Top 7 Yamaha New Oem Fuel Pump Asy 6E5-24410-03-00 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for yamaha new oem fuel pump asy 6e5-24410-03-00

In the ever-evolving landscape of global marine equipment, sourcing the Yamaha new OEM fuel pump assembly 6E5-24410-03-00 presents significant challenges for international B2B buyers. With varying market demands, fluctuating prices, and the necessity for reliable suppliers, understanding how to navigate this complex market is crucial for maintaining operational efficiency. This comprehensive guide addresses these key issues by providing insights into the specifications, applications, and compatibility of the Yamaha fuel pump assembly, alongside strategies for effectively vetting suppliers.

Throughout this guide, you will discover detailed information on the types of Yamaha fuel pump assemblies available, their specific applications across different outboard models, and a thorough analysis of pricing structures in diverse markets, including Africa, South America, the Middle East, and Europe. By equipping buyers with the tools to make informed purchasing decisions, this resource aims to simplify the sourcing process and ensure that you secure high-quality components that meet your operational needs.

Whether you are a distributor in Nigeria, a procurement manager in Germany, or an entrepreneur in Brazil, understanding the nuances of sourcing the Yamaha 6E5-24410-03-00 fuel pump assembly will empower you to make strategic decisions that enhance your business’s competitive edge in the global market.

Understanding yamaha new oem fuel pump asy 6e5-24410-03-00 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Yamaha 6E5-24410-03-00 | OEM part, compatible with multiple outboard models | Marine equipment suppliers, repair shops | Pros: Reliable performance, OEM quality. Cons: Limited compatibility with newer models. |

| Yamaha 6E5-24410-09-00 | Supersedes 6E5-24410-03-00, enhanced durability | Marine engine manufacturers, distributors | Pros: Improved longevity, OEM certified. Cons: Higher price point. |

| Yamaha 692-24410-00-00 | Compact design, suitable for smaller engines | Small boat repair shops | Pros: Cost-effective, easy installation. Cons: May not meet high-performance needs. |

| Yamaha 6EK-24410-00-00 | Advanced fuel efficiency features | High-performance marine applications | Pros: Optimized for performance, better fuel economy. Cons: More complex installation. |

| Yamaha 61U-24410-00-00 | Designed for larger outboard engines | Large marine vessels, commercial fleets | Pros: High capacity, robust design. Cons: Bulkier, may require more maintenance. |

What Are the Characteristics of the Yamaha 6E5-24410-03-00 Fuel Pump Assembly?

The Yamaha 6E5-24410-03-00 is a widely recognized OEM part specifically designed for various outboard engine models. This fuel pump assembly is characterized by its compatibility with multiple Yamaha engines, ensuring that businesses in marine repair and maintenance can cater to a diverse clientele. Buyers appreciate its reliability and OEM quality, making it a preferred choice for marine equipment suppliers and repair shops. However, its limited compatibility with newer engine models may restrict its market appeal.

How Does the Yamaha 6E5-24410-09-00 Differ from Other Variants?

The Yamaha 6E5-24410-09-00 serves as an upgraded version of the 6E5-24410-03-00, offering enhanced durability and performance. This variant is particularly appealing to marine engine manufacturers and distributors looking for reliable components that meet higher standards. While it boasts improved longevity and OEM certification, its higher price point may deter cost-sensitive buyers. Nevertheless, its reputation for quality makes it a valuable asset for businesses focused on long-term reliability.

What Are the Advantages of the Yamaha 692-24410-00-00 Model?

The Yamaha 692-24410-00-00 model is designed for smaller outboard engines, making it a popular choice among small boat repair shops. Its compact design and cost-effective pricing are significant advantages, allowing businesses to offer competitive service without compromising on quality. Installation is straightforward, which can lead to faster turnaround times for repairs. However, it may not satisfy the requirements of high-performance applications, limiting its use in more demanding marine environments.

Why Choose the Yamaha 6EK-24410-00-00 for High-Performance Needs?

For businesses focused on high-performance marine applications, the Yamaha 6EK-24410-00-00 is an optimal choice. This fuel pump assembly features advanced fuel efficiency technologies, making it suitable for those looking to enhance their engine’s performance. While it provides superior fuel economy and optimized functionality, the complexity of installation may be a consideration for some buyers. Marine operators looking to maximize performance will find this model particularly beneficial.

What Makes the Yamaha 61U-24410-00-00 Suitable for Larger Engines?

The Yamaha 61U-24410-00-00 is specifically designed for larger outboard engines, catering to commercial fleets and larger marine vessels. Its robust design and high-capacity features make it ideal for demanding applications where reliability is critical. While it may require more maintenance due to its bulkier nature, businesses that prioritize high performance and durability will find this model a worthwhile investment. Its suitability for larger engines ensures that it meets the needs of a specific segment within the marine industry.

Key Industrial Applications of yamaha new oem fuel pump asy 6e5-24410-03-00

| Industry/Sector | Specific Application of yamaha new oem fuel pump asy 6e5-24410-03-00 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Fishing | Replacement in Yamaha outboard engines for commercial fishing vessels | Ensures reliable fuel delivery, enhancing operational efficiency and reducing downtime. | Compatibility with specific Yamaha models and availability for bulk purchase. |

| Recreational Boating | Used in leisure boats to maintain optimal engine performance | Improves fuel efficiency and engine longevity, leading to cost savings in fuel and maintenance. | Availability of OEM parts and warranty options for peace of mind. |

| Agriculture | Utilized in agricultural boats for irrigation and transport in remote areas | Provides dependable performance in challenging environments, ensuring continuous operation. | Sourcing from reputable suppliers to ensure genuine OEM quality. |

| Transportation & Logistics | Employed in boats for transporting goods across waterways | Enhances logistical efficiency by ensuring reliable fuel systems in marine transport. | Assessing lead times and shipping options for international buyers. |

| Industrial Marine Applications | Used in commercial vessels for fishing, tourism, and cargo transport | Increases productivity and reduces operational costs through improved fuel management. | Evaluating technical support and service agreements post-purchase. |

How Is the Yamaha New OEM Fuel Pump Assembly Used in Marine & Fishing Industries?

