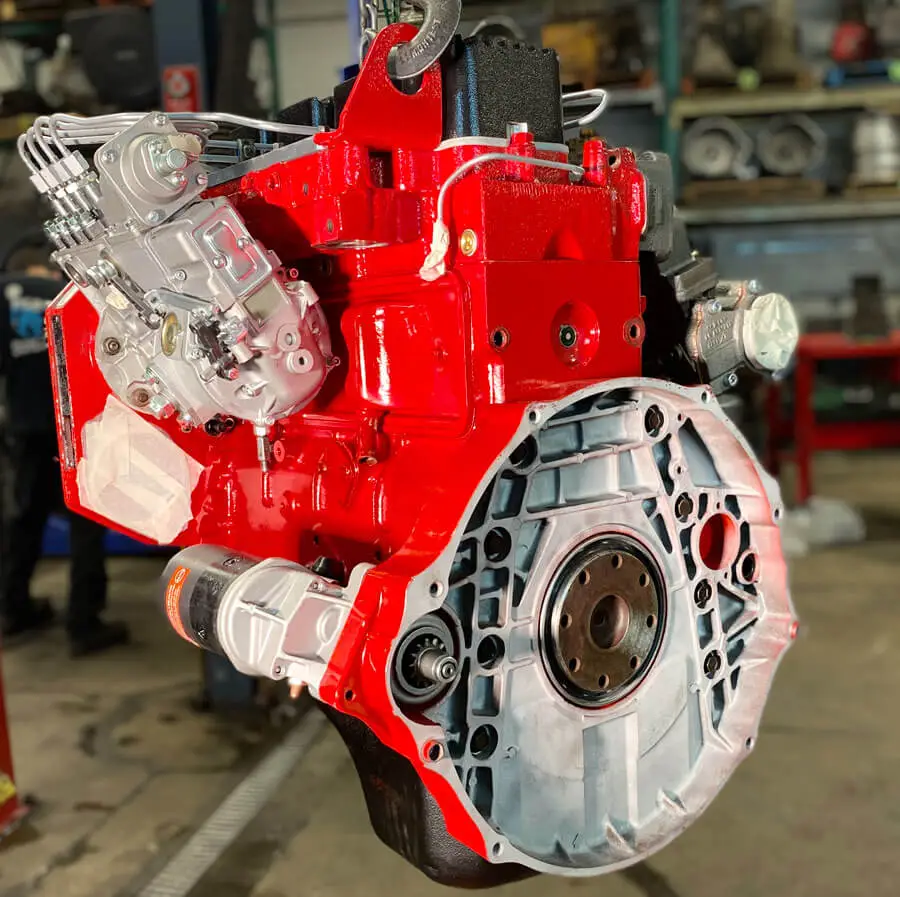

Illustrative image related to 4bt cummins for sale

Why is the Cummins 4BT Ideal for Marine Applications?

The marine sector benefits from the Cummins 4BT engine’s robust performance, particularly in small boats and bilge pumps. Its ability to operate efficiently in harsh marine environments makes it a reliable choice for boat operators. When sourcing this engine, buyers must assess weight and space constraints for installation, ensuring it fits within the design and operational requirements of their vessels.

What Makes the Cummins 4BT Popular for Off-Road Vehicles?

The off-road vehicle market, particularly among enthusiasts, has embraced the Cummins 4BT engine for Jeep and 4×4 conversions. Its exceptional low-end torque is ideal for tackling challenging terrains, making it a favorite among off-roaders. Buyers interested in these conversions should verify the engine’s adaptability for modifications, ensuring it meets their specific performance needs while complying with local regulations.

3 Common User Pain Points for ‘4bt cummins for sale’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Suppliers for 4BT Cummins Engines

The Problem: B2B buyers, especially those in regions like Africa and South America, often struggle to identify trustworthy suppliers for 4BT Cummins engines. The vast array of options can lead to confusion, especially when considering factors like quality, warranty, and after-sales support. Buyers may encounter suppliers who promise low prices but fail to deliver on quality, resulting in costly downtime and repairs. Furthermore, shipping logistics can complicate the purchasing process, making it imperative to find a supplier who can handle international transactions smoothly.

Illustrative image related to 4bt cummins for sale

The Solution: To effectively source reliable suppliers, buyers should conduct thorough market research and leverage online platforms dedicated to industrial equipment. Utilizing industry-specific forums and networks can provide insights into reputable suppliers who have successfully served other businesses. When evaluating suppliers, it’s crucial to ask for customer testimonials and case studies that illustrate their track record. Additionally, buyers should prioritize suppliers that offer comprehensive warranties and after-sales service packages, as these are indicators of reliability. Establishing a direct line of communication with potential suppliers can also facilitate a better understanding of their capabilities and product offerings.

