Is Your Rubber Floor Molding Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for rubber floor molding

In today’s dynamic global market, sourcing high-quality rubber floor molding can present significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for durable, versatile, and aesthetically pleasing flooring solutions is compounded by varying regional standards, supplier reliability, and fluctuating costs. This guide aims to demystify the complexities of rubber floor molding procurement, offering an in-depth analysis of the different types available, their applications across various industries, and essential factors to consider when selecting suppliers.

By exploring the diverse applications of rubber floor molding—from commercial spaces to industrial environments—buyers will gain insights into its performance characteristics and benefits. The guide also emphasizes effective supplier vetting processes, ensuring that international buyers can identify trustworthy manufacturers and distributors. Furthermore, we delve into cost considerations, providing a framework for budget planning and negotiation strategies tailored to different markets.

Armed with this comprehensive knowledge, B2B buyers will be empowered to make informed purchasing decisions that align with their specific needs, ultimately enhancing their operational efficiency and project outcomes. This resource serves not only as a roadmap for sourcing rubber floor molding but also as a strategic tool for navigating the intricacies of the global marketplace.

Understanding rubber floor molding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cove Base | Curved design, seamless transition between floor and wall | Commercial spaces, healthcare facilities | Pros: Aesthetic appeal, easy to clean. Cons: May require professional installation. |

| Toeless Base | Flat design without a toe, minimalistic look | Retail environments, offices | Pros: Sleek appearance, easier to maintain. Cons: Less durable in high-traffic areas. |

| Thermoplastic Rubber (TPR) | High flexibility and durability, resistant to fading | Schools, gyms, industrial facilities | Pros: Long-lasting, versatile. Cons: Higher initial cost. |

| Standard Rubber Base | Available in various colors and heights, versatile | Restaurants, hotels, residential applications | Pros: Cost-effective, easy installation. Cons: Can wear out over time in high-traffic areas. |

| Vent Cove Base | Designed with ventilation, prevents moisture buildup | Laboratories, food processing areas | Pros: Hygienic, reduces mold growth. Cons: More expensive than standard options. |

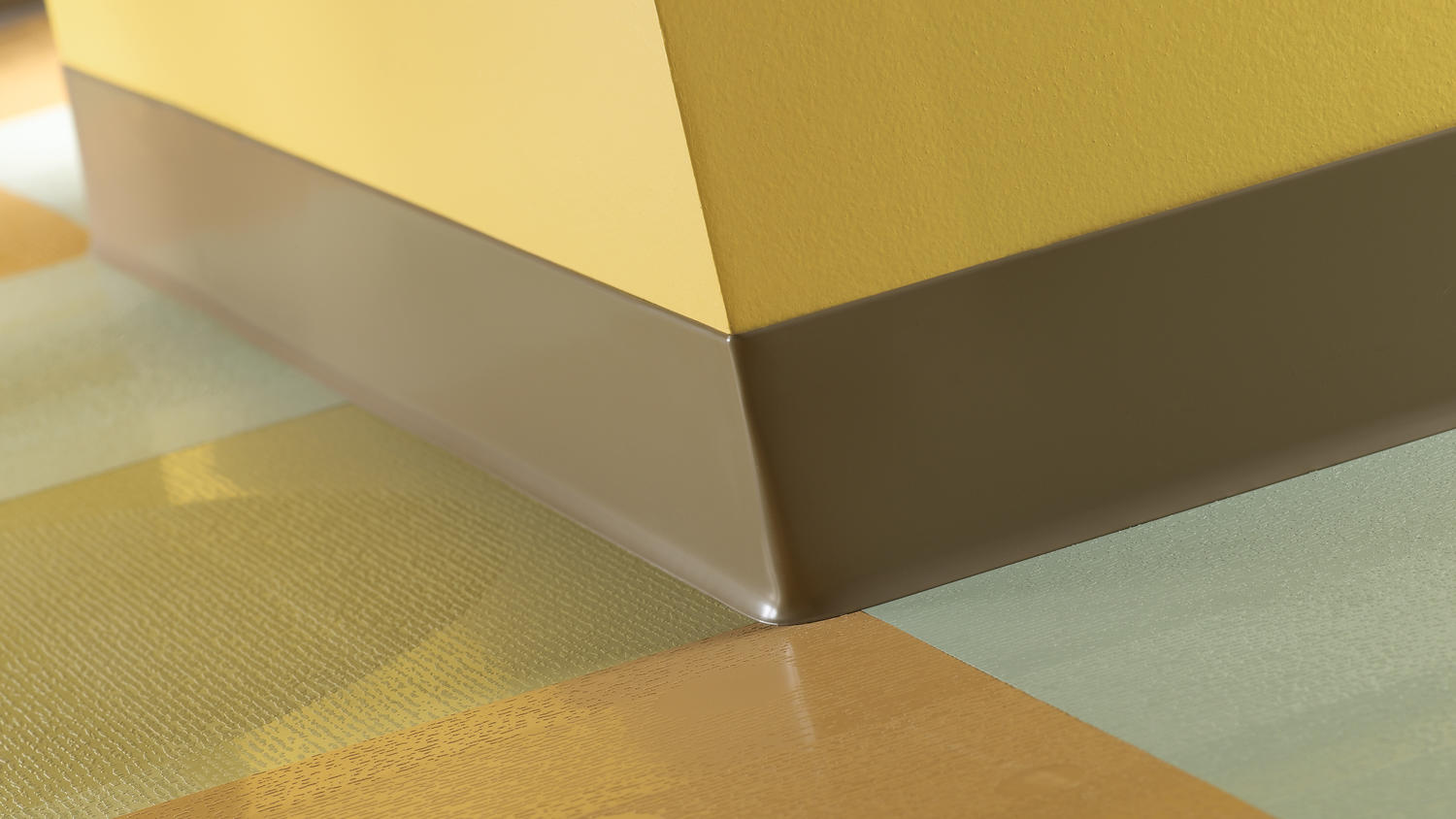

What are the Characteristics and Suitability of Cove Base Rubber Floor Molding?

Cove base molding features a curved design that creates a seamless transition from the floor to the wall, making it ideal for commercial spaces and healthcare facilities. Its aesthetic appeal is complemented by its functionality, as it is easy to clean and helps prevent dirt accumulation. When considering purchasing, B2B buyers should evaluate the installation requirements, as professional installation may be necessary to achieve the desired look and durability.

Illustrative image related to rubber floor molding

How Does Toeless Base Rubber Molding Differ from Other Options?

