Unlocking Value: A Strategic Analysis of the Rotary Tumbler Market

Introduction: Navigating the Global Market for rotary tumbler

In today’s competitive landscape, sourcing the right rotary tumbler can be a daunting task for B2B buyers, especially when navigating the diverse offerings available in the global market. With varying specifications, applications, and price points, it’s crucial to understand which options align best with your operational needs. This guide serves as a comprehensive resource, delving into the different types of rotary tumblers, their applications across industries, and the nuances of supplier vetting.

Buyers will find actionable insights on cost considerations and features that enhance performance, such as capacity, material quality, and technological advancements. With a focus on international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—this guide is tailored to empower your purchasing decisions.

By providing detailed comparisons and expert recommendations, we aim to equip you with the knowledge necessary to make informed choices that optimize your operations. Whether you’re looking for commercial-grade tumblers or specialized models for specific materials, this guide will help you navigate the complexities of sourcing, ensuring that you invest in equipment that meets your business requirements effectively.

Understanding rotary tumbler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Rotary Tumblers | High capacity, robust construction, and often stainless steel drums | Jewelry manufacturing, metal finishing | Pros: Efficient for large batches; durable. Cons: Higher initial investment; may require more space. |

| Standard Rotary Tumblers | Typically smaller, suitable for hobbyists and small businesses | Crafting, small-scale rock polishing | Pros: Affordable; user-friendly. Cons: Limited capacity; longer processing times. |

| Specialty Rotary Tumblers | Designed for specific materials (e.g., brass, ceramics) | Firearms cleaning, ceramics finishing | Pros: Tailored performance for specific tasks; often includes specialized media. Cons: Niche applications may limit versatility. |

| Dual-Drum Rotary Tumblers | Features two barrels for simultaneous processing | Mass production, varied material types | Pros: Increases throughput; allows for different processes at once. Cons: More complex operation; higher cost. |

| Vibratory vs. Rotary Tumblers | Comparison of speed and efficiency in processing | Rock tumbling, jewelry polishing | Pros: Faster processing times; lower grit use. Cons: Different finish quality; may not suit all materials. |

What Are Commercial Rotary Tumblers and Their Benefits for B2B Buyers?

Commercial rotary tumblers are designed for high-volume applications, making them ideal for businesses in jewelry manufacturing and metal finishing. These machines feature robust construction, often with stainless steel drums, which enhances durability and longevity. When considering a commercial rotary tumbler, buyers should evaluate their production capacity needs, as these machines can handle larger batches efficiently. However, the initial investment is higher, and they may require more floor space compared to smaller units.

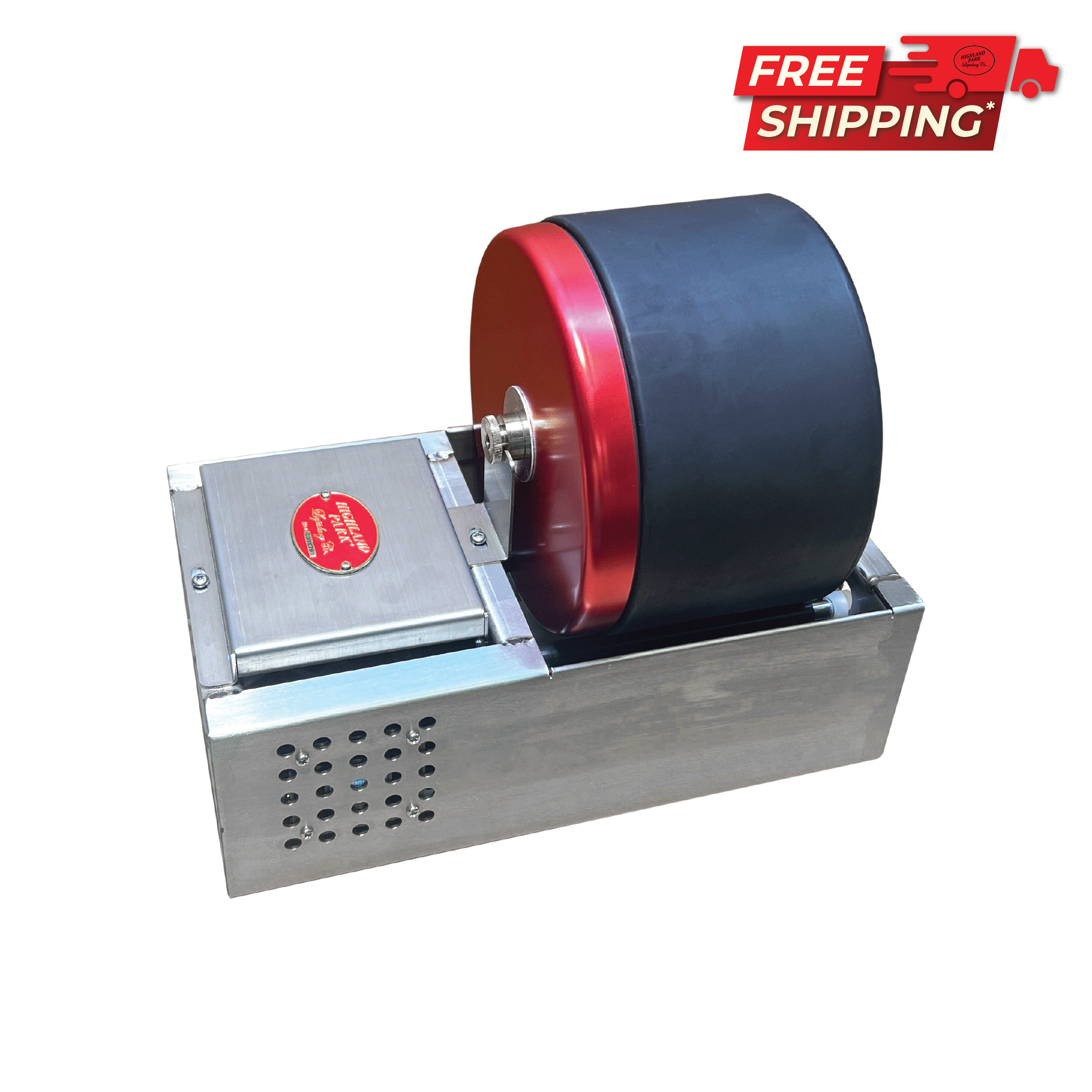

Illustrative image related to rotary tumbler

How Do Standard Rotary Tumblers Cater to Small Businesses?

