Is Your 55 Gallon Barrel Uses Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 55 gallon barrel uses

In an increasingly interconnected world, sourcing versatile 55 gallon barrel uses poses a significant challenge for international B2B buyers. Whether your needs lie in storage solutions, waste management, or innovative upcycling projects, understanding the multifaceted applications of these barrels is crucial for making informed purchasing decisions. This comprehensive guide delves into the various types of 55 gallon barrels available in the global market, highlighting their applications across industries, from agriculture to manufacturing.

As you navigate this guide, you will find valuable insights into supplier vetting, enabling you to identify reliable partners that meet your specific requirements. We will also explore cost considerations, ensuring you understand the financial implications of your investments. Additionally, the guide offers practical advice on the safe handling and repurposing of barrels, catering to sustainability goals that are increasingly important in today’s business landscape.

By equipping yourself with this knowledge, you can make strategic decisions that enhance your operational efficiency while addressing local market needs in regions like Africa, South America, the Middle East, and Europe, including key markets such as Brazil and Saudi Arabia. Together, we will unlock the potential of 55 gallon barrels, transforming them from mere containers into essential assets for your business operations.

Understanding 55 gallon barrel uses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Storage Barrels | Made from steel or plastic, designed for heavy-duty use | Chemical storage, oil, and fuel transport | Pros: Durable, secure; Cons: Heavier, more expensive. |

| Rainwater Harvesting Barrels | Often made from recycled plastic, equipped with a spigot | Agriculture, landscaping, water conservation | Pros: Eco-friendly, cost-saving; Cons: Limited to water collection. |

| Upcycled Furniture Barrels | Transformed into chairs, tables, or planters; customizable | Hospitality, event planning, home décor | Pros: Unique designs, promotes sustainability; Cons: May require maintenance. |

| Food-Grade Barrels | Made of food-safe materials, often lined; airtight seal | Food storage, beverage transport | Pros: Safe for consumables, versatile; Cons: Higher cost, may require certification. |

| Waste Management Barrels | Designed for easy disposal, often color-coded | Waste management, recycling programs | Pros: Efficient waste segregation; Cons: Limited lifespan, may require frequent replacement. |

What Are Industrial Storage Barrels and Their B2B Relevance?

Industrial storage barrels are primarily constructed from steel or high-density polyethylene (HDPE), designed to withstand the rigors of heavy-duty applications. These barrels are ideal for storing chemicals, oils, and fuels, making them essential for manufacturing, logistics, and energy sectors. When purchasing, businesses should consider the barrel’s resistance to corrosion and its ability to maintain integrity under various environmental conditions. The investment in durable barrels can lead to long-term savings by minimizing leaks and spills.

How Do Rainwater Harvesting Barrels Benefit Businesses?

Rainwater harvesting barrels are typically made from recycled plastic and feature a spigot for easy access. They are widely used in agriculture and landscaping to collect and store rainwater, promoting sustainability and reducing water costs. Businesses involved in environmental management or those looking to improve their green credentials will find these barrels particularly advantageous. Key purchasing considerations include the barrel’s capacity, material durability, and compatibility with existing systems for effective water usage.

What Are Upcycled Furniture Barrels and Their Market Potential?

Upcycled furniture barrels are creatively repurposed into functional items such as chairs, tables, or planters. This innovative use appeals to businesses in the hospitality and event planning industries, where unique and sustainable décor is increasingly valued. Buyers should assess the design versatility and durability of these products, as well as the potential for customization to meet specific aesthetic requirements. Investing in upcycled furniture not only enhances brand image but also aligns with eco-conscious consumer trends.

Why Choose Food-Grade Barrels for Safe Storage?

Food-grade barrels are constructed from materials that meet safety standards for storing consumables. They are commonly used in the food and beverage industries for transporting and storing items such as grains, liquids, and ingredients. Buyers must ensure that these barrels are certified for food safety, as this can impact compliance with health regulations. The initial higher cost is often offset by the assurance of product safety and quality.

What Are the Advantages of Waste Management Barrels?

Waste management barrels are specifically designed for efficient waste disposal and are often color-coded for easy segregation. These barrels are crucial for businesses involved in waste management and recycling programs, helping them adhere to environmental regulations. When purchasing, companies should consider the barrel’s capacity, material longevity, and the frequency of waste disposal needs. While these barrels may have a limited lifespan, their role in promoting responsible waste management practices is invaluable.

Key Industrial Applications of 55 gallon barrel uses

| Industry/Sector | Specific Application of 55 Gallon Barrel Uses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Storage and transportation of hydrocarbons | Ensures safe containment and transport of fuels | Compliance with safety regulations, material integrity, and certifications |

| Agriculture | Rainwater harvesting and irrigation systems | Reduces water costs and conserves resources | Availability of food-grade barrels, durability, and weather resistance |

| Chemical Manufacturing | Mixing and storage of chemicals | Enhances efficiency in production processes | Chemical compatibility, structural integrity, and proper labeling |

| Food and Beverage | Bulk storage of liquids and ingredients | Improves supply chain efficiency | Food-grade certification, cleanliness, and resistance to contamination |

| Waste Management | Collection and recycling of hazardous waste | Promotes environmental sustainability | Compliance with hazardous waste regulations and proper disposal methods |

How Are 55 Gallon Barrels Used in the Oil and Gas Industry?

In the oil and gas sector, 55-gallon barrels are primarily utilized for the safe storage and transportation of hydrocarbons, including crude oil and various refined products. These barrels provide a robust solution to prevent spills and leaks, which can have severe environmental and financial implications. Buyers in this industry must ensure that the barrels meet stringent safety regulations and possess the necessary certifications for hazardous materials. Additionally, the integrity of the barrel material is crucial to withstand the corrosive nature of some hydrocarbons, making sourcing from reputable suppliers essential.