The toeless base molding offers a flat design that eliminates the toe, resulting in a minimalistic and contemporary appearance. This style is particularly suitable for retail environments and offices where aesthetics are paramount. While it is easier to maintain due to its flat surface, buyers should be aware that it may not hold up as well in high-traffic areas compared to more robust options.

Why Choose Thermoplastic Rubber (TPR) for Your Projects?

Thermoplastic rubber is renowned for its high flexibility and durability, making it a preferred choice for schools, gyms, and industrial facilities. Its resistance to fading and wear ensures a long-lasting solution, although it typically comes at a higher initial cost. B2B buyers should consider the long-term benefits versus upfront expenses when selecting TPR, especially in environments that demand resilience.

What are the Benefits of Standard Rubber Base Molding?

Standard rubber base molding is versatile and available in a wide range of colors and heights, making it suitable for various applications, including restaurants and hotels. Its cost-effectiveness and ease of installation are significant advantages for B2B buyers looking for reliable solutions. However, it is essential to note that this option may wear out faster in high-traffic areas, necessitating potential replacements.

When Should You Consider Vent Cove Base Rubber Molding?

Vent cove base molding is specifically designed with ventilation features that help prevent moisture buildup, making it an excellent choice for laboratories and food processing areas. Its hygienic properties can significantly reduce the risk of mold growth, appealing to buyers in health-sensitive industries. Although it tends to be more expensive than standard options, the long-term benefits in hygiene and safety often justify the investment.

Key Industrial Applications of rubber floor molding

| Industry/Sector | Specific Application of rubber floor molding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Wall base in hospitals and clinics | Enhances hygiene, easy to clean, and prevents mold growth | Compliance with health regulations, durability, and color options |

| Education | Flooring in schools and universities | Provides safety, sound absorption, and aesthetic appeal | Material safety certifications, slip-resistance, and ease of installation |

| Retail | Base molding in retail spaces | Improves aesthetics, protects walls, and is easy to maintain | Variety of colors, durability against wear, and cost-effectiveness |

| Hospitality | Wall base in hotels and restaurants | Enhances guest experience and provides easy maintenance | Design flexibility, moisture resistance, and brand alignment |

| Manufacturing & Warehousing | Protective molding in factories and warehouses | Reduces damage to walls and provides a clean finish | Heavy-duty options, resistance to chemicals, and installation requirements |

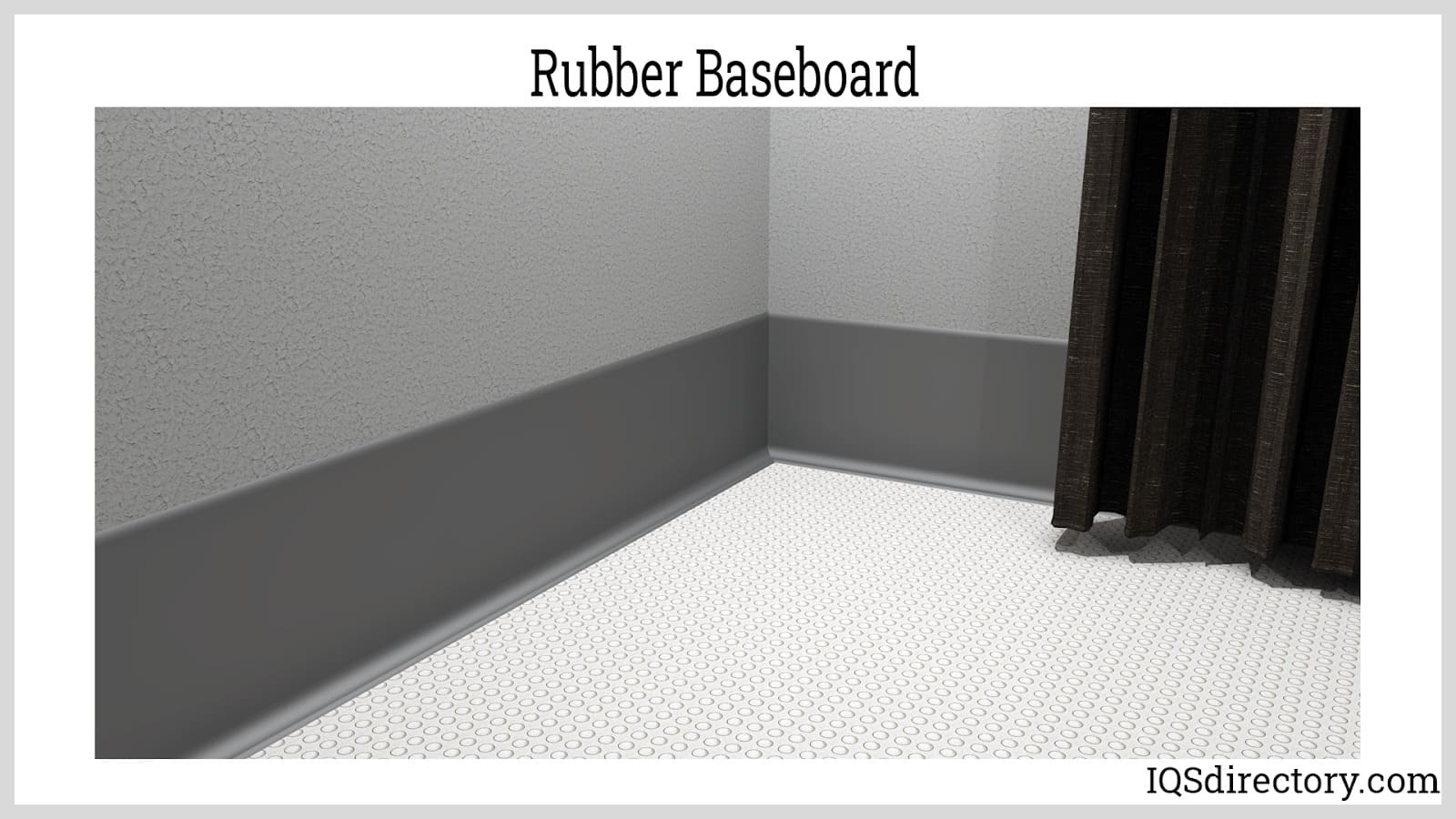

How is Rubber Floor Molding Used in Healthcare Settings?

