A B2B Buyer’s Guide to Patches On Socks: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for patches on socks

In today’s competitive landscape, sourcing patches for socks presents a unique challenge for international B2B buyers. Whether you are a retailer looking to enhance your product line or a manufacturer seeking to minimize costs while maximizing quality, understanding the nuances of the global market for patches on socks is crucial. This guide delves into the various types of patches, their applications, and the latest trends that are shaping consumer preferences across different regions, including Africa, South America, the Middle East, and Europe, particularly in markets like Saudi Arabia and Brazil.

As you navigate this complex marketplace, you will find comprehensive insights on supplier vetting processes, cost considerations, and effective sourcing strategies tailored to your specific business needs. From embroidered logos to custom designs, the options are vast, and knowing how to leverage these can empower your purchasing decisions. This guide aims to equip you with the knowledge necessary to make informed choices, ensuring that your products not only meet market demands but also stand out in a crowded field. By understanding the dynamics of patch sourcing, you can enhance your brand’s identity and drive customer loyalty, ultimately positioning your business for success in the global arena.

Understanding patches on socks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Embroidered Patches | High-quality stitching, customizable designs, durable | Branding, promotional items | Pros: Professional appearance, long-lasting. Cons: Higher cost, longer production time. |

| Iron-On Patches | Easy application, typically made of fabric or vinyl | Quick repairs, custom designs | Pros: Simple to apply, versatile. Cons: May not withstand heavy wear, less durable. |

| Printed Patches | Full-color designs, suitable for complex graphics | Fashion, events, personal branding | Pros: Vibrant colors, intricate designs possible. Cons: Limited durability, may fade over time. |

| Knit Patches | Integrated into the sock fabric, seamless design | Sportswear, casual wear | Pros: Durable, comfortable fit. Cons: Limited design options, more complex manufacturing. |

| Silicone Patches | Non-slip, adds grip, typically used for functional purposes | Athletic socks, performance wear | Pros: Enhances functionality, prevents slipping. Cons: Less aesthetic appeal, may not suit all styles. |

What are the Characteristics of Embroidered Patches on Socks?

Embroidered patches are distinguished by their intricate designs created through high-quality stitching. They are often used for branding and promotional purposes, making them ideal for businesses looking to enhance their corporate identity. When considering embroidered patches, B2B buyers should evaluate factors such as thread quality, colorfastness, and the potential for customization. Although they come with a higher price tag and longer production times, the professional appearance and durability make them a worthwhile investment.

How Do Iron-On Patches Compare in Use and Application?

Iron-on patches offer an easy and efficient solution for both decorative and functional needs. Made from fabric or vinyl, these patches can be applied quickly with heat, making them suitable for repairs or custom designs. B2B buyers should consider the patch’s adhesive quality and the material’s resistance to wear and washing. While they are versatile and cost-effective, the durability may be less than that of embroidered options, making them better suited for less demanding applications.

What Advantages Do Printed Patches Provide for Branding?

Printed patches allow for full-color designs, making them perfect for fashion-forward brands and events where visual impact is essential. They can accommodate intricate graphics that might be challenging to achieve with embroidery. B2B buyers should assess the printing technology used, as it influences the patch’s longevity and color vibrancy. While printed patches can create striking visuals, they may fade over time, so they are best for short-term promotional items rather than long-lasting applications.

Why Are Knit Patches Considered Ideal for Sportswear?

Knit patches are integrated into the sock fabric, providing a seamless look and feel. They are particularly favored in sportswear for their durability and comfort. B2B buyers should focus on the knitting technique and the thickness of the fabric to ensure optimal performance. Although knit patches offer a robust solution, they may have limited design options compared to other types, making them less suitable for highly detailed branding needs.

What Role Do Silicone Patches Play in Athletic Socks?

Silicone patches are designed to enhance the functionality of socks, providing non-slip features that are particularly beneficial in athletic applications. These patches can help prevent slipping during physical activities, making them a popular choice for performance wear. B2B buyers should consider the patch’s placement and design to ensure it complements the overall sock style. While silicone patches may not offer the same aesthetic appeal as other types, their practical advantages make them invaluable in sportswear contexts.

Key Industrial Applications of patches on socks

| Industry/Sector | Specific Application of patches on socks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Custom branded patches for promotional socks | Enhances brand visibility and customer loyalty | Bulk order capabilities, design flexibility, quick turnaround |

| Sports & Athletics | Reinforcement patches for performance socks | Increases durability and performance for athletes | Material quality, moisture-wicking properties, sizing options |

| Fashion & Apparel | Decorative patches for fashion-forward sock designs | Attracts trend-conscious consumers and boosts sales | Trend alignment, customization options, quick design approval |

| Healthcare & Wellness | Functional patches for therapeutic socks | Addresses specific health needs, enhances comfort | Compliance with health regulations, material safety, design efficacy |

| Military & Tactical | Durable patches for tactical and uniform socks | Improves functionality and uniform appearance | Compliance with military specifications, durability, and comfort |

How Can Retailers Leverage Patches on Socks for Branding?