Standard rotary tumblers are typically smaller and cater to hobbyists and small businesses. They are user-friendly and affordable, making them accessible for those new to tumbling or operating on a limited budget. While they are suitable for crafting and small-scale rock polishing, buyers should be aware that their limited capacity may lead to longer processing times. This makes them less ideal for larger operations, but they are perfect for niche markets or artisanal businesses.

What Are Specialty Rotary Tumblers and When Should They Be Used?

Specialty rotary tumblers are designed for specific materials, such as brass or ceramics, and are often used in applications like firearms cleaning or ceramics finishing. These tumblers provide tailored performance, often including specialized media to enhance the cleaning or polishing process. Buyers should consider their specific needs when selecting a specialty tumbler, as the niche applications may limit versatility. However, for businesses focused on particular materials, these tumblers can yield superior results.

What Advantages Do Dual-Drum Rotary Tumblers Offer?

Dual-drum rotary tumblers feature two barrels that allow for simultaneous processing, significantly increasing throughput. This design is advantageous for mass production environments where varied material types are processed concurrently. While these machines can enhance operational efficiency, buyers should consider the complexity of operation and the higher cost associated with dual-drum systems. They are ideal for businesses looking to maximize productivity and reduce processing times.

Illustrative image related to rotary tumbler

How Do Vibratory and Rotary Tumblers Compare in B2B Applications?

Vibratory tumblers differ from rotary tumblers in terms of speed and efficiency. They are known for faster processing times and lower grit consumption, making them suitable for rock tumbling and jewelry polishing. However, the finish quality may vary depending on the material being processed. B2B buyers should weigh the advantages of quicker cycles against the potential need for different finishes, ensuring they choose the right type of tumbler based on their specific operational requirements.

Key Industrial Applications of rotary tumbler

| Industry/Sector | Specific Application of Rotary Tumbler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Jewelry Manufacturing | Polishing and finishing jewelry pieces | Enhances surface quality and aesthetic appeal | Look for tumblers with adjustable speed and capacity |

| Mining and Mineral Processing | Rock polishing for gem and mineral extraction | Improves the quality of finished gemstones | Consider durability and maintenance requirements |

| Firearms and Ammunition | Cleaning brass casings for reloading | Ensures precision and reliability in ammunition production | Evaluate capacity, cleaning efficiency, and media options |

| Automotive Parts Manufacturing | Deburring and surface finishing of metal components | Reduces production costs and improves product lifespan | Focus on size, noise levels, and operational efficiency |

| Craft and Hobby Industries | Rock tumbling for decorative stones and beads | Adds value to craft products through enhanced aesthetics | Assess compatibility with various materials and grit types |

How is Rotary Tumbler Used in Jewelry Manufacturing?

In the jewelry manufacturing sector, rotary tumblers are essential for polishing and finishing jewelry pieces. These machines use a combination of abrasives and water to smooth out rough surfaces, ensuring that the final product is both visually appealing and comfortable to wear. For international buyers, particularly from regions like Africa and Europe, it’s crucial to select tumblers that offer adjustable speeds and barrel capacities to accommodate different jewelry sizes and materials, enhancing production efficiency and quality.

What Role Does Rotary Tumbler Play in Mining and Mineral Processing?

In mining, rotary tumblers serve a critical role in the polishing of rocks and minerals, particularly gemstones. By using these tumblers, companies can achieve a high-quality finish on stones, which significantly enhances their market value. Buyers in South America and the Middle East should prioritize tumblers that are durable and require minimal maintenance, as they often operate in challenging environments. This ensures a consistent output of high-quality polished stones.

How is Rotary Tumbler Beneficial for Firearms and Ammunition Industries?

Firearms and ammunition manufacturers utilize rotary tumblers for cleaning brass casings prior to reloading. The tumblers effectively remove carbon and debris, ensuring that the casings are in optimal condition for precision and reliability. For businesses in regions like Saudi Arabia and Nigeria, sourcing tumblers with large capacities and effective cleaning capabilities is essential to meet production demands while maintaining high standards of quality.

What Advantages Does Rotary Tumbler Offer in Automotive Parts Manufacturing?

In the automotive sector, rotary tumblers are employed for deburring and surface finishing of metal components. This process not only improves the aesthetic quality of parts but also extends their lifespan by removing sharp edges and imperfections. When sourcing tumblers, manufacturers in Africa and Europe should consider factors such as size, noise levels, and operational efficiency to optimize their production processes and reduce costs.

How Do Craft and Hobby Industries Utilize Rotary Tumblers?

Craft and hobby industries leverage rotary tumblers for tumbling decorative stones and beads, enhancing their visual appeal. This process adds significant value to the final products, making them more attractive to consumers. International buyers should assess the compatibility of tumblers with various materials and grit types to ensure they can meet diverse crafting needs, particularly in regions with growing craft markets.