What Role Do 55 Gallon Barrels Play in Agriculture?

In agriculture, 55-gallon barrels are increasingly used for rainwater harvesting and irrigation systems. By collecting and storing rainwater, farmers can significantly reduce their water costs and ensure a sustainable water supply for their crops. This practice is particularly valuable in regions prone to drought, such as parts of Africa and South America. Buyers should look for barrels that are food-grade to ensure that no harmful chemicals leach into the water. Furthermore, durability and resistance to UV light are important factors to consider when sourcing these barrels for outdoor use.

Why Are 55 Gallon Barrels Important in Chemical Manufacturing?

Chemical manufacturers often employ 55-gallon barrels for mixing and storing various chemicals. These barrels facilitate efficient production processes by allowing for easy handling and transportation of materials. However, it is vital that these barrels are compatible with the specific chemicals being stored to prevent reactions that could lead to hazardous situations. Buyers in this sector should prioritize sourcing barrels that are labeled for chemical use and ensure they come with certifications verifying their structural integrity and safety standards.

How Do Food and Beverage Industries Utilize 55 Gallon Barrels?

In the food and beverage sector, 55-gallon barrels are commonly used for the bulk storage of liquids and ingredients, such as oils, syrups, and juices. Utilizing these barrels can streamline supply chain operations, enabling businesses to maintain inventory more efficiently. Buyers must ensure that the barrels are food-grade certified and thoroughly cleaned to prevent contamination. Additionally, sourcing barrels with features that resist corrosion and are easy to clean is crucial for maintaining product quality and safety.

What Is the Use of 55 Gallon Barrels in Waste Management?

In waste management, 55-gallon barrels are essential for the collection and recycling of hazardous waste. These barrels provide a controlled environment to safely store waste materials until proper disposal can be arranged. They play a crucial role in promoting environmental sustainability by facilitating the safe handling of potentially harmful substances. Buyers need to consider compliance with local and international hazardous waste regulations when sourcing these barrels. Proper labeling and handling procedures are also necessary to ensure safety and compliance throughout the waste management process.

3 Common User Pain Points for ’55 gallon barrel uses’ & Their Solutions

Scenario 1: Sourcing Quality 55 Gallon Barrels for Industrial Use

The Problem: B2B buyers often face challenges when sourcing 55-gallon barrels that meet their specific needs, especially in regions where availability may be limited. Inconsistent quality, uncertainty about previous contents, and compliance with local regulations can create barriers to efficient procurement. This situation is particularly frustrating for businesses in industries such as food and beverage, chemicals, and pharmaceuticals, where the integrity of the container is paramount for both safety and compliance.

The Solution: To overcome these sourcing challenges, buyers should establish relationships with reputable suppliers who specialize in industrial packaging. Prioritize suppliers that provide detailed documentation regarding the barrels’ previous contents and condition. Request certification or compliance reports that align with industry standards, such as ISO or FDA regulations. Additionally, consider using an online marketplace that aggregates suppliers, allowing for easier comparison of product specifications and prices. This approach not only streamlines the procurement process but also ensures that you receive high-quality barrels suitable for your specific applications.

Scenario 2: Properly Cleaning and Preparing Used Barrels for Repurposing

The Problem: Many companies opt to repurpose used 55-gallon barrels to save costs or support sustainability initiatives. However, improper cleaning can lead to contamination and safety hazards, particularly if the barrels previously held hazardous materials. B2B buyers may struggle with understanding the correct cleaning protocols and may inadvertently expose their employees or customers to harmful residues.

The Solution: It’s essential to develop a thorough cleaning protocol tailored to the history of each barrel. Start by determining the previous contents of the barrel; this will dictate the cleaning process. For barrels that held non-hazardous materials, a simple wash with biodegradable detergent and water may suffice. For those that contained chemicals, follow a multi-step cleaning approach, including a thorough rinse with hot water, followed by a vinegar solution to neutralize any lingering odors. Always conduct a test for residual contaminants, especially if the barrels will be used for food or agricultural applications. Providing staff with training on proper cleaning techniques will ensure safety and compliance, allowing for successful repurposing.

Scenario 3: Ensuring Compliance with Regulatory Standards for Barrel Usage

The Problem: As international regulations surrounding packaging and storage become increasingly stringent, B2B buyers must navigate complex compliance requirements when using 55-gallon barrels. This is particularly relevant for businesses operating across borders in regions like Africa, South America, and the Middle East, where regulations may vary significantly. Failure to comply can result in fines, product recalls, and damage to brand reputation.

The Solution: To manage compliance effectively, companies should stay informed about local and international regulations relevant to their industry. This includes understanding the requirements for materials used in barrels, labeling, and transportation. Collaborating with legal or regulatory consultants can provide clarity on compliance obligations specific to each market. Additionally, implementing a compliance management system can help track regulatory changes and ensure that all barrels used meet the necessary standards. Regular audits of storage practices and documentation can also safeguard against compliance risks, ensuring that your business operates smoothly in various regulatory environments.

Strategic Material Selection Guide for 55 gallon barrel uses

What Are the Key Properties of Different Materials Used for 55 Gallon Barrels?