In the retail sector, patches on socks can serve as a powerful branding tool. Retailers can create custom-branded patches that enhance product visibility and foster customer loyalty. By offering unique designs that resonate with their target audience, retailers can differentiate themselves in a competitive market. Buyers should consider suppliers that provide bulk order capabilities, design flexibility, and a quick turnaround to meet seasonal demands and promotional events.

What Are the Advantages of Using Patches in Sports and Athletic Socks?

In the sports and athletics industry, patches are often used to reinforce high-wear areas of performance socks, such as heels and toes. This application not only extends the lifespan of the socks but also enhances performance by providing additional support. Buyers in this sector must prioritize material quality, moisture-wicking properties, and availability of various sizing options to cater to different athlete needs.

How Do Fashion Brands Benefit from Decorative Patches on Socks?

Fashion and apparel brands can utilize decorative patches to create trendy, eye-catching sock designs that appeal to consumers. These patches can be used to convey brand identity or seasonal trends, effectively boosting sales. For international buyers, it’s essential to align with current fashion trends, offer customization options, and ensure a quick design approval process to capitalize on market opportunities.

What Role Do Patches Play in Healthcare and Wellness Socks?

In the healthcare and wellness sectors, patches can be integrated into therapeutic socks to address specific health needs, such as compression or support. These functional patches enhance comfort and usability for patients. Buyers must ensure compliance with health regulations, prioritize material safety, and confirm the efficacy of the design to meet the unique requirements of healthcare applications.

How Are Patches Used in Military and Tactical Socks?

In military and tactical applications, durable patches are essential for enhancing the functionality and uniform appearance of socks. These patches can signify rank, unit, or specific functionalities required in the field. Buyers in this sector should ensure that their sourcing aligns with military specifications, focusing on durability and comfort to meet the rigorous demands faced by personnel in various environments.

3 Common User Pain Points for ‘patches on socks’ & Their Solutions

Scenario 1: The Challenge of Customization for Brand Identity

The Problem: B2B buyers often face difficulties in sourcing patches for socks that align with their brand identity. Custom patches are essential for promoting brand recognition, but the process of selecting the right design, colors, and quality can be overwhelming. Many suppliers may not offer the flexibility needed for intricate custom designs or may have minimum order quantities that do not align with the buyer’s current needs. This can lead to frustration and wasted resources, especially for companies looking to launch a new product line or promotional campaign.

The Solution: To effectively address this challenge, buyers should prioritize suppliers that specialize in custom patches for socks and offer a variety of customization options, including different materials, sizes, and attachment methods. When evaluating suppliers, consider their portfolio of previous work to ensure they can meet your design specifications. Additionally, leverage technology by using digital mock-ups to visualize how the patches will look on the socks. This can save time and resources by allowing for quick iterations before final production. Establishing a strong partnership with a supplier that provides a low minimum order quantity and quick turnaround times can also help in executing promotional strategies effectively without significant upfront investment.

Scenario 2: Durability Concerns with Patches on Socks

The Problem: Another significant pain point is the durability of patches on socks, particularly in high-wear areas like the heel and toe. B2B buyers may find that patches can easily peel or fray, especially after multiple washes, which can lead to dissatisfaction among end customers. This is particularly problematic for businesses that offer premium products, as compromised quality can tarnish their reputation and lead to returns.

The Solution: To mitigate these durability concerns, buyers should look for patches made from high-quality materials that are specifically designed for textile applications. Opt for patches that utilize heat-sealing or strong adhesive backing methods to ensure they can withstand repeated wear and laundering. Furthermore, consider sourcing patches that are reinforced with stitching around the edges, which can enhance their longevity. It is also advisable to conduct wash tests during the sampling phase to assess how well the patches hold up under real-world conditions. By choosing suppliers that offer guarantees on the durability of their patches, businesses can protect their brand reputation and customer satisfaction.

Scenario 3: Cost Management in Bulk Orders of Patches

The Problem: Managing costs effectively while ordering patches for socks in bulk can be a significant challenge for B2B buyers. The initial investment can be high, especially for companies looking to order a wide variety of patches for different sock designs. Buyers may also struggle with understanding the pricing structures and how to optimize their orders to avoid excess inventory or wastage.

The Solution: To navigate cost management, buyers should engage in thorough market research to identify suppliers that offer competitive pricing and flexible bulk order options. Establishing relationships with suppliers who provide tiered pricing based on order volume can lead to significant savings. Additionally, consider collaborating with other businesses for group purchases to reach minimum order quantities while diversifying designs. Implementing an inventory management system can help track patch usage and sales trends, allowing buyers to adjust future orders based on actual demand. Finally, requesting samples before placing a large order can ensure that the quality meets expectations, reducing the risk of costly mistakes down the line.

Strategic Material Selection Guide for patches on socks

When selecting materials for patches on socks, it is essential to consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used for patches, tailored for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Cotton for Sock Patches?

Cotton is a natural fiber known for its breathability and softness. It typically withstands moderate temperatures and pressures, making it suitable for everyday wear. Cotton patches can be easily dyed and printed, allowing for vibrant designs.