In healthcare facilities such as hospitals and clinics, rubber floor molding is essential for maintaining hygiene and aesthetic standards. It is installed along the base of walls to create a seamless transition between the floor and wall, preventing dirt accumulation and mold growth. Buyers in this sector must prioritize materials that comply with health regulations, ensuring they are easy to clean and durable. The variety of colors available allows for customization, contributing to a welcoming environment for patients.

Illustrative image related to rubber floor molding

What Role Does Rubber Floor Molding Play in Educational Institutions?

Educational institutions utilize rubber floor molding to enhance safety and comfort within classrooms and common areas. The material provides sound absorption, which is vital for creating a conducive learning atmosphere. Additionally, its slip-resistant properties help prevent accidents. International buyers from regions like Africa and South America should consider sourcing options that meet material safety certifications and offer ease of installation, as schools often require quick renovations during off-peak times.

How Does Rubber Floor Molding Benefit Retail Spaces?

In retail environments, rubber floor molding is used to enhance the overall aesthetic while protecting walls from damage caused by carts and foot traffic. Its durability and ease of maintenance make it an attractive option for store owners looking to maintain a clean and professional appearance. Buyers should evaluate the variety of colors and styles available to match their brand identity, while also considering cost-effectiveness, especially in high-traffic areas.

Why is Rubber Floor Molding Important in the Hospitality Industry?

Hotels and restaurants benefit from rubber floor molding as it enhances guest experience through improved aesthetics and easy maintenance. The material is often chosen for its moisture resistance and ability to withstand heavy foot traffic, making it ideal for high-use areas. Buyers in this sector should focus on design flexibility to align with their branding while ensuring that the products meet durability standards to minimize replacement costs.

How is Rubber Floor Molding Utilized in Manufacturing and Warehousing?

In manufacturing and warehousing settings, rubber floor molding serves as a protective barrier along walls to reduce damage from equipment and personnel movement. This not only preserves the integrity of the facility but also contributes to a cleaner appearance. Buyers should seek heavy-duty options that resist chemicals and meet specific installation requirements, ensuring longevity and effectiveness in demanding environments.

3 Common User Pain Points for ‘rubber floor molding’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Rubber Floor Molding for Specific Environments

The Problem: B2B buyers often face the challenge of selecting the appropriate rubber floor molding that meets the specific requirements of their environment. For instance, a manufacturing facility may require moldings that can withstand heavy foot traffic and resist chemicals, while a healthcare facility might prioritize moldings that are hygienic and easy to clean. This variability can lead to confusion, resulting in improper choices that may not perform adequately in the intended setting.

The Solution: To address this issue, buyers should start by clearly defining the environment in which the rubber floor molding will be installed. This includes assessing factors such as foot traffic levels, exposure to chemicals, and cleanliness requirements. When sourcing rubber floor molding, look for products that specify their suitability for different environments, such as commercial-grade or healthcare-grade ratings. Additionally, consider consulting manufacturers or suppliers that provide detailed technical data sheets, which outline the performance characteristics of various rubber moldings. Engage in conversations with industry peers or specialists who can share insights based on their experiences. This thorough approach will empower buyers to make informed decisions tailored to their specific needs.

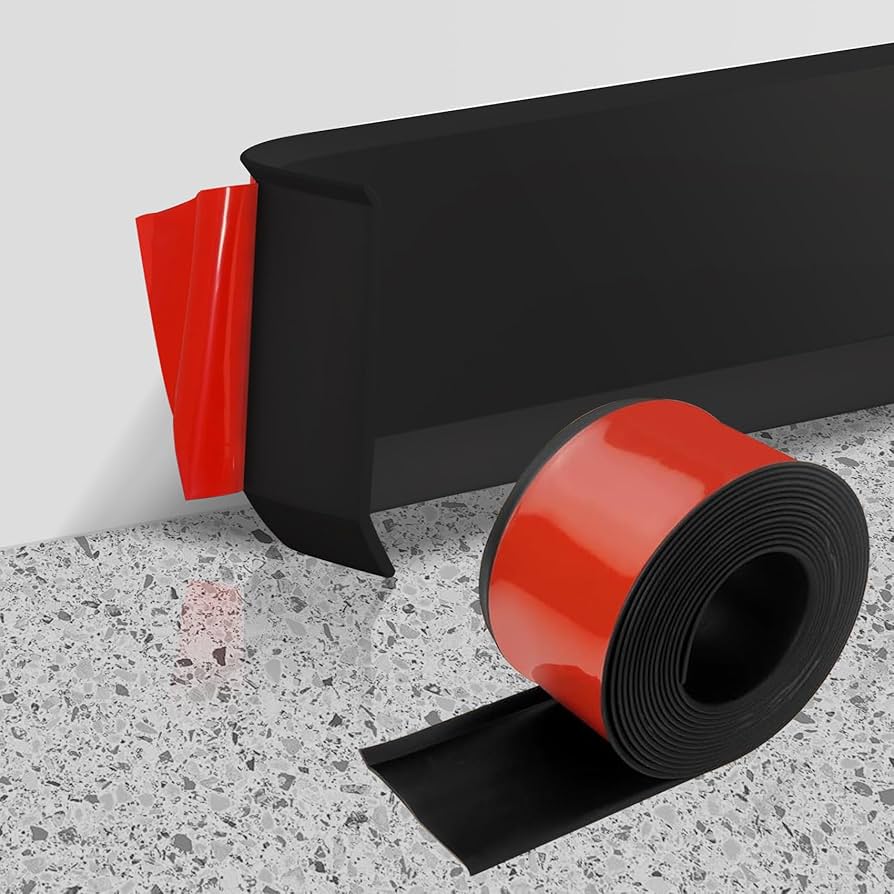

Scenario 2: Installation Challenges Leading to Increased Labor Costs

The Problem: Many B2B buyers encounter significant challenges during the installation of rubber floor molding. Improper installation can lead to aesthetic issues, such as gaps or misalignments, and can also increase labor costs due to the need for rework. For example, a buyer might find that the moldings they selected require special tools or techniques for installation that their team is not familiar with, leading to delays and frustration.

The Solution: To mitigate installation challenges, buyers should prioritize sourcing rubber floor molding that is designed for ease of installation. Look for products that come with clear installation guidelines, and consider moldings that are flexible and pre-cut for standard dimensions, which can simplify the process. Additionally, investing in training for the installation team can provide them with the necessary skills to handle the molding correctly. Many manufacturers offer training sessions or instructional videos, which can be invaluable. Lastly, consider partnering with experienced installers who have a proven track record with rubber floor moldings. This can not only reduce labor costs but also ensure a professional finish that meets the desired standards.