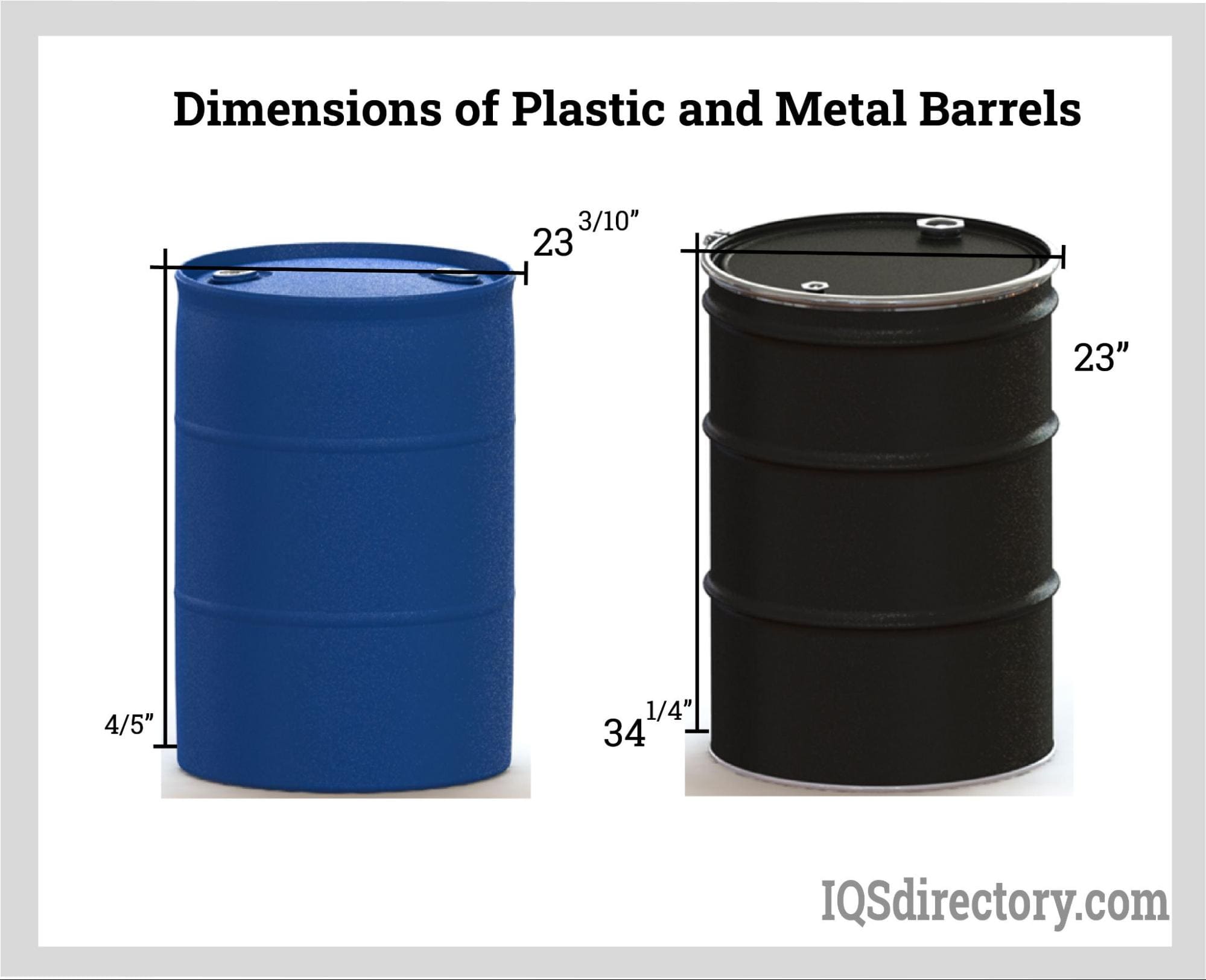

When selecting materials for 55-gallon barrels, businesses must consider various factors, including the intended use, environmental conditions, and regulatory compliance. The most common materials include steel, plastic, and fiber, each offering unique properties and applications.

Steel Barrels: What Are Their Advantages and Limitations?

Steel barrels are renowned for their durability and strength. They typically have a high-pressure rating and excellent corrosion resistance, especially when coated. This makes them suitable for storing hazardous materials, chemicals, and liquids. However, the weight of steel can be a drawback, making transportation more costly. Additionally, while they are resistant to many chemicals, they can corrode if exposed to moisture without proper treatment.

Illustrative image related to 55 gallon barrel uses

For international buyers, particularly in regions like Africa and the Middle East, compliance with standards such as ASTM and DIN is crucial. Many countries have regulations regarding the storage of hazardous materials, and steel barrels often meet these requirements. However, buyers should ensure that the barrels are certified for the specific media they intend to store.

Plastic Barrels: How Do They Compare in Terms of Cost and Versatility?

Plastic barrels are lightweight, cost-effective, and resistant to a wide range of chemicals, making them ideal for various applications, including food storage and agricultural use. They typically have lower temperature and pressure ratings compared to steel, but their corrosion resistance is excellent. The manufacturing process for plastic barrels is generally less complex, allowing for quicker production times.

However, plastic barrels may not be suitable for high-pressure applications or for storing certain solvents that can degrade the material. For B2B buyers in South America and Europe, it is essential to consider the barrel’s history, especially regarding previous contents, to ensure safety and compliance with local regulations.

Illustrative image related to 55 gallon barrel uses

Fiber Drums: What Are Their Unique Properties and Applications?

Fiber drums are made from compressed paper or cardboard, offering a lightweight alternative to metal and plastic barrels. They are often used for dry goods and non-hazardous materials. Their porous nature allows for breathability, which can be beneficial for certain products. However, fiber drums are not suitable for liquids and have limited resistance to moisture and chemicals.

From a B2B perspective, fiber drums may appeal to companies focused on sustainability, as they are often recyclable. However, buyers should be aware of their limitations regarding strength and moisture exposure, particularly in humid climates like those found in parts of Africa and South America.