Pros: Cotton patches are comfortable against the skin and can absorb moisture, which is beneficial in warmer climates. They are also biodegradable, appealing to environmentally conscious consumers.

Cons: Cotton is less durable than synthetic fibers and may wear out faster, especially in high-friction areas like the heel. It can also shrink or lose shape if not pre-treated properly.

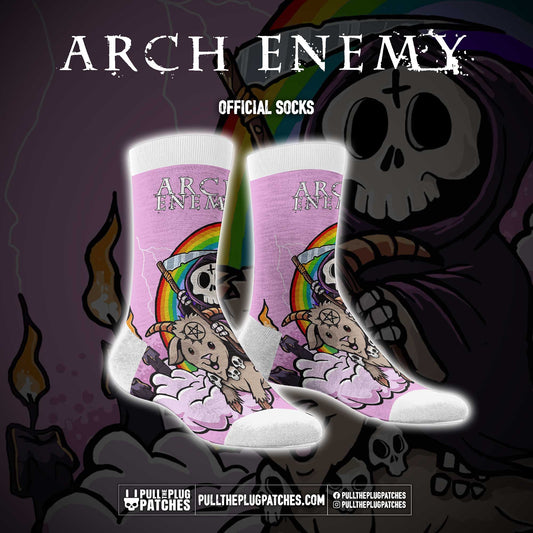

Illustrative image related to patches on socks

Impact on Application: Cotton patches are ideal for casual and fashion socks but may not perform well in athletic or high-performance scenarios.

Considerations for International Buyers: Compliance with environmental regulations is crucial, particularly in Europe, where sustainability standards are stringent. Buyers should also consider local preferences for natural materials, especially in regions like Africa and South America.

How Does Polyester Compare as a Material for Sock Patches?

Polyester is a synthetic fiber known for its strength and resistance to stretching, shrinking, and wrinkling. It can withstand higher temperatures and is less prone to fading, making it suitable for vibrant colors.

Pros: Polyester patches are highly durable, making them suitable for athletic socks and heavy wear. They are also moisture-wicking, which helps keep feet dry during physical activities.

Cons: While polyester is durable, it is less breathable than cotton, which may lead to discomfort in hot climates. Additionally, the environmental impact of synthetic materials can be a concern for eco-conscious consumers.

Impact on Application: Polyester is ideal for performance and athletic socks due to its moisture management properties. It can also be used in fashion applications but may not appeal to all consumers.

Considerations for International Buyers: Buyers should be aware of regulations regarding synthetic materials, particularly in Europe. Certifications like Oeko-Tex can assure compliance with safety standards.

What Are the Advantages of Using Nylon for Sock Patches?

Nylon is another synthetic material renowned for its exceptional strength and elasticity. It is resistant to abrasion and can endure high levels of wear and tear, making it an excellent choice for patches in high-stress areas.

Pros: Nylon patches offer superior durability and can maintain their shape over time. They are also lightweight and quick-drying, which is beneficial for athletic applications.

Cons: Nylon can be less comfortable against the skin compared to natural fibers and may cause irritation in sensitive individuals. It also has a higher environmental impact than cotton.

Illustrative image related to patches on socks

Impact on Application: Nylon is particularly suitable for performance socks and outdoor applications where durability is paramount.

Considerations for International Buyers: Compliance with international standards for synthetic materials is essential. Buyers should also consider local market preferences, as some regions may favor natural over synthetic materials.

How Does Leather Stand Up as a Material for Sock Patches?

Leather is a natural material known for its durability and aesthetic appeal. While not commonly used for traditional sock patches, it can add a unique touch to fashion-oriented products.

Pros: Leather patches are incredibly durable and can withstand significant wear. They offer a premium look and feel, which can enhance the product’s overall value.

Cons: Leather can be expensive and requires specific care to maintain its appearance. It is also less breathable than cotton or polyester, which may affect comfort.

Impact on Application: Leather patches are best suited for high-end fashion socks rather than everyday wear. They can provide a distinctive style but may not be practical for all consumers.

Considerations for International Buyers: Buyers should be aware of ethical sourcing and animal welfare standards, particularly in regions where consumers are increasingly concerned about these issues.

Summary Table

| Material | Typical Use Case for patches on socks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual and fashion socks | Soft and breathable | Less durable, prone to wear | Low |

| Polyester | Athletic and performance socks | Highly durable and moisture-wicking | Less breathable | Medium |

| Nylon | Performance and outdoor socks | Superior strength and elasticity | Can cause skin irritation | Medium |

| Leather | High-end fashion socks | Premium look and durability | Expensive and requires maintenance | High |

This strategic material selection guide provides essential insights for B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for patches on socks

What Are the Main Stages of Manufacturing Patches on Socks?

The manufacturing process for patches on socks consists of several critical stages, each contributing to the overall quality and durability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing patches for socks.

Illustrative image related to patches on socks

Material Preparation: What Materials Are Used in Sock Patches?

The first stage involves selecting the right materials for the patches. Common materials include cotton, polyester, and nylon, which are chosen for their durability, comfort, and ease of application. For instance, cotton patches offer breathability, while polyester is favored for its resistance to wear and tear. The choice of material significantly affects the patch’s performance and how well it adheres to the sock.