Illustrative image related to rubber floor molding

Scenario 3: Long-Term Durability Concerns Affecting ROI

The Problem: A common concern among B2B buyers is the long-term durability and maintenance of rubber floor molding. Buyers may worry that the products they choose will wear down quickly, leading to replacement costs that could have been avoided. For instance, a retail environment may experience heavy traffic, raising concerns about scuffing, fading, or cracking of the moldings over time.

The Solution: To enhance the long-term durability of rubber floor molding, buyers should focus on sourcing high-quality, commercial-grade products that come with robust warranties. Look for moldings that have been tested for durability against specific wear factors such as abrasion, moisture, and chemical resistance. Additionally, consider the finish of the molding; for instance, a textured surface may better hide scuffs compared to a smooth one. Regular maintenance also plays a crucial role in extending the life of rubber moldings. Establish a cleaning schedule that uses the recommended products for rubber flooring, which can prevent buildup of dirt and grime that could lead to deterioration. Engaging with manufacturers for maintenance guidelines can provide insights tailored to the specific products purchased, ensuring buyers maximize their return on investment over time.

Strategic Material Selection Guide for rubber floor molding

What Are the Key Properties of Common Materials Used in Rubber Floor Molding?

When selecting materials for rubber floor molding, it is essential to consider their properties, performance, and suitability for various applications. The following materials are commonly used in the industry:

1. Natural Rubber

Key Properties: Natural rubber exhibits excellent elasticity and tensile strength, making it suitable for high-impact applications. It has a good temperature resistance, typically ranging from -40°F to 175°F (-40°C to 80°C), and offers moderate resistance to abrasion and wear.

Illustrative image related to rubber floor molding

Pros & Cons: The primary advantage of natural rubber is its superior flexibility and comfort underfoot, which is ideal for commercial spaces. However, it is less resistant to UV light and ozone, leading to potential degradation over time. Additionally, natural rubber can be more expensive compared to synthetic alternatives.

Impact on Application: Natural rubber is compatible with various media, including water and light chemicals. However, it may not be suitable for environments with harsh chemicals or extreme temperatures.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as EN 14041 for resilient floor coverings. Understanding local preferences for sustainability may also influence material choices.

2. Synthetic Rubber (SBR)

Key Properties: Styrene-butadiene rubber (SBR) is known for its durability and resistance to abrasion, making it a popular choice for high-traffic areas. It can withstand temperatures from -30°F to 180°F (-34°C to 82°C) and has good resistance to chemicals and oils.

Pros & Cons: SBR’s primary advantage is its cost-effectiveness and availability in various grades, making it suitable for diverse applications. However, it may not offer the same level of comfort and flexibility as natural rubber, which can be a drawback in certain settings.

Impact on Application: SBR is highly compatible with various media, including oils and solvents, making it suitable for industrial environments. Its durability makes it ideal for areas with heavy foot traffic.

Considerations for International Buyers: Compliance with ASTM D2000 standards is crucial for buyers in North America, while European buyers may need to adhere to EN standards. Understanding the local market’s preferences for synthetic materials is also important.

3. Thermoplastic Rubber (TPR)

Key Properties: TPR combines the properties of rubber and thermoplastics, offering excellent flexibility and durability. It has a temperature range of -40°F to 140°F (-40°C to 60°C) and is resistant to UV light, making it suitable for outdoor applications.

Pros & Cons: TPR is easy to mold and shape, allowing for intricate designs and profiles. Its resistance to fading and cracking is a significant advantage. However, it can be more expensive than traditional rubber options and may require specialized manufacturing processes.

Impact on Application: TPR is compatible with various cleaning agents and is ideal for environments requiring frequent cleaning, such as hospitals and schools. Its flexibility allows for installation in curved or complex areas.

Considerations for International Buyers: Buyers should ensure compliance with international safety and environmental standards, such as REACH in Europe. Understanding local preferences for design and aesthetics can also influence material selection.

4. Ethylene Propylene Diene Monomer (EPDM)

Key Properties: EPDM is known for its excellent weather resistance and durability. It can withstand extreme temperatures, from -60°F to 300°F (-51°C to 149°C), and offers high resistance to ozone, UV light, and aging.

Pros & Cons: The key advantage of EPDM is its longevity and low maintenance requirements, making it a cost-effective choice over time. However, it may not provide the same level of comfort as softer rubber materials, which could be a consideration for residential applications.

Impact on Application: EPDM is suitable for outdoor applications and environments exposed to harsh weather conditions. Its chemical resistance makes it ideal for industrial settings.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations should ensure that EPDM products meet local compliance standards. Understanding the market’s demand for eco-friendly materials can also impact purchasing decisions.

Summary Table of Material Selection

| Material | Typical Use Case for rubber floor molding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Commercial spaces, gyms | Superior flexibility and comfort | Less UV and ozone resistance | Medium |

| Synthetic Rubber (SBR) | Industrial environments | Cost-effective and durable | Less comfort compared to natural rubber | Low |

| Thermoplastic Rubber (TPR) | Hospitals, schools | Excellent design flexibility | Higher manufacturing costs | High |

| Ethylene Propylene Diene Monomer (EPDM) | Outdoor applications, industrial settings | Exceptional weather resistance | Less comfort for residential use | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various rubber materials for floor molding, enabling informed purchasing decisions tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber floor molding

What Are the Key Stages in the Manufacturing Process of Rubber Floor Molding?

The manufacturing of rubber floor molding involves several critical stages that ensure the final product meets the desired quality and performance standards. Understanding these stages can help B2B buyers evaluate suppliers and their capabilities.

Material Preparation: What Raw Materials Are Used?

The first stage in the manufacturing process is the preparation of raw materials, primarily rubber compounds. These compounds are typically made from natural rubber, synthetic rubber, or a blend of both, depending on the desired properties such as durability, flexibility, and resistance to chemicals or wear. Additives like fillers, stabilizers, and colorants are mixed into the rubber to enhance performance characteristics and aesthetic appeal.

The quality of the raw materials is crucial, as they directly impact the molding process and the final product’s performance. Suppliers should provide documentation verifying the quality and source of their materials, which can be a deciding factor for B2B buyers.

Forming: How Is Rubber Molded into Its Final Shape?