Summary Table of Material Selection for 55 Gallon Barrels

| Material | Typical Use Case for 55 Gallon Barrel Uses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Storing hazardous chemicals and liquids | High durability and corrosion resistance | Heavy and may corrode without treatment | High |

| Plastic | Food storage, agricultural use | Lightweight and cost-effective | Limited pressure rating and chemical compatibility | Medium |

| Fiber | Packaging dry goods and non-hazardous materials | Lightweight and recyclable | Not suitable for liquids and moisture-sensitive | Low |

In conclusion, selecting the right material for 55-gallon barrels requires careful consideration of the intended application, regulatory compliance, and environmental factors. By understanding the properties and limitations of each material, international B2B buyers can make informed decisions that align with their operational needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon barrel uses

What Are the Key Stages in the Manufacturing Process of 55-Gallon Barrels?

The manufacturing process of 55-gallon barrels involves several key stages that ensure the product meets industry standards and customer expectations. Understanding these stages is crucial for international B2B buyers who need reliable and compliant products.

1. Material Preparation: What Raw Materials Are Used?

The first stage in the manufacturing process is the selection and preparation of raw materials. For metal barrels, high-quality steel or aluminum is typically used, while plastic barrels are made from high-density polyethylene (HDPE). The materials are sourced from reputable suppliers to ensure consistency in quality. Steel sheets are cut to size and treated to prevent rust, while HDPE pellets are prepared for molding.

Illustrative image related to 55 gallon barrel uses

2. Forming: How Are Barrels Shaped?

In the forming stage, metal sheets are either rolled into cylindrical shapes or molded into barrels, depending on the material. For metal barrels, a process called deep drawing is often used, where sheets are pressed into molds to form the barrel shape. For plastic barrels, injection molding is employed, where molten plastic is injected into a mold. This stage is critical as it determines the structural integrity and dimensions of the barrels.

3. Assembly: What Are the Key Components?

The assembly stage involves attaching various components, such as lids and bungs, which are essential for sealing the barrels. For metal barrels, welding techniques may be utilized to secure the seams, while plastic barrels often use heat sealing or mechanical fastening. This stage ensures that the barrels can withstand pressure and are leak-proof, which is vital for transporting liquids.

4. Finishing: What Techniques Ensure Quality?

Finishing processes include surface treatment, painting, and labeling. Metal barrels may undergo galvanization to enhance corrosion resistance, while plastic barrels are often UV-treated to prevent degradation from sunlight. High-quality paints and coatings are applied to ensure durability and aesthetic appeal. This stage also involves quality checks to ensure that the barrels meet specific requirements.

Illustrative image related to 55 gallon barrel uses

How Is Quality Assurance Implemented in Barrel Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that barrels meet international and industry-specific standards. For B2B buyers, understanding these QA measures is vital for making informed purchasing decisions.

International Standards: Which Certifications Should Buyers Look For?

One of the key international standards for quality management systems is ISO 9001. This certification indicates that a manufacturer adheres to quality management principles, including strong customer focus, the involvement of top management, and a process approach. In addition to ISO 9001, industry-specific certifications such as CE marking (European Conformity) and API (American Petroleum Institute) certifications are also essential. These certifications demonstrate compliance with safety and environmental regulations, particularly for barrels used in hazardous material transportation.

Quality Control Checkpoints: What Are the Key Stages?

Quality control (QC) is typically implemented at various checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any defective materials are rejected or returned to suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to assess dimensional accuracy, structural integrity, and other critical parameters. This ensures that any deviations from the standards can be corrected in real-time.

-

Final Quality Control (FQC): Once the barrels are assembled, a final inspection is conducted to check for leaks, dimensional accuracy, and surface quality. This stage often includes pressure testing for metal barrels and visual inspections for plastic barrels.

What Common Testing Methods Are Used in Barrel Manufacturing?

To ensure that the barrels meet safety and quality standards, various testing methods are employed:

-

Hydrostatic Testing: For metal barrels, this involves filling the barrel with water and pressurizing it to check for leaks and structural integrity.

-

Visual Inspection: A thorough visual examination is conducted to identify any surface defects, such as dents, rust, or improper welds.

-

Dimensional Testing: This ensures that the barrels conform to specified measurements, such as height, diameter, and volume.

-

Chemical Resistance Testing: For barrels intended for chemical storage, tests are conducted to ensure that the materials can withstand exposure to various substances without degrading.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source 55-gallon barrels should take proactive steps to verify the quality control processes of potential suppliers:

-

Conduct Supplier Audits: Regular audits of suppliers can help assess their manufacturing processes, quality control measures, and compliance with international standards. This is particularly important for buyers in regions such as Africa and South America, where quality assurance practices may vary.

-

Request Quality Reports: Suppliers should provide documentation that outlines their quality control processes, including results from IQC, IPQC, and FQC stages. These reports can help buyers understand the consistency and reliability of the products.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for international buyers who may not have the resources to conduct on-site inspections.

What Are the QC Nuances for International B2B Buyers?

International buyers must navigate specific challenges when it comes to quality control:

-

Understanding Local Regulations: Different regions may have varying regulations regarding barrel manufacturing and safety standards. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Differences in Quality Expectations: Cultural perceptions of quality can differ significantly. Buyers from Europe may have higher expectations regarding quality assurance compared to those from other regions. Clear communication regarding quality standards is essential.

-

Language Barriers: Language differences can create challenges in understanding quality reports and specifications. Buyers should ensure they have access to translated documents or use bilingual representatives to facilitate communication.

Conclusion: Why Manufacturing and Quality Assurance Matter for B2B Buyers

In summary, understanding the manufacturing processes and quality assurance measures for 55-gallon barrels is essential for international B2B buyers. By focusing on key manufacturing stages, relevant quality standards, and effective verification methods, buyers can ensure they select reliable suppliers that meet their specific needs. This knowledge not only enhances supply chain efficiency but also helps mitigate risks associated with product quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon barrel uses’

This guide is designed to assist B2B buyers in effectively sourcing and utilizing 55-gallon barrels across various applications. Whether for storage, transportation, or innovative upcycling projects, following this checklist will ensure a streamlined procurement process and optimal use of these versatile containers.