Scenario 2: Uncertainty About Engine Specifications and Compatibility

The Problem: Many buyers face confusion regarding the specific engine models and their compatibility with existing equipment. The Cummins 4BT engine comes in various configurations, such as naturally aspirated, turbocharged, and aftercooled versions, leading to potential mismatches during installation. This uncertainty can cause delays and increased costs, as businesses may have to return or exchange engines that do not meet their operational needs.

The Solution: To mitigate this issue, buyers should engage in a detailed analysis of their existing machinery and operational requirements before making a purchase. Maintaining a checklist of essential specifications—such as horsepower, torque ratings, and intended applications—can help ensure that the selected engine aligns with the intended use. Furthermore, buyers should consult with experienced engineers or mechanics who specialize in Cummins engines to gain insights into the correct specifications. Suppliers that provide detailed product descriptions and compatibility charts can also aid in making informed decisions. It is advisable to inquire about the Control Parts List (CPL) of the engine, which will facilitate the identification of the right parts and enhance compatibility.

Scenario 3: Challenges in Engine Maintenance and Support Services

The Problem: After purchasing a 4BT Cummins engine, B2B buyers may encounter difficulties in accessing maintenance services and spare parts, particularly in remote areas or regions with less established supply chains. The lack of local support can lead to extended downtimes and inefficient operations, especially if the engine requires specialized knowledge for repairs and maintenance.

The Solution: To address maintenance challenges, buyers should prioritize suppliers who offer comprehensive support and resources. This includes not only providing spare parts but also access to technical support and training for local mechanics. Buyers should consider establishing a partnership with suppliers who can offer ongoing maintenance services or training programs for their teams. Developing a local network of certified mechanics who are trained to handle Cummins engines can also enhance operational efficiency. Additionally, implementing a proactive maintenance schedule and keeping an inventory of critical spare parts can help minimize downtime. Buyers are encouraged to utilize digital platforms for ordering parts and accessing maintenance manuals, ensuring they have the necessary resources to keep their engines in optimal condition.

Illustrative image related to 4bt cummins for sale

Strategic Material Selection Guide for 4bt cummins for sale

What Are the Key Materials Used in 4BT Cummins Engines?

The Cummins 4BT engine, known for its versatility and durability, relies on various materials that significantly impact its performance and longevity. Understanding these materials is crucial for international B2B buyers looking to invest in engines that meet their operational needs.

What Are the Key Properties of Cast Iron in 4BT Cummins Engines?

Cast iron is a primary material used in the engine block and cylinder head of the 4BT Cummins. It exhibits excellent compressive strength and thermal conductivity, which are essential for managing the high temperatures and pressures within the engine. Cast iron can withstand temperatures up to 1,200°F (650°C) and offers good resistance to wear and deformation.

Pros & Cons:

Cast iron is durable and relatively inexpensive, making it a popular choice for engine components. However, it is heavy, which can impact the overall weight of the vehicle or equipment. Additionally, manufacturing processes for cast iron can be complex, requiring precise casting techniques to avoid defects.

Illustrative image related to 4bt cummins for sale

Impact on Application:

The thermal properties of cast iron allow for effective heat dissipation, crucial for maintaining engine performance. However, its weight may limit its suitability in applications where weight reduction is critical, such as in off-road vehicles.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local sourcing of cast iron parts to reduce costs. Compliance with local standards, such as ASTM or DIN, is essential for ensuring quality and compatibility.

How Does Aluminum Enhance Performance in 4BT Cummins Engines?

Aluminum is often used in components such as the oil pan and intake manifold due to its lightweight and corrosion-resistant properties. Aluminum can withstand temperatures up to 1,200°F (650°C) but is generally less durable than cast iron under high-stress conditions.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which can improve fuel efficiency and overall vehicle performance. However, it is more expensive than cast iron and can be prone to deformation under extreme stress, which may limit its use in high-torque applications.

Illustrative image related to 4bt cummins for sale

Impact on Application:

Aluminum’s corrosion resistance makes it ideal for applications in marine environments or regions with high humidity. However, its lower strength-to-weight ratio compared to cast iron may necessitate thicker components, potentially negating some weight advantages.

Considerations for International Buyers:

Buyers in Europe, particularly Germany, may prioritize aluminum components for their lightweight benefits. Understanding local regulations regarding aluminum recycling and environmental compliance can also influence purchasing decisions.

What Role Does Steel Play in the Durability of 4BT Cummins Engines?

Steel is commonly used in critical components such as crankshafts, connecting rods, and camshafts due to its high tensile strength and fatigue resistance. Steel can handle extreme pressures and temperatures, making it suitable for high-performance applications.

Illustrative image related to 4bt cummins for sale

Pros & Cons:

Steel’s strength and durability make it an excellent choice for high-stress applications. However, it is heavier than aluminum, which can affect overall vehicle weight. Additionally, the manufacturing process for steel components can be more complex, leading to higher costs.