The next step involves the forming of the rubber into the desired shape. This is typically achieved through various molding techniques, including:

-

Compression Molding: This method involves placing a pre-measured amount of rubber into a heated mold. Pressure is then applied, causing the rubber to conform to the shape of the mold. This technique is cost-effective for small production runs and complex shapes.

-

Injection Molding: In this method, rubber is heated until it becomes pliable and then injected into a mold. This technique allows for greater precision and is suitable for high-volume production runs.

-

Extrusion: In this process, rubber is forced through a die to create long shapes, such as strips or profiles. This is ideal for producing consistent cross-sections and is often used for wall base molding.

Each technique has its benefits and is selected based on factors such as production volume, complexity of the design, and material characteristics.

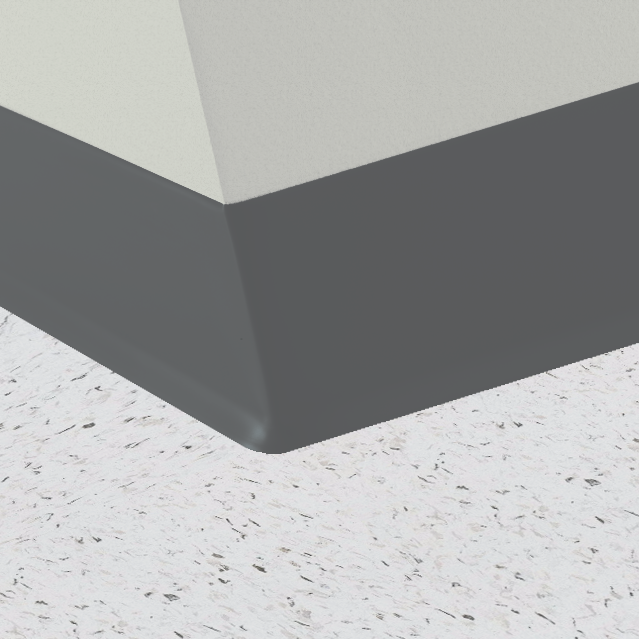

Assembly and Finishing: What Additional Steps Are Involved?

After the rubber is formed, it undergoes assembly, if necessary, especially for products that require multiple components. This may include attaching the rubber molding to backing materials or adding special features like adhesive strips for easy installation.

Illustrative image related to rubber floor molding

Finishing processes such as trimming, surface treatment, and quality checks are conducted to ensure that the molding meets aesthetic and functional standards. Finishing can also involve applying coatings or treatments that enhance durability, UV resistance, or color stability.

What Quality Assurance Standards Are Relevant for Rubber Floor Molding?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for B2B buyers who require reliable products. Several international standards and industry-specific certifications can guide buyers in their selection of suppliers.

Which International Standards Should Buyers Consider?

One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 demonstrates a supplier’s commitment to consistent quality and continuous improvement.

Other relevant certifications include:

-

CE Marking: Required for products sold in the European Economic Area, indicating that the product meets health, safety, and environmental protection standards.

-

API Standards: Particularly relevant for products used in oil and gas applications, ensuring that the rubber components can withstand harsh environments.

Buyers should inquire about a supplier’s certifications and how they align with their specific market requirements.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, involving several checkpoints to ensure that products meet specified standards.

How Are QC Checkpoints Structured?

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predetermined specifications. This helps prevent defects from entering the production process.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor quality. This includes checking the consistency of material properties, dimensions, and adherence to the specified manufacturing processes.

-

Final Quality Control (FQC): Once production is complete, a comprehensive assessment is conducted on the finished products. This includes testing for physical properties, durability, and compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is vital in ensuring product reliability. Here are some methods:

-

Audits: Conducting audits of the supplier’s facilities can provide insight into their manufacturing processes and quality management systems. This can be done by the buyer or through third-party organizations.

-

Quality Reports: Requesting regular quality reports can help buyers track the supplier’s performance over time. These reports should detail any defects, corrective actions taken, and overall production quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can be conducted at various stages of production, offering additional assurance to buyers.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may face unique challenges when sourcing rubber floor molding. Understanding local regulations, import standards, and regional certifications is essential. For instance, buyers in the European Union must ensure that products meet CE marking requirements, while those in the Middle East may need to comply with specific local standards.

Additionally, cultural differences in business practices may influence the communication of quality expectations. Establishing clear, documented agreements regarding quality standards and processes can help mitigate misunderstandings.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is crucial for B2B buyers seeking reliable rubber floor molding products. By focusing on material preparation, forming techniques, quality standards, and verification methods, buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber floor molding’

The following guide provides a structured approach for B2B buyers looking to source rubber floor molding effectively. By following these steps, you can ensure a successful procurement process tailored to your specific needs.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for your rubber floor molding. Consider factors such as thickness, color, and type (e.g., coved or toeless). Establishing clear specifications is essential to prevent miscommunication with suppliers and ensure the products meet your project’s needs.

- Thickness: Common options range from 1/8 inch to thicker variants; choose based on durability and application.

- Color and Style: Ensure the aesthetic aligns with your overall design vision, as rubber molding is available in a wide array of colors.

Step 2: Research Market Trends

Understanding current trends in rubber floor molding can give you a competitive edge. Investigate which styles and materials are gaining popularity in your target markets, particularly in regions like Africa, South America, and Europe.

- Sustainability: Eco-friendly materials are increasingly in demand; consider sourcing from suppliers who offer sustainable options.

- Durability: Look for innovations in rubber formulations that enhance longevity and performance.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions. A solid supplier relationship is crucial for long-term success.

Illustrative image related to rubber floor molding

- Certifications: Check for industry certifications that indicate quality standards (e.g., ISO, CE).

- Experience: Prefer suppliers with a proven track record in rubber floor molding, especially in your region.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, request samples of the rubber floor molding. This step allows you to evaluate the material’s quality, flexibility, and color accuracy.

- Testing: Consider conducting tests for durability, resistance to wear, and ease of installation.

- Comparison: Use samples to compare different suppliers, ensuring you choose the best quality for your needs.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, enter negotiations focusing on pricing, payment terms, and delivery schedules. Effective negotiation can significantly impact your bottom line.

- Bulk Discounts: Inquire about discounts for larger orders, which can lead to substantial savings.

- Payment Options: Establish clear payment terms that suit both parties, considering options like letters of credit for international transactions.

Step 6: Verify Logistics and Delivery Capabilities

Confirm the supplier’s logistics capabilities to ensure timely delivery of your rubber floor molding. Reliable shipping is vital to maintaining project timelines.

- Shipping Methods: Understand the available shipping options and their associated costs.