Once the materials are selected, they undergo processes such as dyeing and printing to achieve the desired colors and designs. This step ensures that the patches not only match the socks aesthetically but also retain their color and integrity after multiple washes.

Forming: How Are Patches Shaped and Sized?

In the forming stage, the prepared materials are cut into the desired shapes and sizes. This is typically done using precision cutting machines that ensure consistency and accuracy across large production runs. Advanced technologies, such as laser cutting, can also be employed to create intricate designs that are increasingly popular in the market.

This stage may include the application of adhesives or backing materials that enhance the patches’ ability to bond with the sock fabric. It is crucial to select adhesives that are compatible with both the sock material and the patch to prevent peeling or lifting over time.

Illustrative image related to patches on socks

Assembly: What Techniques Are Used to Attach Patches to Socks?

The assembly phase involves the actual application of patches to the socks. This can be achieved through various methods, including sewing, ironing, or using adhesive backing. Each method has its pros and cons:

-

Sewing: This method is robust and provides a long-lasting hold, making it suitable for high-quality socks. It requires skilled labor and can be time-consuming.

-

Ironing: Iron-on patches are popular for their ease of application. They allow for quick production but may not offer the same durability as sewn patches, especially under heavy wear conditions.

-

Adhesive Backing: This method simplifies the application process, allowing for mass production. However, the quality of the adhesive is vital; inferior adhesives can lead to premature failure.

During this phase, it is also essential to ensure that the patches are aligned correctly and securely attached to maintain the overall aesthetic and functional integrity of the socks.

Finishing: What Quality Enhancements Are Made in the Final Stage?

The finishing stage focuses on quality enhancements that improve the overall appeal and performance of the socks. This includes final inspections for defects, trimming excess materials, and applying any necessary treatments to enhance durability and comfort, such as anti-slip coatings or moisture-wicking properties.

Illustrative image related to patches on socks

Additionally, packaging plays a crucial role in this stage. Proper packaging not only protects the product during transit but also enhances the presentation for retail. B2B buyers should consider suppliers that offer custom packaging solutions that align with their branding needs.

How Is Quality Assurance Implemented in the Manufacturing of Sock Patches?

Quality assurance (QA) is a critical component of the manufacturing process for sock patches, ensuring that products meet the necessary standards before they reach the market. A robust QA process can significantly reduce defects and enhance customer satisfaction.

What International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international quality standards, such as ISO 9001, which outlines the requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established a systematic approach to managing quality throughout the production process.

Additionally, industry-specific standards such as CE marking in Europe and ASTM standards in the U.S. can provide further assurance regarding the safety and performance of the products. Buyers in different regions, such as Africa and South America, should verify if specific local standards apply to their markets.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before production begins. Ensuring that materials meet predefined specifications helps prevent defects in the final product.

-

In-Process Quality Control (IPQC): During production, periodic inspections are conducted to monitor processes and identify potential issues early. This proactive approach allows for real-time adjustments and minimizes waste.

-

Final Quality Control (FQC): Before shipping, a final inspection assesses the finished product against quality standards. This stage may include physical tests to check the strength and durability of the patches, as well as visual inspections for any cosmetic defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. This can include:

-

Audits: Conducting supplier audits can provide insights into their manufacturing processes and quality management systems. It allows buyers to assess compliance with international standards and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history and any corrective actions taken in response to previous defects.

-

Third-party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes. This is especially important for international buyers, as it helps mitigate risks associated with overseas sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality control. Factors such as varying regulatory standards, cultural differences, and logistical complexities can impact the sourcing process.

-

Regulatory Compliance: Buyers must ensure that products comply with both the exporting and importing countries’ regulations. This includes understanding specific labeling requirements and safety standards.

-

Cultural Considerations: Building strong relationships with suppliers is essential. Cultural differences can influence communication styles and business practices, making it crucial for buyers to approach negotiations and quality discussions with cultural sensitivity.

-

Logistical Challenges: The transportation of goods across borders can introduce risks related to product integrity. B2B buyers should work with suppliers who have robust logistics and supply chain management practices to ensure that products are delivered in optimal condition.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions that align with their business goals and customer expectations. Prioritizing quality and reliability in their sourcing strategies will ultimately enhance their competitive edge in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘patches on socks’

Introduction

This guide serves as a comprehensive checklist for B2B buyers aiming to procure patches for socks. Whether you are a retailer, a promotional products company, or a manufacturer, understanding the nuances of sourcing patches can help you enhance product offerings, improve customer satisfaction, and ensure quality. Follow these steps to streamline your sourcing process effectively.

Illustrative image related to patches on socks

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as the type of patches (embroidered, woven, or printed), size, color options, and material compatibility with the socks. Establishing these specifications will help you communicate effectively with potential suppliers and ensure that the final products meet your quality standards.

- Consider your target market: Different regions may have varying preferences for patch designs and functionalities.

- Assess durability: Ensure that the patches can withstand regular washing and wear.