Step 1: Identify Your Specific Needs

Understanding the intended use of the barrels is essential. Different applications, such as chemical storage, water collection, or creative projects, may require specific materials or barrel types (e.g., plastic vs. metal). Make a list of your requirements, including any industry regulations or safety standards that must be adhered to.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers specializing in 55-gallon barrels. Look for established companies with a solid reputation and experience in your specific market region, especially if you are sourcing from Africa, South America, the Middle East, or Europe. Utilize platforms like LinkedIn, trade shows, and industry forums to gather insights and recommendations.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications. Compliance with international standards such as ISO 9001 or specific industry regulations is crucial for ensuring product quality and safety. Request documentation proving their adherence to safety and environmental regulations, particularly if the barrels are intended for food-grade or hazardous material storage.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to assess the quality, durability, and suitability of the barrels for your specific application. Check for any signs of wear, leaks, or contamination, and ensure that they meet your technical specifications.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms and conditions that protect your interests. Discuss pricing, payment terms, delivery schedules, and return policies. It’s also wise to include clauses regarding liability for defective products, especially if the barrels are used for hazardous materials.

Step 6: Plan for Logistics and Transportation

Consider the logistics of transporting the barrels to your location. Evaluate the supplier’s shipping capabilities, costs, and estimated delivery times. Ensure that they can accommodate any specific handling requirements, especially if you are sourcing from international suppliers.

Step 7: Implement a Quality Assurance Process

After receiving the barrels, implement a quality assurance process to ensure they meet your requirements. This may include regular inspections, compliance checks, and maintenance protocols. Establishing a quality management system can help mitigate risks and ensure long-term satisfaction with your procurement.

By following this step-by-step checklist, B2B buyers can ensure a successful sourcing process for 55-gallon barrels, maximizing their utility and value in various applications.

Comprehensive Cost and Pricing Analysis for 55 gallon barrel uses Sourcing

What Are the Key Cost Components in Sourcing 55 Gallon Barrels?

Understanding the cost structure of 55-gallon barrels is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of material—metal (steel or plastic) or composite—greatly influences cost. Metal barrels typically incur higher raw material costs but offer durability and reusability. Plastic barrels, while often cheaper, may not have the same longevity.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as some in Africa and South America, buyers may find more competitive pricing. However, in Europe and the Middle East, labor costs could inflate the overall price.

-

Manufacturing Overhead: This includes utilities, facility costs, and other indirect expenses. Efficient manufacturing processes can help reduce these costs, which may be passed on to buyers.

-

Tooling: Customization of barrels, such as specific fittings or colors, requires specialized tooling, which can lead to higher initial costs.

-

Quality Control: Ensuring barrels meet safety and quality standards involves additional costs. Buyers should consider the certifications (e.g., UN certification for hazardous materials) when evaluating overall pricing.

-

Logistics: Shipping costs can vary based on distance, transport methods, and Incoterms used. Understanding the logistics involved is essential for budgeting.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary based on market demand, competition, and relationship with the buyer.

How Do Price Influencers Affect the Cost of 55 Gallon Barrels?

Several factors can influence the price of 55-gallon barrels, making it essential for buyers to understand these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Custom specifications can increase costs significantly. Buyers should evaluate whether customization is necessary or if standard barrels will suffice.

-

Material Quality and Certifications: Higher quality materials and certifications often come at a premium. However, they may offer better long-term value through durability and compliance with regulations.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with proven track records may charge more, but they often provide better service and quality assurance.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects shipping responsibilities and costs. Buyers should choose terms that minimize their total cost while ensuring reliable delivery.

What Buyer Tips Can Help Reduce Costs in Sourcing 55 Gallon Barrels?

To maximize cost-efficiency and minimize total cost of ownership (TCO), buyers should consider the following strategies:

-

Negotiate Terms: Always negotiate pricing, payment terms, and shipping costs. Suppliers may offer better rates for repeat business or long-term contracts.

-

Assess Total Cost of Ownership: Evaluate not just the purchase price but also logistics, storage, and potential waste. This comprehensive view helps identify the best value.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, import duties, and taxes that can affect overall pricing. Engage local experts to navigate these complexities.

-

Leverage Local Suppliers: In regions like Africa and South America, sourcing from local manufacturers can reduce shipping costs and lead times.

-

Maintain Clear Communication: Establishing a solid relationship with suppliers can lead to better pricing and service. Regular communication ensures that both parties understand expectations and requirements.

Conclusion: What Should Buyers Remember About Pricing for 55 Gallon Barrels?

While costs can fluctuate based on various factors, international B2B buyers should remain vigilant in their sourcing strategies. By understanding cost components, price influencers, and negotiation tactics, buyers can effectively manage their budgets and ensure they receive the best value for their investments. Always approach pricing discussions with a clear understanding of the total cost of ownership and the specific needs of your business.

Disclaimer: Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other external factors. Always consult with suppliers for the most current pricing.

Alternatives Analysis: Comparing 55 gallon barrel uses With Other Solutions

Introduction to Alternatives in Storage and Transportation Solutions

In the realm of industrial storage and transportation, the use of 55-gallon barrels is widespread due to their versatility and robustness. However, various alternatives are available that may better suit specific business needs, especially for companies in regions like Africa, South America, the Middle East, and Europe. This analysis compares the traditional 55-gallon barrel against two viable alternatives: intermediate bulk containers (IBCs) and collapsible containers. Each option presents unique advantages and disadvantages, making it essential for B2B buyers to consider their specific requirements when selecting a solution.