- Lead Times: Clarify lead times for production and delivery to manage your project schedule effectively.

Step 7: Establish Post-Purchase Support

After procurement, ensure there is a system in place for post-purchase support. This includes warranties, return policies, and customer service access.

- Warranties: Inquire about warranties covering defects or performance issues, providing peace of mind for your investment.

- Customer Service: Ensure that support channels are accessible for any inquiries or issues that may arise post-purchase.

By following this comprehensive sourcing checklist, B2B buyers can streamline their procurement process for rubber floor molding, ultimately leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for rubber floor molding Sourcing

What Are the Key Cost Components of Rubber Floor Molding?

When sourcing rubber floor molding, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of rubber used (e.g., thermoplastic rubber, natural rubber) significantly influences material costs. Higher-quality materials that offer durability and flexibility tend to command higher prices.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with higher wages will typically see increased costs in production, while automated manufacturing processes may reduce these expenses.

-

Manufacturing Overhead: This includes the costs associated with factory operations, utilities, and maintenance. Efficient factories may have lower overhead, which can translate to better pricing for buyers.

-

Tooling: Custom molds and tools for specific designs add to initial costs. Buyers looking for unique specifications should consider these expenses as part of their total investment.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but may increase costs. Certifications (e.g., ISO, ASTM) also add to the overhead due to compliance requirements.

-

Logistics: Shipping costs, including freight and insurance, are critical, particularly for international buyers. These can fluctuate based on distance, shipping methods, and fuel prices.

-

Margin: Supplier profit margins vary. Buyers should be aware of typical margins in their region to better assess pricing fairness.

How Do Price Influencers Affect Sourcing Decisions for Rubber Floor Molding?

Several factors influence pricing in the rubber floor molding market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs. Understanding a supplier’s MOQ can help buyers gauge potential savings.

-

Specifications and Customization: Custom designs or specific color requirements can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Premium materials and certifications often lead to higher prices but can enhance product longevity and performance, affecting long-term cost efficiency.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may charge more but offer better service and product assurance.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for calculating total landed costs. This affects budgeting and can influence negotiations.

What Are Effective Buyer Tips for Negotiating Rubber Floor Molding Prices?

When negotiating prices for rubber floor molding, international B2B buyers should consider the following strategies:

-

Leverage Volume Discounts: Consolidate orders to meet or exceed MOQs, thereby securing better pricing per unit.

-

Conduct Total Cost of Ownership Analysis: Evaluate the long-term costs associated with the product, including maintenance and replacement, rather than just the initial purchase price.

-

Negotiate Payment Terms: Flexible payment options can ease cash flow, allowing buyers to manage their budgets more effectively.

-

Research Market Prices: Stay informed about prevailing prices in the market to ensure negotiations are grounded in reality. Use this knowledge to challenge any perceived overpricing.

-

Understand Regional Pricing Nuances: Be aware of local economic factors that may influence pricing in different regions, especially when sourcing from Africa, South America, the Middle East, and Europe. Prices can fluctuate based on currency exchange rates, tariffs, and local demand.

Disclaimer on Indicative Prices for Rubber Floor Molding

Pricing for rubber floor molding can vary significantly based on numerous factors, including market conditions, supplier negotiations, and geographical differences. The figures mentioned in this analysis serve as a general guide and should not be considered definitive. Always consult with suppliers for the most accurate and current pricing tailored to specific needs.

Alternatives Analysis: Comparing rubber floor molding With Other Solutions

When considering flooring solutions, rubber floor molding is a popular choice due to its durability and aesthetic appeal. However, various alternatives exist that may better suit specific applications or preferences. Understanding these alternatives allows B2B buyers to make informed decisions based on their unique requirements.

Comparison Table

| Comparison Aspect | Rubber Floor Molding | Vinyl Wall Base | Wood Wall Base |

|---|---|---|---|

| Performance | Highly durable, resistant to moisture and scuffs | Good durability but less moisture-resistant | Natural appearance, but prone to warping |

| Cost | Moderate ($2.68 – $3.57/sq. ft.) | Lower ($2.00 – $3.99/sq. ft.) | Higher ($3.00 – $5.00/sq. ft.) |

| Ease of Implementation | Requires adhesive and proper cutting | Easy to install with adhesive or nails | More complex installation, may require finishing |

| Maintenance | Low maintenance, easy to clean | Low maintenance, but may discolor over time | Requires regular maintenance and refinishing |

| Best Use Case | Commercial spaces, gyms, and hospitals | Residential and light commercial settings | High-end residential or office environments |

What are the Advantages and Disadvantages of Vinyl Wall Base?

Vinyl wall base is a cost-effective alternative to rubber floor molding. It is lightweight and easy to install, making it suitable for both residential and commercial spaces. Vinyl is available in various colors and patterns, allowing for aesthetic flexibility. However, it is less durable than rubber, particularly in high-moisture areas, and may discolor over time.

How Does Wood Wall Base Compare to Rubber Floor Molding?

Wood wall base offers a natural and elegant look, making it a preferred choice for high-end residential or office environments. It can provide better insulation and a traditional aesthetic that rubber cannot match. However, wood is more susceptible to moisture damage and can warp or crack over time. Installation is also more labor-intensive, often requiring finishing processes to achieve the desired look.

Illustrative image related to rubber floor molding

Conclusion: How Can B2B Buyers Choose the Right Flooring Solution?

When selecting between rubber floor molding and its alternatives, B2B buyers should assess their specific needs, including the environment, aesthetic preferences, and budget constraints. Rubber floor molding excels in durability and low maintenance, making it ideal for high-traffic commercial applications. Conversely, if cost is a primary concern or if a natural aesthetic is desired, vinyl or wood may be better suited for residential or less demanding environments. By carefully considering these factors, buyers can select the flooring solution that best aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for rubber floor molding

What Are the Key Technical Properties of Rubber Floor Molding?

Understanding the essential technical properties of rubber floor molding is crucial for B2B buyers who need reliable, durable, and cost-effective flooring solutions. Here are some critical specifications to consider:

Material Grade

Rubber floor moldings are typically available in several grades, including commercial and residential. Commercial-grade rubber is engineered for high-traffic environments and offers enhanced durability and resistance to wear. The material’s grade impacts its lifespan and performance, making it vital for buyers to match the product to their specific usage requirements.