3 Common User Pain Points for ‘rotary tumbler’ & Their Solutions

Scenario 1: Insufficient Cleaning Power for Brass Cases

The Problem: B2B buyers in the ammunition manufacturing and reloading sectors often encounter challenges with the cleaning efficiency of rotary tumblers. Specifically, when dealing with brass cases, traditional tumbling methods may not remove carbon buildup effectively, resulting in subpar cleaning results. This inefficiency can lead to increased production times and a higher rate of rejected materials, ultimately impacting profitability.

The Solution: To tackle this issue, buyers should consider investing in rotary tumblers designed for high-performance cleaning, such as those that utilize stainless steel pins and specialized cleaning solutions. For instance, a rotary tumbler with a dual-layer drum and a large capacity can handle up to 1,000 cases at once, ensuring thorough cleaning. Additionally, incorporating a built-in timer can optimize the tumbling process by allowing users to set specific cleaning durations, leading to consistent results. Buyers should source tumblers from reputable suppliers that provide detailed specifications and user reviews, ensuring they select a model that meets their cleaning needs effectively.

Scenario 2: Noise and Vibration Disruption in Production Facilities

The Problem: Many B2B buyers, particularly those operating in jewelry or metalworking industries, face challenges with noise and vibration caused by rotary tumblers during operation. Excessive noise can disrupt the working environment, affecting employee productivity and potentially violating local noise regulations, which can lead to fines or operational halts.

The Solution: To mitigate noise and vibration issues, buyers should look for rotary tumblers equipped with noise-dampening features, such as rubber-lined drums or maintenance-free drive trains. These enhancements significantly reduce operational noise and vibration levels. Additionally, placing the tumbler on vibration-absorbing mats or platforms can further decrease noise and stabilize the machine during operation. Buyers can also consult with manufacturers to customize their equipment to include these features, ensuring a quieter, more compliant workspace.

Scenario 3: High Maintenance Costs and Equipment Downtime

The Problem: Frequent breakdowns and maintenance of rotary tumblers can lead to significant downtime and increased operational costs, which is a common pain point for B2B buyers in manufacturing sectors. The need for regular belt replacements and repairs not only hampers productivity but also affects the bottom line, making it crucial for businesses to seek out more reliable equipment.

The Solution: To reduce maintenance costs and downtime, buyers should prioritize rotary tumblers with maintenance-free designs, such as those that utilize geared drive trains instead of belts. These models eliminate the need for belt replacements, significantly lowering maintenance expenses. Additionally, investing in high-quality tumblers from established manufacturers ensures durability and reliability, further reducing the likelihood of unexpected repairs. Buyers should also implement a routine maintenance schedule to inspect and service the tumblers regularly, ensuring they remain in optimal working condition and prolonging their lifespan. This proactive approach will enhance productivity and reduce long-term costs.

Strategic Material Selection Guide for rotary tumbler

What Are the Key Materials Used in Rotary Tumblers?

When selecting a rotary tumbler for industrial or commercial applications, the choice of materials is crucial. The materials used in the construction of rotary tumblers significantly influence their performance, durability, and suitability for specific tasks. Below, we analyze four common materials used in rotary tumblers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform as a Material for Rotary Tumblers?

Steel, particularly stainless steel, is a popular choice for rotary tumblers due to its strength and durability. Stainless steel offers excellent corrosion resistance, making it suitable for wet tumbling applications where moisture is prevalent. Its ability to withstand high temperatures and pressures also makes it ideal for heavy-duty operations.

Pros: Stainless steel is highly durable and resistant to rust, which extends the lifespan of the tumbler. It is also easy to clean and maintain, ensuring consistent performance.

Cons: The primary drawback is the higher initial cost compared to other materials. Additionally, manufacturing stainless steel components can be complex, requiring specialized equipment.

Impact on Application: Steel tumblers are compatible with various media, including ceramic and plastic, making them versatile for different applications.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM or DIN for quality assurance. In regions like Africa and South America, sourcing high-quality stainless steel can be challenging, impacting availability and cost.

What Role Does Plastic Play in Rotary Tumbler Construction?

Plastic is often used for the barrels of rotary tumblers, particularly in smaller or hobbyist models. Common plastics include high-density polyethylene (HDPE) and polypropylene, which offer good resistance to chemicals and moisture.

Pros: Plastic tumblers are lightweight and generally less expensive than metal options. They are also resistant to rust and corrosion, making them suitable for wet applications.

Cons: While durable, plastic may not withstand high temperatures or heavy loads as effectively as metal. Over time, plastics can become brittle, especially under UV exposure.

Impact on Application: Plastic tumblers are best suited for lighter applications and are compatible with softer media, such as plastic pellets.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding plastic materials, especially in regions with strict environmental policies.

Why Choose Rubber for Rotary Tumblers?

Rubber is commonly used as a lining material in rotary tumblers to reduce noise and provide cushioning. This material is particularly useful in commercial settings where noise reduction is essential.

Pros: Rubber dampens vibrations and noise, enhancing user comfort. It also protects the tumbler’s internal components from wear and tear.

Cons: Rubber can degrade over time, especially when exposed to certain chemicals or extreme temperatures. This degradation may necessitate more frequent replacements.

Impact on Application: Rubber linings are compatible with various tumbling media and can help protect sensitive materials during the tumbling process.

Considerations for International Buyers: Buyers should consider the sourcing of rubber materials, ensuring they meet international standards for quality and safety.

How Does Aluminum Compare in Rotary Tumbler Applications?

Aluminum is another material used in rotary tumblers, particularly in the construction of lightweight models. It offers a good balance between weight and strength.

Pros: Aluminum is lightweight, making it easier to handle and transport. It also has good corrosion resistance, particularly when anodized.

Illustrative image related to rotary tumbler

Cons: While strong, aluminum may not be as durable as stainless steel under heavy use. It can also be more expensive than plastic options.

Impact on Application: Aluminum tumblers are suitable for applications requiring mobility and ease of use, though they may not be ideal for heavy-duty tasks.