In the marine and fishing industries, the Yamaha new OEM fuel pump assembly (6E5-24410-03-00) is integral to maintaining the performance of Yamaha outboard engines. It ensures a consistent and reliable fuel supply, which is crucial for commercial fishing operations that rely on boats for daily catches. By minimizing fuel delivery issues, businesses can significantly reduce downtime, which directly impacts profitability. Buyers in this sector should ensure compatibility with their specific Yamaha models and consider bulk purchasing options to manage costs effectively.

What Role Does the Yamaha Fuel Pump Play in Recreational Boating?

For recreational boating, the Yamaha fuel pump assembly enhances the overall boating experience by optimizing engine performance. This component is essential for ensuring fuel efficiency, which not only improves the boating experience but also leads to long-term savings on fuel and maintenance. International buyers, particularly from regions with vibrant recreational boating cultures, should prioritize the availability of OEM parts and warranty options to safeguard their investments.

How Is This Fuel Pump Assembly Beneficial for Agricultural Applications?

In agriculture, especially in remote areas where water transport is vital, the Yamaha fuel pump assembly is used in agricultural boats. These vessels often perform irrigation and transport tasks, requiring dependable fuel systems to ensure operational continuity. The assembly’s reliability in harsh conditions helps farmers maintain productivity and manage resources effectively. Buyers should focus on sourcing from reputable suppliers to guarantee the authenticity and quality of the OEM parts.

What Advantages Does the Fuel Pump Provide in Transportation & Logistics?

The transportation and logistics sector benefits from the Yamaha fuel pump assembly by enhancing the efficiency of marine transport operations. Boats used for transporting goods across waterways depend on reliable fuel systems to maintain schedules and reduce delays. For international buyers, assessing lead times and shipping options is crucial to ensure timely delivery and uninterrupted service.

How Does the Fuel Pump Assembly Support Industrial Marine Applications?

In industrial marine applications, the Yamaha new OEM fuel pump assembly is utilized in various commercial vessels, including those involved in fishing, tourism, and cargo transport. Its role in improving fuel management directly contributes to increased productivity and reduced operational costs. Buyers should evaluate the availability of technical support and service agreements post-purchase to ensure long-term satisfaction and performance.

3 Common User Pain Points for ‘yamaha new oem fuel pump asy 6e5-24410-03-00’ & Their Solutions

Scenario 1: Navigating Supply Chain Delays for Critical Components

The Problem: In the B2B landscape, international buyers often face significant challenges in sourcing critical components like the Yamaha new OEM fuel pump assembly (6E5-24410-03-00). This can be particularly problematic when dealing with supply chain disruptions caused by geopolitical issues, natural disasters, or logistical bottlenecks. Delays in receiving essential parts can halt operations, leading to lost revenue and strained relationships with customers who rely on timely service.

The Solution: To mitigate supply chain delays, B2B buyers should establish relationships with multiple suppliers. This strategy not only diversifies risk but also ensures that if one supplier faces delays, alternative sources can be tapped. Additionally, utilizing platforms that offer real-time inventory tracking can provide visibility into stock levels and estimated delivery times. Implementing a Just-In-Time (JIT) inventory system can also help by reducing the amount of stock held and ensuring that orders are placed only when necessary, thus minimizing the impact of delays on operations.

Scenario 2: Ensuring Compatibility with Existing Equipment

The Problem: Buyers often encounter compatibility issues when sourcing replacement parts like the Yamaha fuel pump assembly. With numerous models and variations in the Yamaha product line, selecting the correct part can be daunting. This is particularly true for businesses operating older models or specialized equipment that may not have clear specifications available online. Misordering can lead to wasted time, increased costs, and operational downtime.

The Solution: To address compatibility concerns, it is crucial for buyers to conduct thorough research before making a purchase. This includes cross-referencing the Yamaha part number with existing inventory and consulting with technical experts or manufacturers’ representatives. Creating a detailed specification sheet that includes model numbers, production years, and any unique features of the existing equipment can also streamline the ordering process. Additionally, investing in training for procurement staff on identifying and sourcing OEM parts can enhance overall efficiency.