Impact on Application:

The robustness of steel components allows for reliable performance in heavy-duty applications, such as construction equipment and industrial machinery. However, in applications where weight is a concern, such as off-road vehicles, the added weight may be a disadvantage.

Considerations for International Buyers:

International buyers should be aware of the varying steel grades and standards (e.g., ASTM, JIS) across regions. Ensuring compliance with these standards can impact the quality and performance of the engine components.

How Does Composite Material Usage Affect 4BT Cummins Engines?

Composite materials, such as reinforced plastics, are increasingly being used in non-structural components like covers and housings. These materials can withstand moderate temperatures and offer excellent corrosion resistance.

Pros & Cons:

Composites are lightweight and can be molded into complex shapes, which can reduce manufacturing costs. However, they may not withstand high temperatures or pressures as effectively as metals, limiting their use in critical engine components.

Impact on Application:

The use of composite materials can lead to significant weight savings, improving fuel efficiency in lighter applications. However, their limitations in high-stress environments may restrict their use in heavy-duty industrial applications.

Considerations for International Buyers:

Buyers should consider the availability and local regulations regarding composite materials, particularly in regions with stringent environmental standards. Understanding the lifecycle and recyclability of these materials can also influence purchasing decisions.

Summary Table of Materials for 4BT Cummins Engines

| Material | Typical Use Case for 4BT Cummins for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Engine block, cylinder head | High durability and thermal conductivity | Heavy and complex manufacturing | Low |

| Aluminum | Oil pan, intake manifold | Lightweight and corrosion-resistant | More expensive and less durable under stress | Med |

| Steel | Crankshafts, connecting rods, camshafts | High tensile strength and fatigue resistance | Heavier than aluminum, complex manufacturing | Med |

| Composite | Covers, housings | Lightweight and moldable | Limited high-temperature and pressure resistance | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for 4bt cummins for sale

What Are the Key Stages in the Manufacturing Process of 4BT Cummins Engines?

The manufacturing process for 4BT Cummins engines involves several critical stages, each designed to ensure that the final product meets the high standards expected by international B2B buyers. Understanding these stages can help buyers make informed decisions when sourcing engines.

1. Material Preparation

The foundation of any robust engine starts with the selection of high-quality raw materials. For the Cummins 4BT, this typically includes cast iron for the engine block and aluminum for components such as the cylinder head. Suppliers often adhere to strict material specifications, which may include chemical composition, mechanical properties, and dimensional tolerances. Before production begins, materials undergo inspection to verify compliance with these standards, ensuring that only the best materials enter the manufacturing process.

2. Forming Techniques

Once the materials are prepared, the next phase is forming. This can involve processes such as casting, machining, and forging. For instance, the engine block is usually produced through sand casting, which allows for complex geometries and excellent surface finishes. Following casting, precision machining is performed to achieve tight tolerances on critical surfaces, such as cylinder bores and main bearing journals. This is essential for ensuring proper fit and function in the assembled engine.

Illustrative image related to 4bt cummins for sale

3. Assembly Process

The assembly of the 4BT Cummins engines is a meticulous process that requires skilled labor and precise tools. This stage typically follows a well-defined sequence:

- Sub-Assembly: Components such as the cylinder head, camshaft, and crankshaft are first assembled individually.

- Main Assembly: These sub-assemblies are then brought together to form the complete engine. Each component is carefully torqued and aligned according to OEM specifications.

- Final Assembly: This stage includes the installation of ancillary components like the oil pump, fuel injectors, and turbocharger.

Throughout the assembly process, workers conduct visual inspections and measurements to ensure that each part meets quality standards.

4. Finishing Touches

After assembly, engines undergo a finishing phase that may include painting, surface treatment, and installation of stickers or labels. This not only enhances the aesthetic appeal but also provides vital information regarding compliance and specifications. The finishing process often includes a thorough cleaning to remove any contaminants that could affect performance or longevity.

How Is Quality Assurance Implemented in the Manufacturing of 4BT Cummins Engines?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B buyers who require consistent product reliability. The QA process for 4BT Cummins engines includes several key elements:

Relevant International Standards for Quality Assurance

Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems and customer satisfaction. Compliance with ISO 9001 ensures that manufacturers maintain a consistent approach to quality throughout the production process. Additionally, industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, particularly for engines intended for specific applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet specified standards. Only materials that pass this inspection are allowed into the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections and measurements are conducted to verify that components remain within tolerances. This includes checks during casting, machining, and assembly phases.

-

Final Quality Control (FQC): Before shipping, each engine undergoes a comprehensive inspection that includes functional tests, performance evaluations, and emissions testing. This ensures that the engine meets all operational specifications and regulatory requirements.

What Common Testing Methods Are Used to Ensure Engine Quality?