Considerations for International Buyers: Compliance with international standards is crucial, and buyers should ensure that aluminum components are sourced from reputable suppliers to avoid quality issues.

Summary Table of Material Selection for Rotary Tumblers

| Material | Typical Use Case for rotary tumbler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High durability and corrosion resistance | Higher initial cost | High |

| Plastic | Hobbyist and light applications | Lightweight and cost-effective | May degrade under UV exposure | Low |

| Rubber | Noise reduction and cushioning | Dampens noise and protects components | Degrades over time | Medium |

| Aluminum | Lightweight and portable models | Easy to handle and transport | Less durable than steel | Medium |

This analysis highlights the importance of material selection in rotary tumblers, enabling international B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rotary tumbler

What Are the Main Stages in the Manufacturing Process of Rotary Tumblers?

The manufacturing of rotary tumblers involves several critical stages, each contributing to the product’s overall quality and performance. Understanding these stages is essential for B2B buyers, especially when sourcing from international suppliers.

Material Preparation: What Materials Are Used in Rotary Tumblers?

The first stage is material preparation, where high-quality raw materials are selected. Common materials include:

- Metal Alloys: Stainless steel is often used for the drum and internal components due to its corrosion resistance and durability. The choice of alloy affects the tumbler’s longevity and effectiveness.

- Rubber or Foam: These materials are used for lining the drum to minimize noise and protect the items being tumbled.

- Drive Components: Motor and gearbox materials must be robust to handle the continuous operation and load.

Suppliers should be transparent about their sourcing and material specifications, as these factors significantly influence the tumbler’s performance and lifespan.

Forming: How Are Rotary Tumblers Shaped and Assembled?

In the forming stage, the prepared materials are shaped into components. This typically involves:

- Machining: Precision machining techniques are used to create the drum, motor housing, and other components. CNC (Computer Numerical Control) machines are common for ensuring accuracy.

- Injection Molding: For rubber or plastic parts, injection molding may be employed to achieve consistent shapes and designs.

These methods ensure that each component fits together correctly, which is crucial for the tumbler’s operational efficiency.

Assembly: What Is the Assembly Process for Rotary Tumblers?

Once the individual parts are formed, they are assembled into a complete rotary tumbler. This process includes:

- Component Integration: Each part, from the motor to the drum, is integrated carefully. This often requires skilled labor to ensure that everything aligns correctly and functions as intended.

- Electrical Wiring: If the tumbler features electronic controls (e.g., timers), the wiring and circuitry must be installed accurately to prevent malfunctions.

Quality at this stage is critical, as improper assembly can lead to operational failures or safety hazards.

Illustrative image related to rotary tumbler

Finishing: How Is the Final Product Prepared for Market?

The final stage involves finishing processes that enhance the tumbler’s aesthetic appeal and protect it from environmental factors. This can include:

- Surface Treatments: Coatings may be applied to prevent rust and improve durability. Powder coating is common for metal parts.

- Final Inspections: Each unit undergoes a thorough inspection to check for defects, ensuring that only products meeting quality standards reach the market.

What Quality Assurance Standards Are Relevant for Rotary Tumblers?

Quality assurance is vital in the manufacturing of rotary tumblers, particularly for international buyers who may have specific compliance requirements. Understanding these standards is essential for ensuring product quality and reliability.

International Standards: What Certifications Should Buyers Look For?

Many manufacturers seek certifications to demonstrate their commitment to quality. Key certifications include:

- ISO 9001: This standard focuses on quality management systems and is relevant across industries, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

For buyers from regions like Africa and South America, understanding these certifications can help ensure they are selecting reliable suppliers.

Industry-Specific Standards: Are There Additional Certifications for Rotary Tumblers?

Certain industries may have additional standards that rotary tumblers need to meet, such as:

- API (American Petroleum Institute): For tumblers used in the oil and gas sector, compliance with API standards can be crucial.

- ASTM International: This organization develops and publishes voluntary consensus technical standards for materials and products, which can apply to specific types of rotary tumblers.

B2B buyers should verify that suppliers hold the necessary certifications for their specific application.

Illustrative image related to rotary tumbler

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is an ongoing process that occurs at various stages of manufacturing. Understanding these checkpoints can help buyers assess supplier reliability.

Incoming Quality Control (IQC): How Are Raw Materials Inspected?

Before manufacturing begins, raw materials undergo inspection to ensure they meet specified standards. Key aspects include:

- Material Certification: Suppliers should provide certificates of compliance for the materials used, confirming they meet required specifications.

- Visual Inspections: Any visible defects should be documented and addressed before production starts.

This initial step is critical in preventing issues that could arise from substandard materials.

In-Process Quality Control (IPQC): How Is the Manufacturing Process Monitored?

During the manufacturing process, ongoing inspections are conducted to ensure quality standards are upheld. This includes:

- Dimensional Checks: Regular measurements of components are taken to ensure they fit together correctly.

- Functional Testing: Motors and electronic controls may be tested during assembly to catch any issues early.

Implementing rigorous IPQC measures helps maintain product integrity throughout the manufacturing process.

Final Quality Control (FQC): What Happens Before Products Leave the Factory?

Once assembly is complete, a final inspection is conducted to verify that the finished rotary tumblers meet all quality standards. Key activities include:

- Performance Testing: The finished tumbler is tested for operational efficiency and safety.

- Documentation Review: All manufacturing and testing documentation is reviewed to ensure compliance with standards.

This final checkpoint is crucial for ensuring that only high-quality products reach the customer.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes can be challenging but essential. Here are effective strategies:

Supplier Audits: What Should Buyers Look For?

Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. During an audit, consider:

- Facility Inspection: Examine the manufacturing facility for cleanliness, organization, and adherence to safety protocols.