Step 2: Research and Identify Potential Suppliers

Begin your search for suppliers by leveraging online directories, trade shows, and industry recommendations. Look for manufacturers that specialize in sock patches and have a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe.

- Check for industry experience: Suppliers with extensive experience are more likely to understand your specific needs.

- Review their portfolio: Assess past projects to gauge their design capabilities and quality.

Step 3: Evaluate Supplier Capabilities

Thoroughly assess each supplier’s capabilities to ensure they can meet your specifications. Request detailed information about their production processes, quality control measures, and customization options.

- Inquire about minimum order quantities (MOQs): This will impact your inventory management and cash flow.

- Verify production timelines: Ensure they can meet your deadlines without compromising quality.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of their patches. This step is critical for evaluating the quality, design accuracy, and overall feel of the patches.

- Conduct wear tests: Test the patches on actual socks to assess adhesion and durability.

- Solicit feedback from your team: Gather insights from different stakeholders to ensure the patches meet collective expectations.

Step 5: Verify Certifications and Compliance

Ensure that your chosen suppliers adhere to relevant industry standards and certifications. This is particularly important when sourcing from different regions, as compliance can vary widely.

- Check for ethical sourcing practices: This is increasingly important to consumers and can enhance your brand’s reputation.

- Review safety standards: Ensure that materials used are non-toxic and safe for consumers.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication at this stage can prevent misunderstandings later.

- Discuss bulk order discounts: Leverage your purchasing power to negotiate better rates.

- Confirm shipping arrangements: Understand the logistics involved, especially if you’re dealing with international suppliers.

Step 7: Establish a Quality Assurance Process

Finally, set up a quality assurance process to monitor the patches throughout the production and delivery phases. This ensures that the final products align with your specifications and quality standards.

- Implement inspection protocols: Regular checks can help identify issues before they escalate.

- Gather customer feedback: Post-sale feedback can provide insights for future sourcing decisions.

By following these steps, you can effectively navigate the complexities of sourcing patches for socks, ensuring that your products meet market demands and quality expectations.

Illustrative image related to patches on socks

Comprehensive Cost and Pricing Analysis for patches on socks Sourcing

What are the Key Cost Components for Patches on Socks?

When analyzing the cost structure for sourcing patches on socks, several components come into play. First, materials represent a significant portion of the cost. Common materials include cotton, polyester, and specialized fabrics for durability and comfort. The choice of materials can influence both the quality and the price point.

Next, labor costs must be considered. This includes wages for workers involved in the design, production, and quality control processes. Depending on the region, labor costs can vary significantly, impacting overall pricing. Additionally, manufacturing overhead—which includes utilities, facility costs, and administrative expenses—contributes to the final cost.

Tooling costs, particularly for custom designs or intricate patterns, can also add to expenses. These may include the costs of specialized equipment or molds required to produce unique patches. Furthermore, quality control (QC) processes ensure that the final product meets specific standards, which can add both time and expense to production.

Illustrative image related to patches on socks

Finally, logistics costs, such as shipping and handling, especially for international buyers, can greatly affect the total cost. These expenses can vary widely based on the shipping method, distance, and any tariffs or customs duties applicable to the destination country.

How Do Price Influencers Affect Sourcing Decisions for Patches on Socks?

Several factors can influence the pricing of patches on socks. Volume and minimum order quantities (MOQ) play a critical role. Suppliers often provide discounts for larger orders, making it beneficial for buyers to purchase in bulk. Additionally, the level of customization and the complexity of designs will affect pricing. Simple patches may cost less than those requiring intricate embroidery or unique color combinations.

The choice of materials also directly impacts price. Premium materials will lead to higher costs but can enhance the product’s overall quality and appeal. Similarly, buyers should consider the quality certifications of materials, as certified products may command higher prices due to their assurance of quality and compliance with industry standards.

Supplier factors such as reputation, reliability, and geographic location can also influence costs. Suppliers in regions with higher labor costs may have higher prices, but they may also provide better quality or faster turnaround times. Furthermore, understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping, which can affect the total landed cost of products.

What Buyer Tips Can Help Optimize Costs for Patches on Socks?

When sourcing patches on socks, buyers should focus on effective negotiation strategies. Building long-term relationships with suppliers can lead to better pricing and more favorable terms over time. It is also essential to evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, maintenance, and potential returns.

Buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should be aware of the pricing nuances that may arise due to regional economic conditions, currency fluctuations, and trade agreements. Understanding these factors can help buyers make informed decisions and mitigate risks associated with international transactions.

Finally, it is crucial to approach pricing discussions with a clear understanding of indicative prices. While suppliers may provide a price range, these figures can fluctuate based on market conditions, raw material costs, and changes in demand. Buyers should always confirm final pricing before placing orders to avoid unexpected costs.

In summary, navigating the cost and pricing landscape for patches on socks requires a comprehensive understanding of both the cost components and the various factors influencing pricing. By leveraging these insights, B2B buyers can make more informed sourcing decisions that align with their business objectives.