To maintain high standards, various testing methods are employed throughout the manufacturing process:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspections are used to identify internal defects without damaging the components. This is crucial for high-stress areas of the engine.

-

Functional Testing: Each engine is typically run on a dynamometer to assess power output, torque characteristics, and overall performance. This ensures that the engine operates efficiently within its specified parameters.

-

Emissions Testing: Given the global emphasis on environmental regulations, emissions testing is performed to ensure compliance with local and international standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some strategies:

1. Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. Buyers should consider scheduling on-site visits to evaluate the supplier’s facilities, equipment, and adherence to quality standards.

Illustrative image related to 4bt cummins for sale

2. Requesting Quality Control Reports

Buyers should ask for detailed quality control documentation, including inspection reports, test results, and certifications. These documents can help verify that the supplier meets both international and industry-specific standards.

3. Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspectors can evaluate the manufacturing processes and ensure compliance with agreed-upon specifications before shipment.

What Quality Certification Nuances Should International Buyers Consider?

When sourcing 4BT Cummins engines from international suppliers, it’s important to understand the nuances of quality certifications:

-

Local Regulations: Different countries may have unique regulations regarding engine emissions and safety. Buyers should ensure that the supplier’s engines meet local standards for their specific markets.

-

Documentation Requirements: International shipments often require specific documentation for customs clearance. Buyers should confirm that their suppliers can provide all necessary certifications and compliance documents.

-

Warranty and After-Sales Support: Understanding the warranty terms and after-sales support can help buyers gauge the reliability and longevity of the engines. Ensure that the supplier offers warranties that align with industry standards and provides accessible support channels.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with 4BT Cummins engines, B2B buyers can make informed decisions and secure reliable products for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4bt cummins for sale’

To assist B2B buyers in successfully procuring Cummins 4BT engines, this guide provides a practical checklist to streamline the sourcing process. By following these steps, you can ensure that your purchase aligns with technical requirements, supplier reliability, and overall business objectives.

Illustrative image related to 4bt cummins for sale

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the 4BT Cummins engine you need. Consider the specific model variation (4BT, 4BTA, etc.), power ratings, and any additional features such as turbocharging or aftercooling. This clarity will help you communicate effectively with suppliers and ensure that you receive the correct engine type.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in Cummins 4BT engines. Utilize industry-specific platforms, trade shows, and online marketplaces to compile a list of potential vendors. Look for suppliers with a proven track record in your region, as local regulations and shipping logistics can significantly impact your procurement process.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management systems are crucial indicators of a supplier’s commitment to quality and reliability. Additionally, inquire about their remanufacturing processes and warranty offerings to assess the durability and support you can expect post-purchase.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that include pricing, delivery timelines, and payment terms. Comparing multiple quotes will not only provide insight into market rates but also help you identify suppliers who offer value-added services, such as extended warranties or technical support. Be cautious of prices that seem too low, as they may indicate compromised quality.

Illustrative image related to 4bt cummins for sale

Step 5: Assess Availability of Parts and Support

Inquire about the availability of replacement parts and technical support for the Cummins 4BT engines you are considering. A reliable supplier should have a robust inventory of essential components and be able to provide ongoing support for maintenance and repairs. This is particularly important if you are sourcing engines for industrial applications, where downtime can result in significant financial losses.

Step 6: Check References and Reviews

Before finalizing your decision, request references from previous clients and check online reviews or testimonials. This step is crucial for understanding the supplier’s reliability and customer service record. Pay attention to feedback regarding delivery times, product quality, and after-sales support to gauge the supplier’s overall reputation in the market.

Step 7: Negotiate Terms and Finalize Agreement

Once you have selected a supplier, engage in negotiations to establish favorable terms of purchase. This may include pricing adjustments, payment schedules, and delivery conditions. Ensure that all agreements are documented in a formal contract to protect both parties and clarify expectations, particularly regarding warranties and service agreements.

Illustrative image related to 4bt cummins for sale

By following this checklist, B2B buyers can navigate the complexities of sourcing Cummins 4BT engines with confidence, ensuring they select the right product from a reliable supplier while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for 4bt cummins for sale Sourcing

What Are the Key Cost Components for Sourcing 4BT Cummins Engines?

When sourcing 4BT Cummins engines, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in the construction of the engine significantly impact costs. OEM parts, which ensure reliability and compliance with specifications, often come at a premium. Buyers should evaluate the balance between price and quality to avoid long-term issues.

-

Labor: Labor costs can vary based on the location of manufacturing. Skilled labor is essential for assembling engines to precise specifications. In regions with higher labor costs, such as Europe, the final price may reflect these expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help keep these costs lower, impacting the overall price of the engine.

-

Tooling: Initial tooling costs for manufacturing can be substantial, especially for custom or modified engines. These costs are typically amortized over the production volume, meaning larger orders can reduce the per-unit cost.