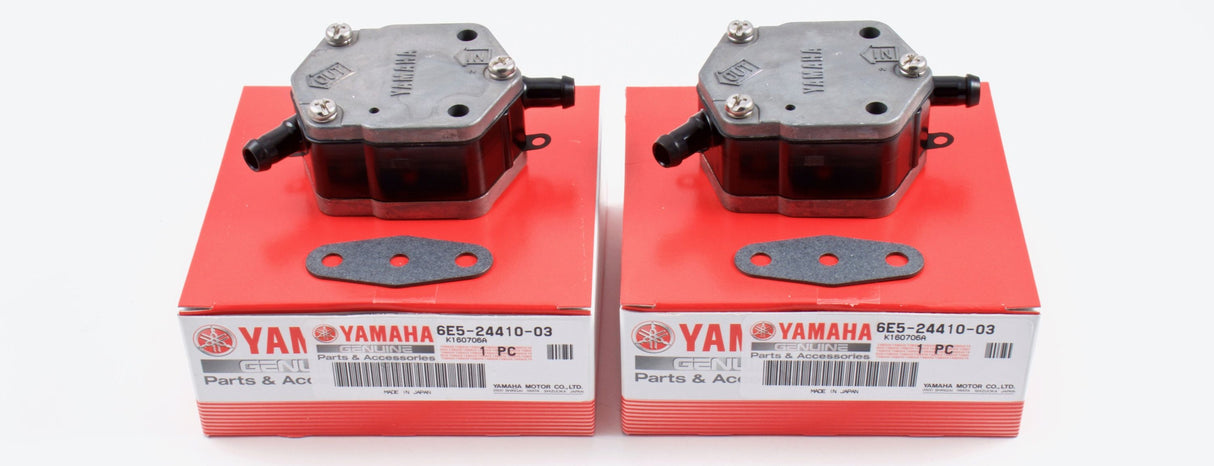

Scenario 3: Managing Quality Assurance in OEM Parts

The Problem: Quality assurance is a significant concern for B2B buyers, especially when dealing with OEM parts like the Yamaha fuel pump assembly. The market is rife with counterfeit or substandard products that can lead to performance issues, safety hazards, and increased maintenance costs. Buyers need assurance that the components they are purchasing meet stringent quality standards, particularly in industries such as marine or automotive where safety and reliability are paramount.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

The Solution: To ensure quality, buyers should prioritize sourcing from reputable dealers or directly from the manufacturer. Establishing partnerships with suppliers who provide certification and warranty for their products can enhance trust. Conducting regular audits of suppliers and requesting samples for testing before committing to larger orders can also help in maintaining quality standards. Additionally, implementing a feedback loop with end-users can provide valuable insights into the performance of the parts and help identify potential quality issues early on.

Strategic Material Selection Guide for yamaha new oem fuel pump asy 6e5-24410-03-00

What Are the Common Materials Used in Yamaha’s OEM Fuel Pump Assembly 6E5-24410-03-00?

When selecting materials for the Yamaha OEM Fuel Pump Assembly 6E5-24410-03-00, it’s essential to consider the specific properties and applications of common materials used in its construction. The right choice can significantly impact performance, durability, and compliance with international standards.

1. Aluminum Alloy

Key Properties: Aluminum alloys are lightweight, corrosion-resistant, and have good thermal conductivity. They typically have a temperature rating up to 150°C (302°F) and can withstand moderate pressures.

Pros & Cons: Aluminum is durable yet lightweight, making it suitable for applications where weight is critical. However, it may not be as strong as some steel alloys, leading to potential deformation under high stress. The manufacturing process is relatively straightforward, but it can be more expensive than some other materials.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for marine environments where saltwater exposure is common. However, care must be taken to ensure compatibility with fuels, as certain additives can cause corrosion.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys. In Africa and South America, local sourcing of aluminum may vary in availability and cost.

2. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 800°C or 1472°F) and pressures. It is known for its strength and durability.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to corrosion, making it suitable for harsh environments. However, it is heavier and more expensive than aluminum, and its manufacturing can be more complex due to the need for specialized tools.

Impact on Application: Stainless steel is compatible with a wide range of fuels and oils, making it a versatile choice for fuel pumps. Its robustness ensures that it can handle the stresses of operation in demanding conditions.

Considerations for International Buyers: Compliance with ASTM A240 standards is crucial for buyers in North America and Europe. Buyers in Africa and South America may need to consider local regulations regarding material sourcing and environmental impact.

3. Polyamide (Nylon)

Key Properties: Polyamide is a synthetic polymer known for its chemical resistance, flexibility, and ability to withstand temperatures up to 100°C (212°F). It is lightweight and has good tensile strength.

Pros & Cons: The primary advantage of polyamide is its resistance to chemical corrosion, making it suitable for fuel applications. However, it may not withstand high pressures and can degrade under prolonged exposure to UV light.

Impact on Application: Polyamide is often used in fuel pumps for components like seals and gaskets, where flexibility and chemical resistance are essential. Its compatibility with various fuels makes it a practical choice.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM D4066 for nylon materials. In regions like Africa and South America, the availability of high-quality polyamide may vary, impacting sourcing decisions.

4. Rubber Compounds

Key Properties: Rubber compounds are known for their elasticity and ability to withstand a wide range of temperatures (from -40°C to 120°C or -40°F to 248°F). They offer excellent sealing properties.

Pros & Cons: Rubber is effective for sealing applications due to its flexibility and resistance to various chemicals. However, it may not be suitable for high-temperature applications and can degrade over time, especially when exposed to oils and fuels.

Impact on Application: Rubber is commonly used in fuel pumps for O-rings and seals, ensuring tight connections to prevent leaks. Its compatibility with fuels makes it an essential material in the assembly.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM D2000 for rubber materials. In regions like Europe, the Middle East, and Africa, sourcing high-quality rubber compounds is essential to ensure performance and longevity.