Illustrative image related to patches on socks

Alternatives Analysis: Comparing patches on socks With Other Solutions

Exploring Alternatives to Patches on Socks

In the dynamic B2B landscape, businesses often seek innovative solutions to enhance their products or services. When it comes to addressing wear and tear on socks, the use of patches is one option, but several alternatives exist that can offer unique benefits. This analysis will compare patches on socks with two other viable solutions: reinforced sock designs and disposable sock options, providing insights into their respective advantages and disadvantages.

| Comparison Aspect | Patches On Socks | Reinforced Sock Designs | Disposable Sock Options |

|---|---|---|---|

| Performance | Effective for covering holes, can last long with proper application. | High durability with built-in reinforcements; designed to resist wear. | Limited durability; designed for single use, often less comfortable. |

| Cost | Low initial cost for materials; potential for savings by extending sock life. | Higher upfront investment, but can reduce replacement costs over time. | Generally low cost per pair, but can add up with frequent replacements. |

| Ease of Implementation | Requires sewing or adhesive application; may require skills for best results. | No additional work needed post-purchase; ready-to-wear solution. | Very easy; simply use and dispose. |

| Maintenance | Minimal maintenance; requires occasional reapplication. | Very low maintenance; designed to withstand regular wear. | No maintenance; however, contributes to waste. |

| Best Use Case | Ideal for extending the life of high-quality socks. | Best for regular use in demanding environments (e.g., work, sports). | Suitable for situations where hygiene is paramount (e.g., healthcare, travel). |

Detailed Breakdown of Alternatives

Reinforced Sock Designs

Reinforced sock designs utilize advanced textile technologies to enhance durability. These socks feature additional material in high-wear areas, such as the heel and toe, which helps prevent holes from forming. The main advantage of this solution is its longevity; businesses can save on costs associated with frequent sock replacements. However, the initial investment is higher compared to standard socks with patches. For B2B buyers targeting industries where durability is critical—such as athletics or manual labor—reinforced sock designs may represent a more reliable long-term solution.

Disposable Sock Options

Disposable socks are designed for single use, making them a convenient option for certain situations. They are particularly beneficial in environments where hygiene is essential, such as hospitals or during travel. The ease of use is a significant advantage, as they require no maintenance and can be discarded after use. However, the cost can accumulate over time, especially for businesses needing to provide a large quantity. Additionally, the environmental impact of disposable products could be a concern for companies focused on sustainability.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the most suitable solution for addressing sock wear and tear, B2B buyers must assess their specific needs and operational contexts. Patches on socks are an economical choice for extending the life of quality products, while reinforced sock designs offer durability for demanding applications. Conversely, disposable sock options provide unmatched convenience in hygiene-sensitive scenarios. By weighing performance, cost, ease of implementation, maintenance, and use cases, businesses can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for patches on socks

What Are the Essential Technical Properties for Patches on Socks?

When sourcing patches for socks, it is vital to consider several technical properties that ensure durability, performance, and aesthetic appeal. Here are some key specifications:

-

Material Composition

The choice of material for patches significantly impacts both functionality and comfort. Common materials include cotton, polyester, and nylon. Cotton offers breathability and softness, while polyester provides durability and resistance to wear. Understanding material properties helps buyers select patches that align with their product offerings and customer expectations. -

Adhesive Type

The adhesive used in patches is crucial for durability. Options include heat-activated adhesives, pressure-sensitive adhesives, and fabric glues. Heat-activated adhesives bond well when applied with an iron, while pressure-sensitive adhesives allow for easy application without heat. Selecting the appropriate adhesive ensures the patch adheres well to the sock, preventing premature detachment. -

Patch Thickness

The thickness of the patch affects both comfort and appearance. Thicker patches may provide added protection against wear but can compromise comfort if they create bulk. Conversely, thinner patches offer a sleek look but may not withstand heavy use. Buyers should evaluate the intended use of the socks to determine the optimal patch thickness. -

Size and Shape

Patches come in various sizes and shapes, impacting their visual appeal and functionality. Standard shapes include circles, squares, and custom designs. Understanding the size and shape requirements helps buyers communicate effectively with suppliers and ensures that patches fit well on the socks without altering their intended use. -

Colorfastness

Colorfastness refers to the ability of the patch color to resist fading or bleeding when washed. This property is essential for maintaining the aesthetic quality of the socks over time. Buyers should inquire about colorfastness ratings to ensure the patches retain their vibrant colors through multiple washes.

What Are Common Trade Terms Used in the Patches on Socks Industry?

Familiarizing yourself with industry jargon can streamline communication and enhance negotiation processes. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand. In the context of patches, an OEM might create custom patches designed for a specific sock brand. Understanding OEM relationships can help buyers navigate sourcing options effectively. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost considerations. Buyers should assess their needs against the MOQ to optimize their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the patches industry, submitting an RFQ allows buyers to compare offers from different manufacturers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping and delivery. Understanding Incoterms helps B2B buyers clarify costs and risks associated with transporting patches from manufacturers to their locations. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. This term is vital for planning inventory and ensuring timely product launches. Buyers should inquire about lead times during negotiations to align supply with demand cycles. -

Custom Design Approval

This term refers to the process of reviewing and approving design mock-ups before production begins. Ensuring that designs meet specifications before manufacturing can prevent costly errors and ensure product quality.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing patches for socks, ultimately enhancing product quality and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the patches on socks Sector

What Are the Current Market Dynamics and Key Trends in the Patches on Socks Sector?