-

Quality Control (QC): Rigorous QC processes ensure that engines meet safety and performance standards, which may incur additional costs. However, investing in quality control can lead to lower failure rates and reduced warranty claims, ultimately benefiting buyers.

-

Logistics: Transportation costs, including shipping and handling, can vary significantly based on distance and mode of transport. For international buyers, understanding Incoterms is crucial as they determine responsibility for shipping costs and risk.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on market demand, competition, and the supplier’s reputation.

How Do Pricing Influencers Affect the Cost of 4BT Cummins Engines?

Several factors can influence the pricing of 4BT Cummins engines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing needs.

-

Specifications and Customization: Customized engines or specific configurations may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected pricing changes.

-

Materials and Quality Certifications: Engines built with high-quality materials or certified for specific industries may come at a premium. Buyers in regions with stringent regulations should prioritize certified products to ensure compliance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for determining who bears the shipping costs and risks, affecting overall pricing.

What Buyer Tips Can Help Optimize Costs When Sourcing 4BT Cummins Engines?

-

Negotiation: Always negotiate terms with suppliers. Leverage volume purchasing or long-term contracts to secure better pricing.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Engines with a higher initial cost may offer lower TCO through better fuel efficiency and durability.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa and South America may face additional customs duties and taxes. It’s essential to factor these into the overall budget.

-

Stay Informed on Market Trends: Fluctuations in raw material prices or changes in trade policies can affect engine costs. Staying updated allows buyers to make informed purchasing decisions.

-

Consider Local Regulations: Compliance with local emissions and safety regulations can affect engine specifications and costs. Ensure that the sourced engines meet these requirements to avoid penalties.

Disclaimer on Indicative Prices

Prices for 4BT Cummins engines can vary widely based on the factors discussed above. It is advisable for buyers to obtain quotes from multiple suppliers and consider the total cost implications before making purchasing decisions.

Alternatives Analysis: Comparing 4bt cummins for sale With Other Solutions

Introduction: Evaluating Alternatives for Diesel Engine Solutions

When considering a diesel engine for industrial or automotive applications, the Cummins 4BT engine stands out for its durability and performance. However, there are various alternatives available in the market that cater to similar needs. This analysis will compare the 4BT Cummins engine against two viable alternatives: the Isuzu 4BD1 engine and the Ford 6.7L Power Stroke engine. Understanding these options can help B2B buyers identify the best fit for their specific operational requirements.

Comparison Table

| Comparison Aspect | 4BT Cummins For Sale | Isuzu 4BD1 Engine | Ford 6.7L Power Stroke Engine |

|---|---|---|---|

| Performance | 105 hp, 265 lb-ft torque | 90 hp, 160 lb-ft torque | 450 hp, 935 lb-ft torque |

| Cost | Moderate initial investment | Lower initial cost | Higher initial investment |

| Ease of Implementation | Straightforward for existing setups | Requires custom mounts for some vehicles | Complex, may need extensive modifications |

| Maintenance | Low maintenance; widely available parts | Moderate; parts availability can vary | Higher maintenance costs and complexity |

| Best Use Case | Industrial applications; off-roading | Light-duty vehicles; small machinery | Heavy-duty applications; towing and hauling |

Detailed Breakdown of Alternatives

Isuzu 4BD1 Engine

The Isuzu 4BD1 is a compact diesel engine that offers moderate power output and torque, making it suitable for light-duty applications. One of its significant advantages is its lower initial cost compared to the 4BT Cummins. However, the engine’s performance may not meet the demands of heavier industrial applications, and parts availability can be inconsistent, particularly in remote regions. This engine is best suited for businesses seeking a cost-effective solution for light machinery or vehicles.

Ford 6.7L Power Stroke Engine

The Ford 6.7L Power Stroke engine is a powerful option that delivers significantly more horsepower and torque than the 4BT Cummins. This engine is ideal for heavy-duty applications, such as towing and hauling, making it a popular choice among fleet operators. However, the initial investment is notably higher, and the complexity of installation can be a barrier for some users. Additionally, maintenance costs can escalate, particularly for those not familiar with the engine’s advanced technology. Businesses that require robust performance for demanding tasks may find the Power Stroke a worthwhile investment despite its higher costs.

Conclusion: Choosing the Right Diesel Engine Solution

Selecting the right diesel engine solution involves assessing various factors, including performance, cost, maintenance, and specific application needs. The 4BT Cummins engine excels in versatility and ease of integration, making it a strong contender for many businesses, particularly in industrial and off-road settings. However, alternatives like the Isuzu 4BD1 and Ford 6.7L Power Stroke offer unique advantages that may align better with specific operational requirements. B2B buyers should carefully evaluate their needs, considering both immediate costs and long-term operational efficiency, to make an informed decision that enhances their business performance.

Essential Technical Properties and Trade Terminology for 4bt cummins for sale

What Are the Key Technical Properties of 4BT Cummins Engines?