- Quality Management Systems: Review the supplier’s documentation regarding their quality management practices.

These audits can help ensure that suppliers meet the necessary standards and are capable of delivering high-quality products.

Quality Reports and Documentation: What Information Should Be Requested?

Buyers should request quality reports from suppliers, which may include:

- Test Results: Documentation of performance and safety tests conducted on the products.

- Certification Copies: Copies of relevant certifications (e.g., ISO 9001, CE marking) that confirm compliance with standards.

This documentation is crucial for verifying that the supplier adheres to quality control standards.

Third-Party Inspections: How Can External Verification Enhance Confidence?

Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control processes. This can include:

- Random Product Sampling: Inspecting a sample of products from a batch to verify quality.

- Process Audits: Assessing the manufacturing process to ensure compliance with industry standards.

Third-party inspections can enhance buyer confidence, especially in regions where supplier reliability may be uncertain.

Conclusion: Ensuring Quality in Rotary Tumblers for B2B Buyers

Understanding the manufacturing processes and quality assurance measures for rotary tumblers is crucial for B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and effective verification strategies, buyers can make informed decisions when sourcing rotary tumblers from suppliers across Africa, South America, the Middle East, and Europe. This comprehensive approach not only ensures product quality but also fosters long-term partnerships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotary tumbler’

This guide aims to provide international B2B buyers with a comprehensive checklist to efficiently source rotary tumblers. By following these steps, you can make informed decisions that align with your operational needs and budget considerations, particularly if you are sourcing from regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to rotary tumbler

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider factors such as the type of materials you plan to tumble, the desired capacity, and the specific features you need, such as noise reduction or automated timers. This step ensures that you narrow down your options to tumblers that will effectively meet your operational demands.

Step 2: Research Market Trends and Prices

Investigate current market trends and pricing for rotary tumblers. Prices can vary significantly based on brand, capacity, and features, so it’s essential to establish a budget. Look for price comparisons across different suppliers and regions to ensure you are getting a competitive rate, especially when sourcing internationally.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, including their manufacturing processes, certifications, and customer testimonials. Engaging with previous buyers can also provide insights into the supplier’s performance and customer service.

- Check for Certifications: Ensure the supplier meets international quality standards such as ISO certifications or any specific industry standards relevant to your needs.

- Assess Product Range: A supplier with a diverse range of models can offer you better options tailored to your specific requirements.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples or detailed specifications of their rotary tumblers. Testing a sample can reveal the product’s performance, build quality, and suitability for your needs. This step is critical to avoid any mismatches between expectations and actual performance.

Illustrative image related to rotary tumbler

Step 5: Verify Warranty and After-Sales Support

Confirm the warranty terms and after-sales support provided by the supplier. A robust warranty can protect your investment and ensure long-term support in case of technical issues. Inquire about the availability of spare parts and maintenance services, as these can significantly impact operational continuity.

Step 6: Understand Shipping and Customs Regulations

When sourcing internationally, familiarize yourself with shipping logistics and customs regulations in your region. Ensure that the supplier can handle these aspects efficiently, as delays in shipping can affect your business operations. Consider factors such as shipping costs, delivery times, and any potential customs duties.

Step 7: Finalize Contracts and Payment Terms

Once you have selected a supplier, it’s time to finalize the contract. Clearly outline payment terms, delivery timelines, and penalties for non-compliance. Ensure that all agreements are documented to protect your interests and facilitate smooth transactions.

By following this structured approach, B2B buyers can effectively navigate the complexities of sourcing rotary tumblers, ensuring they select the right equipment for their operations while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for rotary tumbler Sourcing

What Are the Key Cost Components in Rotary Tumbler Manufacturing?

Understanding the cost structure of rotary tumblers is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to rotary tumbler

-

Materials: The choice of materials significantly impacts the price. High-quality stainless steel, for example, increases durability but also costs more. Specialty components like rubber linings for noise reduction can also add to material costs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer a price advantage, but this could affect quality.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor. Efficient production facilities can minimize overhead costs, which can be a point of negotiation.

-

Tooling: The initial investment in molds and machinery can be substantial. Suppliers may pass these costs onto buyers, particularly for custom designs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, which can increase costs. However, for B2B buyers, investing in quality control can reduce warranty claims and maintenance costs in the long run.

-

Logistics: Shipping costs can vary widely based on location and shipping method. International buyers must consider tariffs and import duties, which can significantly affect the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding a supplier’s cost structure can provide leverage during negotiations.

How Do Price Influencers Affect Rotary Tumbler Costs?

Several factors influence the pricing of rotary tumblers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also affect pricing.

-

Specifications and Customization: Custom designs or additional features (e.g., enhanced capacity, specific materials) usually come at a premium. Buyers should weigh the benefits against the additional costs.

-

Materials: The choice of materials directly impacts durability and performance. Higher-quality materials may lead to higher upfront costs but can result in long-term savings through reduced maintenance.

-

Quality Certifications: Products that comply with international quality standards or certifications may command higher prices. However, these certifications can also enhance buyer confidence and reduce risk.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and reliability.

-

Incoterms: The choice of Incoterms can influence the total cost. For instance, DDP (Delivered Duty Paid) includes shipping and customs fees, while EXW (Ex Works) requires buyers to manage these aspects, potentially increasing overall expenses.

What Are Some Essential Buyer Tips for Rotary Tumbler Sourcing?

To maximize value when sourcing rotary tumblers, consider the following tips:

-

Negotiation: Always negotiate pricing and terms. Leverage volume orders or long-term contracts to secure better rates.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes purchase price, shipping, maintenance, and potential downtime. A cheaper tumbler may lead to higher long-term costs if it requires frequent repairs.