Summary Table

| Material | Typical Use Case for yamaha new oem fuel pump asy 6e5-24410-03-00 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Body and structural components | Lightweight and corrosion-resistant | Less strong than steel alloys | Medium |

| Stainless Steel | Critical structural components | Excellent corrosion resistance and strength | Heavier and more expensive | High |

| Polyamide (Nylon) | Seals and gaskets | Chemical resistance and flexibility | Limited pressure resistance | Medium |

| Rubber Compounds | O-rings and seals | Effective sealing properties | Degrades over time, especially with fuels | Low |

This strategic material selection guide provides a comprehensive overview of materials suitable for the Yamaha OEM Fuel Pump Assembly 6E5-24410-03-00, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for yamaha new oem fuel pump asy 6e5-24410-03-00

What Are the Main Stages in the Manufacturing Process of Yamaha’s OEM Fuel Pump Assembly?

The manufacturing process of the Yamaha new OEM fuel pump assembly (SKU: 6E5-24410-03-00) involves several critical stages designed to ensure high performance and reliability. Each stage is meticulously executed to meet the stringent requirements of outboard engine applications.

-

Material Preparation

The process begins with the selection of high-quality materials, typically including durable plastics and metals that can withstand marine environments. These materials undergo rigorous inspection to confirm their specifications and quality before moving to the next stage. -

Forming

The forming process includes techniques such as injection molding for plastic components and stamping for metal parts. Advanced machinery is utilized to ensure precision and consistency in dimensions, which is crucial for the assembly’s overall performance. This stage is pivotal, as any discrepancies can lead to inefficiencies in the fuel pump’s operation. -

Assembly

During the assembly phase, components are put together in a controlled environment to minimize contamination. Skilled technicians follow detailed assembly protocols, which include the integration of seals, pumps, and electronic components. This phase is critical for ensuring that all parts work harmoniously, providing optimal fuel flow and pressure. -

Finishing

The finishing stage involves applying protective coatings and surface treatments to enhance durability and resistance to corrosion. This may include anodizing metal components or applying sealants to prevent fuel leakage. Quality checks are conducted at this stage to ensure that the assembly meets Yamaha’s high standards before it is packaged for distribution.

What Quality Assurance Measures Are Implemented in the Manufacturing of Fuel Pump Assemblies?

Quality assurance (QA) is fundamental in the manufacturing of the Yamaha fuel pump assembly, ensuring that each unit meets international standards and customer expectations.

-

International Standards Compliance

The manufacturing process adheres to ISO 9001 standards, which emphasize a quality management system focused on continuous improvement. Compliance with these standards is critical, particularly for international buyers who require assurance of product quality and reliability. -

Industry-Specific Certifications

In addition to ISO 9001, the fuel pump assembly may also meet certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards, ensuring that the product is safe and effective for use in various applications. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality criteria. This helps prevent defects from being introduced at the outset.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the assembly’s progress and quality. This includes dimensional checks and functional tests.

– Final Quality Control (FQC): Once the assembly is complete, it undergoes comprehensive testing, including pressure tests and performance evaluations, to ensure it operates according to design specifications.

Which Testing Methods Are Commonly Used in Quality Assurance for Fuel Pump Assemblies?

Several testing methods are employed to validate the performance and reliability of the fuel pump assembly:

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

- Hydraulic Testing: This method evaluates the assembly’s ability to withstand pressure without leakage. It simulates real-world operating conditions, ensuring that the pump will perform reliably in marine environments.

- Flow Rate Testing: This test measures the amount of fuel the pump can deliver over a specific period, ensuring it meets the required specifications for various outboard engines.

- Durability Testing: Components are subjected to stress tests to simulate long-term usage. This includes exposure to extreme temperatures and corrosive environments to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some effective strategies:

-

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance measures firsthand. This provides insights into the supplier’s commitment to quality and adherence to international standards. -

Quality Reports

Requesting detailed quality reports from suppliers can provide transparency regarding their quality control processes, including test results and compliance with international standards. This documentation serves as a valuable resource for buyers to evaluate supplier reliability. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can occur at various stages of production, offering an additional layer of assurance for buyers.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, it is vital to understand the nuances of quality control that may differ from local standards:

- Cultural and Regulatory Differences: Quality expectations can vary widely across regions. Buyers should familiarize themselves with local regulations and industry standards to ensure compliance.

- Communication Barriers: Language differences can lead to misunderstandings regarding quality requirements. Establishing clear communication channels and utilizing translation services can mitigate this risk.

- Logistics and Supply Chain Considerations: Delays or issues in shipping can affect the perceived quality of a product. Buyers should consider suppliers’ logistical capabilities and their ability to meet delivery timelines consistently.

By carefully evaluating these factors and implementing robust quality assurance measures, B2B buyers can confidently source the Yamaha OEM fuel pump assembly, ensuring they receive a product that meets their operational needs and maintains high standards of performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘yamaha new oem fuel pump asy 6e5-24410-03-00’

Introduction

This practical sourcing guide aims to assist B2B buyers in efficiently procuring the Yamaha new OEM fuel pump assembly (SKU: 6E5-24410-03-00). With a clear checklist, buyers can navigate the complexities of sourcing, ensuring they select the right supplier and product for their specific needs.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications required for the Yamaha fuel pump assembly. This includes compatibility with specific Yamaha outboard models, as this part is tailored for various engine types. Identifying these details upfront helps streamline the procurement process and ensures that you avoid costly errors.

Step 2: Research Potential Suppliers

Engage in thorough research to identify potential suppliers of the Yamaha fuel pump assembly. Use online platforms, industry directories, and trade shows to compile a list of reputable suppliers. Pay attention to their market presence and the range of products they offer, ensuring they specialize in OEM parts and have a solid reputation in the marine industry.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001, which indicates quality management practices. This step is crucial as it reflects the supplier’s commitment to quality and reliability, which are vital in the marine industry where safety is paramount.