When considering a purchase of 4BT Cummins engines, understanding the technical specifications is crucial for making informed decisions. Here are some of the critical specifications that B2B buyers should be aware of:

-

Engine Configuration and Size

The Cummins 4BT is a 3.9-liter, four-cylinder diesel engine. This compact size allows for versatility in various applications, from industrial machinery to off-road vehicles. The smaller footprint means easier installation in tight spaces, making it an attractive option for businesses looking to optimize their equipment. -

Power Output and Torque

The standard power output for a 4BT engine ranges from 105 hp to 140 hp, depending on the specific model and configuration. Torque is a significant factor, with standard ratings around 265 lb-ft at 1,600 rpm. High torque at low RPM is essential for applications requiring heavy lifting or towing, making the 4BT suitable for diverse industries, including construction and agriculture. -

Material Grade and Durability

The engine components are typically constructed from high-grade cast iron and aluminum, ensuring durability and resistance to wear. This material selection is vital for B2B buyers who prioritize longevity and low maintenance costs in their operations. Understanding material specifications can help businesses gauge the engine’s performance and lifespan. -

Fuel Efficiency

The 4BT Cummins engine is known for its fuel efficiency, often achieving 30-40 miles per gallon with performance upgrades. This attribute is particularly appealing to businesses aiming to reduce operational costs and enhance sustainability. Buyers should evaluate fuel consumption metrics to calculate long-term savings. -

CPL (Control Parts List)

The CPL is crucial for identifying the correct parts for maintenance and repairs. Each variant of the 4BT engine has a unique CPL, which outlines the essential components and specifications necessary for service. This knowledge enables businesses to streamline their procurement processes and avoid costly downtime. -

Warranty and Support

Most suppliers offer warranties ranging from 12 months to multiple years on parts and labor. Understanding warranty terms can provide peace of mind for buyers, ensuring they receive support in case of defects or failures. It’s essential to compare warranty offerings from different suppliers to select the most favorable terms.

Which Trade Terms Are Commonly Used in 4BT Cummins Transactions?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms related to the sale of 4BT Cummins engines:

-

OEM (Original Equipment Manufacturer)

This term refers to parts or components that are made by the original manufacturer of the engine. In the context of 4BT engines, purchasing OEM parts ensures compatibility and reliability, which is critical for maintaining operational efficiency. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ helps businesses plan their inventory and budget accordingly. For 4BT Cummins engines, knowing the MOQ can also assist in negotiating bulk purchase discounts. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. When procuring 4BT engines, submitting an RFQ can yield competitive pricing and detailed information on delivery timelines and payment terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, insurance, and liability. Familiarity with these terms is crucial for international buyers, especially those from regions like Africa or the Middle East, to ensure clear expectations regarding shipment and delivery. -

Aftermarket Parts

Aftermarket parts are components made by companies other than the original manufacturer. While they may offer cost savings, understanding the quality and compatibility of these parts is essential for long-term performance and reliability. -

Lead Time

Lead time refers to the amount of time from when an order is placed until it is delivered. For businesses relying on 4BT engines for critical operations, knowing the lead time is vital for planning and minimizing disruptions in service.

Understanding these technical properties and trade terms will empower B2B buyers to make well-informed decisions when purchasing 4BT Cummins engines, ensuring they select the best options for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 4bt cummins for sale Sector

What Are the Global Drivers Influencing the 4BT Cummins Market?

The market for 4BT Cummins engines is primarily driven by the demand for versatile, fuel-efficient, and durable diesel engines across various sectors. Key industries utilizing these engines include construction, agriculture, transportation, and marine applications, particularly in developing regions such as Africa and South America, where infrastructure development is a priority. The trend towards diesel engines is bolstered by their reputation for high torque and low operating costs, making them ideal for heavy-duty tasks. Furthermore, the increase in off-road and recreational vehicle markets in Europe and the Middle East is expanding the customer base for these engines.

Emerging technologies in B2B sourcing, such as e-commerce platforms and digital marketplaces, are reshaping how international buyers access 4BT Cummins engines. These platforms offer real-time inventory updates, competitive pricing, and enhanced transparency, allowing buyers from diverse regions to make informed purchasing decisions. Additionally, the integration of AI and data analytics is improving supply chain efficiency, enabling suppliers to better predict demand and optimize inventory management.

How Is Sustainability Influencing Sourcing Trends in the 4BT Cummins Market?

Sustainability and ethical sourcing are becoming increasingly important for B2B buyers in the 4BT Cummins market. The environmental impact of diesel engines, particularly concerning emissions, has prompted manufacturers and buyers to seek solutions that minimize ecological footprints. This has led to a growing emphasis on the remanufacturing of engines, where worn parts are refurbished to meet OEM specifications, thereby reducing waste and promoting resource efficiency.