Comparison Table

| Comparison Aspect | 55 Gallon Barrel Uses | Intermediate Bulk Container (IBC) | Collapsible Container |

|---|---|---|---|

| Performance | Durable, versatile, and reusable; suitable for liquids and solids. | High capacity (up to 330 gallons), designed for bulk liquids; excellent for transport. | Lightweight, space-efficient, and ideal for dry goods; easy to handle. |

| Cost | Generally low initial cost; can vary based on material and condition. | Higher initial investment, but cost-effective for bulk storage. | Moderate cost; savings in shipping and storage when collapsed. |

| Ease of Implementation | Simple to use; requires minimal training. | Requires equipment for loading and unloading; may need more handling knowledge. | Easy to set up and use; minimal training required. |

| Maintenance | Regular cleaning needed; can rust if not properly maintained. | Low maintenance; durable materials resist damage. | Requires cleaning; durability depends on material. |

| Best Use Case | Ideal for small to medium-volume storage and transport of liquids and solids. | Best for large-scale operations needing bulk liquid storage. | Suitable for shipping and storing dry goods, especially in limited space. |

Detailed Breakdown of Alternatives

What are Intermediate Bulk Containers (IBCs)?

Intermediate bulk containers (IBCs) are large containers designed for the bulk storage and transport of liquids and granulated substances. They typically have a capacity of 330 gallons and are made from durable materials such as plastic or metal. IBCs are often stackable, which helps save space during transport and storage.

Pros: The main advantages of IBCs include their high capacity, which reduces the frequency of refills, and their robust design that can withstand harsh conditions. Their compatibility with various liquids makes them versatile for different industries.

Illustrative image related to 55 gallon barrel uses

Cons: However, the initial investment is higher compared to 55-gallon barrels, and they may require specialized handling equipment for loading and unloading. Businesses must also consider the need for additional training for staff to manage these larger containers effectively.

What are Collapsible Containers?

Collapsible containers are lightweight and can be folded down when not in use, making them an excellent option for companies looking to optimize storage space. Typically made from durable plastic, these containers are designed for dry goods and can often be nested within each other.

Pros: The primary advantage of collapsible containers is their space efficiency. When collapsed, they occupy significantly less space, reducing shipping costs. They are also easy to set up and disassemble, making them user-friendly.

Cons: On the downside, collapsible containers are generally not suited for liquids, limiting their application. Additionally, while they are durable, their longevity can be affected by the materials used, necessitating careful selection based on the intended use.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting between 55-gallon barrels, IBCs, and collapsible containers, B2B buyers should consider several factors, including the type of goods being stored or transported, the volume required, cost-effectiveness, and ease of handling. For businesses dealing with smaller quantities or a variety of products, 55-gallon barrels might still be the ideal choice. However, for operations requiring bulk storage or those with limited space, IBCs or collapsible containers may offer significant advantages. Ultimately, the decision should align with the operational needs and logistical capabilities of the business to ensure optimal efficiency and cost savings.

Essential Technical Properties and Trade Terminology for 55 gallon barrel uses

What Are the Key Technical Properties of 55 Gallon Barrels?

When selecting 55-gallon barrels for industrial applications, understanding their technical properties is essential for ensuring compatibility with specific needs. Here are some critical specifications to consider:

-

Material Grade

Most 55-gallon barrels are constructed from steel or high-density polyethylene (HDPE). Steel barrels are often preferred for their durability and resistance to impact, while HDPE barrels are lighter and resistant to corrosion. The choice of material affects not only the barrel’s lifespan but also its suitability for storing various substances, including hazardous materials. -

Weight Capacity

The weight capacity of a 55-gallon barrel is a crucial specification, particularly for industries involved in transporting heavy liquids or solids. Steel barrels typically have a higher weight tolerance compared to plastic ones. Ensuring that the selected barrel can handle the intended contents without risk of failure is vital for safety and compliance. -

Seal Integrity

The ability of the barrel to maintain a secure seal is critical for preventing leaks and contamination. Barrels may come with different types of closures (e.g., screw tops, bungs) that determine their sealing effectiveness. A robust seal is essential for hazardous materials, as leaks can lead to environmental hazards and regulatory violations. -

Temperature Resistance

Different materials offer varying levels of resistance to temperature fluctuations. Steel barrels can withstand higher temperatures, making them suitable for storing hot liquids. In contrast, HDPE barrels may warp under extreme heat. Understanding the temperature resistance of the barrel material is essential for maintaining the integrity of the stored contents. -

Compliance Standards

Barrels often need to meet specific compliance standards, such as UN certification for hazardous materials. This certification ensures that the barrel can safely contain and transport dangerous goods. Buyers should verify that the barrels meet local and international regulations to avoid legal issues and ensure safety. -

Recyclability

The recyclability of the barrel material is becoming increasingly important in a sustainable business environment. Steel barrels can be recycled multiple times, while HDPE is also recyclable but may have limitations based on local facilities. Understanding the environmental impact of barrel materials can influence purchasing decisions, especially for companies focused on sustainability.

What Are Common Trade Terms Related to 55 Gallon Barrels?