-

Pricing Nuances for International Buyers: Understand the currency exchange rates and economic conditions of the supplier’s country. Fluctuations can impact pricing. Additionally, factor in potential delays in logistics, especially in regions with less robust infrastructure.

-

Supplier Research: Conduct thorough research on potential suppliers. Check for reviews, quality ratings, and compliance with international standards to ensure reliability.

-

Sample Orders: Before committing to a large order, request samples to assess quality and performance. This can help avoid costly mistakes and ensure the tumbler meets your specific needs.

Disclaimer on Indicative Prices

Prices for rotary tumblers can vary significantly based on the aforementioned factors. The prices mentioned in various sources range from approximately $125 for basic models to over $1,200 for commercial-grade tumblers. Buyers should conduct thorough market research to obtain accurate and current pricing tailored to their specific requirements.

Alternatives Analysis: Comparing rotary tumbler With Other Solutions

Exploring Alternatives to Rotary Tumblers in the B2B Market

In the realm of industrial and commercial applications, rotary tumblers are widely recognized for their effectiveness in polishing and cleaning various materials. However, businesses often seek alternatives that may better suit their specific needs, whether it be cost efficiency, speed, or ease of use. This section will compare rotary tumblers with two viable alternatives: vibratory tumblers and ultrasonic cleaners.

Comparison Table

| Comparison Aspect | Rotary Tumbler | Vibratory Tumbler | Ultrasonic Cleaner |

|---|---|---|---|

| Performance | Effective for polishing and cleaning; slower process | Faster than rotary; superior for medium and fine polishing | Excellent for detailed cleaning; very fast |

| Cost | $125 – $1,295 depending on size and features | $200 – $800 depending on capacity and brand | $300 – $2,000 depending on features and size |

| Ease of Implementation | Simple setup; requires monitoring throughout process | Easy to use; generally requires less monitoring | Requires setup but minimal monitoring during operation |

| Maintenance | Regular belt replacements; durable but can wear down | Minimal maintenance; typically more robust design | Requires cleaning solutions; infrequent maintenance |

| Best Use Case | Ideal for larger batches and various materials | Best for medium to fine polishing; efficient for smaller batches | Excellent for intricate cleaning; ideal for detailed parts |

Detailed Breakdown of Alternatives

Vibratory Tumblers

Vibratory tumblers provide a significant advantage over rotary tumblers in terms of speed. They can complete medium and fine polishing processes in one to three days, compared to the week or more required by rotary tumblers. This efficiency not only saves time but also reduces electricity consumption and the amount of grit required per pound of material. However, they may not be as effective for larger batches and can require a more substantial initial investment. Businesses focusing on smaller production runs or those needing quick turnaround times will find vibratory tumblers a compelling choice.

Ultrasonic Cleaners

Ultrasonic cleaners utilize high-frequency sound waves to create microscopic bubbles in a cleaning solution, providing an unparalleled level of detail in cleaning. They are particularly effective for cleaning intricate parts and removing contaminants from hard-to-reach areas. While they can be more expensive and may require specialized cleaning solutions, the time-saving aspect and thoroughness make them ideal for industries needing precision, such as electronics and jewelry manufacturing. However, they may not be suitable for all materials, especially larger bulk items.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right tumbling or cleaning solution, B2B buyers should consider their specific operational requirements, including batch size, material type, and desired turnaround time. Rotary tumblers excel in handling larger volumes at a moderate pace, making them suitable for general polishing tasks. In contrast, vibratory tumblers offer efficiency for medium to fine polishing, while ultrasonic cleaners provide detailed cleaning for intricate items. Evaluating these aspects will enable businesses to make informed decisions that align with their operational goals and budgets.

Illustrative image related to rotary tumbler

Essential Technical Properties and Trade Terminology for rotary tumbler

What Are the Key Technical Properties of Rotary Tumblers?

When evaluating rotary tumblers for industrial applications, several technical properties are essential for B2B buyers to consider. These specifications can significantly impact operational efficiency, product quality, and overall return on investment.

-

Barrel Material: The barrel material is crucial for durability and performance. Common materials include high-density polyethylene (HDPE) and stainless steel. HDPE is lightweight and resistant to corrosion, making it ideal for non-abrasive materials. Conversely, stainless steel barrels are more robust and can withstand aggressive tumbling processes, particularly when using abrasive media. Selecting the right material ensures longevity and minimizes maintenance costs.

-

Capacity: The capacity of a rotary tumbler, often measured in liters or pounds, indicates the volume of material it can process in a single batch. For example, tumblers with capacities ranging from 3 to 12 liters are suitable for small-scale operations, while larger models, such as those with 66 liters, cater to industrial needs. Understanding capacity requirements helps businesses optimize production cycles and manage inventory effectively.

-

Drive Mechanism: The drive mechanism refers to the system that powers the tumbler’s rotation. Tumblers can have either belt-driven or direct-drive systems. Belt-driven models may require more maintenance due to belt wear, while direct-drive systems offer higher efficiency and reduced maintenance needs. Buyers should assess their operational environment to choose the most appropriate drive mechanism for their needs.

-

Speed and RPM: The rotation speed, measured in revolutions per minute (RPM), affects the tumbling action and the efficiency of the polishing process. Higher RPMs generally lead to faster processing times but may require careful monitoring to prevent damage to delicate materials. Understanding the relationship between speed and material sensitivity is vital for achieving desired outcomes.

-

Noise Level: Noise levels during operation can impact workplace environments, especially in settings where sound control is critical. Tumblers equipped with noise-dampening features, such as rubber linings, can significantly reduce operational noise. Buyers should consider noise levels in relation to their work environment to ensure compliance with local regulations and employee comfort.