Buyers are also prioritizing suppliers who demonstrate a commitment to sustainability through certifications and green materials. Utilizing ISO 9001 certified components and ensuring compliance with environmental regulations are essential for suppliers aiming to attract discerning international customers. By investing in sustainable practices, companies can not only improve their market positioning but also meet the increasing regulatory demands from various regions, including Europe and the Middle East, which are implementing stricter emissions standards.

Illustrative image related to 4bt cummins for sale

What Is the Historical Context of the 4BT Cummins Engine?

The Cummins 4BT engine has a rich history, dating back to its introduction in the late 1980s. Initially designed for commercial and industrial applications, the 4BT quickly gained popularity due to its compact size and robust performance. Its versatility allowed it to be adapted for various uses, from step vans to off-road vehicles, making it a staple in the diesel engine market.

Over the years, the 4BT engine has undergone several iterations, enhancing its efficiency and power output while maintaining its reputation for reliability. The rise of the remanufactured engine market has also transformed the sourcing landscape, providing buyers with cost-effective options without compromising quality. This evolution reflects the ongoing adaptability of the 4BT Cummins engine, which continues to meet the diverse needs of international B2B buyers across multiple sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of 4bt cummins for sale

-

How do I determine the right Cummins 4BT engine for my application?

To select the appropriate Cummins 4BT engine, first identify the specific requirements of your application, such as horsepower, torque, and fuel efficiency. Consider the environment in which the engine will operate—whether it’s for industrial use, off-roading, or marine applications. Additionally, check the engine’s Control Parts List (CPL) to ensure compatibility with your existing systems. Consulting with a knowledgeable supplier can provide insights into the best model suited for your needs. -

What is the best way to source Cummins 4BT engines internationally?

When sourcing Cummins 4BT engines internationally, it’s essential to work with reputable suppliers who have experience in global trade. Look for suppliers with strong customer reviews and verified credentials. Utilize trade platforms and industry networks to find potential suppliers. Conduct due diligence, including asking for references and checking compliance with international shipping regulations and warranty terms, to ensure a smooth purchasing process. -

What are the typical payment terms for purchasing Cummins 4BT engines?

Payment terms for Cummins 4BT engines can vary depending on the supplier and the order size. Common terms include upfront payment, partial deposits followed by payment on delivery, or net 30/60/90 days for established relationships. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card, letters of credit) and any associated fees. Always negotiate terms that align with your cash flow needs and risk management practices. -

How can I ensure the quality of the Cummins 4BT engines I purchase?

To ensure the quality of Cummins 4BT engines, request detailed specifications and certifications from the supplier. Look for warranties that cover parts and labor, typically ranging from 12 months to several years. Ask for information about the remanufacturing process, including parts used and testing procedures. Conducting a quality assurance inspection before shipment can also mitigate risks associated with defects or subpar performance. -

What is the minimum order quantity (MOQ) for Cummins 4BT engines?

The MOQ for Cummins 4BT engines can vary significantly by supplier and region. Some suppliers may offer flexible terms for smaller orders, while others might require a minimum quantity to ensure cost-effectiveness. It’s advisable to discuss your specific needs with suppliers directly and explore options for bulk purchasing discounts or group orders with other businesses to meet MOQ requirements. -

Are there customization options available for Cummins 4BT engines?

Yes, many suppliers offer customization options for Cummins 4BT engines to meet specific application needs. Customizations can include modifications to the engine’s power output, fuel pump types, or additional components such as turbochargers. Discuss your requirements with the supplier to understand the available options and any implications for pricing and lead times. Be aware that custom orders may involve longer delivery times. -

What logistics considerations should I keep in mind when importing Cummins 4BT engines?

When importing Cummins 4BT engines, consider logistics factors such as shipping methods, customs duties, and local regulations. Work with freight forwarders experienced in handling heavy machinery to ensure compliance with international shipping laws. Verify the lead time for delivery and plan for potential delays. Additionally, ensure proper insurance coverage during transit to protect against any damage or loss. -

What are the common applications for Cummins 4BT engines in different industries?

Cummins 4BT engines are versatile and commonly used across various industries. They are popular in industrial applications like generators, forklifts, and construction equipment due to their durability and low-rpm torque. In the automotive sector, they are frequently used in off-road vehicles, RVs, and step vans. Understanding the specific demands of your industry can help you determine the best use cases for the 4BT engine in your operations.

Top 7 4Bt Cummins For Sale Manufacturers & Suppliers List

1. Cummins – Diesel Engines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Brand: Cummins, Number of Cylinders: 4, Fuel Type: Diesel, Engine Sizes: 2 L, 2.8 L, 3.9 L, 4.5 L, 5.9 L, 8 L, Condition: New, Used, New other (see details), Price Range: Under $7,500, $7,500 to $15,000, Over $15,000, Shipping: Arrives in 2-4 days, Free Shipping, Local Pickup within 25mi.