The patches on socks sector is experiencing significant growth, driven by rising consumer demand for customization and personalization. As global markets expand, particularly in Africa, South America, the Middle East, and Europe, buyers are increasingly seeking unique products that reflect individual styles and cultural identities. The trend towards personalization is not merely aesthetic; it also encompasses functionality, as many consumers look for solutions to extend the lifespan of their socks, such as patching holes to avoid waste.

Emerging technologies, such as digital printing and advanced embroidery techniques, are revolutionizing the production process, allowing for greater design flexibility and faster turnaround times. International B2B buyers should leverage these technologies to meet local market demands efficiently. Moreover, e-commerce platforms are becoming essential for sourcing, as they provide a wide array of options and the ability to compare suppliers quickly.

Sourcing trends are also shifting towards partnerships with local artisans and manufacturers, particularly in emerging markets. This not only supports local economies but also enhances product authenticity, which is appealing to consumers increasingly concerned about the origins of their purchases. As such, B2B buyers should prioritize suppliers who demonstrate a strong understanding of local cultural aesthetics and preferences.

How Are Sustainability and Ethical Sourcing Influencing the Patches on Socks Market?

Sustainability has become a cornerstone of sourcing strategies within the patches on socks sector. Environmental concerns regarding textile waste and the carbon footprint of production processes are prompting businesses to adopt more sustainable practices. Buyers are increasingly interested in sourcing patches made from organic or recycled materials, which significantly reduce the environmental impact.

Ethical sourcing is equally important, as consumers become more aware of the social implications of their purchases. Suppliers that can demonstrate compliance with fair labor practices and transparent supply chains will stand out in a competitive marketplace. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as valuable indicators of a supplier’s commitment to sustainability and ethics.

Illustrative image related to patches on socks

B2B buyers should actively seek partnerships with manufacturers who prioritize sustainability and ethical practices. This not only enhances brand reputation but also meets the growing consumer demand for responsible products, making it a strategic advantage in the global market.

What Is the Brief Evolution and History of Patches on Socks Relevant to B2B Buyers?

Historically, patches have been utilized as practical solutions for mending clothing, including socks, as far back as the early 20th century. The rise of consumer culture in the mid-20th century saw a shift towards decorative patches, transforming them from mere functional items to fashion statements.

In recent years, the advent of social media and influencer marketing has accelerated the popularity of personalized and custom patches on socks, particularly among younger demographics. This evolution is essential for B2B buyers to understand, as it informs current trends in consumer preferences and the demand for customizable products. Recognizing the historical context allows buyers to anticipate future trends and make informed sourcing decisions that align with market demands.

By staying attuned to these dynamics, B2B buyers can effectively navigate the patches on socks sector, ensuring they meet customer needs while promoting sustainability and ethical practices.

Illustrative image related to patches on socks

Frequently Asked Questions (FAQs) for B2B Buyers of patches on socks

-

How do I select the right patches for socks?

When choosing patches for socks, consider the intended use and design elements. Look for patches made from durable materials that can withstand wear and washing. Customization options, such as size, color, and design intricacy, are crucial for branding. Evaluate the application method (iron-on, sew-on, etc.) to ensure it aligns with your production capabilities. Additionally, check the supplier’s portfolio to assess the quality of previous work and ensure it meets your brand standards. -

What types of patches are best for different sock styles?

The best patch type depends on the sock style and purpose. For athletic socks, consider durable and moisture-resistant patches that can handle movement and sweat. Embroidered patches provide a classic touch for dress socks, while heat-transfer patches work well for casual styles. If you’re looking for versatility, iron-on patches are easy to apply and can be used on various sock types. Always consider the sock material to ensure compatibility with the patch. -

What are the minimum order quantities (MOQs) for patches on socks?

Minimum order quantities for patches on socks can vary widely among suppliers, typically ranging from 50 to several hundred units. It’s essential to discuss MOQs with potential vendors during the sourcing process. Some manufacturers may offer lower MOQs for initial orders or samples, while others may require higher quantities for customized designs. Always clarify these details upfront to avoid potential issues in your procurement process. -

How can I ensure the quality of patches on socks?

To ensure quality, request samples before placing a bulk order. Evaluate the stitching, durability, and washability of the patches. Additionally, inquire about the supplier’s quality assurance processes, including material sourcing and production techniques. Look for reviews or testimonials from other businesses to gauge their reputation. Establishing a clear communication channel with the supplier can also help in addressing any quality concerns during production. -

What payment terms should I expect when sourcing patches for socks?

Payment terms can vary significantly depending on the supplier and your location. Common terms include a deposit upfront, with the balance due upon delivery or after inspection. Some suppliers might offer credit terms for long-standing customers. It’s advisable to negotiate terms that suit your cash flow and ensure secure transactions. Always request a detailed invoice and confirm the payment methods accepted, especially for international orders. -

What are the shipping options for international orders of patches on socks?