What Are the Common Trade Terms Used in Rotary Tumblers?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms related to rotary tumblers that buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of rotary tumblers, OEMs are crucial for sourcing high-quality components and ensuring compatibility with existing systems. Buyers should seek OEM products to guarantee reliability and performance.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for businesses looking to scale their operations. Buyers should evaluate their needs against supplier MOQs to ensure they can meet demand without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document that companies send to suppliers to obtain pricing information for specific products or services. In the context of rotary tumblers, an RFQ can help buyers compare costs and negotiate better terms. Crafting a clear and detailed RFQ can facilitate better supplier responses and more accurate pricing.

-

Incoterms (International Commercial Terms): Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs during transportation. For B2B buyers, understanding Incoterms is vital for managing logistics and ensuring compliance with international shipping regulations.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Lead time can vary significantly based on supplier capabilities and stock availability. Buyers should factor in lead times when planning production schedules to avoid delays in operations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing rotary tumblers, ensuring they select the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the rotary tumbler Sector

What Are the Key Market Trends Influencing the Rotary Tumbler Sector?

The global rotary tumbler market is experiencing robust growth driven by several key factors, including the rising demand for jewelry polishing, rock tumbling, and brass cleaning applications. Industries such as jewelry manufacturing, lapidary arts, and firearms are increasingly adopting rotary tumblers for their efficiency and effectiveness in cleaning and polishing. Furthermore, advancements in technology are leading to the development of more sophisticated tumblers that offer enhanced features like built-in timers, dual-layer drums for noise reduction, and maintenance-free drive systems.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of the emerging trends that influence sourcing decisions. The growing emphasis on automation and digitalization in manufacturing processes is reshaping how businesses source rotary tumblers. Companies are increasingly seeking suppliers that offer smart features and connectivity options, allowing for better monitoring and control of the tumbling process. Additionally, the trend towards customization is gaining traction, with buyers looking for machines that can be tailored to their specific operational needs.

Price sensitivity remains a critical factor, especially in emerging markets. Buyers are likely to compare costs across suppliers while also considering the total cost of ownership, including maintenance and operational efficiency. Therefore, understanding local market dynamics and pricing strategies is essential for international buyers to make informed purchasing decisions.

How Are Sustainability and Ethical Sourcing Impacting the Rotary Tumbler Market?

Sustainability is becoming a crucial consideration for B2B buyers in the rotary tumbler sector. The environmental impact of manufacturing processes and the materials used in rotary tumblers are under increasing scrutiny. Buyers are now more inclined to partner with suppliers who prioritize sustainable practices, such as using eco-friendly materials and minimizing waste in production. This shift is not only beneficial for the environment but also enhances brand reputation and customer loyalty.

Moreover, ethical sourcing is gaining prominence as businesses aim to ensure that their supply chains are transparent and responsible. Buyers should seek suppliers that comply with international labor standards and demonstrate a commitment to fair trade practices. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can provide assurance that suppliers are adhering to responsible sourcing practices.

The use of ‘green’ materials, such as recycled plastics and sustainably sourced metals, is becoming increasingly popular in the rotary tumbler market. Suppliers that integrate these materials into their products can differentiate themselves and appeal to environmentally conscious buyers. As sustainability continues to influence purchasing decisions, international B2B buyers should prioritize relationships with suppliers that align with their ethical values and sustainability goals.

Illustrative image related to rotary tumbler

What Is the Historical Context of Rotary Tumblers for B2B Buyers?

The rotary tumbler has evolved significantly since its inception in the mid-20th century. Initially designed for simple rock polishing, advancements in technology have transformed these machines into sophisticated tools used across various industries. The introduction of electric motors replaced manual operation, significantly increasing efficiency and consistency in the tumbling process.

Throughout the years, rotary tumblers have adapted to the changing needs of users, incorporating features such as variable speed controls, improved drum designs, and noise reduction technologies. These innovations have expanded their applications beyond rock polishing to include jewelry manufacturing and brass cleaning, making them indispensable in multiple sectors.

As international B2B buyers navigate the rotary tumbler market, understanding the historical evolution of these machines can provide valuable insights into the technological advancements and market dynamics that shape today’s offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of rotary tumbler

-

How do I solve issues with rotary tumbler performance?

To resolve performance issues with rotary tumblers, first check for worn belts or misalignment, as these can lead to ineffective tumbling. Ensure that the drum is properly loaded; overloading can hinder movement and polishing efficiency. Additionally, verify that the right type and amount of media are being used for the materials you are processing. Regular maintenance, including cleaning and lubrication of moving parts, can also help maintain optimal performance. -

What is the best rotary tumbler for commercial use?

For commercial applications, look for rotary tumblers with larger capacities and robust construction. Models like the C20 and C40 commercial tumblers are designed for high-volume operations, offering durability and efficiency. Features such as adjustable speed, noise reduction, and ease of maintenance are crucial. Consider your specific workload and materials to choose a tumbler that meets your production needs without compromising quality. -

What factors should I consider when sourcing rotary tumblers internationally?

When sourcing rotary tumblers internationally, evaluate factors such as supplier reliability, product quality, and compliance with local regulations. Research the supplier’s reputation through reviews and industry connections. Ensure they offer warranties and customer support. Additionally, consider logistics costs, shipping times, and customs regulations in your country, as these can significantly affect your overall investment. -

What are typical minimum order quantities (MOQs) for rotary tumblers?

Minimum order quantities (MOQs) for rotary tumblers can vary widely based on the supplier and the specific model. Many manufacturers may set MOQs between 5 to 20 units for bulk orders, while others might offer flexibility for smaller orders. It’s advisable to communicate your requirements directly with suppliers to negotiate terms that suit your business needs, especially if you are a startup or looking to test the market. -

What payment terms are commonly offered by rotary tumbler suppliers?