Step 4: Request Product Samples

Always request product samples before making a bulk purchase. Assessing the quality of the Yamaha fuel pump assembly firsthand allows you to evaluate its construction, durability, and overall fit for your needs. Additionally, ensure the sample matches your specifications to avoid discrepancies once the order is placed.

Step 5: Review Pricing and Payment Terms

Collect quotes from different suppliers and analyze their pricing structures. Look beyond the unit price; consider shipping costs, bulk discounts, and payment terms. Understanding the total cost of ownership will help you make a more informed decision and negotiate better terms with your chosen supplier.

Step 6: Check Lead Times and Availability

Inquire about lead times and product availability to ensure timely delivery. Since the Yamaha fuel pump assembly may be in high demand, understanding when you can expect your order is crucial for planning. Suppliers should provide clear timelines and be transparent about any potential delays.

Step 7: Establish a Communication Channel

Maintain open lines of communication with your chosen supplier. Establishing a clear communication channel ensures that any issues can be addressed promptly, fostering a strong business relationship. Regular updates on order status, shipping details, and after-sales support will enhance your overall procurement experience.

By following these steps, you can effectively navigate the sourcing process for the Yamaha new OEM fuel pump assembly, ensuring a successful procurement experience tailored to your business needs.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

Comprehensive Cost and Pricing Analysis for yamaha new oem fuel pump asy 6e5-24410-03-00 Sourcing

What Are the Key Cost Components for the Yamaha New OEM Fuel Pump Assembly?

When analyzing the cost structure of the Yamaha new OEM fuel pump assembly (SKU: 6E5-24410-03-00), several components must be considered:

-

Materials: The primary materials used in the manufacturing of fuel pumps include high-grade plastics, metals, and rubber components. The quality of these materials affects both the durability and performance of the fuel pump, which can influence pricing.

-

Labor: Labor costs are incurred during the assembly process. Skilled labor is often required for precision assembly and quality checks, especially for OEM products that adhere to stringent manufacturing standards.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, facility maintenance, and equipment depreciation. These costs are typically distributed across all products manufactured, impacting the overall pricing.

-

Tooling: The initial investment in tooling and molds for production can be significant. This is especially true for complex parts that require custom tooling, which can increase the upfront costs but may be amortized over a larger production run.

-

Quality Control (QC): Ensuring that each fuel pump meets Yamaha’s quality standards involves rigorous testing and inspection processes. This adds to the production costs but is crucial for maintaining brand integrity and customer satisfaction.

-

Logistics: This includes the costs of transporting the fuel pumps from the manufacturing facility to the distribution points. Logistics costs can vary significantly based on the shipping method, distance, and any tariffs or duties applicable in different regions.

-

Margin: Finally, manufacturers and distributors will include a profit margin in their pricing structure. This margin reflects the value added by the supplier, including services such as warranty support and customer service.

How Do Price Influencers Impact the Cost of the Fuel Pump Assembly?

Several factors influence the pricing of the Yamaha fuel pump assembly, particularly for international B2B buyers:

-

Volume/MOQ: Pricing often decreases with higher order volumes. Suppliers may offer better rates for bulk purchases, which is beneficial for businesses looking to stock inventory.

-

Specifications/Customization: Custom specifications may lead to increased costs due to the need for specialized materials or manufacturing processes. Buyers should assess whether customization is necessary for their applications.

-

Materials: The choice of materials can significantly impact the price. Higher-quality materials may lead to a higher initial cost but can result in lower maintenance costs and longer lifespan, influencing the Total Cost of Ownership (TCO).

-

Quality and Certifications: Products that meet international quality standards or have specific certifications may command a premium price. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge higher prices due to their track record and customer service capabilities.

-

Incoterms: The terms of shipping and delivery can also influence costs. Understanding Incoterms is crucial for managing shipping responsibilities, duties, and risks, which can vary by region.

What Buyer Tips Should International B2B Buyers Consider?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe (e.g., Nigeria, Germany), the following tips can enhance cost efficiency:

-

Negotiation: Always engage in negotiations with suppliers. There may be room for discounts, especially for bulk orders or long-term contracts.

-

Total Cost of Ownership (TCO): Look beyond the initial price. Consider maintenance, repair, and replacement costs over the product’s lifecycle. A cheaper fuel pump may lead to higher costs in the long run if it requires frequent replacements.

-

Pricing Nuances: Be aware of regional pricing variations due to factors like shipping costs, tariffs, and local demand. Understanding these nuances can help in making informed purchasing decisions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Long-term partnerships often result in improved service and support.

-

Market Research: Conduct thorough research to compare prices across different suppliers. This can provide leverage during negotiations and help identify the most cost-effective options.

Conclusion

In summary, understanding the comprehensive cost structure and pricing dynamics of the Yamaha new OEM fuel pump assembly can significantly benefit international B2B buyers. By considering key cost components, price influencers, and strategic buyer tips, businesses can make informed purchasing decisions that align with their operational needs and financial goals. Always remember that indicative prices may fluctuate based on market conditions and supplier agreements, so it’s essential to stay informed and adaptable.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

Alternatives Analysis: Comparing yamaha new oem fuel pump asy 6e5-24410-03-00 With Other Solutions

When evaluating the Yamaha New OEM Fuel Pump Assembly 6E5-24410-03-00, it’s essential to consider viable alternatives in the market. This analysis will help international B2B buyers understand their options, weighing the strengths and weaknesses of various fuel pump solutions. Understanding these alternatives will enable buyers to make informed purchasing decisions based on their unique operational requirements.