Shipping options for international orders typically include air freight, sea freight, and courier services. Air freight is faster but often more expensive, while sea freight is more economical for larger orders but takes longer. Discuss with your supplier about shipping methods they offer and their associated costs. Ensure that they provide tracking information and clarify any customs duties or taxes that may apply upon arrival in your country. -

How can I customize patches for my brand?

Customization options for patches on socks generally include selecting colors, sizes, and designs. Most suppliers allow you to upload your logo or artwork, which they can then transform into patches. Consider discussing your branding needs during initial communications to ensure the supplier can meet your specifications. Additionally, ask about the number of colors allowed in the design and the various materials available for the patches to achieve your desired look. -

What should I consider when vetting suppliers for patches on socks?

When vetting suppliers, assess their experience in the industry and their capacity to handle your order size. Look for certifications that indicate quality standards, such as ISO or similar. Request references or case studies from previous clients to evaluate their reliability and service quality. Additionally, check their communication responsiveness and willingness to collaborate on designs, as these factors significantly impact your overall experience and satisfaction.

Top 7 Patches On Socks Manufacturers & Suppliers List

1. Reddit – Sock Mending Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Mending socks with patches using materials like old T-shirts or other worn socks. Suggested methods include using a sewing machine to stitch zig-zag over the patch or hand-stitching with minimal stitching, such as a basic whip stitch. Concerns include the comfort of seams on socks and the durability of patch materials.

2. Etsy – Iron on Patches for Socks

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Iron on Patches for Socks available on Etsy. Price range: $1.07 to $120.00. Various designs including custom name patches, vintage cassette tape patches, and embroidered patches. Some patches are sold in pairs, and there are options for bulk purchases like a 12-pc “Trucker Hat Bundle”. Discounts available on select items. Sellers include ClinchCustoms and HungryBearDesigns.

3. Vivipins – Embroidered Logo Socks

Domain: vivipins.com

Registered: 2017 (8 years)

Introduction: Embroidered Logo Socks – Brand Designs – Patch & Icon

– Item No: 313

– Limited-Time Offer: 20% off custom orders

– Free Shipping on all orders

– Overall Review: 4.9 stars

– Available Sock Base Colors: Goldenrod, Crimson, Mint, Pink, Blue, Orange, Purple, Gray, Black, Teal, Yellow, White (12 colors)

– Sizes Available: Men’s Standard (Size M/ US 10 – 13), Men’s Small (Size S/ US 6 – 9), Women’s

– Th…

4. Brother – Customizable Socks with Unique Patches

Domain: brother-usa.com

Registered: 2000 (25 years)

Introduction: Custom socks with cute patches, suitable for personalizing your wardrobe or as gifts. The process involves using a Brother sewing machine to create unique designs. Ideal for DIY enthusiasts and those looking to add a personal touch to their clothing.

5. Stance – Icon Patches Crew Socks Box Set

Domain: stance.com

Introduction: {“product_name”: “Icon Patches Crew Socks Box Set”, “price”: {“original”: “$45.00”, “discounted”: “$39.90”}, “final_sale”: true, “color”: “DARKROYAL”, “features”: {“pairs”: 3, “exclusive_patches”: 4, “height”: “Crew”, “material”: “76% combed cotton, 17% polyester, 4% nylon, 3% elastane”, “cushioning”: “Medium Cushioning”, “targeted_cushioning”: true, “arch_support”: true, “seamless_toe_closure”: t…

6. Sewing – Repairing Sock Holes

Domain: sewing.patternreview.com

Registered: 2001 (24 years)

Introduction: Discussion about repairing sock holes, specifically in the heel area. Suggestions include using patches, gluing, or darning techniques. Concerns raised about the durability of glue versus sewing methods. Recommendations for materials include durable yet thin and flexible fabrics for patches. Mention of reinforced heel socks as an alternative. Discussion also touches on personal care for feet to pr…

7. Facebook – Junk Socks

Domain: facebook.com

Introduction: junk socks

Strategic Sourcing Conclusion and Outlook for patches on socks

How Can Strategic Sourcing Enhance Your Business in the Patches on Socks Market?

In conclusion, strategic sourcing for patches on socks presents a unique opportunity for international B2B buyers to maximize value while enhancing product offerings. By leveraging custom designs and innovative materials, businesses can not only cater to diverse consumer preferences but also build brand loyalty through unique, personalized products. The growing trend of sustainable and durable patch solutions further aligns with increasing consumer demand for quality, making this an essential consideration in sourcing strategies.

Moreover, as buyers from regions such as Africa, South America, the Middle East, and Europe navigate the global marketplace, establishing reliable partnerships with manufacturers can lead to significant cost savings and improved supply chain efficiency. Engaging with suppliers who offer rapid turnaround times and flexible order quantities can enhance your competitive edge.

Looking forward, now is the ideal time to explore the potential of patches on socks in your product line. Embrace the opportunity to innovate and differentiate your offerings by sourcing high-quality patches that resonate with your target markets. Let’s collaborate to meet the evolving needs of consumers and elevate your brand’s presence in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.