2. Freedom Engine & Transmissions – Cummins 4BT Crate Engine

Domain: dalessuperstore.com

Registered: 2010 (15 years)

Introduction: {“name”: “Cummins 4BT Crate Engine (Inline or Rotary)”, “sku”: “4BT-NEW”, “brand”: “Freedom Engine & Transmissions”, “condition”: “New”, “price”: {“was”: “$7,950.00”, “sale”: “$5,845.00”, “savings”: “$2,105.00”, “discount_percentage”: “26%”}, “shipping”: {“type”: “Freight”, “cost”: “Free Shipping”}, “weight”: “400.0 lbs”, “warranty”: “1 year”, “engine_specifications”: {“type”: “4BT”, “displacement…

3. Cummins – Used Diesel Engines for Sale

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used Cummins Diesel Engines for Sale. Key details include: 234 listings available, various models such as 4BT, 6B, QSB4.5, and more. Horsepower ranges from low to high. Locations include California, Colorado, Illinois, Louisiana, North Carolina, Pennsylvania, Texas, West Virginia, and Alberta. Condition options: New/Rebuilt (169) and Used (65). Examples of specific engines: 46 HP Cummins A2300 (19…

4. Summit Core Supply – Cummins 4BT Diesel Engine

Domain: summitcoresupply.com

Registered: 2015 (10 years)

Introduction: {‘engine_type’: ‘Cummins 4BT Diesel Engine’, ‘transmission_type’: ‘EATON 5 Speed Transmission’, ‘sale_price’: ‘$6,650.00 USD’, ‘location’: ‘Springville, PA, US’, ‘contact_phone’: ‘570-983-4105’, ‘financing_options’: ‘Starts at $135/m’, ‘engine_condition’: ‘Used’, ‘engine_horse_power’: ‘130 HP’, ‘stock_number’: ‘3196’, ‘mls_number’: ‘12031639’, ‘cpl_arr’: ‘1839’, ‘availability’: ‘Two available’, ‘n…

5. Cummins 4BT Engine Assys – New and Used for Sale

Domain: truckpartsinventory.com

Registered: 2005 (20 years)

Introduction: New and Used Cummins 4BT Engine Assys for sale. Key details include:

– Location: Hialeah, Florida, US

– Engine Make: Cummins

– Engine Model: 4BT

– Price Range: $3,500.00 – $11,995.00

– Stock Numbers: Various (e.g., 005055, 002551, 002946, etc.)

– Engine Types: Good Used, Used, Rebuilt

– Engine Specifications: 3.9L Diesel Engine, Inline Fuel Pump, Serial Numbers provided for specific units, HP rati…

6. Cummins – Used 4BT Engines for Sale

Domain: mylittlesalesman.com

Registered: 1996 (29 years)

Introduction: Used Cummins 4BT Engines for Sale

– Manufacturer: Cummins

– Model: 4BT

– Condition: Used

– Engine Types Available: 4 cylinder turbo diesel

– Horsepower Range: 100 HP to 130 HP

– Engine Displacement: 3.9 L

– Fuel Type: Diesel

– Features: Turbocharged, mechanical VE style rotary fuel pump, air to air aftercooled

– Applications: Fits various equipment including skid steers, wood chippers, hydraulic p…

7. 4BT Engines – Quality Performance

Domain: 4btswaps.com

Registered: 2006 (19 years)

Introduction: 4BT engines are sourced from various places, including former members of forums, eBay, and specific sellers like Chad Mckinney. Prices for 4BT engines in running condition typically range from $3500 to $4000, but can vary based on condition and included components. It’s advised to expect additional costs for inspections and potential rebuilds, with total swap costs potentially reaching $8000 to $1…

Strategic Sourcing Conclusion and Outlook for 4bt cummins for sale

In the evolving landscape of industrial and automotive applications, the Cummins 4BT engine stands out for its versatility, durability, and efficiency. As international B2B buyers seek reliable power solutions, understanding the nuances of sourcing these engines is crucial. The availability of long blocks and extended long block engines tailored for specific applications enables businesses to minimize downtime and optimize performance.

Strategic sourcing not only enhances operational efficiency but also drives cost savings and ensures compliance with local regulations. Buyers from regions such as Africa, South America, the Middle East, and Europe must leverage their purchasing power by partnering with reputable suppliers who offer high-quality remanufactured components and exceptional customer support.

Looking ahead, the demand for Cummins 4BT engines is expected to grow, fueled by trends in off-road applications and industrial machinery. By proactively engaging with suppliers and exploring advanced engine technologies, businesses can position themselves for long-term success. Take the next step in your sourcing strategy and connect with trusted suppliers to secure the best solutions for your operational needs.

Illustrative image related to 4bt cummins for sale

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.