Comparison Table

| Comparison Aspect | Yamaha New OEM Fuel Pump Asy 6E5-24410-03-00 | Alternative 1: Yamaha 6E5-24410-09-00 | Alternative 2: Yamaha 692-24410-00-00 |

|---|---|---|---|

| Performance | Reliable for various Yamaha outboard models | Improved design, supersedes 6E5-24410-03-00 | Adequate for smaller engines, lower flow rate |

| Cost | $48.82 | $129.99 | $45.99 |

| Ease of Implementation | Simple installation process for compatible models | Slightly more complex due to design changes | Straightforward installation |

| Maintenance | Low maintenance, OEM quality | Similar maintenance requirements | Lower durability may require more frequent checks |

| Best Use Case | Ideal for older Yamaha outboards | Best for newer models needing upgrades | Suitable for budget-conscious buyers with older engines |

Detailed Breakdown of Alternatives

Alternative 1: Yamaha 6E5-24410-09-00

This fuel pump assembly is a direct upgrade over the 6E5-24410-03-00, offering improved performance due to its refined design. While it comes at a higher price point, the additional cost may justify the enhanced reliability for newer models. The installation is slightly more complex, which could pose a challenge for less experienced technicians. This product is ideal for businesses looking to upgrade their outboard engines without compromising on quality.

Alternative 2: Yamaha 692-24410-00-00

Positioned as a more budget-friendly option, the Yamaha 692-24410-00-00 is suitable for smaller outboard engines. While it offers a lower price, it does not match the flow rate and performance of the other two alternatives. Maintenance needs are similar, but its lower durability could mean more frequent replacements. This alternative is best for businesses focused on cost savings, especially for older models that may not require high-performance pumps.

Conclusion

Choosing the right fuel pump assembly requires a clear understanding of your specific operational needs. For B2B buyers, factors such as engine compatibility, performance requirements, and budget constraints are crucial. The Yamaha New OEM Fuel Pump Assembly 6E5-24410-03-00 stands out for its reliability in older models, while the 6E5-24410-09-00 offers a higher performance alternative for newer engines. Conversely, the 692-24410-00-00 provides a cost-effective solution for businesses managing older, less demanding outboards. By carefully weighing these factors, buyers can select the best fuel pump solution that aligns with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for yamaha new oem fuel pump asy 6e5-24410-03-00

What Are the Key Technical Properties of the Yamaha OEM Fuel Pump Assembly 6E5-24410-03-00?

When sourcing the Yamaha OEM Fuel Pump Assembly 6E5-24410-03-00, understanding its technical specifications is crucial for ensuring compatibility and performance in various applications. Here are some essential properties to consider:

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

-

Material Composition

The fuel pump assembly is typically made from high-grade materials such as marine-grade aluminum and reinforced plastics. This material selection is vital for durability, especially in harsh marine environments where exposure to saltwater and varying temperatures can lead to corrosion and failure. Ensuring the right material can extend the lifespan of the pump, leading to lower replacement costs. -

Flow Rate

The flow rate, measured in gallons per hour (GPH), indicates how much fuel the pump can transfer within a specific timeframe. For the Yamaha 6E5-24410-03-00, understanding the flow rate is essential for matching it with engine requirements. A pump with an inadequate flow rate may lead to engine performance issues, while an excessively high rate can cause flooding. -

Pressure Rating

The pressure rating, often specified in pounds per square inch (PSI), is crucial for ensuring that the pump can deliver fuel at the required pressure for optimal engine performance. A pump that operates outside its pressure rating can lead to inefficient fuel delivery and potential engine damage. Therefore, it’s essential to ensure that the pump meets the specifications of the engine it will service. -

Electrical Specifications

This includes voltage and amperage ratings, which are vital for ensuring compatibility with the electrical system of the outboard motor. The Yamaha fuel pump typically operates at 12 volts, and knowing the amperage helps in selecting the right wiring and fuses. Mismatched electrical specifications can lead to pump failure or electrical fires. -

Dimensional Tolerances

Precise measurements of the pump’s dimensions, including length, width, and height, are crucial for installation. Tolerances should be within acceptable limits to ensure a proper fit within the engine compartment. Poor fit can result in vibration, noise, and premature wear. -

Compatibility with Engine Models

The 6E5-24410-03-00 is compatible with various Yamaha outboard models from the 1980s and 1990s. Knowing which models the pump is compatible with is crucial for B2B buyers to avoid costly mistakes and ensure the right part is supplied for the right application.

What Are the Common Trade Terms Related to the Yamaha Fuel Pump Assembly?

Understanding industry terminology is key for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the Yamaha OEM Fuel Pump Assembly:

-

OEM (Original Equipment Manufacturer)

OEM refers to products made by the original manufacturer of the equipment. In this case, the Yamaha fuel pump assembly is an OEM part, ensuring it meets the same specifications and quality standards as the original component that came with the outboard engine. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for inventory management and cost planning. For B2B buyers, negotiating MOQ can help reduce excess inventory and optimize cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant information for a specific product or service. This process is essential for comparing costs and making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps in understanding shipping responsibilities, risk transfer, and cost allocation, which is particularly important for international buyers from regions like Africa, South America, and Europe. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead time is essential for inventory management and planning, especially for businesses that rely on just-in-time inventory systems. -

Warranty and Return Policy

Warranty refers to the manufacturer’s guarantee on the product, while the return policy outlines the terms under which a product can be returned. Being aware of these terms can protect buyers against defective products and ensure satisfaction with their purchases.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing the Yamaha OEM Fuel Pump Assembly 6E5-24410-03-00, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the yamaha new oem fuel pump asy 6e5-24410-03-00 Sector

What Are the Current Market Dynamics and Key Trends for Yamaha New OEM Fuel Pump Asy 6E5-24410-03-00?