Thickness

The thickness of rubber molding can vary, commonly ranging from 1/8 inch to 1/4 inch. Thicker moldings provide better sound absorption and impact resistance, which can be particularly beneficial in settings like schools or hospitals. Buyers should assess the thickness relative to the expected foot traffic and environmental conditions to ensure optimal performance.

Shore Hardness

This measurement indicates the rubber’s hardness, typically assessed on the Shore A scale. A hardness rating between 60-90 is common for flooring applications. Softer moldings (lower Shore A ratings) provide better cushioning but may wear faster, while harder moldings offer greater durability. Choosing the right hardness is essential for balancing comfort and longevity in various settings.

Tolerance

Tolerance refers to the allowable variation in the dimensions of the molding. A tighter tolerance means that the rubber molding will fit better during installation, reducing gaps and potential issues down the line. For B2B buyers, understanding tolerance is crucial for ensuring compatibility with existing structures and minimizing installation complications.

Color Fastness

Color fastness indicates how well the rubber maintains its color when exposed to various environmental factors such as sunlight and cleaning agents. High color fastness is essential for maintaining the aesthetic appeal of the flooring over time, particularly in commercial spaces where appearance matters. Buyers should inquire about the color stability of the products they are considering.

Illustrative image related to rubber floor molding

What Are Common Trade Terms Used in Rubber Floor Molding Procurement?

Navigating the procurement of rubber floor molding involves familiarizing oneself with industry-specific terminology. Here are some essential terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rubber floor molding, this term often refers to companies that create custom moldings for specific projects or clients. Understanding OEM relationships can help buyers identify potential suppliers for tailored solutions.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs based on their needs and the supplier’s capabilities to ensure they acquire sufficient product without excess.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. When dealing with rubber floor molding, submitting an RFQ helps buyers compare costs and terms across different vendors, facilitating informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers engaged in cross-border procurement, as they dictate aspects such as shipping costs, risk, and delivery responsibilities.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the rubber floor molding industry, lead times can vary significantly based on customization, production schedules, and shipping logistics. Buyers should consider lead times when planning installations to avoid project delays.

Warranty

A warranty is a guarantee provided by the manufacturer concerning the quality and longevity of the product. In the rubber floor molding sector, warranties can vary in length and terms, and understanding these can help buyers assess the risk of defects or failures in their flooring investment.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing rubber floor molding, ensuring they select products that meet their specific needs and standards.

Navigating Market Dynamics and Sourcing Trends in the rubber floor molding Sector

What Are the Current Market Dynamics and Key Trends in the Rubber Floor Molding Sector?

The rubber floor molding market is witnessing significant transformation driven by several global factors. The increasing focus on sustainable building practices and the demand for durable, low-maintenance flooring options are paramount. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly prioritizing products that not only meet aesthetic and functional requirements but also align with sustainable practices.

Emerging trends in B2B sourcing include the adoption of digital platforms that streamline procurement processes. Technologies such as e-procurement systems and online marketplaces are reshaping how buyers engage with suppliers, enhancing efficiency and transparency. Additionally, the rise of smart building technologies is influencing the selection of materials, with rubber floor molding being favored for its acoustic properties and comfort underfoot.

International buyers are also responding to fluctuating raw material prices and supply chain disruptions. This has prompted a shift towards localized sourcing strategies, allowing companies to mitigate risks associated with long-distance shipping and tariffs. Furthermore, the growing trend of customization in flooring solutions is becoming more prevalent, encouraging manufacturers to offer tailored products that meet specific regional needs.

How Is Sustainability and Ethical Sourcing Shaping the Rubber Floor Molding Industry?

Sustainability is at the forefront of the rubber floor molding sector, with an increasing emphasis on reducing environmental impact throughout the supply chain. Buyers are now more conscious of the ecological footprint of their purchases, seeking materials that are recycled, biodegradable, or sourced from responsible suppliers.

Illustrative image related to rubber floor molding

Ethical sourcing practices are also gaining traction, as companies recognize the importance of maintaining transparency and accountability in their supply chains. Certifications such as LEED (Leadership in Energy and Environmental Design) and Cradle to Cradle signify that products meet stringent environmental standards, which can be a decisive factor for B2B buyers.

Moreover, the adoption of eco-friendly rubber compounds, such as those derived from reclaimed tires, is becoming a preferred choice among manufacturers. This not only helps in reducing waste but also appeals to customers looking to enhance their sustainability credentials. As the market evolves, the integration of sustainable practices will be critical for companies aiming to maintain competitive advantage and meet the growing demand for environmentally responsible products.

What Is the Historical Context of Rubber Floor Molding in B2B Sourcing?

The history of rubber floor molding dates back to the mid-20th century when it emerged as a practical solution for high-traffic areas requiring durable and easy-to-clean flooring options. Initially popular in commercial settings, the versatility and resilience of rubber began to gain traction in residential markets as well.

Illustrative image related to rubber floor molding

Over the decades, advancements in manufacturing technology have led to improved formulations that enhance performance characteristics such as flexibility, colorfastness, and resistance to wear and tear. The evolution of design aesthetics has also played a crucial role, with manufacturers introducing a wide array of colors and patterns to meet diverse consumer preferences.

As sustainability concerns became more pronounced in the late 20th century, the industry began shifting toward more eco-friendly materials and practices, setting the stage for the current market dynamics characterized by a focus on ethical sourcing and environmental responsibility. This historical context is essential for B2B buyers to understand the trajectory of the industry and the implications for future sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber floor molding

-

How do I choose the right rubber floor molding for my project?

Selecting the appropriate rubber floor molding involves considering several factors, including the type of facility (commercial or residential), the aesthetic preferences, and functional requirements. Assess the thickness, flexibility, and durability of the molding to ensure it meets your project’s demands. Additionally, consider the color and design options available, as these can significantly affect the overall appearance of the space. Consulting with a supplier can provide insights into the best choices based on your specific needs and local climate conditions. -

What is the best type of rubber molding for high-traffic areas?

For high-traffic areas, opt for commercial-grade rubber floor molding that is thicker and more durable, typically around 1/8 inch. Molding options designed for flexibility, such as those that can easily navigate corners and curves, are ideal. Look for products that are scuff and scratch-resistant, ensuring they maintain their appearance over time. Brands that specialize in commercial applications often have tailored solutions, so it’s beneficial to consult with manufacturers or suppliers who understand your specific environmental challenges. -

What are the typical minimum order quantities (MOQ) for rubber floor molding?