In the B2B world, familiarity with trade terminology can enhance communication and negotiation efficiency. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are marketed by another company. In the context of barrels, an OEM might produce barrels that are branded and sold under a different company’s name, influencing pricing and availability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for budget planning and inventory management, as it can affect purchasing strategies for companies that require smaller quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specified products. For 55-gallon barrels, an RFQ helps businesses compare prices, terms, and conditions from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and risk transfer. Understanding Incoterms is crucial for companies involved in global trade of barrels to ensure clarity in contracts. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the products. For businesses requiring timely delivery of 55-gallon barrels, understanding lead times is essential for inventory management and operational efficiency. -

Beverage Grade vs. Industrial Grade

These terms differentiate between barrels intended for food and beverage use versus those meant for industrial applications. Beverage-grade barrels are manufactured with strict hygiene standards, while industrial-grade barrels might not meet these standards but are suitable for non-consumable liquids. Identifying the correct grade is vital for compliance and safety in storage applications.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon barrel uses Sector

What Are the Key Market Trends Affecting 55 Gallon Barrel Uses?

The market for 55-gallon barrels is experiencing significant transformation driven by various global factors. One of the primary drivers is the increasing demand for bulk storage solutions across industries such as chemicals, food and beverage, and pharmaceuticals. In regions like Africa and South America, the growth of the agricultural sector has spurred demand for barrels for storage and transportation of liquids and solids. Additionally, the rise of e-commerce is pushing manufacturers to seek efficient packaging and logistics solutions, further amplifying the need for durable and versatile barrels.

Technological advancements are reshaping sourcing trends, with an increasing emphasis on digital supply chain management tools. These technologies enable international buyers to streamline procurement processes, track shipments in real-time, and optimize inventory levels. Moreover, the COVID-19 pandemic has accelerated the adoption of e-procurement platforms, allowing buyers from regions such as the Middle East and Europe to access a wider range of suppliers and negotiate better deals. Emerging trends also include the integration of IoT devices for monitoring barrel conditions and ensuring compliance with safety standards, enhancing operational efficiency.

How Is Sustainability Influencing Sourcing Decisions for 55 Gallon Barrels?

Sustainability is becoming a critical consideration in the sourcing of 55-gallon barrels. Environmental concerns are driving businesses to seek eco-friendly solutions, and the barrel industry is responding with innovative materials and designs. Buyers are increasingly looking for barrels made from recycled materials or those that can be repurposed for other uses, such as rainwater collection or composting. This shift not only helps reduce waste but also aligns with global sustainability goals.

Ethical sourcing is equally vital, with businesses prioritizing suppliers that adhere to sustainable practices and fair labor standards. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wooden barrels are becoming essential for buyers wanting to ensure their supply chains are responsible. By choosing certified suppliers, businesses can mitigate risks associated with environmental damage and promote corporate social responsibility, which is particularly important for companies targeting environmentally conscious consumers in Europe and North America.

What Is the Historical Context of 55 Gallon Barrels in B2B Markets?

The use of 55-gallon barrels has a rich history that dates back to the mid-20th century when they became a standard for transporting and storing liquids across various industries. Initially designed for oil and chemical storage, these barrels have evolved significantly, finding applications in food and beverage, pharmaceuticals, and even agriculture. Over the years, innovations in materials and manufacturing processes have enhanced the durability and versatility of barrels, making them an indispensable asset in the global supply chain. Today, their ability to be reused and repurposed aligns with the growing emphasis on sustainability in B2B practices, further solidifying their relevance in modern markets.

Conclusion

In conclusion, international B2B buyers must navigate a dynamic landscape when sourcing 55-gallon barrels. Understanding market trends, prioritizing sustainability, and recognizing the historical context can empower businesses to make informed procurement decisions. As the demand for efficient storage solutions continues to grow, aligning sourcing strategies with these insights will be crucial for success in the evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon barrel uses

-

How do I determine the best use for a 55-gallon barrel in my business?

To identify the optimal use for a 55-gallon barrel, consider your industry needs and the specific applications that can benefit from these barrels. Common uses include storage for liquids, chemicals, or food products, as well as innovative solutions like rainwater collection systems or waste management. Evaluate the materials you intend to store, the required certifications (such as food-grade quality), and how the barrel’s design can facilitate your operational processes. Consulting with suppliers can also provide insights into popular applications within your sector. -

What are the key factors to consider when sourcing 55-gallon barrels internationally?

When sourcing 55-gallon barrels from international suppliers, prioritize factors like the supplier’s reputation, compliance with international quality standards, and their ability to meet your specific needs. Review their certifications, such as ISO or food safety standards, and check for customer reviews or testimonials. Additionally, consider the logistics involved, including shipping costs, lead times, and import regulations in your country. Establishing clear communication with the supplier can also help address any concerns before placing an order. -

What customization options are available for 55-gallon barrels?

Customization options for 55-gallon barrels may include color, material (steel or plastic), and additional features such as lids, fittings, or specific printing for branding. Some manufacturers offer barrels with customized dimensions or modifications for specific applications, like valves for dispensing liquids. Before proceeding, consult with suppliers to understand their capabilities and any minimum order quantities (MOQ) that may apply to customized orders. This can enhance your branding and functional requirements while ensuring compliance with industry standards. -

What are the typical minimum order quantities (MOQ) for 55-gallon barrels?

Minimum order quantities for 55-gallon barrels can vary significantly depending on the supplier and the type of barrel (plastic vs. steel). Generally, MOQs can range from a few dozen to several hundred units. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms, especially if you require a smaller quantity for testing purposes or specific projects. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worthwhile to explore these options. -

What payment terms should I expect when purchasing 55-gallon barrels internationally?

Payment terms for international purchases of 55-gallon barrels typically include options like advance payment, letter of credit, or payment upon delivery. The terms may vary based on the supplier’s policies, your business relationship, and the order’s size. It’s prudent to clarify payment options and associated risks upfront, including currency exchange rates and transaction fees. Establishing a secure payment method can help mitigate financial risks and ensure a smoother transaction process. -

How can I ensure the quality of 55-gallon barrels before purchase?