The global market for the Yamaha new OEM fuel pump assembly, specifically the 6E5-24410-03-00, is influenced by several key drivers that shape the purchasing decisions of international B2B buyers. First, the increasing demand for efficient and reliable marine engines, particularly in emerging markets such as Nigeria and Brazil, is propelling the sales of OEM parts. As recreational and commercial boating activities grow, the need for high-quality fuel pump assemblies becomes paramount. Additionally, advancements in manufacturing technology, including just-in-time (JIT) sourcing and digital supply chain management, are allowing buyers to streamline their procurement processes, ensuring timely delivery of critical components.

Furthermore, the market is witnessing a shift towards e-commerce platforms that facilitate direct transactions between manufacturers and international buyers. This trend is especially prominent in Europe and the Middle East, where buyers seek to leverage competitive pricing and enhanced product availability. The rise of online marketplaces not only promotes transparency in pricing but also allows buyers to compare various suppliers easily.

Emerging technologies such as data analytics and AI are also reshaping sourcing strategies. By utilizing predictive analytics, businesses can better forecast demand trends and optimize inventory management. This strategic approach not only mitigates risks associated with stock shortages but also enhances overall supply chain efficiency.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00

How Is Sustainability and Ethical Sourcing Reshaping the B2B Landscape for Fuel Pump Assemblies?

The increasing emphasis on sustainability and ethical sourcing is significantly impacting the B2B procurement landscape for products like the Yamaha 6E5-24410-03-00 fuel pump assembly. Buyers are increasingly aware of the environmental implications of their sourcing decisions, pushing suppliers to adopt more sustainable practices. This includes utilizing eco-friendly materials and ensuring that their manufacturing processes minimize waste and energy consumption.

The importance of ethical supply chains cannot be overstated, particularly in regions like Africa and South America, where corporate social responsibility (CSR) is becoming a critical component of business operations. Buyers are now seeking suppliers who can demonstrate compliance with international environmental standards and certifications, such as ISO 14001. These certifications not only enhance a supplier’s credibility but also align with the growing consumer preference for sustainable products.

Moreover, sourcing from manufacturers that prioritize ethical labor practices further strengthens a company’s brand reputation. As businesses strive to align with global sustainability goals, the demand for “green” certifications and materials in the fuel pump assembly sector is expected to rise. This trend presents an opportunity for B2B buyers to differentiate themselves in the market while contributing to a more sustainable future.

How Has the Market for Yamaha OEM Fuel Pumps Evolved Over Time?

The evolution of the Yamaha OEM fuel pump market, particularly the 6E5-24410-03-00 model, reflects broader trends within the marine industry. Initially introduced in the late 1980s, this fuel pump assembly was designed to meet the increasing demands for reliable performance in Yamaha outboard motors. Over the decades, technological advancements have led to significant improvements in fuel efficiency and engine performance, which in turn increased the longevity and reliability of these OEM parts.

As the marine industry faced growing environmental scrutiny, Yamaha responded by integrating more sustainable practices into their manufacturing processes. This shift not only enhanced product quality but also aligned with the changing preferences of international buyers who are increasingly prioritizing sustainability. Today, the Yamaha 6E5-24410-03-00 is recognized not just for its performance but also for its role in promoting environmentally responsible boating practices, making it a preferred choice among B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of yamaha new oem fuel pump asy 6e5-24410-03-00

-

How do I determine if the Yamaha OEM fuel pump assembly 6E5-24410-03-00 is compatible with my outboard engine?

To ensure compatibility, refer to the specifications and model numbers listed for the Yamaha 6E5-24410-03-00 fuel pump assembly. This product is designed for various Yamaha outboard models from 1984 to 2004, including 115HP, 130HP, and 150HP engines. You can also consult your engine’s manual or contact a Yamaha dealer for confirmation. It’s crucial to match the SKU and model year to avoid any operational issues. -

What are the advantages of sourcing Yamaha OEM parts like the 6E5-24410-03-00?

Sourcing genuine Yamaha OEM parts guarantees quality, durability, and optimal performance for your outboard engine. OEM parts are manufactured to meet Yamaha’s strict standards, reducing the risk of failure compared to aftermarket alternatives. Additionally, using OEM parts can help maintain your warranty and ensure compliance with local regulations, which is particularly important in international markets. -

What should I consider when vetting suppliers for Yamaha fuel pumps?

When vetting suppliers, consider their reputation, certifications, and customer reviews. Verify their experience in handling Yamaha parts and their ability to meet international shipping regulations. Request references or case studies from previous clients, particularly those in your region. Additionally, assess their response time and customer service quality, as these factors can significantly impact your supply chain efficiency. -

What are the typical payment terms for purchasing Yamaha fuel pumps in bulk?

Payment terms can vary by supplier but often include options such as net 30, net 60, or payment in advance. For bulk purchases, you may be able to negotiate better terms, such as discounts for early payment or extended credit. Ensure you clarify all payment conditions before finalizing the order to avoid misunderstandings. Consider using secure payment methods that offer buyer protection. -

What is the minimum order quantity (MOQ) for the Yamaha fuel pump assembly?