Common payment terms for rotary tumbler purchases include advance payment, letter of credit, or payment upon delivery. Some suppliers may also offer net 30 or net 60 terms for established business relationships. It’s essential to clarify these terms before placing an order, as they can affect cash flow. Consider discussing options for partial payments based on delivery milestones, especially for larger orders. -

How can I ensure quality assurance (QA) for rotary tumblers?

To ensure quality assurance for rotary tumblers, request detailed specifications and certifications from the supplier. Implement a quality control process that includes pre-shipment inspections and testing of samples before full production. Establish clear communication channels for feedback and support. Additionally, consider suppliers who offer warranties and after-sales service to address any potential issues post-purchase. -

What logistics considerations should I keep in mind when importing rotary tumblers?

When importing rotary tumblers, consider shipping methods (air vs. sea), estimated delivery times, and associated costs. Factor in customs duties, taxes, and any necessary permits for importation. Work with a reliable freight forwarder who understands the specific regulations for your region. Proper packaging is crucial to prevent damage during transit, so ensure that the supplier uses appropriate materials. -

Can I customize my rotary tumbler order?

Yes, many manufacturers offer customization options for rotary tumblers, including size, color, and additional features like noise reduction or enhanced durability. Discuss your specific requirements with potential suppliers to see what customization options they provide. Custom orders may have different lead times and MOQs, so be prepared for these variations in your procurement strategy.

Top 7 Rotary Tumbler Manufacturers & Suppliers List

1. Lortone – Rotary Tumblers and Rock Tumbling Kits

Domain: lortone.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”3A Rotary Tumbler”,”price”:”$125.00″},{“name”:”3A Rock Tumbling Kit”,”price”:”$169.00″},{“name”:”33B Rotary Tumbler”,”price”:”$185.00″},{“name”:”33B Rock Tumbling Kit”,”price”:”$229.00″},{“name”:”45C Rotary Tumbler”,”price”:”$175.00″},{“name”:”QT6″,”price”:”$315.00″},{“name”:”QT12″,”price”:”$350.00″},{“name”:”QT66″,”price”:”$360.00″},{“name”:”C20 Commercial Tumbler”,”price”:”…

2. Kingsley North – Rotary Tumblers

Domain: kingsleynorth.com

Registered: 1997 (28 years)

Introduction: Rotary Tumblers available at Kingsley North include:

1. Lortone Model QT12 Tumbler – $350.00 (Out of stock)

2. Lortone Model 33B Tumbler – $185.00 (Out of stock)

3. Thumler’s Model B Rock Tumbler – $329.99 (In stock)

4. Thumler’s Model AR-6: 9 Pound Tumbler – $239.99 (In stock)

5. Thumler’s Model AR-12: 12 Pound Tumbler – $274.99 (Out of stock)

6. Thumler’s 3 lb. Tumbler – Model “T” – $149.20 (Out…

3. Otto Frei – Rotary Tumblers

Domain: ottofrei.com

Registered: 2000 (25 years)

Introduction: This company, Otto Frei – Rotary Tumblers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Lortone – Rolling Tumbler

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vibratory tumblers are aggressive and require frequent tending to avoid damaging stones, while rotary tumblers are more forgiving for beginners. The user recommends starting with a rolling tumbler, specifically the Lortone brand, which is durable and has replacement parts available. Vibratory tumblers can lead to disappointing results and damage if not monitored closely. The user has experience wi…

5. HPLapidary – Rotary Tumbler 4.5lb Rubber Barrel

Domain: hplapidary.com

Registered: 2009 (16 years)

Introduction: {“name”: “Rotary Tumbler 4.5lb Rubber Barrel”, “sku”: “RT4504”, “price”: “$34”, “stock”: “In stock”, “shipping”: “FREE SHIPPING on all orders over $50.00 (in contiguous USA)”, “return_policy”: “30 days return policy for refunds, exchanges, or in-house credit. Items must be in original packaging and show no signs of wear. Non-returnable items include special orders and used equipment.”}

6. Rebel – 17 Tumbler (Low Speed)

Domain: rockshed.com

Registered: 2001 (24 years)

Introduction: Rotary Rock Tumblers available for sale include various models and kits from brands such as Rebel, Tumble-Bee, and Lortone. Key products include:

– Rebel 17 Tumbler (Low Speed) – $275.00

– Rebel 17 Tumbler (High Speed) – $260.00

– Rebel 17 Barrel – $110.00

– Rebel 17 Drive Belt – $7.50

– Tumble-Bee 1 x 4lb. Rock Tumbler – $105.00

– Tumble-Bee 1 x 4lb. Rock Tumbler Kit – $130.00

– Tumble-Bee…

7. Kassoy – High Speed Rotary Tumbler

Domain: kassoy.com

Introduction: This company, Kassoy – High Speed Rotary Tumbler, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for rotary tumbler

In the evolving landscape of rotary tumblers, strategic sourcing is paramount for B2B buyers seeking to enhance operational efficiency and product quality. Key insights reveal that investing in high-quality tumblers not only improves the end product—whether in jewelry, rock polishing, or brass cleaning—but also significantly reduces long-term operational costs. Buyers should prioritize vendors who offer robust warranties and excellent customer service, ensuring support throughout the lifecycle of the equipment.

Additionally, the choice between rotary and vibratory tumblers should be informed by specific operational needs. While rotary tumblers excel in certain applications, vibratory models offer faster processing times and reduced material consumption, making them an attractive option for many businesses.

As international buyers from regions such as Africa, South America, the Middle East, and Europe explore sourcing opportunities, now is the time to leverage competitive pricing and advanced technology in rotary tumblers. By aligning with reputable suppliers and embracing innovative solutions, businesses can position themselves for growth in this dynamic market. Take action today—evaluate your current processes and consider upgrading your equipment to meet the demands of a rapidly changing industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to rotary tumbler

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.