To ensure the quality of 55-gallon barrels, request product samples or certifications that verify compliance with industry standards, such as FDA or UN regulations for hazardous materials. Conducting a factory visit or utilizing third-party inspection services can provide additional assurance regarding the manufacturing process. Engaging in open dialogue with the supplier about their quality control measures and warranty policies can also help establish confidence in the product’s reliability and performance. -

What are the logistics considerations when importing 55-gallon barrels?

When importing 55-gallon barrels, logistics considerations include shipping methods, customs regulations, and potential tariffs or duties. Determine whether you will use air or sea freight, as this can significantly affect delivery times and costs. Ensure you are familiar with the import documentation required by your country, including bills of lading and certificates of origin. Collaborating with a logistics provider experienced in international shipping can streamline the process and help navigate any challenges that may arise. -

What are some common uses for upcycled 55-gallon barrels in various industries?

Upcycled 55-gallon barrels are increasingly popular across various industries for innovative applications. In agriculture, they can serve as rainwater collection systems or planters. In construction, they can be repurposed as waste bins or storage containers. Additionally, businesses are creatively using them for furniture or decorative items, enhancing sustainability efforts. Understanding these diverse applications can inspire new ways to incorporate upcycled barrels into your operations, potentially reducing costs and environmental impact.

Top 7 55 Gallon Barrel Uses Manufacturers & Suppliers List

1. Pinterest – Creative Barrel Projects

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 55 gallon, Kids play spaces, DIY crafts, Plastic Barrel Boat, Plastic Barrel Raft, Nuclear Waste Barrel, Water Collection System, Barrel Projects, Water Collection Garden Solutions

2. iForge Iron – 55 Gallon Steel Drum

Domain: iforgeiron.com

Registered: 2001 (24 years)

Introduction: 55 gallon steel drum; uses include: 55 forge, parts pan, storage containers, holds about 400 pounds of coal, heavy anvil stand, bulk storage for solids, charcoal retort, tumbler, barrel stove, heat exchanger, fire pit, outdoor fireplace, anchor for docks, cable stays for towers, floats for docks, sheet steel stock, smokers, BBQ grills, stock watering tubs, feeders, patio fireplaces, trailer fender…

3. Garage Journal – Versatile 55 Gallon Plastic Drums

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: Plastic 55 gallon drums, used for various purposes including garbage cans, recycling containers, electrolysis tubs, rainwater collection, scrap metal containers, and as bases for docks and rafts. They can be cut for different uses, such as creating buckets or drain pans. Generally food-grade containers, but caution is advised as they may have previously contained hazardous materials.

4. Down to Earth Community Gardens – Food Grade Plastic Barrels

Domain: downtoearthcommunitygardens.wordpress.com

Registered: 2000 (25 years)

Introduction: 55 gallon plastic barrels are versatile and can be used for various homestead projects. They should be food grade (made from HDPE) and have contained only food items. Possible uses include: raised garden beds, trailers, compost bins, bee hives, tree swings, outdoor planters, barrel boats, outdoor furniture, dog houses, rain barrels, strawberry planters, root cellars, floating docks, washing statio…

5. Houzz – Sourcing Food-Grade 55 Gallon Drums

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Used 55 gallon drums can be sourced from auto shops after being emptied. Considerations for use include:

– Preference for food-grade drums to avoid contamination from previous contents (e.g., motor oil).

– Recommendations to clean thoroughly with safe cleaning agents (e.g., Simple Green) and to line with heavy-duty plastic bags to prevent leaching of metal components.

– Suitable for personal us…

6. Lexington Container Company – Drum Projects & Outdoor Solutions

Domain: lexingtoncontainercompany.com

Registered: 2009 (16 years)

Introduction: 55 gallon plastic drum projects, 55 gallon metal drum projects, BBQ grill, Ugly drum smokers, Rain barrels, Composters, Deer feeders, Drum smoker, Floating docks, Floating rafts, Water storage, Wood stoves. Specific projects include: Steel drum deer feeder, Ugly drum smoker, Custom cut out burn barrel, Vogelzang wood stove, Barrel composter, Rain barrels made from olive and pickle barrels, Olive b…

7. Bushcraft USA – 55 Gallon Steel Drums

Domain: bushcraftusa.com

Registered: 2008 (17 years)

Introduction: 55 gallon steel drums, previously contained food-grade materials (olive oil, coconut oil), potential uses include: burn barrels, waste oil heaters, water catchment storage, wood smokers (horizontal or vertical), feed storage for animals (pigs, chickens, horses), rotary composters, trash barrels, barrel stoves, fuel storage, shallow cold cellars, planters for herbs, raised herb gardens, and food st…

Strategic Sourcing Conclusion and Outlook for 55 gallon barrel uses

In conclusion, the versatility of 55-gallon barrels presents a myriad of opportunities for international B2B buyers across diverse sectors. From storage solutions in manufacturing and agriculture to innovative applications in upcycling and eco-friendly initiatives, these barrels can significantly enhance operational efficiency and sustainability. Strategic sourcing of 55-gallon barrels not only ensures cost-effectiveness but also fosters a commitment to environmental responsibility, which is increasingly important in today’s global market.

Illustrative image related to 55 gallon barrel uses

For businesses in Africa, South America, the Middle East, and Europe, leveraging the benefits of 55-gallon barrels can lead to competitive advantages. As you explore sourcing options, consider suppliers who prioritize quality, safety, and sustainability. Engage with local and international partners who understand your specific needs and can provide tailored solutions.

Looking ahead, the demand for reusable and adaptable materials like 55-gallon barrels will continue to grow. We encourage you to take proactive steps in sourcing these valuable assets to enhance your operational capabilities and contribute to a more sustainable future. Embrace the potential of strategic sourcing today, and position your business for success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 55 gallon barrel uses