The minimum order quantity for the Yamaha 6E5-24410-03-00 fuel pump assembly can differ among suppliers. Some may have a MOQ of as low as 10 units, while others might require higher quantities to justify shipping costs. It’s advisable to discuss your specific needs with potential suppliers, as they may be flexible based on your purchasing history or future orders. -

How can I ensure quality assurance when sourcing Yamaha OEM parts?

To ensure quality assurance, request documentation such as certificates of authenticity or quality control reports from your supplier. Establish a clear return policy in case the parts do not meet your expectations. Additionally, consider ordering a sample batch before committing to a larger order, which allows you to inspect the products firsthand for quality and compatibility. -

What logistics considerations should I keep in mind when importing Yamaha fuel pumps?

When importing, factor in shipping costs, customs duties, and delivery timelines. Work with suppliers who provide reliable shipping options and trackable shipments to avoid delays. Be aware of any import regulations specific to your country, particularly in Africa, South America, or the Middle East, as these can affect the delivery process. Having a local customs broker can facilitate smoother transactions. -

Can I customize the Yamaha fuel pump assembly for specific applications?

While Yamaha OEM parts are typically standardized for specific models, some suppliers may offer customization options for bulk orders. This could include modifications to fit unique engine specifications or integrating additional features. Discuss your requirements with the supplier to see if they can accommodate your needs. Keep in mind that customization may lead to longer lead times and additional costs.

Top 7 Yamaha New Oem Fuel Pump Asy 6E5-24410-03-00 Manufacturers & Suppliers List

1. Yamaha – Fuel Pump Assembly

Domain: yamahaonlineparts.com

Registered: 2007 (18 years)

Introduction: This company, Yamaha – Fuel Pump Assembly, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Yamaha – 6E5-24410-09-00 Fuel Pump Assembly

Domain: wholesalemarine.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Yamaha 6E5-24410-09-00 Fuel Pump Assembly”, “sku”: “YAM-6E5-24410-09-00”, “price”: {“original”: “$149.49”, “discounted”: “$129.99”}, “availability”: “In Stock – Ships Today”, “shipping_info”: “Free shipping over $99”, “description”: “Genuine OEM Yamaha part. Supersedes 6E5-24410-03-00”, “warnings”: “California Residents: WARNING Cancer and Reproductive Harm – P65Warnings.ca.gov”,…

3. YAMAHA – OEM Fuel Pump & Hose Assembly

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”YAMAHA OEM FUEL PUMP & HOSE ASSY”,”Part Number”:”6E5-24410-03-00″,”Condition”:”Used”,”Condition Description”:”An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended.”,”Quantity Available”:1,”Item Description”:”Fits various Yamaha motors. Removed from a 2004 Yamaha LZ200TXRC HPDI #20 Y00449.”,”Price”:…

4. Yamaha – Fuel Pump Assembly

Domain: partsvu.com

Registered: 2015 (10 years)

Introduction: Yamaha Fuel Pump Assembly – 6E5-24410-03-00

SKU: 6E5-24410-03-00

Price: $48.82 (MSRP: $54.40)

Availability: Backordered

Description: A crucial component for ensuring consistent and reliable fuel delivery to Yamaha outboard engines. Designed for smooth and efficient operation under various marine conditions. Built with high-quality materials for durability and long-lasting performance. Easy install…

5. Yamaha Motors – 6E5-24410-03-00 Fuel Pump Assembly

Domain: crowleymarine.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “6E5-24410-03-00 Fuel Pump Assembly”, “brand”: “Yamaha Motors”, “sku”: “6E5-24410-03-00”, “price”: “$46.24”, “original_price”: “$54.40”, “discount”: “15%”, “country_of_origin”: “Japan”, “satisfaction_rating”: 4.59, “ratings_count”: 148, “in_stock”: true, “return_policy”: “30 day return policy”, “guaranteed_fitment_models”: 23, “parts_included”: [{“name”: “Plate Washer”, “sku”: “92…

6. Yamaha – Pump Assembly 6E5-24410-10

Domain: alternativedetailing.com

Registered: 2014 (11 years)

Introduction: Pump Assembly for Yamaha 6E5-24410-10

7. Yamaha – Fuel Pump Assembly

Domain: partzilla.com

Registered: 2003 (22 years)

Introduction: YAMAHA OEM SUPERSEDED BY 6E5244100300 FUEL PUMP ASY – 6E5-24410-04-00

Strategic Sourcing Conclusion and Outlook for yamaha new oem fuel pump asy 6e5-24410-03-00

In the competitive landscape of marine parts procurement, the Yamaha OEM Fuel Pump Assembly (SKU: 6E5-24410-03-00) stands out as a critical component for various outboard models. By prioritizing strategic sourcing, international B2B buyers can ensure they acquire high-quality, genuine parts that not only enhance operational efficiency but also extend the lifespan of marine equipment. The affordability of this fuel pump, priced competitively at around $48.82, coupled with the assurance of OEM quality, makes it a valuable addition to any supplier’s inventory.

For businesses in regions like Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and Germany—investing in strategic sourcing of genuine Yamaha parts offers a unique opportunity to build strong relationships with reliable suppliers. This approach not only mitigates risks associated with counterfeit products but also supports sustainable growth through consistent performance and customer satisfaction.

As we look to the future, it is essential for B2B buyers to leverage these insights and establish partnerships that prioritize quality and reliability. By doing so, they can secure a competitive edge in the marketplace and meet the growing demands of their clientele effectively. Embrace strategic sourcing today to position your business for success in the dynamic marine industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to yamaha new oem fuel pump asy 6e5-24410-03-00