Minimum order quantities can vary significantly among suppliers, typically ranging from 100 to 500 linear feet, depending on the product type and manufacturer. For international orders, MOQs may also be influenced by shipping logistics and import regulations. It’s advisable to discuss your project requirements with suppliers upfront to negotiate favorable terms, especially if you’re looking for customization or bulk purchasing options that can help optimize costs. -

How can I ensure the quality of rubber floor molding from international suppliers?

To ensure quality, vet suppliers by checking their certifications and product testing standards. Request samples to evaluate the material’s durability, flexibility, and finish. It’s also crucial to review customer testimonials and case studies to gauge previous performance. Establishing a quality assurance agreement can further protect your interests, stipulating inspection protocols and return policies should the products not meet your specifications. -

What payment terms should I negotiate when sourcing rubber floor molding?

Payment terms can vary widely, but it’s common to negotiate for a deposit (typically 30% to 50%) upfront, with the balance due upon delivery or before shipping. Consider using secure payment methods such as letters of credit or escrow services to minimize risk. Discussing terms clearly and upfront helps avoid misunderstandings later, especially in international transactions where currency fluctuations can impact final costs. -

What logistics considerations should I keep in mind when importing rubber floor molding?

Logistics involve several critical factors, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s import regulations. Ensure all documentation, such as bills of lading and invoices, is complete and accurate to avoid delays. Additionally, consider potential tariffs or duties on imported goods, as these can significantly affect overall costs. -

Can rubber floor molding be customized to match specific design needs?

Yes, many manufacturers offer customization options for rubber floor molding, including colors, sizes, and profiles to fit specific design aesthetics. Discuss your requirements with suppliers to explore available customization options, including the possibility of creating unique molds for specialized applications. Be mindful that custom orders may have longer lead times and potentially higher costs, so plan accordingly. -

What are the environmental considerations when sourcing rubber floor molding?

When sourcing rubber floor molding, consider eco-friendly options that are made from recycled materials or have low VOC (volatile organic compounds) emissions. Research suppliers who prioritize sustainability in their manufacturing processes. Many products now come with certifications, such as LEED or GreenGuard, which can be beneficial for projects aiming for environmentally friendly design. Incorporating sustainable materials not only supports environmental goals but can also enhance your company’s reputation in the market.

Top 7 Rubber Floor Molding Manufacturers & Suppliers List

1. Roppe – Vinyl Wall Base A500

Domain: kofflersales.com

Registered: 1999 (26 years)

Introduction: Roppe Vinyl Wall Base-A500: Commercial grade 1/8″ vinyl, available in 120ft rolls & 4ft strips, box/30, on sale now, 10% off, starting at $48.51. Johnsonite | Tarkett Vinyl Wall Base-A505: Commercial grade 1/8″ vinyl, available in 120 ft rolls & 4 ft strips, box/30, on sale now, 20% off, starting at $188.97. Johnsonite | Tarkett Millwork Wall Base-A508: Available in 38 colors, highly durable, extr…

2. Johnsonite – Rubber Wall Base Molding

Domain: installerstore.com

Registered: 2002 (23 years)

Introduction: Johnsonite Rubber Wall Base – Rubber Baseboard Molding

– Available Heights: 4 inch and 6 inch

– Thickness: .125 inch

– Lengths: 4 foot strips, special order coils in 100 foot or 120 foot lengths

– Colors: Over 30 popular colors plus non-stock options

– Installation: Easy application with Cove Base Adhesive or Step Tape

– Features: Will not fade, scuff, crack or shrink; ideal for homes, offices, ga…

3. Rubber Baseboard Trim – Durable Commercial Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber baseboard trim is typically used in commercial applications, particularly in healthcare or manufacturing facilities that require frequent washdown procedures. It has evolved from traditional designs to include options that mimic MDF while providing durability. The product is available in various heights (4″, 6″) and styles, including flat and with a toe. It is noted for being pricey and can…

4. Armstrong Flooring – Flexible Thermoplastic Rubber Solutions

Domain: armstrongflooring.com

Registered: 1999 (26 years)

Introduction: This company, Armstrong Flooring – Flexible Thermoplastic Rubber Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Floorzz – Rubber Wall Base Molding

Domain: commercial.floorzz.com

Registered: 2014 (11 years)

Introduction: This company, Floorzz – Rubber Wall Base Molding, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Floor City – Rubber Wall Base

Domain: floorcity.com

Registered: 2002 (23 years)

Introduction: Rubber Wall Base is a versatile and practical solution for finishing walls with style and durability. It is designed to protect against scuffs, dings, and impact, offering a resilient barrier that enhances the overall aesthetic of any space.

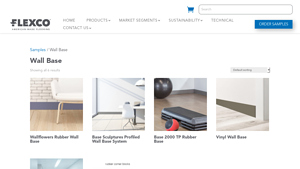

7. Flexco Floors – Wallflowers Rubber Wall Base

Domain: flexcofloors.com

Registered: 2001 (24 years)

Introduction: {“products”:[{“name”:”Wallflowers Rubber Wall Base”,”price”:”$0.00″},{“name”:”Base Sculptures Profiled Wall Base System”,”price”:”$0.00″},{“name”:”Base 2000 TP Rubber Base”,”price”:”$0.00″},{“name”:”Vinyl Wall Base”,”price”:”$0.00″},{“name”:”Health Design Wall Base”,”price”:”$0.00″},{“name”:”Rubber Corner Blocks”,”price”:”$0.00″}]}

Strategic Sourcing Conclusion and Outlook for rubber floor molding

How Can Strategic Sourcing Enhance Your Rubber Floor Molding Procurement?

In the competitive landscape of rubber floor molding, strategic sourcing emerges as a critical driver for success. By leveraging supplier relationships, B2B buyers can secure high-quality materials at competitive prices while ensuring timely deliveries. This is particularly vital for international buyers from Africa, South America, the Middle East, and Europe, where market demands and regulatory standards vary significantly.

Investing time in understanding the diverse product offerings—from commercial-grade options to custom designs—enables buyers to align their procurement strategies with their specific needs. The ability to source sustainably and economically not only enhances product quality but also contributes to brand reputation and customer satisfaction.

Looking ahead, the rubber floor molding market is poised for growth, driven by increasing demand across various sectors, including healthcare, education, and retail. As you consider your sourcing strategies, prioritize partnerships with suppliers who demonstrate innovation and responsiveness to market trends. Engage actively with your suppliers to explore new products and technologies that can elevate your offerings. Now is the time to make informed decisions that will position your business for long-term success in this evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.